Nitrate Removal by Zero-Valent Metals: A Comprehensive Review

Abstract

1. Introduction

2. Removal of Nitrate by Means of Zero-Valent Iron

2.1. Microscopic Iron

2.1.1. Effect of pH

2.1.2. Effect of Dissolved Oxygen

2.1.3. Effect of Initial Nitrate Concentration

2.1.4. Effect of Temperature

2.1.5. Effect of Dissolved Ions

2.2. Nanoscopic Iron

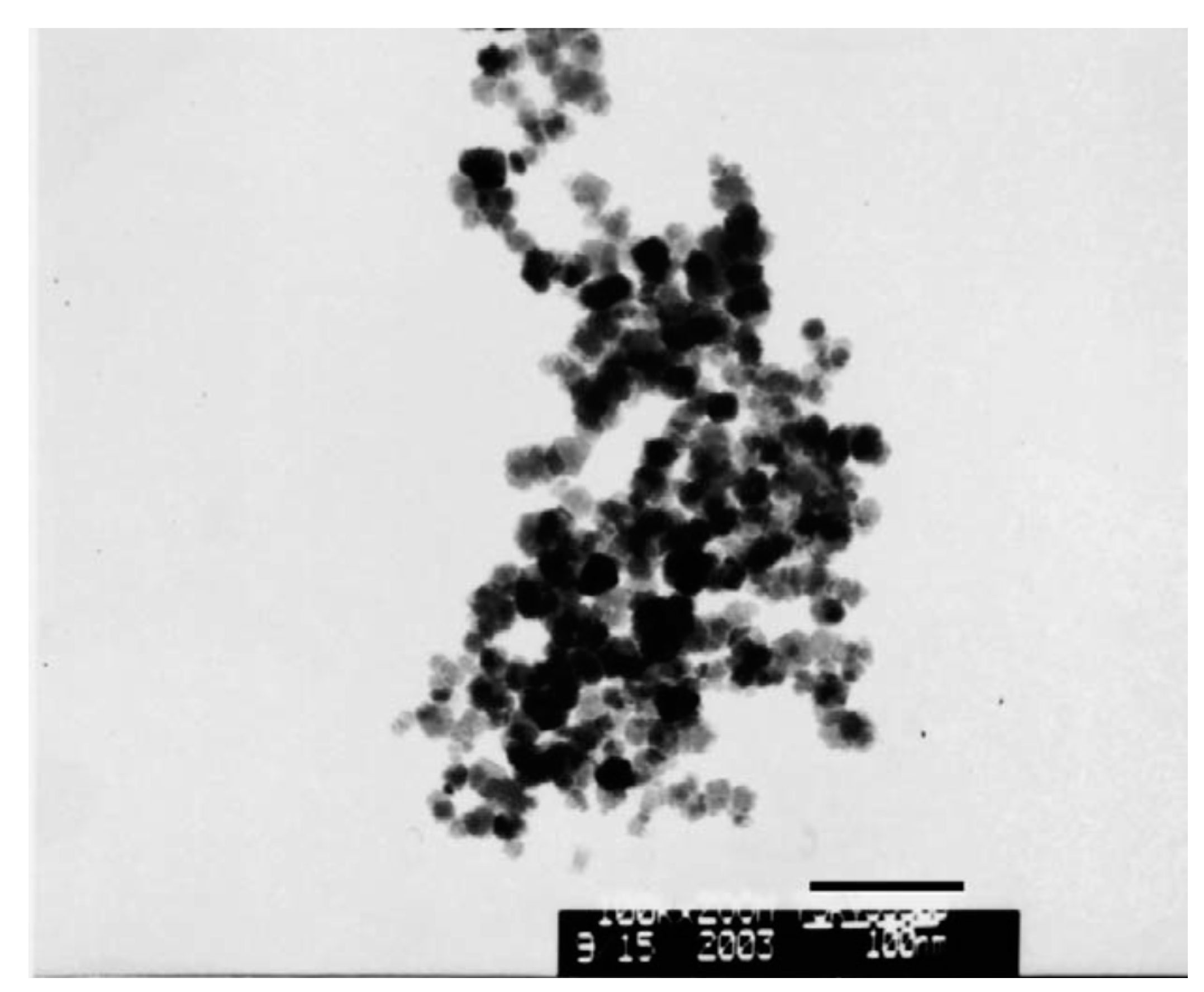

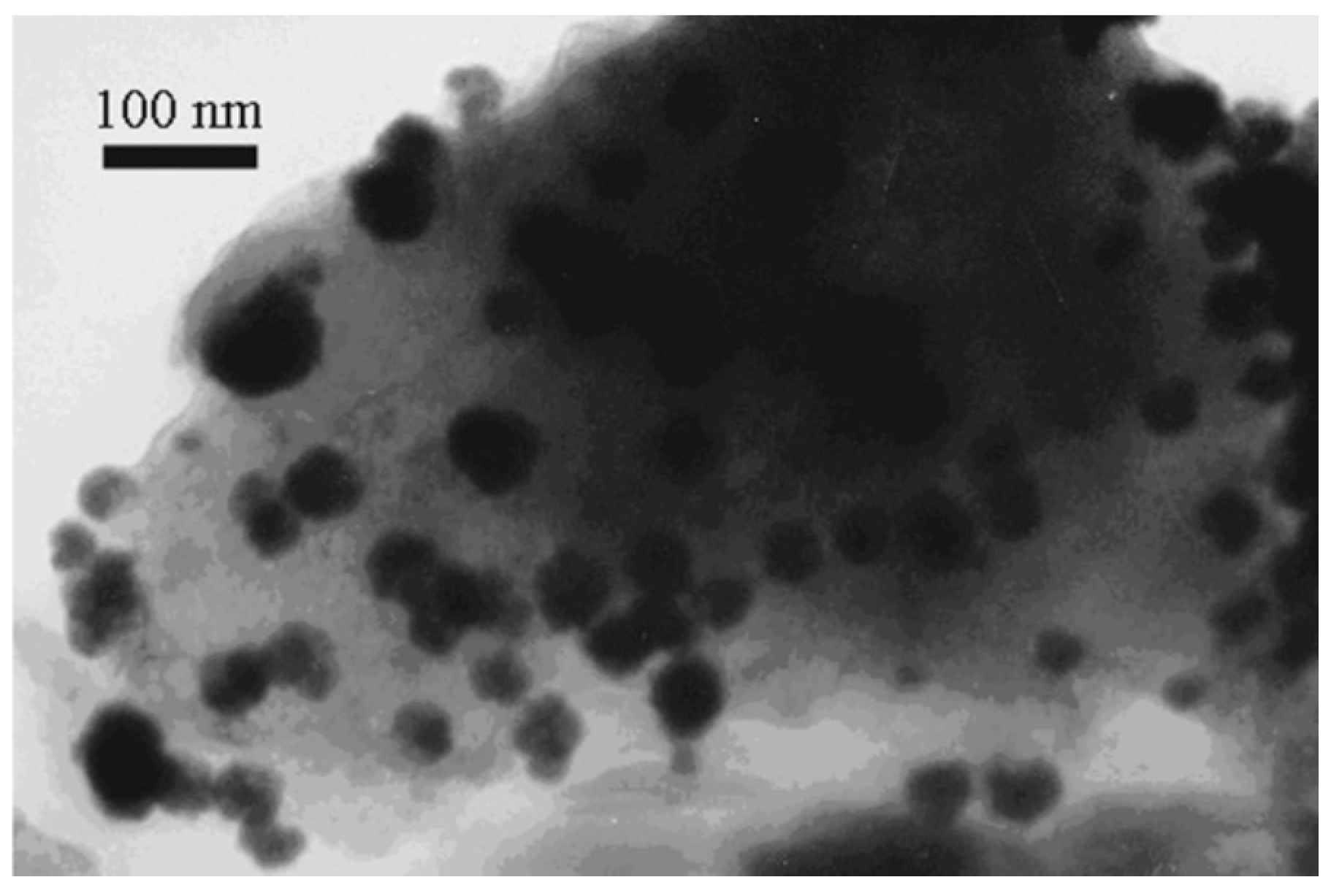

2.2.1. Synthesis of Nanoscopic Zero-Valent Iron

2.2.2. Effect of pH

2.2.3. Effect of Dissolved Oxygen

2.2.4. Effect of Initial Nitrate Concentration

2.2.5. Effect of Temperature

2.2.6. Effect of Dissolved Ions

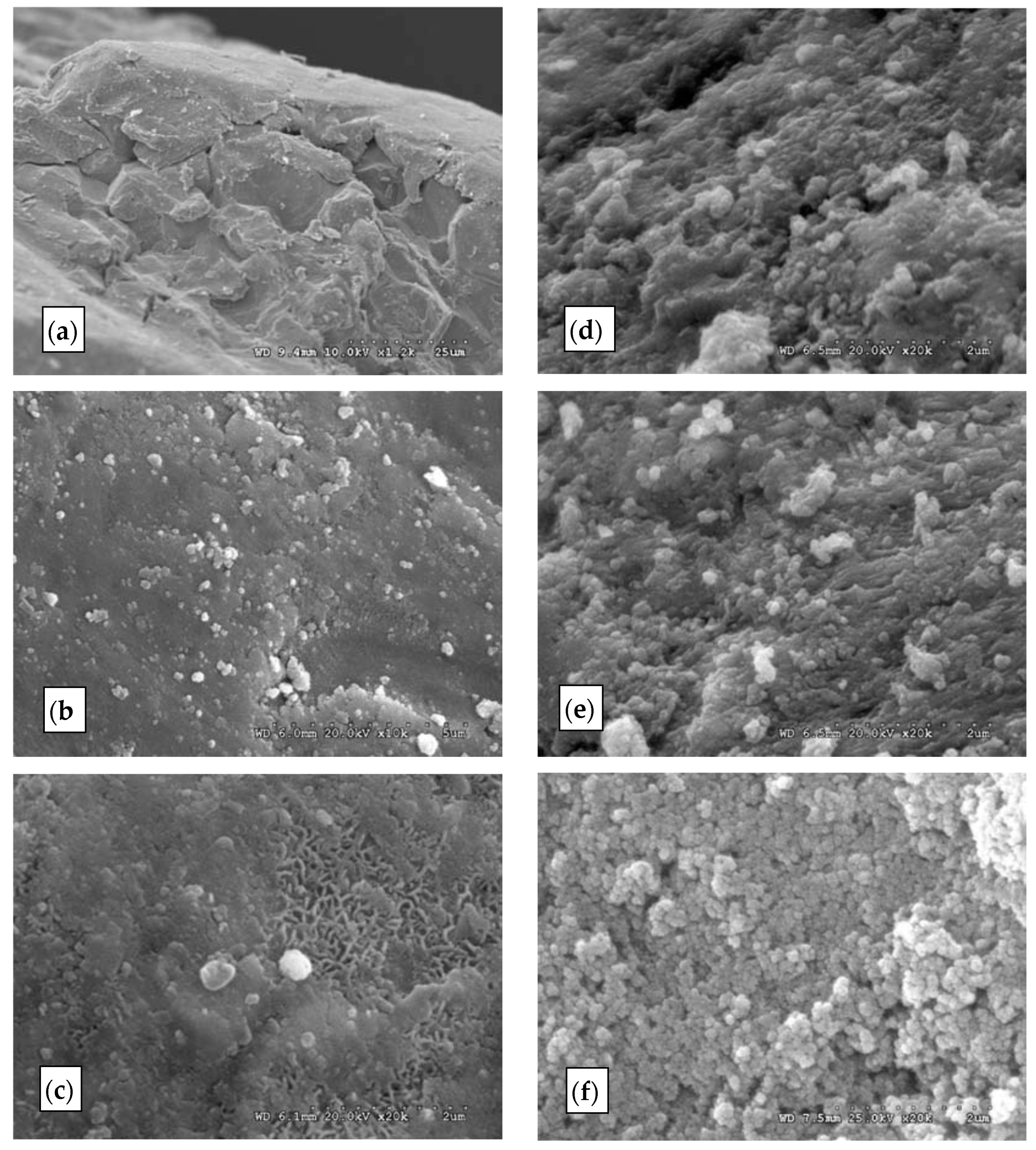

2.2.7. Supported nZVI

Carbonaceous Materials

Clays

Resins

Unconventional Supports

3. Nitrate Removal by Other Zero-Valent Metals

3.1. Zero-Valent Aluminium

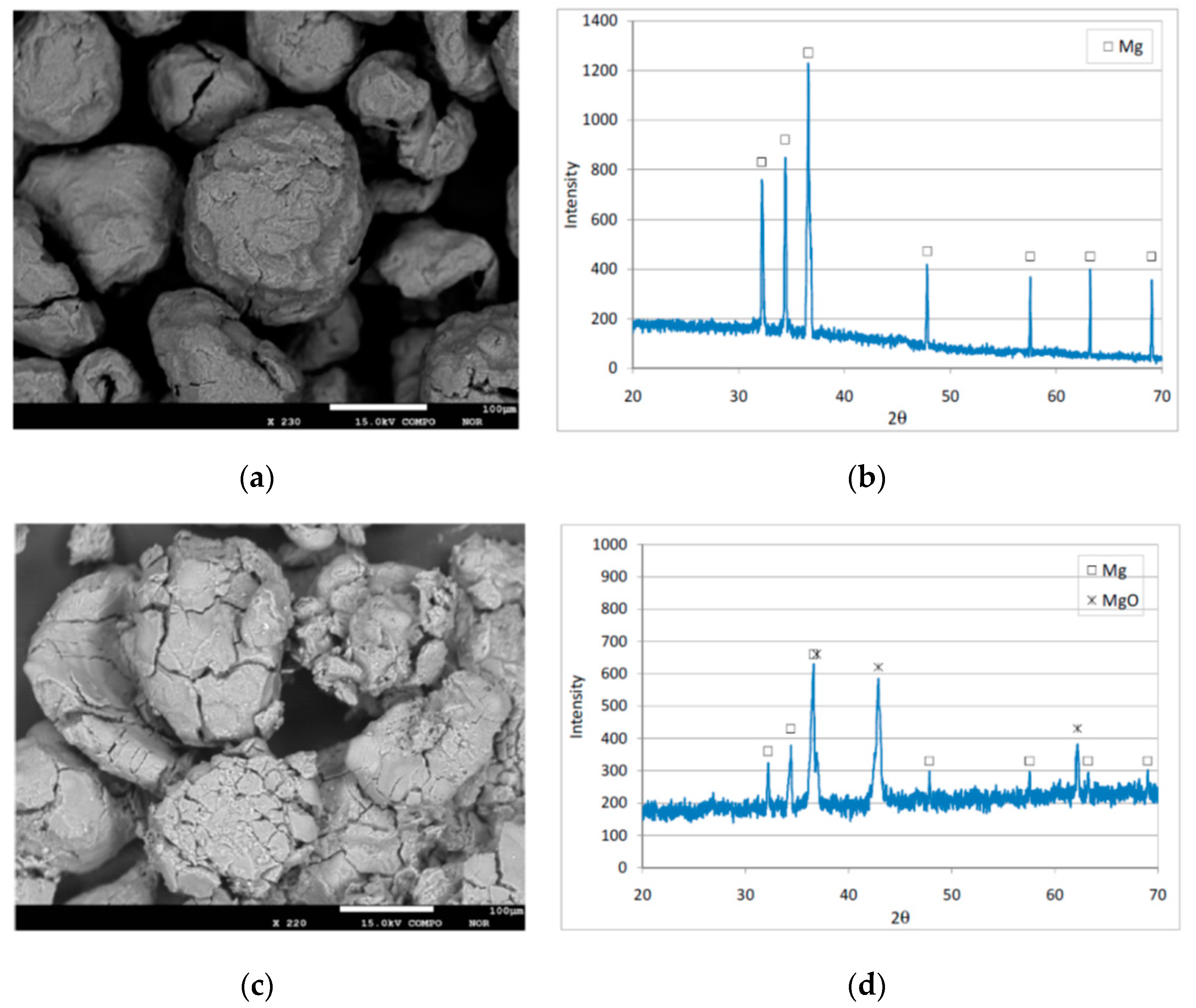

3.2. Zero-Valent Magnesium

3.3. Zero-Valent Copper

3.4. Zero-Valent Zinc

4. Final Considerations and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Camargo, J.A.; Alonso, A. Ecological and toxicological effects of inorganic nitrogen pollution in aquatic ecosystems: A global assessment. Environ. Int. 2006, 32, 831–849. [Google Scholar] [CrossRef] [PubMed]

- Ghaly, A.E.; Ramakrishnan, V.V. Nitrogen sources and cycling in the ecosystem and its role in air, water and soil pollution: A critical review. J. Pollut. Eff. Cont. 2015, 3, 136. [Google Scholar] [CrossRef]

- Fewtrell, L. Drinking-water nitrate, methemoglobinemia, and global burden of disease: A discussion. Environ. Health Perspect. 2004, 112, 1371–1374. [Google Scholar] [CrossRef] [PubMed]

- International Agency for Research on Cancer (IARC). Monographs on the Evaluation of Carcinogenic Risks to Humans. Volume 94. Ingested Nitrate and Nitrite, and Cyanobacterial Peptide Toxins; IARC: Lyon, France, 2010. [Google Scholar]

- Soares, M.I.M. Biological denitrification of groundwater. Water Air Soil Pollut. 2000, 123, 183–193. [Google Scholar] [CrossRef]

- Samatya, S.; Kabay, N.; Yüksel, Ü.; Arda, M.; Yüksel, M. Removal of nitrate from aqueous solution by nitrate selective ion exchange resins. React. Funct. Polym. 2006, 66, 1206–1214. [Google Scholar] [CrossRef]

- Nadin, J. Are the current methods of remediation to reduce nitrate contamination in groundwater in the developing world effective? A systematic review. Plymouth Stud. Sci. 2014, 7, 118–150. [Google Scholar]

- Van der Bruggen, B.; Vandecasteele, C. Removal of pollutants from surface water and groundwater by nanofiltration: Overview of possible applications in the drinking water industry. Environ. Pollut. 2003, 122, 435–445. [Google Scholar] [CrossRef]

- Van der Bruggen, B.; Mänttäri, M.; Nyström, M. Drawbacks of applying nanofiltration and how to avoid them: A review. Sep. Purific. Technol. 2008, 63, 251–263. [Google Scholar] [CrossRef]

- Sharma, S.K.; Sobti, R.C. Nitrate removal from ground water: A review. E-J. Chem. 2012, 9, 1667–1675. [Google Scholar] [CrossRef]

- Shrimali, M.; Singh, K.P. New methods of nitrate removal from water. Environ. Pollut. 2001, 112, 351–359. [Google Scholar] [CrossRef]

- Fu, F.; Dionysiou, D.D.; Liu, H. The use of zero-valent iron for groundwater remediation and wastewater treatment: A review. J. Hazard. Mater. 2014, 267, 194–205. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Wang, W.; Liang, F.; Zhang, W.X. Heavy metal removal using nanoscale zero-valent iron (nZVI): Theory and application. J. Hazard. Mater. 2017, 322, 163–171. [Google Scholar] [CrossRef] [PubMed]

- Nam, S.; Tratnyek, P.G. Reduction of azo dyes with zero-valent iron. Water Res. 2000, 34, 1837–1845. [Google Scholar] [CrossRef]

- Dominguez, C.M.; Romero, A.; Fernandez, J.; Santos, A. In situ chemical reduction of chlorinated organic compounds from lindane production wastes by zero valent iron microparticles. J. Water Process Eng. 2018, 26, 146–155. [Google Scholar] [CrossRef]

- Huang, C.P.; Wang, H.W.; Chiu, P.C. Nitrate reduction by metallic iron. Water Res. 1998, 32, 2257–2264. [Google Scholar] [CrossRef]

- Siciliano, A.; Curcio, G.M.; Limonti, C. Experimental Analysis and Modeling of Nitrate Removal through Zero-Valent Magnesium Particles. Water 2019, 11, 1276. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, J. Reduction of nitrate by zero valent iron (ZVI)-based materials: A review. Sci. Total Environ. 2019, 671, 388–403. [Google Scholar] [CrossRef]

- Kanel, S.R.; Manning, B.; Charlet, L.; Choi, H. Removal of arsenic (III) from groundwater by nanoscale zero-valent iron. Environ. Sci. Technol. 2005, 39, 1291–1298. [Google Scholar] [CrossRef]

- Zhang, W.X. Nanoscale iron particles for environmental remediation: An overview. J. Nanopart. Res. 2003, 5, 323–332. [Google Scholar] [CrossRef]

- Sepehri, S.; Heidarpour, M.; Abedi-Koupai, J. Nitrate removal from aqueous solution using natural zeolite-supported zero-valent iron nanoparticles. Soil Water Res. 2014, 9, 224–232. [Google Scholar] [CrossRef]

- Khalil, A.M.; Eljamal, O.; Amen, T.W.; Sugihara, Y.; Matsunaga, N. Optimized nano-scale zero-valent iron supported on treated activated carbon for enhanced nitrate and phosphate removal from water. Chem. Eng. J. 2017, 309, 349–365. [Google Scholar] [CrossRef]

- Salam, M.A.; Fageeh, O.; Al-Thabaiti, S.A.; Obaid, A.Y. Removal of nitrate ions from aqueous solution using zero-valent iron nanoparticles supported on high surface area nanographenes. J. Mol. Liq. 2015, 212, 708–715. [Google Scholar] [CrossRef]

- Wei, A.; Ma, J.; Chen, J.; Zhang, Y.; Song, J.; Yu, X. Enhanced nitrate removal and high selectivity towards dinitrogen for groundwater remediation using biochar-supported nano zero-valent iron. Chem. Eng. J. 2018, 353, 595–605. [Google Scholar] [CrossRef]

- Murphy, A.P. Chemical removal of nitrate from water. Nature 1991, 350, 223–225. [Google Scholar] [CrossRef]

- Luk, G.K.; Au-Yeung, W.C. Experimental investigation on the chemical reduction of nitrate from groundwater. Adv. Environ. Res. 2002, 6, 441–453. [Google Scholar] [CrossRef]

- Desai, A.B.R. Reduction of Perchlorate and Nitrate by Aluminum Activated by pH Change and Electrochemically Induced Pitting Corrosion. Ph.D. Dissertation, Texas A&M University, College Station, TX, USA, 2010. [Google Scholar]

- Esfahani, A.R.; Datta, T. Nitrate removal from water using zero-valent aluminium. Water Environ. J. 2020, 34, 25–36. [Google Scholar] [CrossRef]

- Cheng, S.F.; Huang, C.Y.; Liu, J.Y. Study of different methods for enhancing the nitrate removal efficiency of a zero-valent metal process. Water Sci. Technol. 2006, 53, 81–87. [Google Scholar] [CrossRef]

- Kumar, M.; Chakraborty, S. Chemical denitrification of water by zero-valent magnesium powder. J. Hazard. Mater. 2006, 135, 112–121. [Google Scholar] [CrossRef]

- Siciliano, A.; Curcio, G.M.; Limonti, C. Chemical denitrification with Mg0 particles in column systems. Sustainability 2020, 12, 2984. [Google Scholar] [CrossRef]

- Ramavandi, B.; Mortazavi, S.B.; Moussavi, G.; Ranjbar, B.; Mamisaheby, S. Experimental investigation of the chemical reduction of nitrate in water by Mg and Cu/Mg bimetallic particles in the absence of any pH-control mechanism. Fresenius Environ. Bull. 2011, 20, 2475–2484. [Google Scholar]

- Mirabi, M.; Ghaderi, E.; Sadabad, H.R. Nitrate reduction using hybrid system consisting of zero valent magnesium powder/activated carbon (Mg0/AC) from water. Process Saf. Environ. Prot. 2017, 111, 627–634. [Google Scholar] [CrossRef]

- Ileri, B.; Ayyildiz, O.; Apaydin, O. Ultrasound-assisted activation of zero-valent magnesium for nitrate denitrification: Identification of reaction by-products and pathways. J. Hazard. Mater. 2015, 292, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Belay, T.A.; Lin, F.M.; Lin, C.Y.; Hsiao, H.M.; Chang, M.F.; Liu, J.C. Reduction of concentrated nitrate by using in situ synthesized zero-valent copper. Water Sci. Technol. 2015, 72, 960–965. [Google Scholar] [CrossRef] [PubMed][Green Version]

- de Sousa, A.F.; Braga, T.P.; Abreu, J.M.; da Costa, L.P.; de Vasconcelos, I.F.; Becker, H.; Longhinotti, E. Synthesis of copper on iron/aluminum oxide mesoporous spheres and application on denitrification reaction. Chem. Eng. J. 2014, 255, 290–296. [Google Scholar] [CrossRef]

- Lucchetti, R.; Onotri, L.; Clarizia, L.; Di Natale, F.; Di Somma, I.; Andreozzi, R.; Marotta, R. Removal of nitrate and simultaneous hydrogen generation through photocatalytic reforming of glycerol over “in situ” prepared zero-valent nano copper/P25. Appl. Catal. B Environ. 2017, 202, 539–549. [Google Scholar] [CrossRef]

- Kamali, M.; Davarazar, M.; Aminabhavi, T.M. Single precursor sonochemical synthesis of mesoporous hexagonal-shape zero-valent copper for effective nitrate reduction. Chem. Eng. J. 2020, 384, 123359. [Google Scholar] [CrossRef]

- Carlson, R.M. Continuous flow reduction of nitrate to ammonia with granular zinc. Anal. Chem. 1986, 58, 1590–1591. [Google Scholar] [CrossRef]

- Chiu, Y.T.; Lin, C.H.; Lee, J.; Lin, K.Y.A. Reduction of nitrate to nitrite in water by acid-washed zero-valent zinc. Sep. Sci. Technol. 2020, 55, 761–770. [Google Scholar] [CrossRef]

- Gandhi, S.; Oh, B.T.; Schnoor, J.L.; Alvarez, P.J. Degradation of TCE, Cr (VI), sulfate, and nitrate mixtures by granular iron in flow-through columns under different microbial conditions. Water Res. 2002, 36, 1973–1982. [Google Scholar] [CrossRef]

- Alowitz, M.J.; Scherer, M.M. Kinetics of nitrate, nitrite, and Cr (VI) reduction by iron metal. Environ. Sci. Technol. 2002, 36, 299–306. [Google Scholar] [CrossRef]

- Rodríguez-Maroto, J.M.; García-Herruzo, F.; García-Rubio, A.; Gómez-Lahoz, C.; Vereda-Alonso, C. Kinetics of the chemical reduction of nitrate by zero-valent iron. Chemosphere 2009, 74, 804–809. [Google Scholar] [CrossRef] [PubMed]

- Choe, S.; Chang, Y.Y.; Hwang, K.Y.; Khim, J. Kinetics of reductive denitrification by nanoscale zero-valent iron. Chemosphere 2000, 41, 1307–1311. [Google Scholar] [CrossRef]

- Cho, D.W.; Song, H.; Kim, B.; Schwartz, F.W.; Jeon, B.H. Reduction of nitrate in groundwater by Fe (0)/Magnetite nanoparticles entrapped in Ca-Alginate beads. Water Air Soil Pollut. 2015, 226, 1–10. [Google Scholar] [CrossRef]

- Comba, S.; Martin, M.; Marchisio, D.; Sethi, R.; Barberis, E. Reduction of nitrate and ammonium adsorption using microscale iron particles and zeolitite. Water Air Soil Pollut. 2012, 223, 1079–1089. [Google Scholar] [CrossRef]

- Hao, Z.W.; Xu, X.H.; Wang, D.H. Reductive denitrification of nitrate by scrap iron filings. J. Zhejiang Univ. Sci. B 2005, 6, 182. [Google Scholar] [CrossRef]

- Hao, S.; Zhang, H. High catalytic performance of nitrate reduction by synergistic effect of zero-valent iron (Fe0) and bimetallic composite carrier catalyst. J. Clean. Prod. 2017, 167, 192–200. [Google Scholar] [CrossRef]

- Choe, S.; Liljestrand, H.M.; Khim, J. Nitrate reduction by zero-valent iron under different pH regimes. Appl. Geochem. 2004, 19, 335–342. [Google Scholar] [CrossRef]

- Ruangchainikom, C.; Liao, C.H.; Anotai, J.; Lee, M.T. Effects of water characteristics on nitrate reduction by the Fe0/CO2 process. Chemosphere 2006, 63, 335–343. [Google Scholar] [CrossRef]

- Ahn, S.Y.; Oh, J.H.; Sohn, K.H. Mechanistic aspects of nitrate reduction by Fe (0) in water. J. Korean Chem. Soc. 2001, 45, 395–398. [Google Scholar]

- Huang, Y.H.; Zhang, T.C.; Shea, P.J.; Comfort, S.D. Effects of oxide coating and selected cations on nitrate reduction by iron metal. J. Environ. Qual. 2003, 32, 1306–1315. [Google Scholar] [CrossRef]

- Huang, Y.H.; Zhang, T.C. Effects of low pH on nitrate reduction by iron powder. Water Res. 2004, 38, 2631–2642. [Google Scholar] [CrossRef] [PubMed]

- Xiaomeng, F.A.N.; Xiaohong, G.U.A.N.; Jun, M.A.; Hengyu, A.I. Kinetics and corrosion products of aqueous nitrate reduction by iron powder without reaction conditions control. J. Environ. Sci. 2009, 21, 1028–1035. [Google Scholar] [CrossRef]

- Suzuki, T.; Moribe, M.; Oyama, Y.; Niinae, M. Mechanism of nitrate reduction by zero-valent iron: Equilibrium and kinetics studies. Chem. Eng. J. 2012, 183, 271–277. [Google Scholar] [CrossRef]

- Xu, J.; Hao, Z.; Xie, C.; Lv, X.; Yang, Y.; Xu, X. Promotion effect of Fe2+ and Fe3O4 on nitrate reduction using zero-valent iron. Desalination 2012, 284, 9–13. [Google Scholar] [CrossRef]

- Zhang, Y.; Douglas, G.B.; Pu, L.; Zhao, Q.; Tang, Y.; Xu, W.; Ye, Z. Zero-valent iron-facilitated reduction of nitrate: Chemical kinetics and reaction pathways. Sci. Total Environ. 2017, 598, 1140–1150. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Shan, C.; Mei, Y.; Jiang, Z.; Guan, X.; Pan, B. Improving reductive performance of zero valent iron by H2O2/HCl pretreatment: A case study on nitrate reduction. Chem. Eng. J. 2018, 334, 2255–2263. [Google Scholar] [CrossRef]

- Huang, Y.H.; Zhang, T.C. Effects of dissolved oxygen on formation of corrosion products and concomitant oxygen and nitrate reduction in zero-valent iron systems with or without aqueous Fe2+. Water Res. 2005, 39, 1751–1760. [Google Scholar] [CrossRef]

- Lee, S.; Yun, Y.; Kim, D.G. Nitrate reduction by micro-scale zero-valent iron particles under oxic condition. KSCE J. Civ. Eng. 2017, 21, 2119–2127. [Google Scholar] [CrossRef]

- Westerhoff, P.; James, J. Nitrate removal in zero-valent iron packed columns. Water Res. 2003, 37, 1818–1830. [Google Scholar] [CrossRef]

- Hansen, H.C.B.; Koch, C.B.; Nancke-Krogh, H.; Borggaard, O.K.; Sørensen, J. Abiotic nitrate reduction to ammonium: Key role of green rust. Environ. Sci. Technol. 1996, 30, 2053–2056. [Google Scholar] [CrossRef]

- Hansen, H.C.B.; Koch, C.B. Reduction of nitrate to ammonium by sulphate green rust: Activation energy and reaction mechanism. Clay Miner. 1998, 33, 87–101. [Google Scholar] [CrossRef]

- Guo, X.; Yang, Z.; Liu, H.; Lv, X.; Tu, Q.; Ren, Q.; Xia, X.; Jing, C. Common oxidants activate the reactivity of zero-valent iron (ZVI) and hence remarkably enhance nitrate reduction from water. Sep. Purif. Technol. 2015, 146, 227–234. [Google Scholar] [CrossRef]

- Siantar, D.P.; Schreier, C.G.; Chou, C.S.; Reinhard, M. Treatment of 1, 2-dibromo-3-chloropropane and nitrate-contaminated water with zero-valent iron or hydrogen/palladium catalysts. Water Res. 1996, 30, 2315–2322. [Google Scholar] [CrossRef]

- Ahn, S.C.; Oh, S.Y.; Cha, D.K. Enhanced reduction of nitrate by zero-valent iron at elevated temperatures. J. Hazard. Mater. 2008, 156, 17–22. [Google Scholar] [CrossRef]

- Ji, M.K.; Ahn, Y.T.; Khan, M.A.; Abou-Shanab, R.A.; Cho, Y.; Choi, J.Y.; Jeon, B.H. Removal of nitrate and ammonium ions from livestock wastewater by hybrid systems composed of zero-valent iron and adsorbents. Environ. Technol. 2011, 32, 1851–1857. [Google Scholar] [CrossRef]

- Liou, Y.H.; Lo, S.L.; Lin, C.J.; Kuan, W.H.; Weng, S.C. Effects of iron surface pretreatment on kinetics of aqueous nitrate reduction. J. Hazard. Mater. 2005, 126, 189–194. [Google Scholar] [CrossRef]

- Liou, Y.H.; Lo, S.L.; Lin, C.J.; Kuan, W.H.; Weng, S.C. Chemical reduction of an unbuffered nitrate solution using catalyzed and uncatalyzed nanoscale iron particles. J. Hazard. Mater. 2005, 127, 102–110. [Google Scholar] [CrossRef]

- Siciliano, A. Use of nanoscale zero-valent iron (NZVI) particles for chemical denitrification under different operating conditions. Metals 2015, 5, 1507–1519. [Google Scholar] [CrossRef]

- Lien, H.L.; Zhang, W.X. Transformation of chlorinated methanes by nanoscale iron particles. J. Environ. Eng. 1999, 125, 1042–1047. [Google Scholar] [CrossRef]

- Wang, C.B.; Zhang, W.X. Synthesizing nanoscale iron particles for rapid and complete dechlorination of TCE and PCBs. Environ. Sci. Technol. 1997, 31, 2154–2156. [Google Scholar] [CrossRef]

- Hwang, Y.H.; Kim, D.G.; Shin, H.S. Mechanism study of nitrate reduction by nano zero valent iron. J. Hazard. Mater. 2011, 185, 1513–1521. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, A.; Dutta, S.; Mukherjee, I.; Biswas, S.; Chatterjee, S.; Saha, R. Template-free synthesis of flower-shaped zero-valent iron nanoparticle: Role of hydroxyl group in controlling morphology and nitrate reduction. Adv. Powder Technol. 2017, 28, 2256–2264. [Google Scholar] [CrossRef]

- Liou, Y.H.; Lo, S.L.; Kuan, W.H.; Lin, C.J.; Weng, S.C. Effect of precursor concentration on the characteristics of nanoscale zerovalent iron and its reactivity of nitrate. Water Res. 2006, 40, 2485–2492. [Google Scholar] [CrossRef]

- Eljamal, R.; Eljamal, O.; Khalil, A.M.; Saha, B.B.; Matsunaga, N. Improvement of the chemical synthesis efficiency of nano-scale zero-valent iron particles. J. Environ. Chem. Eng. 2018, 6, 4727–4735. [Google Scholar] [CrossRef]

- Wang, T.; Lin, J.; Chen, Z.; Megharaj, M.; Naidu, R. Green synthesized iron nanoparticles by green tea and eucalyptus leaves extracts used for removal of nitrate in aqueous solution. J. Clean. Prod. 2014, 83, 413–419. [Google Scholar] [CrossRef]

- Lee, N.; Choi, K.; Uthuppu, B.; Jakobsen, M.H.; Hwang, Y.; Broholm, M.M.; Lee, W. Synthesis of iron nanoparticles with poly (1-vinylpyrrolidone-co-vinyl acetate) and its application to nitrate reduction. Adv. Environ. Res. 2014, 3, 107–116. [Google Scholar] [CrossRef][Green Version]

- Wang, W.; Jin, Z.H.; Li, T.L.; Zhang, H.; Gao, S. Preparation of spherical iron nanoclusters in ethanol–water solution for nitrate removal. Chemosphere 2006, 65, 1396–1404. [Google Scholar] [CrossRef]

- Li, T.; Zhang, Y.; Geng, B.; Wang, D.; Wang, S.; Jin, Z.H. Preparation of nanoiron by water-in-oil (W/O) microemulsion for reduction of nitrate in water. In Proceedings of the 2nd International Conference on Bioinformatics and Biomedical Engineering, Shanghai, China, 16–17 May 2008; pp. 3339–3342. [Google Scholar] [CrossRef]

- Tielong, L.I.; Shujing, L.I.; Shuaima, W.A.N.G.; Yi, A.N.; Zhaohui, J.I.N. Preparation of Nanoiron by water-in-Oil (W/O) microemulsion for reduction of nitrate in groundwater. J. Water Res. Prot. 2009, 1, 1–57. [Google Scholar] [CrossRef][Green Version]

- Chen, S.S.; Hsu, H.D.; Li, C.W. A new method to produce nanoscale iron for nitrate removal. J. Nanopart. Res. 2004, 6, 639–647. [Google Scholar] [CrossRef]

- Kassaee, M.Z.; Motamedi, E.; Mikhak, A.; Rahnemaie, R. Nitrate removal from water using iron nanoparticles produced by arc discharge vs. reduction. Chem. Eng. J. 2011, 166, 490–495. [Google Scholar] [CrossRef]

- Liu, H.B.; Chen, T.H.; Chang, D.Y.; Chen, D.; Liu, Y.; He, H.P.; Yuan, P.; Frost, R. Nitrate reduction over nanoscale zero-valent iron prepared by hydrogen reduction of goethite. Mater. Chem. Phys. 2012, 133, 205–211. [Google Scholar] [CrossRef]

- Vilardi, G.; Di Palma, L. Kinetic Study of Nitrate Removal from Aqueous Solutions Using Copper-Coated Iron Nanoparticles. Bull. Environ. Contam. Toxicol. 2017, 98, 359–365. [Google Scholar] [CrossRef] [PubMed]

- Shubair, T.; Eljamal, O.; Khalil, A.M.; Matsunaga, N. Multilayer system of nanoscale zero valent iron and Nano-Fe/Cu particles for nitrate removal in porous media. Sep. Purif. Technol. 2018, 193, 242–254. [Google Scholar] [CrossRef]

- Su, Y.; Adeleye, A.S.; Huang, Y.; Sun, X.; Dai, C.; Zhou, X.; Zhang, Y.; Keller, A.A. Simultaneous removal of cadmium and nitrate in aqueous media by nanoscale zerovalent iron (nZVI) and Au doped nZVI particles. Water Res. 2014, 63, 102–111. [Google Scholar] [CrossRef] [PubMed]

- Khalil, A.M.; Eljamal, O.; Jribi, S.; Matsunaga, N. Promoting nitrate reduction kinetics by nanoscale zero valent iron in water via copper salt addition. Chem. Eng. J. 2016, 287, 367–380. [Google Scholar] [CrossRef]

- Kim, D.G.; Hwang, Y.H.; Shin, H.S.; Ko, S.O. Kinetics of nitrate adsorption and reduction by nano-scale zero valent iron (NZVI): Effect of ionic strength and initial pH. KSCE J. Civ. Eng. 2016, 20, 175–187. [Google Scholar] [CrossRef]

- Ryu, A.; Jeong, S.W.; Jang, A.; Choi, H. Reduction of highly concentrated nitrate using nanoscale zero-valent iron: Effects of aggregation and catalyst on reactivity. Appl. Catal. B Environ. 2011, 105, 128–135. [Google Scholar] [CrossRef]

- Sohn, K.; Kang, S.W.; Ahn, S.; Woo, M.; Yang, S.K. Fe (0) nanoparticles for nitrate reduction: Stability, reactivity, and transformation. Environ. Sci. Technol. 2006, 40, 5514–5519. [Google Scholar] [CrossRef]

- Yang, G.C.; Lee, H.L. Chemical reduction of nitrate by nanosized iron: Kinetics and pathways. Water Res. 2005, 39, 884–894. [Google Scholar] [CrossRef]

- Zhang, J.; Hao, Z.; Zhang, Z.; Yang, Y.; Xu, X. Kinetics of nitrate reductive denitrification by nanoscale zero-valent iron. Process Saf. Environ. Prot. 2010, 88, 439–445. [Google Scholar] [CrossRef]

- Hwang, Y.H.; Kim, D.G.; Ahn, Y.T.; Moon, C.M.; Shin, H.S. Fate of nitrogen species in nitrate reduction by nanoscale zero valent iron and characterization of the reaction kinetics. Water Sci. Technol. 2010, 61, 705–712. [Google Scholar] [CrossRef] [PubMed]

- Siciliano, A. Removal of Cr (VI) from water using a new reactive material: Magnesium Oxide supported nanoscale zero-valent iron. Materials 2016, 9, 666. [Google Scholar] [CrossRef] [PubMed]

- Siciliano, A.; Limonti, C. Nanoscopic zero-valent iron supported on MgO for lead removal from waters. Water 2018, 10, 404. [Google Scholar] [CrossRef]

- Li, Z.; Sun, Y.; Yang, Y.; Han, Y.; Wang, T.; Chen, J.; Tsang, D.C. Biochar-supported nanoscale zero-valent iron as an efficient catalyst for organic degradation in groundwater. J. Hazard. Mater. 2020, 383, 121240. [Google Scholar] [CrossRef]

- Li, X.; Zhou, M.H.; Pan, Y.W.; Xu, L. Pre-magnetized Fe0/persulfate for notably enhanced degradation and dechlorination of 2,4-dichlorophenol. Chem. Eng. J. 2017, 307, 1092–1104. [Google Scholar] [CrossRef]

- Li, S.; Yang, F.; Li, J.; Cheng, K. Porous biochar-nanoscale zero-valent iron composites: Synthesis, characterization and application for lead ion removal. Sci. Total Environ. 2020, 746, 141037. [Google Scholar] [CrossRef]

- Zhu, H.; Jia, Y.; Wu, X.; Wang, H. Removal of arsenic from water by supported nano zero-valent iron on activated carbon. J. Hazard. Mater. 2009, 172, 1591–1596. [Google Scholar] [CrossRef]

- Liu, X.; Lai, D.; Wang, Y. Performance of Pb (II) removal by an activated carbon supported nanoscale zero-valent iron composite at ultralow iron content. J. Hazard. Mater. 2019, 361, 37–48. [Google Scholar] [CrossRef]

- Zhu, H.; Huang, Q.; Fu, S.; Zhang, X.; Shi, M.; Liu, B. Removal of Molybdenum (VI) from Raw Water Using Nano Zero-Valent Iron Supported on Activated Carbon. Water 2020, 12, 3162. [Google Scholar] [CrossRef]

- Horzum, N.; Demir, M.M.; Nairat, M.; Shahwan, T. Chitosan fiber-supported zero-valent iron nanoparticles as a novel sorbent for sequestration of inorganic arsenic. RSC Adv. 2013, 3, 7828–7837. [Google Scholar] [CrossRef]

- Wang, C.; Huang, R.; Sun, R. Green one-spot synthesis of hydrochar supported zero-valent iron for heterogeneous Fenton-like discoloration of dyes at neutral pH. J. Mol. Liquids 2020, 320, 114421. [Google Scholar] [CrossRef]

- Wang, C.; Huang, R.; Sun, R.; Yang, J.; Dionysiou, D.D. Microplastics separation and subsequent carbonization: Synthesis, characterization, and catalytic performance of iron/carbon nanocomposite. J. Clean. Prod. 2022, 330, 129901. [Google Scholar] [CrossRef]

- Kim, S.A.; Kamala-Kannan, S.; Lee, K.J.; Park, Y.J.; Shea, P.J.; Lee, W.H.; Oh, B.T. Removal of Pb (II) from aqueous solution by a zeolite–nanoscale zero-valent iron composite. Chem. Eng. J. 2013, 217, 54–60. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Meng, J.; Liu, X.; Xu, J.; Wang, F.; Brookes, P. Zeolite-supported nanoscale zero-valent iron: New findings on simultaneous adsorption of Cd (II), Pb (II), and As (III) in aqueous solution and soil. J. Hazard. Mater. 2018, 344, 1–11. [Google Scholar] [CrossRef]

- Bhowmick, S.; Chakraborty, S.; Mondal, P.; Van Renterghem, W.; Van den Berghe, S.; Roman-Ross, G.; Iglesias, M. Montmorillonite-supported nanoscale zero-valent iron for removal of arsenic from aqueous solution: Kinetics and mechanism. Chem. Eng. J. 2014, 243, 14–23. [Google Scholar] [CrossRef]

- Wu, L.; Liao, L.; Lv, G.; Qin, F. Stability and pH-independence of nano-zero-valent iron intercalated montmorillonite and its application on Cr (VI) removal. J. Contam. Hhydrol. 2015, 179, 1–9. [Google Scholar] [CrossRef]

- Rao, W.; Liu, H.; Lv, G.; Wang, D.; Liao, L. Effective degradation of Rh 6G using montmorillonite-supported nano zero-valent iron under microwave treatment. Materials 2018, 11, 2212. [Google Scholar] [CrossRef]

- Shi, L.N.; Zhang, X.; Chen, Z.L. Removal of chromium (VI) from wastewater using bentonite-supported nanoscale zero-valent iron. Water Res. 2011, 45, 886–892. [Google Scholar] [CrossRef]

- Bao, T.; Damtie, M.M.; Hosseinzadeh, A.; Wei, W.; Jin, J.; Vo, H.N.P.; Ni, B.J. Bentonite-supported nano zero-valent iron composite as a green catalyst for bisphenol A degradation: Preparation, performance, and mechanism of action. J. Environ. Manag. 2020, 260, 110105. [Google Scholar] [CrossRef]

- Shi, L.N.; Lin, Y.M.; Zhang, X.; Chen, Z.L. Synthesis, characterization and kinetics of bentonite supported nZVI for the removal of Cr (VI) from aqueous solution. Chem. Eng. J. 2011, 171, 612–617. [Google Scholar] [CrossRef]

- Xu, C.; Yang, W.; Liu, W.; Sun, H.; Jiao, C.; Lin, A.J. Performance and mechanism of Cr (VI) removal by zero-valent iron loaded onto expanded graphite. J. Environ. Sci. 2018, 67, 14–22. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Cao, Y.; Wei, E.; Gong, T.; Xian, Q. Facile synthesis of graphene nano zero-valent iron composites and their efficient removal of trichloronitromethane from drinking water. Chemosphere 2016, 146, 32–39. [Google Scholar] [CrossRef] [PubMed]

- Tang, H.; Cheng, W.; Yi, Y.; Ding, C.; Nie, X. Nano zero valent iron encapsulated in graphene oxide for reducing uranium. Chemosphere 2021, 278, 130229. [Google Scholar] [CrossRef] [PubMed]

- Mehrabi, N.; Masud, A.; Afolabi, M.; Hwang, J.; Ortiz, G.A.C.; Aich, N. Magnetic graphene oxide-nano zero valent iron (GO–nZVI) nanohybrids synthesized using biocompatible cross-linkers for methylene blue removal. RSC Adv. 2019, 9, 963–973. [Google Scholar] [CrossRef]

- Xing, R.; He, J.; Hao, P.; Zhou, W. Graphene oxide-supported nanoscale zero-valent iron composites for the removal of atrazine from aqueous solution. Coll. Surf. A Physicochem. Eng. Asp. 2020, 589, 124466. [Google Scholar] [CrossRef]

- Fan, M.; Li, T.; Hu, J.; Cao, R.; Wu, Q.; Wei, X.; Ruan, W. Synthesis and characterization of reduced graphene oxide-supported nanoscale zero-valent iron (nZVI/rGO) composites used for Pb (II) removal. Materials 2016, 9, 687. [Google Scholar] [CrossRef]

- Kamarehie, B.; Aghaalib, E.; Musavic, S.A.; Hashemid, S.Y.; Jafaria, A. Nitrate removal from aqueous solutions using granular activated carbon modified with iron nanoparticles. IJE Trans. A Basics 2018, 31, 554–563. [Google Scholar] [CrossRef]

- Teng, W.; Bai, N.; Liu, Y.; Liu, Y.; Fan, J.; Zhang, W.X. Selective nitrate reduction to dinitrogen by electrocatalysis on nanoscale iron encapsulated in mesoporous carbon. Environ. Sci. Technol. 2018, 52, 230–236. [Google Scholar] [CrossRef]

- Motamedi, E.; Atouei, M.T.; Kassaee, M.Z. Comparison of nitrate removal from water via graphene oxide coated Fe, Ni and Co nanoparticles. Mater. Res. Bull. 2014, 54, 34–40. [Google Scholar] [CrossRef]

- Zhang, H.; Jin, Z.H.; Lu, H.; Qin, C.H. Synthesis of nanoscale zero-valent iron supported on exfoliated graphite for removal of nitrate. Trans. Nonferrous Met. Soc. China 2006, 16, s345–s349. [Google Scholar] [CrossRef]

- Wang, J.; Deng, Z.; Feng, T.; Fan, J.; Zhang, W.X. Nanoscale zero-valent iron (nZVI) encapsulated within tubular nitride carbon for highly selective and stable electrocatalytic denitrification. Chem. Eng. J. 2021, 417, 129160. [Google Scholar] [CrossRef]

- Islam, M.A.; Morton, D.W.; Johnson, B.B.; Pramanik, B.K.; Mainali, B.; Angove, M.J. Opportunities and constraints of using the innovative adsorbents for the removal of cobalt (II) from wastewater: A review. Environ. Nanotechnol. Monitor. Manag. 2018, 10, 435–456. [Google Scholar] [CrossRef]

- Islam, M.A.; Awual, M.R.; Angove, M.J. A review on nickel (II) adsorption in single and binary component systems and future path. J. Environ. Chem. Eng. 2019, 7, 103305. [Google Scholar] [CrossRef]

- Zeng, Y.; Walker, H.; Zhu, Q. Reduction of nitrate by NaY zeolite supported Fe, Cu/Fe and Mn/Fe nanoparticles. J. Hazard. Mater. 2017, 324, 605–616. [Google Scholar] [CrossRef]

- Dong, L.; Lin, L.; Li, Q.; Huang, Z.; Tang, X.; Wu, M.; Scholz, M. Enhanced nitrate-nitrogen removal by modified attapulgite-supported nanoscale zero-valent iron treating simulated groundwater. J. Environ. Manag. 2018, 213, 151–158. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Li, J.; Hu, L.; Zheng, X. Enhanced removal of nitrate by a novel composite: Nanoscale zero valent iron supported on pillared clay. Chem. Eng. J. 2011, 171, 526–531. [Google Scholar] [CrossRef]

- Fateminia, F.S.; Falamaki, C. Zero valent nano-sized iron/clinoptilolite modified with zero valent copper for reductive nitrate removal. Process Saf. Environ. Prot. 2013, 91, 304–310. [Google Scholar] [CrossRef]

- Islam, M.A.; Angove, M.J.; Morton, D.W. Recent innovative research on chromium (VI) adsorption mechanism. Environ. Nanotechnol. Monitor. Manag. 2019, 12, 100267. [Google Scholar] [CrossRef]

- Jiang, Z.; Lv, L.; Zhang, W.; Du, Q.; Pan, B.; Yang, L.; Zhang, Q. Nitrate reduction using nanosized zero-valent iron supported by polystyrene resins: Role of surface functional groups. Water Res. 2011, 45, 2191–2198. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, S.; Pan, B.; Wang, W.; Wang, X.; Lv, L.; Zhang, Q. A fabrication strategy for nanosized zero valent iron (nZVI)–polymeric anion exchanger composites with tunable structure for nitrate reduction. J. Hazard. Mater. 2012, 233, 1–6. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, H.; Liu, J.; Chen, J.; Wei, S.; Jiang, Z. Effect of humic acid on the nitrate removal by strong base anion exchanger supported nanoscale zero-valent iron composite. Water Air Soil Pollut. 2018, 229, 1–10. [Google Scholar] [CrossRef]

- Shi, J.; Yi, S.; He, H.; Long, C.; Li, A. Preparation of nanoscale zero-valent iron supported on chelating resin with nitrogen donor atoms for simultaneous reduction of Pb2+ and . Chem. Eng. J. 2013, 230, 166–171. [Google Scholar]

- Zhou, Y.; Li, X. Green synthesis of modified polyethylene packing supported tea polyphenols-NZVI for nitrate removal from wastewater: Characterization and mechanisms. Sci. Total Environ. 2022, 806, 150596. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.S.; Gong, J.; Huong, C.V.; Oh, D.S.; Chang, Y.S. Macroporous alginate substrate-bound growth of Fe0 nanoparticles with high redox activities for nitrate removal from aqueous solutions. Chem. Eng. J. 2016, 298, 206–213. [Google Scholar] [CrossRef]

- Anbia, M.; Kamel, L. Preparation of pyramids structured silicon as a support for nano sized zero valent iron particles for nitrate removal from water. Silicon 2018, 10, 1851–1859. [Google Scholar] [CrossRef]

- Nidheesh, P.V.; Khatri, J.; Singh, T.A.; Gandhimathi, R.; Ramesh, S.T. Review of zero-valent aluminium based water and wastewater treatment methods. Chemosphere 2018, 200, 621–631. [Google Scholar] [CrossRef]

- Yang, Y.; Gai, W.Z.; Zhou, J.G.; Deng, Z.Y. Surface modified zero-valent aluminum for Cr (VI) removal at neutral pH. Chem. Eng. J. 2020, 395, 125140. [Google Scholar] [CrossRef]

- Bokare, A.D.; Choi, W. Zero-valent aluminum for oxidative degradation of aqueous organic pollutants. Environ. Sci. Technol. 2009, 43, 7130–7135. [Google Scholar] [CrossRef]

- Yang, S.; Zheng, D.; Ren, T.; Zhang, Y.; Xin, J. Zero-valent aluminum for reductive removal of aqueous pollutants over a wide pH range: Performance and mechanism especially at near-neutral pH. Water Res. 2017, 123, 704–714. [Google Scholar] [CrossRef]

- Cai, M.Q.; Wei, X.Q.; Song, Z.J.; Jin, M.C. Decolorization of azo dye Orange G by aluminum powder enhanced by ultrasonic irradiation. Ultrason. Sonochem. 2015, 22, 167–173. [Google Scholar] [CrossRef]

- Wang, A.; Guo, W.; Hao, F.; Yue, X.; Leng, Y. Degradation of Acid Orange 7 in aqueous solution by zero-valent aluminum under ultrasonic irradiation. Ultrason. Sonochem. 2014, 21, 572–575. [Google Scholar] [CrossRef]

- Lee, G.; Park, J. Reaction of zero-valent magnesium with water: Potential applications in environmental remediation. Geochim. Cosmochim. Acta 2013, 102, 162–174. [Google Scholar] [CrossRef]

- Siciliano, A.; Curcio, G.M.; Limonti, C. Hexavalent chromium reduction by zero-valent magnesium particles in column systems. J. Environ. Manag. 2021, 293, 112905. [Google Scholar] [CrossRef] [PubMed]

- Lee, G.; Park, J.; Harvey, O.R. Reduction of Chromium (VI) mediated by zero-valent magnesium under neutral pH conditions. Water Res. 2013, 47, 1136–1146. [Google Scholar] [CrossRef] [PubMed]

- Ayyildiz, O.; Acar, E.; Ileri, B. Sonocatalytic reduction of hexavalent chromium by metallic magnesium particles. Water Air Soil Pollut. 2016, 227, 1–9. [Google Scholar] [CrossRef]

- Engelmann, M.D.; Doyle, J.G.; Cheng, I.F. The complete dechlorination of DDT by magnesium/palladium bimetallic particles. Chemosphere 2001, 43, 195–198. [Google Scholar] [CrossRef]

- Agarwal, S.; Al-Abed, S.R.; Dionysiou, D.D. Enhanced corrosion-based Pd/Mg bimetallic systems for dechlorination of PCBs. Environ. Sci. Technol. 2007, 41, 3722–3727. [Google Scholar] [CrossRef]

- Wu, S.J.; Liou, T.H.; Mi, F.L. Synthesis of zero-valent copper-chitosan nanocomposites and their application for treatment of hexavalent chromium. Biores. Technol. 2009, 100, 4348–4353. [Google Scholar] [CrossRef]

- Huang, C.C.; Lo, S.L.; Lien, H.L. Zero-valent copper nanoparticles for effective dechlorination of dichloromethane using sodium borohydride as a reductant. Chem. Eng. J. 2012, 203, 95–100. [Google Scholar] [CrossRef]

- Huang, C.C.; Lo, S.L.; Lien, H.L. Synergistic effect of zero-valent copper nanoparticles on dichloromethane degradation by vitamin B12 under reducing condition. Chem. Eng. J. 2013, 219, 311–318. [Google Scholar] [CrossRef]

- Raut, S.S.; Kamble, S.P.; Kulkarni, P.S. Efficacy of zero-valent copper (Cu0) nanoparticles and reducing agents for dechlorination of mono chloroaromatics. Chemosphere 2016, 159, 359–366. [Google Scholar] [CrossRef]

- Ismail, M.; Gul, S.; Khan, M.I.; Khan, M.A.; Asiri, A.M.; Khan, S.B. Green synthesis of zerovalent copper nanoparticles for efficient reduction of toxic azo dyes congo red and methyl orange. Green Process. Synth. 2019, 8, 135–143. [Google Scholar] [CrossRef]

- Liú, D.; Wang, G.; Liŭ, D.; Lin, J.; He, Y.; Li, X.; Li, Z. Photocatalysis using zero-valent nano-copper for degrading methyl orange under visible light irradiation. Opt. Mater. 2016, 53, 155–159. [Google Scholar] [CrossRef]

- Oliveira, L.M.; Nascimento, M.A.; Guimarães, Y.M.; Oliveira, A.F.; Silva, A.A.; Lopes, R.P. Removal of beta-lactams antibiotics through zero-valent copper nanoparticles. J. Braz. Chem. Soc. 2018, 29, 1630–1637. [Google Scholar] [CrossRef]

- Rispoli, F.; Angelov, A.; Badia, D.; Kumar, A.; Seal, S.; Shah, V. Understanding the toxicity of aggregated zero valent copper nanoparticles against Escherichia coli. J. Hazard. Mater. 2010, 180, 212–216. [Google Scholar] [CrossRef]

- Stauber, J.L.; Florence, T.M. Mechanism of toxicity of ionic copper and copper complexes to algae. Mar. Biol. 1987, 94, 511–519. [Google Scholar] [CrossRef]

- Han, Y.; Chen, Z.L.; Tong, L.N.; Yang, L.; Shen, J.M.; Wang, B.Y.; Chen, Q. Reduction of N-Nitrosodimethylamine with zero-valent zinc. Water Res. 2013, 47, 216–224. [Google Scholar] [CrossRef]

- Choi, J.H.; Kim, Y.H. Reduction of 2, 4, 6-trichlorophenol with zero-valent zinc and catalyzed zinc. J. Hazard. Mater. 2009, 166, 984–991. [Google Scholar] [CrossRef]

- Kim, Y.H.; Carraway, E.R. Dechlorination of chlorinated phenols by zero valent zinc. Environ. Technol. 2003, 24, 1455–1463. [Google Scholar] [CrossRef]

| ZVI Size | ZVI (g/L) | T (°C) | Oxygenated Conditions | pH | Efficiency (%) | Main Reaction Products | Refs. | |

|---|---|---|---|---|---|---|---|---|

| 6–10 µm | 20 | 50 * | 25 | anaerobic | 2 ** | 95 | NH3 | [16] |

| >4 ** | negligible | |||||||

| iron filings | 100 | 45 * | 25 | anaerobic | 2.5 ** | 80 | [47] | |

| 4 ** | <10 | |||||||

| 100 mesh | 33 | 100 | 22 | anaerobic | 2 ** | 100 | [49] | |

| 4 ** | <40 | |||||||

| 0.5 mm | 50 | 30 | 24 ± 1 | anaerobic | 2.3 ** | 98 | [52] | |

| 7.1 ** | <10 | |||||||

| 0.5 mm | 25 | 30 | 25 | anaerobic | 2 and 3 | 100 | [53] | |

| 160–200 mesh | 20 | 50 | 20–22 | aerobic | 2 ** | 100 | - | [54] |

| 20–60 mesh | 1000 | 30 | 24 ± 1 | aerobic | 2.5 ** | 100 | [55] | |

| 4.5 ** | 50 | |||||||

| 1.5 µm | 0.416 | 25 | 20 | anaerobic | 1.22 ** | 60 | NH3 | [57] |

| 1.62 ** | 68 | |||||||

| 1.92 ** | 72 | |||||||

| 0.147–0.125 mm | 4 | 20 | 20 ± 1 | anaerobic | <8 ** | 96–100 | [58] | |

| 8 ** | 81.8 | |||||||

| iron powder | 6.25 | 73 * | 25 | anaerobic | 4.7 ** | 100 | [51] | |

| 7 ** | 0 | |||||||

| 1–20 nm | 0.5 | 20 | 25 | anaerobic | 4 | 78 | [82] | |

| 7 | 60 | |||||||

| 50–80 nm | 2 | 100 | 25 | aerobic | ≤4 | 100 | [92] | |

| 5 | 80 | |||||||

| 1–100 nm | 5 | 95 | 20 | aerobic | 3 | 99.9 | [70] | |

| 5 | 73.1 | |||||||

| uncon | 63 | |||||||

| 80 nm (iron cluster) <10 nm (nanoparticles) | 4 | 80 | 25 | aerobic | 3 ** | 100 | [79] | |

| 5 ** | 100 | |||||||

| 7 ** | 100 | |||||||

| uncon | 100 | |||||||

| 80–90 nm | 2 | 80 | 25 | anaerobic | 7 ** | 100 | [81] |

| Support Material | Efficiency * | Main Reaction Products | Refs. |

|---|---|---|---|

| Granular AC from grape wood | >99% | - | [120] |

| Commercial granular AC | >60% | , N2 | [22] |

| Mesoporous carbon | 315 mg N/g Fe | N2 | [121] |

| Biochar | 97% | N2 | [24] |

| High-surface-area nanographene | >80% | , N2 | [23] |

| Graphene oxide | 99% | - | [122] |

| Exfoliated graphite | 100% | [123] | |

| Tubular nitride carbon | 92% | N2 | [124] |

| Natural zeolite | >90% | [21] | |

| Nay zeolite | ≈100% | N2 | [127] |

| Modified attapulgite | 83.8% | [128] | |

| Pillared clay | 100% | , N2 | [129] |

| Clinoptilolite partly coated with Cu0 | >60% | [130] | |

| Microporous alginate | >96.5% | [137] | |

| Functionalized porous polystyrene resin | >80% | [132] | |

| Pyramid-structured silicon | 100% | - | [138] |

| Polyethylene | ≈25.5% | [136] |

| Zero-Valent Metal | Dosage (g/L) | T (°C) | OxygenatedConditions | pH | Efficiency *** (%) | Main Reaction Products | Ref. | |

|---|---|---|---|---|---|---|---|---|

| Al0 | 2.22 | 100 * | 25 | aerobic | 10.25 | 75 | NH3 | [25] |

| 0.3 | 20 | 25 | aerobic | 10.7 | 62 | NH3 | [26] | |

| 0.56 | 14 | 25 | aerobic | 13 | 100 | NH3 | [28] | |

| Mg0 | 2 | 50 | 20–24 | aerobic | 2 | 91 | [30] | |

| 6.67 | 20 | 20 ± 2 | aerobic | 3 | 100 | N2 | [17,31] | |

| 0.387 | 200 * | 25 | aerobic | 6 | 70.5 | N2 | [32] | |

| Cu0 | 0.624 (CuO) | 677 | 60 | anaerobic | 2.1–4.7 ** | 100 | [35] | |

| 100 | 28 | 25 ± 1 | aerobic | 4.5 | 35 | , N2 | [36] | |

| Zn0 | 5 | 10 * | 25 | aerobic | 1–2 | 93.2 | [40] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Curcio, G.M.; Limonti, C.; Siciliano, A.; Kabdaşlı, I. Nitrate Removal by Zero-Valent Metals: A Comprehensive Review. Sustainability 2022, 14, 4500. https://doi.org/10.3390/su14084500

Curcio GM, Limonti C, Siciliano A, Kabdaşlı I. Nitrate Removal by Zero-Valent Metals: A Comprehensive Review. Sustainability. 2022; 14(8):4500. https://doi.org/10.3390/su14084500

Chicago/Turabian StyleCurcio, Giulia Maria, Carlo Limonti, Alessio Siciliano, and Işık Kabdaşlı. 2022. "Nitrate Removal by Zero-Valent Metals: A Comprehensive Review" Sustainability 14, no. 8: 4500. https://doi.org/10.3390/su14084500

APA StyleCurcio, G. M., Limonti, C., Siciliano, A., & Kabdaşlı, I. (2022). Nitrate Removal by Zero-Valent Metals: A Comprehensive Review. Sustainability, 14(8), 4500. https://doi.org/10.3390/su14084500