Spearmint (Mentha spicata) Cultivation in Decoupled Aquaponics with Three Hydro-Components (Grow Pipes, Raft, Gravel) and African Catfish (Clarias gariepinus) Production in Northern Germany

Abstract

:1. Introduction

2. Materials and Methods

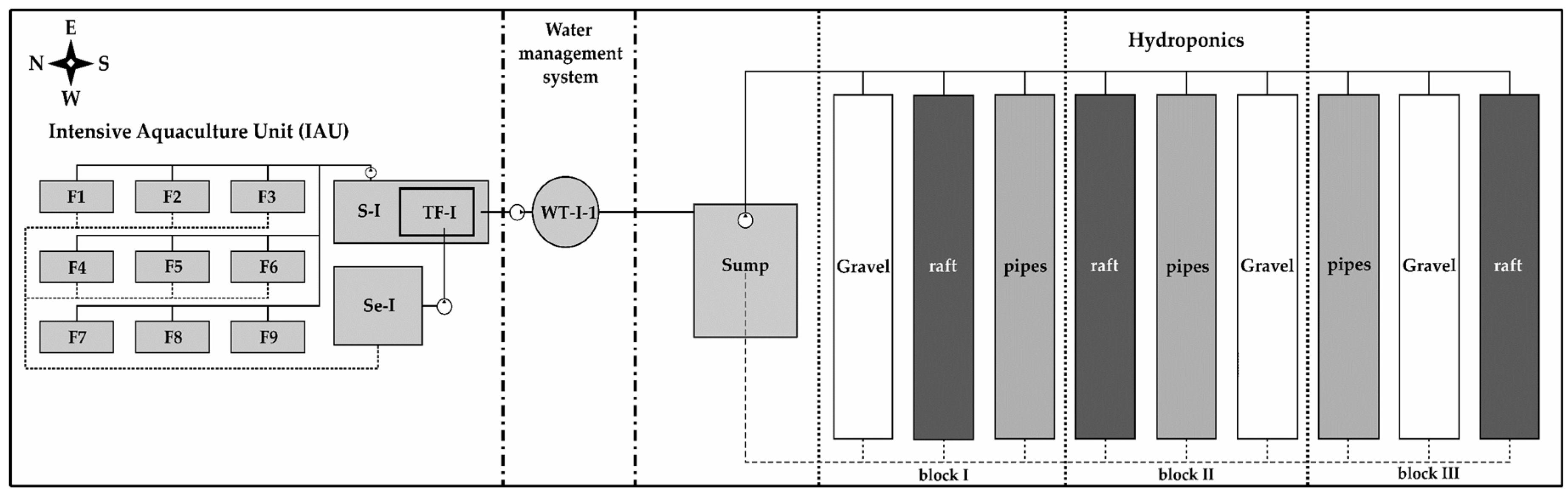

2.1. Aquaponic System Design in the FishGlassHouse (FGH)

2.2. Experimental Hydroponic Components

2.3. Plant and Fish Species

2.4. Physical and Chemical Parameters

2.5. Mathematical and Statistical Analyses

3. Results

3.1. Fish Growth

3.2. Plant Growth

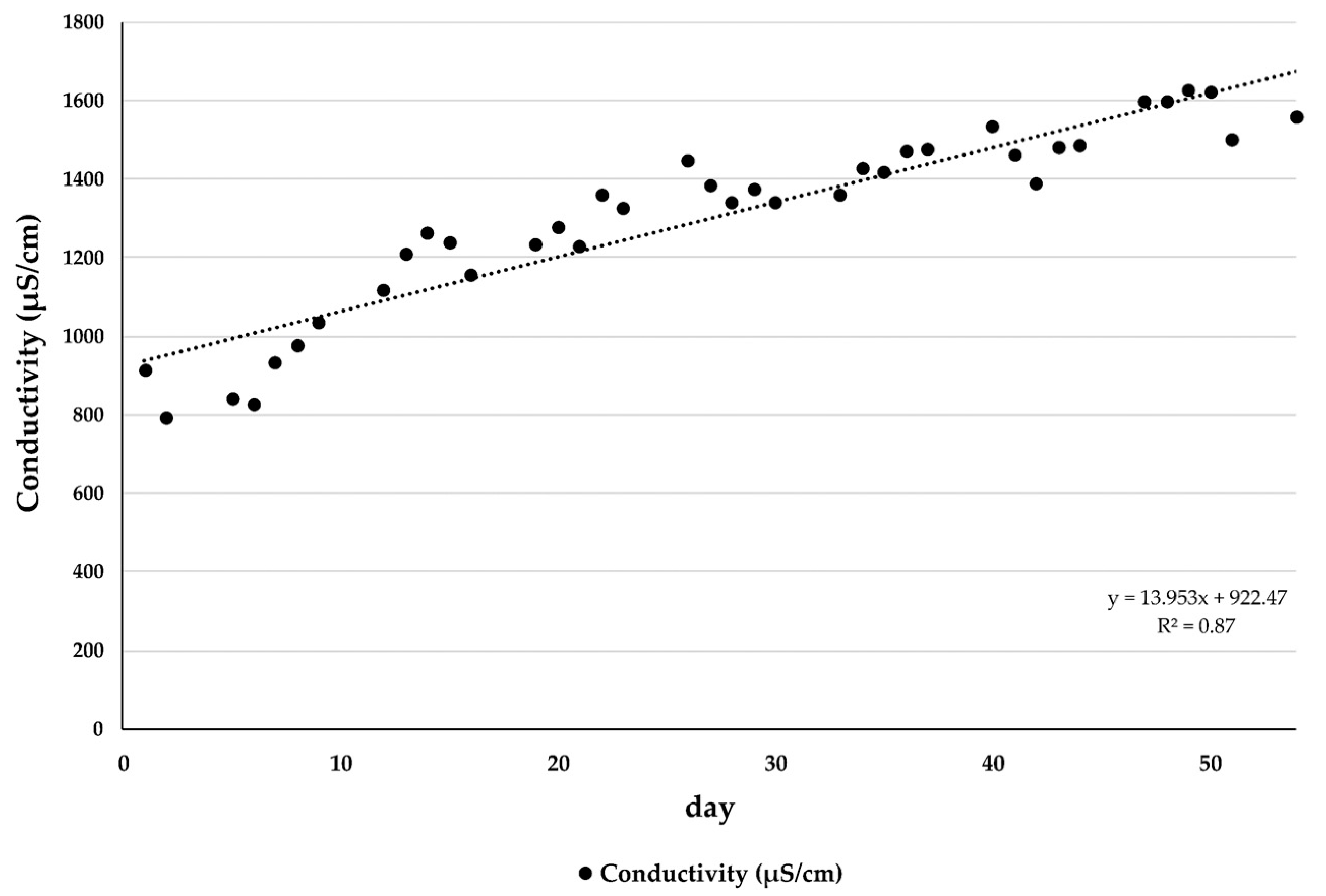

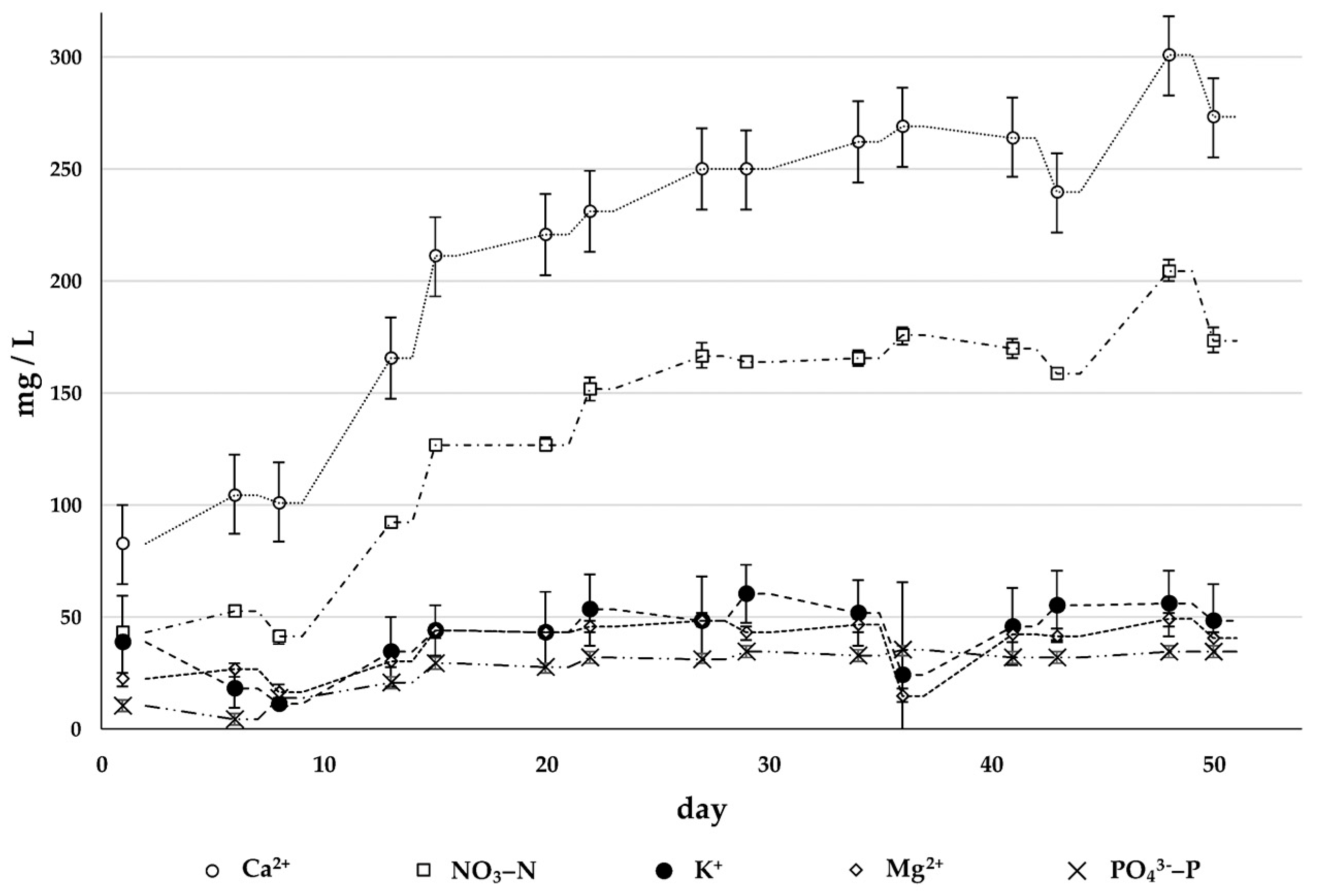

3.3. Physico-Chemical Parameters

4. Discussion

4.1. Fish Growth

4.2. Physico-Chemical Parameters in the Hydroponic Components and Sump

4.3. Plant Growth Parameters

4.3.1. Plant Height Development

4.3.2. Plant Biomass Development

4.3.3. Plant Root Development

4.3.4. Leaf Development

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Palm, H.W.; Knaus, U.; Appelbaum, S.; Goddek, S.; Strauch, S.M.; Vermeulen, T.; Jijakli, M.H.; Kotzen, B. Towards commercial aquaponics: A review of systems, designs, scales and nomenclature. Aquac. Int. 2018, 26, 813–842. [Google Scholar] [CrossRef]

- Thorarinsdottir, R.; Kledal, P.R.; Skar, S.L.G.; Sustaeta, F.; Ragnarsdottir, K.V.; Mankasingh, U.; Pantanella, E.; van de Ven, R.; Shultz, R.C. Aquaponics Guidelines. 2015; 64p. Available online: https://skemman.is/handle/1946/23343?locale=en (accessed on 12 November 2021).

- Maucieri, C.; Nicoletto, C.; Junge, R.; Schmautz, Z.; Sambo, P.; Borin, M. Hydroponic systems and water management in aquaponics: A review. Ital. J. Agron. 2018, 11. [Google Scholar] [CrossRef] [Green Version]

- Kloas, W.; Groß, R.; Baganz, D.; Graupner, J.; Monsees, H.; Schmidt, U.; Staaks, G.; Suhl, J.; Tschirner, M.; Wittstock, B.; et al. A new concept for aquaponic systems to improve sustainability, increase productivity, and reduce environmental impacts. Aquac. Environ. Interact. 2015, 7, 179–192. [Google Scholar] [CrossRef] [Green Version]

- Castillo-Castellanos, D.; Zavala-Leal, I.; Ruiz-Velazco, J.M.; Radilla-García, A.; Nieto-Navarro, J.T.; Romero-Bañuelos, C.A.; González-Hernández, J. Implementation of an experimental nutrient film technique-type aquaponic system. Aquac. Int. 2016, 24, 637–646. [Google Scholar] [CrossRef]

- Knaus, U.; Pribbernow, M.; Xu, L.; Appelbaum, S.; Palm, H.W. Basil (Ocimum basilicum) Cultivation in Decoupled Aquaponics with Three Hydro-Components (Grow Pipes, Raft, Gravel) and African Catfish (Clarias gariepinus) Production in Northern Germany. Sustainability 2020, 12, 8745. [Google Scholar] [CrossRef]

- Pasch, J.; Ratajczak, B.; Appelbaum, S.; Palm, H.W.; Knaus, U. Growth of Basil (Ocimum basilicum) in DRF, Raft, and Grow Pipes with Effluents of African Catfish (Clarias gariepinus) in Decoupled Aquaponics. AgriEngineering 2021, 3, 92–109. [Google Scholar] [CrossRef]

- Pasch, J.; Appelbaum, S.; Palm, H.W.; Knaus, U. Growth of Basil (Ocimum basilicum) in Aeroponics, DRF, and Raft Systems with Effluents of African Catfish (Clarias gariepinus) in Decoupled Aquaponics (s.s.). AgriEngineering 2021, 3, 559–574. [Google Scholar] [CrossRef]

- Love, D.C.; Fry, J.P.; Li, X.; Hill, E.S.; Genello, L.; Semmens, K.; Thompson, R.E. Commercial aquaponics production and profitability: Findings from an international survey. Aquaculture 2015, 435, 67–74. [Google Scholar] [CrossRef] [Green Version]

- Tridge Overview of Mint Imports to Germany. 2021. Available online: https://www.tridge.com/intelligences/mint/DE (accessed on 16 July 2021).

- CBI—The European Market Potential for Fresh Herbs. 2021. Available online: https://www.cbi.eu/market-information/fresh-fruit-vegetables/fresh-herbs/market-potential (accessed on 16 July 2021).

- Espinosa Moya, E.A.; Angel Sahagún, C.A.; Mendoza Carrillo, J.M.; Albertos Alpuche, P.J.; Álvarez-González, C.A.; Martínez-Yáñez, R. Herbaceous plants as part of biological filter for aquaponics system. Aquac. Res. 2016, 47, 1716–1726. [Google Scholar] [CrossRef]

- Kotzen, B.; Appelbaum, S. An Investigation of Aquaponics Using Brackish Water Resources in the Negev Desert. J. Appl. Aquac. 2010, 22, 297–320. [Google Scholar] [CrossRef]

- Knaus, U.; Wenzel, L.; Appelbaum, S.; Palm, H.W. Aquaponics (s.l.) Production of Spearmint (Mentha spicata) with African Catfish (Clarias gariepinus) in Northern Germany. Sustainability 2020, 12, 8717. [Google Scholar] [CrossRef]

- Shete, A.; Verma, A.; Chadha, N.K.; Prakash, C.; Chandrakant, M.; Nuwansi, K.K.T. Evaluation of different hydroponic media for mint (Mentha arvensis) with common carp (Cyprinus carpio) juveniles in an aquaponic system. Aquac. Int. 2017, 25, 1291–1301. [Google Scholar] [CrossRef]

- Somerville, C.; Cohen, M.; Pantanella, E.; Stankus, A.; Lovatelli, A. Small-Scale Aquaponic Food Production. Integrated Fish and Plant Farming; FAO Fisheries and Aquaculture Technical Paper No. 589; FAO: Rome, Italy, 2014; p. 262. [Google Scholar]

- Brämick, U. Jahresbericht zur Deutschen Binnenfischerei 2009. Available online: https://www.bmel-statistik.de/ernaehrung-fischerei/fischerei/aquakultur/ (accessed on 16 July 2021). (In German).

- Brämick, U. Jahresbericht zur Deutschen Binnenfischerei und Binnenaquakultur 2019. Available online: https://www.bmel-statistik.de/ernaehrung-fischerei/fischerei/aquakultur/ (accessed on 16 July 2021). (In German).

- Pantanella, E. Aquaponics and Sustainability: Production, Quality and Nutrient Efficiency in Sweet Basil and African Catfish. Ph.D. Thesis, Università degli Studi della Tuscia, Viterbo, Italy, 2012; pp. 55–77. [Google Scholar]

- Palm, H.W.; Bissa, K.; Knaus, U. Significant factors affecting the economic sustainability of closed aquaponic systems, Part II: Fish and plant growth. AACL Bioflux 2014, 7, 162–175. [Google Scholar]

- Dudley, D.H. Aquaponic Design Plans and Everything You Need to Know, 2nd ed.; Howard Publishing: Brentwood, TN, USA, 2018; 630p. [Google Scholar]

- Ahmad-Qasem, M.H.; Cánovas, J.; Barrajón-Catalán, E.; Micol, V.; Carcel, J.A.; Garcia-Perez, J.V. Kinetic and compositional study of phenolic extraction from olive leaves (var. Serrana) by using power ultrasound. Innov. Food Sci. Emerg. Technol. 2013, 17, 120–129. [Google Scholar] [CrossRef]

- IBM Deutschland GmbH. IBM SPSS Statistics for Windows; Version 27; IBM Deutschland GmbH: Ehningen, Germany, 2011. [Google Scholar]

- Microsoft® Corporation. Microsoft Excel®; Microsoft® Corporation: Redmond, WA, USA, 2010. [Google Scholar]

- Huisman, E.; Richter, C. Reproduction, growth, health control and aquacultural potential of the African catfish, Clarias gariepinus (Burchell 1822). Aquaculture 1987, 63, 1–14. [Google Scholar] [CrossRef]

- Palm, H.W.; Knaus, U.; Wasenitz, B.; Bischoff, A.; Strauch, S. Proportional up scaling of African catfish (Clarias gariepinus Burchell, 1822) commercial recirculating aquaculture systems disproportionally affects nutrient dynamics. Aquaculture 2018, 491, 155–168. [Google Scholar] [CrossRef]

- Akinwole, A.; Faturoti, E. Biological performance of African Catfish (Clarias gariepinus) cultured in recirculating system in Ibadan. Aquac. Eng. 2007, 36, 18–23. [Google Scholar] [CrossRef]

- Hogendoorn, H.; Jansen, J.; Koops, W.; Machiels, M.; Van Ewijk, P.; Van Hees, J. Growth and production of the African catfish, Clarias lazera (C. & V.): II. Effects of body weight, temperature and feeding level in intensive tank culture. Aquaculture 1983, 34, 265–285. [Google Scholar] [CrossRef]

- Henken, A.; Boon, J.; Cattel, B.; Lobée, H. Differences in growth rate and feed utilization between male and female African catfish, Clarias gariepinus (Burchell 1822). Aquaculture 1987, 63, 221–232. [Google Scholar] [CrossRef]

- Van de Nieuwegiessen, P.G.; Olwo, J.; Khong, S.; Verreth, J.; Schrama, J. Effects of age and stocking density on the welfare of African catfish, Clarias gariepinus Burchell. Aquaculture 2009, 288, 69–75. [Google Scholar] [CrossRef]

- Taneja, S.; Chandra, S. Mint. In Handbook of Herbs and Spices; Woodhead Publishing Ltd.: Cambridge, UK, 2012; pp. 366–387. [Google Scholar] [CrossRef]

- Government of Ontario—Mint. 2021. Available online: http://www.omafra.gov.on.ca/CropOp/en/herbs/culinary/mint.html# (accessed on 4 August 2021).

- Vimolmangkang, S.; Sitthithaworn, W.; Vannavanich, D.; Keattikunpairoj, S.; Chittasupho, C. Productivity and quality of volatile oil extracted from Mentha spicata and M. arvensis var. piperascens grown by a hydroponic system using the deep flow technique. J. Nat. Med. 2010, 64, 31–35. [Google Scholar] [CrossRef]

- Sabzalian, M.R.; Heydarizadeh, P.; Zahedi, M.; Boroomand, A.; Agharokh, M.; Sahba, M.R.; Schoefs, B. High performance of vegetables, flowers, and medicinal plants in a red-blue LED incubator for indoor plant production. Agron. Sustain. Dev. 2014, 34, 879–886. [Google Scholar] [CrossRef] [Green Version]

- Delfine, S.; Loreto, F.; Pinelli, P.; Tognetti, R.; Alvino, A. Isoprenoids content and photosynthetic limitations in rosemary and spearmint plants under water stress. Agric. Ecosyst. Environ. 2005, 106, 243–252. [Google Scholar] [CrossRef]

- Lawrence, B.M. Mint: The Genus Mentha. Medicinal and Aromatic Plants—Industrial Profiles; CRC Press/Taylor & Francis Group: Boca Raton, FL, USA, 2007; p. 547. [Google Scholar]

- Akoumianaki-Ioannidou, A.; Rasouli, M.; Podaropoulou, L.; Karapanos, I.; Bilalis, D. Effects of Cultivation System and Fertilization on Seedling Production of Ocimum basilicum L. and Mentha spicata L. Not. Bot. Horti Agrobot. Cluj-Napoca 2015, 43, 131–137. [Google Scholar] [CrossRef] [Green Version]

- Treadwell, D.; Hochmuth, G.; Hochmuth, R.; Simonne, E.; Sargent, S.; Davis, L.; Laughlin, W.; Berry, A. Organic Fertilization Programs for Greenhouse Fresh-cut Basil and Spearmint in a Soilless Media Trough System. HortTechnology 2011, 21, 162–169. [Google Scholar] [CrossRef]

- Hepler, P.K. Calcium: A Central Regulator of Plant Growth and Development. Plant Cell 2005, 17, 2142–2155. [Google Scholar] [CrossRef] [PubMed]

- Kirkby, E.A.; Pilbeam, D.J. Calcium as a plant nutrient. Plant Cell Environ. 1984, 7, 397–405. [Google Scholar] [CrossRef]

- Junge, R.; Antenen, N.; Villarroel, M.; Griessler Bulc, T.; Ovca, A.; Milliken, S. Aquaponics Textbook for Higher Education. AQU@TEACH, Erasmus+ 2020. Zenodo, 2020; 340p. Available online: https://zenodo.org/record/3948179 (accessed on 12 November 2021). [CrossRef]

- Bittsanszky, A.; Uzinger, N.; Gyulai, G.; Mathis, A.; Junge, R.; Villarroel, M.; Kotzen, B.; Komives, T. Nutrient supply of plants in aquaponic systems. Ecocycles 2016, 2, 17–20. [Google Scholar] [CrossRef] [Green Version]

- Choudhury, R.P.; Kumar, A.; Garg, A. Analysis of Indian mint (Mentha spicata) for essential, trace and toxic elements and its antioxidant behaviour. J. Pharm. Biomed. Anal. 2006, 41, 825–832. [Google Scholar] [CrossRef]

- Kizil, S.; Toncer, O. Influence of different harvest times on the yield and oil composition of spearmint (Mentha spicata L. var. spicata). J. Food Agric. Environ. 2006, 3&4, 135–137. [Google Scholar] [CrossRef]

- Zeinali, H.; Arzani, A.; Razmjo, K. Morphological and essential oil content diversity of Iranian mints (Mentha spp.). Iran. J. Sci. Technol. Trans. 2004, 28, 1–9. [Google Scholar] [CrossRef]

- Surendran, U.; Chandran, C.; Joseph, E.J. Hydroponic cultivation of Mentha spicata and comparison of biochemical and antioxidant activities with soil-grown plants. Acta Physiol. Plant. 2017, 39, 26. [Google Scholar] [CrossRef]

- Espinosa-Moya, A.; Alvarez-Gonzalez, A.; Albertos-Alpuche, P.; Guzman-Mendoza, R.; Martínez-Yáñez, R. Growth and development of herbaceous plants in aquaponic systems. Acta Univ. 2018, 28, 1–8. [Google Scholar] [CrossRef]

- Resh, H.M. Hydroponic Food Production: A Definitive Guidebook for the Advanced Home Gardener and the Commercial Hydroponic Grower, 7th ed.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2012; 560p, Available online: https://www.taylorfrancis.com/books/mono/10.1201/b12500/hydroponic-food-production-howard-resh (accessed on 28 November 2021).

- Pascual, M.P.; Lorenzo, G.A.; Gabriel, A. Vertical Farming Using Hydroponic System: Toward a Sustainable Onion Production in Nueva Ecija, Philippines. Open J. Ecol. 2018, 8, 25–41. [Google Scholar] [CrossRef] [Green Version]

- Krishan, K.; Agrawal, E.R.; Tripathi, M.P.; Yadav, U. Fabrication and performance evaluation of a shaped frame hydroponic system for leafy garlic. J. Pharmacogn. Phytochem. 2020, 9, 688–692. [Google Scholar] [CrossRef]

- Zade, N.S.E.; Sadeghi, A.; Moradi, P. Streptomyces strains alleviate water stress and increase peppermint (Mentha piperita) yield and essential oils. Plant Soil 2019, 434, 441–452. [Google Scholar] [CrossRef]

- Chrysargyris, A.; Nikolaidou, E.; Stamatakis, A.; Tzortzakis, N. Vegetative, physiological, nutritional and antioxidant behavior of spearmint (Mentha spicata L.) in response to different nitrogen supply in hydroponics. J. Appl. Res. Med. Arom. Plants 2017, 6, 52–61. [Google Scholar] [CrossRef]

- Khorasaninejad, S.; Mousavi, A.; Soltanloo, H.; Hemmati, K.; Khalighi, A. The effect of salinity stress on growth parameters, essential oil yield and constituent of peppermint (Mentha piperita L.). World Appl. Sci. J. 2010, 11, 1403–1407. [Google Scholar]

- Chand, S.; Pandey, A.; Patra, D.D. Influence of nickel and lead applied in combination with vermicompost on growth and accumulation of heavy metals by Mentha arvensis Linn. cv. ‘Kosi’. IJNPR 2012, 3, 256–261. [Google Scholar]

- Hübner, H.-D.D. Einfluss von Biohumin® auf das Wachstum der Marokkanischen Minze (Mentha spicata L.) und Basilikum (Ocimum basilicum L.) unter extensiver und intensiver aquaponischer Produktion des Afrikanischen Raubwelses Clarias gariepinus (Burchell, 1822). Master’s Thesis, University of Rostock, Rostock, Germany, 2018; 106p. (In German). [Google Scholar]

- Robinson, D. The responses of plants to non-uniform supplies of nutrients. New Phytol. 1994, 127, 635–674. [Google Scholar] [CrossRef]

- Wilson, J.B. A Review of Evidence on the Control of Shoot: Root Ratio, in Relation to Models. Ann. Bot. 1988, 61, 433–449. [Google Scholar] [CrossRef]

- Franco, J.A.; Bañón, S.; Vicente, M.J.; Miralles, J.; Martínez-Sánchez, J.J. Review Article:Root development in horticultural plants grown under abiotic stress conditions—A review. J. Hortic. Sci. Biotechnol. 2011, 86, 543–556. [Google Scholar] [CrossRef]

- Nozzi, V.; Graber, A.; Schmautz, Z.; Mathis, A.; Junge, R. Nutrient Management in Aquaponics: Comparison of Three Approaches for Cultivating Lettuce, Mint and Mushroom Herb. Agronomy 2018, 8, 27. [Google Scholar] [CrossRef] [Green Version]

- Poorter, H.; Nagel, O. The role of biomass allocation in the growth response of plants to different levels of light, CO2, nutrients and water: A quantitative review. Aust. J. Plant Physiol. 2000, 27, 595–607. [Google Scholar]

- Küchenmeister, C. Vergleich von Pflanzenwachstums- und Qualitätsparametern bei Marokkanischer Minze (Mentha spicata, L.) und Basilikum (Ocimum basilicum, L.) unter extensiver und intensiver aquaponischer Produktion des Afrikanischen Raubwelses Clarias gariepinus (Burchell, 1822). Master’s Thesis, University of Rostock, Rostock, Germany, 2018; 91p. (In German). [Google Scholar]

- Khorasaninejad, S.; Mousavi, A.; Soltanloo, H.; Hemmati, K.; Khalighi, A. The effect of drought stress on growth parameters, essential oil yield and constituent of Peppermint (Mentha piperita L.). J. Med. Plants Res. 2011, 5, 5360–5365. [Google Scholar] [CrossRef]

- Janpen, C.; Kanthawang, N.; Inkham, C.; Tsan, F.Y.; Sommano, S.R. Physiological responses of hydroponically-grown Japanese mint under nutrient deficiency. PeerJ. 2019, 7, e7751. [Google Scholar] [CrossRef]

- Kafkafi, U. Chapter 2: Funtions of the root system. In Soilless Culture: Theory and Practice; Raviv, M., Lieth, J.H., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2008; pp. 13–40. Available online: https://www.sciencedirect.com/science/article/pii/B9780444529756500046 (accessed on 28 November 2021).

- Yep, B.; Zheng, Y. Aquaponic trends and challenges—A review. J. Clean. Prod. 2019, 228, 1586–1599. [Google Scholar] [CrossRef]

- Vermeulen, T.; Kamstra, A. The need for systems design for robust aquaponic systems in the urban environment. Acta Hortic. 2013, 1004, 71–77. [Google Scholar] [CrossRef] [Green Version]

- Pattillo, D.A. An Overview of Aquaponic Systems: Hydroponic Components; NCRAC Technical Bulletins; 2017; 19p. Available online: https://lib.dr.iastate.edu/ncrac_techbulletins/19 (accessed on 28 November 2021).

- Rakocy, J.E.; Masser, M.P.; Losordo, T.M. Recirculating Aquaculture Tank Production Systems: Aquaponics—Integrating Fish and Plant Culture; Southern Regional Aquaculture Center Publ. No. 454; United States Department of Agriculture, Cooperative State Research, Education, and Extension Service: Stoneville, MS, USA, 2006; 16p, Available online: https://srac.tamu.edu/categories/view/24 (accessed on 28 November 2021).

- Van Os, E.; Gieling, T.H.; Lieth, J.H. Chapter 13: Technical Equipment in Soilless Production Systems. In Soilless Culture: Theory and Practice, 2nd ed.; Raviv, M., Lieth, J.H., Bar-Tal, A., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2019; pp. 587–635. [Google Scholar] [CrossRef]

- Tisserat, B.; Vaughn, S.F. Growth, morphogenesis, and essential oil production in Mentha spicata L. plantlets in vitro. In Vitro Cell. Dev. Biol.-Anim. 2008, 44, 40–50. [Google Scholar] [CrossRef]

- Ju, J.-H.; Yoon, Y.-H.; Ju, S.-Y. Influence of Substrates and Hydrogels on Spearmint (Mentha spicata) Growth and Flowering in a Rooftop Garden. HortScience 2021, 56, 629–633. [Google Scholar] [CrossRef]

- Jiang, C.; Johkan, M.; Hohjo, M.; Tsukagoshi, S.; Maturo, T. A correlation analysis on chlorophyll content and SPAD value in tomato leaves. Hort. Res. 2017, 71, 37–42. [Google Scholar] [CrossRef]

- Islam, M.R.; Haque, K.S.; Akter, N.; Karim, M.A. Leaf chlorophyll dynamics in wheat based on SPAD meter reading and its relationship with grain yield. J. Sci. Agric. 2014, 8, 13–18. [Google Scholar] [CrossRef]

| Parameters | Weight Class I | Weight Class II | Weight Class III | p-I 1 | p-II 1 | p-III 1 |

|---|---|---|---|---|---|---|

| Fish initial weight (kg) | 0.21 ± 0.03 c | 0.56 ± 0.12 b | 1.36 ± 0.49 a | 0.001 | 0.001 | 0.003 |

| Fish initial length (cm) | 31.24 ± 1.59 c | 43.63 ± 3.18 b | 55.40 ± 5.41 a | 0.001 | 0.001 | 0.001 |

| Fish final weight (kg) | 0.51 ± 0.08 c | 1.16 ± 0.45 b | 1.92 ± 0.53 a | 0.006 | 0.001 | 0.015 |

| Fish final length (cm) | 42.16 ± 2.35 b | 55.38 ± 6.73 a | 63.31 ± 6.15 a | 0.015 | 0.001 | 0.326 |

| Tank initial biomass weight (kg) | 29.34 ± 0.53 c | 88.18 ± 0.56 b | 152.59 ± 1.89 a | 0.001 | 0.001 | 0.001 |

| Tank final biomass weight (kg) | 56.28 ± 3.12 c | 123.71 ± 2.66 b | 173.16 ± 8.33 a | 0.001 | 0.001 | 0.001 |

| Tank biomass weight gain (kg) | 26.94 ± 3.65 a,b | 35.53 ± 3.20 a | 20.58 ± 6.84 b | 0.155 | 0.313 | 0.021 |

| Initial feed per tank (g) | 416.67 ± 15.28 c | 783.33 ± 5.77 b | 953.33 ± 11.55 a | 0.001 | 0.001 | 0.001 |

| Initial feed (%) biomass | 1.42 ± 0.06 a | 0.89 ± 0.01 b | 0.62 ± 0.01 c | 0.008 | 0.004 | 0.001 |

| Final feed per tank (g) | 620.00 ± 17.32 c | 953.33 ± 15.28 b | 1053.33 ± 11.55 a | 0.031 | 0.005 | 0.022 |

| Final feed (%) biomass | 1.10 ± 0.07 a | 0.77 ± 0.01 b | 0.61 ± 0.03 c | 0.031 | 0.005 | 0.022 |

| Feed per tank (kg) | 25.87 ± 0.83 c | 43.64 ± 0.54 b | 50.45 ± 0.57 a | 0.001 | 0.001 | 0.001 |

| FCR | 0.97 ± 0.15 b | 1.23 ± 0.10 a,b | 2.69 ± 1.09 a | 0.873 | 0.037 | 0.069 |

| SGR (%/d) | 1.20 ± 0.14 a | 0.63 ± 0.05 b | 0.23 ± 0.07 c | 0.001 | 0.001 | 0.005 |

| Condition factor (CF) | 0.67 ± 0.04 b | 0.65 ± 0.05 b | 0.74 ± 0.07 a | 0.697 | 0.042 | 0.007 |

| Parameter | Gravel | Raft | Grow Pipes | p-I 1 | p-II 1 | p-III 1 |

|---|---|---|---|---|---|---|

| Plant height (cm) 2 | 57.7 ± 13.1 a | 58.0 ± 17.7 a | 63.6 ± 9.9 a | 0.464 | 0.464 | 0.464 |

| Shoot length (cm) 3 | 60.9 ± 16.3 a | 63.0 ± 19.7 a | 68.9 ± 11.4 a | 0.423 | 0.423 | 0.423 |

| Root length (cm) 3 | 29.7 ± 7.8 b | 64.3 ± 20.5 a | 59.4 ± 15.2 a | 0.001 | 0.001 | 1.000 |

| Total plant height (cm) 3 | 90.6 ± 21.9 b | 127.3 ± 30.4 a | 127.7 ± 20.6 a | 0.001 | 0.001 | 0.999 |

| Shoot fresh weight (g) 3 | 99.0 ± 75.4 a | 139.5 ± 95.7 a | 128.0 ± 46.6 a | 0.367 | 0.396 | 0.946 |

| Root fresh weight (g) 3 | 9.4 ± 9.4 b | 42.8 ± 29.9 a | 41.3 ± 25.7 a | 0.001 | 0.001 | 1.000 |

| Total plant fresh weight (g) 3 | 108.4 ± 83.4 b | 182.2 ± 121.7 a,b | 169.3 ± 62.6 a | 0.087 | 0.041 | 0.962 |

| Shoot/root ratio (S:R) | 2.1 ± 0.5 a | 1.1 ± 0.8 b | 1.2 ± 0.4 b | 0.001 | 0.001 | 0.953 |

| Leaf number (No) | 499.8 ± 228.4 b | 610.5 ± 371.5 a,b | 770.0 ± 224.4 a | 0.587 | 0.002 | 0.270 |

| SPAD (%) | 31.2 ± 5.6 a | 28.4 ± 6.3 a | 29.7 ± 4.8 a | 0.134 | 0.134 | 0.134 |

| Mean biomass per hydroponic component 4 | ||||||

| Fresh biomass (g) | 686.3 ± 98.2 c | 1275.6 ± 33.4 a | 1042.0 ± 35.8 b | 0.001 | 0.005 | 0.029 |

| Dry biomass (g) | 65.7 ± 15.9 b | 102.2 ± 6.1 a | 113.5 ± 12.0 a | 0.023 | 0.007 | 0.520 |

| Root fresh weight (g) | 59.4 ± 2.0 b | 299.4 ± 57.3 a | 257.5 ± 4.7 a | 0.001 | 0.004 | 0.471 |

| Root dry weight (g) | 6.0 ± 0.8 b | 18.5 ± 2.6 a | 21.0 ± 3.0 a | 0.002 | 0.001 | 0.450 |

| Total biomass of hydroponic components 5 | ||||||

| Fresh biomass (g) | 2058.8 | 3826.7 | 3555.7 | - | - | - |

| Dry biomass (g) | 197.0 | 306.5 | 340.5 | - | - | - |

| Root fresh biomass (g) | 178.3 | 898.3 | 866.5 | - | - | - |

| Root dry biomass (g) | 18.1 | 55.6 | 63.1 | - | - | - |

| Parameter | Gravel | Raft | Grow Pipes | p-I 1 | p-II 1 | p-III 1 |

|---|---|---|---|---|---|---|

| DO (mg/L) | 7.6 ± 0.5 b | 8.1 ± 0.2 a | 8.1 ± 0.2 a | 0.001 | 0.001 | 0.834 |

| OS (%) | 90.5 ± 5.8 b | 97.2 ± 1.1 a | 96.6 ± 1.7 a | 0.001 | 0.001 | 0.818 |

| T (°C) | 23.2 ± 1.9 a | 23.2 ± 2.0 a | 23.3 ± 2.0 a | 0.834 | 0.834 | 0.834 |

| PPFD (µmol/m2 s) | 204.5 ± 154.6 a | 236.3 ± 210.5 a | 204.6 ± 141.9 a | 0.068 | 0.068 | 0.068 |

| Light intensity × 100 (lx) | 111.4 ± 93.7 a | 119.3 ± 102.4 a | 115.5 ± 81.7 a | 0.100 | 0.100 | 0.100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Knaus, U.; Zimmermann, J.; Appelbaum, S.; Palm, H.W. Spearmint (Mentha spicata) Cultivation in Decoupled Aquaponics with Three Hydro-Components (Grow Pipes, Raft, Gravel) and African Catfish (Clarias gariepinus) Production in Northern Germany. Sustainability 2022, 14, 305. https://doi.org/10.3390/su14010305

Knaus U, Zimmermann J, Appelbaum S, Palm HW. Spearmint (Mentha spicata) Cultivation in Decoupled Aquaponics with Three Hydro-Components (Grow Pipes, Raft, Gravel) and African Catfish (Clarias gariepinus) Production in Northern Germany. Sustainability. 2022; 14(1):305. https://doi.org/10.3390/su14010305

Chicago/Turabian StyleKnaus, Ulrich, Julia Zimmermann, Samuel Appelbaum, and Harry W. Palm. 2022. "Spearmint (Mentha spicata) Cultivation in Decoupled Aquaponics with Three Hydro-Components (Grow Pipes, Raft, Gravel) and African Catfish (Clarias gariepinus) Production in Northern Germany" Sustainability 14, no. 1: 305. https://doi.org/10.3390/su14010305

APA StyleKnaus, U., Zimmermann, J., Appelbaum, S., & Palm, H. W. (2022). Spearmint (Mentha spicata) Cultivation in Decoupled Aquaponics with Three Hydro-Components (Grow Pipes, Raft, Gravel) and African Catfish (Clarias gariepinus) Production in Northern Germany. Sustainability, 14(1), 305. https://doi.org/10.3390/su14010305