Decentralized Processing Performance of Fruit and Vegetable Waste Discarded from Retail, Using an Automated Thermophilic Composting Technology

Abstract

:1. Introduction

1.1. Issues of Traditional Waste Management Systems for Fruit and Vegetable Waste Discarded from Retail Outlets

1.2. Main Findings and Concerns Related to Composting Processes

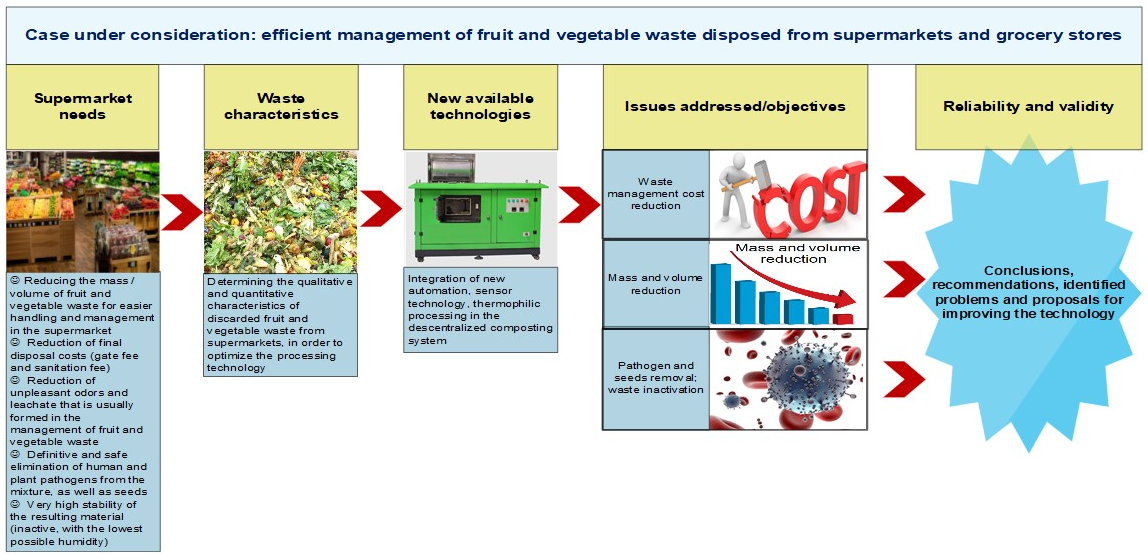

1.3. The Main Aim and Expectations in the Framework of the Current Research Study

2. Materials and Methods

2.1. Research Approach and Legislative Considerations Outlining the Working Methods

2.2. Description of the Composting System and Experimental Design

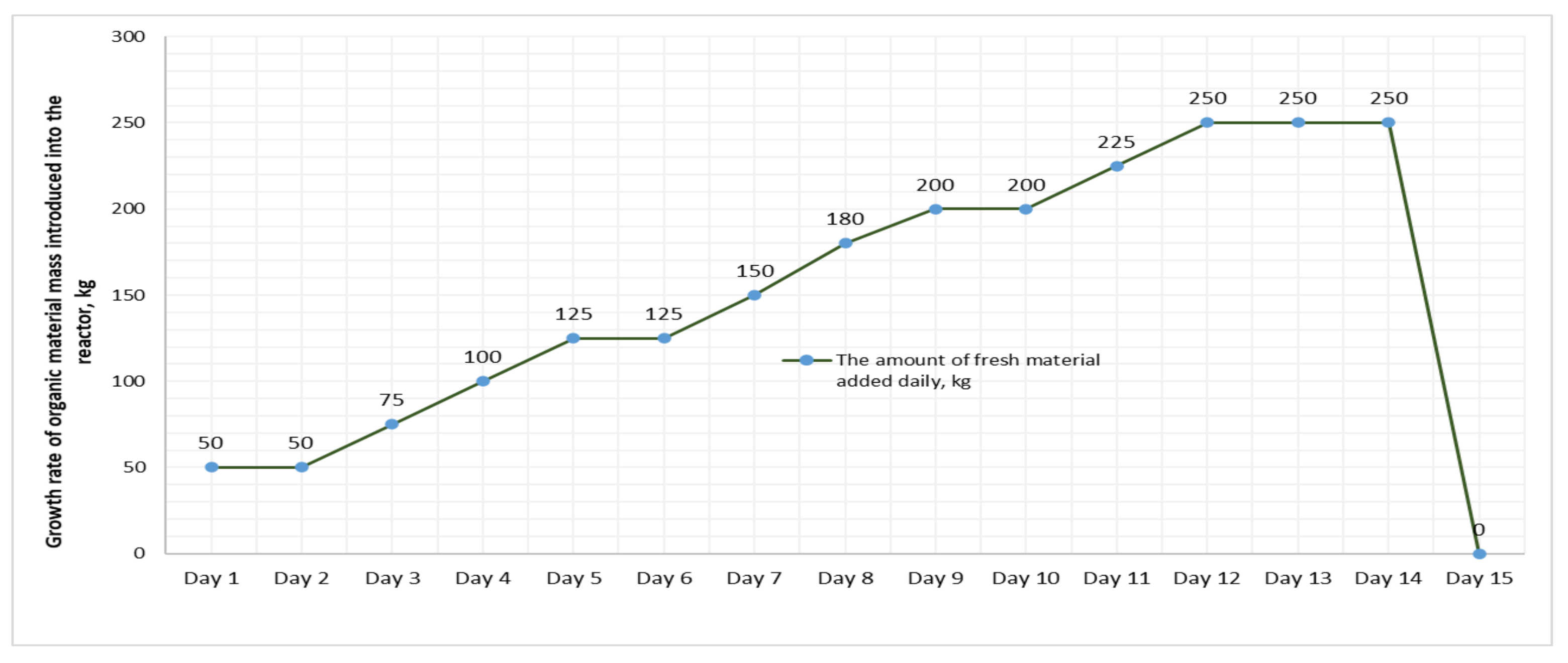

2.3. The Waste Loading Mode in the Thermophilic Regime Approach

2.4. Establishing the Operating Parameters for the Ceramic Heater, Air Pump, and the Mixing System

2.5. Sampling and Characterization Methods for Organic Wastes and Compost

2.6. Mechanism of Dehydration and Mineralization of Vegetable Waste That Contribute to Volume Decreasing

3. Results

3.1. Composition and Characterization of Food Waste Generated by Retail Stores (Category Small Supermarket)

3.2. Pre-Composting Process Performance

3.2.1. Mass and Volume Reduction

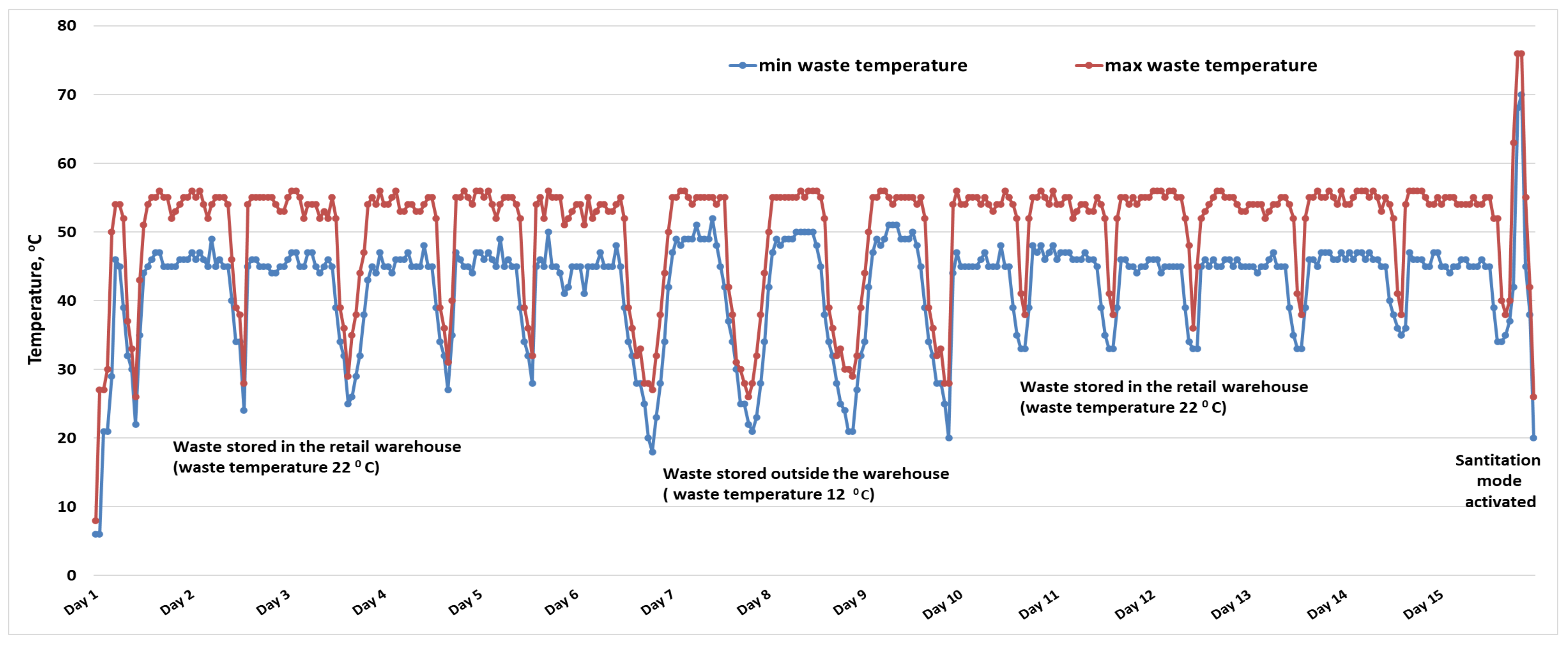

3.2.2. Temperature in the Process

3.2.3. Energy Consumption

4. Discussion

4.1. Assessment of the Context of Romanian Composting Circumstances and the Opportunities Generated by the Proposed New Technology

4.2. Pre-Composting Process Performance Associated with Fruits and Vegetables Wastes

Waste Characteristics

4.3. Moisture Content and Temperature in the Composting Process

4.4. The Mixing and Homogenizing WASTE during Composting

4.5. Pathogen Removal

4.6. Energy Consumption and Expenses Efficiency

4.7. Final Considerations of the Proposed Technological Solution for Supermarkets

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Palaniveloo, K.; Amran, M.A.; Norhashim, N.A.; Mohamad-Fauzi, N.; Peng-Hui, F.; Hui-Wen, L.; Kai-Lin, Y.; Jiale, L.; Chian-Yee, M.G.; Jing-Yi, L.; et al. Food Waste Composting and Microbial Community Structure Profiling. Processes 2020, 8, 723. [Google Scholar] [CrossRef]

- Tedesco, D.E.A.; Scarioni, S.; Tava, A.; Panseri, S.; Zuorro, A. Fruit and Vegetable Wholesale Market Waste: Safety and Nutritional Characterisation for Their Potential Re-Use in Livestock Nutrition. Sustainability 2021, 13, 9478. [Google Scholar] [CrossRef]

- FAO. Global Food Losses and Food Waste—Extent, Causes and Prevention; Food and Agriculture Organization of the United Nations: Rome, Italy, 2011; ISBN 978-92-5-107205-9. [Google Scholar]

- Wang, S.; Wu, Y. Hyperthermophilic Composting Technology for Organic SolidWaste Treatment: Recent Research Advances and Trends. Processes 2021, 9, 675. [Google Scholar] [CrossRef]

- Diekmann, L.; Germelmann, C.C. Leftover Consumption as a Means of Food Waste Reduction in Public Space? Qualitative Insights from Online Discussions. Sustainability 2021, 13, 13564. [Google Scholar] [CrossRef]

- Attanzio, A.; Tesoriere, L.; Poojary, M.M.; Cilla, A. Fruit and Vegetable Derived Waste as a Sustainable Alternative Source of Nutraceutical Compounds. J. Food Qual. 2018, 2018, 8136190. [Google Scholar] [CrossRef]

- Mattsson, L.; Williams, H.; Berghel, J. Waste of fresh fruit and vegetables at retailers in Sweden—Measuring and calculation of mass, economic cost and climate impact. Resour. Conserv. Recycl. 2018, 130, 118–126. [Google Scholar] [CrossRef]

- Sundberg, C.; Yu, D.; Franke-Whittle, I.; Kauppi, S.; Smårs, S.; Insam, H.; Romantschuk, M.; Jönsson, H. Effects of pH and microbial composition on odour in food waste composting. Waste Manag. 2013, 33, 204–211. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Zhang, S.; Wen, Q.; Zheng, J. Effect of aeration rate on composting of penicillin mycelial dreg. J. Environ. Sci. 2015, 37, 172–178. [Google Scholar] [CrossRef]

- Simoes, P.; Marques, R. On the economic performance of the waste sector. A literature review. J. Environ. Manag. 2012, 106, 40–47. [Google Scholar] [CrossRef] [PubMed]

- Nenciu, F.; Paraschiv, M.; Kuncser, R.; Stan, C.; Cocarta, D.; Vladut, V.N. High-Grade Chemicals and Biofuels Produced from Marginal Lands Using an Integrated Approach of Alcoholic Fermentation and Pyrolysis of Sweet Sorghum Biomass Residues. Sustainability 2022, 14, 402. [Google Scholar] [CrossRef]

- Elkadi, A.; Maatouk, M.; Tarik, C.; Raissouni, M. Physicochemical characterization of landfill leachates: A comparison case between Tangier and Agadir (Morocco). J. Mater. Environ. Sci. 2016, 6, 3207–3216. [Google Scholar]

- Bhave, P.P.; Kulkarni, B.N. Effect of active and passive aeration on composting of household biodegradable wastes: A decentralized approach. Int. J. Recycl. Org. Waste Agric. 2019, 8, 335–344. [Google Scholar] [CrossRef] [Green Version]

- Sanchez, O.J.; Ospina, D.A.; Montoya, S. Compost supplementation with nutrients and microorganisms in composting process. Waste Manag. 2017, 69, 136–153. [Google Scholar] [CrossRef] [PubMed]

- Alkoaik, F.N. Integrating aeration and rotation processes to accelerate composting of agricultural residues. PLoS ONE 2019, 14, e0220343. [Google Scholar] [CrossRef]

- Ghaly, A.E.; Alkoaik, F.; Snow, A. Thermal balance of in-vessel composting of tomato plant residues. Can. Biosyst. Eng. 2006, 48, 6.1–6.11. [Google Scholar]

- Huang, Y.; Li, D.Y.; Wang, L.; Yong, C.; Sun, E.H.; Jin, H.M.; Huang, H.Y. Decreased Enzyme Activities, Ammonification Rate and Ammonifiers Contribute to Higher Nitrogen Retention in Hyperthermophilic Pretreatment Composting. Bioresour. Technol. 2019, 272, 521–528. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, J.D.; Huang, H.Y.; Sun, E.H.; Butterly, C.; Xu, Y.D.; He, H.; Zhang, J.; Chang, Z.Z. Spectroscopic Evidence for Hyperthermophilic Pretreatment Intensifying Humification During Pig Manure and Rice Straw Composting. Bioresour. Technol. 2019, 294, 122131. [Google Scholar] [CrossRef]

- Ren, X.N.; Wang, Q.; Zhang, Y.; Awasthi, M.K.; He, Y.F.; Li, R.H.; Zhang, Z.Q. Improvement of Humification and Mechanism of Nitrogen Transformation during Pig Manure Composting with Black Tourmaline. Bioresour. Technol. 2020, 307, 123236. [Google Scholar] [CrossRef]

- Ajay, S.K.; Kazmi, A.A. Mixed organic waste composting using rotary drum composter. Int. J. Environ. Waste Manag. 2008, 2, 24–35. [Google Scholar]

- Hwang, E.Y.; Park, J.S.; Kim, J.D.; Namkoong, W. Effect of aeration mode on the composting of diesel-contaminated soil. J. Ind. Chem. 2006, 12, 694–701. [Google Scholar]

- Rasapoor, M.; Adl, M.; Pourazizi, B. Comparative evaluation of aeration methods for municipal soild waste composting from the perspective of resource management: A practical case study in Tihran, Iran. J. Environ. Manag. 2016, 184, 528–534. [Google Scholar] [CrossRef] [PubMed]

- Tajima, K.; Yoshimura, M.; Kato, M.; Tatsuno, J.; Tamaki, K. Enhancement of composting process by the addition of chicken manure and rice bran to tree pruning chips. Jpn. J. Farm Work Res. 2003, 38, 207–2013. [Google Scholar] [CrossRef]

- Ajay, S.K.; Kazmi, A.A. Effects of turning frequency on compost stability and some chemical characteristics in a rotary drum composter. Chemosphere 2009, 74, 1327–1334. [Google Scholar] [CrossRef]

- Varma, V.S.; Kalamdhad, A.S. Evaluation of chemical and biological characterization during thermophilic composting of vegetable waste using rotary drum composter. Int. J. Environ. Sci. Technol. 2015, 12, 2015–2024. [Google Scholar] [CrossRef] [Green Version]

- Eklind, Y.; Kirchman, H. Composting and storage of organic household waste with different litter amendments. I: Carbon turnover. Bioresour. Technol. 2000, 74, 115–124. [Google Scholar] [CrossRef]

- Hamelers, H.V.M. A Mathematical Model for Composting Kinetics. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 2001. [Google Scholar]

- Moreno, J.; López-González, J.A.; Arcos-Nievas, M.A.; Suárez-Estrella, F.; Jurado, M.M.; Estrella-González, M.J.; López, M.J. Revisiting the Succession of Microbial Populations throughout Composting: A Matter of Thermotolerance. Sci. Total Environ. 2021, 773, 145587. [Google Scholar] [CrossRef]

- Costa, L.A.M.; Costa, M.S.S.M.; Damaceno, F.M.; Chiarelotto, M.; Bofinger, J.; Gazzola, W. Bioaugmentation as A Strategy to Improve the Compost Quality in the Composting Process of Agro-industrial Wastes. Environ. Technol. Innov. 2021, 22, 101478. [Google Scholar] [CrossRef]

- Sakarika, M.; Spiller, M.; Baetens, R.; Donies, G.; Vanderstuy, J.; Vinck, K.; Vrancken, K.C.; Van Barel, G.; Du Bois, E.; Vlaeminck, S.E. Proof of concept of high-rate decentralized pre-composting of kitchen waste: Optimizing design and operationof a novel drum reactor. Waste Manag. 2019, 91, 20–32. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Tang, J.; Liao, H.P.; Liu, X.M.; Zhou, P.X.; Chen, Z.; Rensing, C.; Zhou, S.G. The Distinctive Microbial Community Improves Composting Efficiency in a full-scale Hyperthermophilic Composting. Plant. Bioresour. Technol. 2018, 265, 146–154. [Google Scholar] [CrossRef]

- Strom, P.F. Effect of Temperature on Bacterial Species Diversity in Thermophilic Solid-Waste Composting. Appl. Environ. Microbiol. 1985, 50, 899–905. [Google Scholar] [CrossRef] [Green Version]

- Afonso, S.; Arrobas, M.; Pereira, E.L.; Rodrigues, M.A. Recycling Nutrient-rich Hop Leaves by Composting with Wheat Straw and Farmyard Manure in Suitable Mixtures. J. Environ. Manag. 2021, 284, 112105. [Google Scholar] [CrossRef]

- Kroodsma, W.; Ogink, N.W.M.; Satter, I.H.G.; Willers, H.C. A technique for direct separation of pig excrements followed by on-farm treatment of the components. In Proceedings of the International Conference on Agricultural Engineering, Oslo, Norway, 24–27 August 1998. [Google Scholar]

- Nenciu, F.; Vladut, V. Studies on the perspectives of replacing the classic energy plants with Jerusalem artichoke and Sweet Sorghum, analyzing the impact on the conservation of ecosystems. IOP Conf. Ser. Earth Environ. Sci. 2020, 635, 012002. [Google Scholar] [CrossRef]

- Lin, C.; Cheruiyot, N.K.; Hoang, H.G.; Le, T.H.; Tran, H.T.; Bui, X.T. Benzophenone Biodegradation and Characterization of Malodorous Gas Emissions During Co-composting of FoodWaste with Sawdust and Mature Compost. Environ. Technol. Innov. 2021, 21, 101351. [Google Scholar] [CrossRef]

- Panigrahi, S.; Dubey, B.K. A Critical Review on Operating Parameters and Strategies to Improve the Biogas Yield from Anaerobic Digestion of Organic Fraction of Municipal Solid Waste. Renew. Energy 2019, 143, 779–797. [Google Scholar] [CrossRef]

- Kalamdhad, A.S.; Singn, Y.K.; Ali, M.; Khwairakpam, M.; Kazmi, A.A. Rotary drum composting of vegetable waste and tree leaves. Bioresour. Technol. 2009, 100, 6442–6450. [Google Scholar] [CrossRef] [PubMed]

- Madan, S.; Bhatia, A.; Rajpal, A.; Kazmi, A.A. Maturity assessment of rotary drum and windrow composts in terms of germination index and enzymatic activities. Int. J. Appl. Sci. Eng. Res. 2012, 1, 415–426. [Google Scholar] [CrossRef]

- Matias, M.O.; Arlei, C.; Paulo, B.F.; Paulo, A.V.O. Aeration frequency on accelerated composting of animal carcasses. Cienc. Agrotecnol. 2018, 24, 653–665. [Google Scholar]

- Ghinea, C.; Leahu, A. Monitoring of Fruit and Vegetable Waste Composting Process: Relationship between Microorganisms and Physico-Chemical Parameters. Processes 2020, 8, 302. [Google Scholar] [CrossRef] [Green Version]

- Vishan, I.; Kanekar, H.; Kalamdhad, A. Microbial population, stability and maturity analysis of rotary drum composting of water hyacinth. Biologia 2014, 69, 1303–1313. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Sun, X. Influence of bulking agents on physical, chemical, and microbiological properties during the two-stage composting of green waste. Waste Manag. 2016, 48, 115–126. [Google Scholar] [CrossRef]

- Ciobotaru, I.E.; Nenciu, F.; Vaireanu, D.I. The Electrochemical Generation of Ozone using an Autonomous Photovoltaic System. Rev. Chim. 2013, 64, 1339–1342. [Google Scholar]

- Afolabi, I.S. Moisture Migration and Bulk Nutrients Interaction in a Drying Food Systems: A Review. Food Nutr. Sci. 2014, 5, 692–714. [Google Scholar] [CrossRef] [Green Version]

- Brancoli, P.; Rousta, K.; Bolton, K. Life cycle assessment of supermarket food waste. Resour. Conserv. Recycl. 2017, 118, 39–46. [Google Scholar] [CrossRef]

- Cicatiello, C.; Franco, S.; Pancino, B.; Blasi, E.; Falasconi, L. The dark side of retail food waste: Evidences from in-store data. Resour. Conserv. Recycl. 2017, 125 (Suppl. C), 273–281. [Google Scholar] [CrossRef]

- Buzby, J.C.; Hyman, J. Total and per capita value of food loss in the United States. Food Policy 2012, 37, 561–570. [Google Scholar] [CrossRef]

- Lebersorger, S.; Schneider, F. Food loss rates at the food retail, influencing factors and reasons as a basis for waste prevention measures. Waste Manag. 2014, 34, 1911–1919. [Google Scholar] [CrossRef]

- Scholz, K.; Eriksson, M.; Strid, I. Carbon footprint of supermarket food waste. Resour. Conserv. Recycl. 2015, 94, 56–65. [Google Scholar] [CrossRef]

- Lăcătuşu, A.R.; Cocârţă, D.M.; Lăcătuşu, R. Ex-situ bioremediation efficiency in removing organic and inorganic compounds from artificially and anthropogenic contaminated soil. Carpathian J. Earth Environ. Sci. 2013, 8, 59–70. [Google Scholar]

- Malinauskaite, J.; Jouhara, H.; Czajczyńska, D.; Stanchev, P.; Katsou, E.; Rostkowski, P.; Thorne, R.J.; Colón, J.; Ponsá, S.; Al-Mansour, F.; et al. Municipal solid waste management and waste-to-energy in the context of a circular economy and energy recycling in Europe. Energy 2017, 141, 2013–2044. [Google Scholar] [CrossRef]

- Angouria-Tsorochidou, E.; Teigiserova, D.A.; Thomsen, M. Environmental and economic assessment of decentralized bioenergy and biorefinery networks treating urban biowaste. Resour. Conserv. Recycl. 2022, 176, 105898. [Google Scholar] [CrossRef]

- Tonini, D.; Wandl, A.; Meister, K.; Unceta, P.M.; Taelman, S.E.; Sanjuan-Delmas, D.; Dewulf, J.; Huygens, D. Quantitative sustainability assessment of household food waste management in the Amsterdam Metropolitan Area. Resour. Conserv. Recycl. 2020, 160, 104854. [Google Scholar] [CrossRef]

- Di Matteo, U.; Nastasi, B.; Albo, A.; Astiaso Garcia, D. Energy contribution of OFMSW (Organic Fraction of Municipal Solid Waste) to energy-environmental sustainability in urban areas at small scale. Energies 2017, 10, 229. [Google Scholar] [CrossRef] [Green Version]

- Tiwary, A.; Williams, I.D.; Pant, D.C.; Kishore, V.V.N. Emerging perspectives on environmental burden minimisation initiatives from anaerobic digestion technologies for community scale biomass valorisation. Renew. Sustain. Energy Rev. 2015, 42, 883–901. [Google Scholar] [CrossRef]

- Zeller, V.; Lavigne, C.; D’Ans, P.; Towa, E.; Achten, W.M.J. Assessing the environmental performance for more local and more circular biowaste management options at city-region level. Sci. Total Environ. 2020, 745, 140690. [Google Scholar] [CrossRef] [PubMed]

- Cardei, P.; Nenciu, F.; Ungureanu, N.; Pruteanu, M.A.; Vlăduț, V.; Cujbescu, D.; Găgeanu, I.; Cristea, O.D. Using Statistical Modeling for Assessing Lettuce Crops Contaminated with Zn, Correlating Plants Growth Characteristics with the Soil Contamination Levels. Appl. Sci. 2021, 11, 8261. [Google Scholar] [CrossRef]

- Stoknes, K.; Scholwin, F.; Krzesinski, W.; Wojciechowska, E.; Jasinska, A. Efficiency of a novel “Food to waste to food” system including anaerobic digestion of food waste and cultivation of vegetables on digestate in a bubble-insulated greenhouse. Waste Manag. 2016, 56, 466–476. [Google Scholar] [CrossRef]

| Volume | Total fresh volume of waste introduced in processing | 2235 | Kg |

| Output volume after processing | 268 | Kg | |

| Mass reduction | 1967 | Kg | |

| Reduction rate | 88 | % | |

| Moisture | Initial waste moisture | 89 | % |

| Output moisture (14 days) | 27 | % | |

| Output moisture (15 days) | 21 | % | |

| Moisture reduction rate | 90–92 | % | |

| Pathogen presence (plant and animal) | no pathogen or seeds present | ||

| Dry substance | 79 | % | |

| pH | 4.4 | unit | |

| Loss by calcination (organic matter from dry substance) | 78.05 | % dry substance | |

| Total organic carbon | 45.62 | % dry substance | |

| Total nitrogen | 2.75 | % dry substance | |

| Total phosphorus | 0.533 | % dry substance | |

| Calcium | 13,913 | mg/kg dry substance | |

| Magnesium | 1711 | mg/kg dry substance | |

| Potassium | 13,931 | mg/kg dry substance | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nenciu, F.; Stanciulescu, I.; Vlad, H.; Gabur, A.; Turcu, O.L.; Apostol, T.; Vladut, V.N.; Cocarta, D.M.; Stan, C. Decentralized Processing Performance of Fruit and Vegetable Waste Discarded from Retail, Using an Automated Thermophilic Composting Technology. Sustainability 2022, 14, 2835. https://doi.org/10.3390/su14052835

Nenciu F, Stanciulescu I, Vlad H, Gabur A, Turcu OL, Apostol T, Vladut VN, Cocarta DM, Stan C. Decentralized Processing Performance of Fruit and Vegetable Waste Discarded from Retail, Using an Automated Thermophilic Composting Technology. Sustainability. 2022; 14(5):2835. https://doi.org/10.3390/su14052835

Chicago/Turabian StyleNenciu, Florin, Iustina Stanciulescu, Horia Vlad, Andrei Gabur, Ovidiu Leonard Turcu, Tiberiu Apostol, Valentin Nicolae Vladut, Diana Mariana Cocarta, and Constantin Stan. 2022. "Decentralized Processing Performance of Fruit and Vegetable Waste Discarded from Retail, Using an Automated Thermophilic Composting Technology" Sustainability 14, no. 5: 2835. https://doi.org/10.3390/su14052835

APA StyleNenciu, F., Stanciulescu, I., Vlad, H., Gabur, A., Turcu, O. L., Apostol, T., Vladut, V. N., Cocarta, D. M., & Stan, C. (2022). Decentralized Processing Performance of Fruit and Vegetable Waste Discarded from Retail, Using an Automated Thermophilic Composting Technology. Sustainability, 14(5), 2835. https://doi.org/10.3390/su14052835