Microencapsulation of Lactobacillus plantarum with Improved Survivability Using Pufferfish Skin Gelatin-Based Wall Materials

Abstract

1. Introduction

2. Results and Discussion

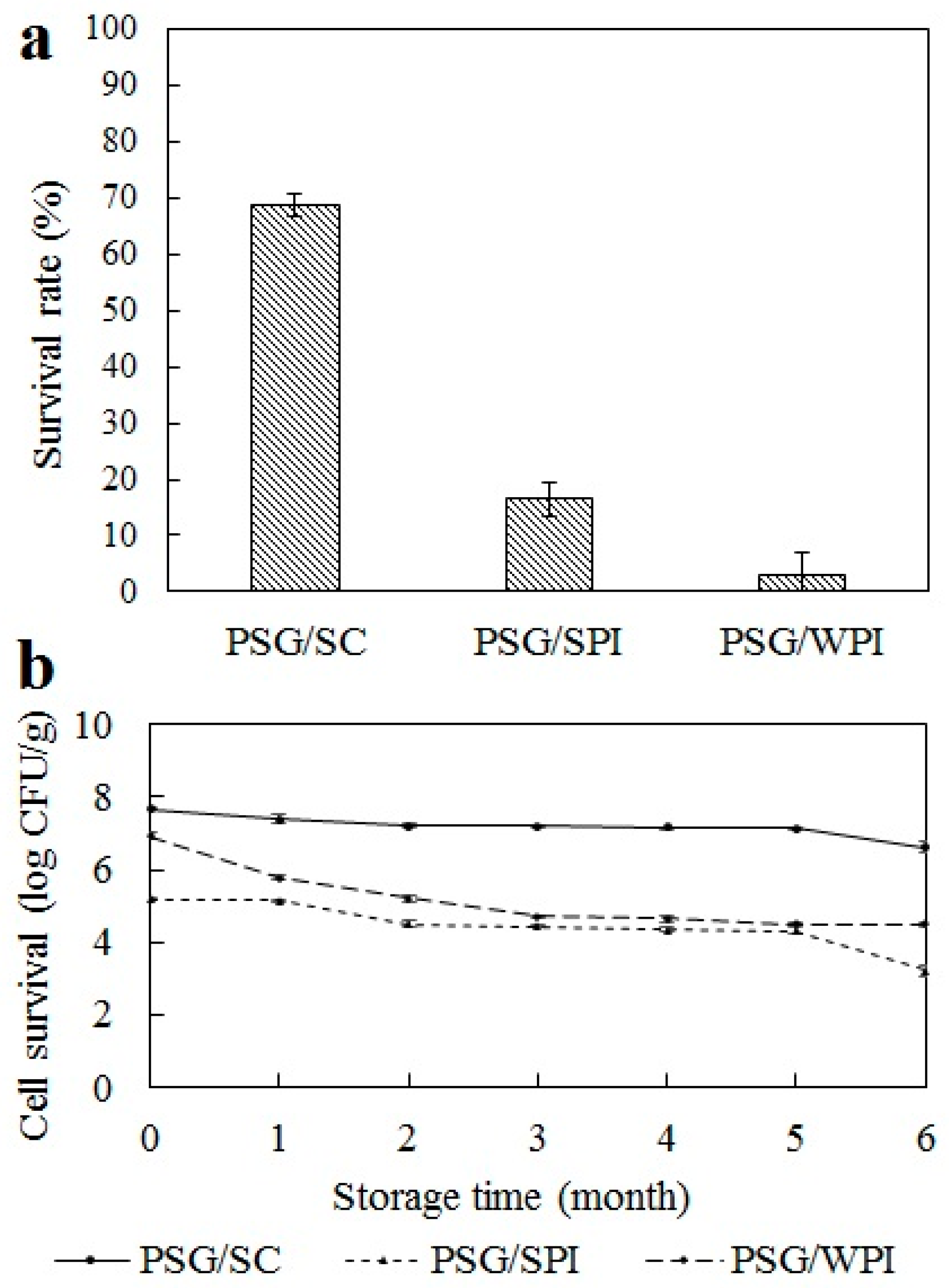

2.1. Effects of Wall Materials on Survivability and Storage Stability

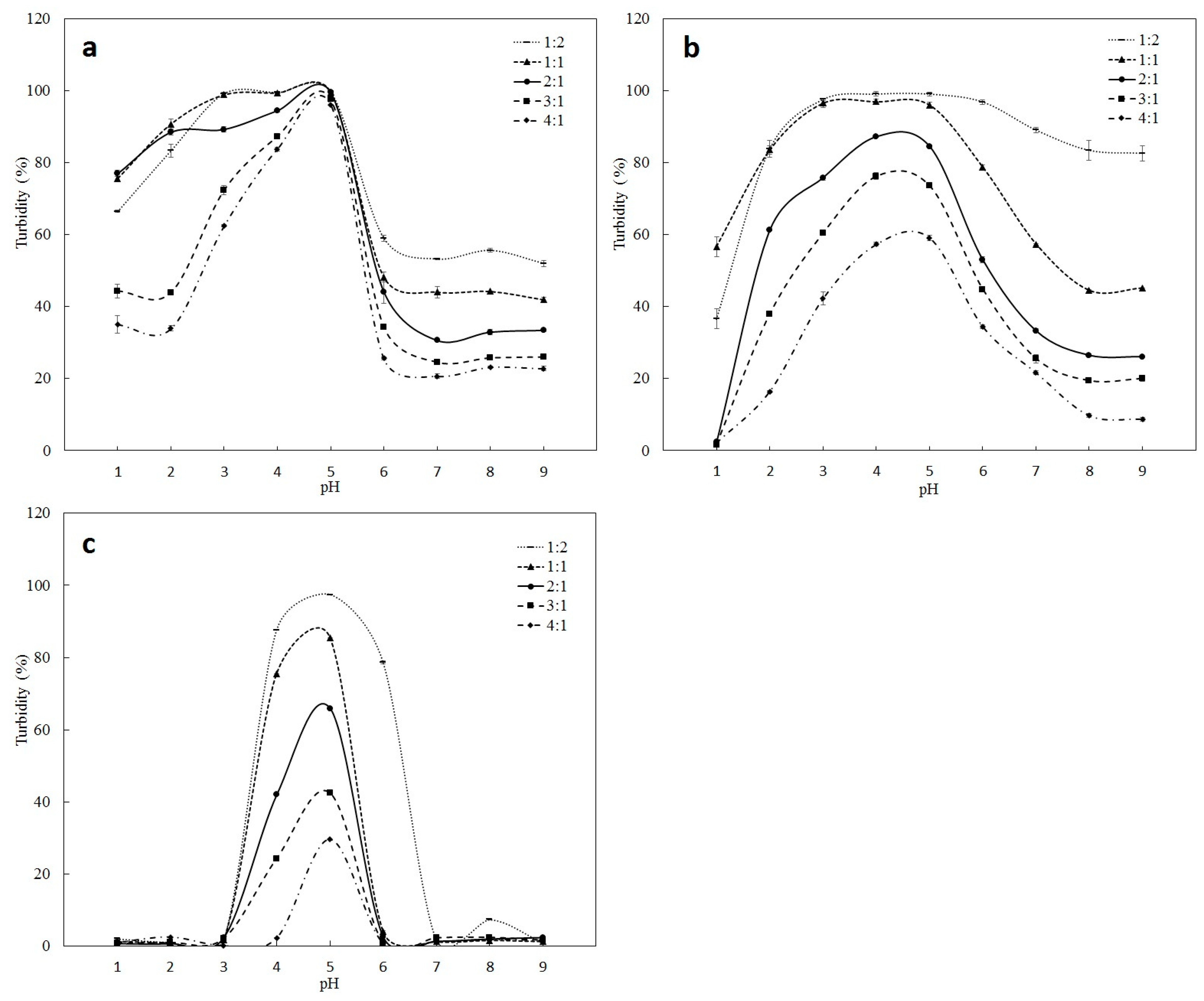

2.2. Effect of Wall Materials on Turbidity

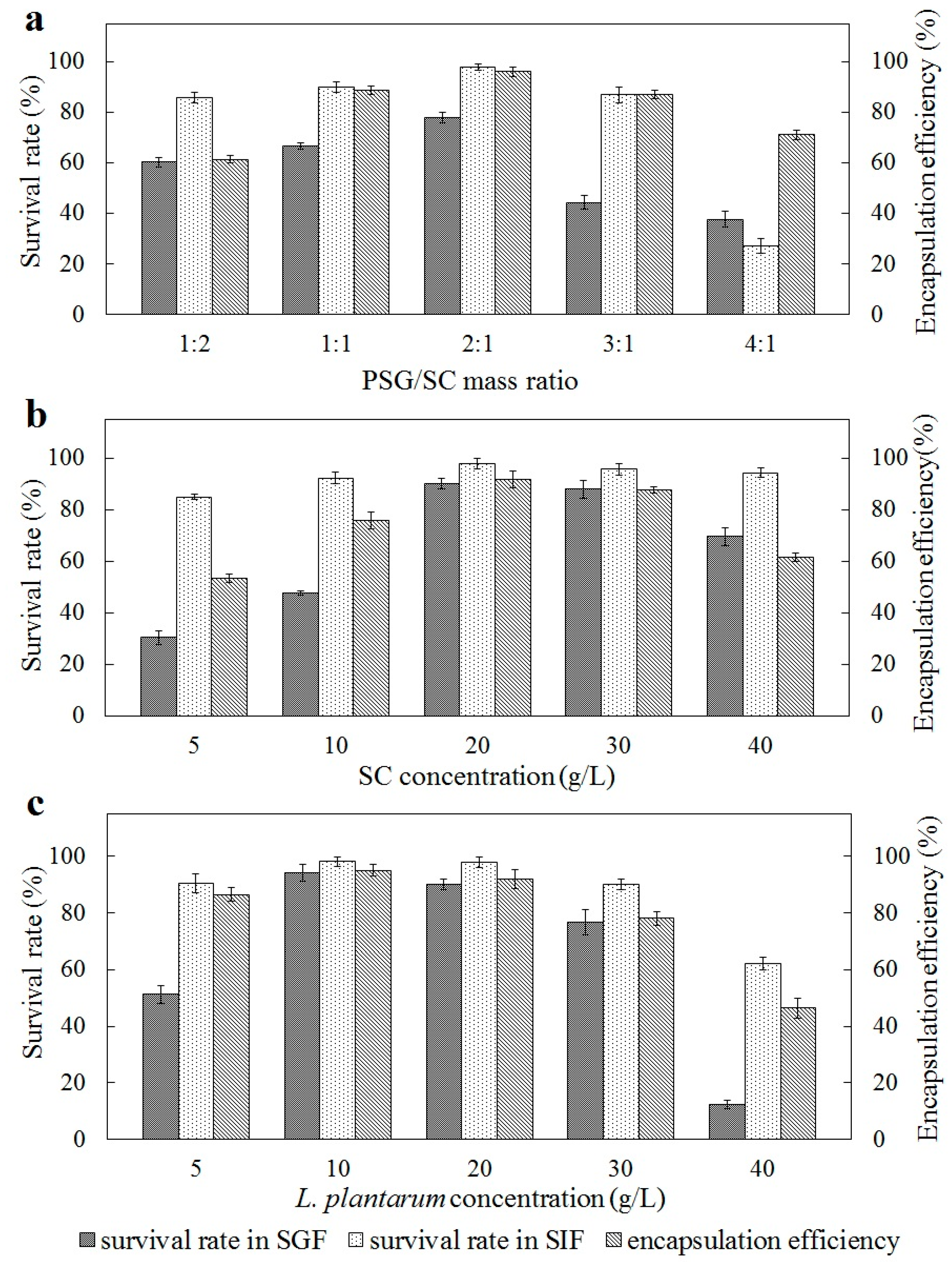

2.3. Effects of PSG/SC Mass Ratio, SC Concentration, and L. plantarum Concentration on Survival Rate and Encapsulation Efficiency

2.4. Effect of Gelatin Species on Microcapsule Performance

2.5. Characterization of Optimized PSG/SC Microcapsules

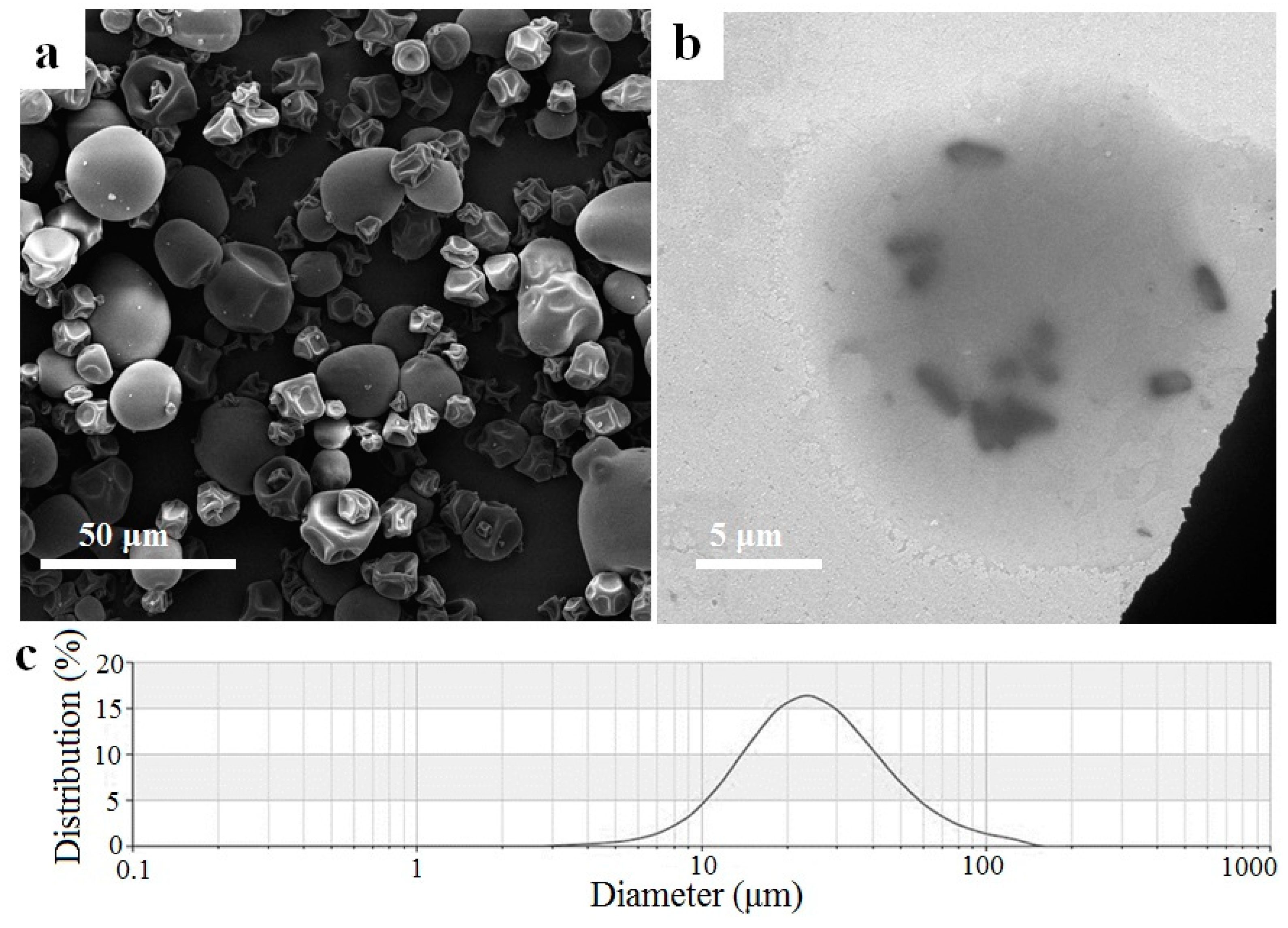

2.5.1. SEM, TEM, and Particle Size Distribution

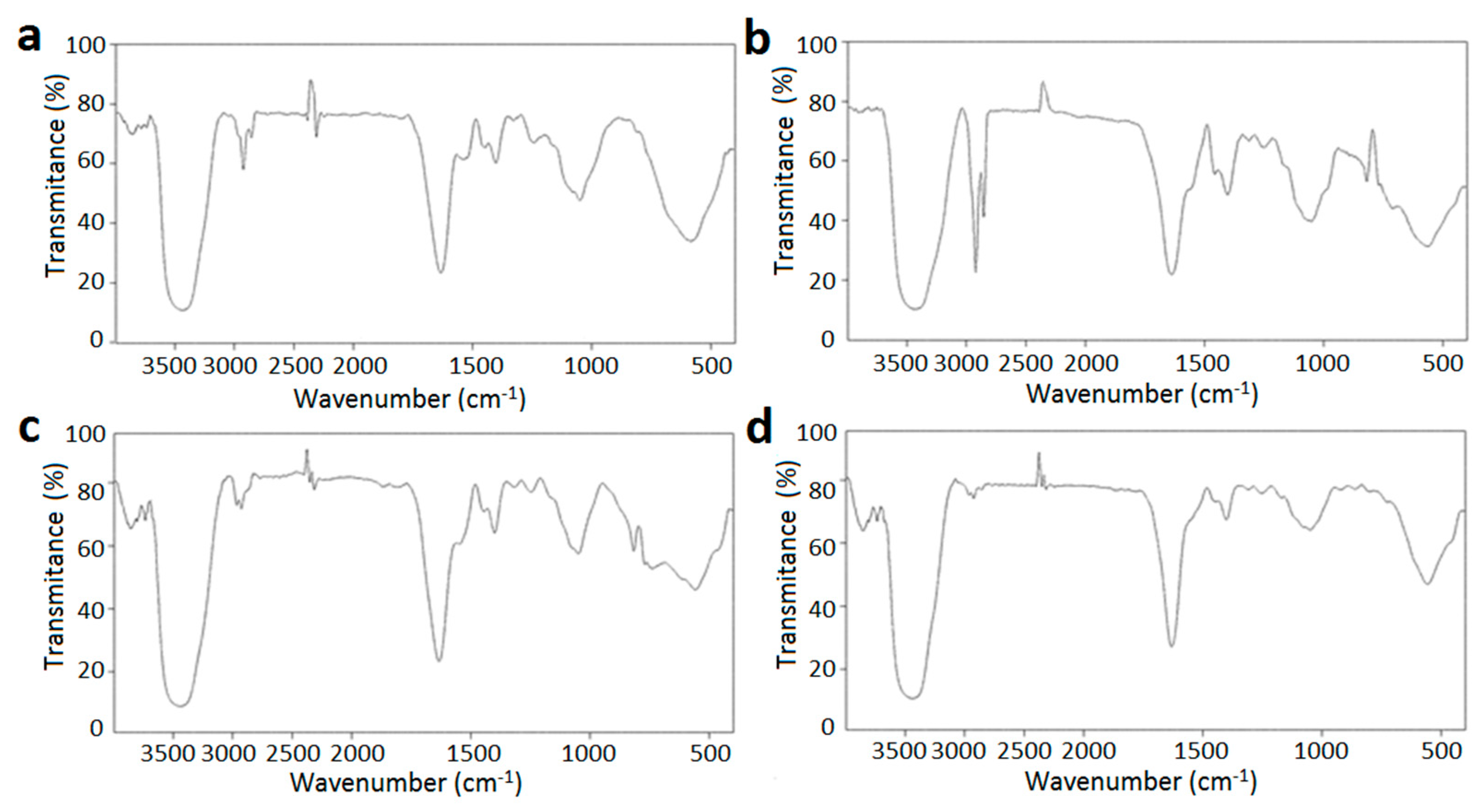

2.5.2. FTIR Analysis

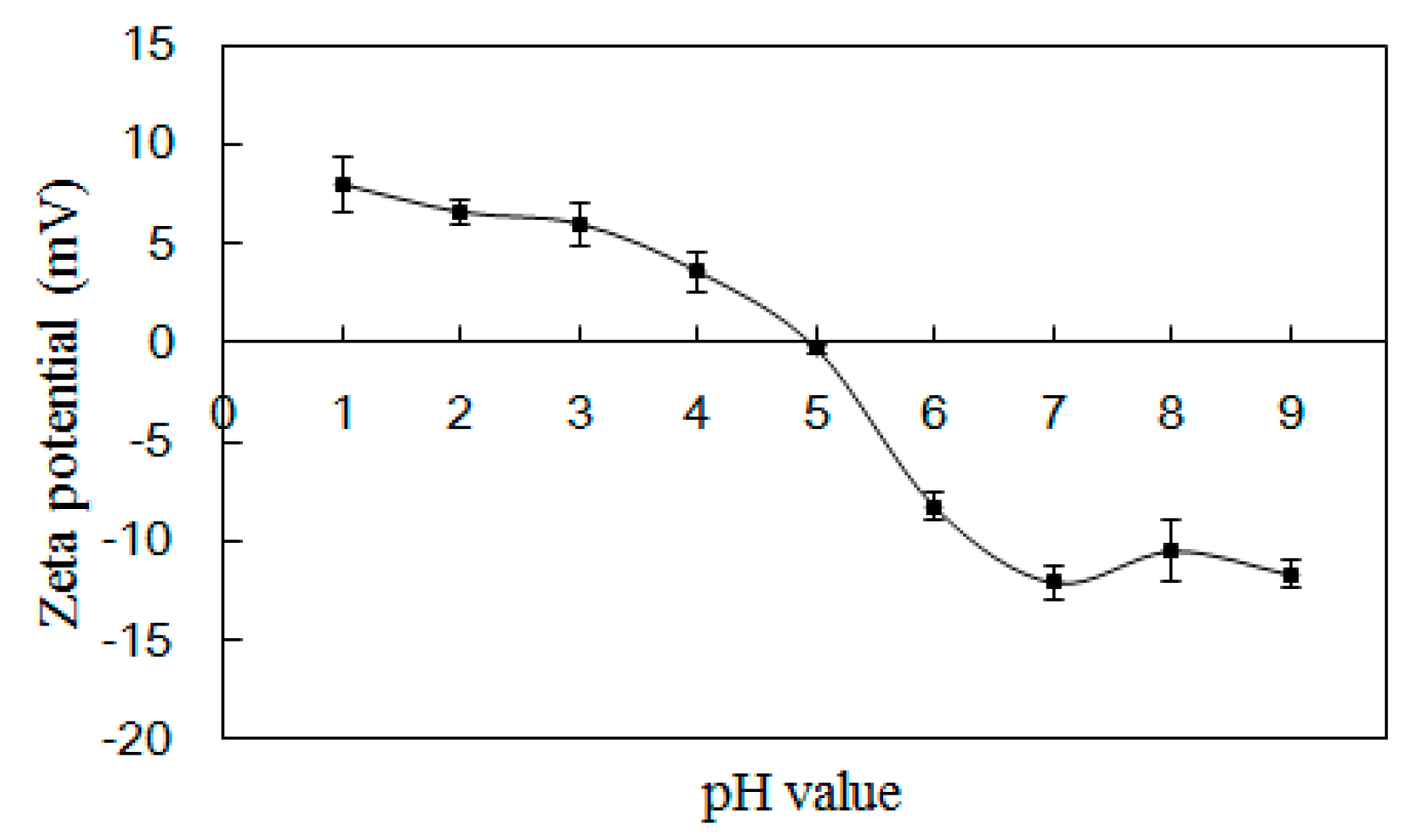

2.5.3. Zeta Potential

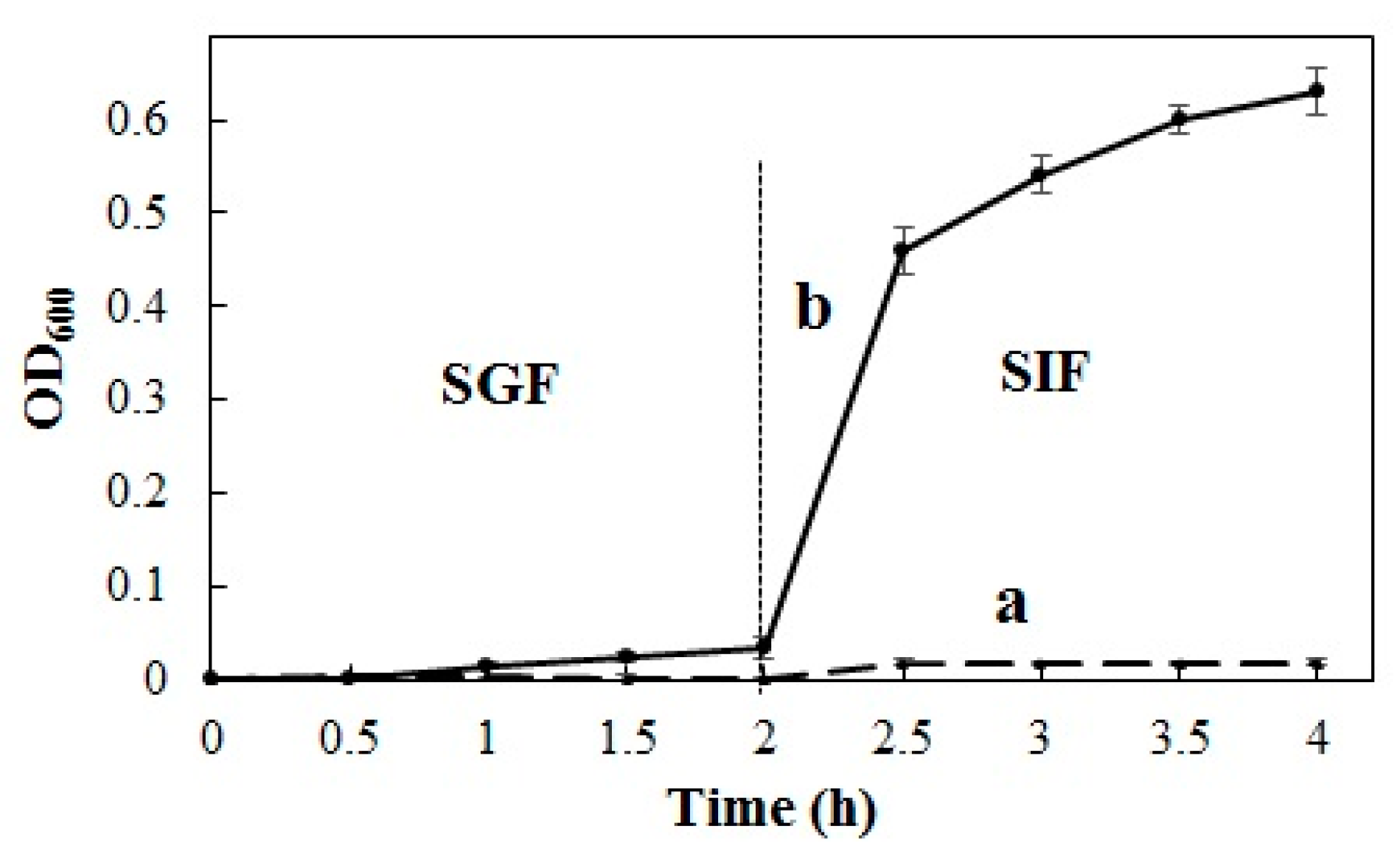

2.5.4. In Vitro Release

3. Materials and Methods

3.1. Materials

3.2. Preparation of Pufferfish Skin Gelatin

3.3. Bacterial Cultivation

3.4. Microencapsulation of L. plantarum

3.5. Viable Count of L. plantarum Microcapsules

3.6. Survival Rate in Simulated Gastrointestinal Fluid

3.7. Storage Experiment

3.8. Turbidity Measurement

3.9. Signal-Factor Experiment

3.10. Determination of Encapsulation Efficiency

3.11. Preparation of L. plantarum-Loaded BG/SC Microcapsules

3.12. Amino Acid Composition

3.13. Zeta Potential Determination

3.14. Morphology and Particle Size

3.15. Infrared

3.16. In Vitro Release Studies

3.17. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Morelli, L.; Pellegrino, P. A critical evaluation of the factors affecting the survival and persistence of beneficial bacteria in healthy adults. Benef. Microbes 2021, 12, 321–331. [Google Scholar] [CrossRef]

- Parsana, Y.; Yadav, M.; Kumar, S. Microencapsulation in the chitosan-coated alginate-inulin matrix of Limosilactobacillus reuteri SW23 and Lactobacillus salivarius RBL50 and their characterization. Carbohydr. Polym. Technol. Appl. 2023, 5, 100285. [Google Scholar] [CrossRef]

- Fraj, J.; Petrović, L.; Đekić, L.; Budinčić, J.M.; Bučko, S.; Katona, J. Encapsulation and release of vitamin C in double W/O/W emulsions followed by complex coacervation in gelatin-sodium caseinate system. J. Food Eng. 2021, 292, 110353. [Google Scholar] [CrossRef]

- Luca, L.; Oroian, M. Influence of different prebiotics on viability of Lactobacillus casei, Lactobacillus plantarum and Lactobacillus rhamnosus encapsulated in alginate microcapsules. Foods 2021, 10, 710. [Google Scholar] [CrossRef]

- Sun, W.; Nguyen, Q.D.; Sipiczki, G.; Ziane, S.R.; Hristovski, K.; Friedrich, L.; Visy, A.; Hitka, G.; Gere, A.; Bujna, E. Microencapsulation of Lactobacillus plantarum 299v strain with whey proteins by lyophilization and its application in production of probiotic apple juices. Appl. Sci. 2023, 13, 318. [Google Scholar] [CrossRef]

- Xu, Y.; Dong, M.; Xiao, H.; Quek, S.Y.; Ogawa, Y.; Ma, G.; Zhang, C. Advances in spray-dried probiotic microcapsules for targeted delivery: A review. Crit. Rev. Food Sci. Nutr. 2023, 17, 1–17. [Google Scholar] [CrossRef]

- Avila-Reyes, S.V.; Garcia-Suarez, F.J.; Jiménez, M.T.; Martín-Gonzalez, M.F.S.; Bello-Perez, L.A. Protection of L. rhamnosus by spray-drying using two prebioticscolloids to enhance the viability. Carbohydr. Polym. 2014, 102, 423–430. [Google Scholar] [CrossRef]

- Du, T.; Liu, Z.; Guan, Q.; Xiong, T.; Peng, F. Application of soy protein isolate–xylose conjugates for improving the viability and stability of probiotics microencapsulated by spray drying. J. Sci. Food Agric. 2023, 103, 6500–6509. [Google Scholar] [CrossRef] [PubMed]

- Ozdemir, N.; Bayrak, A.; Tat, T.; Altay, F.; Kiralan, M.; Kurt, A. Microencapsulation of basil essential oil: Utilization of gum arabic/whey protein isolate/maltodextrin combinations for encapsulation efficiency and in vitro release. J. Food Meas. Charact. 2021, 15, 1865–1876. [Google Scholar] [CrossRef]

- Peñalva, R.; Martínez-López, A.L.; Gamazo, C.; Gonzalez-Navarro, C.; González-Ferrero, C.; Virto-Resano, R.; Brotons-Canto, A.; Vitas, A.; Collantes, M.; Peñuelas, I.; et al. Encapsulation of Lactobacillus plantarum in casein-chitosan microparticles facilitates the arrival to the colon and develops an immunomodulatory effect. Food Hydrocoll. 2023, 136, 108213. [Google Scholar] [CrossRef]

- Vaziri, A.S.; Alemzadeh, I.; Vossoughi, M.; Khorasani, A.C. Co-microencapsulation of Lactobacillus plantarum and DHA fatty acid in alginate-pectin-gelatin biocomposites. Carbohydr. Polym. 2018, 199, 266–275. [Google Scholar] [CrossRef]

- Bastos, B.M.; Farias, B.S.; Casati, M.O.; Engelmann, J.I.; Moura, J.M.; Pinto, L.A.A. Gelatin films from carp skin crosslinked by gallic acid and incorporated with chitosan/tuna lipid fractions. J. Polym. Environ. 2021, 29, 2096–2110. [Google Scholar] [CrossRef]

- Pan, J.F.; Lian, H.L.; Shang, M.; Jin, W.; Hao, R.; Ning, Y.; Zhang, X.; Tang, Y. Physicochemical properties of Chinese giant salamander (Andrias davidianus) skin gelatin as affected by extraction temperature and in comparison with fish and bovine gelatin. J. Food Meas. Charact. 2020, 14, 2656–2666. [Google Scholar] [CrossRef]

- Derkach, S.R.; Voron’ko, N.G.; Kuchina, Y.A.; Kolotova, D.S. Modified fish gelatin as an alternative to mammalian gelatin in modern food technologies. Polymers 2020, 12, 3051. [Google Scholar] [CrossRef]

- Pan, J.; Li, Q.; Jia, H.; Xia, L.; Jin, W.; Shang, M.; Xu, C.; Dong, X. Physiochemical and functional properties of tiger puffer (Takifugurubripes) skin gelatin as affected by extraction conditions. Int. J. Biol. Macromol. 2018, 109, 1045–1053. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhou, D.; Liu, N.; Sun, Y.; Sun, G. Physicochemical and fibril formation properties of pufferfish (Takifugu obscurus) skin collagen from solvent extraction in different conditions. Gels 2023, 9, 17. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, J.; Tian, Z.; Si, Y.; Chen, H.; Gan, J. The Mechanisms of the potential probiotic Lactiplantibacillus plantarum against cardiovascular disease and the recent developments in its fermented foods. Foods 2022, 11, 2549. [Google Scholar] [CrossRef]

- Hao, R.; Chen, Z.; Wu, Y.; Li, D.; Qi, B.; Lin, C.; Zhao, L.; Xiao, T.; Zhang, K.; Wu, J. Improving the survival of Lactobacillus plantarum FZU3013 by phase separated caseinate/alginate gel beads. Int. J. Biol. Macromol. 2024, 260, 129447. [Google Scholar] [CrossRef]

- Guo, Q.; Li, S.; Tang, J.; Chang, S.; Qiang, L.; Du, G.; Yue, T.; Yuan, Y. Microencapsulation of Lactobacillus plantarum by spray drying: Protective effects during simulated food processing, gastrointestinal conditions, and in kefir. Int. J. Biol. Macromol. 2022, 194, 539–545. [Google Scholar] [CrossRef] [PubMed]

- Moumita, S.; Das, B.; Hasan, U.; Jayabalan, R. Effect of long-term storage on viability and acceptability of lyophilized and spray-dried synbiotic microcapsules in dry functional food formulations. LWT-Food Sci. Technol. 2018, 96, 127–132. [Google Scholar] [CrossRef]

- Arslan, S.; Erbas, M.; Tontul, I.; Topuz, A. Microencapsulation of probiotic Saccharomyces cerevisiae var. boulardii with different wall materials by spray drying. LWT-Food Sci. Technol. 2015, 63, 685–690. [Google Scholar] [CrossRef]

- Guo, H.H.; Chen, H.; Yun, Y.; Fang, H.; Chen, S.; Hong, Z. Study on the composition and acute toxicity of collagen peptide chelated zinc from puffer skin. Food Ferment. Ind. 2020, 46, 41–46. [Google Scholar]

- Zhao, M.; Huang, X.; Zhang, H.; Zhang, Y.; Gänzle, M.; Yang, N.; Nishinari, K.; Fang, Y. Probiotic encapsulation in water-in-water emulsion via heteroprotein complex coacervation of type-A gelatin/sodium caseinate. Food Hydrocoll. 2020, 105, 105790. [Google Scholar] [CrossRef]

- Duhoranimana, E.; Karangwa, E.; Lai, L.; Xu, X.; Yu, J.; Xia, S.; Zhang, X.; Muhoza, B.; Habinshuti, I. Effect of sodium carboxymethyl cellulose on complex coacervates formation with gelatin: Coacervates characterization, stabilization and formation mechanism. Food Hydrocoll. 2017, 69, 111–120. [Google Scholar] [CrossRef]

- Kavousi, H.R.; Fathi, M.; Goli, S. Novel cress seed mucilage and sodium caseinatemicroparticles for encapsulation of curcumin: An approach for controlled release. Food Bioprod. Process. 2018, 110, 126–135. [Google Scholar] [CrossRef]

- Ramos, P.E.; Cerqueira, M.A.; Cook, M.T.; Bourbon, A.I.; Khutoryanskiy, V.V.; Charalampoulos, D.; Teixeira, J.A.; Vicente, A.A. Development of an immobilization system for in situ micronutrients release. Food Res. Int. 2016, 90, 121–132. [Google Scholar] [CrossRef]

- Dehkordi, S.S.; Alemzadeh, I.; Vaziri, A.S.; Vossoughi, A. Optimization of alginate-whey protein isolate microcapsules for survivability and release behavior of probiotic bacteria. Appl. Biochem. Biotechnol. 2020, 190, 182–196. [Google Scholar] [CrossRef]

- Jiang, Y.; Zheng, Z.; Zhang, T.; Hendricks, G.; Guo, M. Microencapsulation of Lactobacillus acidophilus NCFM using polymerized whey proteins as wall material. Int. J. Food Sci. Nutr. 2016, 67, 670–677. [Google Scholar] [CrossRef]

- Sun, Q.; Wang, F.; Han, D.; Zhao, Y.; Liu, Z.; Lei, H.; Yang, Z. Preparation and optimization of soy protein isolate–high methoxy pectin microcapsules loaded with Lactobacillus delbrueckii. Int. J. Food Sci. Technol. 2014, 49, 1287–1293. [Google Scholar] [CrossRef]

- Ma, L.; Shang, Y.; Zhu, Y.; Zhang, X.; E, J.; Zhao, L.; Wang, J. Study on microencapsulation of Lactobacillus plantarum LIP-1 by emulsification method. J. Food Process Eng. 2020, 43, e13437. [Google Scholar] [CrossRef]

- Gómez-Guillén, M.C.; Giménez, B.; López-Caballero, M.E.; Montero, M.P. Functional and bioactive properties of collagen and gelatin from alternative sources: A review. Food Hydrocoll. 2011, 25, 1813–1827. [Google Scholar] [CrossRef]

- Pavan Kumar, D.; Chandra, M.V.; Elavarasan, K.; Shamasundar, B.A. Structural properties of gelatin extracted from croaker fish (Johnius sp) skin waste. Int. J. Food Prop. 2017, 20, S2612–S2625. [Google Scholar] [CrossRef]

- Kusumaningrum, I.; Pranoto, Y.; Hadiwiyoto, S. Extraction optimization and characterization of gelatine from fish dry skin of Spanish mackerel (Scomberromorus commersoni). IOP Conf. Ser. Earth Environ. Sci. 2018, 144, 012036. [Google Scholar] [CrossRef]

- Roy, J.C.; Giraud, S.; Ferri, A.; Mossotti, R.; Guan, J.; Salaün, F. Influence of process parameters on microcapsule formation from chitosan—Type B gelatin complex coacervates. Carbohydr. Polym. 2018, 198, 281–293. [Google Scholar] [CrossRef]

- Liu, H.; Gong, J.; Chabot, D.; Miller, S.S.; Cui, S.W.; Ma, J.; Zhong, F.; Wang, Q. Protection of heat-sensitive probiotic bacteria during spray-drying by sodium caseinate stabilized fat particles. Food Hydrocoll. 2015, 51, 459–467. [Google Scholar] [CrossRef]

- Bhagwat, A.; Bhushette, P.; Annapure, U.S. Spray drying studies of probiotic Enterococcus strains encapsulated with whey protein and maltodextrin. Beni-Suef Univ. J. Basic Appl. Sci. 2020, 9, 33. [Google Scholar] [CrossRef]

- De Castro-Cislaghi, F.P.; E Silva, C.D.R.; Fritzen-Freire, C.B.; Lorenz, J.G.; Sant’Anna, E.S. Bifidobacterium Bb-12 microencapsulated by spray drying with whey: Survival under simulated gastrointestinal conditions, tolerance to NaCl, and viability during storage. J. Food Eng. 2012, 113, 186–193. [Google Scholar] [CrossRef]

- Huang, X.; Gänzle, M.; Zhang, H.; Zhao, M.; Fang, Y.; Nishinari, K. Microencapsulation of probiotic lactobacilli with shellac as moisture barrier and to allow controlled release. J. Sci. Food Agric. 2021, 101, 726–734. [Google Scholar] [CrossRef] [PubMed]

- Shaharuddin, S.; Muhamad, I.I. Microencapsulation of alginate-immobilized bagasse with Lactobacillus rhamnosus NRRL 442: Enhancement of survivability and thermotolerance. Carbohydr. Polym. 2015, 119, 173–181. [Google Scholar] [CrossRef]

- Karagozlu, M.; Ocak, B.; Özdestan-Ocak, Ö. Effect of Tannic Acid Concentration on the Physicochemical, Thermal, and Antioxidant Properties of Gelatin/Gum Arabic–Walled Microcapsules Containing Origanum onites L. Essential Oil. Food Bioprocess Technol. 2021, 14, 1231–1243. [Google Scholar] [CrossRef]

- Shaddela, R.; Hesaria, J.; Azadmard-Damirchia, S.; Hamishehkar, H.; Fathi-Achachlouei, B.; Huang, Q. Use of gelatin and gum Arabic for encapsulation of black raspberryanthocyanins by complex coacervation. Int. J. Biol. Macromol. 2018, 107, 1800–1810. [Google Scholar] [CrossRef]

- Li, X.Y.; Chen, X.G.; Cha, D.S.; Park, H.J.; Liu, C.S. Microencapsulation of a probiotic bacteria with alginate–gelatin and its properties. J. Microencapsul. 2009, 26, 315–324. [Google Scholar] [CrossRef]

- Nag, A.; Han, K.; Singh, H. Microencapsulation of probiotic bacteria using pH-induced gelation of sodium caseinate and gellan gum. Int. Dairy J. 2011, 21, 247–253. [Google Scholar] [CrossRef]

- Liao, L.; Wei, X.; Gong, X.; Li, J.; Huang, T.; Xiong, T. Microencapsulation of Lactobacillus casei LK-1 by spray drying related to its stability and in vitro digestion. LWT-Food Sci. Technol. 2017, 82, 82–89. [Google Scholar] [CrossRef]

- Camargo, T.R.; Khelissa, S.; Chihib, N.E.; Dumas, E.; Wang, J.; Valenti, W.C.; Gharsallaoui, A. Preparation and characterization of microcapsules containing antioxidant fish protein hydrolysates: A new use of bycatch in brazil. Mar. Biotechnol. 2021, 23, 321–330. [Google Scholar] [CrossRef]

- Würth, R.; Wiesner, S.; Foerst, P.; Kulozik, U. Impact of the CaCl2 content in the rehydration media on the microcapsule formation out of spray dried capsule precursors for the immobilization of probiotic bacteria. Int. Dairy J. 2017, 68, 75–79. [Google Scholar] [CrossRef]

- Iqbal, R.; Zahoor, T.; Huma, N.; Jamil, A.; Ünlü, G. In-vitro GIT Tolerance of microencapsulated bifidobacterium bifidum ATCC 35914 using polysaccharide-protein matrix. Probiotics Antimicrob. Proteins 2019, 11, 830–839. [Google Scholar] [CrossRef]

- Su, Y.; Zheng, X.; Zhao, Q.; Fu, N.; Xiong, H.; Wu, W.D.; Chen, X.D. Spray drying of Lactobacillus rhamnosus GG with calcium-containing protectant for enhanced viability. Powder Technol. 2019, 358, 87–94. [Google Scholar] [CrossRef]

| Wall Material | Viability of L. plantarum (log CFU/g) | |

|---|---|---|

| Before Spray-Drying | After Spray-Drying | |

| None | 9.0 ± 0.1 | 2.1 ± 0.2 |

| PSG/SC | 9.0 ± 0.2 | 7.7 ± 0.1 |

| PSG/SPI | 8.9 ± 0.3 | 5.2 ± 0.2 |

| PSG/WPI | 9.0 ± 0.1 | 6.9 ± 0.1 |

| Amino Acids | Values (g/100 g Protein) | |

|---|---|---|

| Pufferfish Skin | Commercial Bovine | |

| Aspartic acid (Asp) | 26.16 | 6.67 |

| Threonine (Thr) | 1.25 | 2.05 |

| Serine (Ser) | 0.97 | 3.75 |

| Glutamic acid (Glu) | 9.27 | 9.89 |

| Glycine (Gly) | 13.67 | 19.65 |

| Alanine (Ala) | 7.17 | 7.58 |

| Cystine (Cys) | 0.21 | 1.15 |

| Valine (Val) | 0.90 | 2.81 |

| Methionine (Met) | 0.50 | 0.93 |

| Isoleucine (Ile) | 0.63 | 1.45 |

| Leucine (Leu) | 0.69 | 3.08 |

| Tyrosine (Tyr) | 0.17 | 0.72 |

| Phenylalanine (Phe) | 0.96 | 2.39 |

| Histidine (His) | 1.39 | 0.97 |

| Lysine (Lys) | 1.11 | 4.93 |

| Arginine (Arg) | 6.97 | 8.51 |

| Proline (Pro) | 3.89 | 13.36 |

| Hydroxyproline (Hyp) | 24.09 | 10.11 |

| Total | 100.00 | 100.00 |

| Assay | PSG/SC Mass Ratio | SC Concentration (g/L) | L. plantarum Concentration (g/L) |

|---|---|---|---|

| Effect of PSG/SC mass ratio | 1:2 | 10 | 10 |

| 1:1 | |||

| 2:1 | |||

| 3:1 | |||

| 4:1 | |||

| Effect of SC concentration | 2:1 | 5 | 10 |

| 10 | |||

| 20 | |||

| 30 | |||

| 40 | |||

| Effect of L. plantarum concentration | 2:1 | 20 | 5 |

| 10 | |||

| 20 | |||

| 30 | |||

| 40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, H.; Zhou, Y.; Xie, Q.; Chen, H.; Zhang, Y.; Hong, Z.; Chen, S.; Zhang, M. Microencapsulation of Lactobacillus plantarum with Improved Survivability Using Pufferfish Skin Gelatin-Based Wall Materials. Mar. Drugs 2024, 22, 124. https://doi.org/10.3390/md22030124

Guo H, Zhou Y, Xie Q, Chen H, Zhang Y, Hong Z, Chen S, Zhang M. Microencapsulation of Lactobacillus plantarum with Improved Survivability Using Pufferfish Skin Gelatin-Based Wall Materials. Marine Drugs. 2024; 22(3):124. https://doi.org/10.3390/md22030124

Chicago/Turabian StyleGuo, Honghui, Yelin Zhou, Quanling Xie, Hui Chen, Yiping Zhang, Zhuan Hong, Sijin Chen, and Ming’en Zhang. 2024. "Microencapsulation of Lactobacillus plantarum with Improved Survivability Using Pufferfish Skin Gelatin-Based Wall Materials" Marine Drugs 22, no. 3: 124. https://doi.org/10.3390/md22030124

APA StyleGuo, H., Zhou, Y., Xie, Q., Chen, H., Zhang, Y., Hong, Z., Chen, S., & Zhang, M. (2024). Microencapsulation of Lactobacillus plantarum with Improved Survivability Using Pufferfish Skin Gelatin-Based Wall Materials. Marine Drugs, 22(3), 124. https://doi.org/10.3390/md22030124