Characterization and Arsenic Adsorption Behaviors of Water Treatment Residuals from Waterworks for Iron and Manganese Removal

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization of WTRs

2.3. Bach Adsorption Experiments

2.4. Analytical Methods

3. Result and Discussion

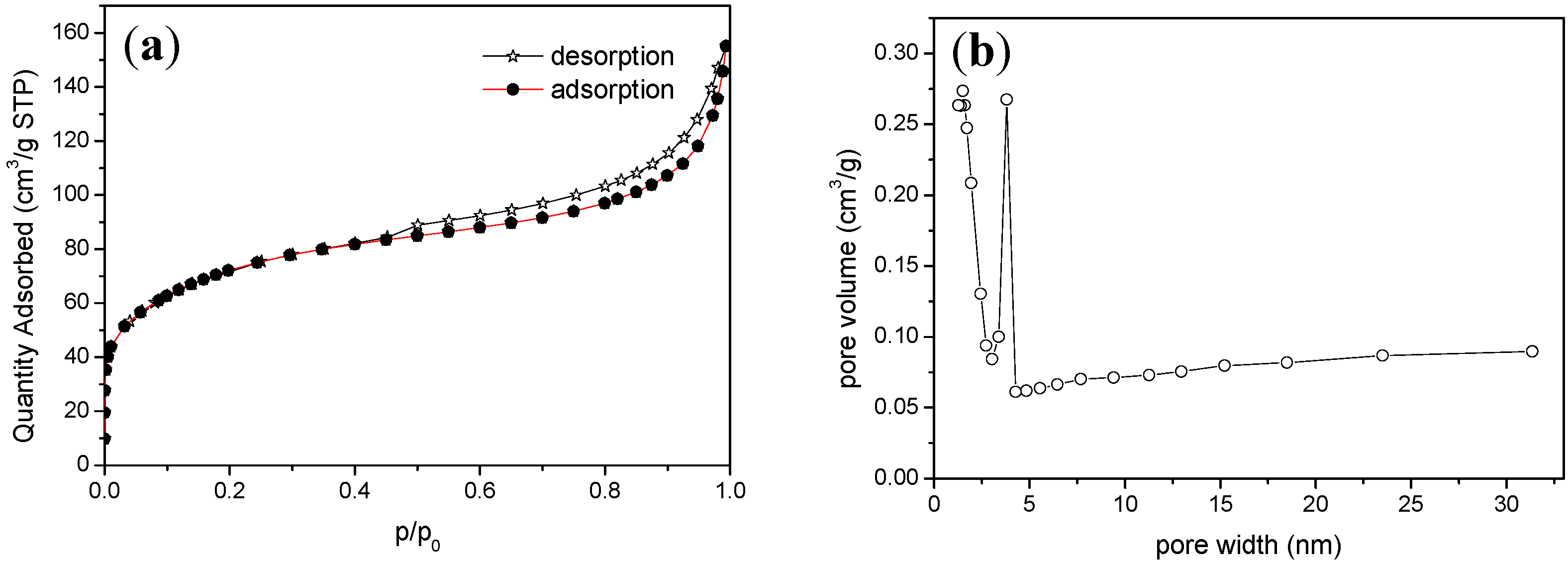

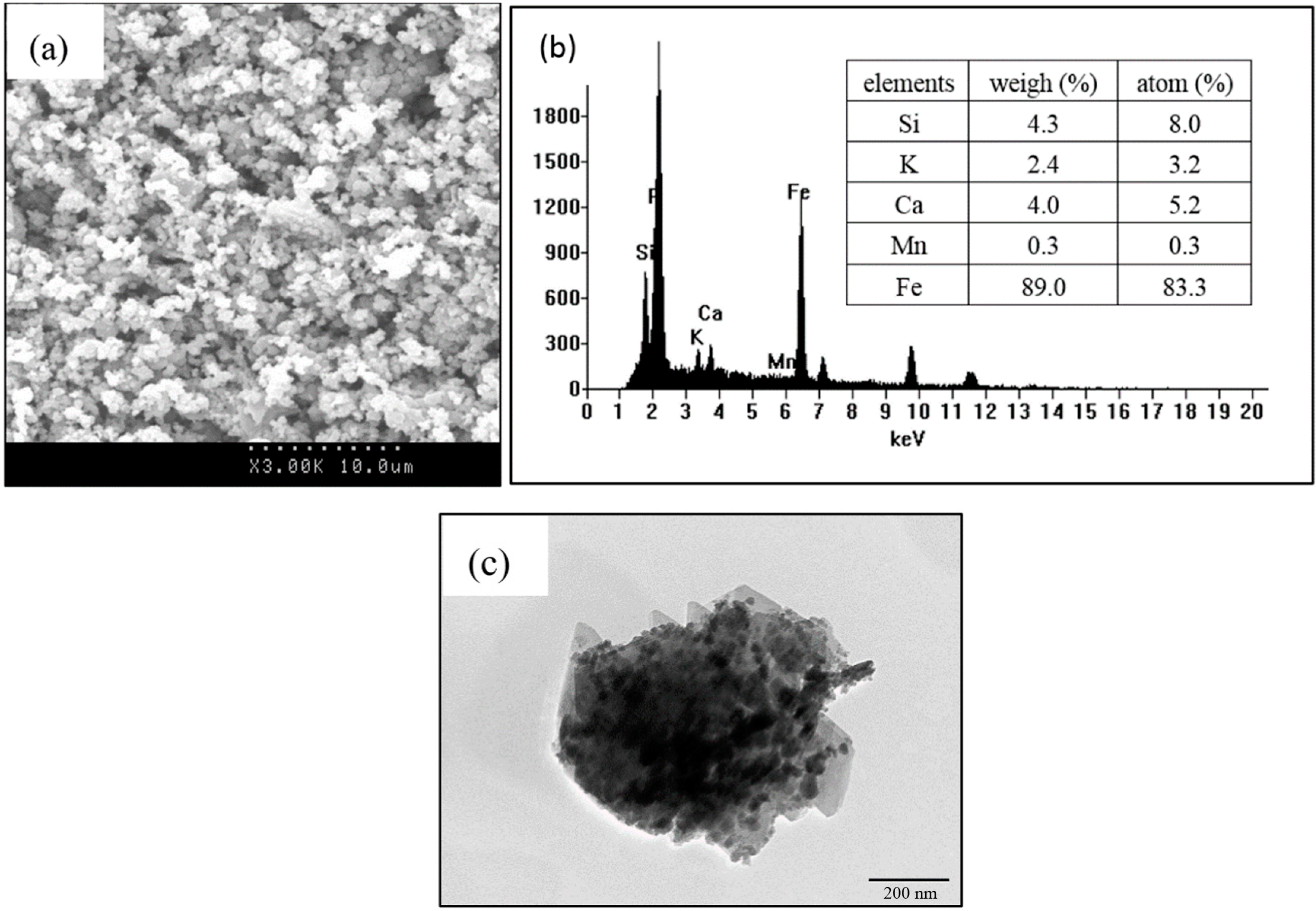

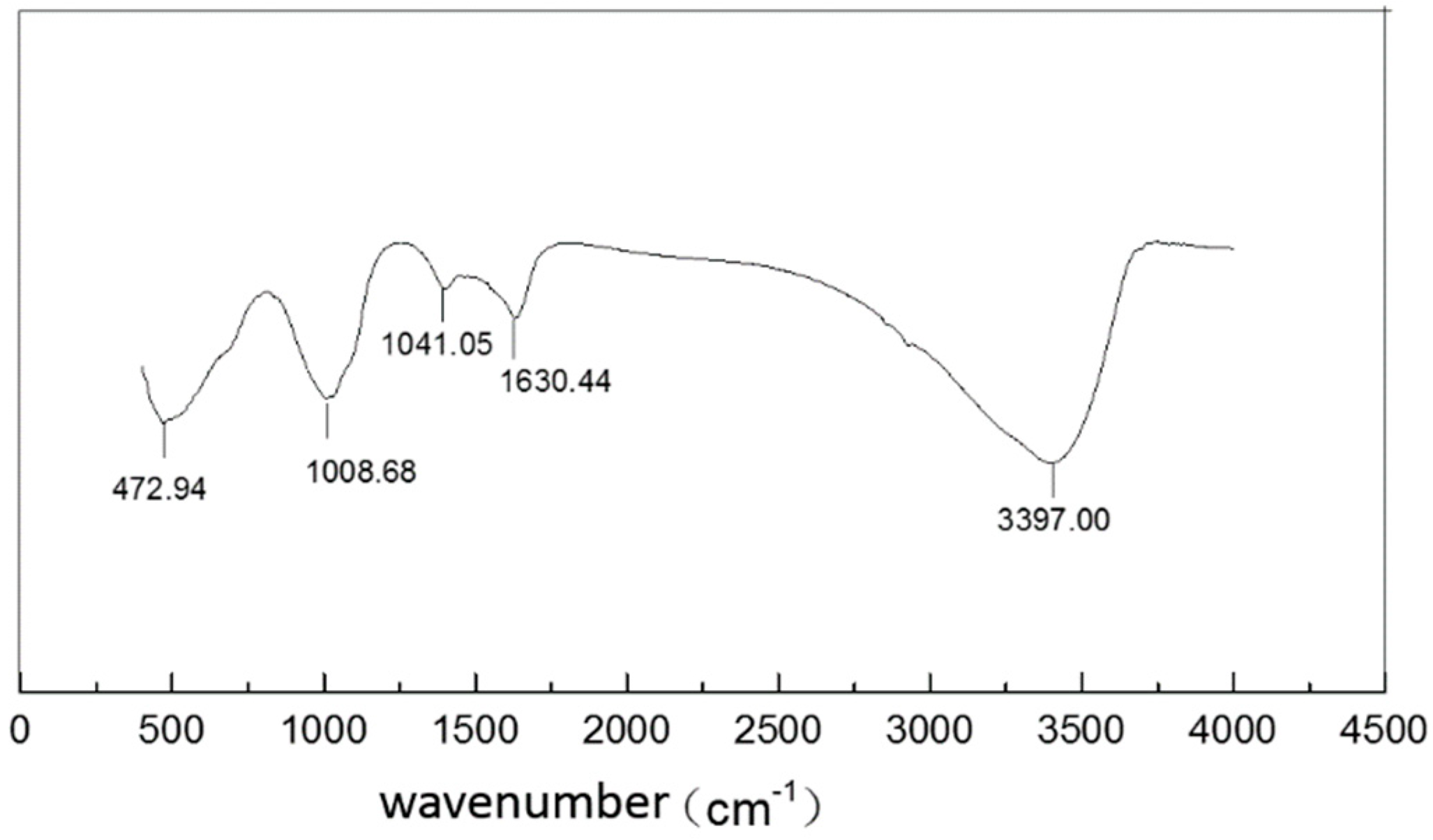

3.1. WTRs Characterization

3.2. Adsorption Kinetics

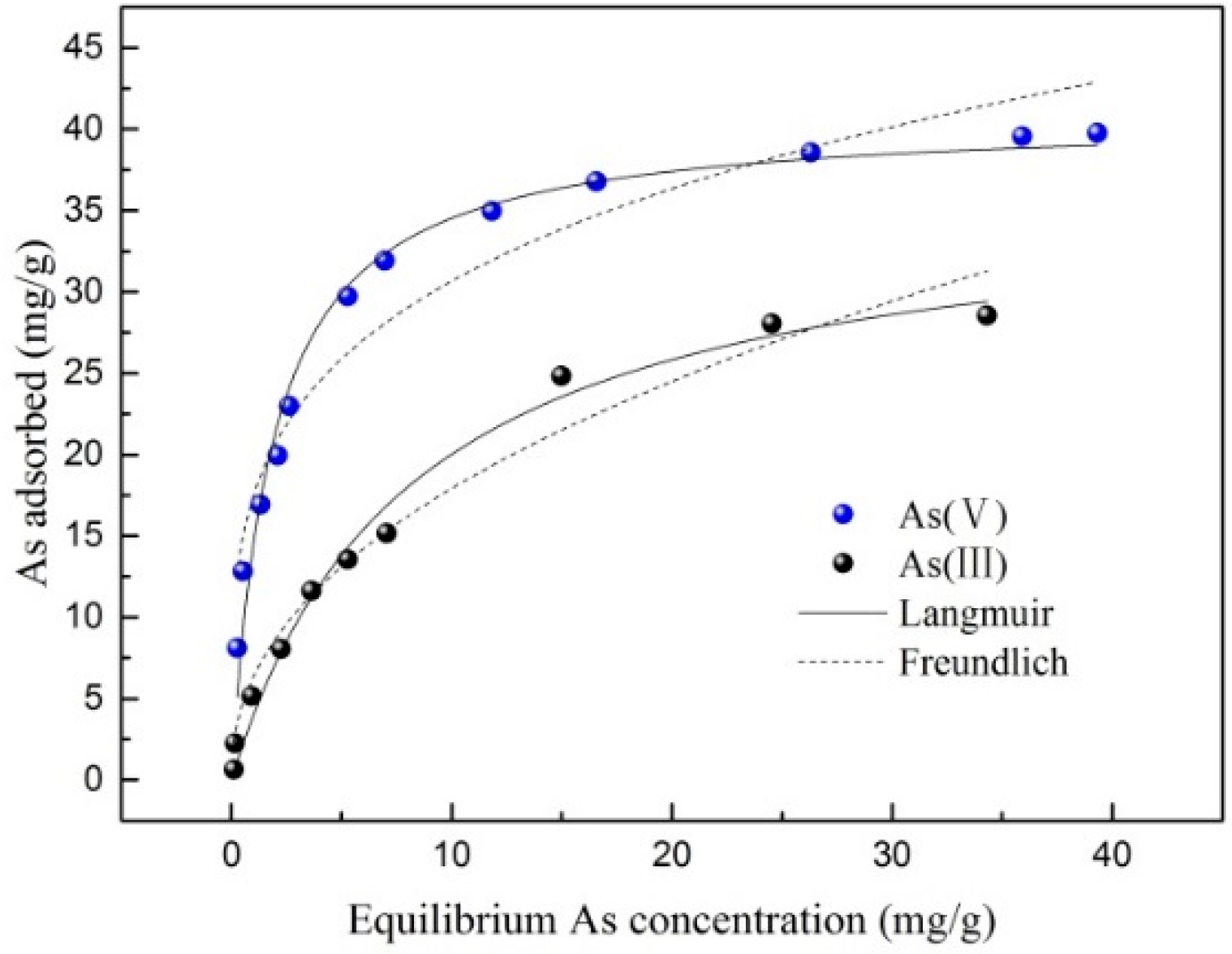

3.3. Adsorption Isotherms

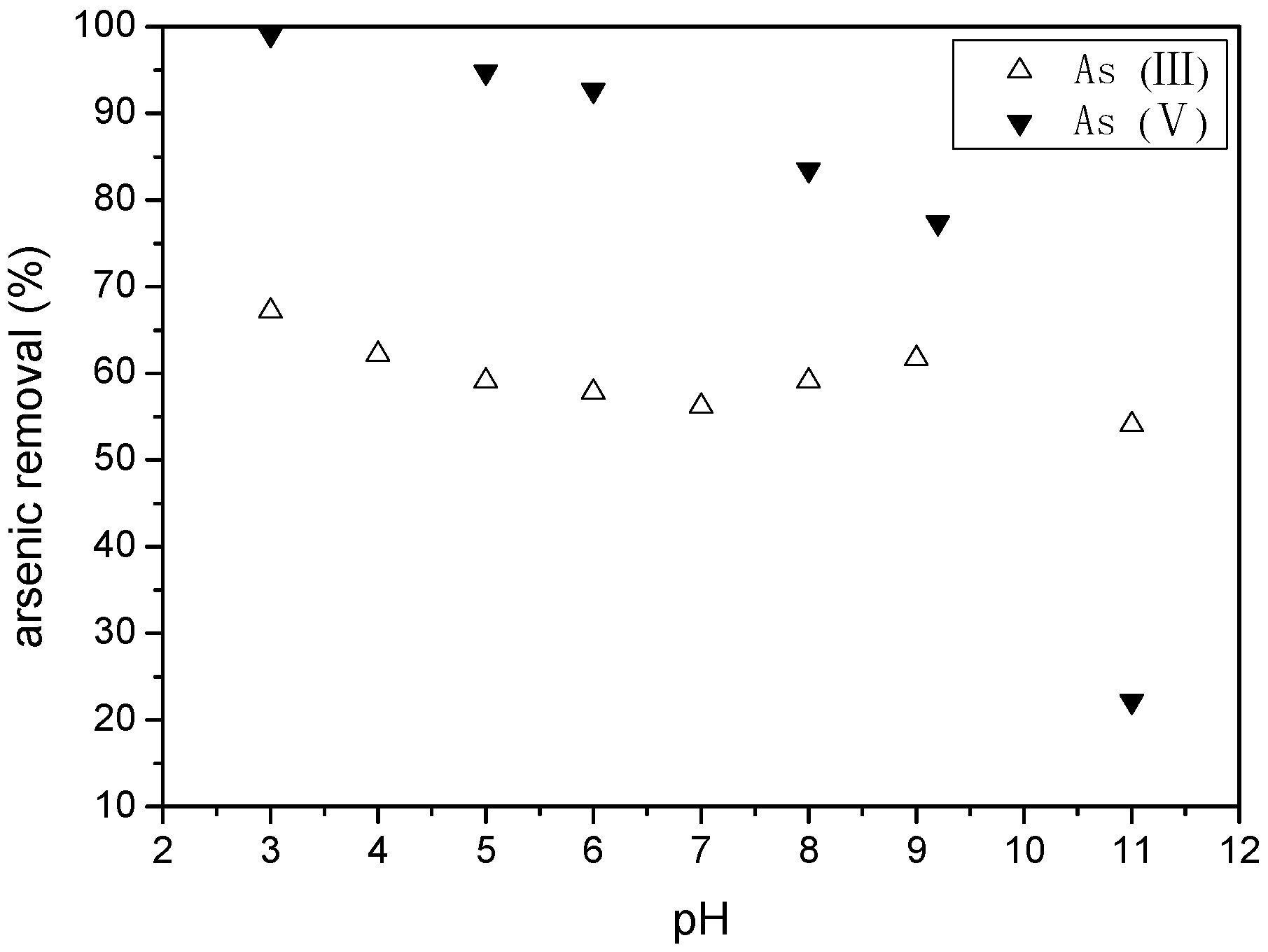

3.4. Influence of Initial pH of Solution and Coexisting Anions

3.5. Possible Mechanisms for Arsenic Adsorption

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mandal, B.K.; Suzuki, K.T. Arenic round the world: A review. Talanta 2002, 58, 201–235. [Google Scholar] [CrossRef]

- Bureau of Indian Standards-BIS10500-report: Indian Standard Drinking Water Specification, 2nd revision. 2012. Available online: http://cgwb.gov.in/Documents/WQ-standards.pdf (accessed on 5 September 2016).

- Sharma, V.K.; Sohn, M. Aquatic arsenic: Toxicity, speciation, transformations, and remediation. Environ. Int. 2009, 35, 743–759. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.S.; Qu, J.H.; Liu, H.J.; Liu, R.P.; Li, G.T. Removal mechanism of As (III) by a novel Fe-Mn binary oxide adsorbent: Oxidation and sorption. Environ. Sci. Technol. 2007, 41, 4613–4619. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.S.; Qu, J.H.; Liu, H.J.; Liu, R.P.; Wu, R.C. Preparation and evaluation of a novel Fe-Mn binary oxide adsorbent for effective arsenite removal. Water Res. 2007, 41, 1921–1928. [Google Scholar] [CrossRef] [PubMed]

- Dhoble, R.M.; Maddigapu, P.R.; Rayalu, S.; Bhole, A.G.; Dhoble, A.S.; Dhoble, S.R. Removal of As(III) from water by magnetic binary oxide particles(MBOP): Experimental studies on fixed bed column. J. Hazard. Mater. 2017, 322, 469–478. [Google Scholar] [CrossRef] [PubMed]

- Aemel, N.K.; Yusoff, A.R.; Lakkaboyana, S.K.; Majid, Z.A.; Salmiati, S. High concentration arsenic removal from aqueous solution using nano-iron ion enrich material (NIIEM) super adsorbent. Chem. Eng. J. 2017, 317, 343–355. [Google Scholar]

- Adio, S.O.; Omar, M.H.; Asif, M.; Saleh, T.A. Arsenic and selenium removal from water using biosynthesized nanoscale zero-valent iron: A factorial design analysis. Process Saf. Environ. Prot. 2017, 107, 518–527. [Google Scholar] [CrossRef]

- Rubinos, D.A.; Spagnoli, G. Assessment of red mud as sorptive landfill liner for the retention of arsenic (V). J. Environ. Manag. 2019, 232, 271–285. [Google Scholar] [CrossRef]

- Karnel, S.R.; Choi, H.; Kim, J.Y.; Vigneswaran, S.; Shim, W.G. Removal of arsenic(III) from groundwater using low-cost industrial by-products-blast furnace slag. Water Qual. Res. J. Can. 2006, 41, 130–139. [Google Scholar] [CrossRef]

- Zhang, K.H.; Zhang, D.X.; Zhang, K. Arsenic removal from water using a novel amorphous adsorbent developed from coal fly ash. Water Sci. Technol. 2016, 73, 1954–1962. [Google Scholar] [CrossRef]

- Zeng, H.P.; Yin, C.; Qiao, T.D.; Yu, Y.P.; Zhang, J.; Li, D. As (V) Removal from water using a novel magnetic particle adsorbent prepared with iron-containing water treatment residuals. ACS Sustain. Chem. Eng. 2018, 6, 14734–14742. [Google Scholar] [CrossRef]

- Newcombe, G.; Hayes, R.; Drikas, M. Granular activated carbon: Importance of surface properties in the adsorption of naturally occurring organics. Colloids Surf. A. 1993, 78, 65–71. [Google Scholar] [CrossRef]

- Zhang, J.; Li, D.; Yang, H.; Chen, L.X.; Gao, J. Mechanism and Engineering Technology of Biological Manganese Fixation and Manganese Removal; China Architecture & Building Press: Beijing, China, 2005. (In Chinese) [Google Scholar]

- Ociński, D.; Jacukowicz-Sobala, I.; Mazur, P.; Raczyk, J.; Kociołek-Balawejder, E. Water treatment residuals containing iron and manganese oxides for arsenic removal from water-characterization of physicochemical properties and adsorption studies. Chem. Eng. J. 2016, 294, 210–221. [Google Scholar] [CrossRef]

- Fan, X.; Parker, D.J.; Smith, M.D. Adsorption kinetics of fluoride on low cost materials. Water Res. 2003, 37, 4929–4937. [Google Scholar] [CrossRef]

- Elkhatib, E.; Mahdy, A.; Sherif, F.; Hamadeen, H. Evaluation of a novel water treatment residual nanoparticles as sorbent for arsenic removal. J. Nanomater. 2015, 3, 1–11. [Google Scholar] [CrossRef]

- Gibbons, M.K.; Gagnon, G.A. Adsorption of arsenic from a Nova Scotia groundwater onto water treatment residual solids. Water Res. 2010, 44, 5740–5749. [Google Scholar] [CrossRef]

- Luo, X.; Wang, C.H.; Luo, S.; Dong, R.; Tu, X.; Zeng, G. Adsorption of As(III) and As(V) from water using magnetite Fe3O4-reduced graphite oxide-MnO2 nanocomposites. Chem. Eng. J. 2012, 187, 45–52. [Google Scholar] [CrossRef]

- Li, Y.R.; Wang, J.; Luan, Z.K.; Liang, Z. Arsenic removal from aqueous solution using ferrous based red mud sludge. J. Hazard. Mater. 2010, 177, 131–137. [Google Scholar] [CrossRef]

- Konstantinos, C.M.; Dibyendu, S.; Rupali, D. Evaluating a drinking-water waste by-product as a novel sorbent for arsenic. Chemosphere 2006, 64, 730–741. [Google Scholar]

- Brechbuhl, Y.; Christl, I.; Elzinga, E.J.; Kretzschmar, R. Competitive sorption of carbonate and arsenic to hematite: Combined ATR-FTIR and batch experiments. J. Colloid Interface Sci. 2012, 377, 313–321. [Google Scholar] [CrossRef]

- Jain, A.; Raven, K.P.; Loeppert, R.H. Arsenite and arsenate adsorption on ferrihydrite: Surface charge reduction and net OH- release stoichiometry. Environ. Sci. Technol. 1999, 33, 1179–1184. [Google Scholar] [CrossRef]

| Langmuir | Freundlich | |||||

|---|---|---|---|---|---|---|

| Qm(mg/g) | KL(L/mg) | R2 | 1/n | KF(mg/g) | R2 | |

| As (III) | 36.525 | 0.120 | 0.982 | 0.437 | 6.615 | 0.974 |

| As (V) | 40.372 | 0.528 | 0.994 | 0.271 | 15.964 | 0.973 |

| Adsorbent | pH | qmax (mg/g) | References | |

|---|---|---|---|---|

| As (III) | As (V) | |||

| Water treatment residual (Fe/Al/Mn) | 7.2 | - | 3.3–50 | [17] |

| Water treatment residual (Fe/Mn oxides) | 8.1 | - | 42.9 | [18] |

| Graphite oxide modified by Fe3O4 and MnO2 | 7.0 | 14.04 | 12.22 | [19] |

| Blast furnace slag | 12 | 1.4 | - | [10] |

| Ferrous based red mud | 7.25 | 0.9 | - | [20] |

| WTRs (Amorphous Al/Fe oxide) | 6.0–6.5 | 15 | - | [21] |

| WTRs from waterworks for Fe and Mn removal | 7.0 | 36.53 | 40.37 | This study |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, H.; Qiao, T.; Zhao, Y.; Yu, Y.; Zhang, J.; Li, D. Characterization and Arsenic Adsorption Behaviors of Water Treatment Residuals from Waterworks for Iron and Manganese Removal. Int. J. Environ. Res. Public Health 2019, 16, 4912. https://doi.org/10.3390/ijerph16244912

Zeng H, Qiao T, Zhao Y, Yu Y, Zhang J, Li D. Characterization and Arsenic Adsorption Behaviors of Water Treatment Residuals from Waterworks for Iron and Manganese Removal. International Journal of Environmental Research and Public Health. 2019; 16(24):4912. https://doi.org/10.3390/ijerph16244912

Chicago/Turabian StyleZeng, Huiping, Tongda Qiao, Yunxin Zhao, Yaping Yu, Jie Zhang, and Dong Li. 2019. "Characterization and Arsenic Adsorption Behaviors of Water Treatment Residuals from Waterworks for Iron and Manganese Removal" International Journal of Environmental Research and Public Health 16, no. 24: 4912. https://doi.org/10.3390/ijerph16244912

APA StyleZeng, H., Qiao, T., Zhao, Y., Yu, Y., Zhang, J., & Li, D. (2019). Characterization and Arsenic Adsorption Behaviors of Water Treatment Residuals from Waterworks for Iron and Manganese Removal. International Journal of Environmental Research and Public Health, 16(24), 4912. https://doi.org/10.3390/ijerph16244912