Agarose Stearate-Carbomer940 as Stabilizer and Rheology Modifier for Surfactant-Free Cosmetic Formulations

Abstract

1. Introduction

2. Results and Discussion

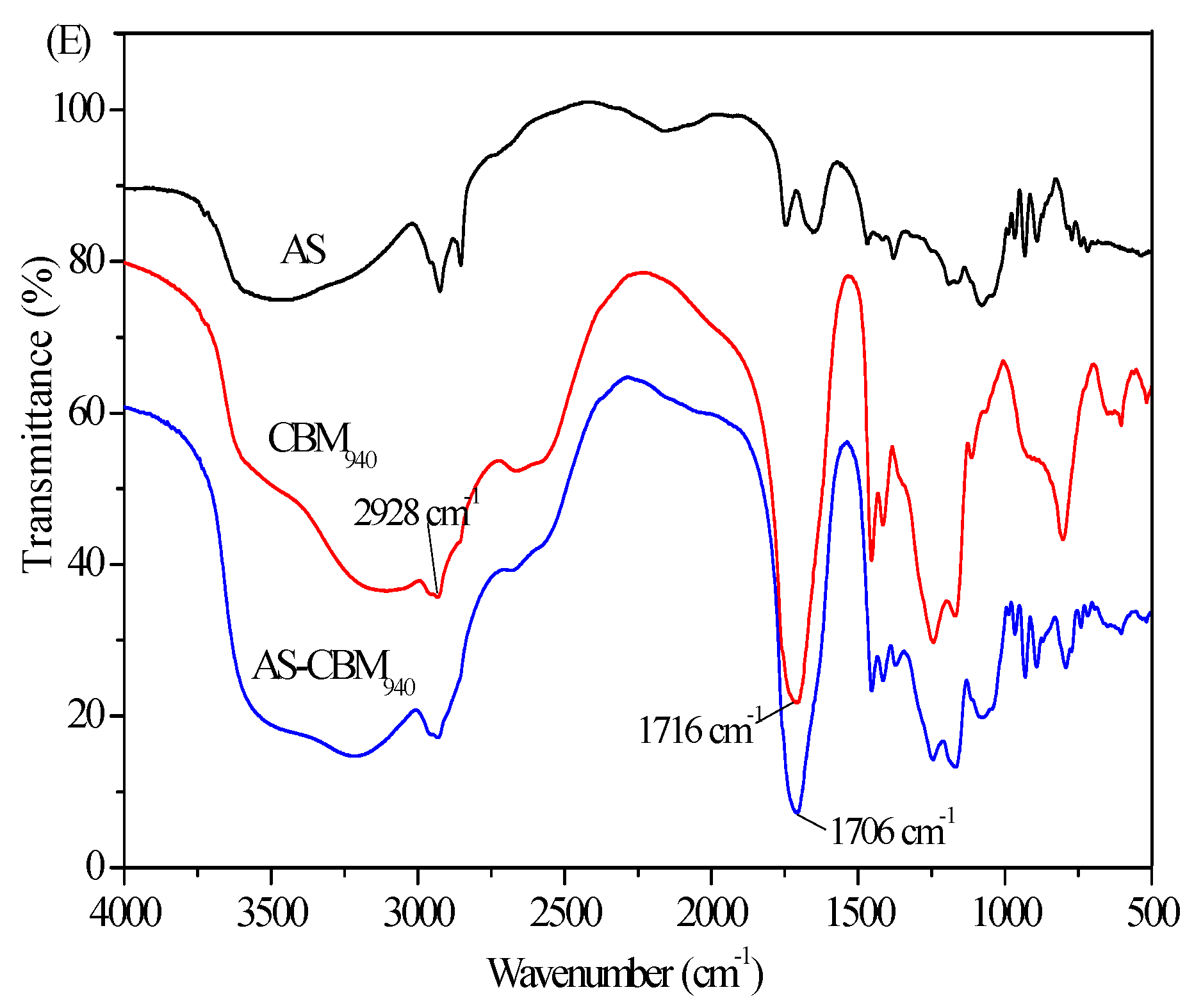

2.1. Characterization of AS

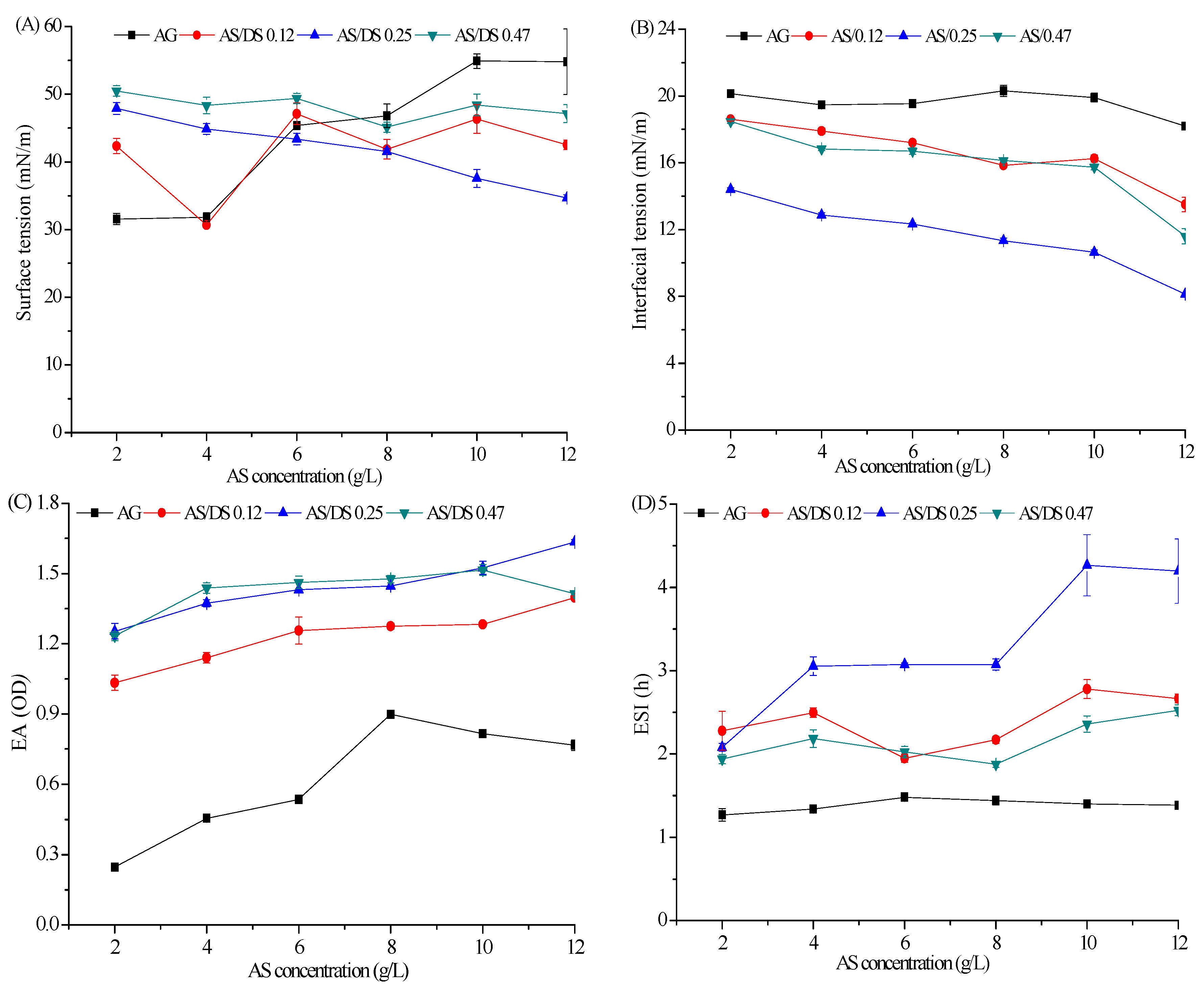

2.2. Analysis of Emulsifying Properties

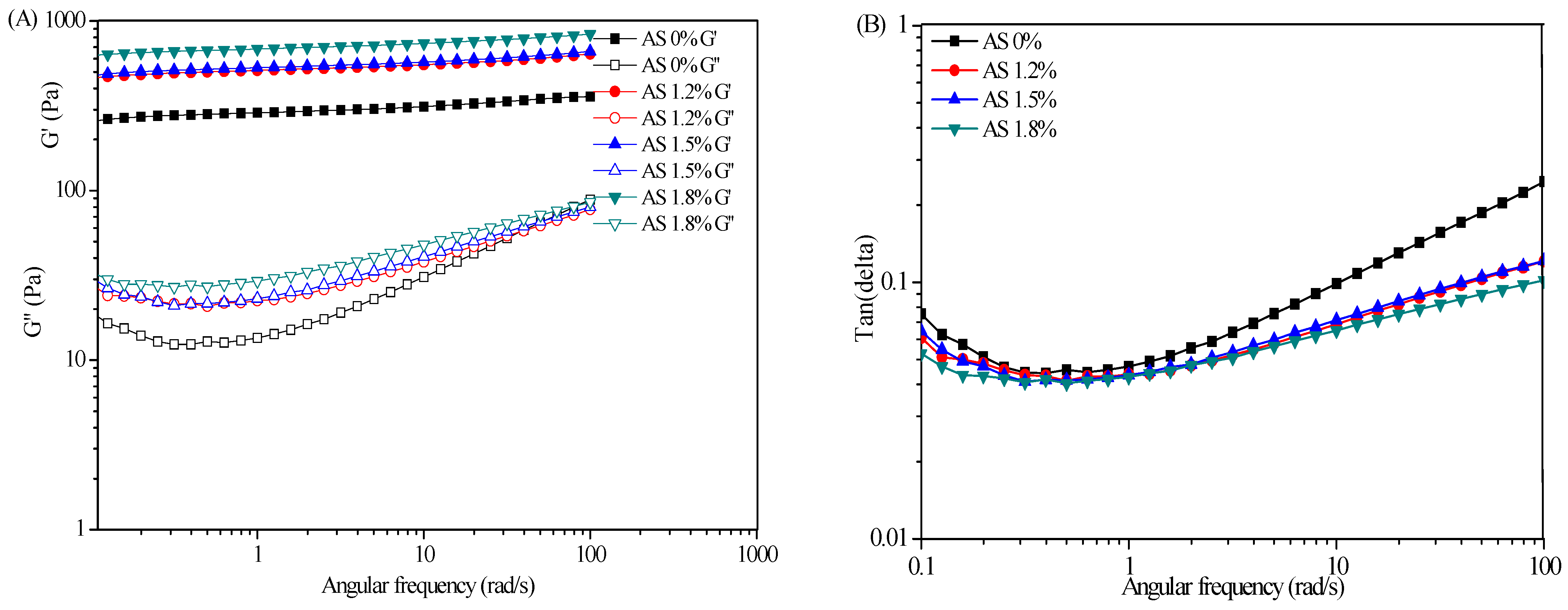

2.3. Influence of AS Concentration on the Rheological Properties of SFC

2.3.1. Steady-Shear Flow and Thixotropic Properties

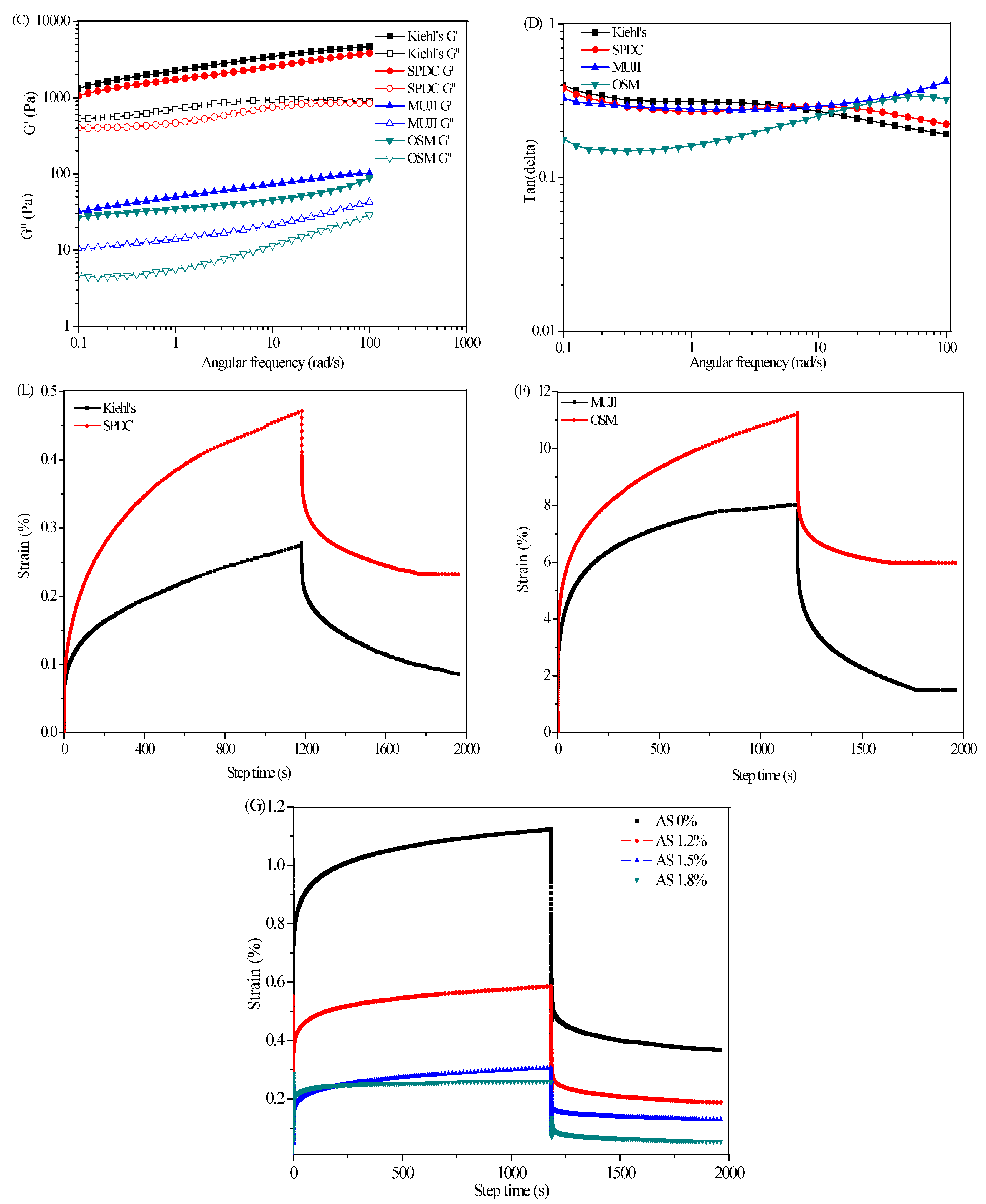

2.3.2. Dynamic Viscoelastic Properties and Creep Recovery Test

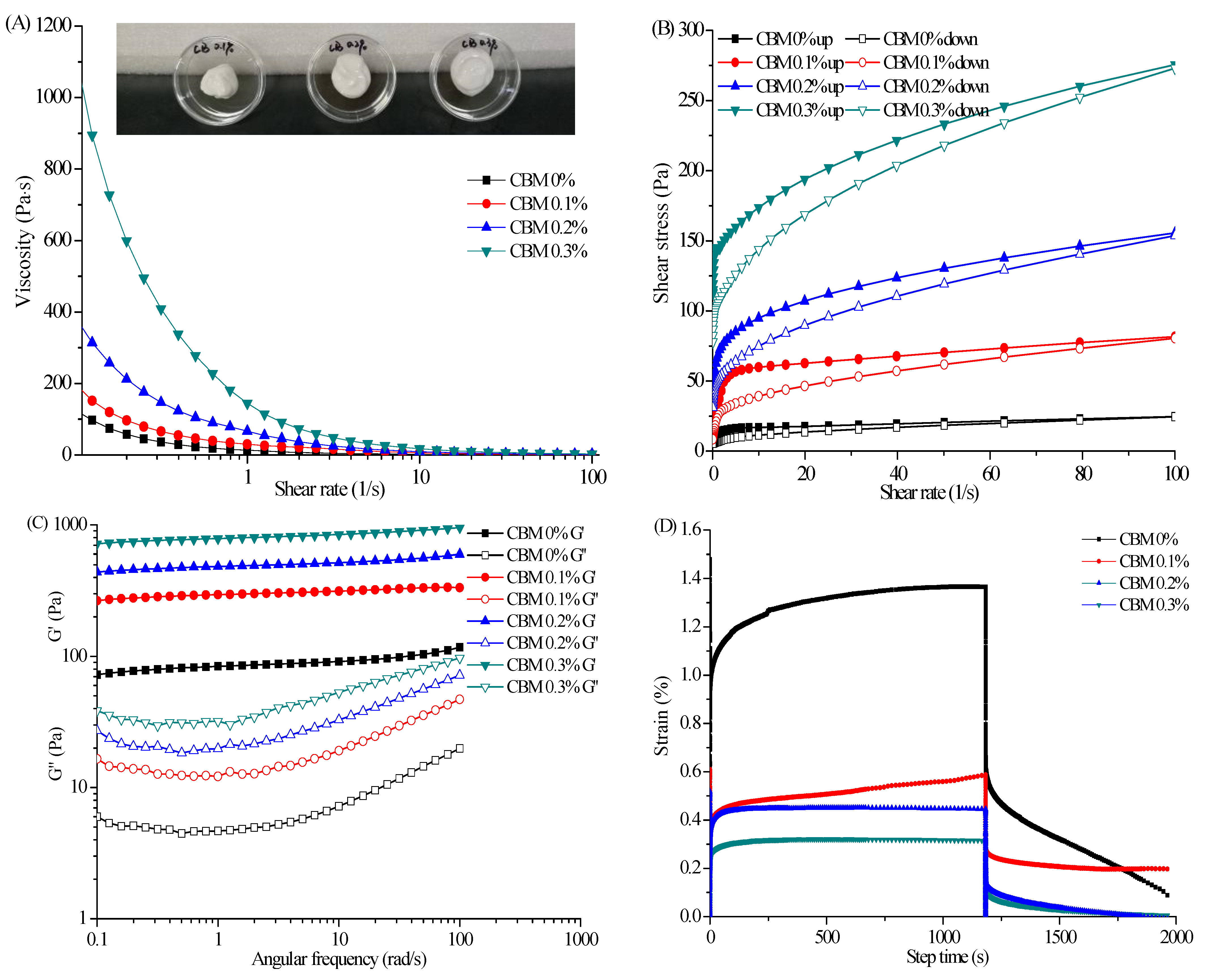

2.4. Influence of CBM940 Concentration on Rheological Properties of SFC

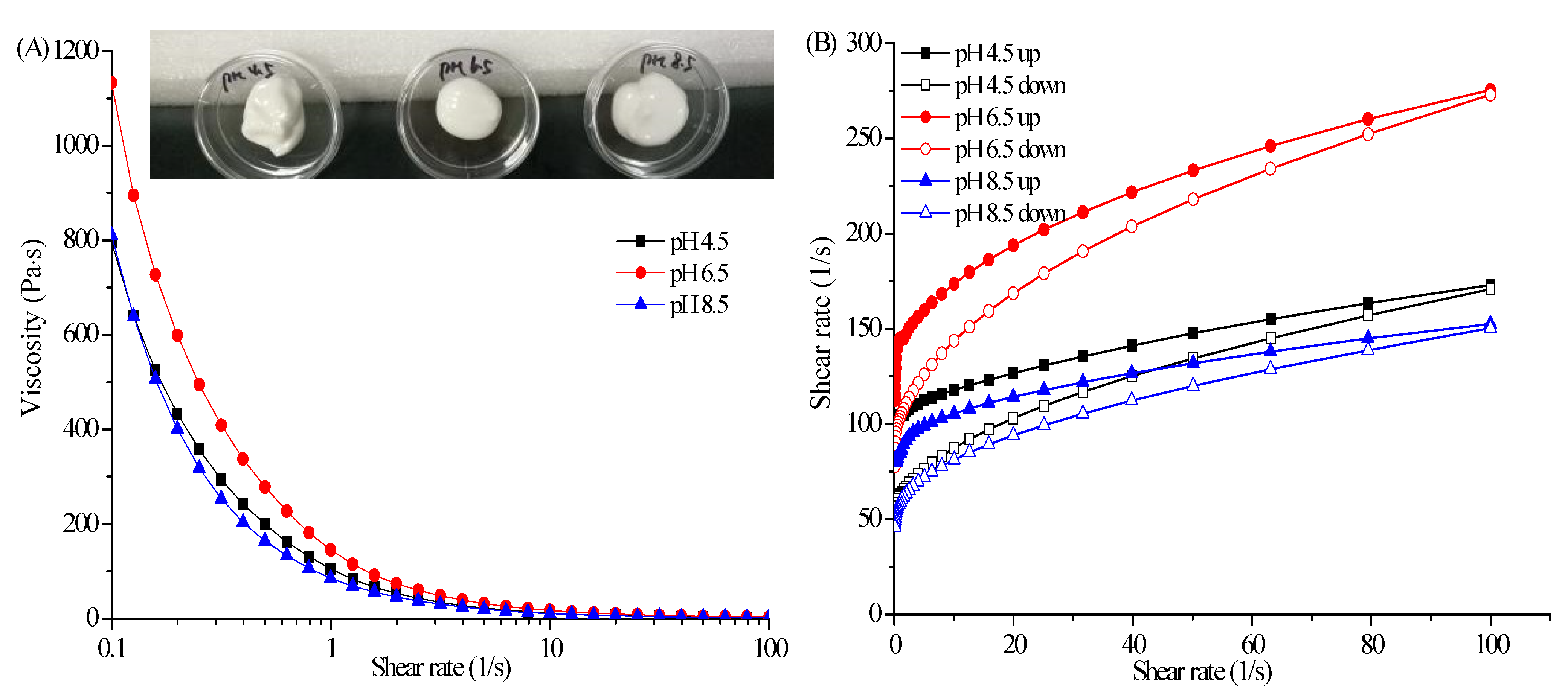

2.5. Influence of pH on Rheological Properties

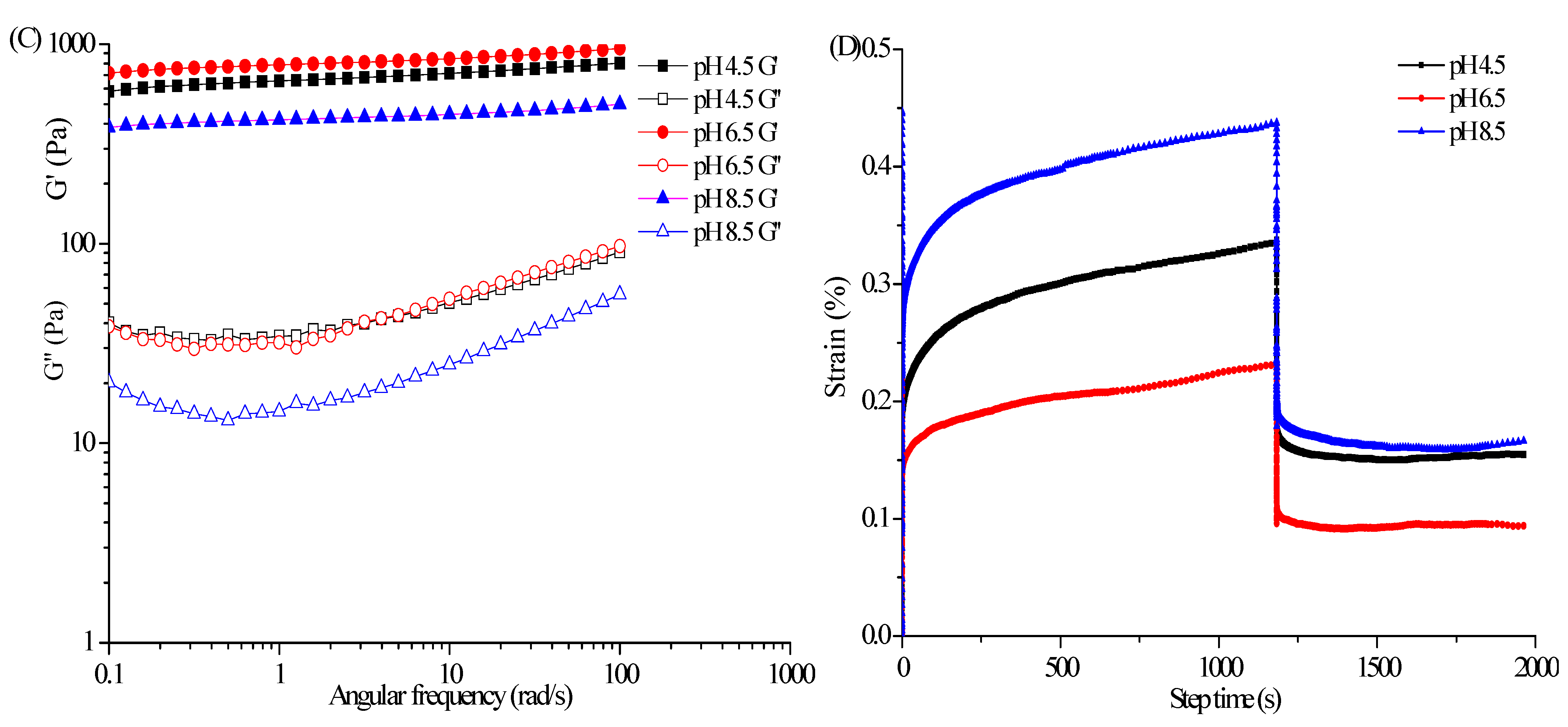

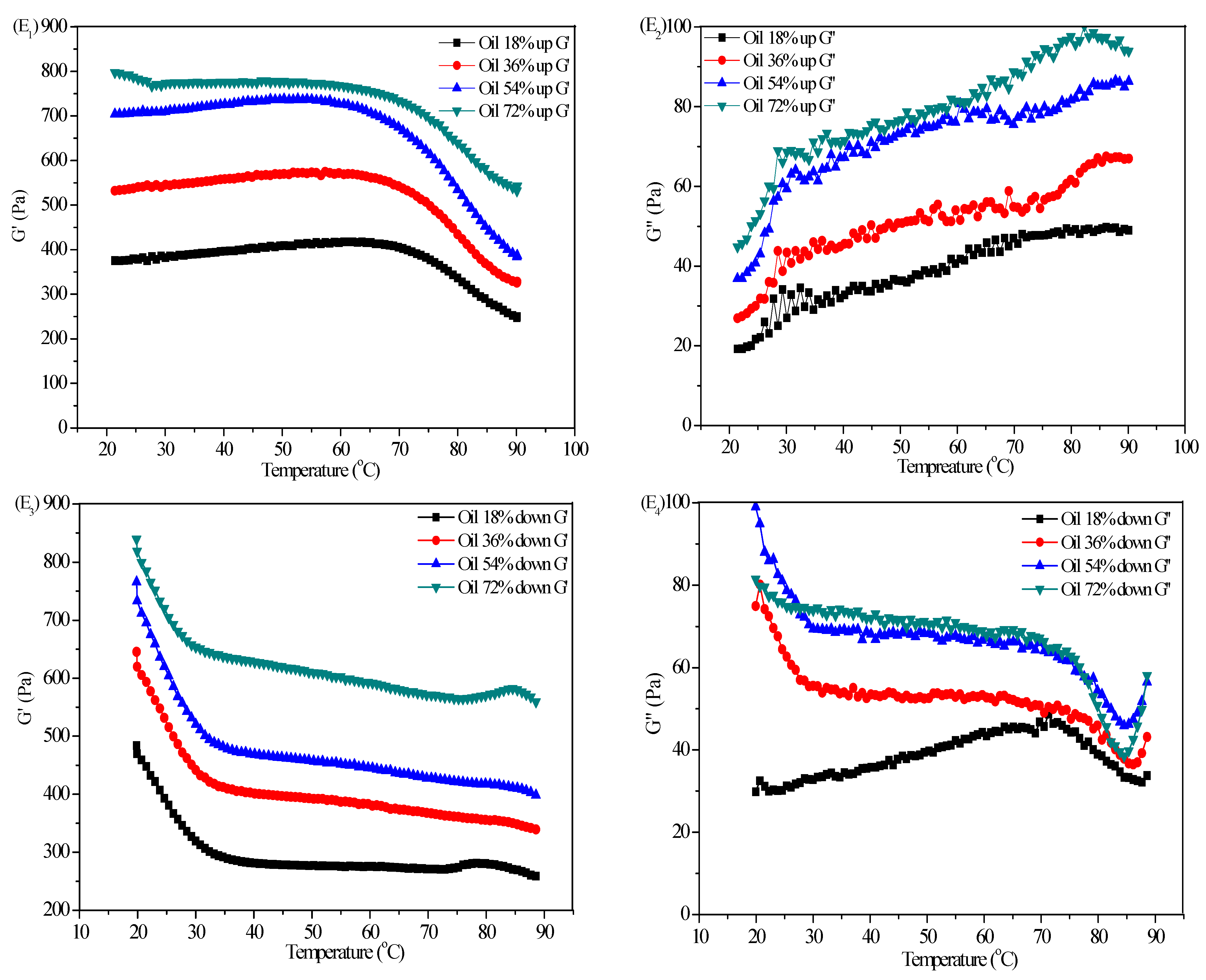

2.6. Influence of Oil Content on Rheological Properties of SFC

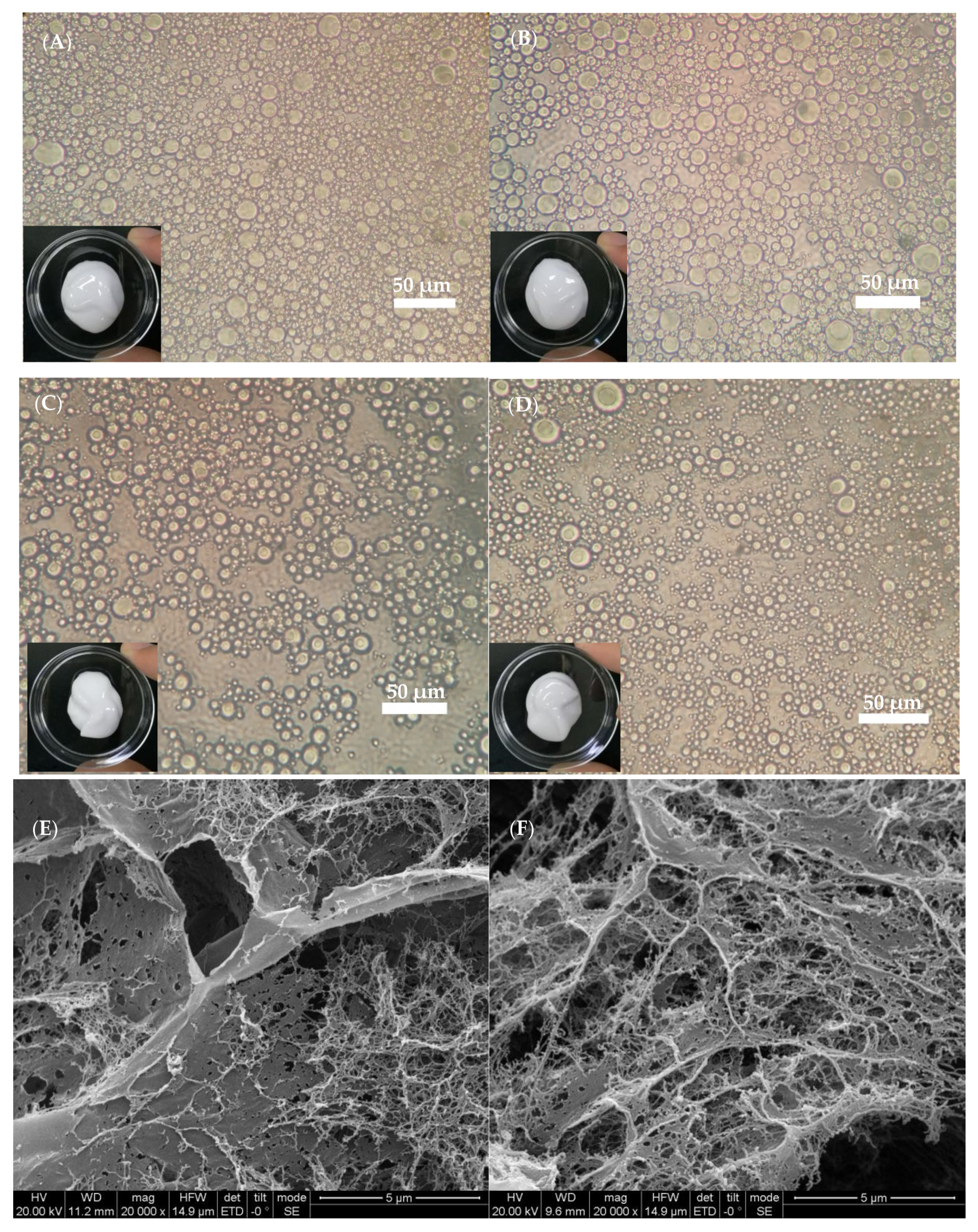

2.7. Morphology and Structureof the SFC

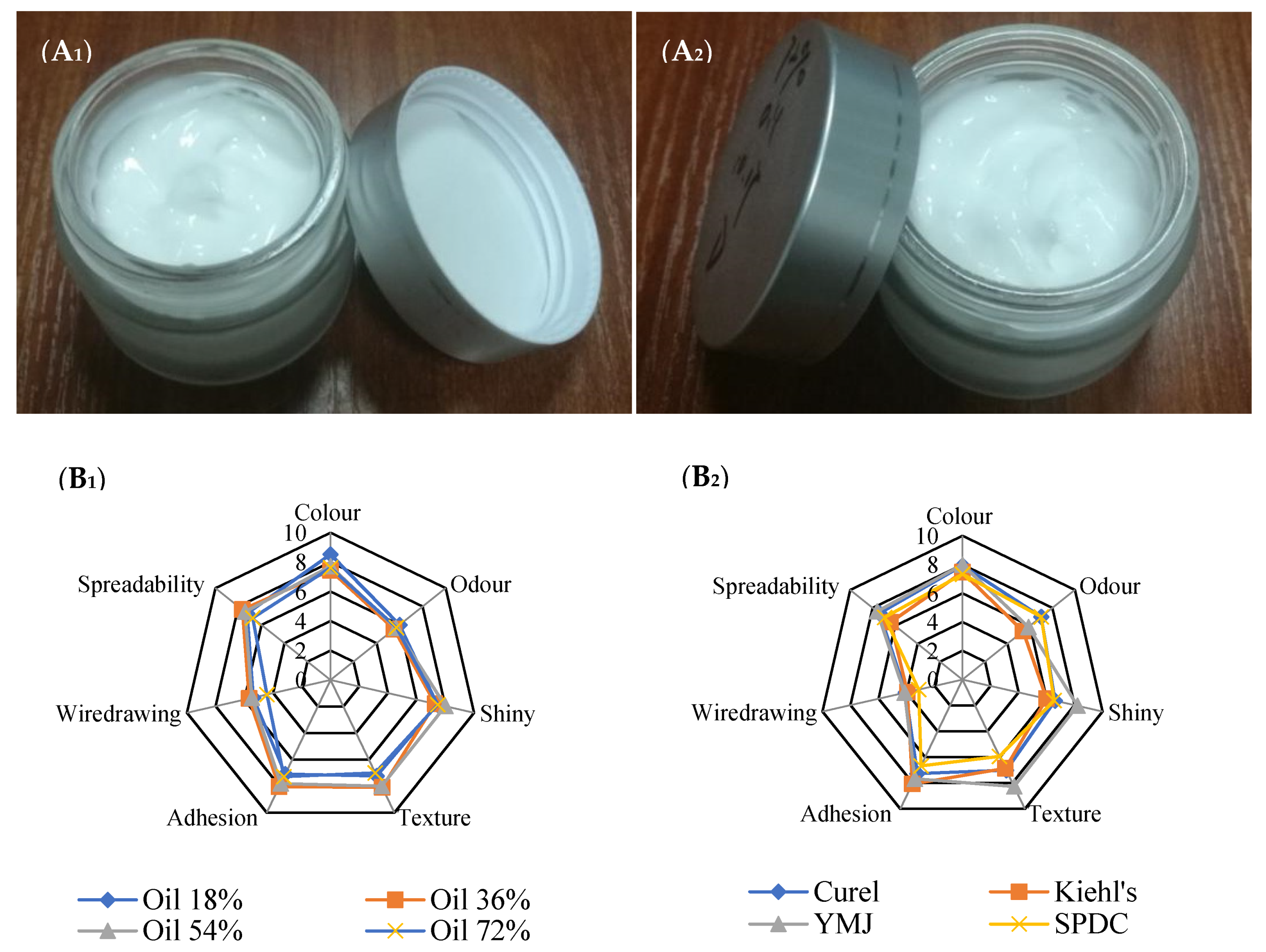

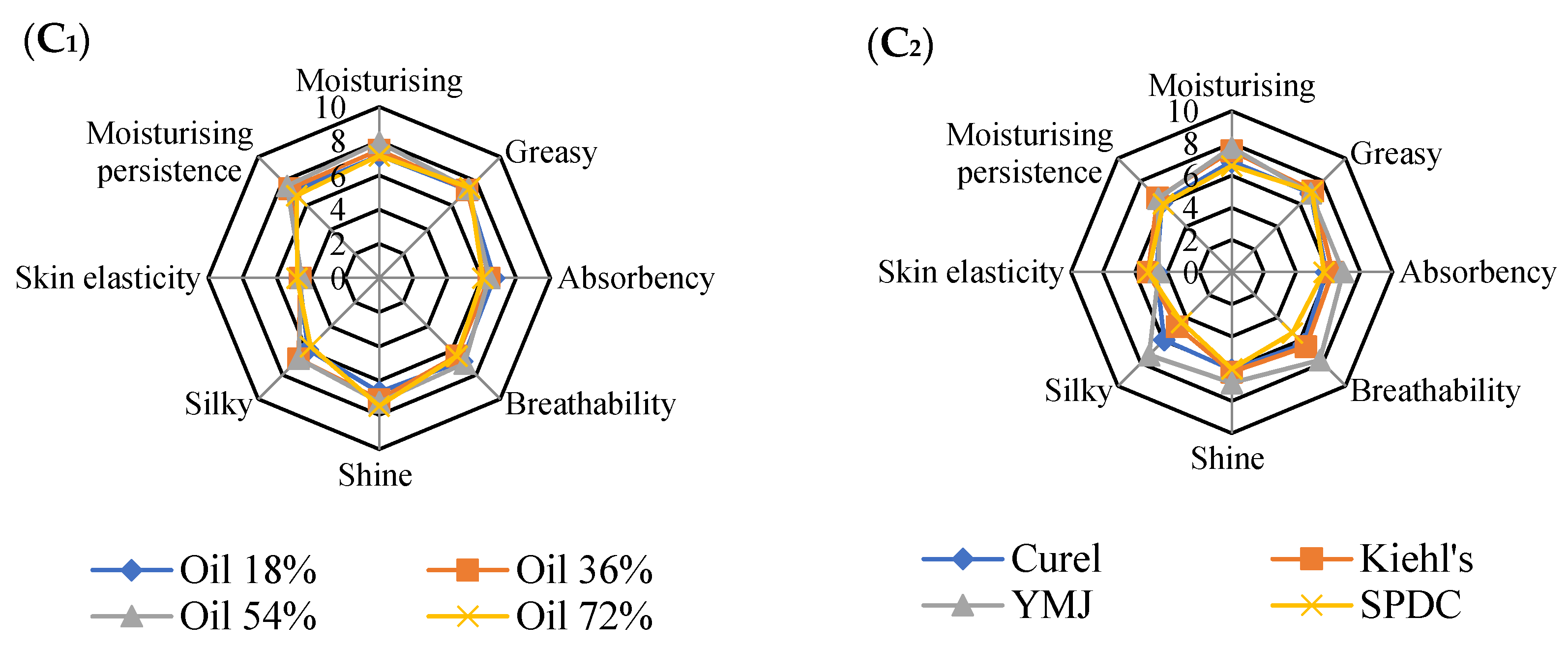

2.8. Comparative Analysisof Sensory Characteristics of SFC and Commercial Cosmetic Moisturizers

3. Materials and Methods

3.1. Materials

3.2. Methods

3.2.1. Synthesis of AS

3.2.2. Characterization of AS

3.2.3. Surface Tension (ST) and Interface Tension (IT)

3.2.4. Emulsifying Ability (EA) and Emulsifying Stability Index (ESI)

3.2.5. Preparation of SFC

3.2.6. Rheological Experiments

3.2.7. Morphology and Microstructure of SFC

3.2.8. Sensory Evaluation of the SFC

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Muda, H.; Aziz, A.; Taher, Z.; Aziz, R. Cosmeceuticals and Natural Cosmetics; Hasham, R., Ed.; Recent Trends in Research into Malaysian Medicinal Plants; Penerbit UTM Press: Skudai, Malaysia, 2017; pp. 126–175. [Google Scholar]

- Costa, R.; Santos, L. Delivery systems for cosmetics—From manufacturing to the skin of natural antioxidants. Powder Technol. 2017, 322, 402–416. [Google Scholar] [CrossRef]

- Venkataramani, D.; Tsulaia, A.; Amin, S. Fundamentals and applications of particle stabilized emulsions in cosmetic formulations. Adv. Colloid Interfac. 2020, 283, 102234. [Google Scholar] [CrossRef]

- Varvaresou, A.; Iakovou, K. Biosurfactants in cosmetics and biopharmaceuticals. Lett. Appl. Microbiol. 2015, 61, 214–223. [Google Scholar] [CrossRef] [PubMed]

- Martins, D.; Rocha, C.; Dourado, F.; Gama, M. Bacterial cellulose-carboxymethyl cellulose (BC: CMC) dry formulation as stabilizer and texturizing agent for surfactant-free cosmetic formulations. Colloid. Surf. A 2021, 617, 126380. [Google Scholar] [CrossRef]

- Dickinson, E. Hydrocolloids acting as emulsifying agents-How do they do it? Food Hydrocoll. 2018, 78, 2–14. [Google Scholar] [CrossRef]

- Xiao, Q.; Chen, G.; Zhang, Y.H.; Weng, H.F.; Cai, M.H.; Xiao, A.F. Evaluation of a novel self-emulsifiable dodecenyl succinylated agarose in microencapsulation of docosahexaenoic acid (DHA) through spray-chilling process. Int. J. Biol. Macromol. 2020, 163, 2314–2324. [Google Scholar] [CrossRef]

- Kouhi, M.; Prabhakaran, M.P.; Ramakrishna, S. Edible polymers: An insight into its application in food, biomedicine and cosmetics. Trends Food Sci. Tech. 2020, 103, 248–263. [Google Scholar] [CrossRef]

- Jamshidian, M.; Savary, G.; Grisel, M.; Picard, C. Stretching properties of xanthan and hydroxypropyl guar in aqueous solutions and in cosmetic emulsions. Carbohydr. Polym. 2014, 112, 334–341. [Google Scholar] [CrossRef]

- Singh, B.; Kumar, A. Graft and crosslinked polymerization of polysaccharide gum to form hydrogel wound dressings for drug delivery applications. Carbohydr. Res. 2020, 489, 107949. [Google Scholar] [CrossRef]

- Zhang, X.F.; Gu, X.Q.; Wang, X.D.; Wang, H.M.; Mao, S.R. Tunable and sustained-release characteristics of venlafaxine hydrochloride from chitosan–carbomer matrix tablets based on in situ formed polyelectrolyte complex film coating. Asian J. Pharm. Sci. 2018, 13, 566–574. [Google Scholar] [CrossRef]

- Zhang, Y.; Ng, W.; Hu, J.; Mussa, S.S.; Ge, Y. Formulation and in vitro stability evaluation of ethosomal carbomer hydrogel for transdermal vaccine delivery. Colloid. Surf. B 2018, 163, 184–191. [Google Scholar] [CrossRef] [PubMed]

- Winkler, H.; Vorwerg, W.; Rihm, R. Thermal and mechanical properties of fatty acid starch esters. Carbohydr. Polym. 2014, 102, 941–949. [Google Scholar] [CrossRef] [PubMed]

- Vanmarcke, A.; Leroy, L.; Stoclet, G.; Crépy, L.D.; Lefebvre, J.M. Influence of fatty chain length and starch composition on structure and properties of fully substituted fatty acid starch esters. Carbohydr. Polym. 2017, 164, 249–257. [Google Scholar] [CrossRef] [PubMed]

- Garg, S.; Jana, A.K. Characterization and evaluation of acylated starch with different acyl groups and degrees of substitution. Carbohydr. Polym. 2011, 83, 1623–1630. [Google Scholar] [CrossRef]

- Xiao, Q.; Weng, H.F.; Chen, G.; Xiao, A.F. Preparation and characterization of octenyl succinic anhydride modified agarose derivative. Food Chem. 2019, 79, 30–39. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.Q.; Chen, X.; McClements, D.J.; Zou, L.Q.; Liu, W. pH-, ion- and temperature-dependent emulsion gels: Fabricated by addition of whey protein to gliadin-nanoparticle coated lipid droplets. Food Hydrocoll. 2018, 77, 870–878. [Google Scholar] [CrossRef]

- Benchabane, A.; Bekkour, K. Rheological properties of carboxymethyl cellulose (CMC) solutions. Colloid Polym. Sci. 2008, 286, 1173–1180. [Google Scholar] [CrossRef]

- Singh, V.; Sethi, R.; Tiwari, A. Structure elucidation and properties of a nonionic galactomannan derived from the Cassia pleurocarpa seeds. Int. J. Biol. Macromol. 2009, 44, 9–13. [Google Scholar] [CrossRef]

- Mao, Y.Y.; McClements, D.J. Modification of emulsion properties by hetero-aggregation of oppositely charged starch-coated and protein-coated fat droplets. Food Hydrocoll. 2013, 33, 320–326. [Google Scholar] [CrossRef]

- Adeli, M.; Samavati, V. Studies on the steady shear flow behavior and chemical properties of water-soluble polysaccharide from Ziziphus lotus fruit. Int. J. Biol. Macromol. 2015, 72, 580–587. [Google Scholar] [CrossRef]

- Huang, Y.B.; Shi, F.L.; Wang, L.M.; Yang, Y.; Khan, B.M.; Cheong, K.L. Preparation and evaluation of Bletillastriata polysaccharide/carboxymethyl chitosan/Carbomer940 hydrogel for wound healing. Int. J. Biol. Macromol. 2019, 132, 729–737. [Google Scholar] [CrossRef]

- Wei, Y.X.; Lin, Y.B.; Xie, R.; Xu, Y.F.; Yao, J. The flow behavior, thixotropy and dynamical viscoelasticity of fenugreek gum. J. Food Eng. 2015, 166, 21–28. [Google Scholar] [CrossRef]

- Liu, J.Z.; Wang, R.K.; Gao, F.Y.; Zhou, J.H.; Cen, K.F. Rheology and thixotropic properties of slurry fuel prepared using municipal waste water sludge and coal. Chem. Eng. Sci. 2012, 76, 1–8. [Google Scholar] [CrossRef]

- Glicerina, V.; Balestra, F.; Rosa, M.D.; Romani, S. Rheological, textural and calorimetric modifications of dark chocolate during process. J. Food Eng. 2013, 199, 173–179. [Google Scholar] [CrossRef]

- Kurt, A.; Cengiz, A.; Kahyaoglu, T. The effect of gum tragacanth on the rheological properties of salep based ice cream mix. Carbohyd. Polym. 2016, 143, 116–123. [Google Scholar] [CrossRef]

- Patel, A.R.; Dumlu, P.; Vermeir, L.; Lewille, B.; Lesaffer, A. Rheological characterization of gel-in-oil-in-gel type structured emulsions. Food Hydrocoll. 2015, 46, 84–92. [Google Scholar] [CrossRef]

- Piau, J.M. Carbopol gels: Elasto viscoplastic and slippery glasses made of individual swollen sponges: Meso- and macroscopic properties, constitutive equations and scaling laws. J. Non-Newton. Fluid Mech. 2007, 144, 1–29. [Google Scholar] [CrossRef]

- Moller, P.; Fall, A.; Chikkadi, V.; Derks, D.; Bonn, D. An attempt to categorize yield stress fluid behavior. Phil. Trans. Math. Phys. Eng. Sci. 2009, 367, 5139–5155. [Google Scholar]

- Manoi, K.; Rizvi, S. Emulsification mechanisms and characterization of cold, gel-like emulsions produced from texturized whey protein concentrate. Food Hydrocoll. 2009, 23, 1837–1847. [Google Scholar] [CrossRef]

- Fu, L.; Tang, C.H. Cold, gel-like whey protein emulsions by microfluidisation emulsification: Rheological properties and microstructures. Food Chem. 2011, 127, 1641–1647. [Google Scholar]

- Line, V.L.S.; Remondetto, G.E.; Subirade, M. Cold gelation of beta-lactoglobulinoil-in-water emulsions. Food Hydrocoll. 2005, 19, 269–278. [Google Scholar] [CrossRef]

- De Vries, A.; Nikiforidis, C.V.; Scholten, E. Natural amphiphilic proteins astri-block Janus particles: Self-sorting into thermo-responsive gels. Europhys. Lett. 2014, 107, 58003. [Google Scholar] [CrossRef]

- Dolz, M.; Hernández, M.J.; Delegido, J. Creep and recovery experimental investigation of low oil content food emulsions. Food Hydrocoll. 2008, 22, 421–427. [Google Scholar] [CrossRef]

- Yilmaz, M.T.; Karaman, S.; Dogan, M.; Yetim, H.; Kayacier, A. Characterization of O/W model system meat emulsions using shear creep and creep recovery tests based on mechanical simulation models and their correlation with texture profile analysis (TPA) parameters. J. Food Eng. 2012, 108, 327–336. [Google Scholar] [CrossRef]

- Rajinder, P. Rheology of high internal phase ratio emulsions. Food Hydrocoll. 2006, 20, 997–1005. [Google Scholar]

- Torquato, S.; Truskett, T.M.; Debenedetti, P.G. Is random close packing of spheres well defined. Phys. Rev. Lett. 2000, 84, 2064–2067. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.J.; Hu, Q.G.; Qian, J.T.; Li, T.; Ma, P.M. Preparation and properties of thermoplastic poly(caprolactone) composites containing high amount of esterified starch without plasticizer. Carbohydr. Polym. 2016, 139, 28–34. [Google Scholar] [CrossRef]

- Teramoto, N.; Shibata, M. Synthesis and properties of pullulan acetate. Thermal properties, biodegradability, and a semi-clear gel formation in organic solvents. Carbohydr. Polym. 2006, 63, 476–481. [Google Scholar] [CrossRef]

- Ren, K.; Lamsal, B.P. Synthesis of some glucose-fatty acid esters by lipase from Candida antarctica and their emulsion functions. Food Chem. 2017, 214, 556–563. [Google Scholar] [CrossRef]

- Lorenzo, G.; Zaritzky, N.; Califano, A. Rheological analysis of emulsion-filled gels based on high acyl gellan gum. Food Hydrocoll. 2013, 30, 672–680. [Google Scholar] [CrossRef]

- Gilbert, L.; Picard, C.; Savary, G.; Grisel, M. Rheological and textural characterization of cosmetic emulsions containing natural and synthetic polymers: Relationships between both data. Colloid Surf. A 2013, 421, 150–163. [Google Scholar] [CrossRef]

| Sensory Characteristic | Definition | Directional teRm/Scoring Standards | |

|---|---|---|---|

| Before rubbing | Color | Degree to which the product looks clear, ranging from yellow to white | Yellow–white/0–9 |

| Odor | Amount of any type of odor, like vegetable oil, lard, grease, or shortening, sweet or maple. | Strong–weak/0–9 | |

| Shiny | Degree to which the product looks shiny, oily, glossy, or sheen. | Slightly–very/0–9 | |

| Texture | impression of the thickness of the sample when it is rubbed between a thumb and a forefinger | Thin–thick/0–9 | |

| Sticky | Amount of the sample that stays on forefinger after short contact (2 s) with the sample in a container | A little–a lot/0–9 | |

| Wiredrawing | Impression of the distance that the product will wiredraw after picking-up | Slightly–very/0–9 | |

| During rubbing | Spreadability | Impression of the area that the product will cover when spread over the skin | A little–a lot/0–9 |

| Moisturizing | Degree to which the product feels moist | A little–a lot/0–9 | |

| Greasy | Degree to which the product feels greasy | Slightly–very/0–9 | |

| Absorbency | Impression of the rate of absorption of the product into the skin | Slowly–quickly/0–9 | |

| Breathability | Degree to which the product leaves an oily or waxy film or coating on the skin after rubbing | A little–a lot/0–9 | |

| Sheen | Degree to which the product looks shiny, glossy, is iridescent or glittery after rubbing | A little–a lot/0–9 | |

| Silky | Degree to which the product feels smooth, silky, or soft on fingers after rubbing | Slightly–very/0–9 | |

| After rubbing | Skin elasticity | Degree to which skin feels firmand elastic after rubbing | Slightly–very/0–9 |

| Moisturizing persistence | Degree to which the product leaves a moisturizing feeling on the skin after rubbing | A little–a lot/0–9 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Q.; Chen, G.; Zhang, Y.-H.; Chen, F.-Q.; Weng, H.-F.; Xiao, A.-F. Agarose Stearate-Carbomer940 as Stabilizer and Rheology Modifier for Surfactant-Free Cosmetic Formulations. Mar. Drugs 2021, 19, 344. https://doi.org/10.3390/md19060344

Xiao Q, Chen G, Zhang Y-H, Chen F-Q, Weng H-F, Xiao A-F. Agarose Stearate-Carbomer940 as Stabilizer and Rheology Modifier for Surfactant-Free Cosmetic Formulations. Marine Drugs. 2021; 19(6):344. https://doi.org/10.3390/md19060344

Chicago/Turabian StyleXiao, Qiong, Guo Chen, Yong-Hui Zhang, Fu-Quan Chen, Hui-Fen Weng, and An-Feng Xiao. 2021. "Agarose Stearate-Carbomer940 as Stabilizer and Rheology Modifier for Surfactant-Free Cosmetic Formulations" Marine Drugs 19, no. 6: 344. https://doi.org/10.3390/md19060344

APA StyleXiao, Q., Chen, G., Zhang, Y.-H., Chen, F.-Q., Weng, H.-F., & Xiao, A.-F. (2021). Agarose Stearate-Carbomer940 as Stabilizer and Rheology Modifier for Surfactant-Free Cosmetic Formulations. Marine Drugs, 19(6), 344. https://doi.org/10.3390/md19060344