Influence of Exhaust System Setup on Working Zone Pollution by Dust during Sawing of Particleboards

Abstract

1. Introduction

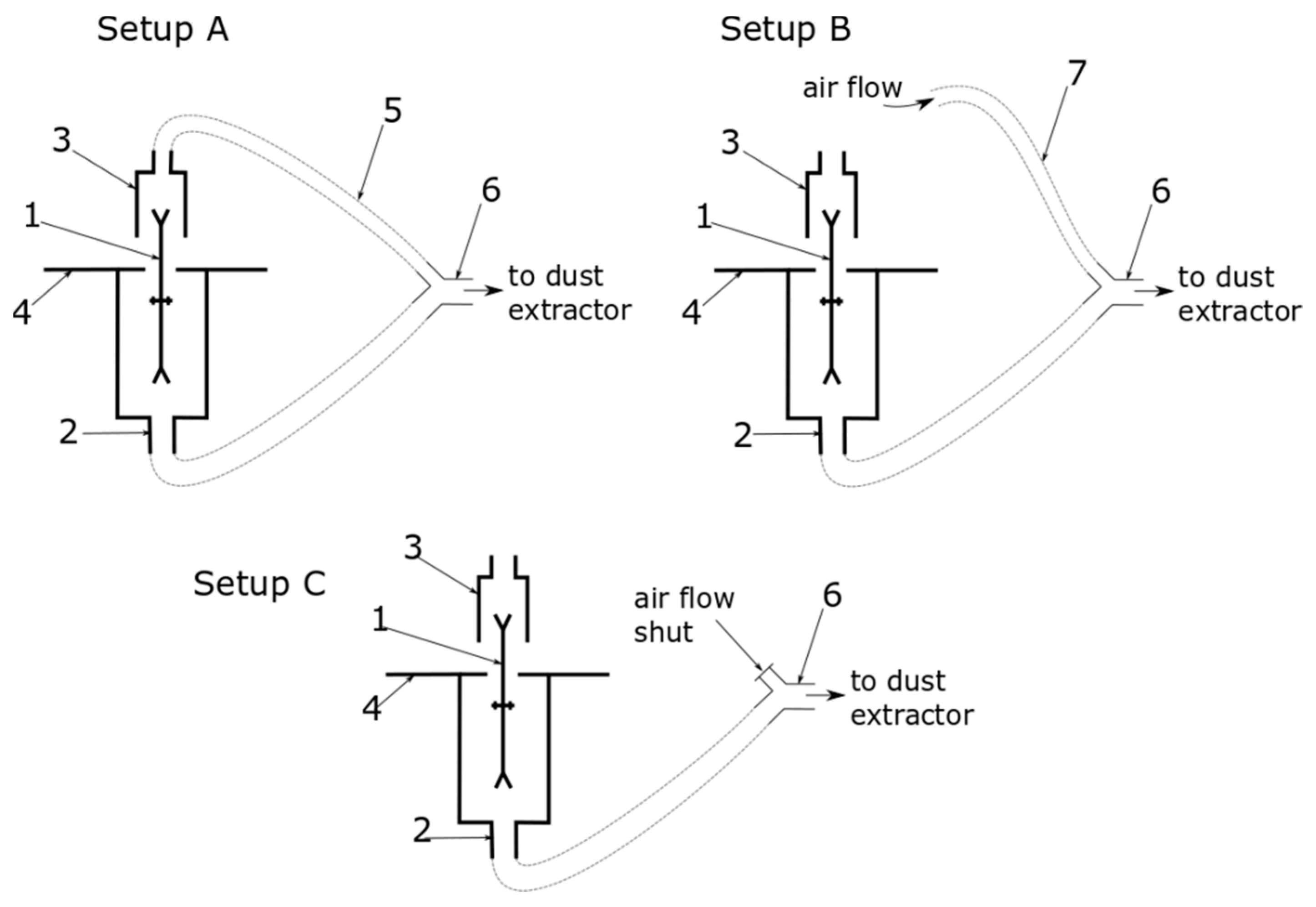

2. Materials and Methods

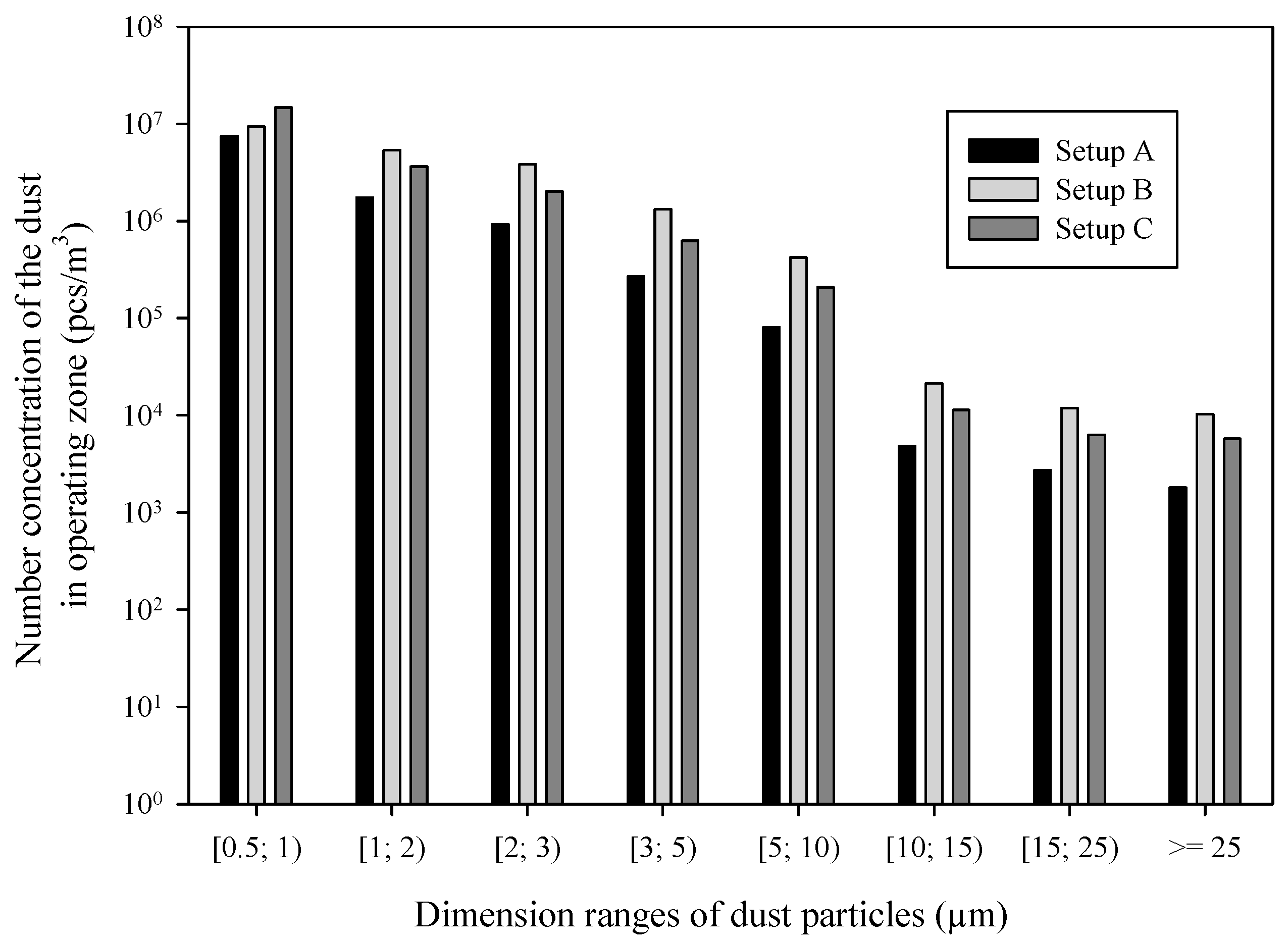

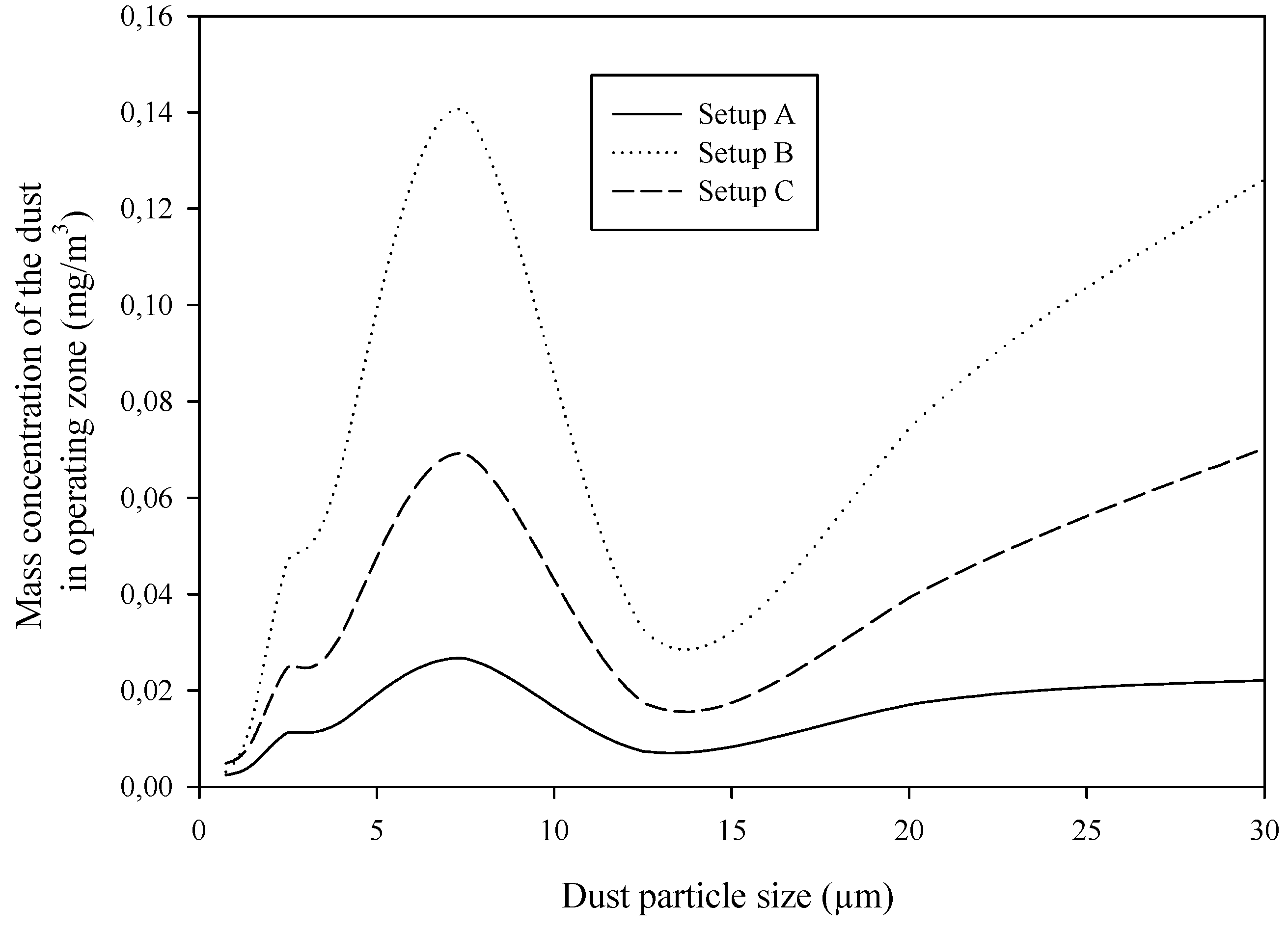

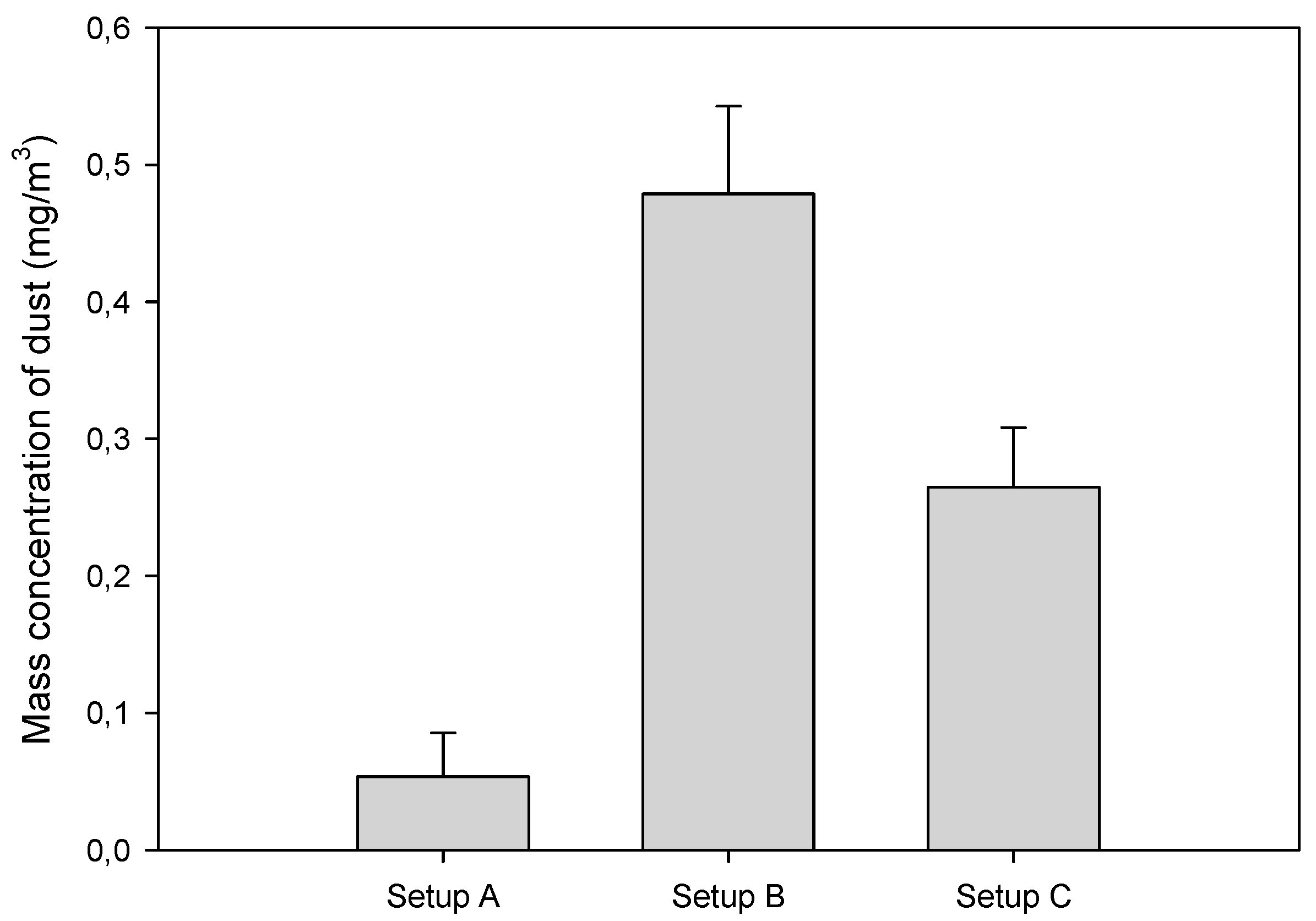

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Palmqvist, J.; Gustafsson, S.-I. Emission of dust in planing and milling of wood. Holz Als Roh Und Werkstoff 1999, 57, 164–170. [Google Scholar] [CrossRef]

- Fujimoto, K.; Takano, T.; Okumura, S. Difference in mass concentration of airborne dust during circular sawing of five wood-based materials. J. Wood Sci. 2011, 57, 149–154. [Google Scholar] [CrossRef]

- Kučerka, M.; Očkajová, A. Thermowood and granularity of abrasive wood dust. Acta Facultatis Xylologiae Zvolen res Publica Slovaca 2018, 60, 43–51. [Google Scholar] [CrossRef]

- Piernik, M.; Rogoziński, T.; Krauss, A.; Pinkowski, G. The influence of the thermal modification of pine (Pinus sylvestris L.) wood on the creation of fine dust particles in plane milling: Fine dust creation in the plane milling of thermally modified pine wood. J. Occup. Health 2019, 61, 481–488. [Google Scholar] [CrossRef]

- Mračková, E.; Krišťák, Ľ.; Kučerka, M.; Gaff, M.; Gajtanska, M. Creation of wood dust during wood processing: Size analysis, dust separation, and occupational health. BioResources 2015, 11, 209–222. [Google Scholar] [CrossRef]

- Baran, S.; Teul, I. Wood dust: An occupational hazard which increases the risk of respiratory disease. J. Physiol. Pharmacol. 2007, 58, 43–50. [Google Scholar]

- Kos, A.; Beljo-Lučić, R.; Šega, K.; Rapp, A.O. Influence of woodworking machine cutting parameters on the surrounding air dustiness. Holz Als Roh Und Werkstoff 2004, 62, 169–176. [Google Scholar] [CrossRef]

- Čavlović, A.; Beljo Lučić, R.; Ištvanić, J. Exposure to wood dust in Croatian woodworking industry. Wood Res. 2009, 54, 109–116. [Google Scholar]

- Chung, K.Y.K.; Cuthbert, R.J.; Revell, G.S.; Wassel, S.G.; Summers, N. A study on dust emission, particle size distribution and formaldehyde concentration during machining of medium density fibreboard. Ann. Occup. Hyg. 2000, 44, 455–466. [Google Scholar] [CrossRef]

- Liou, S.; Cheng, S.; Lai, F.; Yang, J. Respiratory symptoms and pulmonary function in mill workers exposed to wood dust. Am. J. Ind. Med. 1996, 30, 293–299. [Google Scholar] [CrossRef]

- Baran, S.; Swietlik, K.; Teul, I. Lung function: Occupational exposure to wood dust. Eur. J. Med. Res. 2009, 14, 14–17. [Google Scholar] [CrossRef]

- Heikkilä, P.; Martikainen, R.; Kurppa, K.; Husgafvel-Pursiainen, K.; Karjalainen, A. Asthma incidence in wood-processing industries in Finland in a register-based population study. Scand. J. Work Environ. Health. 2008, 34, 66–72. [Google Scholar] [CrossRef]

- Llorente, J.L.; Pérez-Escuredo, J.; Alvarez-Marcos, C.; Suárez, C.; Hermsen, M. Genetic and clinicalaspects of wood dust related intestinal-type sinonasal adenocarcinoma: A review. Eur. Arch. Otorhinolaryngol. 2009, 266, 1–7. [Google Scholar] [CrossRef]

- Jacobsen, G.; Schaumburg, I.; Sigsgaard, T.; Schlünssen, V. Non-malignant respiratory diseases and occupational exposure to wood dust. Part II. Dry wood industry. Ann. Agric. Environ. Med. 2010, 17, 29–44. [Google Scholar]

- Schlünssen, V.; Kespohl, S.; Jacobsen, G.; Raulf-Heimsoth, M.; Schaumburg, I.; Sigsgaard, T. Immunoglobulin E-mediated sensitization to pine and beech dust in relation to wood dust exposure levels and respiratory symptoms in the furniture industry. Scand. J. Work. Environ. Health 2011, 37, 159–167. [Google Scholar] [CrossRef]

- Siew, S.S.; Kauppinen, T.; Kyyrönen, P.; Heikkilä, P.; Pukkala, E. Occupational exposure to wood dust and formaldehyde and risk of nasal, nasopharyngeal, and lung cancer among Finnish men. Cancer Manag. Res. 2012, 4, 223–232. [Google Scholar] [CrossRef]

- Zhang, J.X.; Xu, H.; Shen, T.; Zhu, Q.X. Wood dust exposure and risk of sinonasal and nasopharyngeal cancer: A meta-analysis. Austin J. Dermatol. 2014, 1, 1009. [Google Scholar]

- Hancock, D.G.; Langley, M.E.; Chia, K.L.; Woodman, R.J.; Shanahan, E.M. Wood dust exposure and lung cancer risk: A meta-analysis. Int. J. Cardiol. 2015, 72, 889–898. [Google Scholar] [CrossRef] [PubMed]

- Staffieri, C.; Lovato, A.; Aielli, F.; Bortoletto, M.; Giacomelli, L.; Carrieri, M.; Romeo, S.; Boscolo-Rizzo, P.; Da Mosto, M.C.; Bartolucci, G.B.; et al. Investigating nasal cytology as a potential tool for diagnosing occupational rhinitis in woodworkers. Int. Forum Allergy Rhinol. 2015, 5, 814–819. [Google Scholar] [CrossRef] [PubMed]

- Vallières, E.; Pintos, J.; Parent, M.E.; Siemiatycki, J. Occupational exposure to wood dust and risk of lung cancer in two population-based case-control studies in Montreal, Canada. Environ. Health 2015, 14, 1. [Google Scholar] [CrossRef]

- Wiggans, R.E.; Evans, G.; Fishwick, D.; Barber, C.M. Asthma in furniture and wood processing workers: A systematic review. Occup. Med. 2016, 66, 193–201. [Google Scholar] [CrossRef] [PubMed]

- Top, Y. Relationship between Employees’ Perception of Airborne Wood Dust and Ventilation Applications in Micro-Scale Enterprises Producing Furniture. BioResources 2020, 15, 1252–1264. [Google Scholar] [CrossRef]

- Wieloch, G.; Mostowski, R. The new construction the exhaust fan for woodworking machine dedusting. Ann. WULS—SGGW For. Wood Technol. 2011, 76, 180–183. [Google Scholar]

- Scheeper, B.; Kromhout, H.; Boleij, J.S.M. Wood-dust exposure during wood-working processes. Ann. Occup. Hyg. 1995, 39, 141–154. [Google Scholar] [CrossRef]

- Felder Manuals. Workshop Formatting Saw; Felder KG: Hall in Tirol, Austria, 2015. (In Polish) [Google Scholar]

- Beljo-Lučić, R.; Čavlović, A.O.; Jug, M. Definitions and relation of airborne wood dust fractions. In Proceedings of the 4th International Scientific Conference—Woodworking Techniques, Prague, Czech Republic, 7–10 September 2011. [Google Scholar]

- Očkajová, A.; Beljo Lučić, R.; Čavlović, A.; Terenòvá, J. Reduction of dustiness in sawing wood by universal circular saw. Drvna Industrija 2006, 57, 119–126. [Google Scholar]

- Orłowski, K.A.; Chuchała, D.; Muziński, T.; Barański, J.; Banski, A.; Rogoziñski, T. The effect of wood drying method on the granularity of sawdust obtained during the sawing process using the frame sawing machine. Acta Facultatis Xylologiae Zvolen Res Publica Slovaca 2019, 61, 83–92. [Google Scholar] [CrossRef]

- Black, N.; Dilworth, M.; Summers, N. Occupational Exposure to Wood Dust in the British Woodworking Industry in 1999/2000. Ann. Occup. Hyg. 2007, 51, 249–260. [Google Scholar] [CrossRef]

- Baranski, J.; Jewartowski, M.; Wajs, J.; Orlowski, K.; Pikala, T. Experimental examination and modification of chip suction system in circular sawing machine. Drvna Industrija 2018, 69, 223–230. [Google Scholar] [CrossRef]

- Barański, J.; Pikała, T. Application in circular sawing machines of the experimental results of investigations of the chip removing system operation. Ann. WULS—SGGW For. Wood Technol. 2017, 100, 199–205. [Google Scholar]

- Barański, J.; Jewartowski, M.; Wajs, J.; Orłowski, K. Numerical analysis of chip removing system operation in circular sawing machine using CFD software. Chip Chipless Woodwork. Process. 2018, 11, 31–37. [Google Scholar]

- Mikkelsen, A.B.; Schlünssen, V.; Sigsgaard, T.; Schaumburg, I. Determinants of Wood Dust Exposure in the Danish Furniture Industry. Ann. Occup. Hyg. 2002, 46, 673–685. [Google Scholar] [CrossRef] [PubMed]

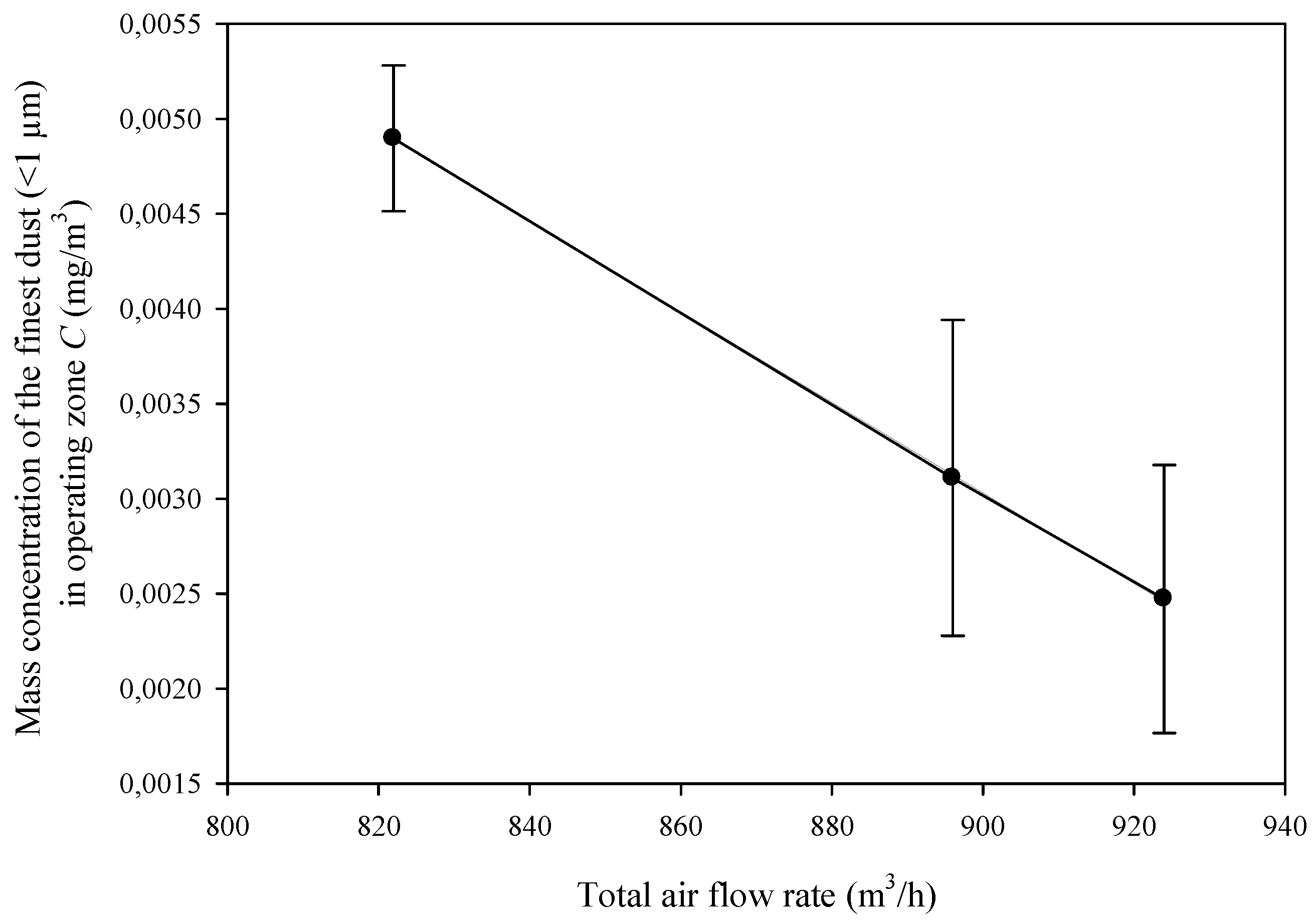

| Dust Extraction Connector | Setup A | Setup B | Setup C |

|---|---|---|---|

| Main dust extraction connector (120 mm) | connected | connected | connected |

| Auxiliary dust extraction connector (80 mm) | connected | Disconnected (maintained air flow in the pipe) | Disconnected (shut air flow in the pipe) |

| Dust Extraction Connector | Setup A | Setup B | Setup C | |||

|---|---|---|---|---|---|---|

| Flow Rate V (m3/h) | ||||||

| Required * | Current ** | Required | Current | Required | Current | |

| Main dust extraction connector (120 mm) | 814 | 708 | 814 | 630 | 814 | 822 |

| Auxiliary dust extraction connector (80 mm) | 362 | 216 | 362 | 264 | – | – |

| Total | 1176 | 924 | 1176 | 896 | 814 | 822 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pałubicki, B.; Hlásková, L.; Rogoziński, T. Influence of Exhaust System Setup on Working Zone Pollution by Dust during Sawing of Particleboards. Int. J. Environ. Res. Public Health 2020, 17, 3626. https://doi.org/10.3390/ijerph17103626

Pałubicki B, Hlásková L, Rogoziński T. Influence of Exhaust System Setup on Working Zone Pollution by Dust during Sawing of Particleboards. International Journal of Environmental Research and Public Health. 2020; 17(10):3626. https://doi.org/10.3390/ijerph17103626

Chicago/Turabian StylePałubicki, Bartosz, Luďka Hlásková, and Tomasz Rogoziński. 2020. "Influence of Exhaust System Setup on Working Zone Pollution by Dust during Sawing of Particleboards" International Journal of Environmental Research and Public Health 17, no. 10: 3626. https://doi.org/10.3390/ijerph17103626

APA StylePałubicki, B., Hlásková, L., & Rogoziński, T. (2020). Influence of Exhaust System Setup on Working Zone Pollution by Dust during Sawing of Particleboards. International Journal of Environmental Research and Public Health, 17(10), 3626. https://doi.org/10.3390/ijerph17103626