Wind energy is the most widely used clean and low-carbon renewable energy with the fastest development. More and more countries have attached great importance to wind turbines, and many wind farms and larger capacity large-scale wind turbines are coming into use. However, because of the harsh natural working environment (especially for offshore large-scale wind turbines) complex and changeable operating condition of large-scale wind turbines (WT), some core components, such as main bearings, frequently fail, resulting in prolonged downtime and increased O&M costs of wind farms [

1]. Therefore, in order to enhance component reliability, avoid faults, and reduce O&M cost, it is of vital practical significance to study the operating condition monitoring methods of the core components of large-scale WTs [

2].

The main bearing of large-scale WTs, as an important physical component of the WT transmission chain, connects the hub and the generator or the gearbox. According to the European Academy of Wind Energy (EAWE) [

3], WT main bearings have been identified as one of the critical components in terms of increasing WT reliability and availability for the transmission system in the wind industry. The WT main bearing is a large component, and its internal structure is complicated. Furthermore, the operating environment of the WT main bearing is very harsh and complex, and the alternating load in the axial and radial directions and strong impact make it prone to failure. According to literature reports, the failure rate of the WT main bearings reaches 15% and 30% [

4]. A lot of research has been carried out on monitoring the operating conditions of the WT main bearings [

5]. These methods are mainly divided into two categories, i.e., vibration-based analysis methods and temperature-based analysis methods. (1) Vibration-based analysis methods include the following. Natili et al. [

6] used the vibration data of the turbine condition monitoring (TCM) to realize multi-scale condition monitoring and fault detection of the WT main bearings. Artigao et al. [

7] used the fast Fourier transform method to analyze the frequency domain of the bearing vibration spectrum to identify bearing faults on the drive chain of wind turbines under different loads. Siegel et al. [

8] used fast Fourier transform and envelope analysis to analyze the frequency domain of bearing vibration spectrum to identify bearing faults on the drive chain of wind turbines. Peeters et al. [

9] proposed a more intelligent automated cepstrum editing procedure (ACEP) for peak automatic selection based on vibration signal parameters to detect bearing faults. Lu et al. [

10] proposed an improved auxiliary classifier generative adversarial network (ACGAN) model with data enhancement function for vibration signal parameters, which balanced vibration data of WT main bearing faults and improved the accuracy of fault diagnosis of the WT main bearing. The above works mainly focus on the analysis and modeling of high-frequency vibration data. However, in the actual wind field SCADA system, the collected data are usually low-frequency vibration data, such as 1 s, 1 min, 5 min, 10 min, etc. These methods may not be suitable. In addition, the relationship between field SCADA data parameters is complex, and the existing shallow machine learning methods have limited ability to extract features. Although the deep learning GAN model is adopted in the literature [

10], its data also comes from the laboratory rather than the field. Therefore, the analysis and modeling of low-frequency vibration data and multi-parameters are less accurate. (2) Temperature-based analysis methods include the following. Zhang [

11] utilized SCADA data to build a neural network model to forecast the temperature of the WT main bearing to diagnose the main bearing failure. Zhao et al. [

12] used SCADA data condition parameters, such as the temperature of the WT main bearing, to build a restricted Boltzmann machine-based deep learning model, which can reconstruct the overall WT main bearing conditions to predict the faults of the WT main bearing. Wang et al. [

13], based on SCADA data, constructed a deep belief network based on a restricted Boltzmann machine (RBM) to predict the temperature of the WT main bearing and to monitor and detect anomalies of the WT main bearing. Zhao et al. [

14] proposed an improved deep belief network based on RBM to reconstruct the normal condition of the WT main bearing and used the reconstruction error to monitor and detect whether the WT main bearing was in an abnormal condition. Yucesan et al. [

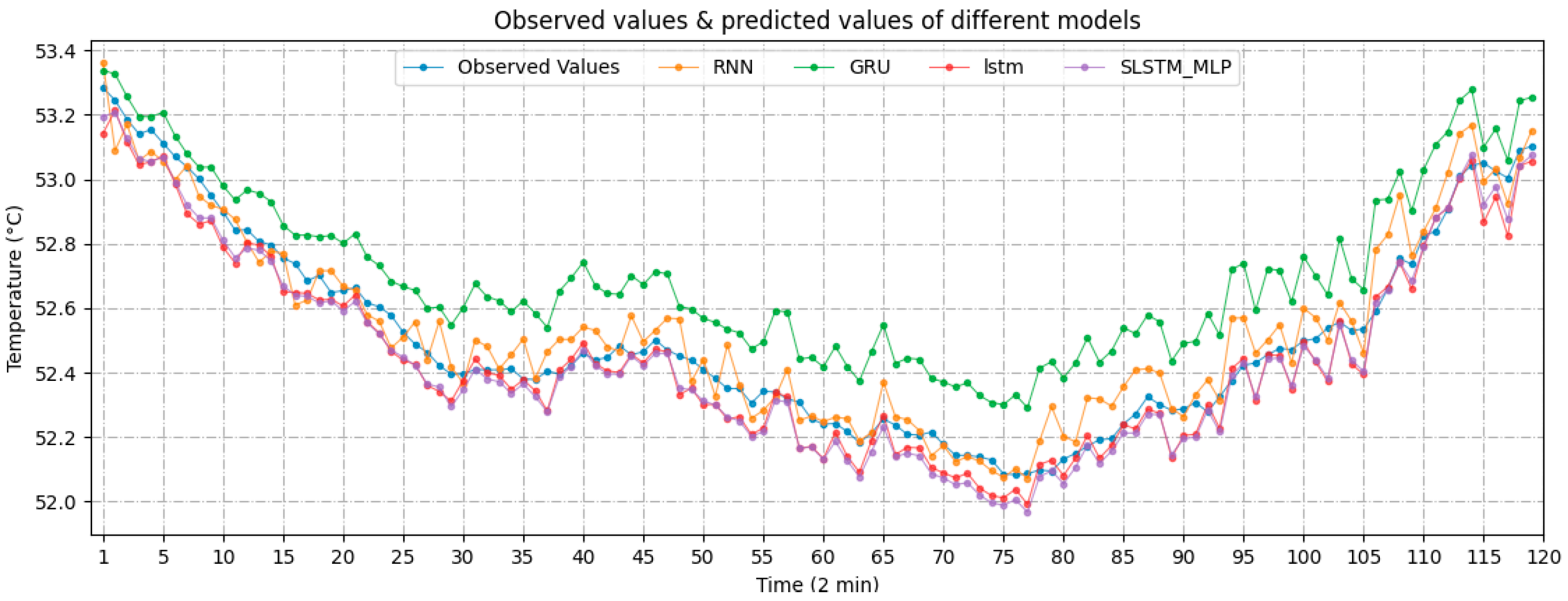

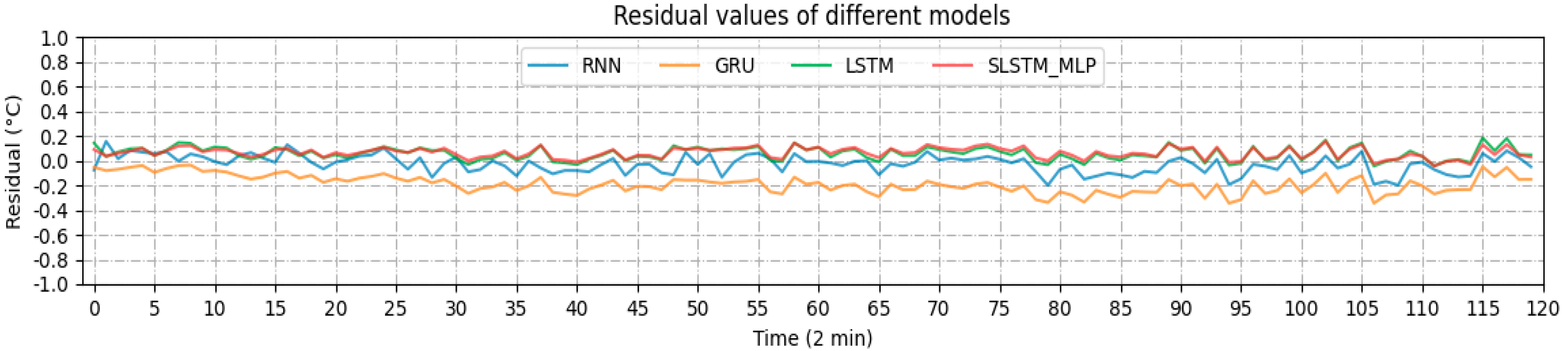

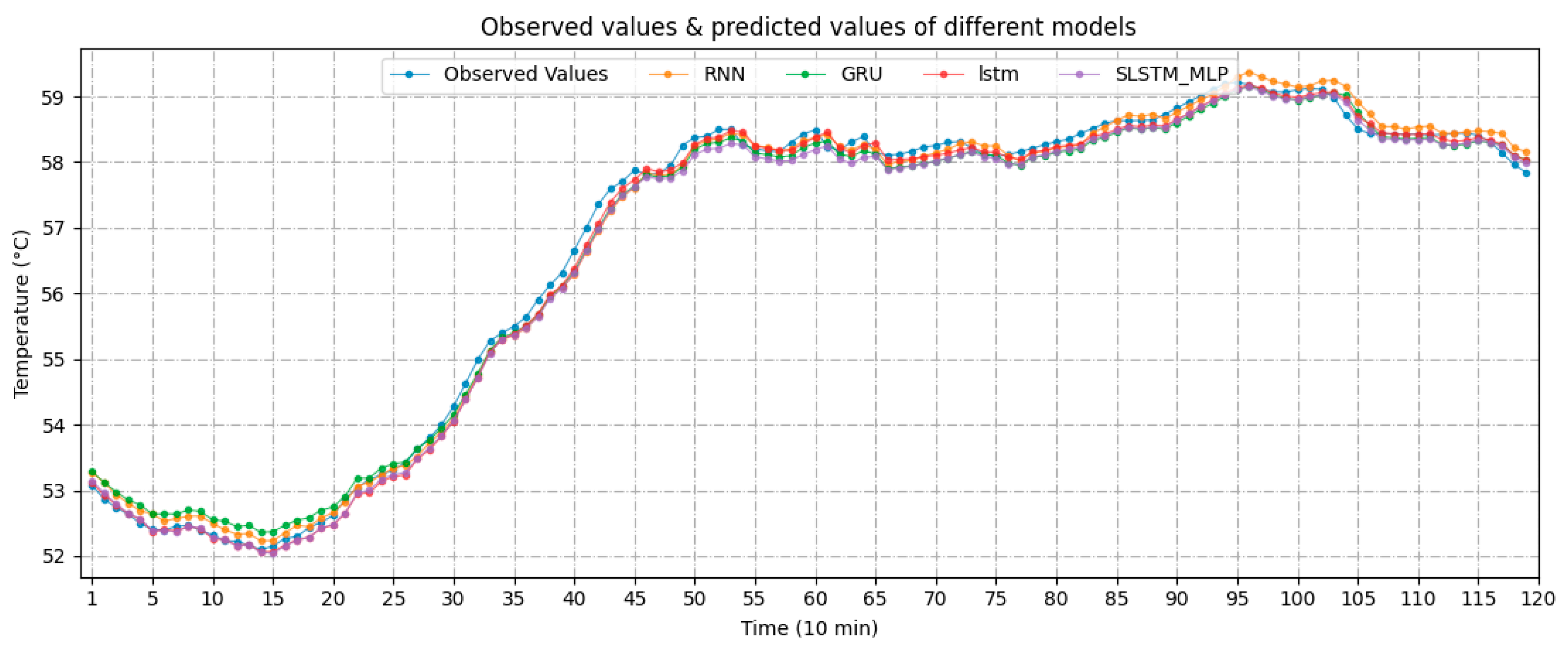

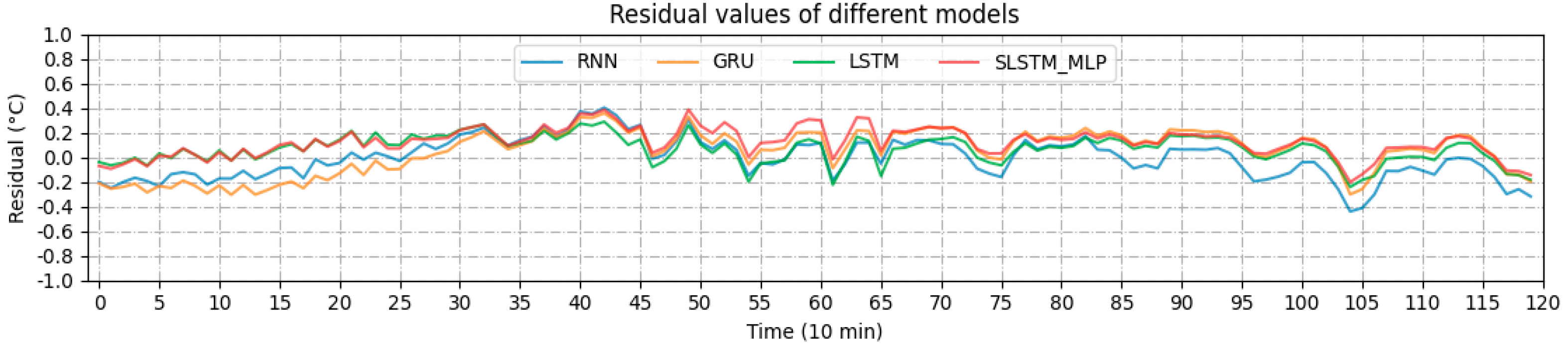

15] established a deep neural network model based on the fusion of physical information and data-driven parameters such as the main bearing temperature to detect the fatigue and oil degradation of the main bearing. The above studies have examined a variety of methods, from simple neural network structure to complex deep belief models. These studies carried out main bearing condition monitoring, fatigue detection, and oil degradation by reconstructing a vector or predicting a single value. However, some methods do not consider wind speed, parameter selection, and model structure determination in detail, and some temperature prediction models have low accuracy and large error.

In summary, condition monitoring and fault detection of the main bearing of large-scale WTs-based on the WT SCADA system has become a research hotspot [

16,

17]. The research results of the vibration-based analysis method and temperature-based analysis method described above have deepened the understanding of operating state monitoring, detection, and fault detection of the main bearing of large-scale WTs based on the application of these methods, such as neural network models, support vector machines, deep belief networks, and adversarial learning. However, some of the models above are shallow machine learning models, which have limited ability to comprehensively extract data features from the SCADA dataset. In addition, parameter selection and structure determination for models are not discussed in detail, which limits the application and promotion of models to a certain extent. Some research needs to be further expanded.

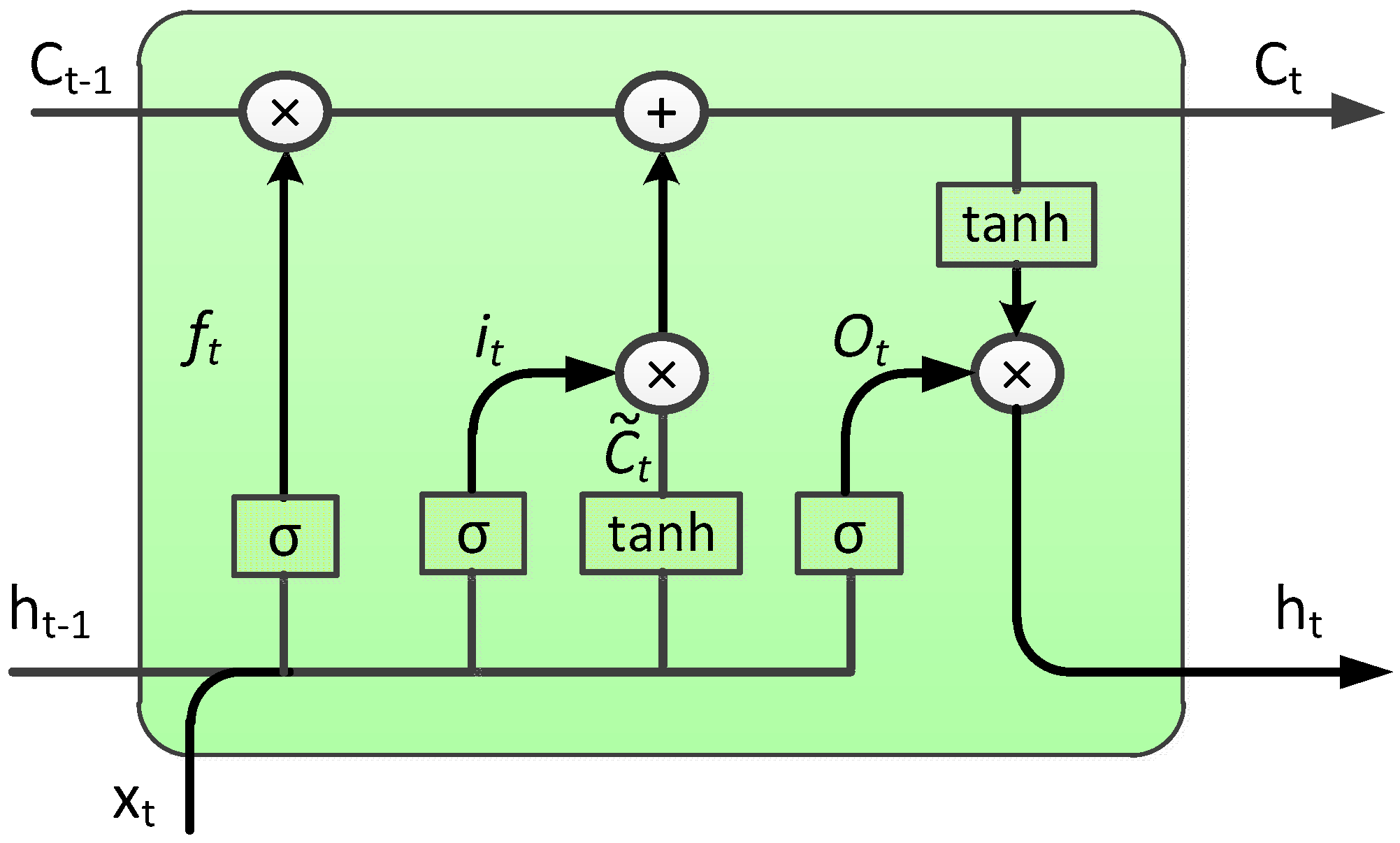

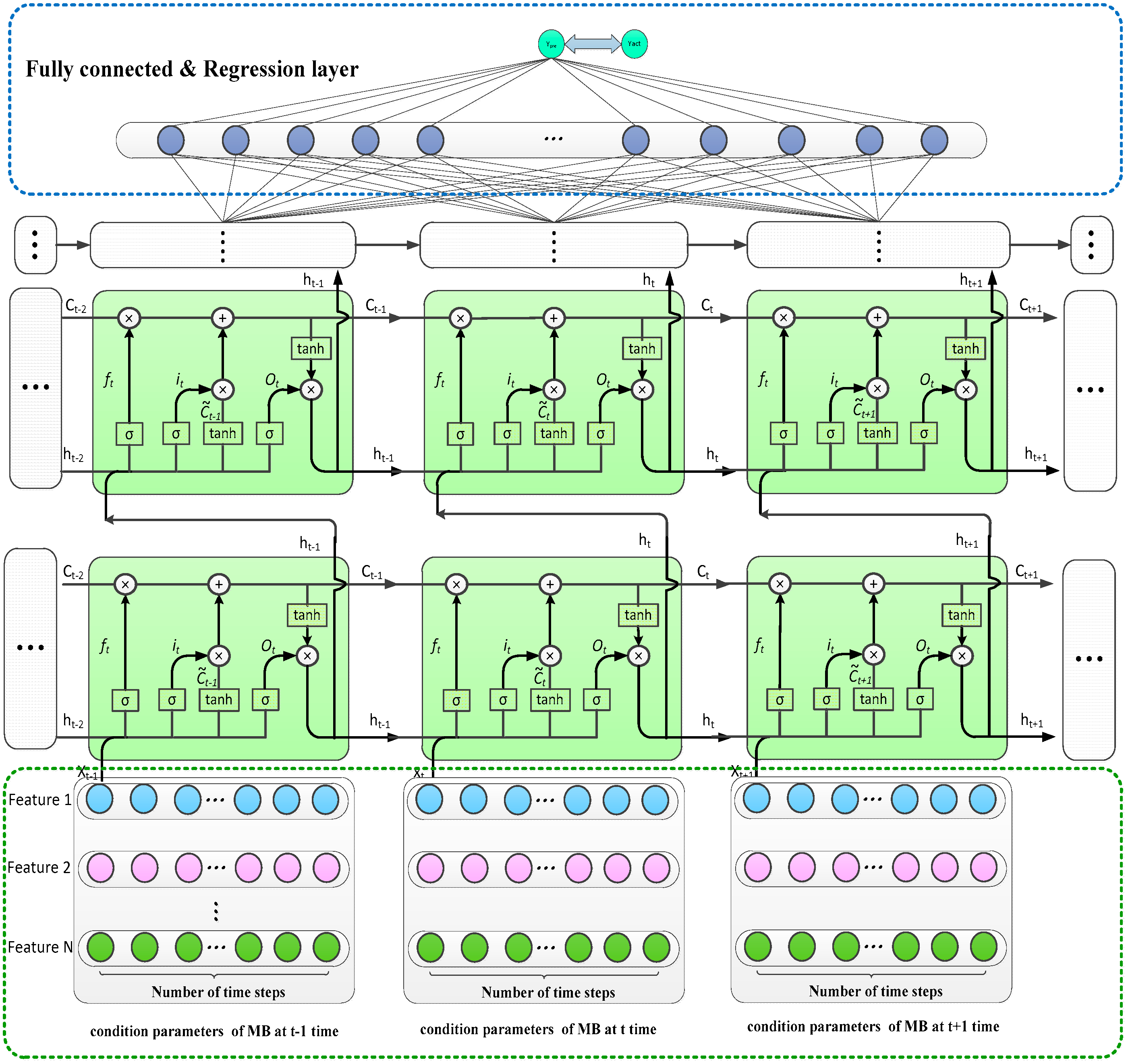

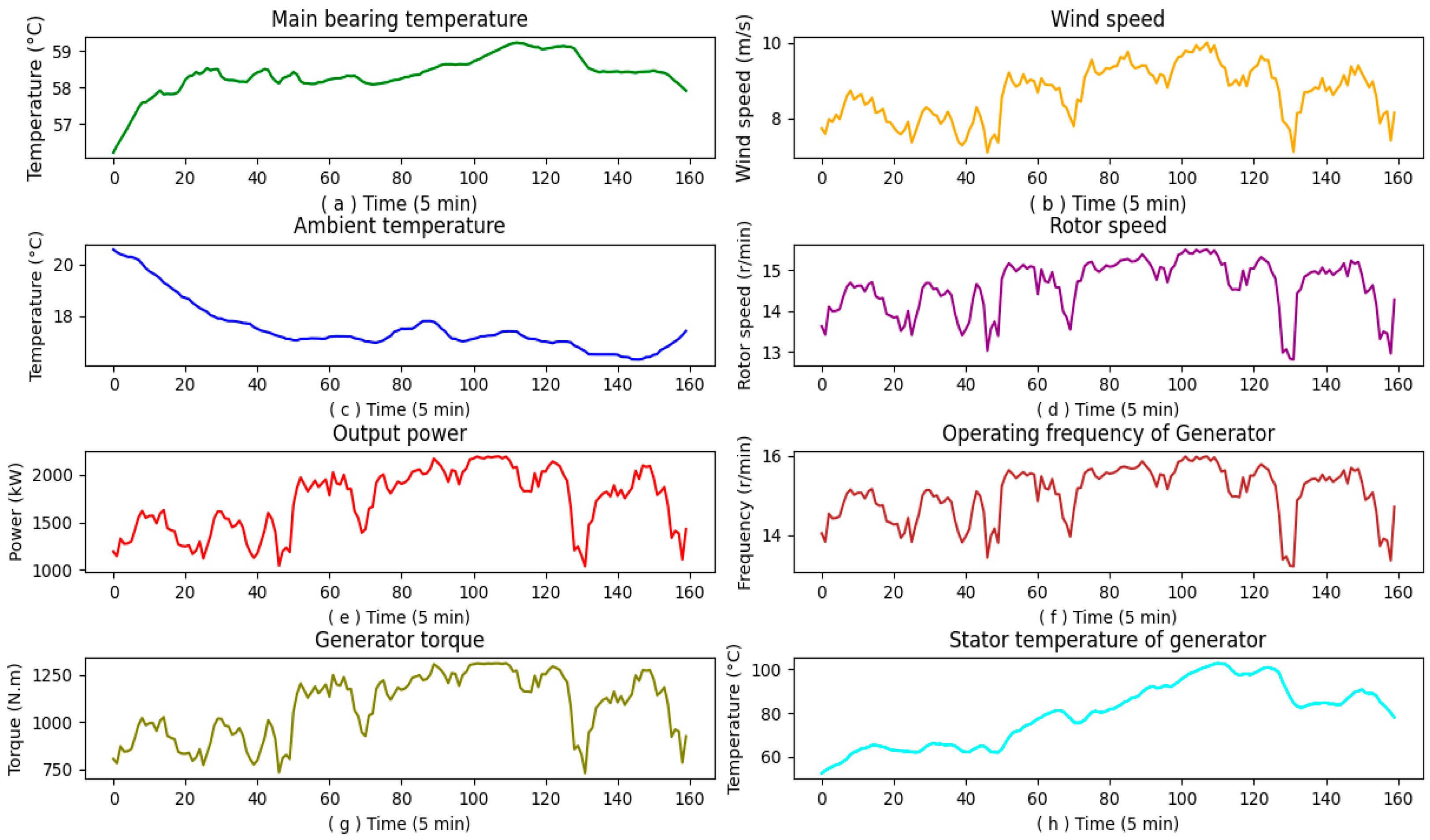

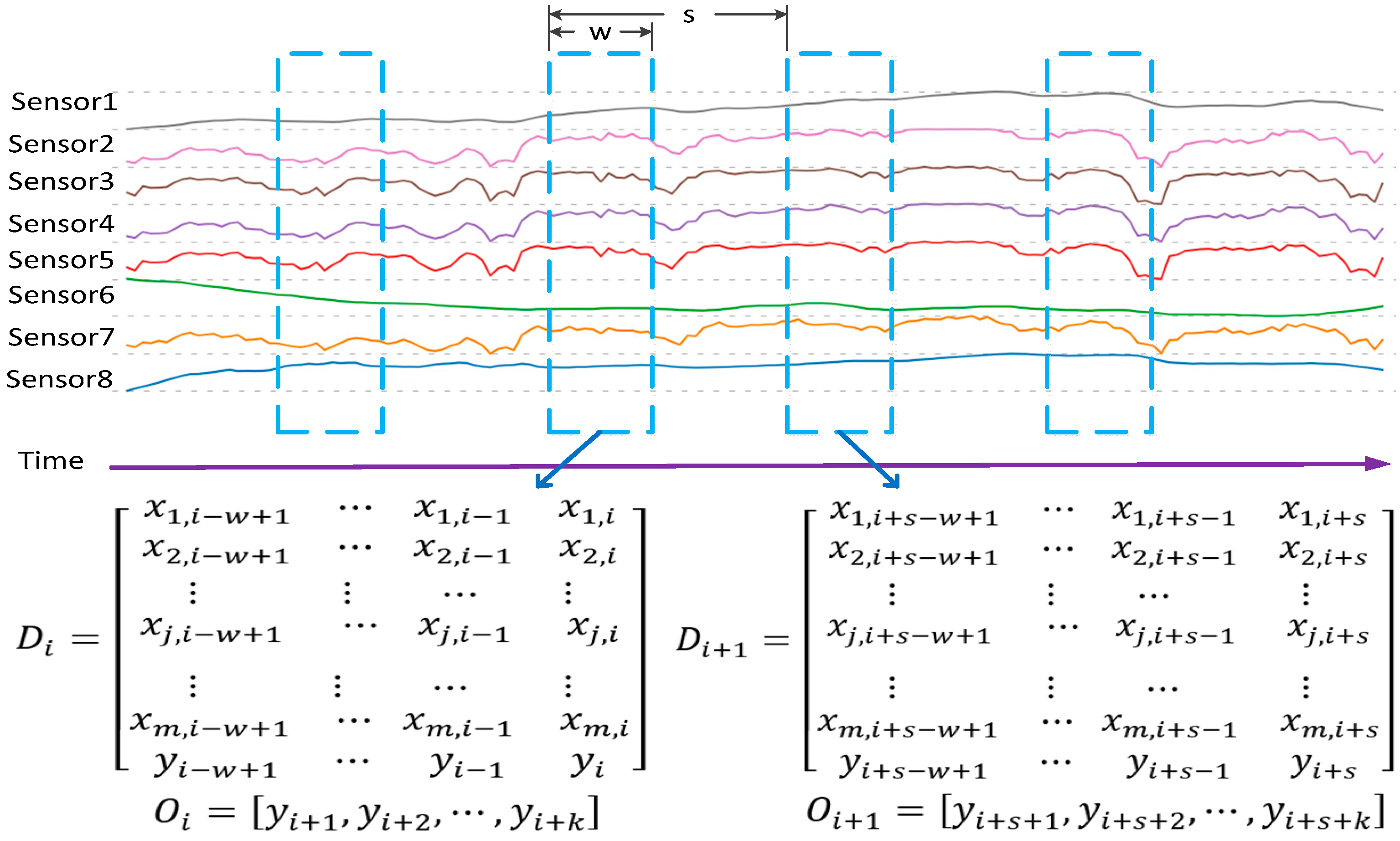

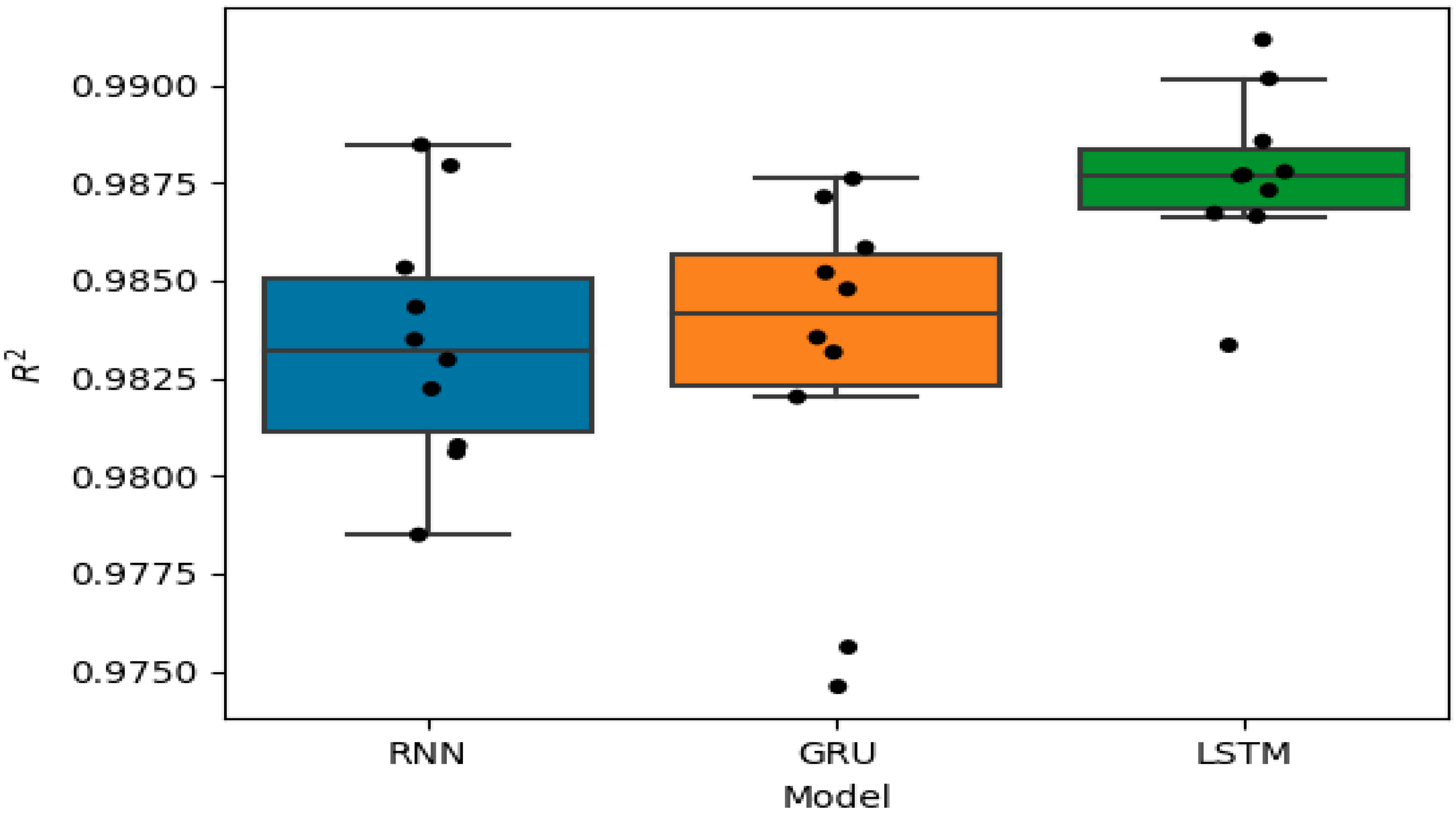

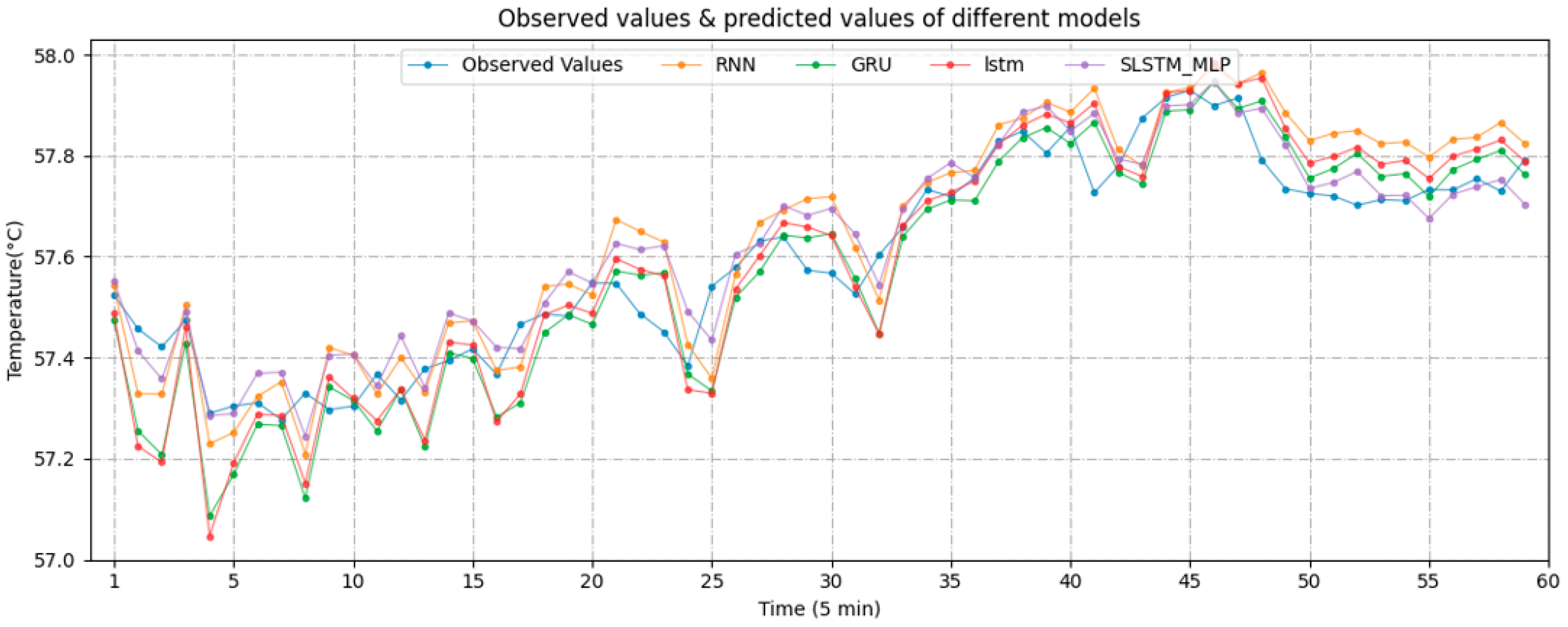

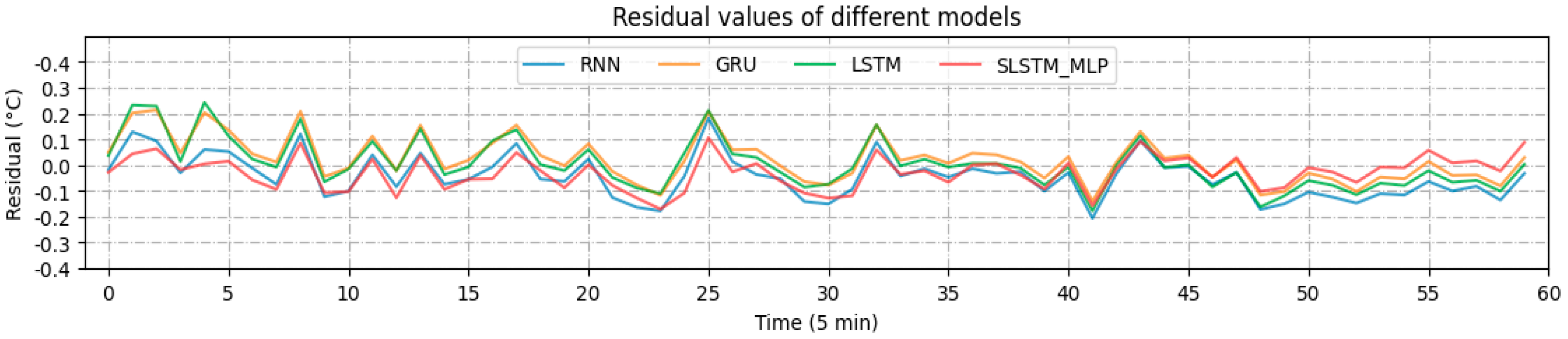

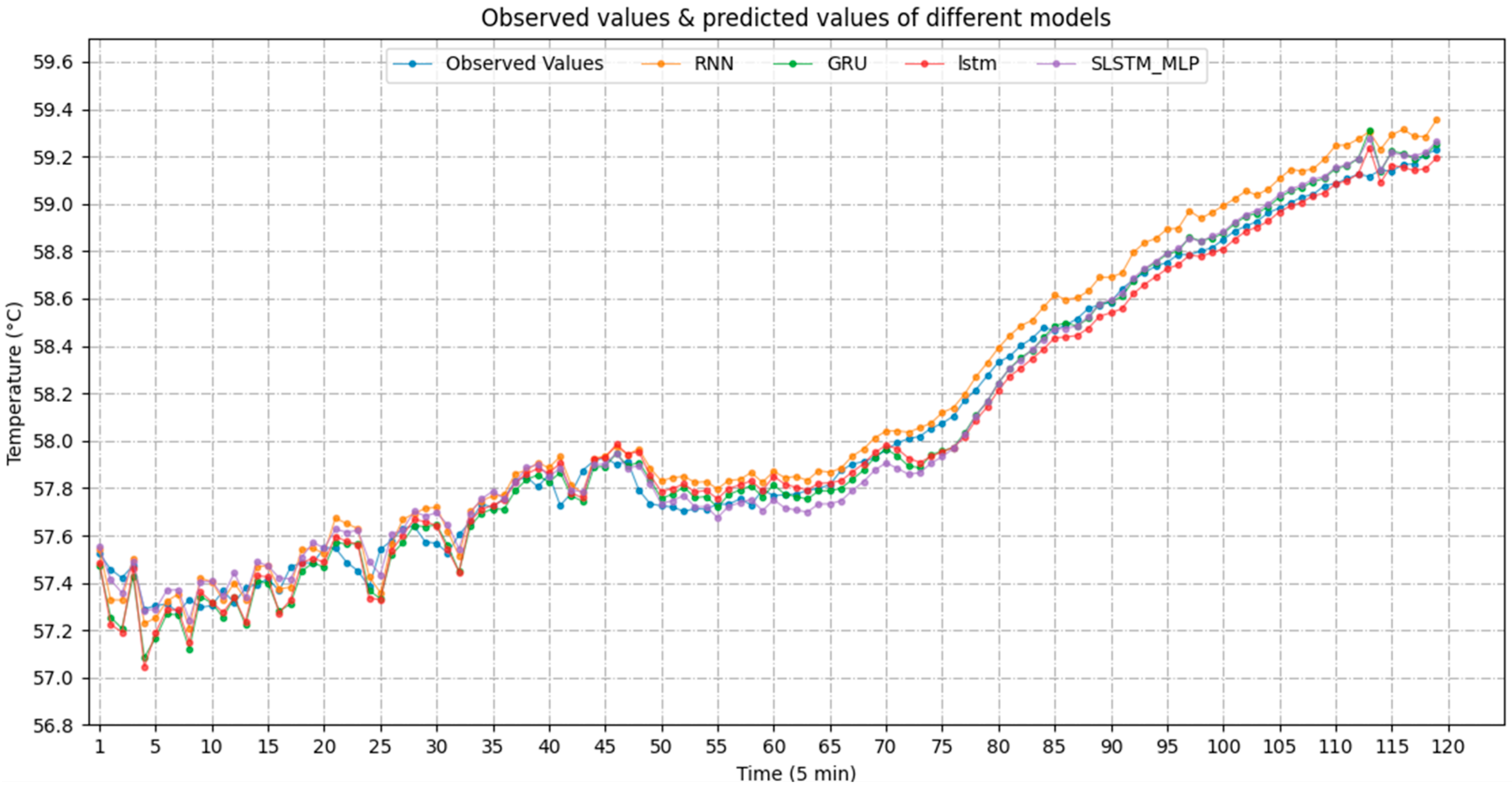

In this paper, we take the main bearing of large-scale direct-driven WTs as the research object to carry out operating condition monitoring and abnormal detection research based on SCADA data from a real wind farm. It is well known that the temperature of the main bearing of large-scale direct-driven WTs is an important parameter to monitor to determine whether the WT main bearing is abnormal. In the long-term monitoring process, temperature time series does not have obvious details of high-frequency mutation, but has certain random characteristics, obvious temporal characteristics, and short-term correlation. The model based on long-short term memory (LSTM) is very suitable for dealing with this situation. LSTM network models have great processing power for solving long-term or short-term time series dependency problems and can be used to automatically learn the temporal dependence structures of complex relationships between the temperature change of the main bearing itself and other related variables. In addition, the LSTM model, its variants, and combination models have been successfully applied in forecasting and classification [

18,

19,

20]. The motivation for this manuscript is to overcome two issues in the existing research: (1) The mining of time series feature information is insufficient in the existing literature research, and temporal characteristics of multivariable parameters are not considered in condition monitoring and anomaly detection. (2) Model structure determination and hyper-parameter selection are not discussed in-depth, and the model has poor reproducibility, which leads to application limitations of the model. Therefore, in this study, we propose a novel deep learning model for temperature forecasting of the main bearing of large-scale direct-driven WTs by using a SCADA dataset from a real wind farm. Taking a single LSTM cell as the basic component, we stack LSTM cells to build a deep model with multiple perceptual regression layers, named stacked long-short term memory with multi-layer perceptron (SLSTM-MLP), to provide robust operating condition monitoring and anomaly detection through multivariate time series datasets. The main contributions of this paper are summarized as follows:

The remainder of this paper is organized as follows.

Section 2 presents the proposed SLSTM-MLP model, including the problem definition, the framework, and training algorithm.

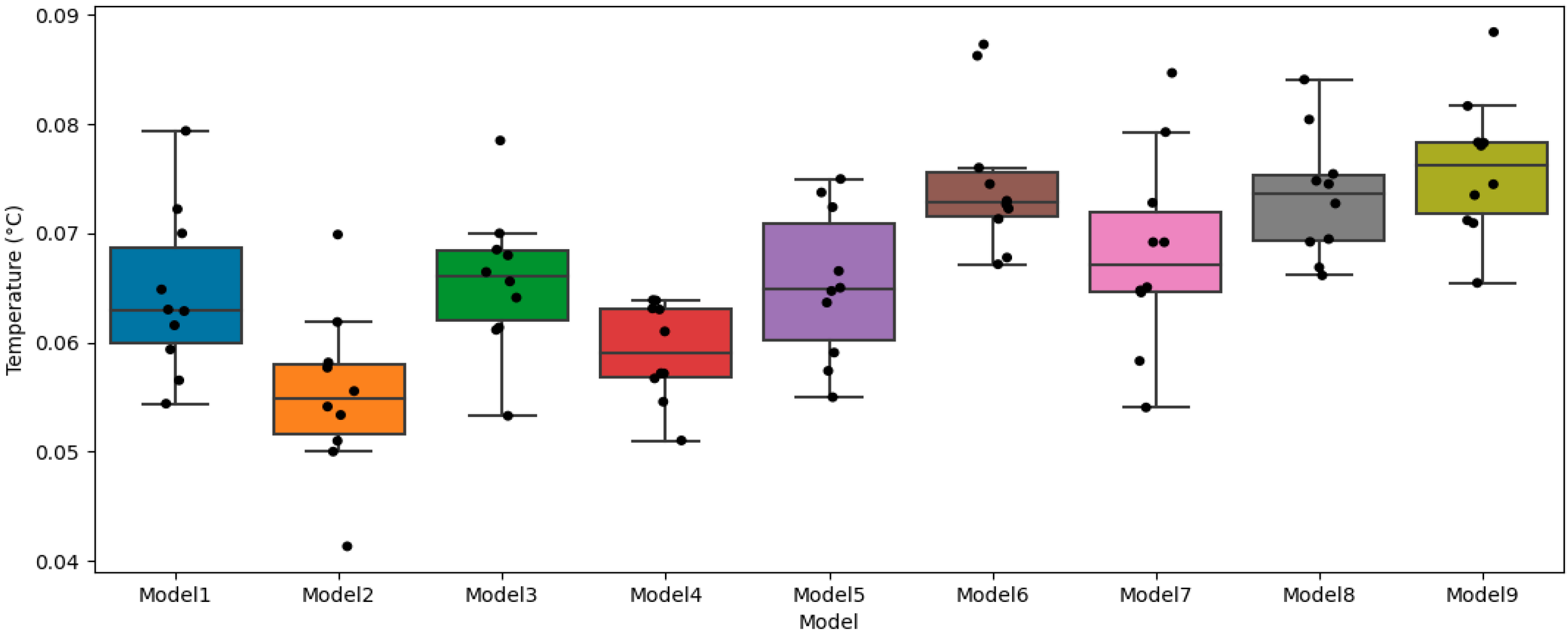

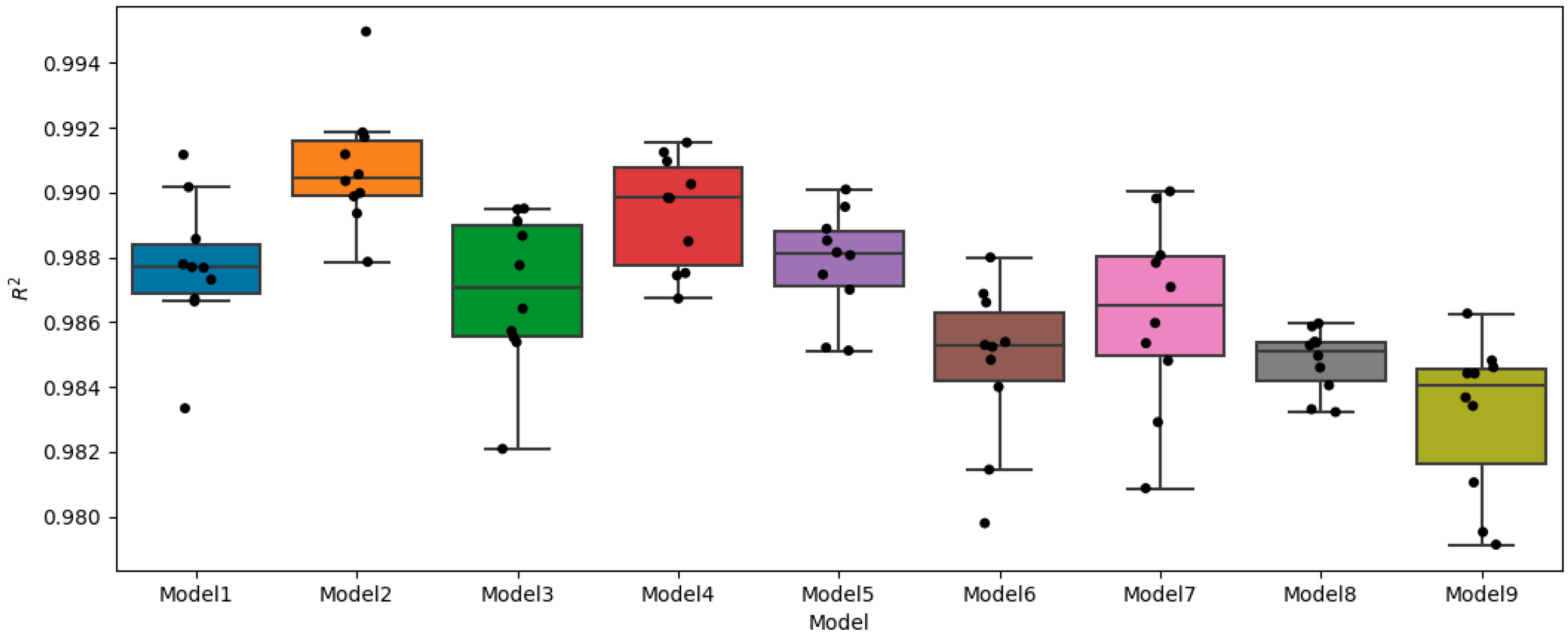

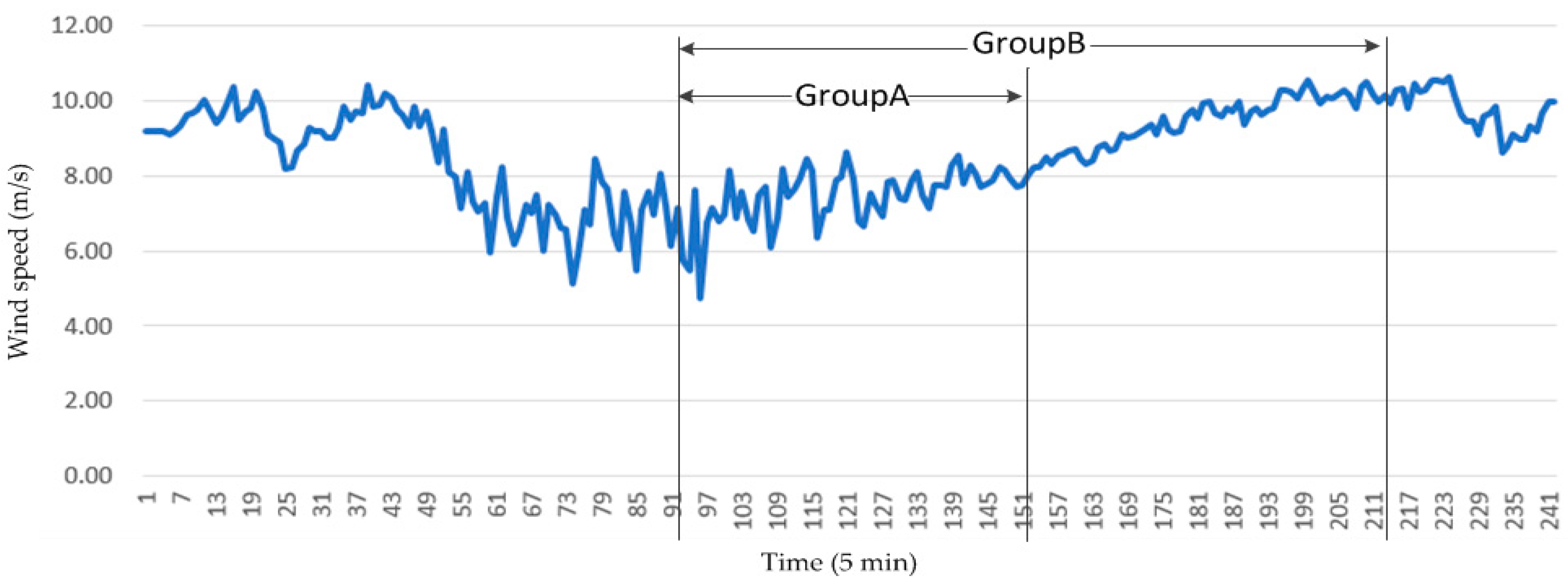

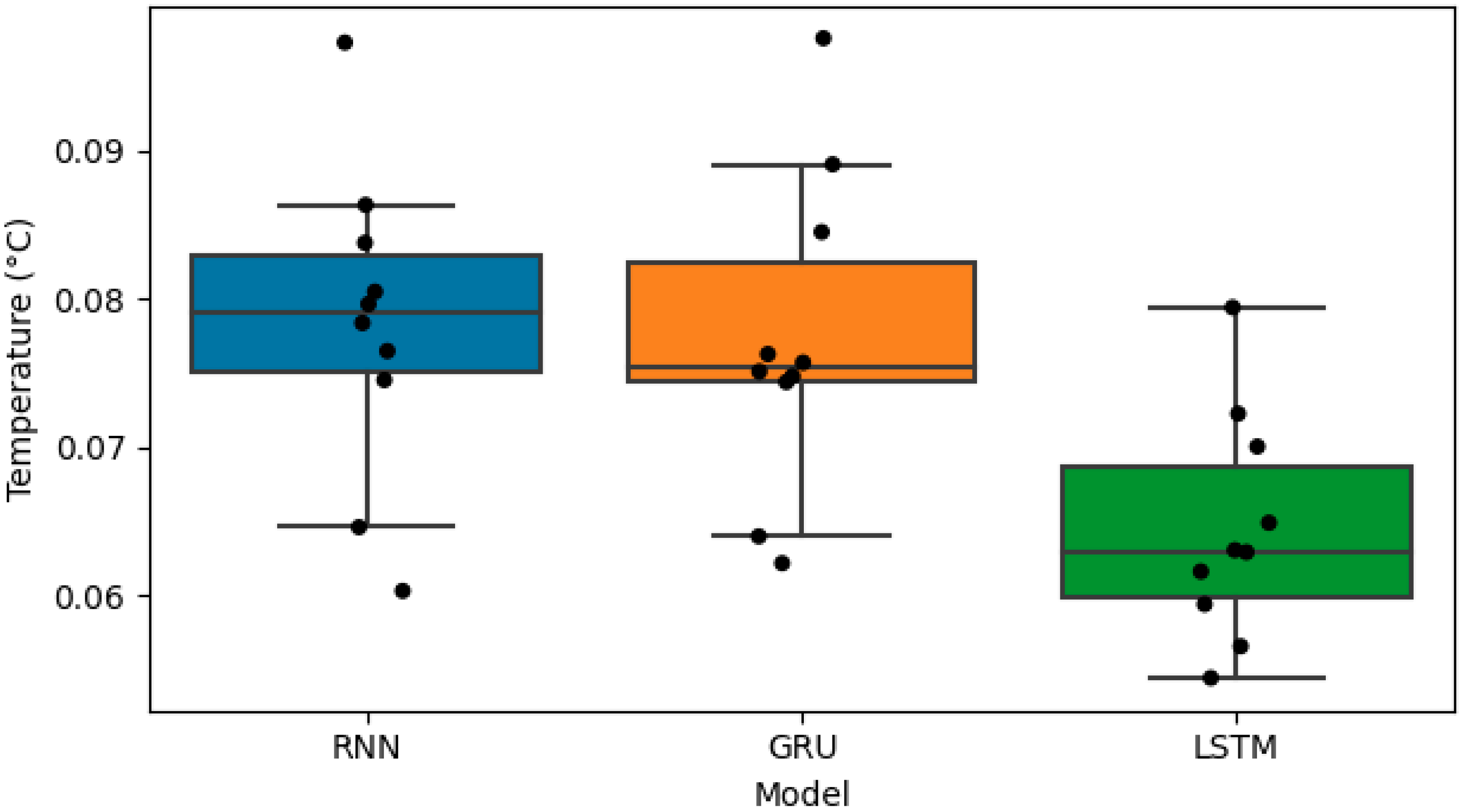

Section 3 describes the experiment setup, data cleansing and resampling, and model structure determination. Performance comparison with other models is presented in

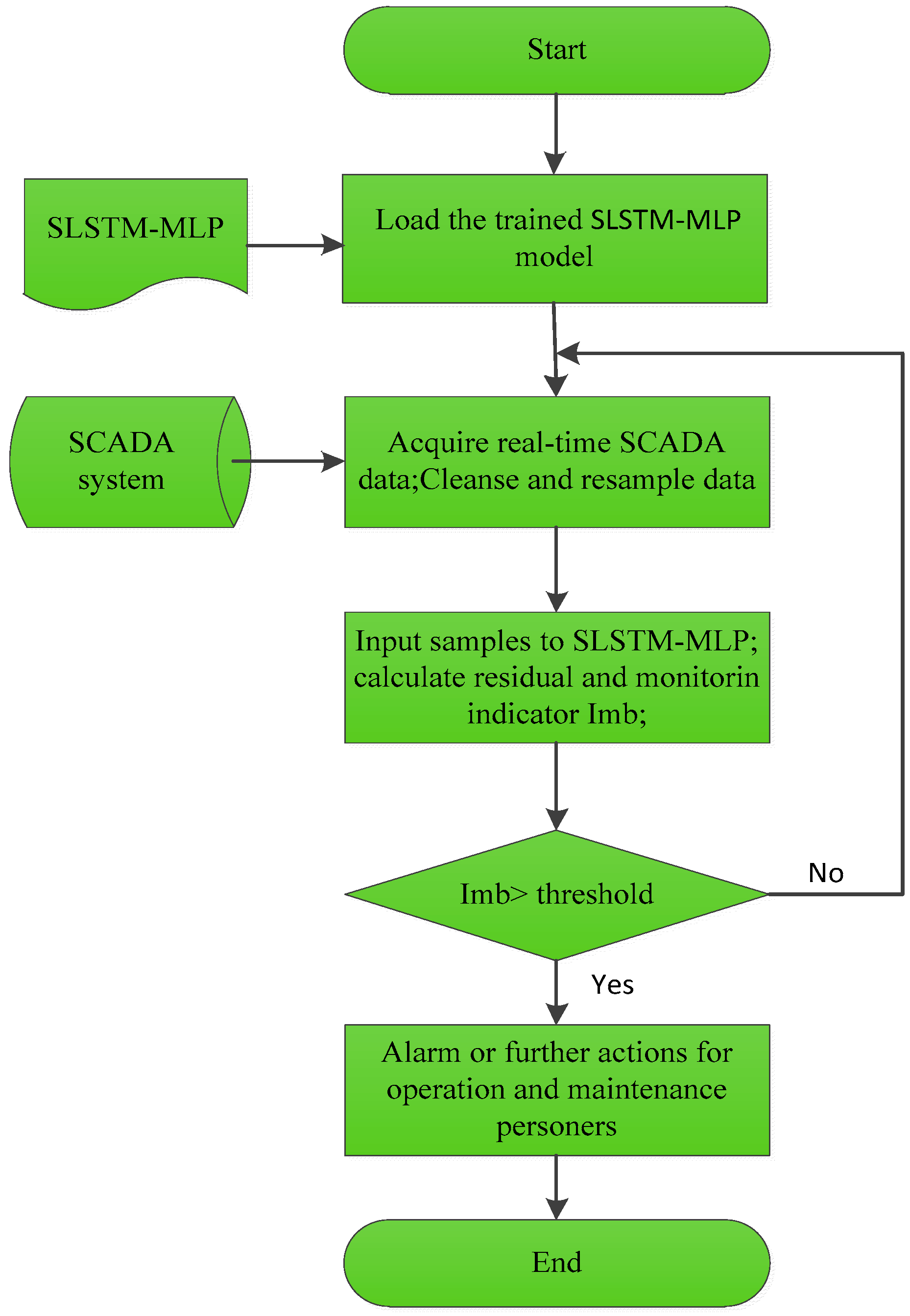

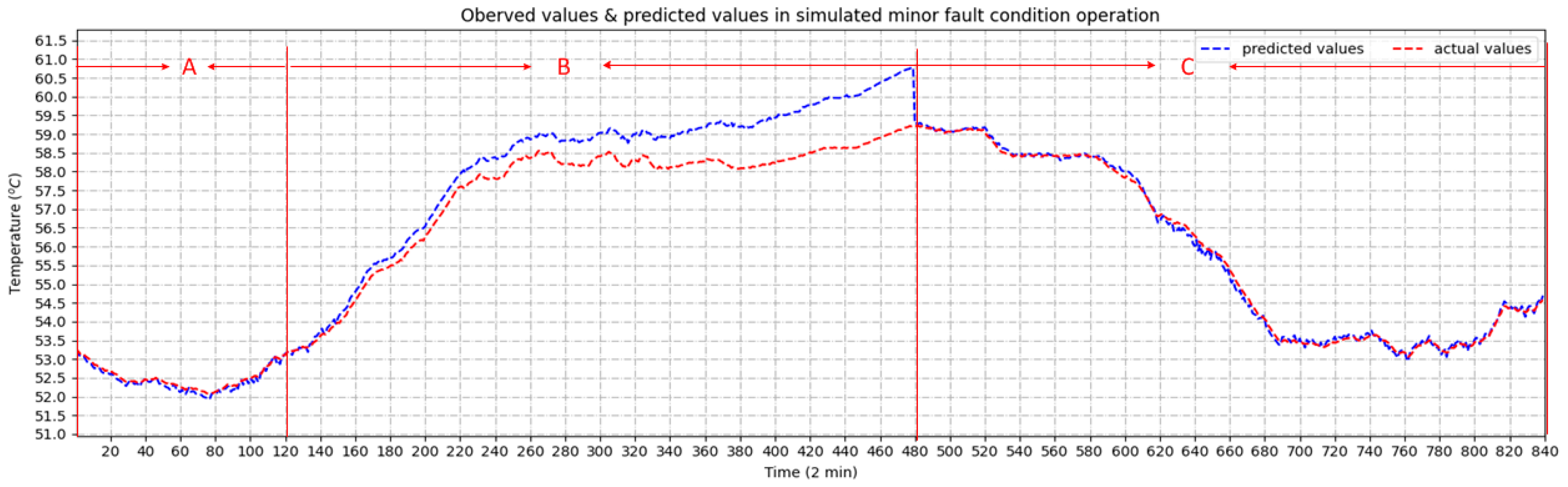

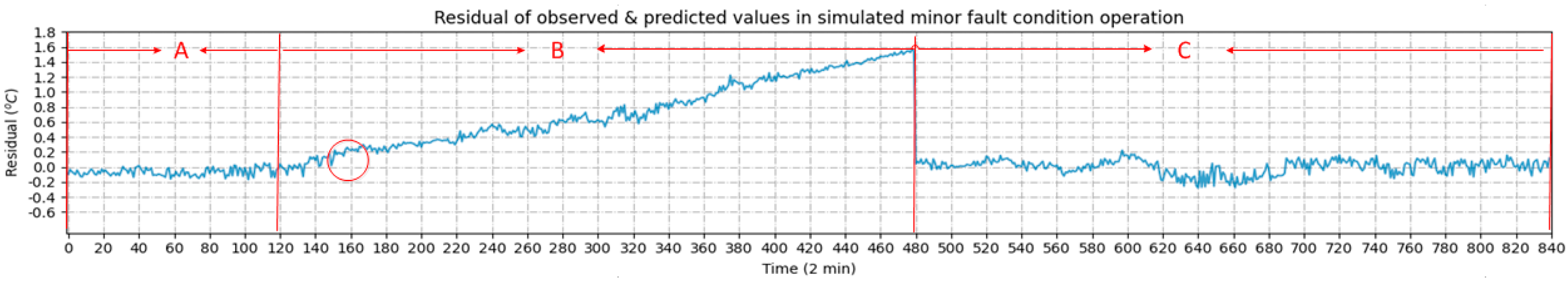

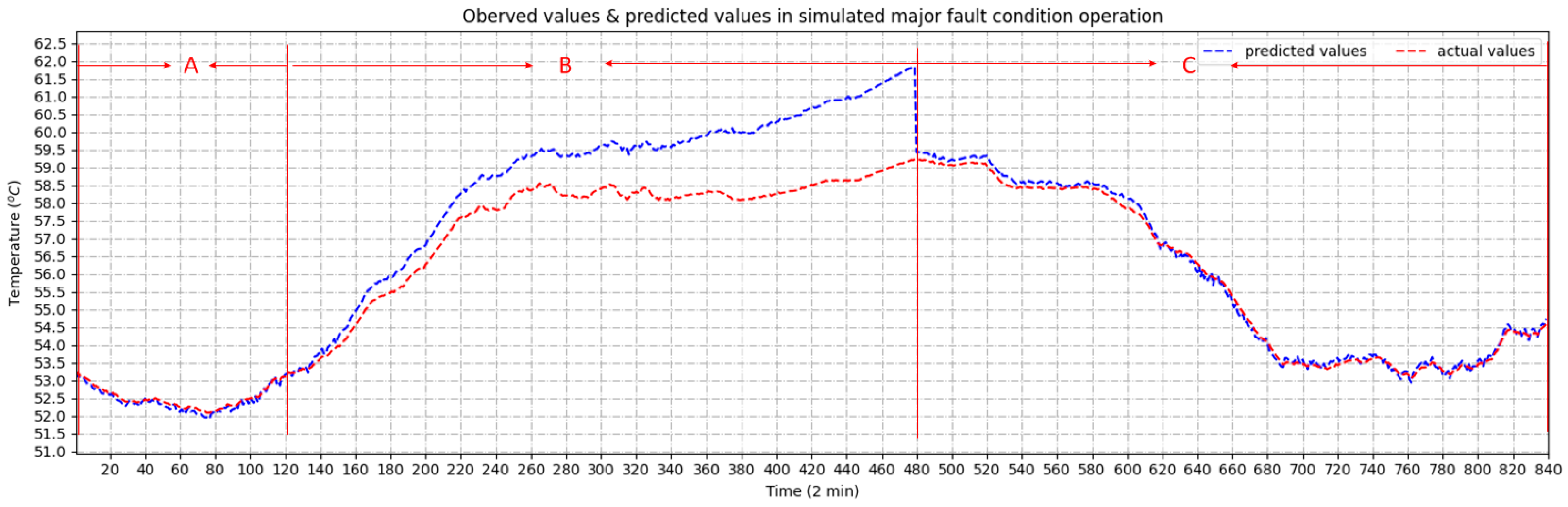

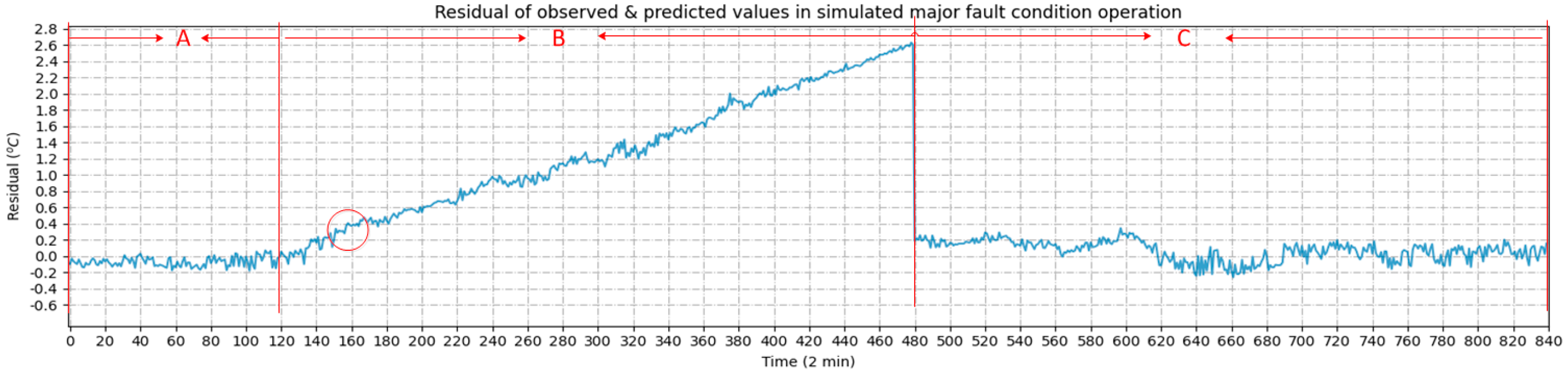

Section 4. The framework for online operating condition monitoring and abnormal detection and fault simulation are presented in

Section 5. Finally, conclusions are drawn in

Section 6.