Innovative Formulation Strategies for Biosimilars: Trends Focused on Buffer-Free Systems, Safety, Regulatory Alignment, and Intellectual Property Challenges

Abstract

1. Introduction

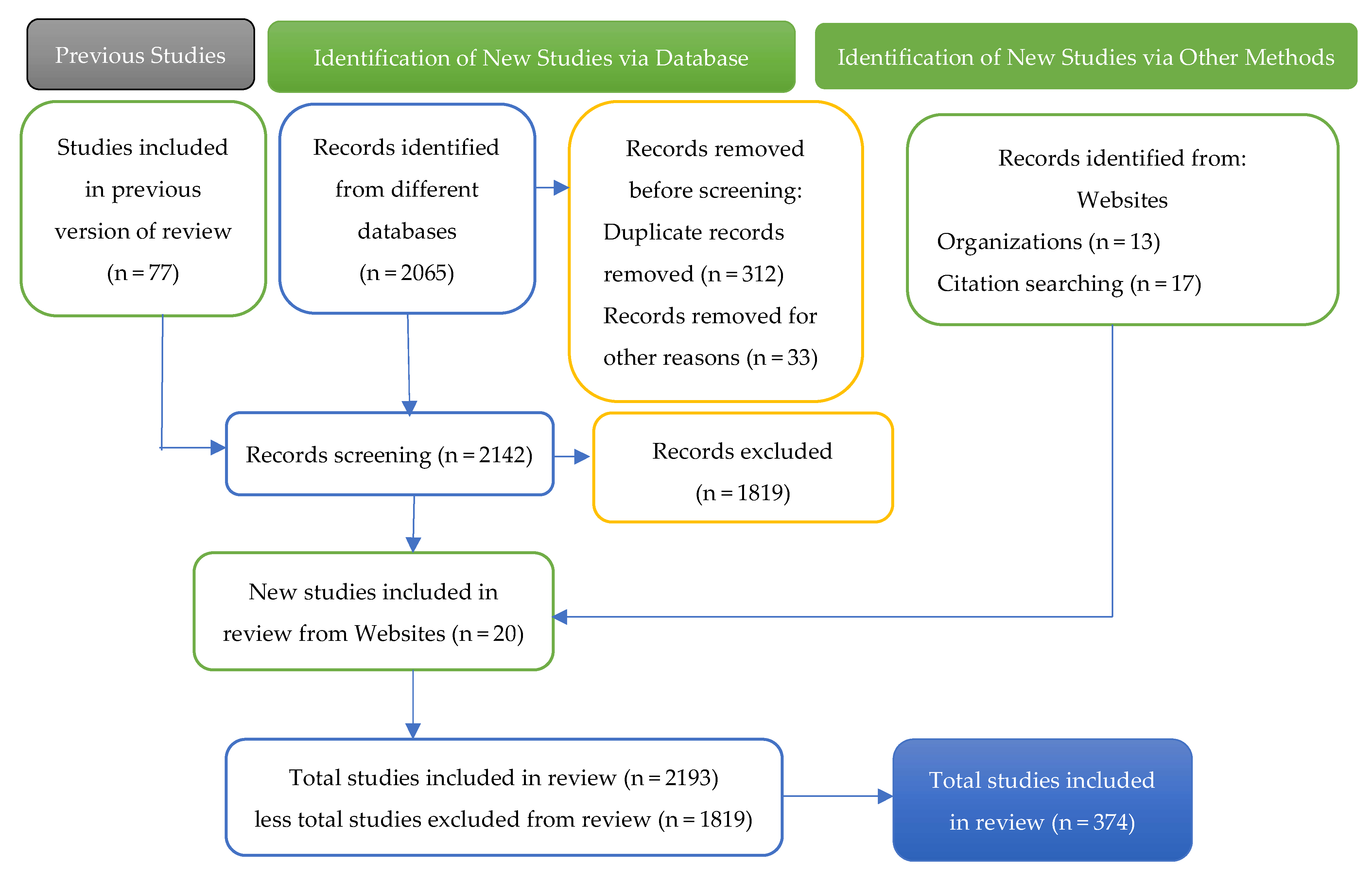

2. Methodology

Keywords and Document Identification Process

3. Design, Manufacturing, and Analytical Characterization of Biosimilars

3.1. Analytical Characterization and Processing Strategies of Biosimilars

- Differences in expression systems (e.g., CHO vs. HEK293);

- Cell culture conditions, including pH, oxygen, and nutrients;

- Bioprocessing variables, such as purification methods or buffer composition.

3.2. Different Strategies and Processing Advances in the Manufacture of Biosimilars

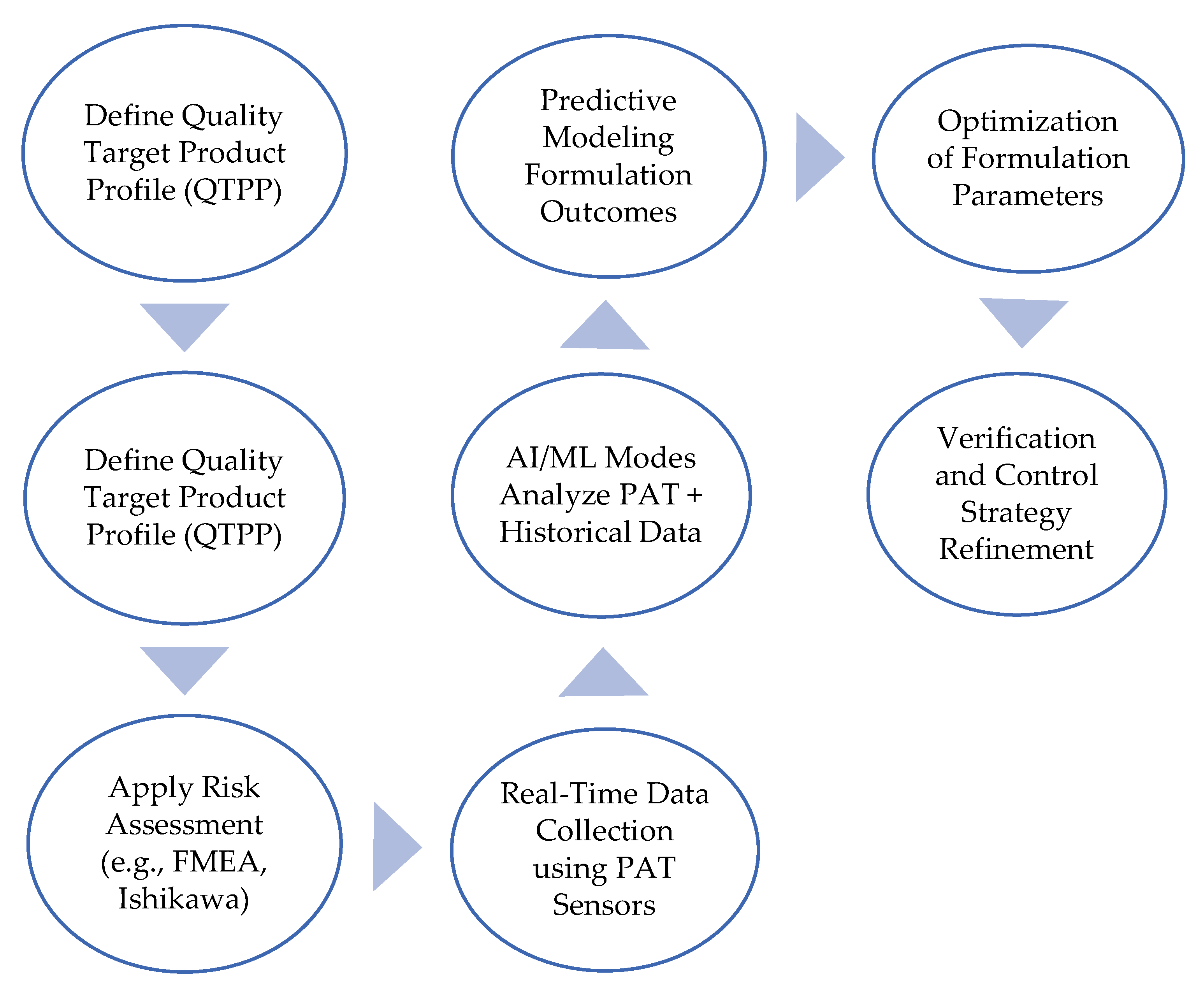

3.3. Integrating AI and Machine Learning into the Biosimilar Development Process

3.4. Innovations in the Field of Bioprocessing

4. Biosimilar Formulations Based on Monoclonal Antibodies and Recombinant Proteins

Dissemination of Novel Ormulations

- Lipid encapsulation: This technology is being explored to improve the bioavailability and stability of therapeutic proteins, particularly in liquid formulations [176].

- Advances in nanotechnology: The use of nanocarriers offers promising strategies to deliver biologics while minimizing immunogenic responses and improving therapeutic effects through targeted delivery systems [179].

5. Advances in Biosimilar Formulation Technologies (Buffer-Free Strategies) and Excipients

5.1. Formulation and Selection of Excipients

5.2. Buffer-Free High-Concentration Formulations and the Role of Excipients in Immunogenicity Mitigation

5.3. Trends in Change: Buffer-Free Formulations

5.4. Classification and Safety Profiles of Approved Biosimilar Formulations

5.5. Formulation Trends and Considerations on Stability, Bioavailability, and Immunogenicity

6. Importance of the FDA and EMA Regulatory Frameworks in the Development of Biosimilars

6.1. FDA and EMA Regulatory Approach to Biosimilars

6.2. ICH-Guided Analytical Characterization in Biosimilar Development

7. IP Challenges Associated with the Development of Biosimilar Formulations

8. Discussion

8.1. Innovation in Formulation and Patient-Centered Strategies

8.2. Analytical and Manufacturing Advances

8.3. Regulatory Evolution and Market Access

8.4. Intellectual Property and Strategic Development

8.5. Clinical and Psychosocial Considerations

8.6. The Role of Digital Tools and Predictive Modeling

9. Conclusions

Future Research Directions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Aspect | Description | The Last Insinuations | Challenges | Refserences |

|---|---|---|---|---|

| Design and formulation of strategies | Molecular design and formulation optimization replicate the stability, efficacy, and immunogenicity of reference biologics through molecular engineering, innovative excipients, and stability enhancements. |

|

| [2,148,209,353,354,355] |

| Cell line and upstream engineering | Development and optimization of cell lines to ensure high similarity with the attributes of the reference product. Production of recombinant proteins using systems such as CHO cells, crucial for protein structure and PTMs. |

|

| [356,357,358,359,360,361] |

| Improvement processes and PAT | Protein purification and recovery that ensures removal of impurities, integrity of protein folding/refolding, and consistency of the product. Real-time monitoring/control through PAT, ensuring QbD. |

|

| [53,57,361,362,363] |

| Analytical Characterization and Bioassays | Structural and functional evaluation using orthogonal methods to establish biosimilarity throughout the body of evidence. |

|

| [37,188,364,365,366,367,368,369] |

| Regulations and Harmonization | Regulatory evaluations that ensure the safety, efficacy, and quality of biosimilars through comparability studies, ensuring that biosimilars comply with the strict FDA/EMA regulatory frameworks. |

|

| [5,37,168,273,370,371] |

| IP, Innovation Strategy, and Market Access | Patents related to formulation, manufacturing, and analytical techniques that affect market entry and competitiveness. |

|

| [371,372,373] |

| Integration of Digital Tools and AI | Application of digital platforms, AI, and simulations to optimize biosimilar development. |

|

| [374,375] |

References

- Bas, T.G. Biosimilars for the next decade in Latin America: A window of opportunity. Expert Opin. Biol. Ther. 2023, 23, 659–669. [Google Scholar] [CrossRef] [PubMed]

- Bas, T.G.; Duarte, V. Biosimilars in the Era of Artificial Intelligence: International Regulations and the Use in Oncological Treatments. Pharmaceuticals 2024, 17, 925. [Google Scholar] [CrossRef] [PubMed]

- Mascarenhas-Melo, F.; Diaz, M.; Gonçalves, M.B.S.; Vieira, P.; Bell, V.; Viana, S.; Nunes, S.; Paiva-Santos, A.C.; Veiga, F. An overview of biosimilars—Development, quality, regulatory issues, and management in healthcare. Pharmaceuticals 2024, 17, 235. [Google Scholar] [CrossRef] [PubMed]

- Raposo, M.C.; Feiteira, C.; Ribeiro, M.H. Regulatory and clinical aspects in biosimilar medicines: Comparability, extrapolation, interchangeability, and safety. Drugs Ther. Perspect. 2025, 41, 111–125. [Google Scholar] [CrossRef]

- Gaylis, N.; Both, C.; Lemke, L.; Richter, O.; Yamauchi, P. ‘Totality of evidence’ approach in the development of GP2017, an approved adalimumab biosimilar. Adv. Ther. 2024, 41, 1795–1814. [Google Scholar] [CrossRef]

- Heinemann, L.; Davies, M.J.; Home, P.; Först, T.; Vilsbøll, T.; Schnell, O. Understanding biosimilar insulins—Development, manufacturing, and clinical trials. J. Diabetes Sci. Technol. 2022, 17, 1649–1661. [Google Scholar] [CrossRef]

- Sarin, D.; Krishna, K.; Nejadnik, M.; Suryanarayanan, R.; Rathore, A. Impact of excipient extraction and buffer exchange on recombinant monoclonal antibody stability. Mol. Pharm. 2024, 21, 1872–1883. [Google Scholar] [CrossRef]

- García-Beloso, N.; Altabás-González, I.; Samartín-Ucha, M.; Gayoso-Rey, M.; Castro-Parga, M.; Salgado-Barreira, Á.; Barreira, Á.S.; Badia, A.C.; Corrales, M.G.P.; Vilas, D.G.; et al. Switching between reference adalimumab and biosimilars in chronic immune-mediated inflammatory diseases: A systematic literature review. Br. J. Clin. Pharmacol. 2021, 88, 1529–1550. [Google Scholar] [CrossRef]

- Germain, M.; Caputo, F.; Metcalfe, S.; Tosi, G.; Spring, K.; Åslund, A.; Pottier, A.; Schiffelers, R.; Ceccaldi, A.; Schmid, R. Delivering the power of nanomedicine to patients today. J. Control. Release 2020, 326, 164–171. [Google Scholar] [CrossRef]

- Vulto, A.G.; Jaquez, O. The process defines the product: What really matters in biosimilar design and production? Rheumatology 2017, 56 (Suppl. S4), iv14–iv29. [Google Scholar] [CrossRef]

- Rahban, M.; Ahmad, F.; Piatyszek, M.A.; Haertlé, T.; Saso, L.; Saboury, A.A. Stabilization challenges and aggregation in protein-based therapeutics in the pharmaceutical industry. RSC Adv. 2023, 13, 35947–35963. [Google Scholar] [CrossRef] [PubMed]

- Akbarian, M.; Chen, S. Instability Challenges and Stabilization Strategies of Pharmaceutical Proteins. Pharmaceutics 2022, 14, 2533. [Google Scholar] [CrossRef] [PubMed]

- Yuanquiong, H.; Eynikel, D.; Boulet, P.; Krikorian, G. Supplementary protection certificates and their impact on access to medicines in Europe: Case studies of sofosbuvir, trastuzumab and imatinib. J. Pharm. Policy Pract. 2020, 13, 1. [Google Scholar] [CrossRef]

- Mehr, S.R.; Brook, R.A. Biosimilars in the USA: Will new efforts to spur approvals and access spur uptake and cost savings? Pharm. Med. 2019, 33, 1–8. [Google Scholar] [CrossRef]

- Dutta, B.; Huys, I.; Vulto, A.G.; Simoens, S. Identifying key benefits in European off-patent biologics and biosimilar markets: It is not only about price! BioDrugs 2019, 34, 159–170. [Google Scholar] [CrossRef]

- Geaghan-Breiner, C. The patent trap: The struggle for competition and affordability in the field of biologic drugs. Columbia J. Law Soc. Probl. 2020, 54, 589. [Google Scholar]

- Barszczewska, O.; Piechota, A. The impact of introducing successive biosimilars on changes in prices of adalimumab, infliximab, and trastuzumab—Polish experiences. Int. J. Environ. Res. Public Health 2021, 18, 6952. [Google Scholar] [CrossRef]

- Vandenplas, Y.; Simoens, S.; Wilder, P.V.; Vulto, A.G.; Huys, I. Off-patent biological and biosimilar medicines in Belgium: A market landscape analysis. Front. Pharmacol. 2021, 12, 644187. [Google Scholar] [CrossRef]

- Carrier, M.A.; Tu, S.S. Why pharmaceutical patent thickets are unique. Tex. Intellect. Prop. Law J. 2023, 32, 79–110. [Google Scholar] [CrossRef]

- Jarab, A.S.; Heshmeh, S.A.; Meslamani, A.Z.A. Bridging the gap: The future of biosimilars regulations. Hum. Vaccines Immunother. 2024, 20, 2362450. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, L.; Li, S.; Yuan, Y.; Jiang, B.; Jiang, Z.; Zhang, X.; Zhou, X.; Liu, M. Detecting biomarkers by dynamic nuclear polarization enhanced magnetic resonance. Natl. Sci. Rev. 2024, 11, nwae228. [Google Scholar] [CrossRef] [PubMed]

- Mennini, F.; Marcellusi, A.; Bini, C.; Rotundo, M.; Giunta, A.; Gasbarrini, A.; Valesini, G.; Canonico, P.L.; Novellino, E.; Orlando, V.; et al. The economic impact of biosimilars in Italy: A scenario analysis. Glob. Reg. Health Technol. Assess. 2019, 2019, 228424031985802. [Google Scholar] [CrossRef]

- Berto, P.; Bellone, M.; Sabinot, A.; Pinto, C.; Martino, M.; Generali, D.; Carriero, P.L.; Sanna, M.D. Budget saving potential of pegfilgrastim biosimilar for the treatment of chemotherapy-induced febrile neutropenia, in Italy. Farmeconomia Health Econ. Ther. Pathw. 2022, 23, 1–12. [Google Scholar] [CrossRef]

- AlRuthia, Y.; Bahari, O.; Alghnam, S.; Alrumaih, A.; Asiri, H.; Alshammari, M.; Alhowimel, M.; Al-Abdulkarim, H.A. Real-world impact of switching from insulin glargine (Lantus®) to Basaglar® and potential cost saving in a large public healthcare system in Saudi Arabia. Front. Public Health 2022, 10, 852721. [Google Scholar] [CrossRef]

- McClean, A.; Cheng, L.; Bansback, N.; Clement, F.; Tadrous, M.; Harrison, M.; Law, M.R. Uptake and spending on biosimilar infliximab and etanercept after new start and switching policies in Canada: An interrupted time series analysis. Arthritis Care Res. 2023, 75, 2011–2021. [Google Scholar] [CrossRef]

- Malakar, S.; Gontor, E.; Dugbaye, M.; Shah, K.; Sinha, S.; Sutaoney, P.; Chauhan, N.S. Cancer treatment with biosimilar drugs: A review. Cancer Innov. 2024, 3, e115. [Google Scholar] [CrossRef]

- Aladul, M.; Fitzpatrick, R.; Chapman, S. The effect of new biosimilars in rheumatology and gastroenterology specialities on UK healthcare budgets: Results of a budget impact analysis. Res. Soc. Adm. Pharm. 2019, 15, 310–317. [Google Scholar] [CrossRef]

- Sheridan, M.; Massich, M.; Ashourian, N. Biosimilars: From Production to Patient. J. Infus. Nurs. 2024, 47, 19–29. [Google Scholar] [CrossRef]

- Tenni, B.; Moir, H.; Townsend, B.; Kilic, B.; Farrell, A.; Keegel, T.; Gleeson, D. What is the impact of intellectual property rules on access to medicines? A systematic review. Glob. Health 2022, 18, 40. [Google Scholar] [CrossRef]

- Garai, P.; Chakraborty, A.; Banerjee, M.; Mukherjee, P. A comprehensive review on biosimilars: Present & future. J. Pharm. Res. Int. 2024, 36, 198–205. [Google Scholar] [CrossRef]

- Ratih, R.; Asmari, M.; Abdel-Megied, A.M.; Elbarbry, F.; Deeb, S.E. Biosimilars: Review of regulatory, manufacturing, analytical aspects and beyond. Microchem. J. 2021, 165, 106143. [Google Scholar] [CrossRef]

- Niazi, S.K. Affordable mRNA novel proteins, recombinant protein conversions, and biosimilars—Advice to developers and regulatory agencies. Biomedicines 2025, 13, 97. [Google Scholar] [CrossRef] [PubMed]

- Patil, N.; Ranjan, A.; Gaurav, G.; Mukherjee, D.; Panda, B.K.; Diksha, D.; Komal; Narang, R.K.; Singh, A. Navigating biosimilar regulatory pathways in emerging markets: Insights from BRICS nations. Appl. Drug Res. Clin. Trials Regul. Aff. 2025, 10, e26673371316219. [Google Scholar] [CrossRef]

- Bhatnagar, A.; Hazra, P.; Pai, H.V.; Vajpai, N.; Ramani, K.; Govindappa, N. Process Development for Biologics Therapeutics. In Approved: The Life Cycle of Drug Development; Springer Nature: Cham, Switzerland, 2025; pp. 249–297. [Google Scholar]

- Ranjan, R. Development of Complex Generics and Similar Biological Products: An Industrial Perspective of Reverse Engineering. AAPS PharmSciTech 2025, 26, 95. [Google Scholar] [CrossRef]

- Manwatkar, S.; Kumar, B. Biosimilars: Promising and rapidly emerging biotherapeutics. In Novel Technologies in Biosystems, Biomedical & Drug Delivery; Springer: Singapore, 2023; pp. 45–67. [Google Scholar] [CrossRef]

- Nupur, N.; Joshi, S.; Gulliarme, D.; Rathore, A. Analytical similarity assessment of biosimilars: Global regulatory landscape, recent studies and major advancements in orthogonal platforms. Front. Bioeng. Biotechnol. 2022, 10, 832059. [Google Scholar] [CrossRef]

- Naas, H.; Mehennaoui, S.; Gharbi, A. Characterization of biosimilars: Description of the analytical approach. GSC Biol. Pharm. Sci. 2023, 25, 215–221. [Google Scholar] [CrossRef]

- Pathak, M.; Pokhriyal, P.; Gandhi, I.; Khambhampaty, S. Implementation of chemometrics, design of experiments, and neural network analysis for prior process knowledge assessment, failure modes and effect analysis, scale-down model development, and process characterization for a chromatographic purification of teriparatide. Biotechnol. Prog. 2022, 38, e3252. [Google Scholar] [CrossRef]

- Wasalathanthri, D.; Rehmann, M.; Song, Y.; Gu, Y.; Luo, M.; Shao, C.; Shao, C.; Chemmalil, L.; Lee, J.; Ghose, S.; et al. Technology outlook for real-time quality attribute and process parameter monitoring in biopharmaceutical development—A review. Biotechnol. Bioeng. 2020, 117, 3182–3198. [Google Scholar] [CrossRef]

- Rahalkar, H.; Sheppard, A.; López-Morales, C.; Lobo, L.; Salek, S. Challenges faced by the biopharmaceutical industry in the development and marketing authorization of biosimilar medicines in BRICS-TM countries: An exploratory study. Pharm. Med. 2021, 35, 235–251. [Google Scholar] [CrossRef]

- Chemmalil, L.; Prabhakar, T.; Kuang, J.; West, J.; Tan, Z.; Ehamparanathan, V.; Song, Y.; Xu, J.; Ding, J.; Li, Z. Online/at-line measurement, analysis and control of product titer and critical product quality attributes (CQAs) during process development. Biotechnol. Bioeng. 2020, 117, 3757–3765. [Google Scholar] [CrossRef]

- García-Holgado, A.; Marcos-Pablos, S.; García-Peñalvo, F.J. Guidelines for performing systematic research projects reviews. Int. J. Interact. Multimed. Artif. Intell. 2020, 6, 9. [Google Scholar] [CrossRef]

- Mengist, W.; Soromessa, T.; Legese, G. Method for conducting systematic literature review and meta-analysis for environmental science research. MethodsX 2020, 7, 100777. [Google Scholar] [CrossRef] [PubMed]

- Scells, H.; Zuccon, G.; Koopman, B.; Clark, J. Automatic Boolean query formulation for systematic review literature search. In Proceedings of the WWW ’20: The Web Conference 2020, Taipei, Taiwan, 20–24 April 2020; pp. 1071–1081. [Google Scholar]

- Scells, H.; Zuccon, G.; Koopman, B. A comparison of automatic Boolean query formulation for systematic reviews. Inf. Retr. J. 2021, 24, 3–28. [Google Scholar] [CrossRef]

- Page, M.; McKenzie, J.; Bossuyt, P.; Boutron, I.; Hoffmann, T.; Mulrow, C.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Akl, E.; Khabsa, J.; Iannizzi, C.; Piechotta, V.; Kahale, L.; Barker, J.; Skoetz, N. Extension of the PRISMA 2020 Statement for Living Systematic Reviews (PRISMA-LSR): Checklist and Explanation. BMJ 2024, 384, e079183. [Google Scholar] [CrossRef]

- Gusenbauer, M.; Haddaway, N.R. Which academic search systems are suitable for systematic reviews or meta-analyses? Evaluating retrieval qualities of Google Scholar, PubMed, and 26 other resources. Res. Synth. Methods 2020, 11, 181–217. [Google Scholar] [CrossRef]

- Duivelshof, B.; Jiskoot, W.; Beck, A.; Veuthey, J.; Guillarme, D.; D’Atri, V. Glycosylation of biosimilars: Recent advances in analytical characterization and clinical implications. Anal. Chim. Acta 2019, 1089, 1–18. [Google Scholar] [CrossRef]

- Saleem, R.; Cantin, G.; Wikström, M.; Bolton, G.; Kuhns, S.; McBride, H.; Liu, J. Analytical and functional similarity assessment of ABP 710, a biosimilar to infliximab reference product. Pharm. Res. 2020, 37, 114. [Google Scholar] [CrossRef]

- Drobnjaković, M.; Hart, R.A.; Kulvatunyou, B.; Ivezic, N.; Srinivasan, V. Current challenges and recent advances on the path towards continuous biomanufacturing. Biotechnol. Prog. 2023, 39, e3378. [Google Scholar] [CrossRef]

- Sykes, A.; Ingram, L.; Kronthaler, U.; Chevalet, L. Demonstration of physicochemical and functional similarity between Stimufend (pegfilgrastim-fpgk) and Neulasta (pegfilgrastim): A comparative analytical assessment. PLoS ONE 2024, 19, e0309480. [Google Scholar] [CrossRef]

- Nag, K.; Sarker, E.; Kumar, S.; Chakraborty, S.; Khan, M.; Chowdhury, M.; Roy, R.; Roy, R.; Biswas, B.K.; Bappi, E.H.; et al. Satisfying QTPP of erythropoietin biosimilar by QbD through DoE-derived downstream process engineering. Pharmaceutics 2023, 15, 2087. [Google Scholar] [CrossRef] [PubMed]

- Neugebauer, P.; Zettl, M.; Moser, D.; Poms, J.; Kuchler, L.; Sacher, S. Process analytical technology in downstream-processing of drug substances—A review. Int. J. Pharm. 2024, 661, 124412. [Google Scholar] [CrossRef] [PubMed]

- Gyorgypal, A.; Chundawat, S. Integrated process analytical platform for automated monitoring of monoclonal antibody N-linked glycosylation. Anal. Chem. 2022, 94, 6986–6995. [Google Scholar] [CrossRef] [PubMed]

- Puranik, A.; Dandekar, P.; Jain, R. Exploring the potential of machine learning for more efficient development and production of biopharmaceuticals. Biotechnol. Prog. 2022, 38, e3291. [Google Scholar] [CrossRef]

- Demir, F.; Albarri, R.; Ünal, D.Ö. An overview of biotechnological drug’s various techniques of downstream process, guidelines and different chromatographic analysis. Curr. Pharm. Anal. 2024, 20, 729–742. [Google Scholar] [CrossRef]

- Luca, C.; Felletti, S.; Lievore, G.; Chenet, T.; Morbidelli, M.; Sponchioni, M.; Cavazzini, A.; Catani, M. Modern trends in downstream processing of biotherapeutics through continuous chromatography: The potential of multicolumn countercurrent solvent gradient purification. TrAC Trends Anal. Chem. 2020, 132, 116051. [Google Scholar] [CrossRef]

- Kim, H.; Bang, G.; Park, Y.E.; Park, M.; Choi, J.H.; Oh, M.J.; Hwang, H. Advanced Assessment through Intact Glycopeptide Analysis of Infliximab’s Biologics and Biosimilar. Front. Mol. Biosci. 2022, 9, 1006866. [Google Scholar] [CrossRef]

- Coghlan, J.; Benet, A.; Kumaran, P.; Ford, M.; Veale, L.; Skilton, S.J.; Schwendeman, A. Streamlining the Characterization of Disulfide Bond Shuffling and Protein Degradation in IgG1 Biopharmaceuticals under Native and Stressed Conditions. Front. Bioeng. Biotechnol. 2022, 10, 862456. [Google Scholar] [CrossRef]

- Abidin, A.Z.; Snoswell, C.L.; Hanjani, L.S.; Callaghan, G.; Edmonds, M.L. Infliximab Switching from Reference Product to Biosimilar: A Review of Evidence Regarding the Clinical Efficacy, Safety Profile and Immunogenicity. J. Pharm. Pract. Res. 2021, 51, 358–373. [Google Scholar] [CrossRef]

- Bandara, S.A.T.; Raveendran, S. Current Landscape and Future Directions in Cancer Immunotherapy: Therapies, Trials, and Challenges. Cancers 2025, 17, 821. [Google Scholar] [CrossRef]

- Bouvarel, T.; Camperi, J.; Guillarme, D. Multi-dimensional technology—Recent advances and applications for biotherapeutic characterization. J. Sep. Sci. 2024, 47, 2300928. [Google Scholar] [CrossRef] [PubMed]

- Oh, M.J.; Seo, Y.; Seo, N.; An, H.J. MS-based glycome characterization of biotherapeutics with N- and O-glycosylation. Mass Spectrom. Rev. 2025. [Google Scholar] [CrossRef] [PubMed]

- Mans, J.D.; Oyugi, M.; Asmelash, B.; Sommers, C.D.; Rogstad, S. The Use of Mass Spectrometry in Therapeutic Protein Biologics License Applications: A Retrospective Review Revisited. J. Am. Soc. Mass Spectrom. 2023, 34, 2575–2584. [Google Scholar] [CrossRef] [PubMed]

- Song, N.K.; Musa, H.; Soriano, M.; Batger, M.; Hawkins, B.A.; Ramzan, I.; Ong, J. Safety and Efficacy Comparisons of Intravenous Trastuzumab Biosimilars to the Reference Product Medicine in Treatment-Naïve and Switch-Over Patients with Breast Cancer: A Systematic and Meta-Analysis. J. Pharm. Pract. Res. 2023, 54, 1–32. [Google Scholar] [CrossRef]

- Atik, A.E. Comparative Analysis of Glycoform Profiles between Biosimilar and Originator Monoclonal Antibodies by Liquid Chromatography–Mass Spectrometry. J. Turk. Chem. Soc. Sect. A Chem. 2024, 11, 365–376. [Google Scholar] [CrossRef]

- Gupta, S.; Shah, B.; Fung, C.S.; Chan, P.K.; Wakefield, D.L.; Kuhns, S.; Piret, J.M. Engineering Protein Glycosylation in CHO Cells to Be Highly Similar to Murine Host Cells. Front. Bioeng. Biotechnol. 2023, 11, 1113994. [Google Scholar] [CrossRef]

- Rathore, A.S.; Malani, H. Need for a Risk-Based Control Strategy for Managing Glycosylation Profile for Biosimilar Products. Expert Opin. Biol. Ther. 2021, 22, 123–131. [Google Scholar] [CrossRef]

- Coliat, P.; Erb, S.; Diemer, H.; Karouby, D.; Martin, T.; Banerjee, M.; Pivot, X. Influence of Pneumatic Transportation on the Stability of Monoclonal Antibodies. Sci. Rep. 2023, 13, 21875. [Google Scholar] [CrossRef]

- Castel, J.; Delaux, S.; Hernandez-Alba, O.; Cianférani, S. Recent Advances in Structural Mass Spectrometry Methods in the Context of Biosimilarity Assessment: From Sequence Heterogeneities to Higher Order Structures. J. Pharm. Biomed. Anal. 2023, 236, 115696. [Google Scholar] [CrossRef]

- Rocca, D.; Redis, R.S.; Meyer, P.; Rohleff, I.; Oswald, E.; Martin, S.; Bryans, J.S. Abstract 3794: Developing an mRNA Nanomedicine Platform to Democratise Therapeutic Antibodies. Cancer Res. 2025, 85 (Suppl. S1), 3794. [Google Scholar] [CrossRef]

- McGonigle, P. How Biologics Have Changed the Drug Discovery Landscape. Annu. Rev. Pharmacol. Toxicol. 2025, 65, 29–46. [Google Scholar] [CrossRef] [PubMed]

- Sagi, S.; Kalsekar, S.; Kottke, A.; Cohen, H.P. Long-Term Real-World Post-Approval Safety Data of Multiple Biosimilars from One Marketing-Authorization Holder after More Than 18 Years since Their First Biosimilar Launch. Drug Saf. 2023, 46, 1391–1404. [Google Scholar] [CrossRef] [PubMed]

- Böttinger, K.; Regl, C.; Schäpertöns, V.; Rapp, E.; Wohlschlager, T.; Huber, C.G. “Small Is Beautiful”—Examining Reliable Determination of Low-Abundant Therapeutic Antibody Glycovariants. J. Pharm. Anal. 2024, 14, 100982. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Xiang, Y.; Zhang, X.; Sun, Y.; Li, Y.; Wang, L.; Li, J. Analysis Strategy for Identifying the O-Linked Glycan Profile and O-Glycosylation Sites on Recombinant Human Follicle Stimulating Hormone-C-Terminal Peptide (rhFSH-CTP). Molecules 2025, 30, 2141. [Google Scholar] [CrossRef]

- Reddy, J.; Leibiger, T.; Singh, S.; Lee, K.; Papoutsakis, E.; Ierapetritou, M. A novel, site-specific N-linked glycosylation model provides mechanistic insights into the process-condition dependent distinct Fab and Fc glycosylation of an IgG1 monoclonal antibody produced by CHO VRC01 cells. Biotechnol. Bioeng. 2024, 122, 761–778. [Google Scholar] [CrossRef]

- Mesonzhnik, N.V.; Belushenko, A.; Novikova, P.V.; Kukharenko, A.B.; Afonin, M. Enhanced N-Glycan Profiling of Therapeutic Monoclonal Antibodies through the Application of Upper-Hinge Middle-Up Level LC-HRMS Analysis. Antibodies 2024, 13, 66. [Google Scholar] [CrossRef]

- Hudnik, D.; Bohanec, N.; Drobnak, I.; Ernst, P.B.; Hanke, A.T.; Horvat, M.; Omladič, M. Automatic Peak Annotation and Area Estimation of Glycan Map Peaks Directly from Chromatograms. J. Chemom. 2023, 37, e3521. [Google Scholar] [CrossRef]

- David, P.O. Abstract A001: Navigating the Future of Therapeutic Development: Innovations in Safety and Efficacy through Advanced Research Methodologies and Nanotechnology. Mol. Cancer Ther. 2024, 23 (Suppl. S12), A001. [Google Scholar] [CrossRef]

- Eidenberger, L.; Kogelmann, B.; Steinkellner, H. Plant-Based Biopharmaceutical Engineering. Nat. Rev. Bioeng. 2023, 1, 426–439. [Google Scholar] [CrossRef]

- Saunders, M.; Woods, R.J.; Yang, L. Simplifying the Detection and Monitoring of Protein Glycosylation during In Vitro Glycoengineering. Sci. Rep. 2023, 13, 567. [Google Scholar] [CrossRef]

- Barron, A.; Chung, J.; Ferner, R.E.; Leandro, M.; Maru, S.; Scourfield, A.; Sofat, R. Effectiveness of Biosimilar Adoption within a UK Tertiary Hospital: 6-Year Follow-Up. Br. J. Clin. Pharmacol. 2023, 89, 2944–2949. [Google Scholar] [CrossRef] [PubMed]

- Hou, X.; Chen, Y.; Li, X.; Gu, X.; Dong, W.; Shi, J.; Ji, S. Protein Succinylation: Regulating Metabolism and Beyond. Front. Nutr. 2024, 11, 1336057. [Google Scholar] [CrossRef] [PubMed]

- Sharma, C.; Hamza, A.; Boyle, E.; Donu, D.; Cen, Y. Post-Translational Modifications and Diabetes. Biomolecules 2024, 14, 310. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Liu, H.; Bai, B.; Wang, H. Quantification of Epigenetic DNA and RNA Modifications by UHPLC–MS/MS Technologies: New Concepts and New Improvements for the Special Collections. J. Sep. Sci. 2025, 48, e70159. [Google Scholar] [CrossRef]

- Popova, L.; Carr, R.A.; Carabetta, V.J. Recent Contributions of Proteomics to Our Understanding of Reversible Nε-Lysine Acylation in Bacteria. J. Proteome Res. 2024, 23, 2733–2749. [Google Scholar] [CrossRef]

- McClellan, J.; Ómarsdóttir, S.; Roy, N.; Berger, V.; Michel, C.; Berti, F. The totality of evidence approach in the development of AVT02 (adalimumab), a biosimilar to Humira. Ther. Adv. Chronic Dis. 2024, 15, 20406223231223286. [Google Scholar] [CrossRef]

- Lerch, T.; Sharpe, P.; Mayclin, S.; Edwards, T.; Polleck, S.; Rouse, J.; Zou, Q.; Conlon, H.D. Crystal structures of PF-06438179/GP1111, an infliximab biosimilar. BioDrugs 2019, 34, 77–87. [Google Scholar] [CrossRef]

- Tamara, S.; Boer, M.; Heck, A. High-resolution native mass spectrometry. Chem. Rev. 2021, 122, 7269–7326. [Google Scholar] [CrossRef]

- Camperi, J.; Goyon, A.; Guillarme, D.; Zhang, K.; Stella, C. Multi-dimensional LC-MS: The next generation characterization of antibody-based therapeutics by unified online bottom-up, middle-up and intact approaches. Analyst 2021, 146, 747–769. [Google Scholar] [CrossRef]

- Zahel, T. A novel bootstrapping test for analytical biosimilarity. AAPS J. 2022, 24, 112. [Google Scholar] [CrossRef]

- Wen, J.; Razick, A.; How-Volkman, C.; Bernstein, E.; Nadora, D.; Truong, A.; Razick, D.; Akhtar, M.; Karabala, M.; Frezza, E. An exploratory analysis of glucagon-like peptide-1 (GLP-1) agonists and biosimilars: A literature review. Diabetes Obes. Metab. 2024, 27, 1113–1122. [Google Scholar] [CrossRef] [PubMed]

- Pedro, M.; Klijn, M.; Eppink, M.; Ottens, M. Process analytical technique (PAT) miniaturization for monoclonal antibody aggregate detection in continuous downstream processing. J. Chem. Technol. Biotechnol. 2021, 97, 2347–2364. [Google Scholar] [CrossRef]

- Kim, E.; Kim, J.; Kim, M.; Jeong, S.; Choi, D. Process analytical technology tools for monitoring pharmaceutical unit operations: A control strategy for continuous process verification. Pharmaceutics 2021, 13, 919. [Google Scholar] [CrossRef] [PubMed]

- Esmonde-White, K.; Cuellar, M.; Lewis, I. The role of Raman spectroscopy in biopharmaceuticals from development to manufacturing. Anal. Bioanal. Chem. 2021, 414, 969–991. [Google Scholar] [CrossRef] [PubMed]

- Gillespie, C.; Wasalathanthri, D.; Ritz, D.; Zhou, G.; Davis, K.; Wucherpfennig, T.; Hazelwood, N. Systematic assessment of process analytical technologies for biologics. Biotechnol. Bioeng. 2021, 119, 423–434. [Google Scholar] [CrossRef]

- Klein, K.; Gencoglu, M.; Heisterberg, J.; Acha, V.; Stolk, P. The Global Landscape of Manufacturers of Follow-On Biologics: An Overview of Five Major Biosimilar Markets and 15 Countries. BioDrugs 2022, 37, 235–245. [Google Scholar] [CrossRef]

- Gandhi, S.; Patankar, D.; Kashiramka, S.; Rathore, A.S. The Economics of Translating a Biosimilar from Lab to Market in India. Ann. N. Y. Acad. Sci. 2024, 1541, 219–229. [Google Scholar] [CrossRef]

- Lee, J.J.; Lee, N.; Seo, Y.J.; Kim, I. Consistency of Product Quality for SB5, an Adalimumab Biosimilar. BioDrugs 2023, 37, 271–277. [Google Scholar] [CrossRef]

- Lees, J.; Dias, J.; Han, S. Applications of cryo-EM in small molecule and biologics drug design. Biochem. Soc. Trans. 2021, 49, 2627–2638. [Google Scholar] [CrossRef]

- Deshmukh, A.; Goyal, R.; Sundaram, K.; Dange, K.; Lakhote, T.; Niranjan, S.; Bharucha, J.; Mishra, A.; Vats, B.; Tiwari, S.; et al. Analytical sameness methodology for the evaluation of structural, physicochemical, and biological characteristics of ARMLUPEG: A pegfilgrastim biosimilar case study. PLoS ONE 2023, 18, e0289745. [Google Scholar] [CrossRef]

- Stüber, J.C.; Uhland, K.; Reiter, A.; Jakob, S.; Wolschin, F. Comparative Analytical Evaluation of the Proposed Biosimilar FYB206 and Its Reference Medicinal Product Keytruda®. Drugs RD 2024, 24, 447–464. [Google Scholar] [CrossRef] [PubMed]

- Shukla, V.; Niveria, K.; Shashidhar, P.; Verma, A. Dynamic Light Scattering (DLS) Particle Size Analysis for Biomedical Nanotechnology. In Analytical Techniques for Biomedical Nanotechnology; IOP Publishing: Bristol, UK, 2023; pp. 16-1–16-25. [Google Scholar] [CrossRef]

- Kang, H.; Wadhwa, M.; Knežević, I.; Ondari, C.; Simão, M. WHO Guidelines on Biosimilars: Toward Improved Access to Safe and Effective Products. Ann. N. Y. Acad. Sci. 2023, 1521, 96–103. [Google Scholar] [CrossRef] [PubMed]

- Chari, A.; Stark, H. Prospects and limitations of high-resolution single-particle cryo-electron microscopy. Annu. Rev. Biophys. 2023, 52, 391–411. [Google Scholar] [CrossRef] [PubMed]

- Kryshtafovych, A.; Moult, J.; Albrecht, R.; Chang, G.; Chao, K.; Fraser, A.; Greenfield, J.; Hartmann, M.D.; Herzberg, O.; Josts, I.; et al. Computational models in the service of X-ray and cryo-electron microscopy structure determination. Proteins 2021, 89, 1633–1646. [Google Scholar] [CrossRef]

- Tercan, H.; Meisen, T. Machine learning and deep learning based predictive quality in manufacturing: A systematic review. J. Intell. Manuf. 2022, 33, 1879–1905. [Google Scholar] [CrossRef]

- Gangwar, N.; Balraj, K.; Rathore, A. Explainable AI for CHO cell culture media optimization and prediction of critical quality attribute. Appl. Microbiol. Biotechnol. 2024, 108, 308. [Google Scholar] [CrossRef]

- Kumar, N.; Pakalapati, A.; Chandrasekhar, K.; Durthi, C. Comparison of analytical method validation guidelines used for release, stability in biosimilar manufacturing process. Curr. Trends Biotechnol. Pharm. 2024, 18, 1798–1812. [Google Scholar] [CrossRef]

- Borza, B.; Hajba, L.; Guttman, A. N-glycan analysis in molecular medicine: Innovator and biosimilar protein therapeutics. Curr. Mol. Med. 2021, 20, 828–839. [Google Scholar] [CrossRef]

- Kodumuru, R.; Sarkar, S.; Parepally, V.; Chandarana, J. Artificial Intelligence and Internet of Things Integration in Pharmaceutical Manufacturing: A Smart Synergy. Pharmaceutics 2025, 17, 290. [Google Scholar] [CrossRef]

- Wu, C.; Chan, B.; Sarich, Z.; Duan, Y.; Chen, J.; Song, J.; Goudar, C.T. Accelerating Attribute-Focused Process and Product Development through the Development and Deployment of Autonomous Process Analytical Technology Platform System. Biotechnol. Bioeng. 2024, 121, 1256–1269. [Google Scholar] [CrossRef]

- Feng, X.; Ma, Z.; Yu, C.; Xin, R. MRNDR: Multihead Attention-Based Recommendation Network for Drug Repurposing. J. Chem. Inf. Model. 2024, 64, 2654–2669. [Google Scholar] [CrossRef] [PubMed]

- Bao, S.; Chao, B.; Zhang, C.; Li, Y.; Jing-liang, L. Real-Time Tool Wear Monitoring and Multi-Step Forward Prediction Based on Multi-Information Fusion. Meas. Sci. Technol. 2025, 36, 025104. [Google Scholar] [CrossRef]

- Basaure, V. Models in medicine: The digital twin for health. SerieST 2025, 10, 3–16. [Google Scholar] [CrossRef]

- Haq, M.A.U.; Rehman, S.U.; Alhulayyil, H.A.; Alzahrani, T.; AlSagri, H.S.; Faheem, M. Wireless Antenna Sensors for Biosimilar Monitoring toward Cyber-Physical Systems: A Review of Current Trends and Future Prospects. IEEE Access 2023, 11, 132037–132054. [Google Scholar] [CrossRef]

- Kuang, X. Application and Difficulties of Deep Learning in Drug Target Discovery. MedScien 2024, 1, 1–4. [Google Scholar] [CrossRef]

- Kalakoti, Y.; Yadav, S.; Sundar, D. TransDTI: Transformer-based language models for estimating DTIs and building a drug recommendation workflow. ACS Omega 2022, 7, 2706–2717. [Google Scholar] [CrossRef]

- Lee, S.; Cho, J.; Lee, B.; Hwang, D.; Park, J. Design and prediction of aptamers assisted by in silico methods. Biomedicines 2023, 11, 356. [Google Scholar] [CrossRef]

- Saleh, D.; Hess, R.; Ahlers-Hesse, M.; Rischawy, F.; Wang, G.; Grosch, J.; Schwab, T.; Kluters, S.; Studts, J.; Hubbuch, J. A multiscale modeling method for therapeutic antibodies in ion exchange chromatography. Biotechnol. Bioeng. 2022, 120, 125–138. [Google Scholar] [CrossRef]

- Wittkopp, F.; Welsh, J.P.; Todd, R.; Staby, A.; Roush, D.J.; Lyall, J.Y.; Babi, D.K. Current State of Implementation of In Silico Tools in the Biopharmaceutical Industry—Proceedings of the 5th Modeling Workshop. Biotechnol. Bioeng. 2024, 121, 2952–2973. [Google Scholar] [CrossRef]

- Wang, X.; Mohsin, A.; Sun, Y.; Li, C.; Zhuang, Y.; Wang, G. From Spatial-Temporal Multiscale Modeling to Application: Bridging the Valley of Death in Industrial Biotechnology. Bioengineering 2023, 10, 744. [Google Scholar] [CrossRef]

- Dutta, D.J.; Kumar, P.; Singh, A.; Khade, S. Bioprocess Strategies for Enhanced Performance in Single-Use Bioreactors for Biomolecule Synthesis: A Biokinetic Approach. Food Bioeng. 2024, 3, 337–351. [Google Scholar] [CrossRef]

- Islam, A.; Jena, D.; Mondal, N.; Teli, A.; Mondal, S.; Gautam, M. In-silico approaches for drug designing technology: Bridging discovery and development. Curr. Drug Discov. Technol. 2025, 22, e15701638326869. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Pan, S.; Chen, F.; Long, G.; Zhang, C.; Yu, P. A comprehensive survey on graph neural networks. IEEE Trans. Neural Netw. Learn. Syst. 2021, 32, 4–24. [Google Scholar] [CrossRef] [PubMed]

- Ye, W.; Li, J.; Cai, X. MF-GNN: Multi-scale feature-attentive graph neural networks for molecular property prediction. J. Comput. Chem. 2025, 46, e70011. [Google Scholar] [CrossRef]

- Shi, X.; Zhou, L.; Huang, Y.; Wu, Y.; Hong, Z. A review on the applications of graph neural networks in materials science at the atomic scale. Mater. Genome Eng. Adv. 2024, 2, e50. [Google Scholar] [CrossRef]

- Satheeskumar, R. Enhancing drug discovery with AI: Predictive modeling of pharmacokinetics using graph neural networks and ensemble learning. Intell. Pharm. 2025, 3, 127–140. [Google Scholar] [CrossRef]

- Shi, Z.; Ma, M.; Ning, H.; Yang, B.; Dang, J. A multiscale molecular structural neural network for molecular property prediction. Mol. Divers. 2025. [Google Scholar] [CrossRef]

- Pancino, N.; Gallegati, C.; Romagnoli, F.; Bongini, P.; Bianchini, M. Protein–protein interfaces: A graph neural network approach. Int. J. Mol. Sci. 2024, 25, 5870. [Google Scholar] [CrossRef]

- Dong, L.; Shi, S.; Qu, X.; Ding, L.; Wang, B. Ligand binding affinity prediction with fusion of graph neural networks and 3D structure-based complex graph. Phys. Chem. Chem. Phys. 2023, 25, 24110–24120. [Google Scholar] [CrossRef]

- Shi, W.; Singha, M.; Srivastava, G.; Pu, L.; Ramanujam, J.; Bryliński, M. Pocket2drug: An encoder-decoder deep neural network for the target-based drug design. Front. Pharmacol. 2022, 13, 837715. [Google Scholar] [CrossRef]

- Davis, D.; Jackson, K.; Hoppe, C. Evaluation of Cost and Infusion-Related Reactions among Intravenous Trastuzumab, Subcutaneous Trastuzumab, and Trastuzumab Biosimilars at an Academic Medical Center. J. Oncol. Pharm. Pract. 2024, 31, 224–229. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Du, K.; Zhang, W.; Mao, J. Empowering Digital Transformation: The Roles of Platforms. J. Inf. Technol. 2023, 39, 650–667. [Google Scholar] [CrossRef]

- Chkarat, H.; Abid, T.; Sauvée, L. Conditions for a Convergence between Digital Platforms and Sustainability in Agriculture. Sustainability 2023, 15, 14195. [Google Scholar] [CrossRef]

- Junaid, M.A.L. Artificial Intelligence Driven Innovations in Biochemistry: A Review of Emerging Research Frontiers. Biomol. Biomed. 2025, 25, 739–750. [Google Scholar] [CrossRef]

- Langer, E. Single-use technology in biopharmaceutical manufacture and beyond. Chem. Ing. Tech. 2022, 94, 1892–1901. [Google Scholar] [CrossRef]

- Ding, L.; Bazaz, S.; Fardjahromi, M.; Mckinnirey, F.; Saputro, B.; Banerjee, B.; Banerjee, B.; Vesey, G.; Warkiani, M.E. A modular 3D printed microfluidic system: A potential solution for continuous cell harvesting in large-scale bioprocessing. Bioresour. Bioprocess. 2022, 9, 64. [Google Scholar] [CrossRef] [PubMed]

- Saha, R.; Sarkar, M.; Choudhury, S.S.; Kumar, H.; Bhatt, G.; Bhattacharya, S. Evolution of 3D Printing Technology in Fabrication of Microfluidic Devices and Biological Applications: A Comprehensive Review. J. Micromanuf. 2024, 7, 110–140. [Google Scholar] [CrossRef]

- Brunner, V.; Siegl, M.; Geier, D.; Becker, T. Challenges in the Development of Soft Sensors for Bioprocesses: A Critical Review. Front. Bioeng. Biotechnol. 2021, 9, 722202. [Google Scholar] [CrossRef]

- Rivera, E.C.; Yamakawa, C.K.; Rossell, C.E.; Nolasco, J.; Kwon, H.J. Prediction of Intensified Ethanol Fermentation of Sugarcane Using a Deep Learning Soft Sensor and Process Analytical Technology. J. Chem. Technol. Biotechnol. 2023, 99, 207–216. [Google Scholar] [CrossRef]

- Dürauer, A.; Jungbauer, A.; Scharl, T. Sensors and Chemometrics in Downstream Processing. Biotechnol. Bioeng. 2023, 121, 2347–2364. [Google Scholar] [CrossRef]

- Akram, M.; Jabeen, F.; Daniyal, M.; Zainab, R.; Haq, U.u.; Adetunji, C.O.; Egbuna, C.; Ephraim-Emmanuel, B.C.; Patrick-Iwuanyanwu, K.C.; Ogbo, A.B. Genetic engineering of novel products of health significance: Recombinant DNA technology. In Functional Foods and Nutraceuticals; Springer: Cham, Switzerland, 2020; pp. 595–611. [Google Scholar] [CrossRef]

- Bellinvia, S.; Edwards, C.J. Explaining biosimilars and how reverse engineering plays a critical role in their development. Expert Opin. Drug Discov. 2020, 15, 1283–1289. [Google Scholar] [CrossRef] [PubMed]

- Svilenov, H.; Kulakova, A.; Zalar, M.; Golovanov, A.; Harris, P.; Winter, G. Orthogonal techniques to study the effect of pH, sucrose, and arginine salts on monoclonal antibody physical stability and aggregation during long-term storage. J. Pharm. Sci. 2020, 109, 584–594. [Google Scholar] [CrossRef] [PubMed]

- Castañeda Ruiz, A.J.; Shetab Boushehri, M.A.; Phan, T.; Carle, S.; Garidel, P.; Buske, J.; Lamprecht, A. Alternative excipients for protein stabilization in protein therapeutics: Overcoming the limitations of polysorbates. Pharmaceutics 2022, 14, 2575. [Google Scholar] [CrossRef] [PubMed]

- Panda, C.; Kumar, S.; Gupta, S.; Pandey, L.M. Insulin fibrillation under physicochemical parameters of bioprocessing and intervention by peptides and surface-active agents. Crit. Rev. Biotechnol. 2024, 45, 643–664. [Google Scholar] [CrossRef]

- Abitbol, V.; Benkhalifa, S.; Habauzit, C.; Marotte, H. Navigating Adalimumab Biosimilars: An Expert Opinion. J. Comp. Eff. Res. 2023, 12, e230117. [Google Scholar] [CrossRef]

- Wu, Y.; Gardner, R.; Schöneich, C. Near UV and visible light-induced degradation of bovine serum albumin and a monoclonal antibody mediated by citrate buffer and Fe(III): Reduction vs oxidation pathways. Mol. Pharm. 2024, 21, 4060–4073. [Google Scholar] [CrossRef]

- Abdulkareem, R.; Doekhie, A.; Fotaki, N.; Koumanov, F.; Dodson, C.; Sartbaeva, A. Thermal Stabilisation of Lysozyme through Ensilication. Molecules 2024, 29, 4207. [Google Scholar] [CrossRef] [PubMed]

- Akbarian, M.; Farjadian, F. Chitosan-Coated Glass Beads as Stabilizer of Insulin; A Novel Strategy for the Storage of Pharmaceutical Proteins. ChemistrySelect 2024, 9, e202402813. [Google Scholar] [CrossRef]

- Koynov, A.; Lin, W.; Bothe, J.; Schenck, L.; Parajuli, B.; Li, Z.; Ruzanski, R.; Hoffman, N.; Frank, D.; VanAernum, Z. A precipitation-based process to generate a solid formulation of a therapeutic monoclonal antibody: An alternative to lyophilization. JPBI 2025, 2, 2. [Google Scholar] [CrossRef]

- Liu, X.; Dong, Y.; Wang, C.; Guo, Z. Application of Chitosan as Nano Carrier in the Treatment of Inflammatory Bowel Disease. Int. J. Biol. Macromol. 2024, 278, 134899. [Google Scholar] [CrossRef]

- Arcos Rosero, W.A.; Bueno Barbezan, A.; Daruich de Souza, C.; Chuery Martins Rostelato, M.E. Review of Advances in Coating and Functionalization of Gold Nanoparticles: From Theory to Biomedical Application. Pharmaceutics 2024, 16, 255. [Google Scholar] [CrossRef] [PubMed]

- Aparna, M.; Giuggioli, N.R. Chitosan Based Edible Coatings: Enhancing Shelf Life and Quality in Fruits and Vegetables. J. Adv. Biol. Biotechnol. 2024, 27, 178–191. [Google Scholar] [CrossRef]

- Ghafoor, K.; Juhaimi, F.A.; Babiker, E.E.; Ahmed, I.A.M.; Shahzad, S.A.; Alsawmahi, O.N. Quality Attributes of Refrigerated Barhi Dates Coated with Edible Chitosan Containing Natural Functional Ingredients. Foods 2022, 11, 1584. [Google Scholar] [CrossRef] [PubMed]

- Skerritt, J.H. Considerations for mRNA Product Development, Regulation and Deployment Across the Lifecycle. Vaccines 2025, 13, 473. [Google Scholar] [CrossRef]

- Zárate-Moreno, J.C.; Escobar-Sierra, D.M.; Ríos-Estepa, R. Development and Evaluation of Chitosan-Based Food Coatings for Exotic Fruit Preservation. BioTech 2023, 12, 20. [Google Scholar] [CrossRef]

- Aguiar, A.C.d.; Bianchi, J.R.O.; Lopes, J.H.; Ferreira, F.V.; Lona, L.M.F. Nanocellulose-Based Capsules with pH Responsiveness for Colon-Targeted Curcumin Delivery. ACS Appl. Nano Mater. 2025, 8, 2033–2045. [Google Scholar] [CrossRef]

- Hemmingsen, L.M.; Panchai, P.; Julin, K.; Basnet, P.; Nystad, M.; Johannessen, M.; Škalko-Basnet, N. Chitosan-Based Delivery System Enhances Antimicrobial Activity of Chlorhexidine. Front. Microbiol. 2022, 13, 1023083. [Google Scholar] [CrossRef]

- Jia, Y.; Cao, J.; Zhou, J.; Ping, Z. Methyl Chitosan Coating for Glycoform Analysis of Glycoproteins by Capillary Electrophoresis. Electrophoresis 2020, 41, 729–734. [Google Scholar] [CrossRef]

- Cao, X.; Islam, M.N.; Chitrakar, B.; Duan, Z.; Xu, W.; Zhong, S. Effect of Combined Chlorogenic Acid and Chitosan Coating on Antioxidant, Antimicrobial, and Sensory Properties of Snakehead Fish in Cold Storage. Food Sci. Nutr. 2020, 8, 973–981. [Google Scholar] [CrossRef]

- Fan, S.; Wang, H.; Yu, Y.; Cao, S.; Lin, Y. Advancements in the Utilization of Chitosan and Its Derivatives for Metal Corrosion Inhibition: A Comprehensive Review. Acad. J. Sci. Technol. 2024, 11, 81–84. [Google Scholar] [CrossRef]

- Banks, D.; Kempf, J.; Du, Y.; Reichert, P.; Narasimhan, C.; Fang, R.; Kwon, S.; Ling, J.; Lay-Fortenbery, A.; Zhang, Y.; et al. Investigation of protein therapeutics in frozen conditions using DNP MAS NMR: A study on pembrolizumab. Mol. Pharm. 2024, 21, 6363–6375. [Google Scholar] [CrossRef] [PubMed]

- Fox, G.; Bernauer, M.; Stephens, J.; Jackson, B.; Roth, J.; Shelbaya, A. Clinical and economic value of a biosimilar portfolio to stakeholders: An integrative literature review. Clin. Outcomes Res. 2024, 16, 247–416. [Google Scholar] [CrossRef] [PubMed]

- Almaaytah, A. Technical guidance on the physicochemical and functional comparability exercise for trastuzumab biosimilars. Int. J. Appl. Pharm. 2022, 14, 71–76. [Google Scholar] [CrossRef]

- Yang, S. Aspects and implementation of pharmaceutical quality by design from conceptual frameworks to industrial applications. Pharmaceutics 2025, 17, 623. [Google Scholar] [CrossRef] [PubMed]

- Huizinga, T.; Torii, Y.; Muniz, R. Adalimumab biosimilars in the treatment of rheumatoid arthritis: A systematic review of the evidence for biosimilarity. Rheumatol. Ther. 2020, 8, 41–61. [Google Scholar] [CrossRef]

- Cook, J.; McGrath, M.; Dixon, M.; Switchenko, J.; Harvey, R.; Pentz, R. Academic oncology clinicians’ understanding of biosimilars and information needed before prescribing. Ther. Adv. Med. Oncol. 2019, 11, 1758835918818335. [Google Scholar] [CrossRef]

- Derikx, L.; Dolby, H.; Plevris, N.; Lucaciu, L.; Rees, C.; Lyons, M.; Siakavellas, S.I.; Constantine-Cooke, N.; Jenkinson, P.; Su, S.; et al. Effectiveness and safety of adalimumab biosimilar SB5 in inflammatory bowel disease: Outcomes in originator to SB5 switch, double biosimilar switch and bio-naïve SB5 observational cohorts. J. Crohn’s Colitis 2021, 15, 2011–2021. [Google Scholar] [CrossRef]

- Fadhil, H.; Al-Jumaili, A.; Al-Ani, N. Cost-effectiveness analysis of reference infliximab (Remicade) compared to its biosimilar (Remsima) in Iraqi patients with rheumatoid arthritis (conference paper). Iraqi J. Pharm. Sci. 2023, 31, 100–110. [Google Scholar] [CrossRef]

- Smolen, J.; Gonçalves, J.; Quinn, M.; Benedetti, F.; Lee, J. Era of biosimilars in rheumatology: Reshaping the healthcare environment. RMD Open 2019, 5, e000900. [Google Scholar] [CrossRef]

- Blevins, T.; Barve, A.; Raiter, Y.; Aubonnet, P.; Athalye, S.; Sun, B.; Muniz, R. Efficacy and safety of MYL-1501D versus insulin glargine in people with type 1 diabetes mellitus: Results of the INSTRIDE 3 phase 3 switch study. Diabetes Obes. Metab. 2019, 22, 365–372. [Google Scholar] [CrossRef]

- Shuptrine, C.; Chen, Y.; Miriyala, J.; Lenz, K.; Moffett, D.; Nguyen, T.; Michaux, J.; Campbell, K.; Smith, C.; Morra, M.; et al. Lipid-encapsulated mRNAs encoding complex fusion proteins potentiate antitumor immune responses. Cancer Res. 2024, 84, 1550–1559. [Google Scholar] [CrossRef] [PubMed]

- Strickley, R.; Lambert, W. A review of formulations of commercially available antibodies. J. Pharm. Sci. 2021, 110, 2590–2608.e56. [Google Scholar] [CrossRef] [PubMed]

- Kurki, P.; Barry, S.; Bourges, I.; Tsantili, P.; Wolff-Holz, E. Safety, immunogenicity and interchangeability of biosimilar monoclonal antibodies and fusion proteins: A regulatory perspective. Drugs 2021, 81, 1881–1896. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.; Chen, C. Carcinomembrane-camouflaged perfluorochemical dual-layer nanopolymersomes bearing indocyanine green and camptothecin effectuate targeting photochemotherapy of cancer. ACS Biomater. Sci. Eng. 2024, 10, 6332–6343. [Google Scholar] [CrossRef]

- Ionova, Y.; Wilson, L. Biologic excipients: Importance of clinical awareness of inactive ingredients. PLoS ONE 2020, 15, e0235076. [Google Scholar] [CrossRef]

- Krishna, M. Product-related factors and immunogenicity of biotherapeutics. J. Pharm. Innov. 2019, 15, 219–231. [Google Scholar] [CrossRef]

- Grudzinska-Goebel, J.; Benstein, K.; Bloem, K.; Cowan, K.J.; Gorovits, B.; Jadhav, M.; Janssen, M.; Jawa, V.; Kiessling, A.; Kramer, D. Immunogenicity risk assessment for tailored mitigation and monitoring of biotherapeutics during development: Recommendations from the European immunogenicity platform. Front. Immunol. 2025, 16, 1581153. [Google Scholar] [CrossRef]

- Previ, T.; Rodrigues, A. Relationship between innovative and biosimilar trastuzumab used in the treatment of breast cancer: Cross-sectional study of financial impact. J. Cancer Prev. Curr. Res. 2021, 12, 123–126. [Google Scholar] [CrossRef]

- Xin, L.; Lan, L.; Mellal, M.; McChesney, N.; Vaughan, R.; Berdugo, C.; Li, Y.; Zhang, J. Leveraging high-throughput analytics and automation to rapidly develop high-concentration mAb formulations: Integrated excipient compatibility and viscosity screening. Antib. Ther. 2024, 7, 335–350. [Google Scholar] [CrossRef]

- Goli, V.A.R.; Butreddy, A. Biosimilar monoclonal antibodies: Challenges and approaches towards formulation. Chem. -Biol. Interact. 2022, 366, 110116. [Google Scholar] [CrossRef]

- Ingle, R.G.; Fang, W. An Overview of the Stability and Delivery Challenges of Commercial Nucleic Acid Therapeutics. Pharmaceutics 2023, 15, 1158. [Google Scholar] [CrossRef] [PubMed]

- Desai, M.; Kundu, A.; Hageman, M.; Lou, H.; Boisvert, D. Monoclonal Antibody and Protein Therapeutic Formulations for Subcutaneous Delivery: High-Concentration, Low-Volume vs. Low-Concentration, High-Volume. mAbs 2023, 15, 2285277. [Google Scholar] [CrossRef] [PubMed]

- Papamichael, K.; Stocco, G.; Agua, A.R.d. Challenges in Therapeutic Drug Monitoring: Optimizing Biological Treatments in Patients with Inflammatory Bowel Disease and Other Immune-Mediated Inflammatory Diseases. Ther. Drug Monit. 2023, 45, 579–590. [Google Scholar] [CrossRef] [PubMed]

- Ahn, S.; Lee, M.; Baek, Y.; Lee, S. A Randomized Pharmacokinetic Study in Healthy Male Subjects Comparing a High-Concentration, Citrate-Free SB5 Formulation (40 mg/0.4 mL) and Prior SB5 (Adalimumab Biosimilar). Rheumatol. Ther. 2022, 9, 1157–1169. [Google Scholar] [CrossRef]

- D’Abbundo, G.; Nachury, M.; Wartski, A.; Blondeaux, A.; Hambli, S.; Gérard, R.; Wils, P. Switch Acceptance and Persistence of Adalimumab Biosimilars in IBD Patients: A Prospective Observational Study. Ther. Adv. Gastroenterol. 2025, 18, 17562848251332025. [Google Scholar] [CrossRef]

- Lv, J.; Ingle, R.G.; Wu, H.; Liu, C.; Fang, W. Histidine as a Versatile Excipient in the Protein-Based Biopharmaceutical Formulations. Int. J. Pharm. 2024, 662, 124472. [Google Scholar] [CrossRef]

- Zarzar, J.; Khan, T.A.; Bhagawati, M.; Weiche, B.; Sydow-Andersen, J.; Sreedhara, A. High concentration formulation developability approaches and considerations. mAbs 2023, 15, 2211185. [Google Scholar] [CrossRef]

- Ghosh, I.; Gutka, H.J.; Krause, M.E.; Clemens, R.; Kashi, R.S. A systematic review of commercial high concentration antibody drug products approved in the US: Formulation composition, dosage form design and primary packaging considerations. mAbs 2023, 15, 2205540. [Google Scholar] [CrossRef]

- Lebar, B.; Zidar, M.; Mravljak, J.; Šink, R.; Žula, A.; Pajk, S. Alternative buffer systems in biopharmaceutical formulations and their effect on protein stability. Pharm. Acta 2024, 74, 479–493. [Google Scholar] [CrossRef]

- Pardeshi, S.R.; Deshmukh, N.S.; Telange, D.R.; Nangare, S.; Sonar, Y.Y.; Lakade, S.; Harde, M.T.; Pardeshi, C.V.; Gholap, A.; Deshmukh, P.K.; et al. Process development and quality attributes for the freeze-drying process in pharmaceuticals, biopharmaceuticals and nanomedicine delivery: A state-of-the-art review. Future J. Pharm. Sci. 2023, 9, 99. [Google Scholar] [CrossRef]

- Upadhya, R.; Yarger, T.; Blanco, M.; Bothe, J.; Pabit, S.; XI, H. Leveraging SAXS for biologics formulation development in the pharmaceutical industry. Struct. Dyn. 2025, 12 (Suppl. S2), A189. [Google Scholar] [CrossRef]

- Mieczkowski, C. The evolution of commercial antibody formulations. J. Pharm. Sci. 2023, 112, 1801–1810. [Google Scholar] [CrossRef] [PubMed]

- Erfani, A.; Schieferstein, J.; Reichert, P.; Narasimhan, C.; Pastuskovas, C.; Parab, V.; Simmons, D.; Yang, X.; Shanker, A.; Hammond, P.; et al. Crystalline antibody-laden alginate particles: A platform for enabling high concentration subcutaneous delivery of antibodies. Adv. Healthc. Mater. 2023, 12, 2202370. [Google Scholar] [CrossRef] [PubMed]

- Saurabh, S.; Li, Z.; Hollowell, P.; Waigh, T.; Li, P.; Webster, J.; Seddon, J.M.; Kalonia, C.; Lu, J.R.; Bresme, F. Structure and interaction of therapeutic proteins in solution: A combined simulation and experimental study. Mol. Phys. 2023, 121, e2236248. [Google Scholar] [CrossRef] [PubMed]

- Mosca, I.; Pounot, K.; Beck, C.; Colin, L.; Matsarskaia, O.; Grapentin, C.; Seydel, T.; Schreiber, F. Biophysical determinants for the viscosity of concentrated monoclonal antibody solutions. Mol. Pharm. 2023, 20, 4698–4713. [Google Scholar] [CrossRef] [PubMed]

- Zürcher, D.; Wuchner, K.; Arosio, P. Real-Time Observation of Protein Aggregation at Liquid-Liquid Interfaces in a Microfluidic Device. Small 2024, 20, 2401085. [Google Scholar] [CrossRef]

- Meza, N.P.; Hardy, C.A.; Morin, K.H.; Huang, C.; Raghava, S.; Song, J.; Wang, Y. Predicting Colloidal Stability of High-Concentration Monoclonal Antibody Formulations in Common Pharmaceutical Buffers Using Improved Polyethylene Glycol Induced Protein Precipitation Assay. Mol. Pharm. 2023, 20, 5842–5855. [Google Scholar] [CrossRef]

- Kramar, H.I.; Kryvoviaz, O.V.; Tomashevska, Y.O.; Toziuk, O.I.; Kudria, V.V.; Koval, V.M.; Alchuk, O.I. Analysis of the use of excipients in medicines of biological origin. Rep. Vinnytsia Natl. Med. Univ. 2024, 28, 145–150. [Google Scholar] [CrossRef]

- Xiao, E.; Mirabel, C.; Clénet, D.; Zhu, S.; James, A.; Ettorre, L.; Williams, T.; Szeto, J.; Rahman, N.; Ausar, S.F. Formulation development of a COVID-19 recombinant spike protein-based vaccine. Vaccines 2024, 12, 830. [Google Scholar] [CrossRef]

- Rospiccio, M.; Casucci, P.; Arsiccio, A.; Udrescu, C.; Pisano, R. Mechanistic investigation of tert-butanol’s impact on biopharmaceutical formulations: When experiments meet molecular dynamics. Mol. Pharm. 2023, 20, 3975–3986. [Google Scholar] [CrossRef]

- Park, J.; Liu, R.; Kim, A.; Cyr, N.; Boehlein, S.; Resende, M.; Savin, D.A.; Bailey, L.S.; Sumerlin, B.S.; Hudalla, G.A. Sweet corn phytoglycogen dendrimers as a lyoprotectant for dry-state protein storage. J. Biomed. Mater. Res. A 2024, 112, 2026–2041. [Google Scholar] [CrossRef] [PubMed]

- Lebar, B.; Lekić, T.; Košir, P.; Kastelic, M.; Zidar, M.; Mravljak, J.; Pajk, S. Polysorbate stability: Effects of packaging materials, buffers, counterions, and ph. Int. J. Pharm. 2024, 665, 124598. [Google Scholar] [CrossRef] [PubMed]

- Žiberna, M.; Grabnar, P.; Gašperlin, M.; Matjaž, M. Lyophilised protein formulations as a patient-centric dosage form: A contribution toward sustainability paradigm. Acta Pharm. 2024, 74, 289–300. [Google Scholar] [CrossRef] [PubMed]

- Niazi, S. No two classes of biosimilars: Urgent advice to the US Congress and the FDA. J. Clin. Pharm. Ther. 2022, 47, 1352–1361. [Google Scholar] [CrossRef]

- Gianoncelli, A.; Bertuzzi, M.; Guarienti, M.; Vezzoli, S.; Bonini, S.A.; Mastinu, A.; Sigala, S.; Memo, M. Parallelism of chemicostructural properties between filgrastim originator and three of its biosimilar drugs. J. Chem. 2019, 2019, 2751461. [Google Scholar] [CrossRef]

- Ghasriani, H.; Frahm, G.; Johnston, M.; Aubin, Y. Effects of excipients on the structure and dynamics of filgrastim monitored by thermal unfolding studies by CD and NMR spectroscopy. ACS Omega 2020, 5, 31845–31857. [Google Scholar] [CrossRef]

- Arvinte, T.; Poirier, E.; Cudd, A.; Ersayin, N.; Darpin, G.; Dowd, J.; Brokx, S. Aggregation of human plasma and of human blood induced in vitro by filgrastim originator product; effect of PEGylation. Eur. J. Pharm. Biopharm. 2024, 194, 148–158. [Google Scholar] [CrossRef]

- Lonshakov, D.V.; Sheremet’ev, S.V.; Khursevich, E.M.; Bobrysheva, I.V.; Grebennikova, O.A.; Korovkin, S.A. Study of pH-dependent kinetics of filgrastim pegylation with succinimide derivatives of poly(ethylene glycol) and comparison of the properties of pegylated forms obtained under various conditions. Pharm. Chem. J. 2024, 58, 306–319. [Google Scholar] [CrossRef]

- Allegretti, J.; Brady, J.; Wicker, A.; Latymer, M.; Wells, A. Relevance of adalimumab product attributes to patient experience in the biosimilar era: A narrative review. Adv. Ther. 2024, 41, 1775–1794. [Google Scholar] [CrossRef]

- Chiu, I.; Tsai, T. Risk factors of ixekizumab-induced injection site reactions in patients with psoriatic diseases: Report from a single medical center. Biomedicines 2023, 11, 1718. [Google Scholar] [CrossRef]

- Patel, A.; Luu, P. Changes in patient reported pain measures with the citrate-free adalimumab formulation in pediatric inflammatory bowel disease patients. JPGN Rep. 2020, 1, e016. [Google Scholar] [CrossRef] [PubMed]

- Feldman, S.; Reznichenko, N.; Pulka, G.; Kingo, K.; Galdava, G.; Berti, F.; Sobierska, J.; Dias, R.; Guenzi, E.; Otto, H.; et al. Efficacy, safety and immunogenicity of AVT02 versus originator adalimumab in subjects with moderate to severe chronic plaque psoriasis: A multicentre, double-blind, randomised, parallel group, active control, phase III study. BioDrugs 2021, 35, 735–748. [Google Scholar] [CrossRef] [PubMed]

- Uricoli, B.; Birnbaum, L.A.; Do, P.; Kelvin, J.; Jain, J.; Costanza, E.; Chyong, A.; Porter, C.C.; Rafiq, S.; Dreaden, E.C. Engineered cytokines for cancer and autoimmune disease immunotherapy. Adv. Healthc. Mater. 2021, 10, 2002214. [Google Scholar] [CrossRef] [PubMed]

- Barbier, L.; Ebbers, H.C.; Declerck, P.; Simoens, S.; Vulto, A.G.; Huys, I. The efficacy, safety, and immunogenicity of switching between reference biopharmaceuticals and biosimilars: A systematic review. Clin. Pharmacol. Ther. 2020, 108, 734–755. [Google Scholar] [CrossRef] [PubMed]

- Vinukonda, A.; Rapolu, K.; Jadi, R.K.; Devadasu, V.R. Complex peptide injectables: Development and challenges. Int. J. Pept. Res. Ther. 2025, 31, 51. [Google Scholar] [CrossRef]

- Ismail, S.; Esba, L.; Khan, M.; Alabdulkarim, H.; Modimagh, H.; Yousef, C. An institutional guide for formulary decisions of biosimilars. Hosp. Pharm. 2022, 58, 38–48. [Google Scholar] [CrossRef]

- Li, J.; Krause, M.; Chen, X.; Cheng, Y.; Dai, W.; Hill, J.; Huang, M.; Jordan, S.; LaCasse, D.; Narhi, L.; et al. Interfacial stress in the development of biologics: Fundamental understanding, current practice, and future perspective. AAPS J. 2019, 21, 44. [Google Scholar] [CrossRef]

- Velankar, K.; Gawalt, E.; Wen, Y.; Meng, W. Pharmaceutical proteins at the interfaces and the role of albumin. Biotechnol. Prog. 2024, 40, e3474. [Google Scholar] [CrossRef]

- Tosstorff, A.; Menzen, T.; Winter, G. Exploring chemical space for new substances to stabilize a therapeutic monoclonal antibody. J. Pharm. Sci. 2020, 109, 301–307. [Google Scholar] [CrossRef]

- Bramham, J.; Davies, S.; Podmore, A.; Golovanov, A. Stability of a high-concentration monoclonal antibody solution produced by liquid–liquid phase separation. mAbs 2021, 13, 1940666. [Google Scholar] [CrossRef]

- Stolzke, T.; Krieg, F.; Peng, T.; Zhang, H.; Häusler, O.; Brandenbusch, C. Hydroxylpropyl-β-cyclodextrin as potential excipient to prevent stress-induced aggregation in liquid protein formulations. Molecules 2022, 27, 5094. [Google Scholar] [CrossRef] [PubMed]

- Bianco, S.; Hasan, M.; Ahmad, A.; Richards, S.; Dietrich, B.; Wallace, M.; Tang, Q.; Smith, A.J.; Gibson, M.I.; Adams, D.J. Mechanical release of homogenous proteins from supramolecular gels. Nature 2024, 631, 544–548. [Google Scholar] [CrossRef] [PubMed]

- Escobar, E.; Vaclaw, M.; Lozenski, J.; Dhar, P. Using passive microrheology to measure the evolution of the rheological properties of NIST mAb formulations during adsorption to the air–water interface. Langmuir 2024, 40, 4789–4800. [Google Scholar] [CrossRef] [PubMed]

- Arsiccio, A.; McCarty, J.; Pisano, R.; Shea, J. Effect of Surfactants on Surface-Induced Denaturation of Proteins: Evidence of an Orientation-Dependent Mechanism. J. Phys. Chem. B 2018, 122, 11390–11399. [Google Scholar] [CrossRef]

- Buckland, B.C.; Sanyal, G.; Ranheim, T.; Pollard, D.; Searles, J.; Behrens, S.; Pluschkell, S.; Josefsberg, J.; Roberts, C.J. Vaccine process technology—A decade of progress. Biotechnol. Bioeng. 2024, 121, 2604–2635. [Google Scholar] [CrossRef]

- Crommelin, D.J.; Hawe, A.; Jiskoot, W. Formulation of biologics including biopharmaceutical considerations. In Pharmaceutical Biotechnology: Fundamentals and Applications; Springer International Publishing: Cham, Switzerland, 2024. [Google Scholar]

- Nongkhlaw, R.; Patra, P.; Chavrasiya, A.; Nirmal, J.; Dubey, S. Biologics: Delivery options and formulation strategies. In Drug Delivery Aspects; 2020; pp. 115–155. [Google Scholar] [CrossRef]

- Mathias, N.; Huille, S.; Picci, M.; Mahoney, R.P.; Pettis, R.J.; Case, B.; Helk, B.; Kang, D.; Shah, R.; Ma, J.; et al. Towards more tolerable subcutaneous administration: Review of contributing factors for improving combination product design. Adv. Drug Deliv. Rev. 2024, 209, 115301. [Google Scholar] [CrossRef]

- Knowles, S.; Printz, M.; Kang, D.; LaBarre, M.; Tannenbaum, R. Safety of recombinant human hyaluronidase PH20 for subcutaneous drug delivery. Expert Opin. Drug Deliv. 2021, 18, 1673–1685. [Google Scholar] [CrossRef]

- Gracia, G.; Cao, E.; Yuen, D.; Ferreira, V.; Chen, M.; Senyschyn, D.; Mintern, J.D.; Johnston, A.P.; Kang, D.W.; Feeney, O.M.; et al. Abstract B001: Removal of interstitial hyaluronan facilitates subcutaneous administration and lymphatic delivery of anti-CTLA4 antibody and improves anti-tumor efficacy. Cancer Immunol. Res. 2024, 12, B001. [Google Scholar] [CrossRef]

- Nolan, R.; Printz, M. Modeling the subcutaneous pharmacokinetics of antibodies co-administered with rHuPH20. Clin. Transl. Sci. 2024, 17, e13788. [Google Scholar] [CrossRef]

- Shibata, H.; Saitoh, S.; Kiyoshi, M.; Hayashi, Y.; Inaba, K.; Katsura, S.; Sakurai, M.; Komine, Y.; Okabe, S.; Ohbayashi, N.; et al. Survey and establishment of points to consider for application of analytical techniques to evaluate protein aggregates and insoluble particles in biopharmaceuticals: Experiences in japan biopharmaceutical consortium. AAPS J. 2025, 27, 3. [Google Scholar] [CrossRef]

- Fayed, B.; Luo, S.; Yassin, A.E.B. Challenges and recent advances in erythropoietin stability. Pharm. Dev. Technol. 2024, 29, 930–944. [Google Scholar] [CrossRef] [PubMed]

- Bohlius, J.; Bohlke, K.; Castelli, R.; Djulbegović, B.; Lustberg, M.; Martino, M.; Mountzios, G.; Peswani, N.; Porter, L.; Tanaka, T.N.; et al. Management of cancer-associated anemia with erythropoiesis-stimulating agents: ASCO/ASH clinical practice guideline update. Blood Adv. 2019, 3, 1197–1210. [Google Scholar] [CrossRef] [PubMed]

- Fernández-Mendívil, C.; Kinsella, N.; Ebbers, H. A retrospective analysis of the potential impact of differences in aggregates on clinical immunogenicity of biosimilars and their reference products. Clin. Pharmacol. Ther. 2024, 115, 1122–1131. [Google Scholar] [CrossRef] [PubMed]

- Gascón, P.; Goldsmith, D.; Aapro, M.; Dellanna, F.; Esmael, A.; Zabransky, M. Epoetin alfa biosimilar (HX575): A review of 15 years’ post-approval clinical experience. Crit. Rev. Oncol./Hematol. 2023, 181, 103894. [Google Scholar] [CrossRef]

- Venetsanopoulou, A.I.; Voulgari, P.V.; Drosos, A.A. Optimizing withdrawal strategies for anti-TNF-α therapies in rheumatoid arthritis. Expert Opin. Biol. Ther. 2024, 24, 815–825. [Google Scholar] [CrossRef]

- Jyssum, I.; Gehin, J.; Sexton, J.; Kristianslund, E.; Hu, Y.; Warren, D.; Kvien, T.K.; Haavardsholm, E.A.; Syversen, S.W.; Bolstad, N.; et al. Adalimumab serum levels and anti-drug antibodies: Associations to treatment response and drug survival in inflammatory joint diseases. Rheumatology 2023, 63, 1746–1755. [Google Scholar] [CrossRef]

- Zagalo, D.M.; Simões, S.; Sousa, J. Regulatory science approach in pharmaceutical development of follow-on versions of non-biological complex drug products. J. Pharm. Sci. 2022, 111, 2687–2713. [Google Scholar] [CrossRef]

- Monga, A.; Gagan; Jamwal, P.; Sharma, S.; Kaur, A. Biosimilars: A Critical Review of Development, Regulatory Landscape, and Clinical Implications. AAPS PharmSciTech 2025, 26, 46. [Google Scholar] [CrossRef]

- D’Amico, F.; Peyrin-Biroulet, L.; Danese, S. Benefits of biosimilars in the management of patients with inflammatory bowel disease: An international survey. J. Clin. Med. 2024, 13, 3069. [Google Scholar] [CrossRef]

- Seo, N.; Guan, X.; Wang, T.; Chung, H.S.H.; Wikström, M.; Padaki, R.; Kalenian, K.; Kuhns, S.; Matthies, K.; Crouse-Zeineddini, J.; et al. Analytical and functional similarity of aflibercept biosimilar ABP 938 with aflibercept reference product. Ophthalmol. Ther. 2024, 13, 1303–1320. [Google Scholar] [CrossRef]

- Feagan, B.; Marabani, M.; Wu, J.; Faccin, F.; Spronk, C.; Castañeda-Hernández, G. The challenges of switching therapies in an evolving multiple biosimilars landscape: A narrative review of current evidence. Adv. Ther. 2020, 37, 4491–4518. [Google Scholar] [CrossRef] [PubMed]

- Abu-Zaid, M.; Adebajo, A.; Miedany, Y. Potential for Biosimilars in Rheumatology in Africa. Ann. Rheum. Dis. 2023, 82, 1508–1510. [Google Scholar] [CrossRef] [PubMed]

- Joppi, R.; Bertelè, V.; Vannini, T.; Garattini, S.; Banzi, R. Food and Drug Administration vs European Medicines Agency: Review times and clinical evidence on novel drugs at the time of approval. Br. J. Clin. Pharmacol. 2019, 86, 170–174. [Google Scholar] [CrossRef] [PubMed]

- Greene, L.; Singh, R.; Carden, M.; Pardo, C.; Lichtenstein, G. Strategies for overcoming barriers to adopting biosimilars and achieving goals of the Biologics Price Competition and Innovation Act: A survey of managed care and specialty pharmacy professionals. J. Manag. Care Spec. Pharm. 2019, 25, 904–912. [Google Scholar] [CrossRef]

- Shan, H.; Wang, M.; Huang, S.; Liu, H.; Liu, J.; Du, Q. Efficacy and safety of bevacizumab biosimilar (encoda) compared with reference bevacizumab (Avastin) in patients with metastatic colorectal cancer: A multicenter, real-world study. Clin. Med. Insights Oncol. 2024, 18, 11795549241303726. [Google Scholar] [CrossRef]

- Niazi, S. A critical analysis of the FDA’s omics-driven pharmacodynamic biomarkers to establish biosimilarity. Pharmaceuticals 2023, 16, 1556. [Google Scholar] [CrossRef]

- Patel, A.; Bhatt, N.; Prakash, S.S.; Biswas, G.; Nagarkar, R.; Roy, B.; Doshi, M. Rituximab Biosimilar for the Treatment of Diffuse Large B-Cell Lymphoma: A Phase 3 Randomized Study in India. Cancer Chemother. Pharmacol. 2023, 91, 457–468. [Google Scholar] [CrossRef]

- Hariprasad, S.; Gale, R.; Weng, C.; Ebbers, H.; Rezk, M.; Tadayoni, R. An introduction to biosimilars for the treatment of retinal diseases: A narrative review. Ophthalmol. Ther. 2022, 11, 959–982. [Google Scholar] [CrossRef]

- Lin, S.; Lou, Y.; Hao, R.; Shao, Y.; Yü, J.; Lü, F.; Zhang, Y. A Single-Dose, Randomized, Open-Label, Four-Period, Crossover Equivalence Trial Comparing the Clinical Similarity of the Proposed Biosimilar Rupatadine Fumarate to Reference Wystamm® in Healthy Chinese Subjects. Front. Pharmacol. 2024, 15, 1328142. [Google Scholar] [CrossRef]

- Bhatt, M.; Tank, S.; Shah, J.S.; Maheshwari, D. Regulatory Framework and Disparities of Complex Generics in United States, European Union & Latin America. J. Generic Med. 2023, 19, 130–140. [Google Scholar] [CrossRef]

- Sadda, S.R.; Bradvica, M.; Vajas, A.; Sagong, M.; Ernest, J.; Studnička, J.; Woo, S.J. Biosimilar SB15 versus Reference Aflibercept in Neovascular Age-Related Macular Degeneration: 1-Year and Switching Results of a Phase 3 Clinical Trial. BMJ Open Ophthalmol. 2023, 8, e001561. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.J.; Delate, T.; Hui, R.L.; Le, K.; Pham, C. Real-World Noninferiority Assessment of Two Filgrastim Biosimilars in Patients Receiving Myelosuppressive Chemotherapy. JCO Oncol. Pract. 2025, 21, 245–251. [Google Scholar] [CrossRef] [PubMed]

- Gherghescu, I.A.; Delgado-Charro, M.B. The Biosimilar Landscape: An Overview of Regulatory Approvals by the EMA and FDA. Pharmaceutics 2020, 13, 48. [Google Scholar] [CrossRef] [PubMed]

- Wouters, O.J.; Vogel, M.; Feldman, W.B.; Beall, R.F.; Kesselheim, A.S.; Tu, S.S. Differential Legal Protections for Biologics vs Small-Molecule Drugs in the US. JAMA 2024, 332, 2101. [Google Scholar] [CrossRef]

- Available online: http://www.ich.org (accessed on 7 June 2025).

- Yamaci, M. Comparative Forced Degradation Study of Anticomplement C5 Biosimilar and Originator Monoclonal Antibodies. Pharmaceuticals 2025, 18, 579. [Google Scholar] [CrossRef]

- Gaggero, A.; Jeremic, D.; Sattler, R.; Paudel, A.; Urich, J. Evaluation of Analytical Quality by Design Approaches on the Development and Optimization of Size Exclusion Chromatography Analytical Procedures for Bovine Serum Albumin. J. Sep. Sci. 2025, 48, e70168. [Google Scholar] [CrossRef]

- Low, K.; Kok, Y.; Tate, S.; Bi, X. Multilevel—Intact, Subunits, and Peptides—Characterization of Antibody-Based Therapeutics by a Single-Column LC–MS Setup. Anal. Chem. 2025, 97, 5118–5125. [Google Scholar] [CrossRef]

- Wu, G.; Yu, C.; Wang, W.; Du, J.; Fu, Z.; Xu, G.; Wang, L. Mass Spectrometry-Based Charge Heterogeneity Characterization of Therapeutic mAbs with Imaged Capillary Isoelectric Focusing and Ion-Exchange Chromatography as Separation Techniques. Anal. Chem. 2023, 95, 2548–2560. [Google Scholar] [CrossRef]

- Kwok, T.; Chan, S.; Shi, J.; Zhou, M.; Schaefer, A.; Tao, B.; Chen, T. Imaged Capillary Isoelectric Focusing Employing Fluorocarbon and Methylcellulose Coated Fused Silica Capillary for Characterization of Charge Heterogeneity of Protein Biopharmaceuticals. Sep. Sci. Plus 2023, 6, 2200160. [Google Scholar] [CrossRef]

- Dawdy, A.; Trujillo, E.; Liu, Z.; Crone, C.; Kraegenbring, J.; Scheffler, K. Improved Mass Accuracy and Precision for Multi-Attribute Methods Using a New Internally Calibrated High Resolution Orbitrap Mass Detector. Anal. Chem. 2024, 96, 6528–6533. [Google Scholar] [CrossRef]

- Waldenmaier, H.; Gorre, E.; Poltash, M.; Gunawardena, H.; Zhai, X.; Li, J.; Nanda, H. “Lab of the Future”—Today: Fully Automated System for High-Throughput Mass Spectrometry Analysis of Biotherapeutics. J. Am. Soc. Mass Spectrom. 2023, 34, 1073–1085. [Google Scholar] [CrossRef] [PubMed]

- Feldman, R. Paucity of intellectual property rights information in the us biologics system a decade after passage of the biosimilars act. PLoS Med. 2024, 21, e1004381. [Google Scholar] [CrossRef] [PubMed]

- FDA. Guidance for Industry: Q8(R2) Pharmaceutical Development. U.S. Food and Drug Administration; 2009. Available online: https://www.fda.gov/media/71535/download (accessed on 15 May 2025).

- Iqbal, Z.; Sadaf, S. Biosimilars: A comparative study of regulatory, safety and pharmacovigilance monograph in the developed and developing economies. J. Pharm. Pharm. Sci. 2022, 25, 149–182. [Google Scholar] [CrossRef] [PubMed]

- Du, X.; Luo, X.; Guo, Q.; Jiang, X.; Su, Z.; Zhou, W.; Zhang, Y. Assessment of Clinical Benefit, Cost and Uptake of Biosimilars versus Reference Biologics in Immune-Mediated Inflammatory Diseases in China. Front. Public Health 2024, 12, 1476213. [Google Scholar] [CrossRef]

- Amaral, C.; Rodrigues, A.R.; Veiga, F.; Bell, V. Biosimilar medicines: From development process to marketing authorization by the EMA and the FDA. Appl. Sci. 2024, 14, 7529. [Google Scholar] [CrossRef]

- Loche, S.; Kanumakala, S.; Backeljauw, P.; Schwab, K.O.; Lechuga-Sancho, A.M.; Esmael, A.; Urosevic, D.; Boldea, A.; Zabransky, M. Safety and effectiveness of a biosimilar recombinant human growth hormone in children requiring growth hormone treatment: Analysis of final data from PATRO Children, an international, post-marketing surveillance study. Drug Des. Dev. Ther. 2024, 18, 667–684. [Google Scholar] [CrossRef]

- Feldman, W. Patent thickets and product hops: Challenges and opportunities for legislative reform. J. Law Med. Ethics 2025, 1–6. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Petrescu, F.; Alysandratou, E. Bioprinting and intellectual property: Challenges, opportunities, and the road ahead. Bioengineering 2025, 12, 76. [Google Scholar] [CrossRef]

- Asija, A.; Moreira, S.; Ringov, D.; Soares, T. Fragmentation of technology ownership and acquisition strategy of firms. Br. J. Manag. 2023, 35, 1392–1407. [Google Scholar] [CrossRef]

- Druedahl, L.; Almarsdóttir, A.; Sporrong, S.; Bruin, M.; Hoogland, H.; Minssen, T.; van de Weert, M.; Kesselheim, A.S.; Sarpatwari, A. A qualitative study of biosimilar manufacturing and regulatory perceptions on intellectual property and abbreviated approval pathways. Nat. Biotechnol. 2020, 38, 1253–1256. [Google Scholar] [CrossRef]

- Moorkens, E.; Vulto, A.; Huys, I. An overview of patents on therapeutic monoclonal antibodies in Europe: Are they a hurdle to biosimilar market entry? mAbs 2020, 12, 1743517. [Google Scholar] [CrossRef] [PubMed]

- Bettanti, A.; Lanati, A.; Missoni, A. Biopharmaceutical innovation ecosystems: A stakeholder model and the case of Lombardy. J. Technol. Transf. 2021, 47, 1948–1973. [Google Scholar] [CrossRef] [PubMed]

- Camperos, M.; Almodóvar, P. Tracking the literature on strategic alliances in the biotechnology industry: Insights from a bibliometric approach over the last 30 years. Eur. J. Manag. Bus. Econ. 2023, 34, 245–262. [Google Scholar] [CrossRef]

- Allmendinger, A. Opportunities in an evolving pharmaceutical development landscape: Product differentiation of biopharmaceutical drug products. Pharm. Res. 2021, 38, 739–757. [Google Scholar] [CrossRef]

- Edwards, C.; Chyrok, V.; Monnet, J.; Ullmann, M.; Vlachos, P. Fri0088 safety, immunogenicity and efficacy of the proposed biosimilar MSB11022 (modified formulation) compared with adalimumab reference product in patients with moderately to severely active rheumatoid arthritis: AURIEL-RA, a randomised, double-blind, phase III study. Ann. Rheum. Dis. 2019, 78, 707. [Google Scholar] [CrossRef]

- Alvarez, D.; Wolbink, G.; Cronenberger, C.; Orazem, J.; Kay, J. Interchangeability of biosimilars: What level of clinical evidence is needed to support the interchangeability designation in the United States? BioDrugs 2020, 34, 723–732. [Google Scholar] [CrossRef]

- Liu, L.; Wang, L.; Zonderman, J.; Rouse, J.; Kim, H. Automated, high-throughput infrared spectroscopy for secondary structure analysis of protein biopharmaceuticals. J. Pharm. Sci. 2020, 109, 3223–3230. [Google Scholar] [CrossRef]

- Montero-Vílchez, T.; Cuenca-Barrales, C.; Tejero, A.; Martínez-López, A.; Arias-Santiago, S.; Molina-Leyva, A. Switching from adalimumab originator to biosimilar: Clinical experience in patients with hidradenitis suppurativa. J. Clin. Med. 2022, 11, 1007. [Google Scholar] [CrossRef]

- Cavazzoni, P.; Yim, S. The science of biosimilars—Updating interchangeability. JAMA 2024, 332, 1235. [Google Scholar] [CrossRef]

- Horrow, C.; Gabriele, S.; Tu, S.; Sarpatwari, A.; Kesselheim, A. Patent portfolios protecting 10 top-selling prescription drugs. JAMA Intern. Med. 2024, 184, 810. [Google Scholar] [CrossRef]

- Tu, S.; Goode, R.; Feldman, W. Biologic patent thickets and terminal disclaimers. JAMA 2024, 331, 355. [Google Scholar] [CrossRef] [PubMed]

- Tu, S. The long con: An empirical analysis of pharmaceutical patent thickets. Univ. Pitt. Law Rev. 2024, 86, 213. [Google Scholar] [CrossRef]

- Singh, P.; Desai, P.N.; Dutta, V. Rising biosimilars in the Indian biopharmaceutical industry: Emerging challenges and way forward. Technol. Anal. Strateg. Manag. 2021, 35, 1145–1160. [Google Scholar] [CrossRef]

- Balaprabha, G.; Kondapalli, S.; Pochampally, L.; Reddy, T.; Rao, T. Interchangeable biosimilars: A new era in healthcare system. Int. J. Sci. Res. Arch. 2024, 13, 3763–3773. [Google Scholar] [CrossRef]

- Olsen, T.; Beall, R.; Knox, R.; Tu, S.; Kesselheim, A.; Feldman, W. Patents and regulatory exclusivities on FDA-approved insulin products: A longitudinal database study, 1986–2019. PLoS Med. 2023, 20, e1004309. [Google Scholar] [CrossRef] [PubMed]

- Bhardwaj, R. Economics of the Pharmaceutical and Medical Device Industry: Supply Chain, Trade and Innovation; Taylor & Francis: London, UK, 2024. [Google Scholar]

- Franco, P.; Haefliger, S. Competition of regulatory ecosystems in approving medicines: Policy implications in the case of Europe. Drug Discov. Today 2025, 30, 104295. [Google Scholar] [CrossRef]

- Tourdot, S.; Bloem, K.; Champion, L.; Groot, A.S.D.; Ducret, A.; Garidel, P.; Grudzinska-Goebel, J.; Gutknecht, M.; Hickling, T.; Horling, F.; et al. Proceedings of the 15th European immunogenicity platform open symposium on immunogenicity of biopharmaceuticals. mAbs 2025, 17, 2487604. [Google Scholar] [CrossRef]

- Larid, G.; Baudens, G.; Dandurand, A.; Coquerelle, P.; Goëb, V.; Guyot, M.H.; Gervais, E. Differential Retention of Adalimumab and Etanercept Biosimilars Compared to Originator Treatments: Results of a Retrospective French Multicenter Study. Front. Med. 2022, 9, 989514. [Google Scholar] [CrossRef]

- Jacquot, G.; Navarro, P.L.; Grange, C.; Boudali, L.; Harlepp, S.; Pivot, X.; Detappe, A. Landscape of subcutaneous administration strategies for monoclonal antibodies in oncology. Adv. Mater. 2024, 36, 2406604. [Google Scholar] [CrossRef]

- Chabra, S.; Gill, B.; Gallo, G.; Zhu, D.; Pitou, C.; Payne, C.; Accioly, A.; Puig, L. Ixekizumab citrate-free formulation: Results from two clinical trials. Adv. Ther. 2022, 39, 2862–2872. [Google Scholar] [CrossRef]

- Schreiber, S.; Ben-Horin, S.; Leszczyszyn, J.; Dudkowiak, R.; Lahat, A.; Gawdis-Wojnarska, B.; Pukitis, A.; Horynski, M.; Farkas, K.; Kierkus, J.; et al. Randomized controlled trial: Subcutaneous vs intravenous infliximab CT-P13 maintenance in inflammatory bowel disease. Gastroenterology 2021, 160, 2340–2353. [Google Scholar] [CrossRef] [PubMed]

- Pujahari, S.R.; Engla, S.; Soni, R.; Patra, S.; Hanawal, M.K.; Kumar, A. Structural similarity of biological drugs using statistical signal processing and nuclear magnetic resonance spectral pattern analysis. Mol. Pharm. 2025, 22, 2684–2693. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Strauss, D. Advancing innovations in biosimilars. Clin. Pharmacol. Ther. 2022, 113, 11–15. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, A.; Hengelbrock, A.; Strube, J. Continuous biomanufacturing in upstream and downstream processing. Phys. Sci. Rev. 2023, 9, 3167–3222. [Google Scholar] [CrossRef]