Development of the Fatigue Risk Assessment and Management in High-Risk Environments (FRAME) Survey: A Participatory Approach

Abstract

1. Introduction

2. Materials and Methods

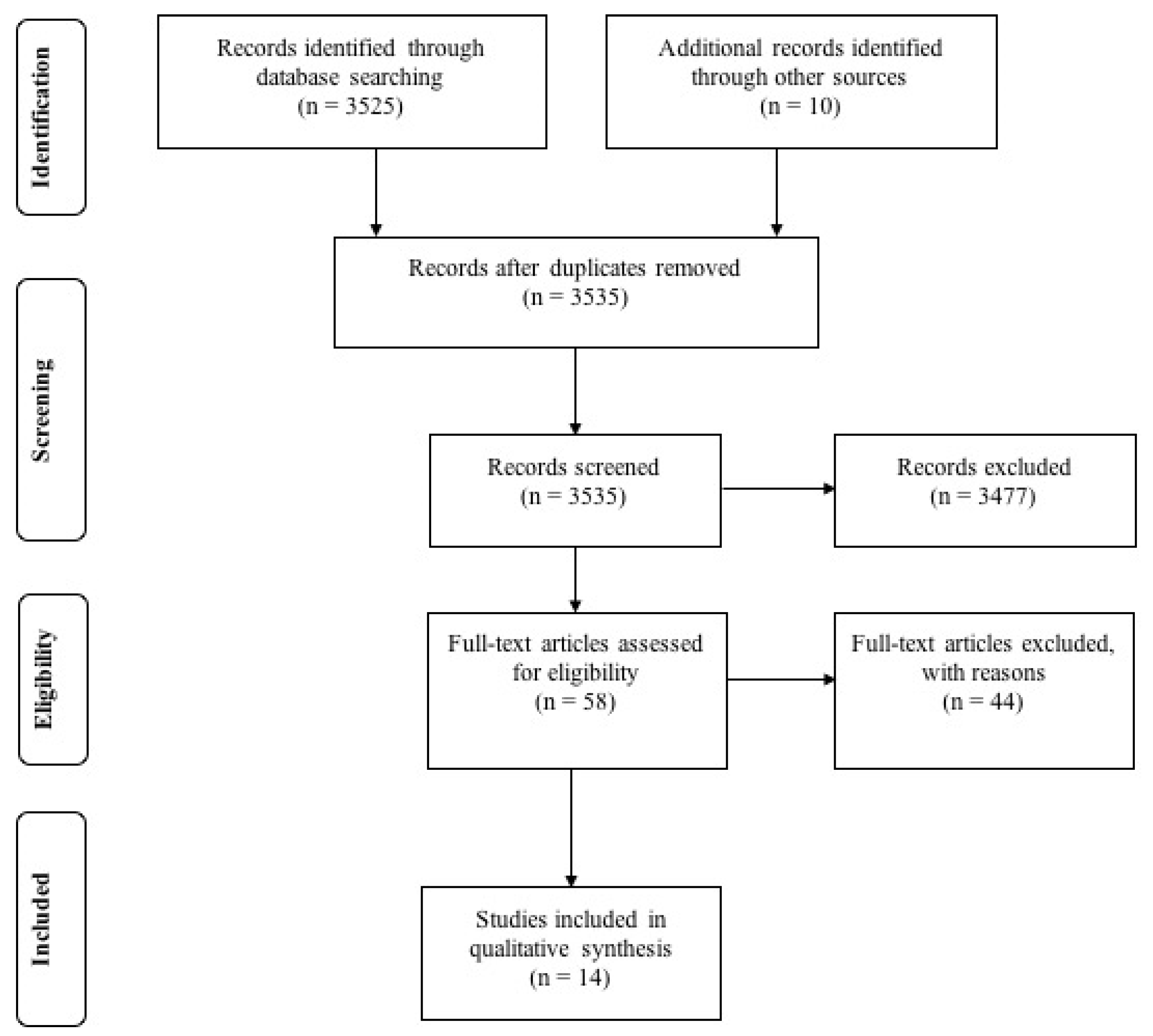

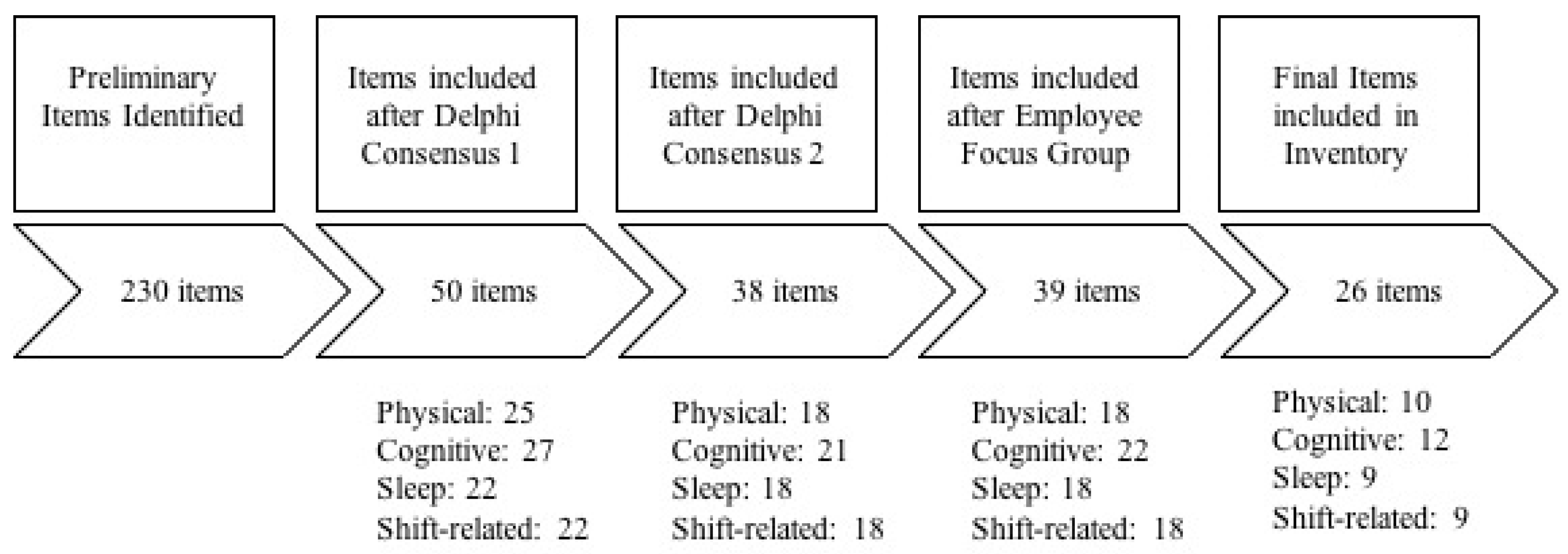

2.1. Fatigue Inventory Development (Phase 1)

2.2. Fatigue Inventory Refinement (Phases 2 and 3)

2.3. Participants

3. Results

3.1. Fatigue Inventory Development (Phase 1)

3.2. Fatigue Inventory Refinement (Phase 2)

3.3. Fatigue Inventory Refinement Through OGE Worker Focus Group (Phase 3)

3.4. Final Fatigue Inventory (FRAME)

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lerman, S.; Eskin, E.; Flower, D.; George, E.C.; Gerson, B.; Hartenbaum, N.; Hursh, S.R.; Moore-Ede, M. Fatigue risk management in the workplace. J. Occup. Environ. Med. 2012, 54, 231–258. [Google Scholar] [CrossRef] [PubMed]

- Caruso, C.C. Negative impacts of shiftwork and long work hours. Rehab. Nur. 2014, 39, 16–25. [Google Scholar] [CrossRef] [PubMed]

- Civil Service Bureau. BP Texas City Final Investigation Report; U.S. Chemical Safety and Hazard Investigation Board: Washington, DC, USA, 2007.

- Cullen, W.D. The Public Inquiry into the Piper Alpha Disaster; Health and Safety Executive: Bootle, UK, 1990.

- Theophilus, S.C.; Esenowo, V.N.; Arewa, A.O.; Ifelebuegu, A.O.; Nnadi, E.O.; Mbanaso, F.U. Human factors analysis and classification system for the oil and gas industry (HFACS-OGI). Reliab. Eng. Syst. Saf. 2017, 167, 168–176. [Google Scholar] [CrossRef]

- Gordon, R.; Flin, R.; Mearns, K. Designing and evaluating a human factors investigation tool (HFIT) for accident analysis. Saf. Sci. 2005, 43, 147–171. [Google Scholar] [CrossRef]

- Gordon, R.; Flin, R.; Mearns, K. Collecting human-factors data from accidents and incidents. Old Product. Facil. 2001, 16, 73–83. [Google Scholar] [CrossRef]

- McLaughlin, P.A.; Sherouse, O. The Impact of Federal Regulation on the 50 States; George Mason University: Fairfax, VA, USA, 2016. [Google Scholar]

- Bureau of Labor Statistics. Number of Fatal Occupational Injuries by Selected Worker and Case Characteristics, 2014–2015; Bureau of Labor Statistics: Washington, DC, USA, 2016.

- Gardner, R. Overview and characteristics of some occupational exposures and health risks on offshore oil and gas installations. Annals Occup. Hyg. 2003, 47, 201–210. [Google Scholar]

- Parkes, K.R. Shift schedules on North Sea oil/gas installations: A systematic review of their impact on performance, safety and health. Saf. Sci. 2012, 7, 1636–1651. [Google Scholar] [CrossRef]

- Sneddon, A.; Mearns, K.; Flin, R. Stress, fatigue, situation awareness and safety in offshore drilling crews. Saf. Sci. 2013, 56, 80. [Google Scholar] [CrossRef]

- DeLuca, J.; Genova, H.M.; Capili, E.J.; Wylie, G.R. Functional neuroimaging of fatigue. Phys. Med. Rehab. Clin. 2009, 20, 325–337. [Google Scholar] [CrossRef]

- Christodoulou, C. The assessment and measurement of fatigue. In Fatigue Window Brain; MIT Press: Cambridge, MA, USA, 2005; pp. 19–35. [Google Scholar]

- Thomas, M.; Sing, H.; Belenky, G.; Holcomb, H.; Mayberg, H.; Dannals, R.; Wagner, H., Jr.; Thorne, D.; Popp, K.; Rowland, L.; Welsh, A. Neural basis of alertness and cognitive performance impairments during sleepiness. I. effects of 24 h of sleep deprivation on waking human regional brain activity. J. Sleep Res. 2000, 9, 335–352. [Google Scholar] [CrossRef] [PubMed]

- Aaronson, L.S.; Teel, C.S.; Cassmeyer, V.; Neuberger, G.B.; Pallikkathayil, L.; Pierce, J.; Press, A.N.; Williams, P.D.; Wingate, A. Defining and measuring fatigue. J. Nurs. Scholars. 1999, 31, 45–50. [Google Scholar] [CrossRef]

- Lal, S.K.L.; Craig, A.A. Critical review of the psychophysiology of driver fatigue. Biol. Psychol. 2001, 55, 173–194. [Google Scholar] [CrossRef]

- Dawson, D.; Searle, A.K.; Paterson, J.L. Look before you (s)leep: Evaluating the use of fatigue detection technologies within a fatigue risk management system for the road transport industry. Sleep Med. Rev. 2014, 18, 141. [Google Scholar] [CrossRef] [PubMed]

- Borghini, G.; Astolfi, L.; Vecchiato, G.; Mattia, D.; Babiloni, F. Measuring neurophysiological signals in aircraft pilots and car drivers for the assessment of mental workload, fatigue and drowsiness. Neurosci. Biobehav. Rev. 2014, 44, 58–75. [Google Scholar] [CrossRef] [PubMed]

- Lal, S.K.L.; Craig, A. Electroencephalography activity associated with driver fatigue. J. Psychophysiol. 2001, 15, 183–189. [Google Scholar] [CrossRef]

- Lamond, N.; Dawson, D.; Roach, G.D. Fatigue assessment in the field: Validation of a hand-held electronic psychomotor vigilance task. Aviat. Space Environ. Med. 2005, 76, 486–489. [Google Scholar] [PubMed]

- Barker, L.M.; Nussbaum, M.A. Fatigue, performance and the work environment: A survey of registered nurses. J. Adv. Nurs. 2011, 67, 1370–1382. [Google Scholar] [CrossRef]

- Winwood, P.C.; Winefield, A.H.; Dawson, D.; Lushington, K. Development and validation of a scale to measure work-related fatigue and recovery: The occupational fatigue exhaustion/recovery scale (OFER). J. Occup. Environ. Med. 2005, 47, 594–606. [Google Scholar] [CrossRef]

- Shortz, A.E.; Franke, M.; Kilic, E.S.; Peres, S.C.; Mehta, R.K. Evaluation of offshore shiftwork using heart rate variability. Proc. Human Factors Ergon. Soc. Annu. Meeting. 2017, 61, 1036–1039. [Google Scholar] [CrossRef]

- Mehta, R.K.; Peres, S.C.; Kannan, P.; Rhee, J.; Shortz, A.E.; Sam Mannan, M. Comparison of objective and subjective operator fatigue assessment methods in offshore shiftwork. J. Loss Prevent. Process Ind. 2017, 48, 376–381. [Google Scholar] [CrossRef]

- Adel, M.; Akbar, R.; Gabraeil, N.S.; Abbas, R.F. Work ability index (WAI) and its association with psychosocial factors in one of the petrochemical industries in Iran. J. Occup. Health. 2012, 54, 112–118. [Google Scholar]

- Chan, M. Fatigue: The most critical accident risk in oil and gas construction. Constr. Manag. Econ. 2011, 29, 341–353. [Google Scholar] [CrossRef]

- Hystad, S.W.; Saus, E.; Sætrevik, B.; Eid, J. Fatigue in seafarers working in the offshore oil and gas re-supply industry: Effects of safety climate, psychosocial work environment and shift arrangement. Int. Marit. Health 2013, 64, 72. [Google Scholar]

- Ulleberg, P.; Rundmo, T. Job stress, social support, job satisfaction and absenteeism among offshore oil personnel. Work Stress 1997, 11, 215–228. [Google Scholar] [CrossRef]

- Chen, W.Q.; Yu, I.; Wong, T.W. Impact of occupational stress and other psychosocial factors on musculoskeletal pain among Chinese offshore oil installation workers. Occup. Environ. Med. 2005, 62, 251–256. [Google Scholar] [CrossRef] [PubMed]

- Quanmin, Z.; Hong, Z.; Jianchun, F. Human factor risk quantification for oil and gas drilling operation. Procedia Eng. 2011, 18, 312–317. [Google Scholar] [CrossRef]

- Zhang, M.; Sparer, E.H.; Murphy, L.A.; Dennerlein, J.T.; Fang, D.; Katz, J.N.; Caban-Martinez, A.J. Development and validation of a fatigue assessment scale for U.S. construction workers. Am. J. Indust. Med. 2015, 58, 220–228. [Google Scholar] [CrossRef]

- Abraham, O.; Jacob, F.B.; Jacob, O. A surgical safety checklist to reduce morbidity and mortality in a global population. ANZ J. Surg. 2007, 77, 621. [Google Scholar]

- Pucher, P.; Brunt, L.; Fanelli, R.; Asbun, H.; Aggarwal, R. SAGES expert delphi consensus: Critical factors for safe surgical practice in laparoscopic cholecystectomy. Surg. Endosc. 2015, 29, 3074–3085. [Google Scholar] [CrossRef]

- Hasson, F.; Keeney, S.; McKenna, H. Research guidelines for the delphi survey technique. J. Adv. Nurs. 2000, 32, 1008. [Google Scholar]

- Okoli, C.; Pawlowski, S.D. The delphi method as a research tool: An example, design considerations and applications. Inf. Manag. 2004, 42, 15–29. [Google Scholar] [CrossRef]

- Damodaran, L. User involvement in the systems design process-a practical guide for users. Behav. Inf. Technol. 1996, 15, 363–377. [Google Scholar] [CrossRef]

- Avers, K.; Johnson, W.B. A review of federal aviation administration fatigue research. Aviat. Psychol. Appl. Hum. Factors 2011, 1, 87–98. [Google Scholar] [CrossRef]

- Hsu, C.; Sandford, B.A. The delphi technique: Making sense of consensus. Pract. Assess. Res. Eval. 2007, 12, 1–8. [Google Scholar]

- Gordon, T.J. The delphi method. Futures Res. Methodol. 1994, 23, 2007. [Google Scholar]

- Beurskens, A.J.; Bultmann, U.; Kant, I.; Vercoulen, J.H.; Bleijenberg, G.; Swaen, G.M. Fatigue among working people: Validity of a questionnaire measure. Occup. Environ. Med. 2000, 57, 353–357. [Google Scholar] [CrossRef]

- Ahsberg, E.; Gamberale, F.; Gustafsson, K. Perceived fatigue after mental work: An experimental evaluation of a fatigue inventory. Ergonomics 2000, 43, 252–268. [Google Scholar] [CrossRef]

- Krupp, L.B.; LaRocca, N.G.; Muir-Nash, J.; Steinberg, A.D. The fatigue severity scale: Application to patients with multiple sclerosis and systemic lupus erythematosus. Arch. Neurol. 1989, 46, 1121–1123. [Google Scholar] [CrossRef]

- Matthews, G.; Desmond, P.A. Personality and multiple dimensions of task-induced fatigue: A study of simulated driving. Pers. Indiv. Differ. 1998, 25, 443–458. [Google Scholar] [CrossRef]

- Stein, K.D.; Martin, S.C.; Hann, D.M.; Jacobsen, P.B. A multidimensional measure of fatigue for use with cancer patients. Cancer Pract. 1998, 6, 143. [Google Scholar] [CrossRef] [PubMed]

- Smets, E.M.A.; Garssen, B.; Bonke, B.; De Haes, J.C.J.M. The multidimensional fatigue inventory (MFI) psychometric qualities of an instrument to assess fatigue. J. Psychosom. Res. 1995, 39, 315–325. [Google Scholar] [CrossRef]

- Carpenter, J.S.; Andrykowski, M.A. Psychometric evaluation of the Pittsburgh sleep quality index. J. Psychosom. Res. 1998, 45, 5–13. [Google Scholar] [CrossRef]

- Kato, T. Development of the sleep quality questionnaire in healthy adults. J. Health Psychol. 2014, 19, 977–986. [Google Scholar] [CrossRef] [PubMed]

- Patterson, P.D.; Buysse, D.J.; Weaver, M.D.; Suffoletto, B.P.; McManigle, K.L.; Callaway, C.W.; Yealy, D.M. Emergency healthcare worker sleep, fatigue, and alertness behavior survey (SFAB): Development and content validation of a survey tool. Accid. Anal. Prev. 2014, 73, 399–411. [Google Scholar] [CrossRef] [PubMed]

- Egleston, B.L.; Miller, S.M.; Meropol, N.J. The impact of misclassification due to survey response fatigue on estimation and identifiability of treatment effects. Stat. Med. 2011, 30, 3560–3572. [Google Scholar] [CrossRef] [PubMed]

- Shortz, A.E.; Hoyle, W.; Peres, S.C.; Mehta, R.K. Fatigue indicators of 12-h day and night shifts in simulated offshore well control scenarios. Proc. Hum. Factors Ergonom. Soc. Annu. Meeting 2018, 62, 897–899. [Google Scholar] [CrossRef]

- API Industrial Hygiene TF Workshop. Fatigue Risk Management Systems for Personnel in the Refining and Petrochemical Industries. Available online: https://www.api.org/environment-health-and-safety/health-safety/process-safety-industry/industrial-hygiene-workshop/~/media/9e82dde5834d4abe915e5a8a9c5b74f5.ashx (accessed on 11 February 2019).

- Bureau of Labor Statistics (BLS). Fatality Data are from the Census of Fatal Occupational Injuries. Nonfatal Injury and Illness Data are from the Survey of Occupational Injuries and Illnesses; Bureau of Labor Statistics: Washington, DC, USA, 2014.

- Rundmo, T.; Hestad, H.; Ulleberg, P. Organizational factors, safety attitudes and workload among offshore oil personnel. Saf. Sci. 1998, 29, 75–87. [Google Scholar] [CrossRef]

- Skogdalen, J.E.; Utne, I.B.; Vinnem, J.E. Developing safety indicators for preventing offshore oil and gas deepwater drilling blowouts. Saf. Sci. 2011, 49, 1187–1199. [Google Scholar] [CrossRef]

- Ross, J.K. Offshore industry shift work-health and social considerations. Occup. Med. 2009, 59, 310–315. [Google Scholar] [CrossRef]

- Gibbs, M.; Hampton, S.; Morgan, L.; Arendt, J. Adaptation of the circadian rhythm of 6-sulphatoxymelatonin to a shift schedule of seven nights followed by seven days in offshore oil installation workers. Neurosci. Lett. 2002, 325, 91–94. [Google Scholar] [CrossRef]

- Bureau of Labor Statistics. Hispanics and Latinos in Industries and Occupations: The Economics Daily; U.S. Bureau of Labor Statistics: Washington, DC, USA, 2015.

| Delphi Panel 1 (n = 8) | Delphi Panel 2 (n = 5) | Worker Focus Group (n = 11) | |

|---|---|---|---|

| Gender | |||

| Male | 6 | 4 | 100% |

| Female | 2 | 1 | |

| Age (Years) | 38.57 (12.45) | 38.40 (17.47) | 44.36 (3.98) |

| Race | |||

| American Indian | 0% | 0% | 18.2% |

| Black or African American | 0% | 0% | 9.1% |

| White | 62.5% | 60% | 18.2% |

| More than one race | 12.5% | 0% | 8.3% |

| Unknown or not reported | 25% | 30% | 41.7% |

| Ethnicity | |||

| Hispanic or Latino | 12.5% | 0% | 54.6% |

| Not Hispanic or Latino | 87.5% | 100% | 27.3% |

| Unknown or not reported | 0% | 0% | 18.2% |

| Education | |||

| Some High School | 0% | 0% | 18.2% |

| HS Graduate or Equivalent | 0% | 0% | 54.6% |

| Some College | 100% | 100% | 9.1% |

| Unknown or not reported | 0% | 0% | 18.2% |

| Experience (Years) | 8.71 (11.22) | 11.70 (11.29) | 16.11 (4.36) |

| Item | Administered | Dimension of Fatigue | ||||

|---|---|---|---|---|---|---|

| Pre-Shift | Post-Shift | Physical | Mental | Sleep | Shift-Related | |

| To what extent are you having to re-do or repeat tasks? | X | X | X | X | X | X |

| To what extent are you experiencing eye strain? | X | X | X | X | X | |

| To what extent do your legs feel tired or heavy? | X | X | X | |||

| To what extent are your joints (e.g., knee or elbow) feeling achy or stiff? | X | X | X | |||

| To what extent are you experiencing stiff muscles? | X | X | X | |||

| To what extent are you having trouble concentrating? | X | X | X | |||

| To what extent are you having trouble paying attention (e.g., like during meetings or briefs)? | X | X | X | |||

| To what extent has your sleepiness interfered with your work? | X | X | X | X | ||

| To what extent are you still tired even after waking up from sleep? | X | X | X | |||

| To what extent did you recover between shifts? | X | X | X | |||

| To what extent did you have trouble sleeping? | X | X | X | |||

| To what extent did you feel exhausted? | X | X | X | X | X | |

| To what extent did you experience cramps in your muscles? | X | X | ||||

| To what extent did you experience rapid heartbeats? | X | X | ||||

| To what extent did your legs feel numb? | X | X | ||||

| To what extent did your arms, hands, and/or fingers feel numb? | X | X | ||||

| To what extent did fatigue interferes with your physical functioning. | X | X | ||||

| To what extend did fatigue interferes with your mental functioning. | X | X | ||||

| To what extent did you experience blurred or distorted vision? | X | X | ||||

| To what extent did you daydream during work duties? | X | X | ||||

| To what extent did you have trouble remembering work-related things (i.e., instructions or procedures)? | X | X | ||||

| To what extent did you find it difficult to pay attention to someone, even when you were being spoken to directly? | X | X | ||||

| To what extent did you find it easy to keep track of everything was going on around you? | X | X | ||||

| To what extent did you have trouble getting back into work after an interruption? | X | X | ||||

| To what extent did you experience difficulty staying awake during work? | X | X | X | |||

| To what extent did you feel drowsy during your shift? | X | X | X | |||

| Total | 11 | 20 | 10 | 12 | 9 | 9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shortz, A.E.; Mehta, R.K.; Peres, S.C.; Benden, M.E.; Zheng, Q. Development of the Fatigue Risk Assessment and Management in High-Risk Environments (FRAME) Survey: A Participatory Approach. Int. J. Environ. Res. Public Health 2019, 16, 522. https://doi.org/10.3390/ijerph16040522

Shortz AE, Mehta RK, Peres SC, Benden ME, Zheng Q. Development of the Fatigue Risk Assessment and Management in High-Risk Environments (FRAME) Survey: A Participatory Approach. International Journal of Environmental Research and Public Health. 2019; 16(4):522. https://doi.org/10.3390/ijerph16040522

Chicago/Turabian StyleShortz, Ashley E., Ranjana K. Mehta, S. Camille Peres, Mark E. Benden, and Qi Zheng. 2019. "Development of the Fatigue Risk Assessment and Management in High-Risk Environments (FRAME) Survey: A Participatory Approach" International Journal of Environmental Research and Public Health 16, no. 4: 522. https://doi.org/10.3390/ijerph16040522

APA StyleShortz, A. E., Mehta, R. K., Peres, S. C., Benden, M. E., & Zheng, Q. (2019). Development of the Fatigue Risk Assessment and Management in High-Risk Environments (FRAME) Survey: A Participatory Approach. International Journal of Environmental Research and Public Health, 16(4), 522. https://doi.org/10.3390/ijerph16040522