Trends in Workplace Injuries in Slovak Forest Enterprises

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Collection and Processing

2.2. Contingency Tables

2.3. Injury Rate Analyses

3. Results

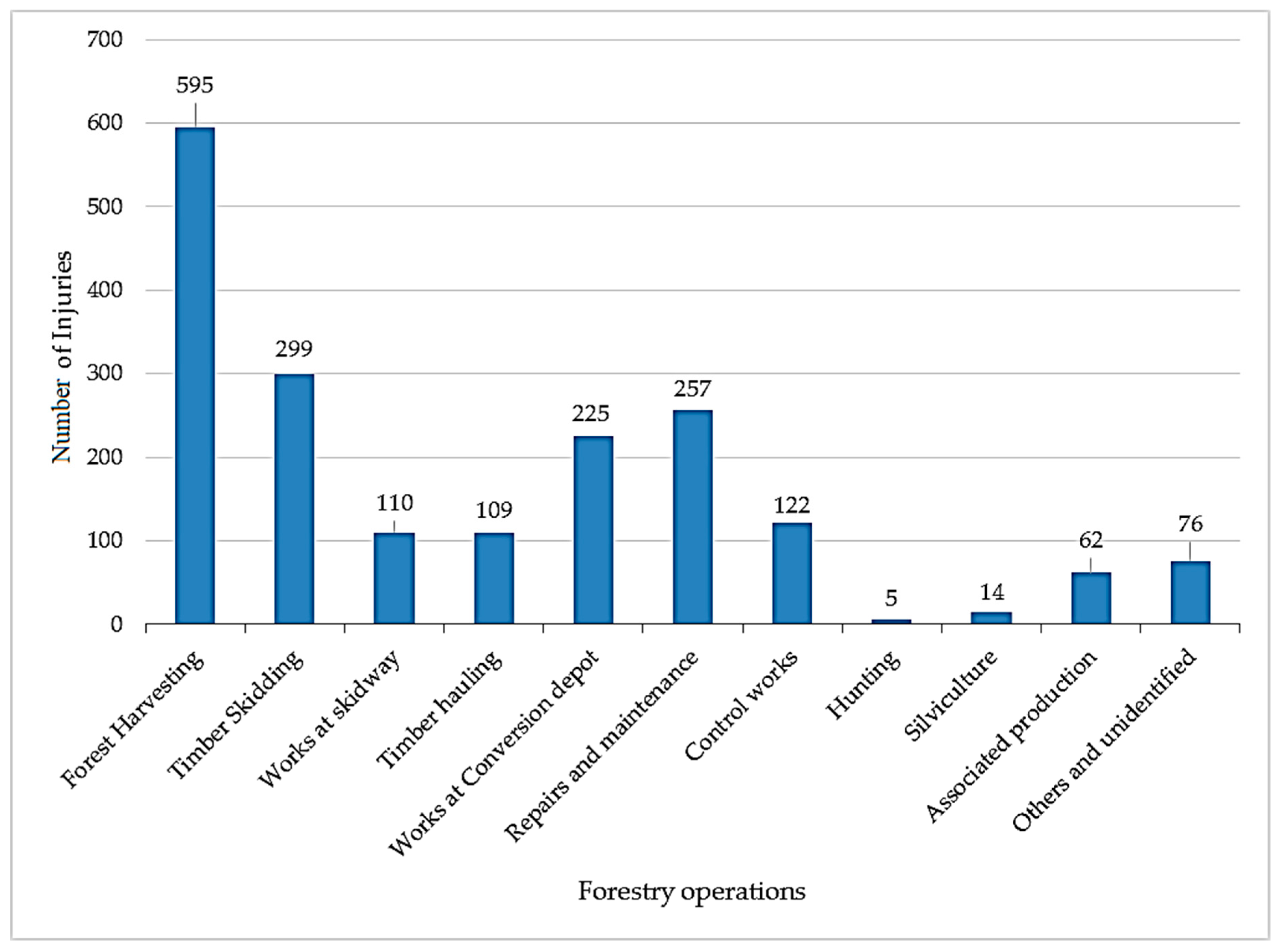

3.1. Injuries in Forestry Operations

- χ2 = 47.4400

- Degree of freedom (DF): 1

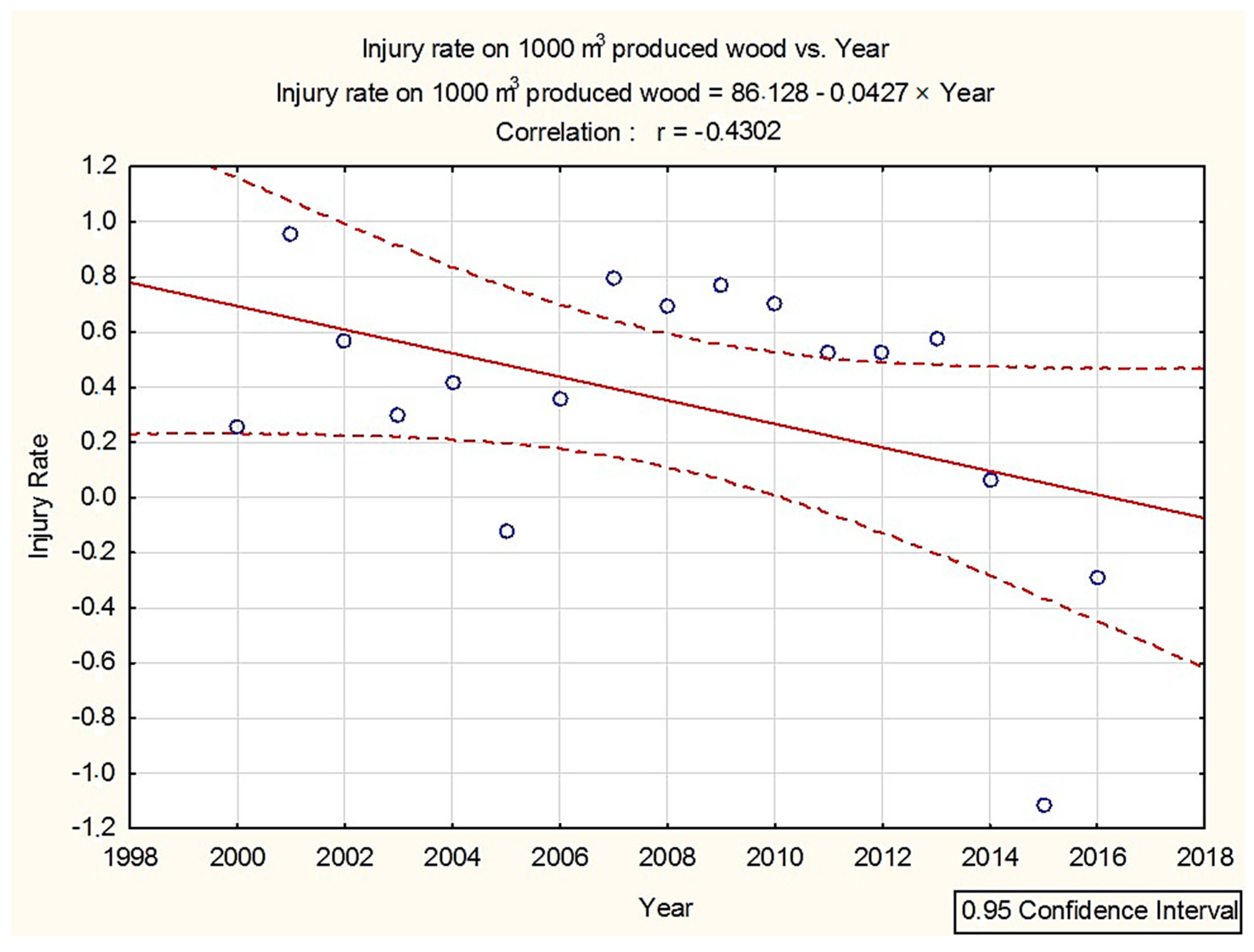

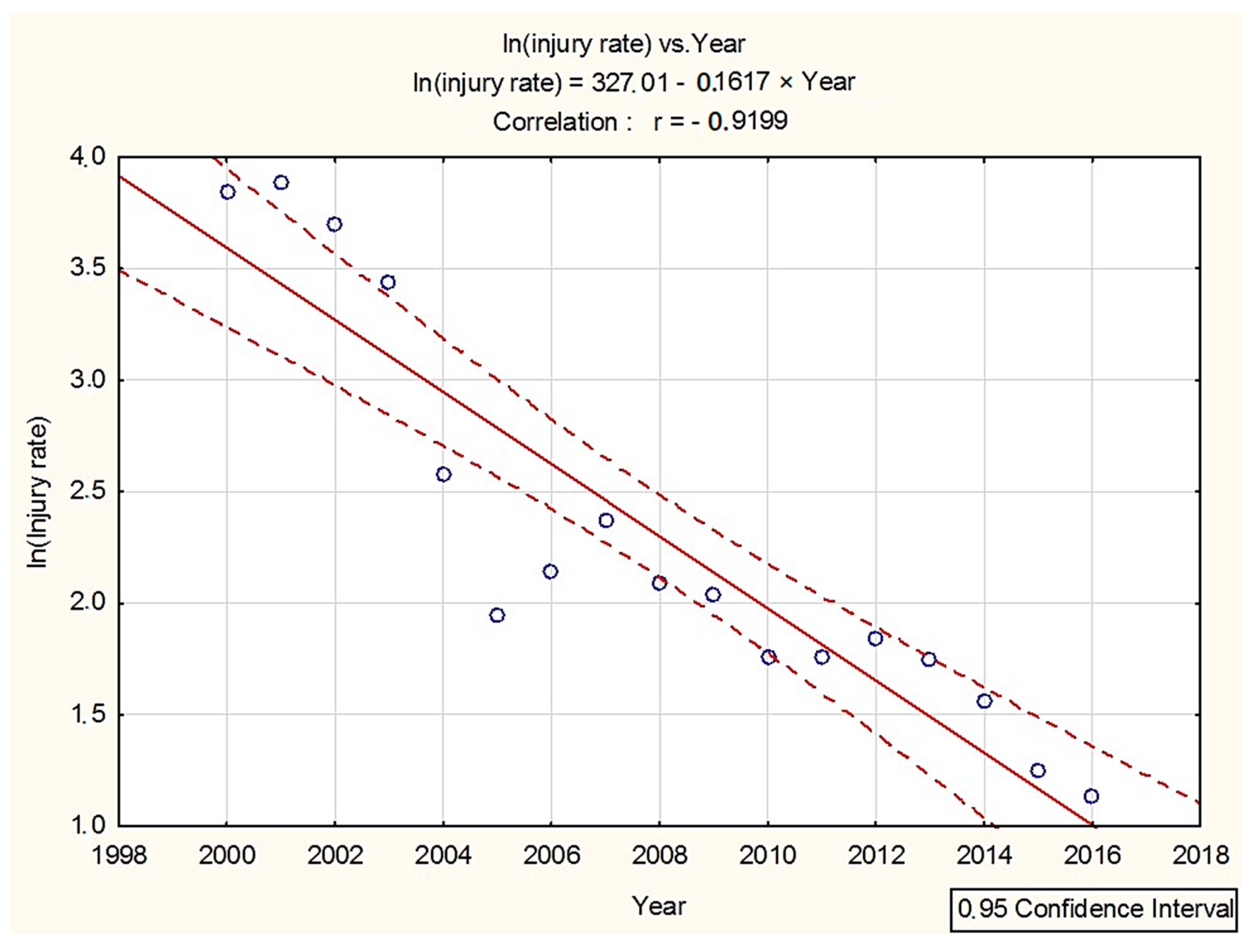

3.2. Injury Rate

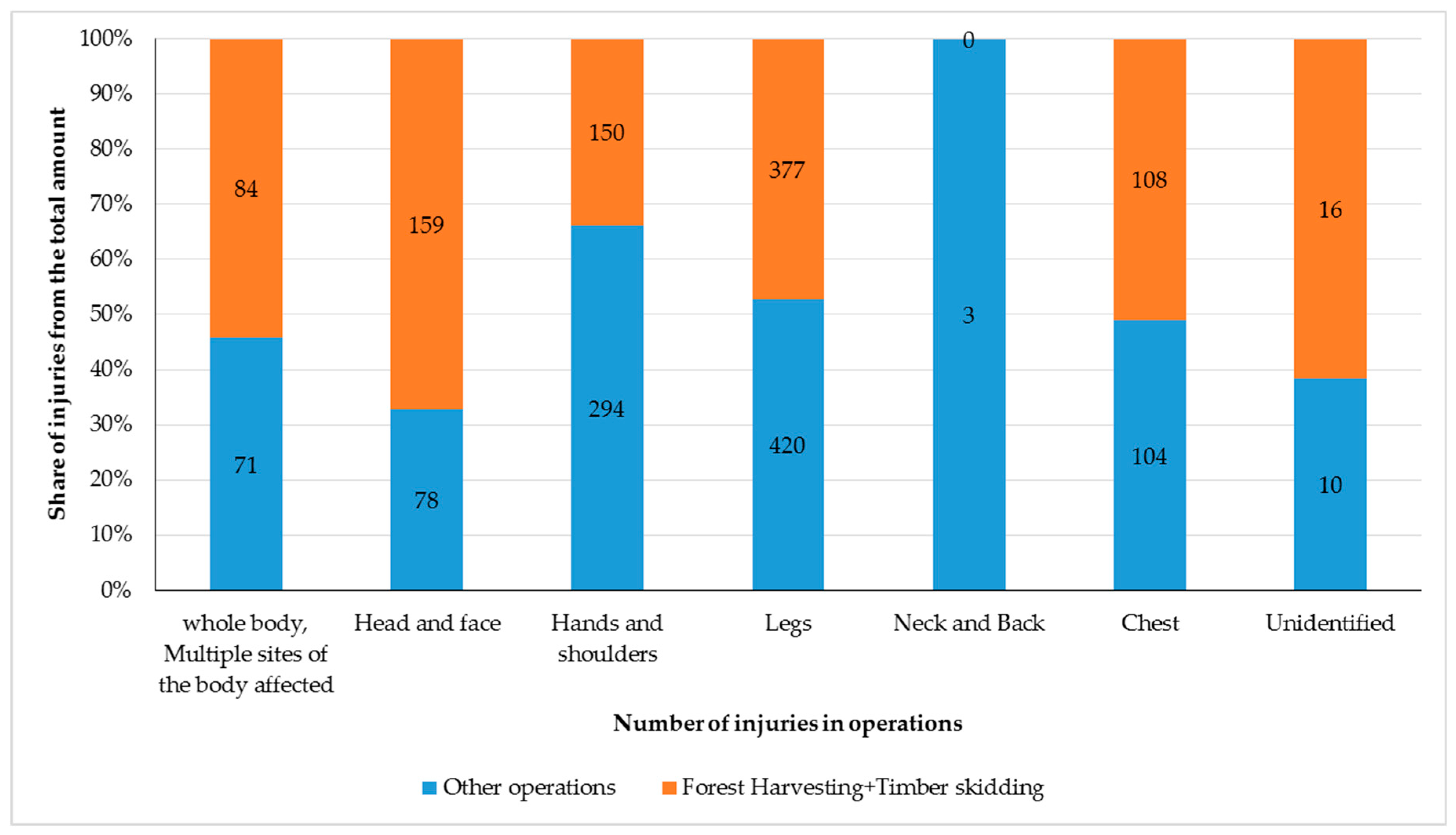

3.3. Injured Body Parts

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Springer, Y.P.; Lucas, D.L.; Castrodale, L.J.; McLaughlin, J.B. Work-related injuries in the Alaska logging industry, 1991–2014. Am. J. Ind. Med. 2018, 61, 32–41. [Google Scholar] [CrossRef]

- Tremblay, A.; Badri, A. A novel tool for evaluating occupational health and safety performance in small and medium-sized enterprises: The case of the Quebec forestry/pulp and paper industry. Saf. Sci. 2018, 101, 282–294. [Google Scholar] [CrossRef]

- Danilovic, M.; Antonic, S.; Dordevic, Z.; Vojvodic, P. Forestry Work-Related Injuries in Forest Estate “Sremska Mitrovica” In Serbia. Sumar. List 2016, 140, 589–598. [Google Scholar]

- Kogler, R.; Quendler, E.; Boxberger, J. Occupational Accidents with Agricultural Machinery in Austria. J. Agromed. 2016, 21, 61–70. [Google Scholar] [CrossRef]

- Richard, S.; Oppliger, A. Zoonotic occupational diseases in forestry workers—Lyme borreliosis, tularemia and leptospirosis in Europe. Ann. Agric. Environ. Med. 2015, 22, 43–50. [Google Scholar] [CrossRef] [PubMed]

- Suchomel, J.; Belanová, K.; Štollmann, V. Analysis of Occupational Diseases Occurring in Forestry and Wood Processing Industry in Slovakia. Drvna Ind. 2011, 62, 219–228. [Google Scholar] [CrossRef]

- Pinzke, S.; Svennefelt, C.A.; Lundqvist, P. Occupational Injuries in Swedish Agriculture: Development and Preventive Actions. J. Agric. Saf. Health. 2018, 24, 193–211. [Google Scholar] [CrossRef]

- Gejdoš, M.; Hitka, M.; Potkány, M.; Balážová, Ž. Analysis of Human Resources and Anthropometric Data Relating to Forestry Machine Operators in Slovakia. In Innovation Management and Education Excellence Through Vision 2020; Soliman, K., Ed.; Ibima Publishing: Milan, Italy, 2016; pp. 2256–2262. [Google Scholar]

- Poje, A.; Potocnik, I.; Kosir, B.; Krc, J. Cutting patterns as a predictor of the odds of accident among professional fellers. Saf. Sci. 2016, 89, 158–166. [Google Scholar] [CrossRef]

- Nkomo, H.; Niranjan, I.; Reddy, P. Effectiveness of Health and Safety Training in Reducing Occupational Injuries Among Harvesting Forestry Contractors in KwaZulu-Natal. Workplace Health Saf. 2018, 66, 499–507. [Google Scholar] [CrossRef]

- Bailer, A.J.; Reed, L.D.; Stayner, L.T. Modeling Fatal Injury Rates Using Poisson Regression: A Case Study of Workers in Agriculture. Forestry, and Fishing. J. Saf. Res. 1997, 28, 177–186. [Google Scholar] [CrossRef]

- Benavides, F.G.; Benach, J.; Martínez, J.M.; González, S. Description of fatal occupational injury rates in five selected European Union countries: Austria, Finland, France, Spain and Sweden. Saf. Sci. 2005, 43, 497–502. [Google Scholar] [CrossRef]

- Vlčková, M. Analysis of Work Accidents and Occupational Diseases Development in Selected Forestry Subjects in Slovakia. Ph.D. Thesis, Technical University in Zvolen, Zvolen, Slovakia, 2004. [Google Scholar]

- Eurostat. European Statistics on Accidents at Work (ESAW)—Summary Methodology; Eurostat: Luxembourg, 2013; ISBN 978-92-79-28419-9. [Google Scholar]

- Edict Nr. 500/2006 The Ministry of Labour, Social Affairs and Family of the Slovak Republic. Pattern of Record of Registered Work Injury; Ministry of Labour, Social Affairs and Family of the Slovak Republic: Bratislava, Slovakia, 2006.

- Nussbaum, E.B. Contingency Tables the Chi-Square Test and Associated Effect Sizes; Routledge: Oxford, UK, 2015; pp. 81–97. [Google Scholar]

- Richardson, J.T.E. The analysis of 2 × 2 contingency tables-Yet again. Stat. Med. 2011, 30, 890. [Google Scholar] [CrossRef]

- Šmelko, Š. Štatistické Metódy v Lesníctve [Statistical Methods in Forestry]; TU Zvolen: Zvolen, Slovakia, 1998; 276p, ISBN 80-228-0684-6. [Google Scholar]

- Breslow, N.E.; Day, N.E. Statistical Methods in Cancer Research Volume I—The Analysis of Case-Control Studies; International Agency for Research on Cancer: Lyon, France, 1980; 338p, ISBN 978-9283201328. [Google Scholar]

- Berry, G. The analysis of mortality by the subject-years method. Biometrics 1983, 39, 173–184. [Google Scholar] [CrossRef]

- Frome, E.L. The analysis of rates using Poisson regression models. Biometrics 1983, 39, 665–674. [Google Scholar] [CrossRef] [PubMed]

- Frome, E.L.; Checkoway, H. Epidemiologic Programs for Computers and Calculators—Use of Poisson Regression-Models in Estimating Incidence Rates and Ratios. Am. J. Epidemiol. 1985, 121, 309–323. [Google Scholar] [CrossRef] [PubMed]

- Whittemore, A.S. Analyzing cohort mortality data. Am. Stat. 1985, 39, 437–441. [Google Scholar] [CrossRef]

- Checkoway, H.; Pearce, N.E.; Crawford-Brown, D.J. Research Methods in Occupational Epidemiology; Oxford University Press: New York, NY, USA, 1989; ISBN 13 9780195092424. [Google Scholar]

- Selvin, S. Practical Biostatical Methods; Duxbury Press: Belmont, CA, USA, 1995; ISBN 0-534-23802-5. [Google Scholar]

- Anonymous. Green Report; Ministry of Agriculture and Rural Development of the Slovak Republic: Bratislava, Slovakia, 2017; 68p, ISBN 978-80-8093-235-0. [Google Scholar]

- Dobson, A.J.; Barnett, A.G. An Introduction to Generalized Linear Models; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2008; ISBN 978-1-58488-950-2. [Google Scholar]

- McCullagh, P.; Nelder, J.A. Generalized Linear Models, Second Edition; Chapman and Hall/CRC Press: Boca-Raton, FL, USA, 1989; ISBN 978-0-41231-760-6. [Google Scholar]

- Gejdoš, M.; Vlčková, M. Analysis of Work Accidents in Timber Transport in Slovakia. In Proceedings of the 18th International Scientific Conference-Logi 2017, České Budějovice, Czech Republic, 18–19 May 2017. [Google Scholar] [CrossRef]

- Hitka, M.; Mračková, E.; Sedmák, R. Changes of anthropometric characteristics of the adult population in Slovakia and their influence on material sources and work safety. Adv. Mat. Res. 2014, 1001, 401–406. [Google Scholar] [CrossRef]

- Kampf, R.; Lorincová, S.; Hitka, M.; Stopka, O. Generational Differences in the Perception of Corporate Culture in European Transport Enterprises. Sustainability 2017, 9, 1561. [Google Scholar] [CrossRef]

- Grzywinski, W.; Sawa, L.; Nowik, A.; Nowicki, G. Structure of work accidents in the Regional Directorate of the State Forests in Szczecinek in the years 1990–2009. Sylwan 2013, 157, 403–411. [Google Scholar]

- Benavides, F.G.; Benach, J.; Muntaner, C.; Delclos, G.L.; Catot, N.; Amable, M. Associations between temporary employment and occupational injury: What are the mechanisms? Occup. Environ. Med. 2006, 63, 416–421. [Google Scholar] [CrossRef]

- Varakina, Z.L.; Vyazmin, A.M.; Sannikov, A.L.; Nygard, C.H.; Grjibovski, A.M. Fatal occupational injuries in the Arkhangelsk region, Northwest Russia. Occup. Med.-Oxf. 2010, 60, 470–475. [Google Scholar] [CrossRef] [PubMed]

- Feyer, A.M.; Wiliamson, A.M.; Stout, N.; Driscoll, T.; Usher, H.; Langley, J.D. Comparison of work related fatal injuries in the United States, Australia, and New Zealand: Method and overall findings. Inj. Prev. 2001, 7, 22–28. [Google Scholar] [CrossRef] [PubMed]

- Suchomel, J. Analysis of Selected Criteria and Methods for Modelling and Optimization of Harvesting Process; Habilitation Work; Technical University in Zvole: Zvolen, Slovakia, 1999; p. 148. [Google Scholar]

- Lindroos, O.; Burstrom, L. Accident rates and types among self-employed private forest owners. Accid. Anal. Prev. 2010, 42, 1729–1735. [Google Scholar] [CrossRef] [PubMed]

- Lefort, A.J., Jr.; De Hoop, C.F.; Pine, J.C.; Marx, B.D. Characteristics of injuries in the logging industry of Louisiana, USA: 1986 to 1998. Int. J. For. Eng. 2003, 14, 75–89. [Google Scholar] [CrossRef]

- Montorselli, N.B.; Lombardini, C.; Magagnotti, N.; Marchi, E.; Neri, F.; Picchi, G.; Spinelli, R. Relating safety, productivity and company type for motor- manual logging operations in the Italian Alps. Accid. Anal. Prev. 2010, 42, 2013–2017. [Google Scholar] [CrossRef] [PubMed]

| Variable B | Classes of Variable B | Total | ||||||

|---|---|---|---|---|---|---|---|---|

| Variable A | B1 | B2 | … | BJ | … | Bm | ||

| Classes of Variable A | A1 | n11 | n12 | … | … | … | n1m | n1A |

| A2 | n21 | n22 | … | … | … | n2m | n2A | |

| . | . | . | . | . | . | |||

| Ai | ni1 | ni2 | … | niJ | … | nim | nJA | |

| . | . | . | . | . | . | |||

| Ak | nK1 | nK2 | nKJ | nKm | nkA | |||

| Total | nB1 | nB2 | … | nBJ | … | nBm | N | |

| Phase | Injuries/Abundance | A-Injuries | B-Injuries | Σ |

|---|---|---|---|---|

| Forest harvesting + timber skidding | Real injuries | 96 | 126 | 222 |

| Expected abundance | 63 | 159 | ||

| Other | Real injuries | 32 | 199 | 231 |

| Expected abundance | 65 | 166 | ||

| Σ | 128 | 325 | 453 |

| Simple Regression Results with Dependence Variable: C (Injury Rate) R = 0.9199, R2 = 0.8463, Edited R2 = 0.8360, F (1,15) = 82.5660, p | ||||||

|---|---|---|---|---|---|---|

| N = 17 | B | Standard Error from b | b | Standard Error from b | T (15) | p-value |

| Absolute term | 327.0145 | 35.7358 | 9.1509 | 0.0000 | ||

| Year | −0.9199 | 0.1012 | −0.1617 | 0.0178 | −9.0865 | 0.0000 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gejdoš, M.; Vlčková, M.; Allmanová, Z.; Balážová, Ž. Trends in Workplace Injuries in Slovak Forest Enterprises. Int. J. Environ. Res. Public Health 2019, 16, 141. https://doi.org/10.3390/ijerph16010141

Gejdoš M, Vlčková M, Allmanová Z, Balážová Ž. Trends in Workplace Injuries in Slovak Forest Enterprises. International Journal of Environmental Research and Public Health. 2019; 16(1):141. https://doi.org/10.3390/ijerph16010141

Chicago/Turabian StyleGejdoš, Miloš, Mária Vlčková, Zuzana Allmanová, and Žaneta Balážová. 2019. "Trends in Workplace Injuries in Slovak Forest Enterprises" International Journal of Environmental Research and Public Health 16, no. 1: 141. https://doi.org/10.3390/ijerph16010141

APA StyleGejdoš, M., Vlčková, M., Allmanová, Z., & Balážová, Ž. (2019). Trends in Workplace Injuries in Slovak Forest Enterprises. International Journal of Environmental Research and Public Health, 16(1), 141. https://doi.org/10.3390/ijerph16010141