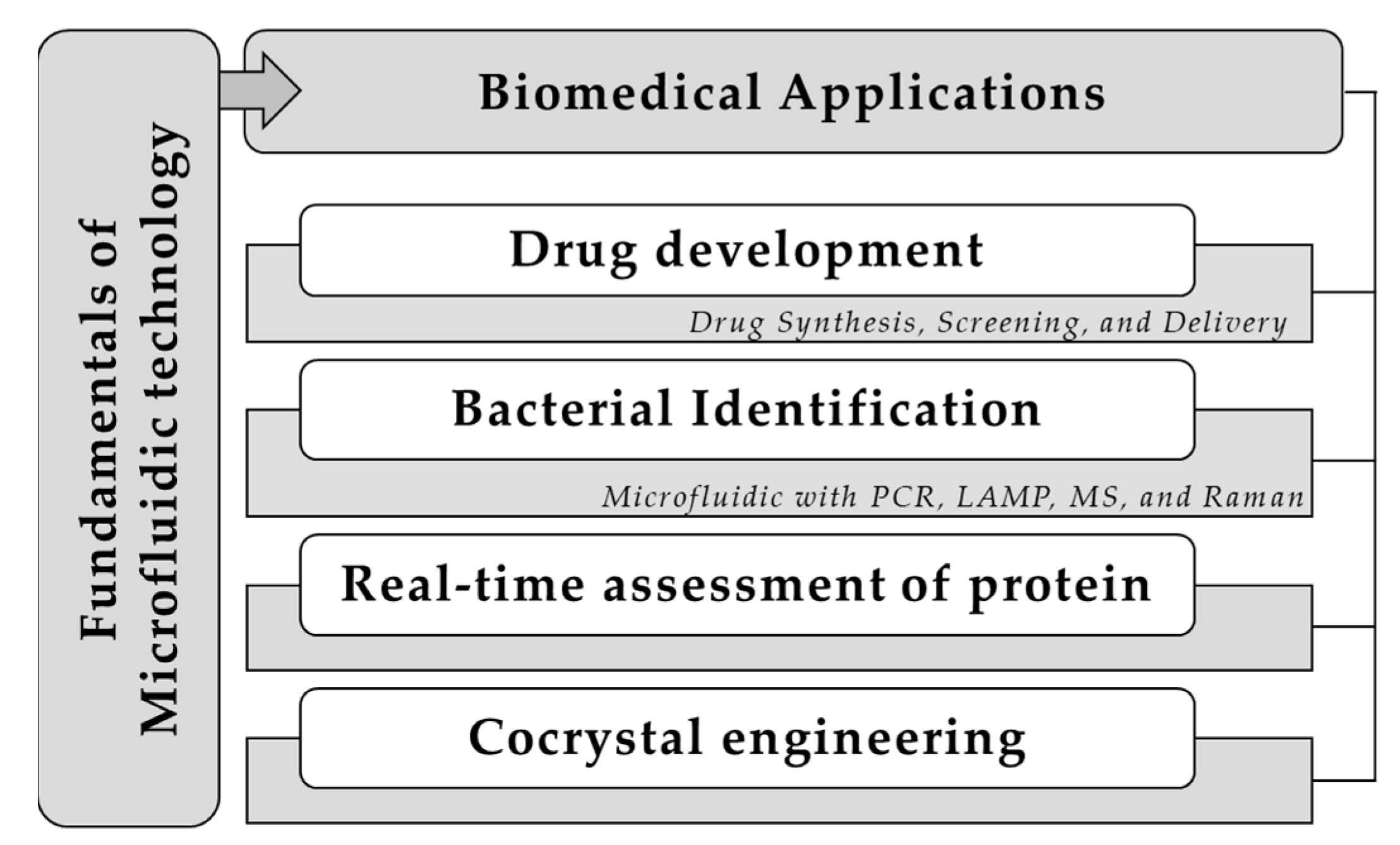

Microfluidic Formulation for Biomedical Applications

1. Introduction

2. Droplet-Based Microfluidic for Pharmaceutical Applications

3. Bacterial Identification

4. Real-Time Assessment of Protein

5. Cocrystal Engineering

6. Conclusions

Funding

Acknowledgments

Conflicts of Interest

List of Contributions

- Ngoc, T.; Trinh, D.; Dang, H.; Do, K.; Nam, N.N.; Dan, T.T.; The, K.; Trinh, L.; Lee, N.Y. Droplet-Based Microfluidics: Applications in Pharmaceuticals. Pharmaceuticals 2023, 16, 937. https://doi.org/10.3390/PH16070937.

- Daniel, F.; Kesterson, D.; Lei, K.; Hord, C.; Patel, A.; Kaffenes, A.; Congivaram, H.; Prakash, S. Application of Microfluidics for Bacterial Identification. Pharmaceuticals 2022, 15, 1531. https://doi.org/10.3390/PH15121531.

- Kuzman, D.; Klančnik, U.; Grum, E.; Derganc, J. Real-Time Assessment of the Size Changes of Individual Sub-Visible Protein Particles under Buffer Variations: A Microfluidic Study. Pharmaceuticals 2023, 16, 1002. https://doi.org/10.3390/PH16071002.

- Kara, A.; Kumar, D.; Healy, A.M.; Lalatsa, A.; Serrano, D.R.; Trinh, L.; Kara, A.; Kumar, D.; Healy, A.M.; Lalatsa, A.; et al. Continuous Manufacturing of Cocrystals Using 3D-Printed Microfluidic Chips Coupled with Spray Coating. Pharmaceuticals 2023, 16, 1064. https://doi.org/10.3390/PH16081064.

References

- Burklund, A.; Tadimety, A.; Nie, Y.; Hao, N.; Zhang, J.X.J. Advances in Diagnostic Microfluidics. Adv. Clin. Chem. 2020, 95, 1–72. [Google Scholar] [CrossRef] [PubMed]

- Limbut, W.; Promsuwan, K.; Kongkaew, S.; Thavarungkul, P.; Mak, W.C. Emerging Functional Materials for Microfluidic Biosensors. In Microfluidic Biosensors; Academic Press: Cambridge, MA, USA, 2023; pp. 195–231. [Google Scholar] [CrossRef]

- Van Den Berg, A.; Craighead, H.; Yang, P.; Mark, D.; Haeberle, S.; Günter, A.; Roth, G.; Felix Von Stettenz, A.; Zengerlez, R. Microfluidic Lab-on-a-Chip Platforms: Requirements, Characteristics and Applications. Chem. Soc. Rev. 2010, 39, 1153–1182. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, J.; Sun, R.; Han, S.; Yang, Z.; Teng, L. Microfluidics for Nano-Drug Delivery Systems: From Fundamentals to Industrialization. Acta Pharm. Sin. B 2023, 13, 3277–3299. [Google Scholar] [CrossRef] [PubMed]

- Zhao, P.; Wang, J.; Chen, C.; Wang, J.; Liu, G.; Nandakumar, K.; Li, Y.; Wang, L. Microfluidic Applications in Drug Development: Fabrication of Drug Carriers and Drug Toxicity Screening. Micromachines 2022, 13, 200. [Google Scholar] [CrossRef] [PubMed]

- Niculescu, A.G.; Chircov, C.; Bîrcă, A.C.; Grumezescu, A.M. Fabrication and Applications of Microfluidic Devices: A Review. Int. J. Mol. Sci. 2021, 22, 2011. [Google Scholar] [CrossRef] [PubMed]

- Moragues, T.; Arguijo, D.; Beneyton, T.; Modavi, C.; Simutis, K.; Abate, A.R.; Baret, J.C.; deMello, A.J.; Densmore, D.; Griffiths, A.D. Droplet-Based Microfluidics. Nat. Rev. Methods Primers 2023, 3, 32. [Google Scholar] [CrossRef]

- Mak, K.K.; Pichika, M.R. Artificial Intelligence in Drug Development: Present Status and Future Prospects. Drug Discov. Today 2019, 24, 773–780. [Google Scholar] [CrossRef] [PubMed]

- Lonchamps, P.L.; He, Y.; Wang, K.; Lu, X. Detection of Pathogens in Foods Using Microfluidic “Lab-on-Chip”: A Mini Review. J. Agric. Food Res. 2022, 10, 100430. [Google Scholar] [CrossRef]

- Li, W.; Ma, X.; Yong, Y.C.; Liu, G.; Yang, Z. Review of Paper-Based Microfluidic Analytical Devices for in-Field Testing of Pathogens. Anal. Chim. Acta 2023, 1278, 341614. [Google Scholar] [CrossRef] [PubMed]

- Berlanda, S.F.; Breitfeld, M.; Dietsche, C.L.; Dittrich, P.S. Recent Advances in Microfluidic Technology for Bioanalysis and Diagnostics. Anal. Chem. 2021, 93, 311–331. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Cai, L.; Liang, S.; Zhang, Q.; Lin, S.; Li, M.; Yang, Q.; Li, C.; Han, Z.; Yang, C. Digital Microfluidics for Biological Analysis and Applications. Lab. Chip 2023, 23, 1169–1191. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Wei, H.; Du, Y. Microfluidic Bioanalysis Based on Nanozymes. TrAC Trends Anal. Chem. 2023, 158, 116858. [Google Scholar] [CrossRef]

- Carneiro, R.L.; de Melo, C.C.; de Alvarenga, B.R.; Dayo Owoyemi, B.C.; Ellena, J.; da Silva, C.C.P. Mechanochemical Synthesis and Characterization of a Novel AAs–Flucytosine Drug–Drug Cocrystal: A Versatile Model System for Green Approaches. J. Mol. Struct. 2022, 1251, 132052. [Google Scholar] [CrossRef]

- Pawar, N.; Saha, A.; Nandan, N.; Parambil, J.V. Solution Cocrystallization: A Scalable Approach for Cocrystal Production. Crystals 2021, 11, 303. [Google Scholar] [CrossRef]

- Puigmartí-Luis, J. Microfluidic Platforms: A Mainstream Technology for the Preparation of Crystals. Chem. Soc. Rev. 2014, 43, 2253–2271. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trinh, K.T.L. Microfluidic Formulation for Biomedical Applications. Pharmaceuticals 2023, 16, 1587. https://doi.org/10.3390/ph16111587

Trinh KTL. Microfluidic Formulation for Biomedical Applications. Pharmaceuticals. 2023; 16(11):1587. https://doi.org/10.3390/ph16111587

Chicago/Turabian StyleTrinh, Kieu The Loan. 2023. "Microfluidic Formulation for Biomedical Applications" Pharmaceuticals 16, no. 11: 1587. https://doi.org/10.3390/ph16111587

APA StyleTrinh, K. T. L. (2023). Microfluidic Formulation for Biomedical Applications. Pharmaceuticals, 16(11), 1587. https://doi.org/10.3390/ph16111587