Research on Dynamic Temperature at Outlet of Centrally Staged Combustor Based on TDLAS Technology

Abstract

1. Introduction

2. Materials and Methods

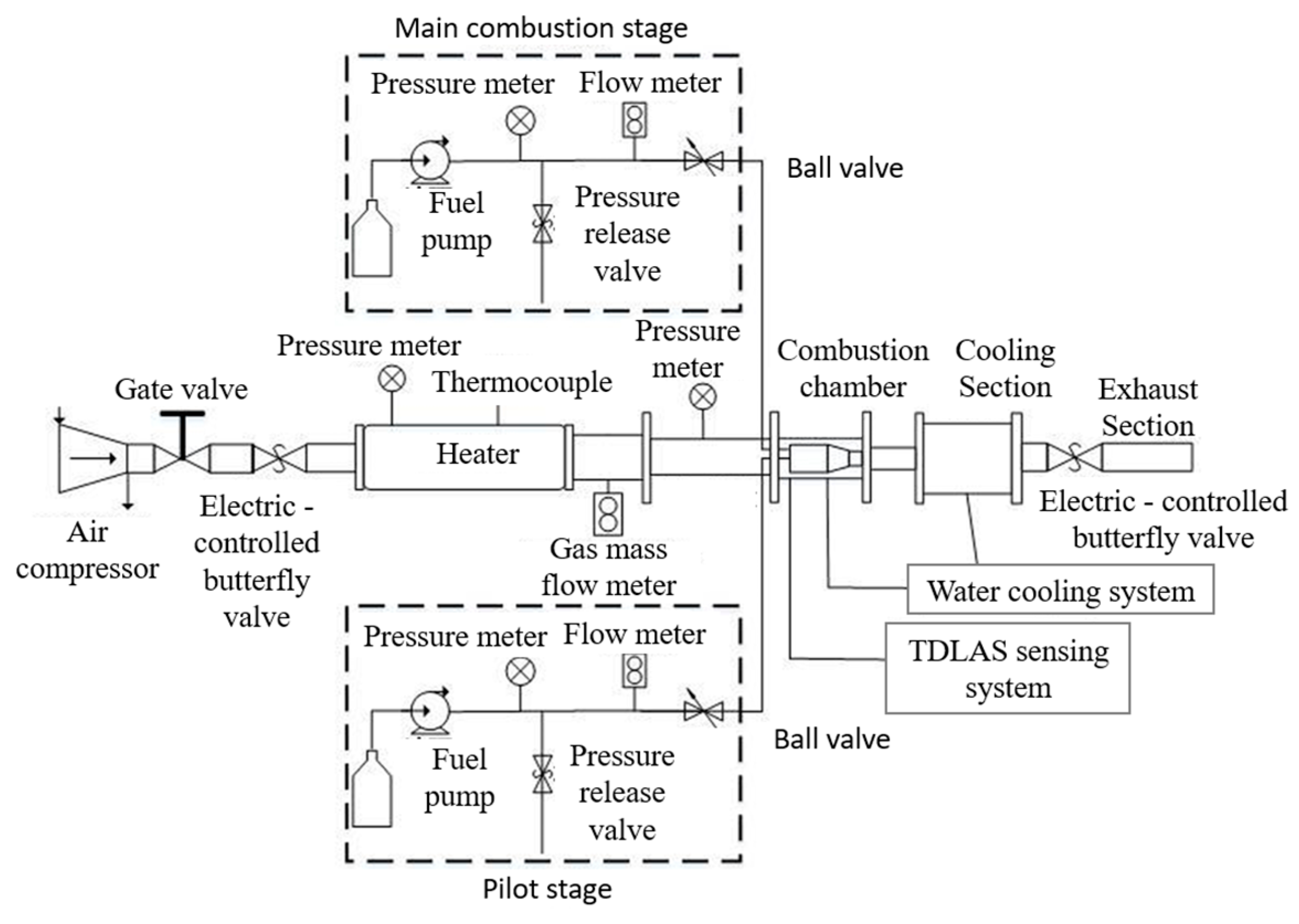

2.1. Experimental System

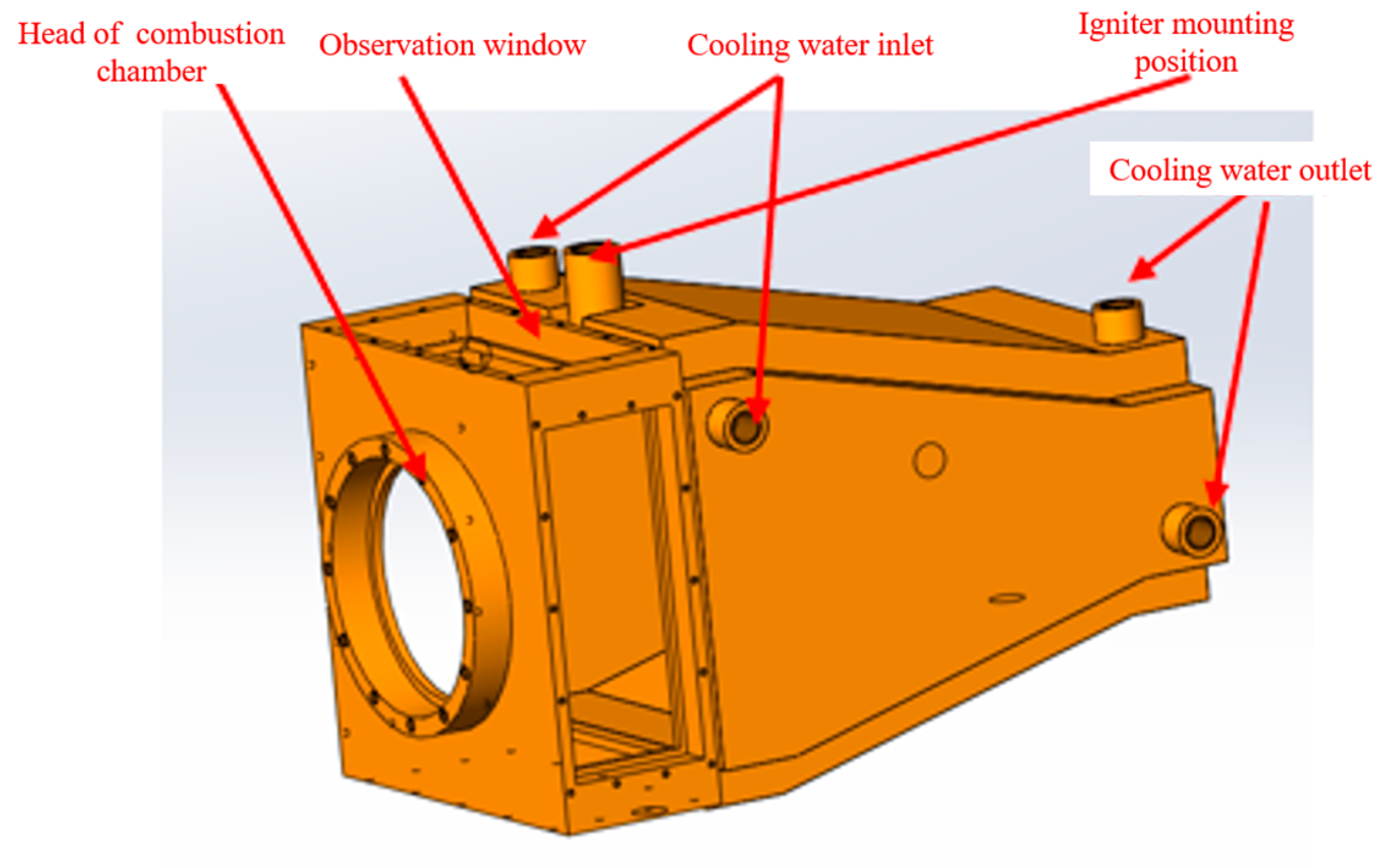

2.2. Measurement Specimen

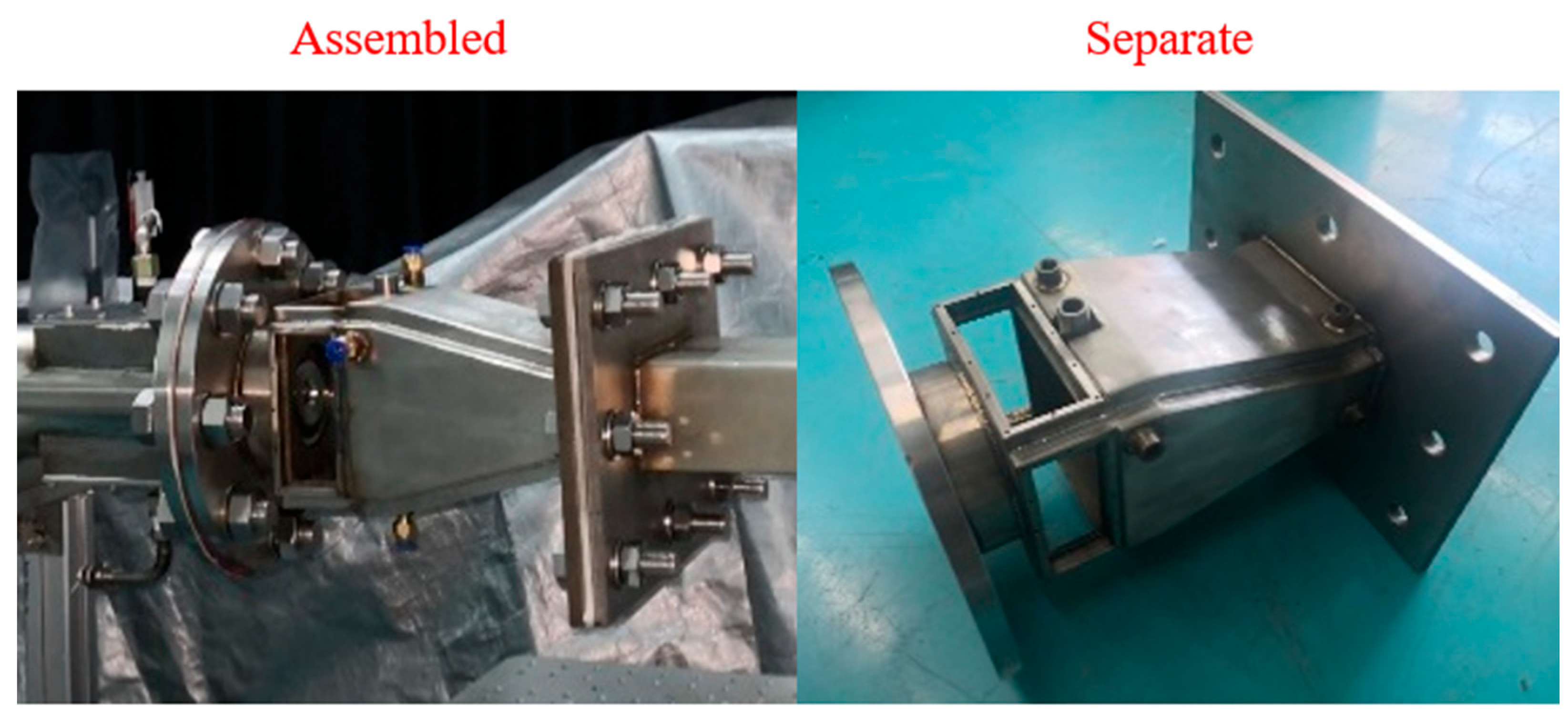

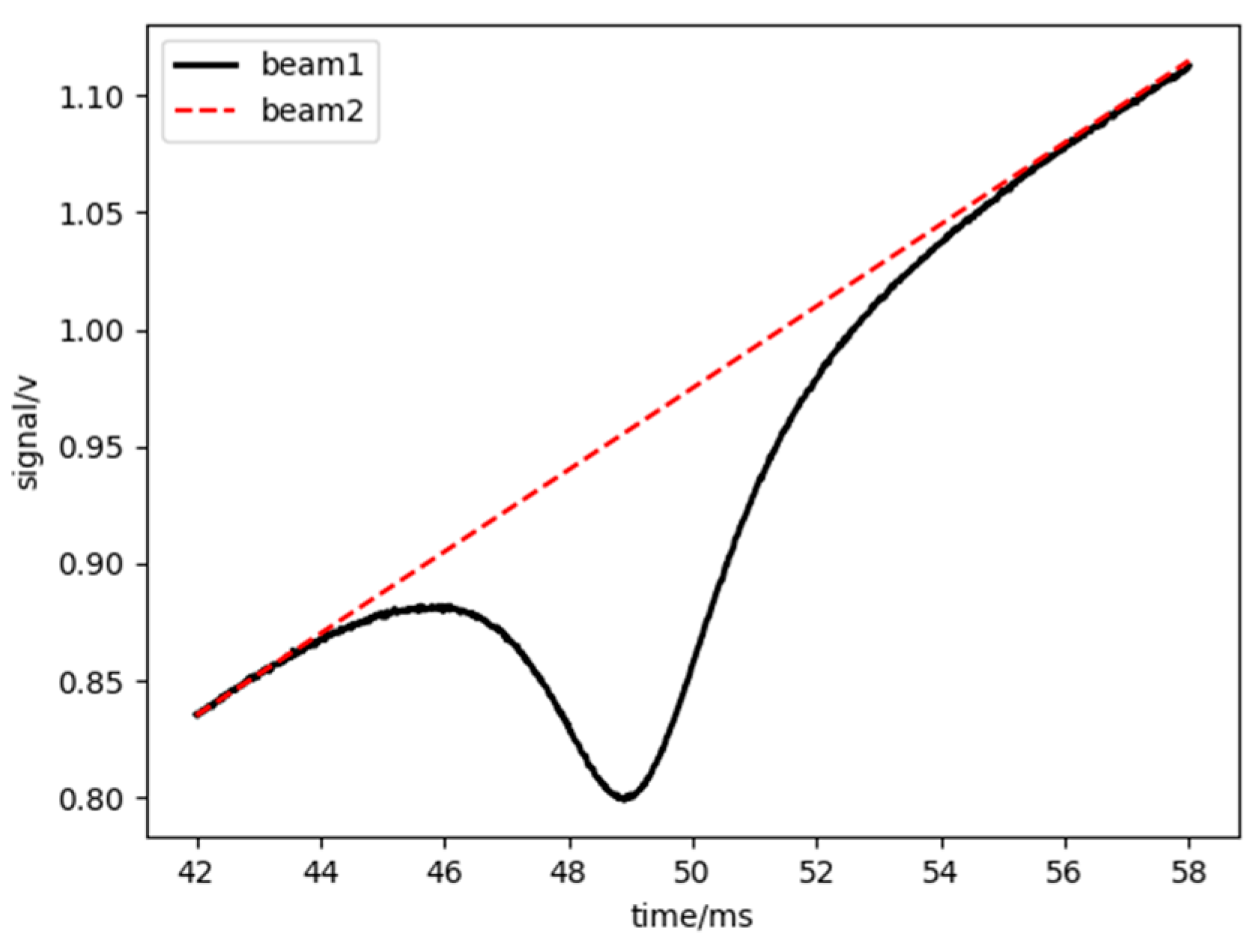

2.3. Sensing System

2.4. Experimental Condition

3. Results

3.1. Steady-State Temperature Measurement Results

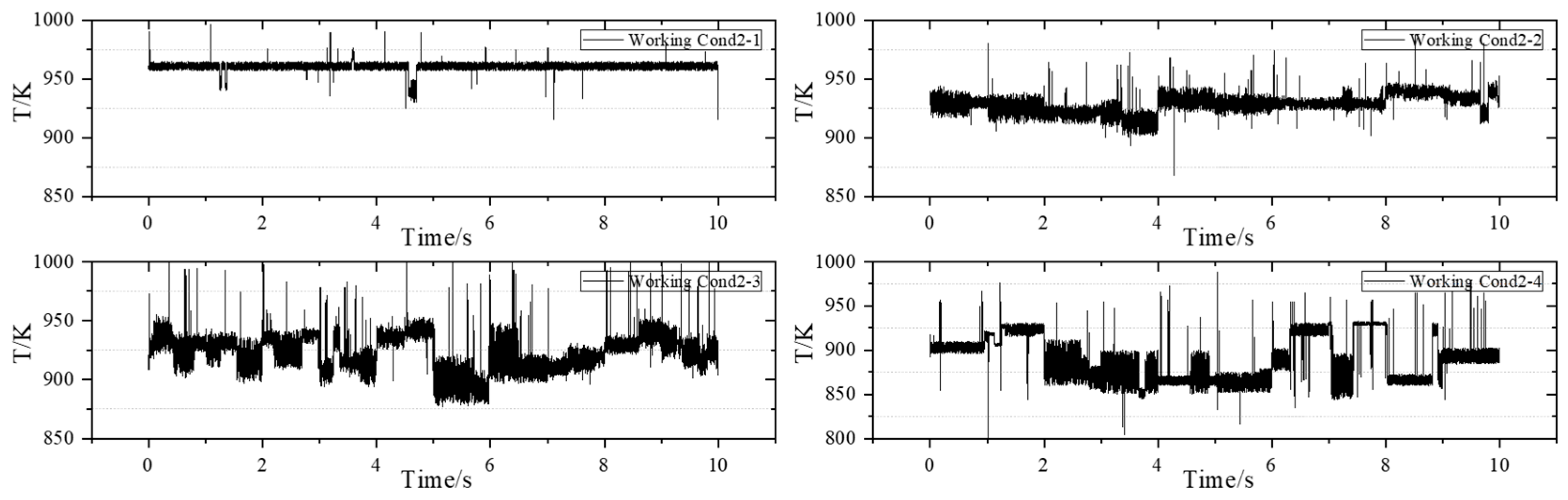

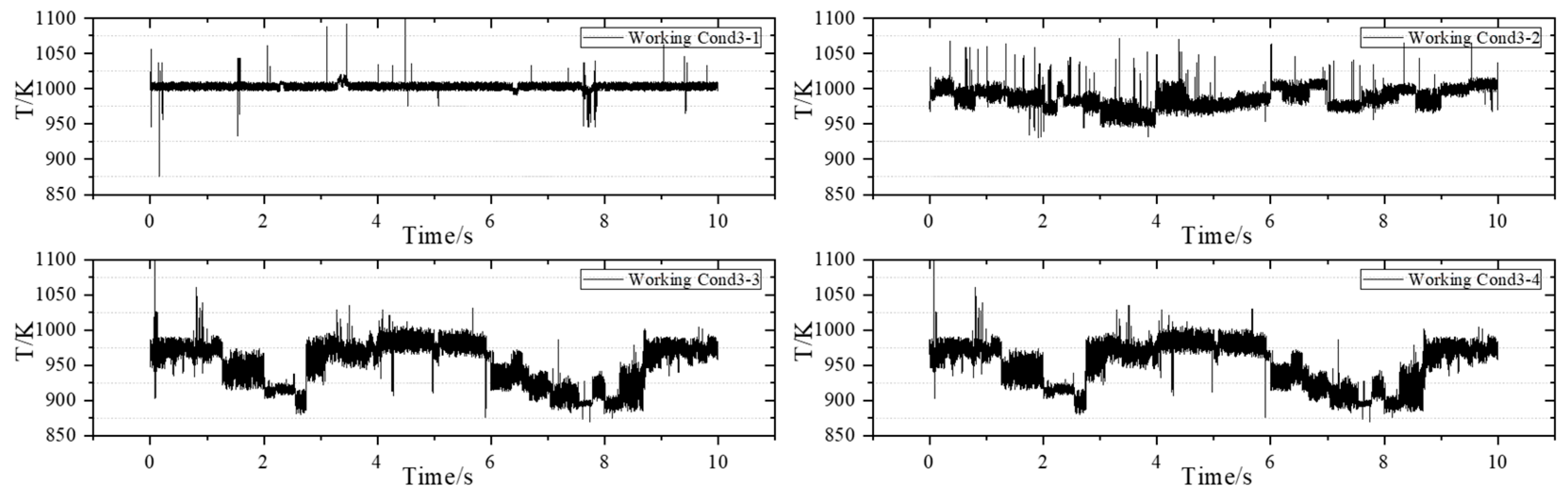

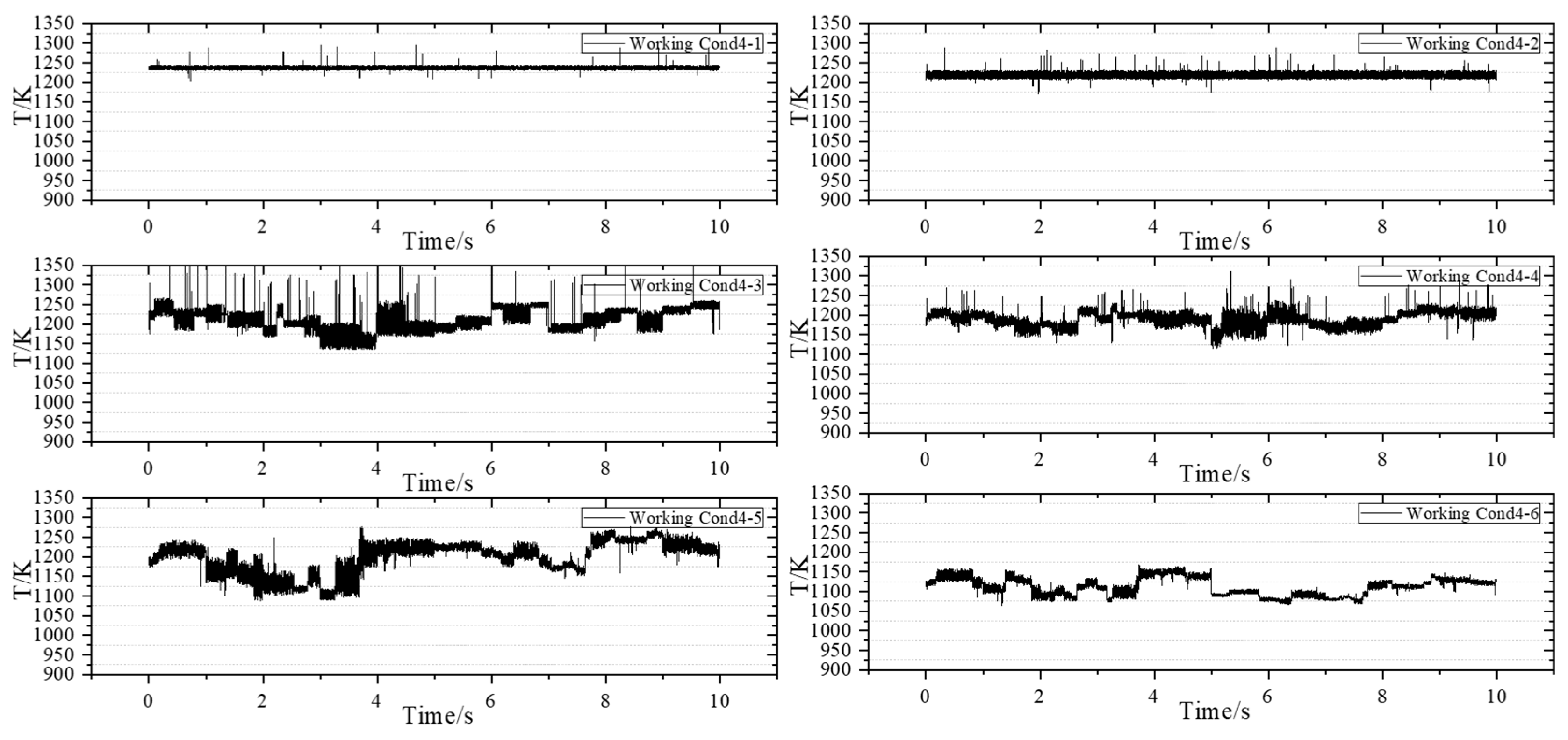

3.2. Measurement Results Under the Acquisition Frequency of 1 kHz

3.3. Measurement Results Under the Acquisition Frequency of 10 kHz

4. Conclusions

- (1)

- The TDLAS system, at an acquisition frequency of 1 kHz, exhibits a certain dynamic collection capacity, capable of reflecting some detailed temperature variations. In contrast, the data collected at 10 kHz can reveal more intricate temperature changes, with enhanced continuity and noise resistance. The combined utilization of 10 kHz and 1 kHz frequencies enables a more comprehensive reflection of the dynamic temperature characteristics of the temperature field.

- (2)

- The outlet temperature change of the centrally staged combustor is affected by multiple combustion parameters. Under the condition that the fuel–air ratio and the staging ratio remain the same, increasing the airflow rate will enhance the degree of fuel atomization, make the combustion more uniform, and increase the outlet temperature, while the temperature oscillation phenomenon is significantly enhanced. Under the condition that the airflow and the fuel–air ratio remain unchanged, in order to alleviate the high-frequency temperature oscillations, the staging ratio of the centrally staged combustor can be increased, and at the same time, the average temperature at the outlet of the combustion chamber will be slightly increased. This provides a data basis for adjusting the engine thrust and combustion efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Lin, Y.; Han, M.; Wang, Y.; Han, X.; Wang, J. Study on the Influence of Primary Stage Parameters on NOx Emissions in Centrally-Staged Combustion Chambers. J. Combust. Sci. Technol. 2025, 31, 1–7. [Google Scholar]

- Liu, Y.; Hui, X.; Wang, J.C.; Wang, X.; Han, M. Effect of Pre-stage Swirl Number on Ignition Performance of Centrally-Staged Combustion Chambers. J. Aerosp. Power 2022, 37, 2335–2343. [Google Scholar]

- Tan, J.; He, Y.; Zhu, R.; Zhu, Y.; Wang, Z. Experimental study on co-Firing characteristics of ammonia with pulverized coal in a staged combustion drop tube furnace. Proc. Combust. Inst. 2023, 39, 3217–3225. [Google Scholar] [CrossRef]

- Zou, B.W.; Xu, Q.H.; Cao, W.; Zhang, C.; Lin, Y. Lean blow-Out mechanism of a centrally-staged combustor coupled with recirculation zones. J. Aerosp. Power 2013, 28, 1759–1763. [Google Scholar]

- Yan, X.C.; Han, M.; Han, X.; Zhang, C.; Wang, J.; He, P.; Gao, X. Research on combustion oscillation control of a central staged combustor based on Helmholtz resonators. J. Beijing Univ. Aeronaut. Astronaut. 2024, 50, 3854–3862. [Google Scholar]

- Wang, X.C.; Liu, A.G.; Wu, X.Q.; Zhang, Y. Numerical study on lean premixed swirling combustion characteristics of methane/hydrogen blended fuels. J. Shanghai Jiao Tong Univ. 2024, 58, 1179–1187. [Google Scholar]

- Emiris, I.; Whitelaw, J.H. Control of combustion oscillations. Combust. Sci. Technol. 2003, 175, 157–184. [Google Scholar] [CrossRef]

- Sun, P.F.; Lu, Q.L.; Ge, B.; Zang, X. Experimental study on oscillating combustion characteristics, flame structure, and NOx emissions of LPP combustors. J. Eng. Therm. Energy Power 2024, 39, 149–157. [Google Scholar]

- Pu, W.Q. Analysis of the Influence of Constraints and Aerodynamic Loads on Pressure Oscillation and Structural Vibration. Ph.D. Thesis, Harbin Engineering University, Harbin, China, 2023. [Google Scholar]

- Wang, B.; Li, T.; Ge, L.; Ogawa, H. Optimization of combustion chamber geometry for natural gas engines with diesel micro-pilot-induced ignition. Energy Convers. Manag. 2016, 122, 552–563. [Google Scholar]

- De Giorgi, M.G.; Campilongo, S.; Ficarella, A. Development of a real time intelligent health monitoring platform for aero-engine. MATEC Web Conf. 2018, 233, 00007. [Google Scholar]

- Qin, Z.Y.; Wang, X.Y.; Han, X.; Lin, Y. A combustion oscillation prediction method for central staged combustors based on pre-trained models. J. Propuls. Technol. 2024, 45, 187–194. [Google Scholar]

- Wang, X.H.; Liu, Y.; Zhang, X.; Yang, C.; Li, H. Characteristic analysis of dynamic pressure signals of unstable combustion in a central-Staged swirling combustor. J. Aerosp. Power 2023, 38, 2883–2894. [Google Scholar]

- Tao, C.; Zhang, C.; Xue, X.; Fan, X.; Gao, J.; Feng, X.; Gao, X. Flame dynamics and combustion instability induced by flow-flame interactions in a centrally-staged combustor. Aerosp. Sci. Technol. 2023, 142, 108635. [Google Scholar] [CrossRef]

- Salam, S.; Verma, T.N. An empirical investigation on the influence of operating conditions on internal combustion engine behavior and their graded significance. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 47, 8501–8519. [Google Scholar] [CrossRef]

- Gao, X.Z.; Liu, Z.L.; Yan, Z.H. Development trends of non-contact measurement technologies for turbine engine combustors. Tactical Missile Technol. 2024, 1, 57–67. [Google Scholar]

- Gao, D.Y. Research on Quasi—Continuous Tunable Laser Absorption Spectroscopy Technology and Instrument Development. Ph.D. Thesis, Tianjin University, Tianjin, China, 2012. [Google Scholar]

- Huang, A.; Cao, Z.; Zhao, W.; Zhang, H.; Xu, L. Frequency-division multiplexing and main peak scanning WMS method for TDLAS tomography in flame monitoring. IEEE Trans. Instrum. Meas. 2020, 69, 9087–9096. [Google Scholar]

- Zhao, J.R. Research on Measurement Methods of Temperature and Velocity of High-Temperature Gas Flow Based on TDLAS; Dalian University of Technology: Dalian, China, 2022. [Google Scholar]

- Cao, X.; Hou, Q.Y.; Tan, W. Research on the design of inlet temperature control for an aero—Engine combustion chamber. China Inf. Times 2024, 1, 127–130. [Google Scholar]

- Zhang, C.; Lin, Y.Z.; Xu, H.S.; Xu, Q. Development status and level of low-emission combustor technology for civil aero-engines. Acta Aeronaut. Astronaut. Sin. 2014, 35, 332–350. [Google Scholar]

- Han, X.; Laera, D.; Morgans, A.; Sung, C.; Hui, X.; Lin, Y. Flame macrostructures and thermoacoustic instabilities in stratified swirling flames. Proc. Combust. Inst. 2019, 37, 5377–5384. [Google Scholar] [CrossRef]

- Oshina, I.; Spigulis, J. Beer–Lambert law for optical tissue diagnostics: Current state of the art and the main limitations. J. Biomed. Opt. 2021, 26, 100901. [Google Scholar]

- Ma, L.; Ning, H.; Wu, J.; Ren, W. In situ flame temperature measurements using a mid-infrared two-line H2O laser-absorption thermometry. Combust. Sci. Technol. 2018, 190, 393–408. [Google Scholar] [CrossRef]

- Stancik, A.L.; Brauns, E.B. A simple asymmetric line-shape for fitting infrared absorption spectra. Vib. Spectrosc. 2008, 47, 66–69. [Google Scholar] [CrossRef]

- Luo, C. Two-dimensional Temperature Distribution Tomographic Diagnosis Technology Based on TDLAS. Ph.D. Thesis, Xiamen University, Xiamen, China, 2018. [Google Scholar]

- Lu, Y.; Yin, X.D.; Yu, B.H.; Liu, X.; Xiong, Y.; Dong, L. Time-division multiplexing methane multi-point monitoring system based on TDLAS. Electron. Test 2014, 42–44. [Google Scholar] [CrossRef]

| S/N | Airflow (g/s) | Fuel Flow (g/s) | Oil-Gas Ratio | Staging Ratio (%) |

|---|---|---|---|---|

| 1-1 | 62.0 | 2.48 | 0.04 | 100 |

| 1-2 | 50 | |||

| 1-3 | 20 | |||

| 1-4 | 0 | |||

| 2-1 | 84.0 | 3.36 | 0.04 | 100 |

| 2-2 | 50 | |||

| 2-3 | 20 | |||

| 2-4 | 0 | |||

| 3-1 | 119.0 | 4.76 | 0.04 | 100 |

| 3-2 | 50 | |||

| 3-3 | 20 | |||

| 3-4 | 0 | |||

| 4-1 | 182.0 | 7.28 | 0.04 | 100 |

| 4-2 | 50 | |||

| 4-3 | 20 | |||

| 4-4 | 10 | |||

| 4-5 | 0 | |||

| 4-6 | 6.37 | 0.035 | 20 |

| S/N | Airflow (g/s) | Fuel Flow (g/s) | Incoming Pressure (MPa) | Oil–Gas Ratio | Staging Ratio (%) |

|---|---|---|---|---|---|

| 1 | 61.0 | 2.44 | 0.1 | 0.04 | 20 |

| 2 | 178.0 | 7.12 | 0.1 | 0.04 | 20 |

| 3 | 178.0 | 7.12 | 0.1 | 0.04 | 10 |

| 4 | 187.0 | 7.48 | 0.21 | 0.04 | 20 |

| 5 | 178.0 | 6.23 | 0.1 | 0.035 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuang, H.; Zhong, X.; Wei, J.; Xing, F.; Hai, Z. Research on Dynamic Temperature at Outlet of Centrally Staged Combustor Based on TDLAS Technology. Sensors 2025, 25, 2256. https://doi.org/10.3390/s25072256

Kuang H, Zhong X, Wei J, Xing F, Hai Z. Research on Dynamic Temperature at Outlet of Centrally Staged Combustor Based on TDLAS Technology. Sensors. 2025; 25(7):2256. https://doi.org/10.3390/s25072256

Chicago/Turabian StyleKuang, Hui, Xianpu Zhong, Junhao Wei, Fei Xing, and Zhenyin Hai. 2025. "Research on Dynamic Temperature at Outlet of Centrally Staged Combustor Based on TDLAS Technology" Sensors 25, no. 7: 2256. https://doi.org/10.3390/s25072256

APA StyleKuang, H., Zhong, X., Wei, J., Xing, F., & Hai, Z. (2025). Research on Dynamic Temperature at Outlet of Centrally Staged Combustor Based on TDLAS Technology. Sensors, 25(7), 2256. https://doi.org/10.3390/s25072256