Characterization of Silica Exposure during Manufacturing of Artificial Stone Countertops

Abstract

1. Introduction

2. Methods

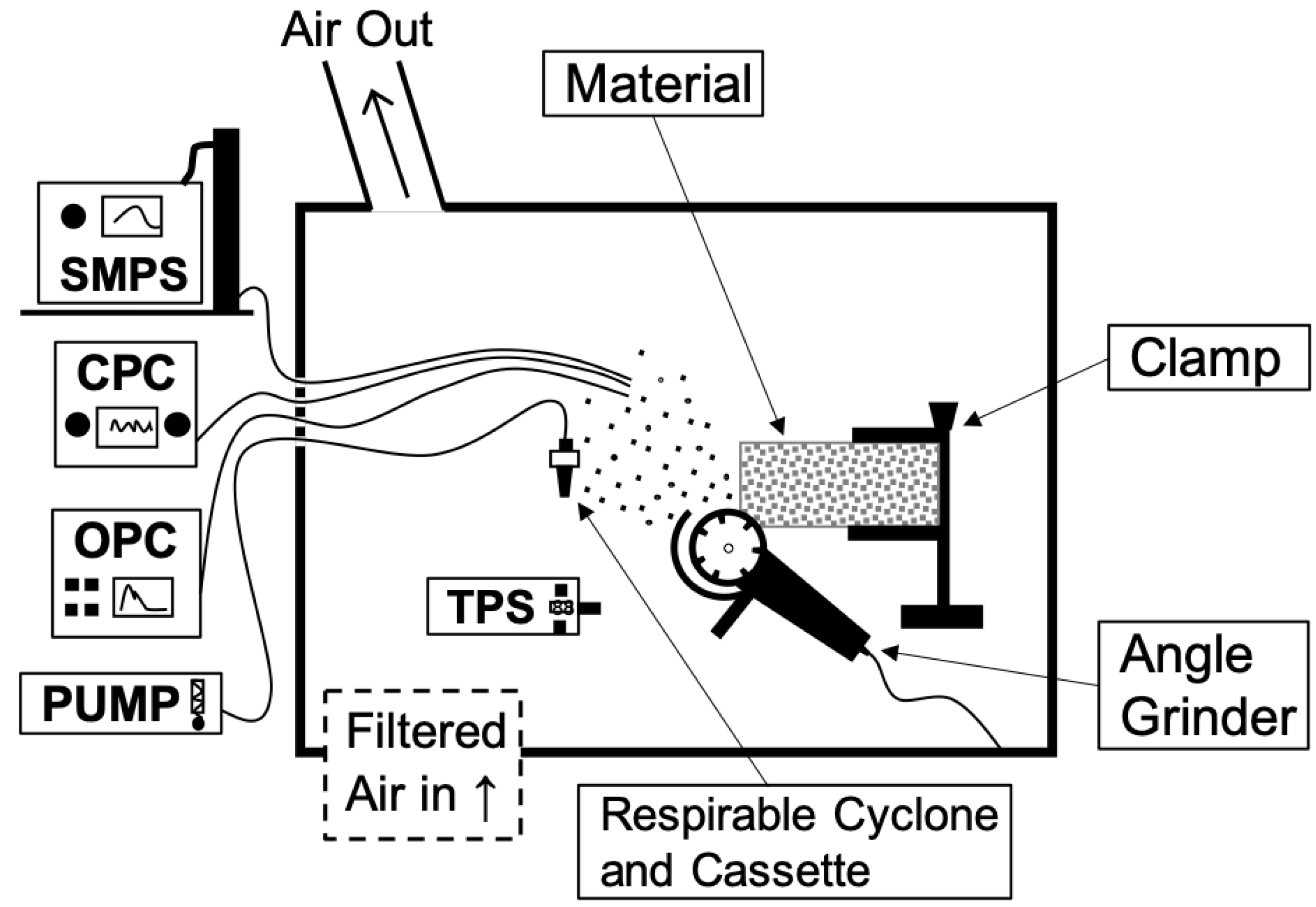

2.1. Particle Generation

2.2. Sample Materials

2.3. Particle Sampling and Characterization

2.4. Sampling Protocol

2.5. Data Analysis

3. Results and Discussion

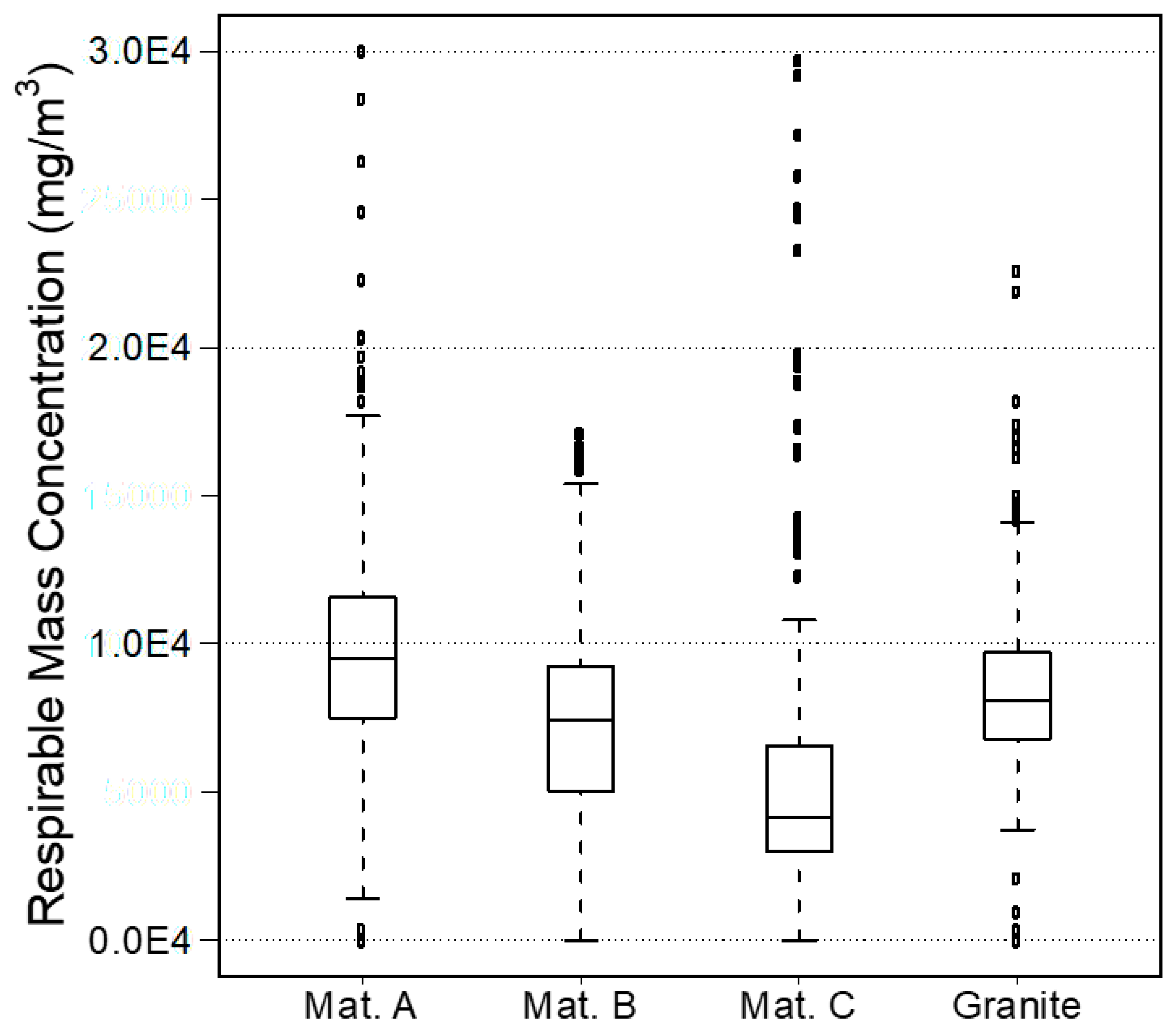

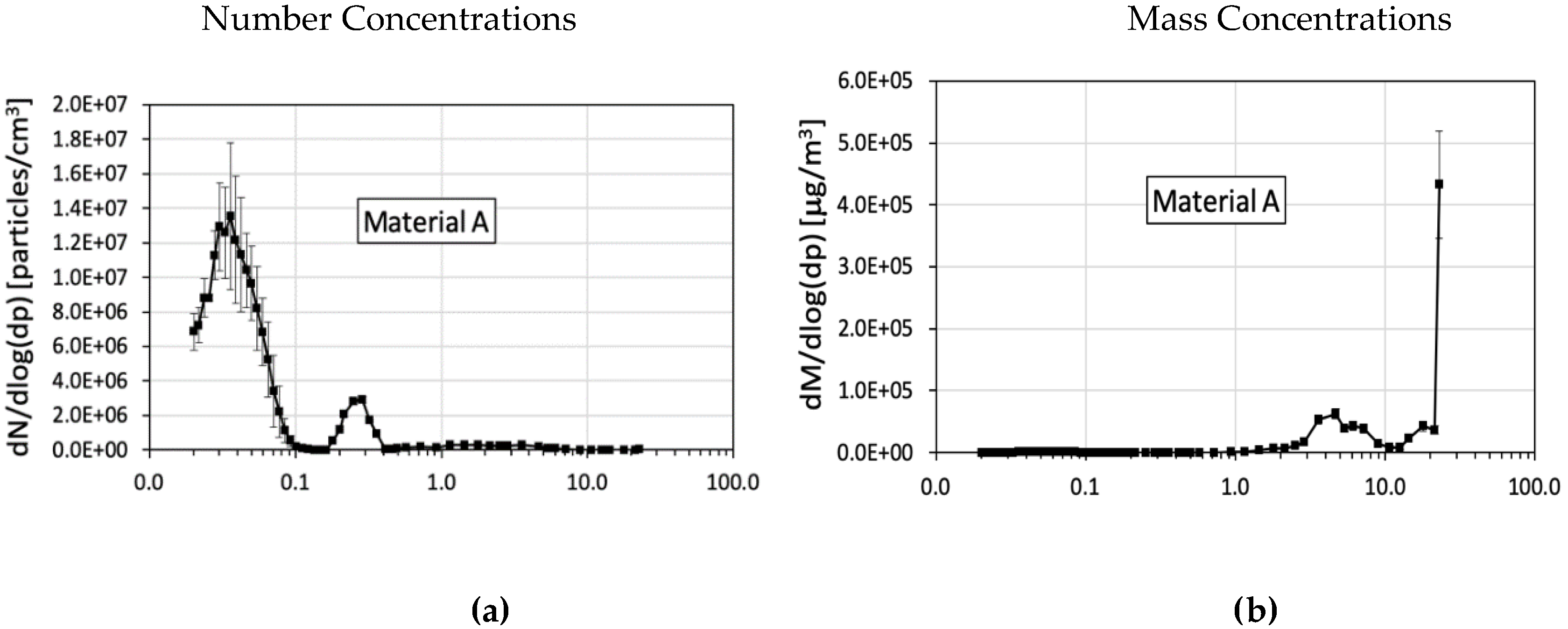

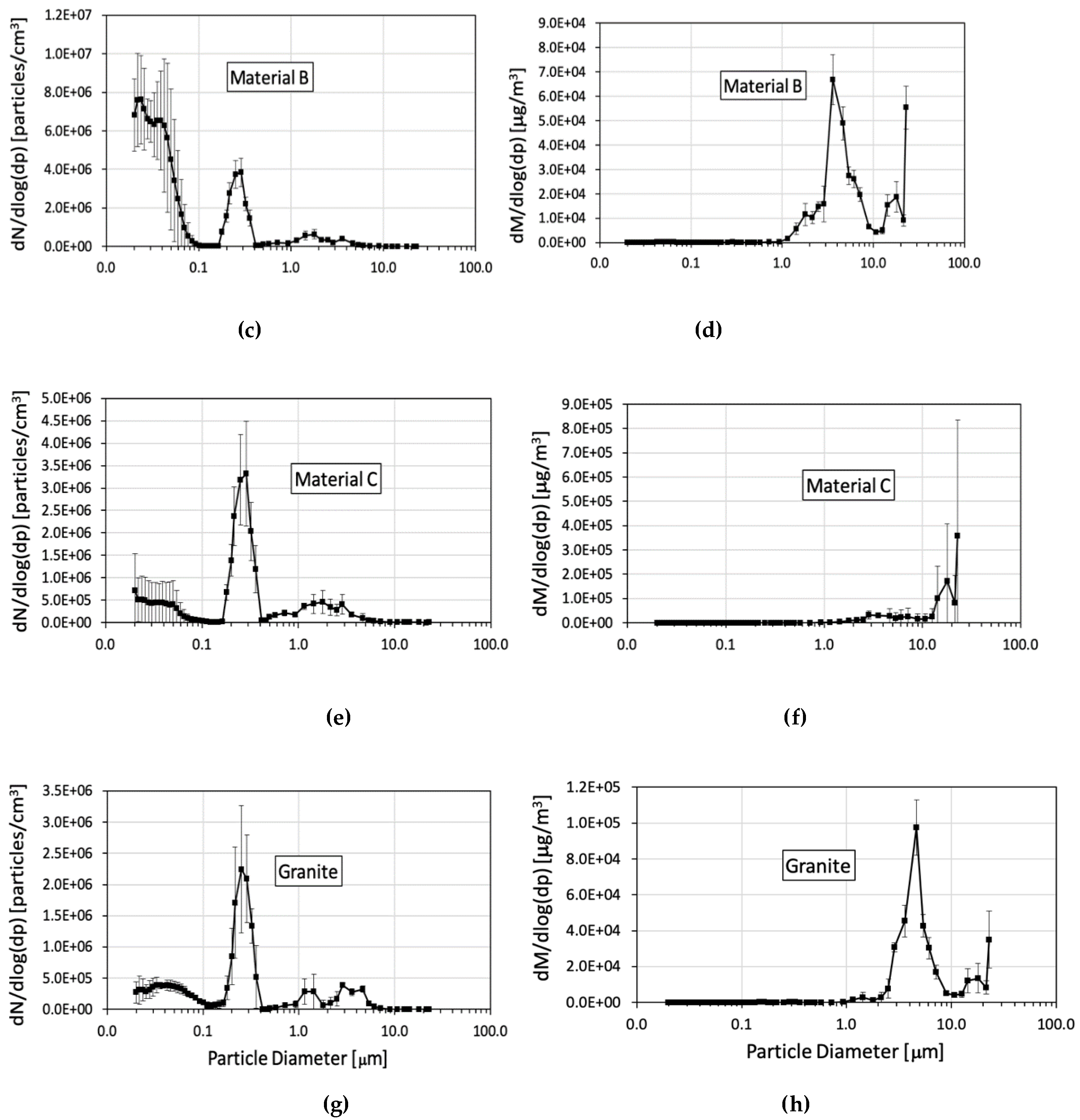

3.1. Direct-Read Instruments Analysis

3.2. Silica Concentrations

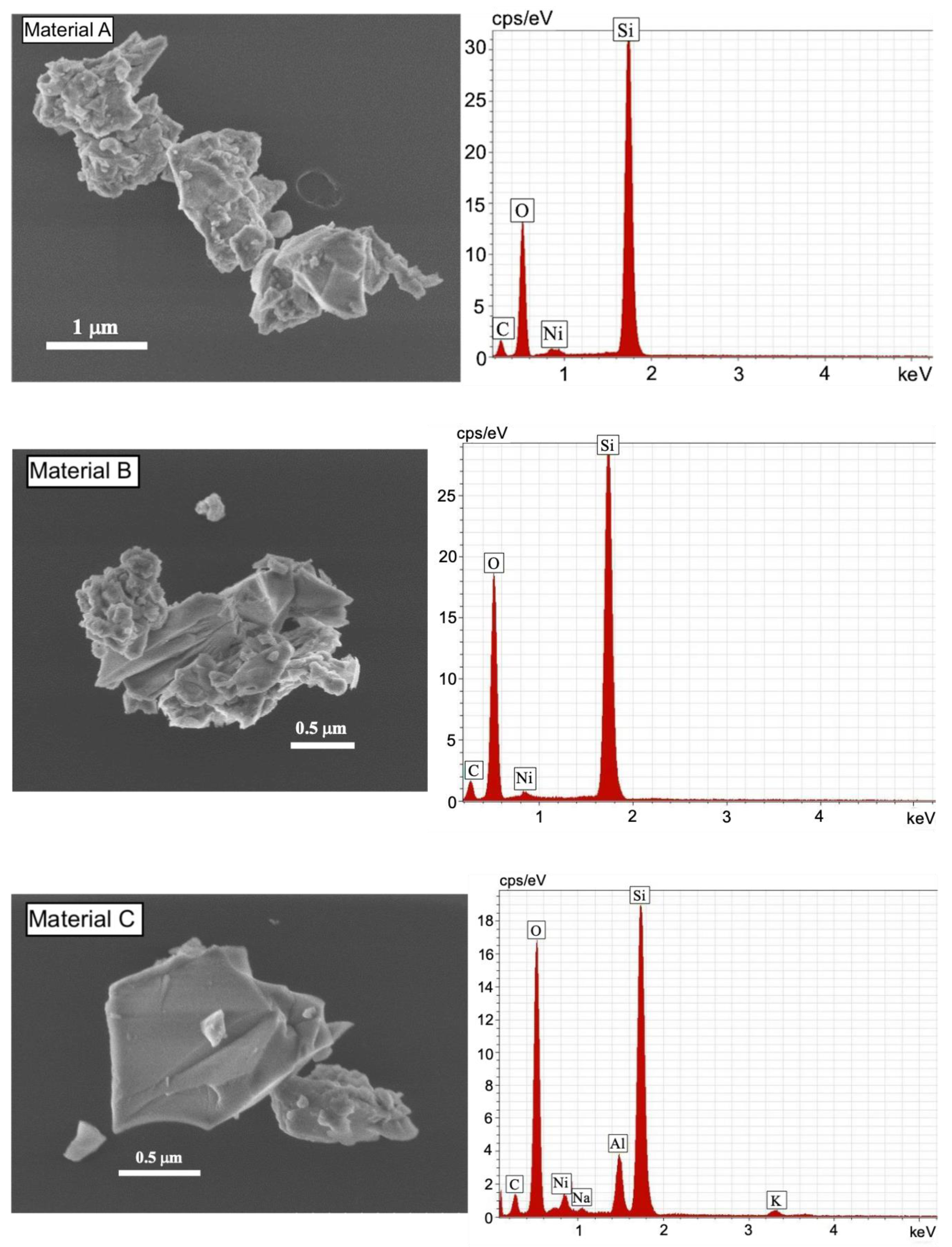

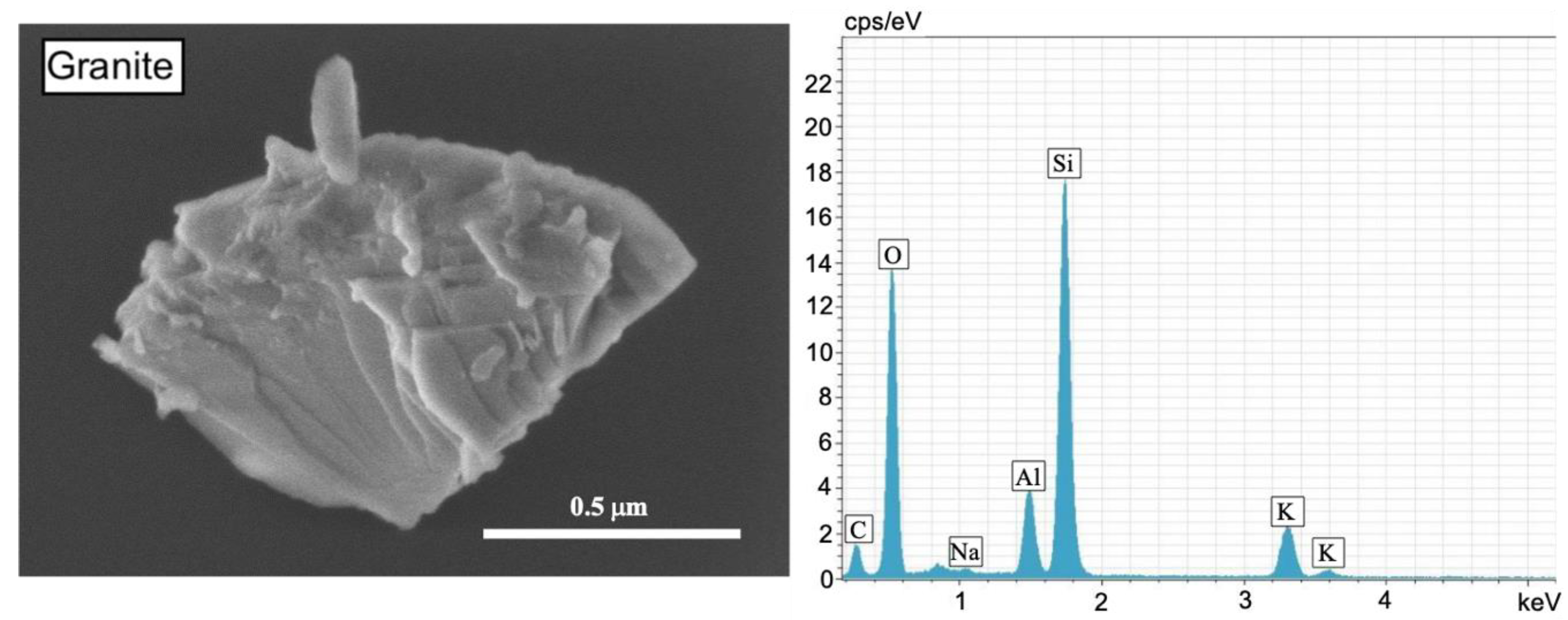

3.3. Microscopy Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Occupational Safety and Health Administration. Occupational Safety and Health Administration—Silica, Crystalline. Available online: https://www.osha.gov/dsg/topics/silicacrystalline/ (accessed on 27 January 2020).

- Anthony, J.W. Handbook of Mineralogy; Mineral Data Publishing: Chantilly, VA, USA, 1990; Volume 4. [Google Scholar]

- Barnes, H.; Goh, N.S.L.; Leong, T.L.; Hoy, R. Silica-associated lung disease: An old-world exposure in modern industries. Respirology 2019, 24, 1165–1175. [Google Scholar] [CrossRef]

- NIOSH. NIOSH Pocket Guide to Chemical Hazards; U.S. Government Printing Office: Pittsburgh, PA, USA, 2007; DHHS Publication No. 2005-149.

- Saiyed, H.; Chatterjee, B. Rapid progression of silicosis in slate pencil workers: II. A follow-up study. Am. J. Ind. Med. 1985, 8, 135–142. [Google Scholar] [CrossRef] [PubMed]

- Seaton, A.; Legge, J.; Henderson, J.; Kerr, K. Accelerated silicosis in scottish stonemasons. Lancet 1991, 337, 341–344. [Google Scholar] [CrossRef]

- Calisti, R.; Ballatori, G. Fatal silicosis in a funeral arts’ craftsman. Med. Lav. 2016, 107, 478–484. [Google Scholar] [PubMed]

- Pérez, J.J.B.; Montiel, V.A.; Salgado-Barreira, Á.; Moure, M.A.A.; Díaz, A.C.C.; Dominguez, L.C.; Bello, M.E.G.; Villar, A.F.; Barcala, F.J.G. The 6-minute walk test as a tool for determining exercise capacity and prognosis in patients with silicosis. Arch. Bronconeumol. 2019, 55, 88–92. [Google Scholar] [CrossRef]

- Nicol, L.; McFarlane, P.; Hirani, N.; Reid, P. Six cases of silicosis: Implications for health surveillance of stonemasons. Occup. Med. 2015, 65, 220–225. [Google Scholar] [CrossRef]

- Cohen, C.; Fireman, E.; Ganor, E.; Man, A.; Ribak, J.; Lerman, Y. Accelerated silicosis with mixed-dust pneumoconiosis in a hard-metal grinder. J. Occup. Environ. Med. 1999, 41, 480–485. [Google Scholar] [CrossRef] [PubMed]

- Akgun, M.; Araz, O.; Ucar, E.Y.; Karaman, A.; Alper, F.; Gorguner, M.; Kreiss, K. Silicosis appears inevitable among former denim sandblasters: A 4-year follow-up study. Chest 2015, 148, 647–654. [Google Scholar] [CrossRef]

- Alper, F.; Akgun, M.; Onbas, O.; Araz, O. CT findings in silicosis due to denim sandblasting. Eur. Radiol. 2008, 18, 2739. [Google Scholar] [CrossRef]

- Özkan, M.; Ayan, A.; Arik, D.; Balkan, A.; Öngürü, Ö.; Gümüş, S. FDG PET findings in a case with acute pulmonary silicosis. Ann. Nucl. Med. 2009, 23, 883. [Google Scholar] [CrossRef]

- de la Hoz, R.E.; Rosenman, K.; Borczuk, A. Silicosis in dental supply factory workers. Respir. Med. 2004, 98, 791–794. [Google Scholar] [CrossRef] [PubMed]

- Perez-Alonso, A.; Córdoba-Doña, J.A.; Millares-Lorenzo, J.L.; Figueroa-Murillo, E.; García-Vadillo, C.; Romero-Morillo, J. Outbreak of silicosis in Spanish quartz conglomerate workers. Int. J. Occup. Environ. Health 2014, 20, 26–32. [Google Scholar] [CrossRef] [PubMed]

- Kramer, M.R.; Blanc, P.D.; Fireman, E.; Amital, A.; Guber, A.; Rhahman, N.A.; Shitrit, D. Artificial stone silicosis: Disease resurgence among artificial stone workers. Chest 2012, 142, 419–424. [Google Scholar] [CrossRef] [PubMed]

- Friedman, G.K.; Harrison, R.; Bojes, H.; Worthington, K.; Filios, M. Silicosis in a Countertop Fabricator—Texas, 2014. Mmwr. Morb. Mortal. Wkly. Rep. 2015, 64, 129. [Google Scholar]

- Mazurek, J.M.; Schleiff, P.L.; Wood, J.M.; Hendricks, S.A.; Weston, A. Update: Silicosis Mortality—United States, 1999–2013. Mmwr. Morb. Mortal. Wkly. Rep. 2015, 64, 653. [Google Scholar]

- Paolucci, V.; Romeo, R.; Sisinni, A.G.; Bartoli, D.; Mazzei, M.A.; Sartorelli, P. Silicosis in workers exposed to artificial quartz conglomerates: Does it differ from chronic simple silicosis? Arch. Bronconeumol. 2015, 51, e57–e60. [Google Scholar] [CrossRef]

- Grubstein, A.; Shtraichman, O.; Fireman, E.; Bachar, G.N.; Noach-Ophir, N.; Kramer, M.R. Radiological evaluation of artificial stone silicosis outbreak: Emphasizing findings in lung transplant recipients. J. Comput. Assist. Tomogr. 2016, 40, 923–927. [Google Scholar] [CrossRef]

- Ronsmans, S.; Decoster, L.; Keirsbilck, S.; Verbeken, E.K.; Nemery, B. Artificial stone-associated silicosis in Belgium. Occup. Environ. Med. 2019, 76, 133–134. [Google Scholar] [CrossRef]

- Hoy, R.F.; Baird, T.; Hammerschlag, G.; Hart, D.; Johnson, A.R.; King, P.; Putt, M.; Yates, D.H. Artificial stone-associated silicosis: A rapidly emerging occupational lung disease. Occup. Environ. Med. 2018, 75, 3–5. [Google Scholar] [CrossRef]

- Pascual Del Pobil y Ferré, M.A.; Sevila, R.G.; Rodenas, M.G.; Medel, E.B.; Reos, E.F.; Carbonell, J.G. Silicosis: A former occupational disease with new occupational exposure scenarios. Rev. Clín. Española 2019, 219, 26–29. [Google Scholar] [CrossRef]

- NIOSH. NIOSH Hazard Review Health Effects of Occupational Exposure to Respirable Crystalline Silica. Available online: http://www.cdc.gov/niosh/docs/2002-129/pdfs/2002-129.pdf (accessed on 8 October 2018).

- Seaton, A.; Cherrie, J.W. Quartz exposures and severe silicosis: A role for the hilar nodes. Occup. Environ. Med. 1998, 55, 383–386. [Google Scholar] [CrossRef] [PubMed]

- Leung, C.C.; Yu, I.T.S.; Chen, W. Silicosis. Lancet 2012, 379, 2008–2018. [Google Scholar] [CrossRef]

- Ndlovu, N.; Nelson, G.; Vorajee, N.; Murray, J. 38 years of autopsy findings in South African mine workers. Am. J. Ind. Med. 2016, 59, 307–314. [Google Scholar] [CrossRef] [PubMed]

- Horn, A. Silicosis Death Dust Audit Reveals ‘Major Epidemic Worse than Asbestos’. Available online: https://www.abc.net.au/news/2019-02-21/silicosis-death-dust-audit-reveals-major-epidemic-worse-asbestos/10830452 (accessed on 7 February 2020).

- Mazurek, J.M.; Attfield, M.D. Silicosis mortality among young adults in the United States, 1968–2004. Am. J. Ind. Med. 2008, 51, 568–578. [Google Scholar] [CrossRef] [PubMed]

- Bang, K.M.; Mazurek, J.M.; Wood, J.M.; White, G.E.; Hendricks, S.A.; Weston, A. Silicosis mortality trends and new exposures to respirable crystalline silica-United States, 2001–2010. Mmwr. Morb. Mortal. Wkly. Rep. 2015, 64, 117–120. [Google Scholar]

- Esswein, E.J.; Breitenstein, M.; Snawder, J.; Kiefer, M.; Sieber, W.K. Occupational exposures to respirable crystalline silica during hydraulic fracturing. J. Occup. Environ. Hyg. 2013, 10, 347–356. [Google Scholar] [CrossRef]

- Simcox, N.J.; Lofgren, D.; Leons, J.; Camp, J. Silica exposure during granite countertop fabrication. Appl. Occup. Environ. Hyg. 1999, 14, 577–582. [Google Scholar] [CrossRef]

- Bartoli, D.; Banchi, B.; Di Benedetto, F.; Farina, G.A.; Iaia, T.E.; Poli, C.; Romanelli, M.; Scancarello, G.; Tarchi, M. Silicosis in employees in the processing of kitchen, bar and shop countertops made from quartz resin composite. Provisional results of the environmental and health survey conducted within the territory of USL 11 of Empoli in Tuscany among employees in the processing of quertz resing compositre materials and review of the literature. Ital. J. Occup. Environ. Hyg. 2012, 3, 138–143. [Google Scholar]

- Li, Y.; Ren, S. Building Decorative Materials; Elsevier: Cambridge, UK, 2011. [Google Scholar]

- Quartzform. About. Available online: https://www.quartzforms.com/en/about (accessed on 7 February 2020).

- Silestone. Quartz Vs Granite Countertops. Available online: https://www.silestoneusa.com/quartz-vs-granite-countertops/ (accessed on 7 February 2020).

- Cooper, J.H.; Johnson, D.L.; Phillips, M.L. Respirable silica dust suppression during artificial stone countertop cutting. Ann. Occup. Hyg. 2014, 59, 122–126. [Google Scholar]

- Qi, C.; LO, L.-M. Engineering Control of Silica Dust from Stone Countertop Fabrication and Installation; CDC NIOSH: Washington, DC, USA, 2016.

- Reilly, M.J.; Timmer, S.J.; Rosenman, K.D. The burden of silicosis in Michigan: 1988–2016. Ann. Am. Thorac. Soc. 2018, 15, 1404–1410. [Google Scholar] [CrossRef]

- Vadillo, C.G.; Gómez, J.S.; Morillo, J.R. Silicosis in quartz conglomerate workers. Arch. Bronconeumol. 2011, 1, 53. [Google Scholar] [CrossRef]

- Maynard, A.D.; Jensen, P.A. Aerosol measurement in the workplace. In Aerosol Measurement: Principles, Techniques, and Applications; Baron, P., Willeke, K., Eds.; Van Nostrand Reinhold: New York, NY, USA, 2001; pp. 779–799. [Google Scholar]

- Hinds, W.C. Aerosol Technology, Properties, Behavior, and Measurement of Aerosol Particles, 2nd ed.; John Wiley & Sons Inc.: New York, NY, USA, 1999. [Google Scholar]

- NIOSH. NIOSH Manual of Analytical Methods; U.S. Government Printing Office: Washington, DC, USA, 2003.

- Oberdorster, G.; Sharp, Z.; Atudorei, V.; Elder, A.; Gelein, R.; Lunts, A.; Kreyling, W.; Cox, C. Extrapulmonary translocation of ultrafine carbon particles following whole-body inhalation exposure of rats. J. Toxicol. Environ. Health A 2002, 65, 1531–1543. [Google Scholar] [CrossRef] [PubMed]

- Guarnieri, G.; Bizzotto, R.; Gottardo, O.; Velo, E.; Cassaro, M.; Vio, S.; Putzu, M.G.; Rossi, F.; Zuliani, P.; Liviero, F. Multiorgan accelerated silicosis misdiagnosed as sarcoidosis in two workers exposed to quartz conglomerate dust. Occup. Environ. Med. 2019, 76, 178–180. [Google Scholar] [CrossRef] [PubMed]

- OSHA. Appendix C—Supplementary Exposure Limits. Available online: https://www.cdc.gov/niosh/npg/nengapdxc.html (accessed on 28 February 2020).

- GudU. Direttiva (UE) 2017/2398 del Parlamento Europeo e del Consiglio. Available online: https://eur-lex.europa.eu/legal-content/IT/TXT/PDF/?uri=CELEX:32017L2398&from=DA (accessed on 23 March 2020).

- IARC. Silica, Some Silicates, Coal Dust and Para-Aramid Fibrils: IARC Monographs on the Evaluation of Carcinogenic Risks to Humans, Vol. 68. JSTOR 1998, 9, 351–353. [Google Scholar]

- Phillips, M.L.; Johnson, D.L.; Johnson, A.C. Determinants of respirable silica exposure in stone countertop fabrication: A preliminary study. J. Occup. Environ. Hyg. 2013, 10, 368–373. [Google Scholar] [CrossRef]

- Johnson, D.L.; Phillips, M.L.; Qi, C.; Van, A.T.; Hawley, D.A. Experimental evaluation of respirable dust and crystalline silica controls during simulated performance of stone countertop fabrication tasks with powered hand tools. Ann. Work Expo. Health 2017, 61, 711–723. [Google Scholar] [CrossRef]

| Material | Manufacturer Reported Composition | Sample Dimensions (Height × Width × Thickness) |

|---|---|---|

| A | Inorganic mineral fillers (85–95%) Polymerized polyester resin (5–15%) Additives and pigments (<5%) | 21.6 × 35 × 1.95 cm |

| B | Quartz (>85%) Resin and color pigments (<15%) | 10 × 10 × 0.6 cm |

| C | Aluminosilicates Silica (<11%) Zircon (depending on product) Inorganic pigments (<7%) | 19 × 28 × 1.15 cm |

| Granite | Unspecified | 29.5 × 29.5 × 2.7 cm |

| Test | H₀ | p-Value |

|---|---|---|

| ANOVA | All means are equal | <0.0001 |

| Mood’s Median | All medians are equal | <0.0001 |

| Kruskal–Wallis | All medians are equal | <0.0001 |

| Material–Run | Weight Percentages of Crystalline Silica Minerals (%) | Airborne Dust Concentrations (mg/m3) | |||||

|---|---|---|---|---|---|---|---|

| Quartz | Cristobalite | Tridymite | Respirable | Quartz | Cristobalite | Tridymite | |

| A–1 | 52.8 | <0.4 | <0.4 | 78.9 | 41.7 | <0.3 | <0.3 |

| A–2 | 48.6 | <0.3 | <0.3 | 106.7 | 51.8 | <0.3 | <0.3 |

| A–3 | 53.0 | <0.3 | <0.3 | 111.4 | 59.0 | <0.3 | <0.3 |

| Average | 51.4 | <0.3 | <0.3 | 99.0 | 50.8 | <0.3 | <0.3 |

| St Dev | 2.5 | 0.1 | 0.1 | 17.6 | 8.7 | 0.0 | 0.0 |

| B–1 | 55.3 | <0.3 | <0.3 | 87.4 | 48.4 | <0.3 | <0.3 |

| B–2 | 51.4 | <0.3 | <0.3 | 94.3 | 48.5 | <0.3 | <0.3 |

| B–3 | 54.4 | <0.3 | <0.3 | 84.9 | 46.1 | <0.3 | <0.3 |

| Average | 53.6 | <0.3 | <0.3 | 88.9 | 47.7 | <0.3 | <0.3 |

| St Dev | 2.0 | 0.0 | 0.0 | 4.9 | 1.3 | 0.0 | 0.0 |

| C–1 | 4.9 | <0.4 | <0.4 | 77.3 | 3.8 | <0.3 | <0.3 |

| C–2 | 4.0 | <0.3 | <0.3 | 90.5 | 3.7 | <0.3 | <0.3 |

| C–3 | 4.4 | <0.4 | <0.4 | 80.0 | 3.5 | <0.3 | <0.3 |

| Average | 4.4 | <0.4 | <0.4 | 82.6 | 3.7 | <0.3 | <0.3 |

| St Dev | 0.5 | 0.1 | 0.1 | 7.0 | 0.1 | 0.0 | 0.0 |

| Granite–1 | 8.6 | <0.3 | <0.3 | 356.4 | 30.6 | <1.2 | <1.2 |

| Granite–2 | 7.9 | <0.3 | <0.3 | 420.3 | 33.3 | <1.2 | <1.2 |

| Granite–3 | 7.1 | <0.2 | <0.2 | 514.6 | 36.5 | <1.2 | <1.2 |

| Average | 7.9 | <0.3 | <0.3 | 430.4 | 33.5 | <1.2 | <1.2 |

| St Dev | 0.8 | 0.1 | 0.1 | 79.6 | 2.9 | 0.0 | 0.0 |

| Sample | Total Crystalline Silica (Weight %) | Respirable Silica in Bulk <10 μm (Weight %) | Respirable Silica in Bulk <5 μm (Weight %) |

|---|---|---|---|

| Material A | 90.8 § | 20.93 | 10.02 |

| Material B | 91.2 § | 14.16 | 5.48 |

| Material C | 9.6 * | 1.79 | 0.58 |

| Granite | 30.7 * | 5.25 | 2.71 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carrieri, M.; Guzzardo, C.; Farcas, D.; Cena, L.G. Characterization of Silica Exposure during Manufacturing of Artificial Stone Countertops. Int. J. Environ. Res. Public Health 2020, 17, 4489. https://doi.org/10.3390/ijerph17124489

Carrieri M, Guzzardo C, Farcas D, Cena LG. Characterization of Silica Exposure during Manufacturing of Artificial Stone Countertops. International Journal of Environmental Research and Public Health. 2020; 17(12):4489. https://doi.org/10.3390/ijerph17124489

Chicago/Turabian StyleCarrieri, Mariella, Carly Guzzardo, Daniel Farcas, and Lorenzo G. Cena. 2020. "Characterization of Silica Exposure during Manufacturing of Artificial Stone Countertops" International Journal of Environmental Research and Public Health 17, no. 12: 4489. https://doi.org/10.3390/ijerph17124489

APA StyleCarrieri, M., Guzzardo, C., Farcas, D., & Cena, L. G. (2020). Characterization of Silica Exposure during Manufacturing of Artificial Stone Countertops. International Journal of Environmental Research and Public Health, 17(12), 4489. https://doi.org/10.3390/ijerph17124489