Light-Controlled Soft Switches for Optical Logic Gate Operations

Abstract

:1. Introduction

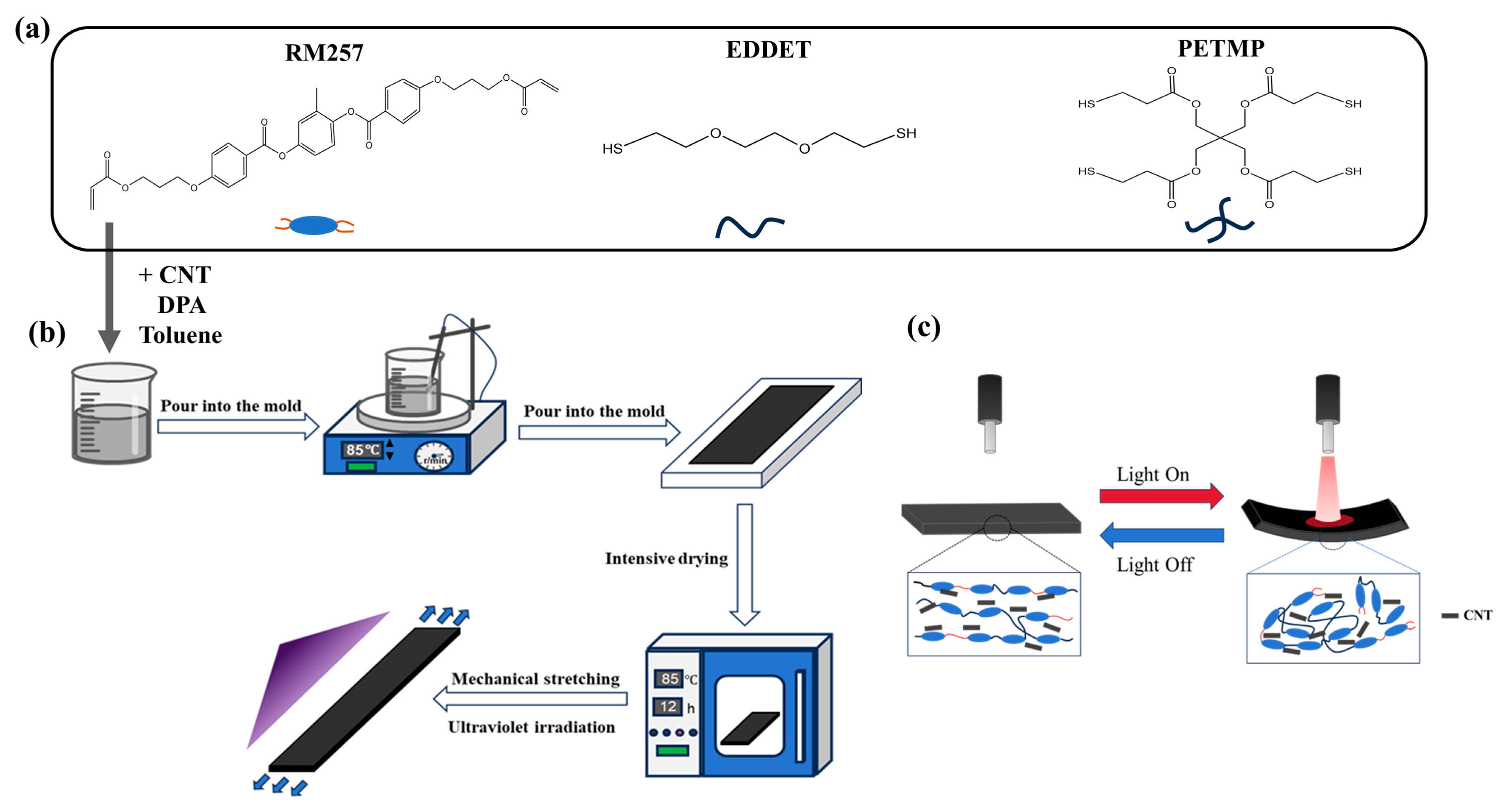

2. Materials and Methods

3. Results and Discussion

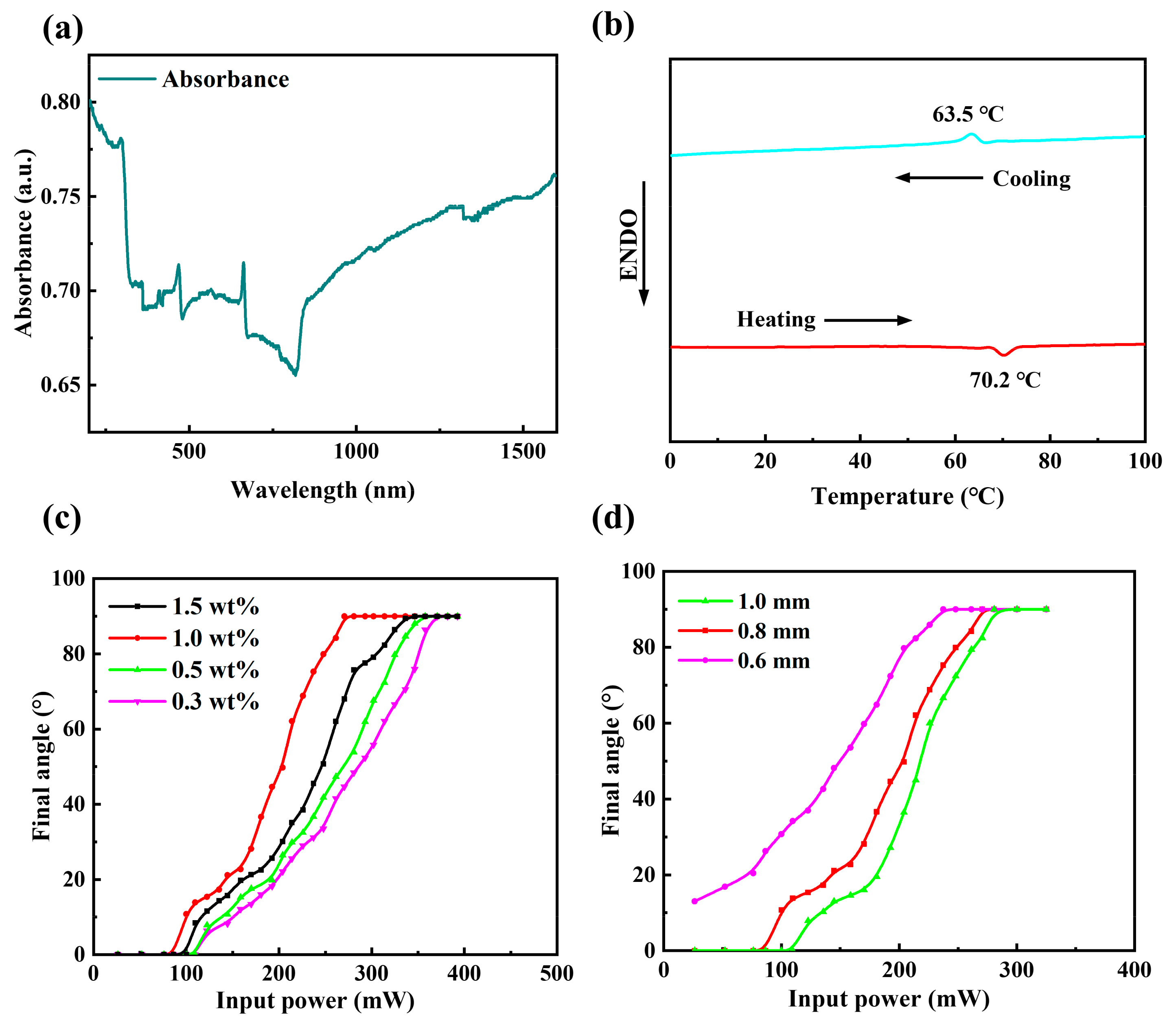

3.1. CNT-LCE Actuation Performance Test

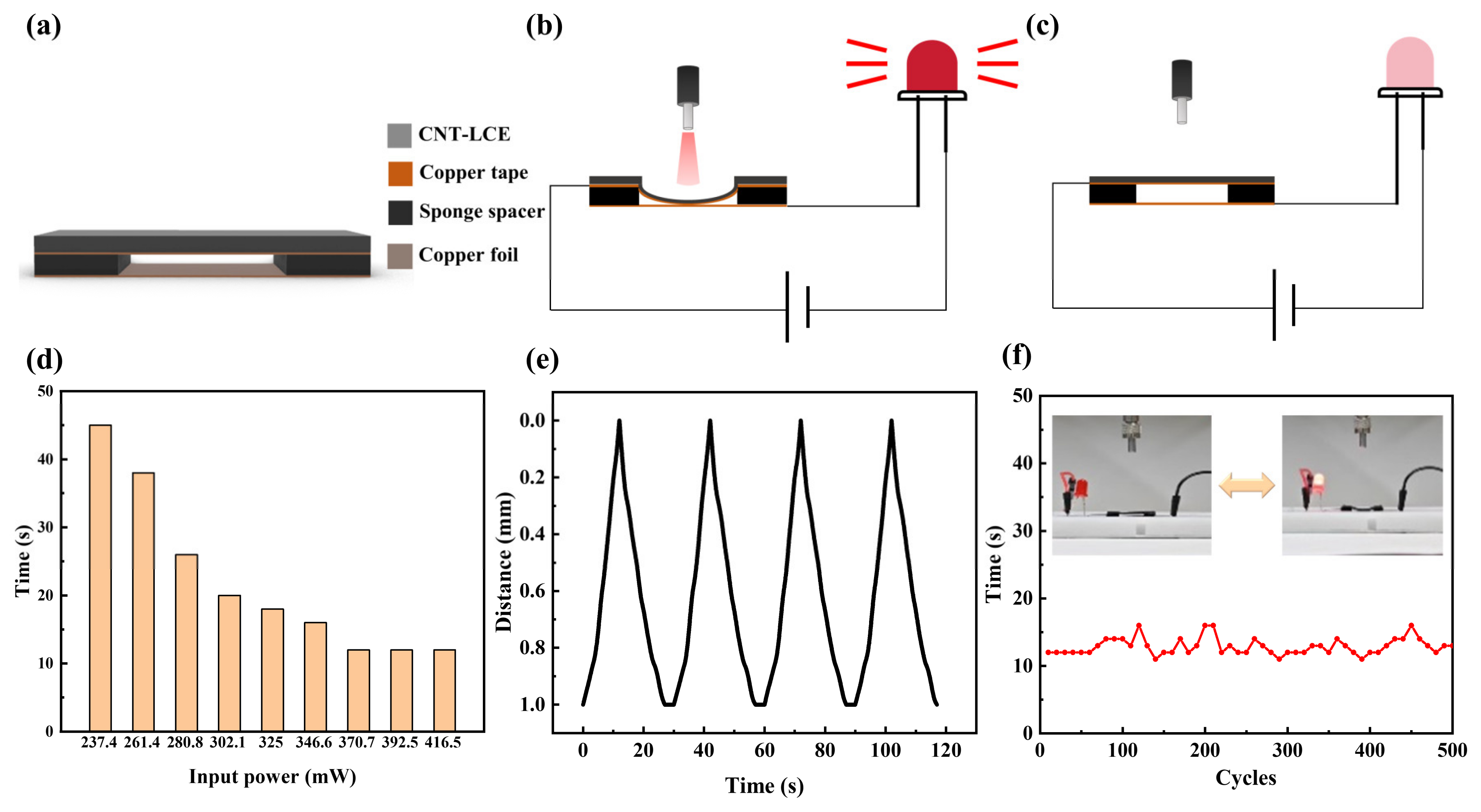

3.2. Optical Switch Performance Test

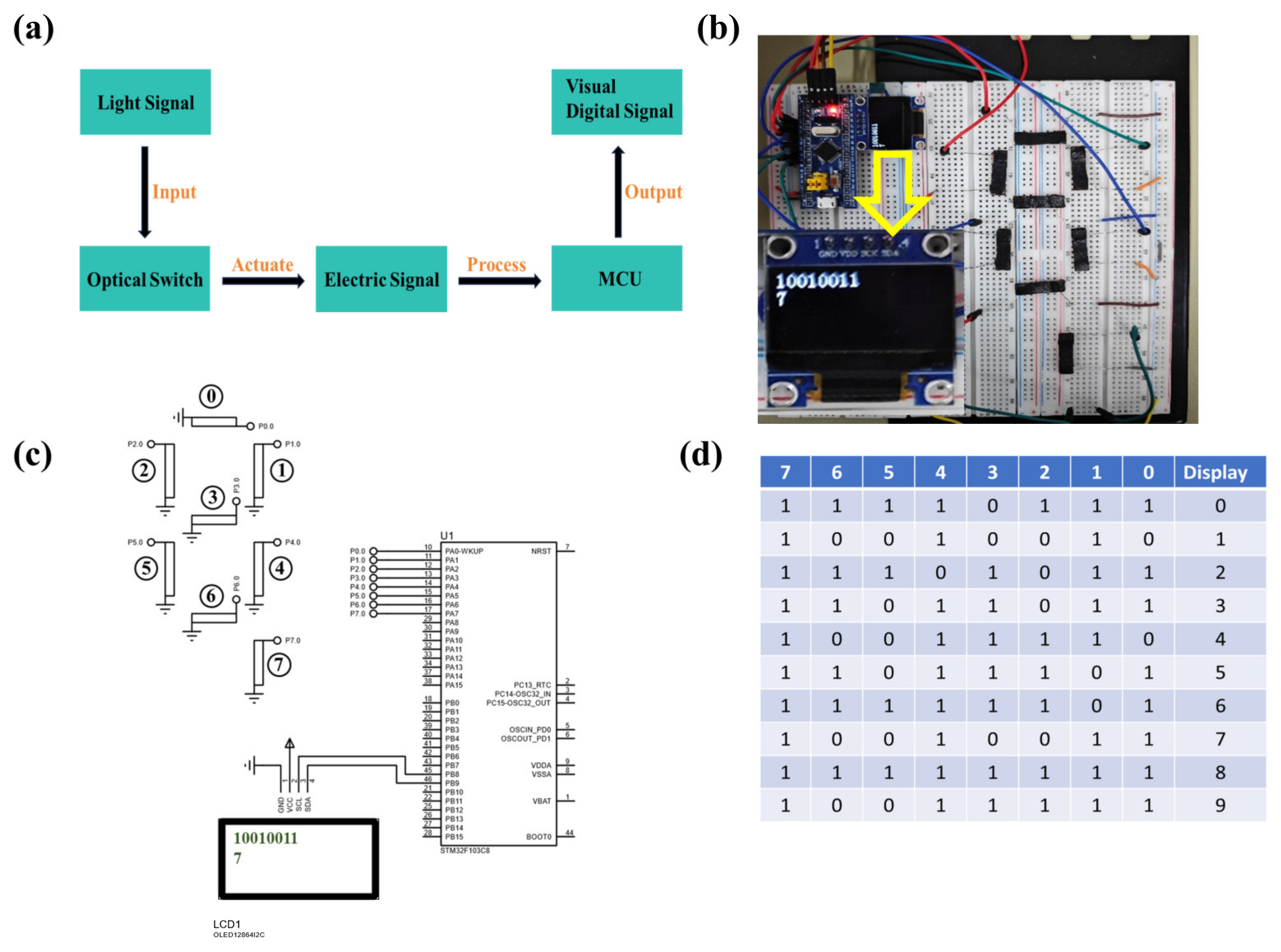

3.3. Application

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Preston, D.J.; Rothemund, P.; Jiang, H.J.; Nemitz, M.P.; Rawson, J.; Suo, Z.; Whitesides, G.M. Digital Logic for Soft Devices. Proc. Natl. Acad. Sci. USA 2019, 116, 7750–7759. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Song, C.; Wu, J.; Zou, B.; Zhang, Z.; Hu, Z.; Zou, A.; Wang, Z.; Cho, Y.; Yang, Z.; et al. Thermal Computing with Mechanical Transistors. Adv. Funct. Mater. 2024, 34, 2401244. [Google Scholar] [CrossRef]

- El-Atab, N.; Canas, J.C.; Hussain, M.M. Pressure-Driven Two-Input 3D Microfluidic Logic Gates. Adv. Sci. 2020, 7, 1903027. [Google Scholar] [CrossRef]

- Tsai, H.; Ghosh, D.; Panaccione, W.; Su, L.-Y.; Wang, L.; Cao, L.R.; Tretiak, S.; Nie, W. Addressing the Voltage Induced Instability Problem of Perovskite Semiconductor Detectors. ACS Energy Lett. 2022, 7, 3871–3879. [Google Scholar] [CrossRef]

- Jin, T.; Liu, Y.; Xiong, Y.; Pang, J.; Wu, H.; Yuan, S.; Xu, L.; Zheng, Z.; Tang, J.; Niu, G. Enhancing High-Voltage Stability of CsPbBr₃ Radiation Detectors Through Surface Treatment and Electrode Replacement. IEEE Electron Device Lett. 2023, 44, 1620–1623. [Google Scholar] [CrossRef]

- Wu, Y.; Guo, Z.; Zhu, W.-H.; Wan, W.; Zhang, J.; Li, W.; Li, X.; Tian, H.; Li, A.D.Q. Photoswitching between Black and Colourless Spectra Exhibits Resettable Spatiotemporal Logic. Mater. Horiz. 2016, 3, 124–129. [Google Scholar] [CrossRef]

- Fei, L.; Yu, W.; Wu, Z.; Yin, Y.; Moth-Poulsen, K.; Wang, C. Optically Controlled Thermochromic Switching for Multi-Input Molecular Logic. Angew. Chem. Int. Ed. 2022, 61, e202212483. [Google Scholar] [CrossRef]

- Tholen, H.M.; Ambulo, C.P.; Lee, K.M.; Buskohl, P.R.; Harne, R.L. Optomechanical Computing in Liquid Crystal Elastomers. Soft Matter 2023, 19, 6978–6986. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, Q.; Jin, J.; Liao, W.; Xia, Z. Mn2+-Doped Hybrid Halides with Excitation-Dependent Tricolor Luminescence for All-Optical Logic Gate Operations. Adv. Opt. Mater. 2024, 12, 2401887. [Google Scholar] [CrossRef]

- Jin, Y.; Lin, Y.; Kiani, A.; Joshipura, I.D.; Ge, M.; Dickey, M.D. Materials Tactile Logic via Innervated Soft Thermochromic Elastomers. Nat. Commun. 2019, 10, 4187. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, X.; Wang, Y.; Fang, Z.; Jiang, H.; Yang, Q.; Zhu, X.; Liu, M.; Fan, X.; Kong, J. Untethered Soft Microrobots with Adaptive Logic Gates. Adv. Sci. 2023, 10, 2206662. [Google Scholar] [CrossRef]

- Li, X.; Hu, Z.; Liu, Q.; Xie, T.; Wang, X.; Huang, L.; Wu, Y. Reconfigurable and Parallel Computable Soft Mechanical Switch by Liquid Metal. Adv. Funct. Mater. 2024, 34, 2312511. [Google Scholar] [CrossRef]

- El Helou, C.; Buskohl, P.R.; Tabor, C.E.; Harne, R.L. Digital Logic Gates in Soft, Conductive Mechanical Metamaterials. Nat. Commun. 2021, 12, 1633. [Google Scholar] [CrossRef] [PubMed]

- Mei, T.; Meng, Z.; Zhao, K.; Chen, C.Q. A Mechanical Metamaterial with Reprogrammable Logical Functions. Nat. Commun. 2021, 12, 7234. [Google Scholar] [CrossRef]

- Pan, Y.; Shi, Y.; Chen, Z.; Chen, J.; Hou, M.; Li, C.-W.; Yi, C. Design of Multiple Logic Gates Based on Chemically Triggered Fluorescence Switching of Functionalized Polyethyleneimine. ACS Appl. Mater. Interfaces 2016, 8, 9472–9482. [Google Scholar] [CrossRef]

- Han, L.; Si, J.; Zhu, B.; Wang, R.; Wu, C.; Guo, M. A Multidirectional Locomotion Light-Driven Soft Crawling Robot. Adv. Funct. Mater. 2023, 33, 2305046. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, Q.; Liu, Z.; Alsaid, Y.; Shi, P.; Khalid Jawed, M.; He, X. Sunlight-Powered Self-Excited Oscillators for Sustainable Autonomous Soft Robotics. Sci. Robot. 2023, 8, eadf4753. [Google Scholar] [CrossRef]

- Roucan, M.; Kielmann, M.; Connon, S.J.; Bernhard, S.S.R.; Senge, M.O. Conformational Control of Nonplanar Free Base Porphyrins: Towards Bifunctional Catalysts of Tunable Basicity. Chem. Commun. 2018, 54, 26–29. [Google Scholar] [CrossRef]

- Yang, Y.; Shen, Y. Light-Driven Carbon-Based Soft Materials: Principle, Robotization, and Application. Adv. Opt. Mater. 2021, 9, 2100035. [Google Scholar] [CrossRef]

- Kang, J.; Bai, C.; Liu, S.; Jia, Y. Light-Induced Nontethered Rolling of Liquid Crystal Elastomer and Carbon Nanotube Composite Ring. ACS Appl. Polym. Mater. 2024, 6, 2709–2718. [Google Scholar] [CrossRef]

- Ahn, C.; Liang, X.; Cai, S. Bioinspired Design of Light-Powered Crawling, Squeezing, and Jumping Untethered Soft Robot. Adv. Mater. Technol. 2019, 4, 1900185. [Google Scholar] [CrossRef]

- Chen, M.; Gao, M.; Bai, L.; Zheng, H.; Qi, H.J.; Zhou, K. Recent Advances in 4D Printing of Liquid Crystal Elastomers. Adv. Mater. 2023, 35, 2209566. [Google Scholar] [CrossRef]

- Wang, J.; Yang, B.; Yu, M.; Yu, H. Light-Powered Self-Sustained Oscillators of Graphene Oxide/Liquid Crystalline Network Composites Showing Amplitude and Frequency Superposition. ACS Appl. Mater. Interfaces 2022, 14, 15632–15640. [Google Scholar] [CrossRef] [PubMed]

- Zheng, K.; Tian, B.; Guo, P.; Zhan, H.; Liang, J.; Wu, Y.; Wu, W. Liquid Crystal Elastomer-Based All-Printed Actuator and Sensing Array Systems. Chem. Eng. J. 2024, 492, 152172. [Google Scholar] [CrossRef]

- Nie, Z.; Wang, M.; Huang, S.; Liu, Z.; Yang, H. Multimodal Self-sustainable Autonomous Locomotions of Light-driven Seifert Ribbon Actuators Based on Liquid Crystal Elastomers. Angew. Chem. 2023, 135, e202304081. [Google Scholar] [CrossRef]

- Jeong, Y.-J.; Park, S.-Y. Light-Responsive Actuator of Azobenzene-Containing Main-Chain Liquid Crystal Elastomers with Allyl Sulfide Dynamic Exchangeable Linkages. ACS Appl. Mater. Interfaces 2024, 16, 2788–2801. [Google Scholar] [CrossRef]

- Qian, N.; Bisoyi, H.K.; Wang, M.; Huang, S.; Liu, Z.; Chen, X.; Hu, J.; Yang, H.; Li, Q. A Visible and Near-Infrared Light-Fueled Omnidirectional Twist-Bend Crawling Robot. Adv. Funct. Mater. 2023, 33, 2214205. [Google Scholar] [CrossRef]

- Zhang, X.; Yao, L.; Yan, H.; Zhang, Y.; Han, D.; He, Y.; Li, C.; Zhang, J. Optical Wavelength Selective Actuation of Dye Doped Liquid Crystalline Elastomers by Quasi-Daylight. Soft Matter 2022, 18, 9181–9196. [Google Scholar] [CrossRef]

- Mainik, P.; Hsu, L.; Zimmer, C.W.; Fauser, D.; Steeb, H.; Blasco, E. DLP 4D Printing of Multi-Responsive Bilayered Structures. Adv. Mater. Technol. 2023, 8, 2300727. [Google Scholar] [CrossRef]

- Zhai, Y.; Ng, T.N. Self-Sustained Robots Based on Functionally Graded Elastomeric Actuators Carrying up to 22 Times Their Body Weight. Adv. Intell. Syst. 2023, 5, 2100085. [Google Scholar] [CrossRef]

- Kumar, K.; Knie, C.; Bléger, D.; Peletier, M.A.; Friedrich, H.; Hecht, S.; Broer, D.J.; Debije, M.G.; Schenning, A.P.H.J. A Chaotic Self-Oscillating Sunlight-Driven Polymer Actuator. Nat. Commun. 2016, 7, 11975. [Google Scholar] [CrossRef] [PubMed]

- Zeng, H.; Wani, O.M.; Wasylczyk, P.; Priimagi, A. Light-Driven, Caterpillar-Inspired Miniature Inching Robot. Macromol. Rapid Commun. 2018, 39, 1700224. [Google Scholar] [CrossRef] [PubMed]

- Pilz Da Cunha, M.; Debije, M.G.; Schenning, A.P.H.J. Bioinspired Light-Driven Soft Robots Based on Liquid Crystal Polymers. Chem. Soc. Rev. 2020, 49, 6568–6578. [Google Scholar] [CrossRef] [PubMed]

- Dong, L.; Zhao, Y. Photothermally Driven Liquid Crystal Polymer Actuators. Mater. Chem. Front. 2018, 2, 1932–1943. [Google Scholar] [CrossRef]

- Sutar, R.S.; Latthe, S.S.; Wu, X.; Nakata, K.; Xing, R.; Liu, S.; Fujishima, A. Design and Mechanism of Photothermal Soft Actuators and Their Applications. J. Mater. Chem. A 2024, 12, 17896–17922. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Wu, H.; Niu, Q.; Yan, X.; Wang, X. Light-Controlled Soft Switches for Optical Logic Gate Operations. Sensors 2025, 25, 2051. https://doi.org/10.3390/s25072051

Wang C, Wu H, Niu Q, Yan X, Wang X. Light-Controlled Soft Switches for Optical Logic Gate Operations. Sensors. 2025; 25(7):2051. https://doi.org/10.3390/s25072051

Chicago/Turabian StyleWang, Chuang, Hao Wu, Quanwang Niu, Xiaohong Yan, and Xiangfu Wang. 2025. "Light-Controlled Soft Switches for Optical Logic Gate Operations" Sensors 25, no. 7: 2051. https://doi.org/10.3390/s25072051

APA StyleWang, C., Wu, H., Niu, Q., Yan, X., & Wang, X. (2025). Light-Controlled Soft Switches for Optical Logic Gate Operations. Sensors, 25(7), 2051. https://doi.org/10.3390/s25072051