Surface Crack Detection of Aluminum Alloy Using Injected Direct Current-Magnetic Field Measurement Method

Abstract

1. Introduction

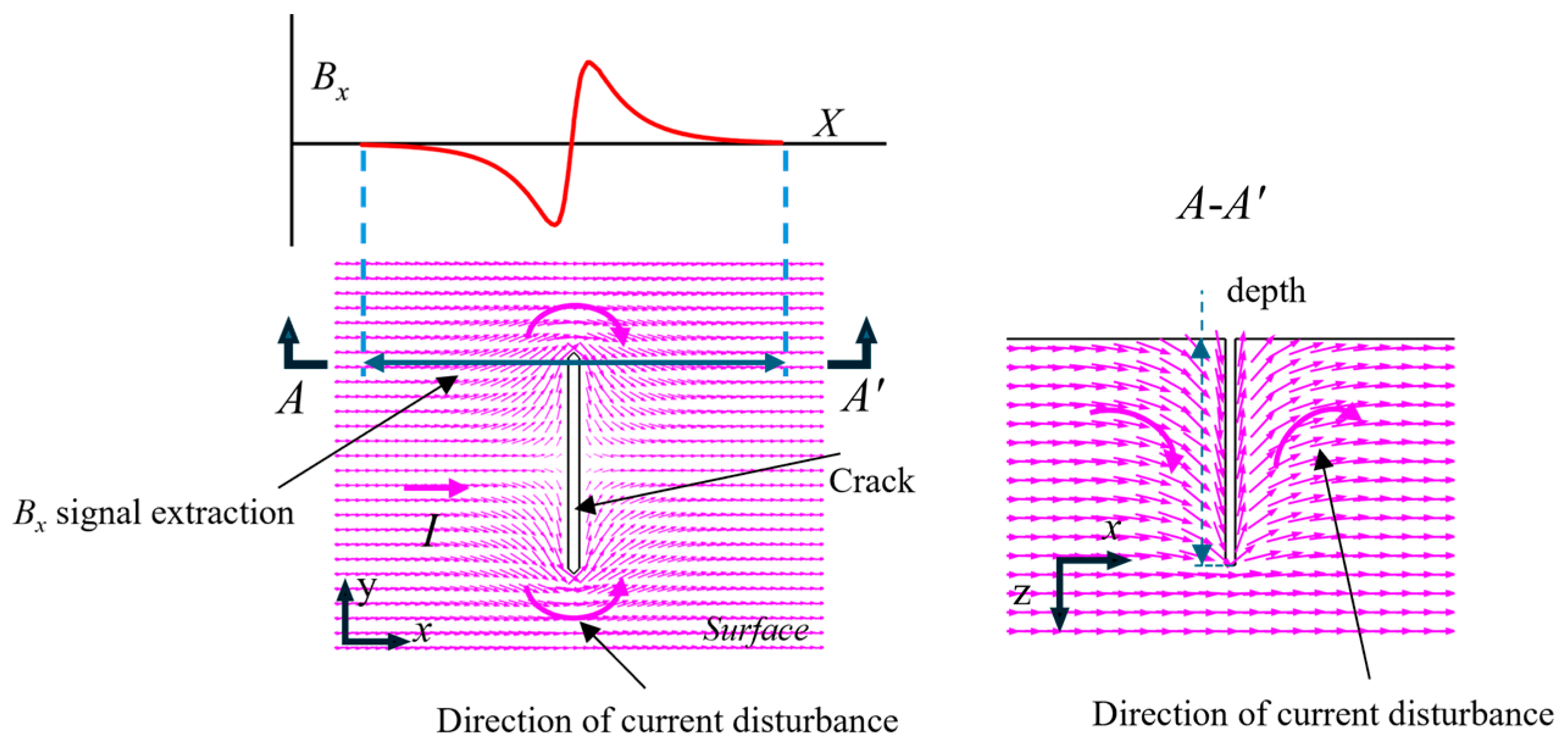

2. Theories of IDC-MFM

3. Finite Element Simulation

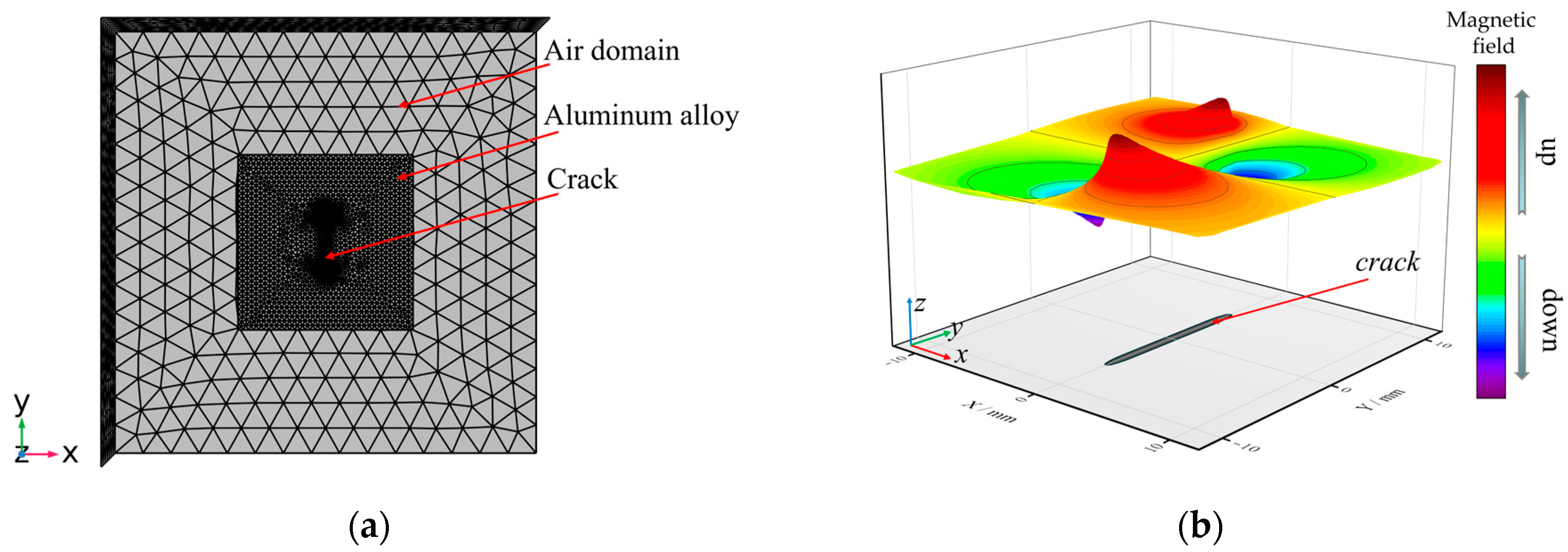

3.1. 3D Modelling

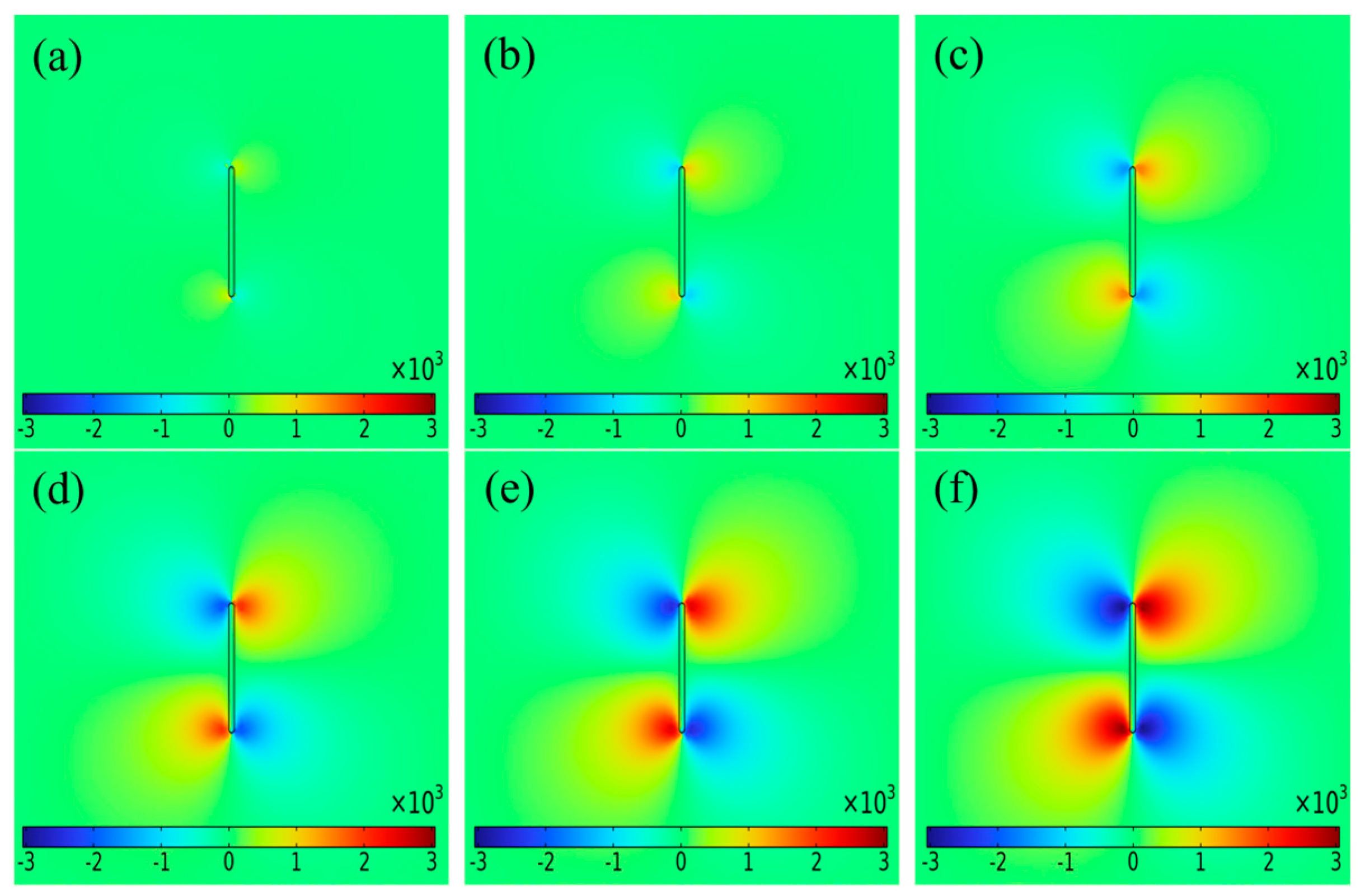

3.2. Simulation

3.3. Simulation Results

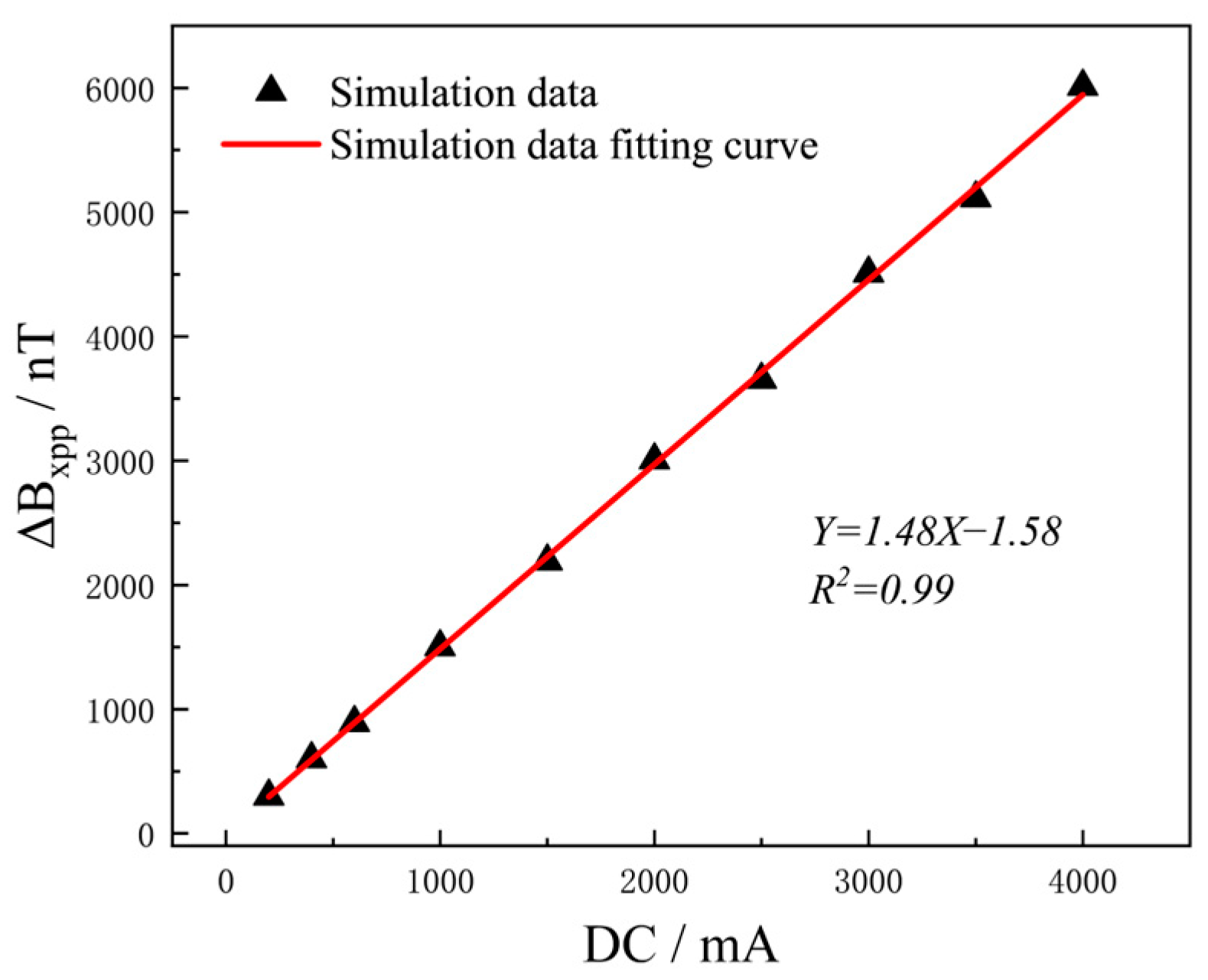

3.3.1. Influence of DC Intensity on ΔBxpp

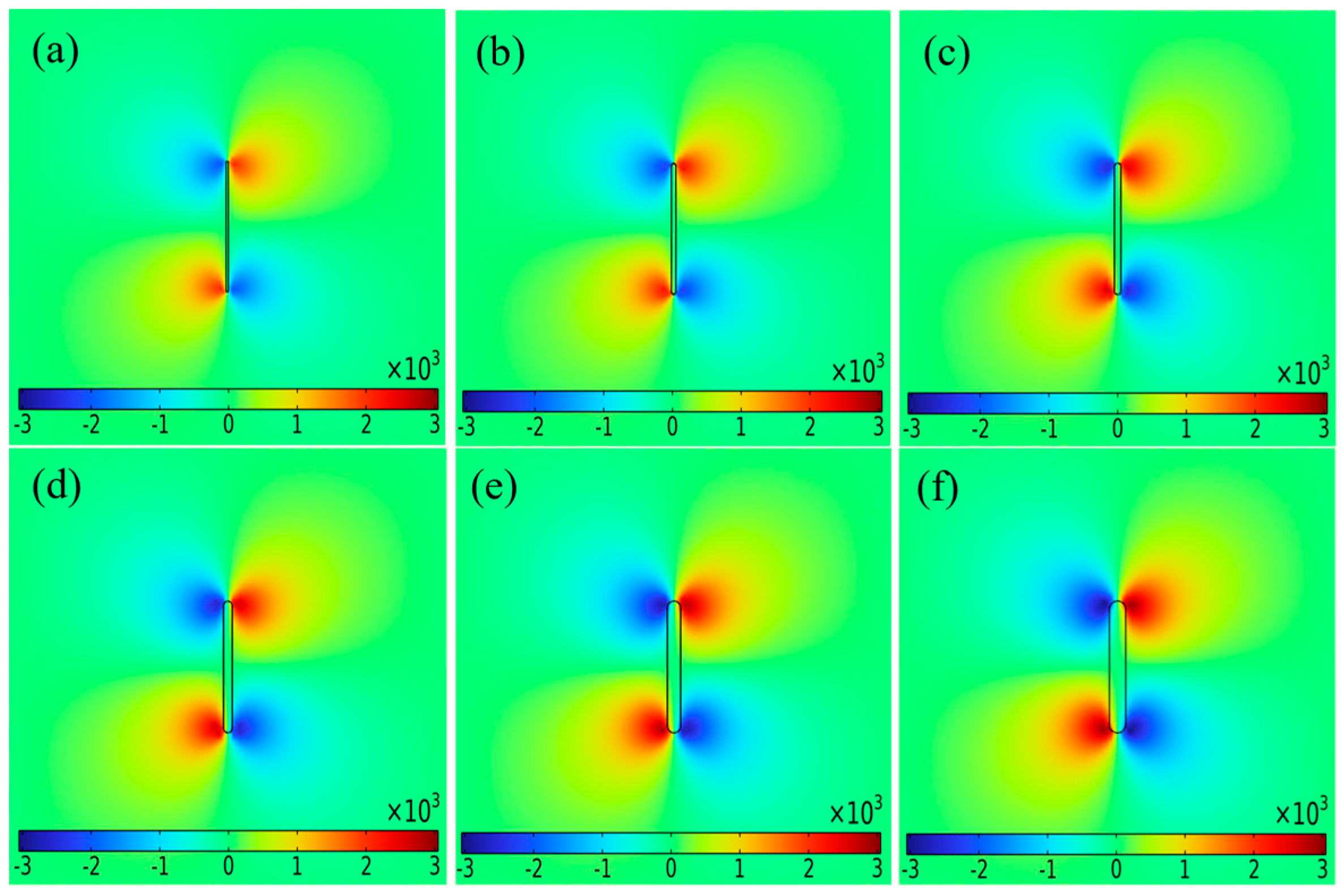

3.3.2. Influence of Crack Width on ΔBxpp

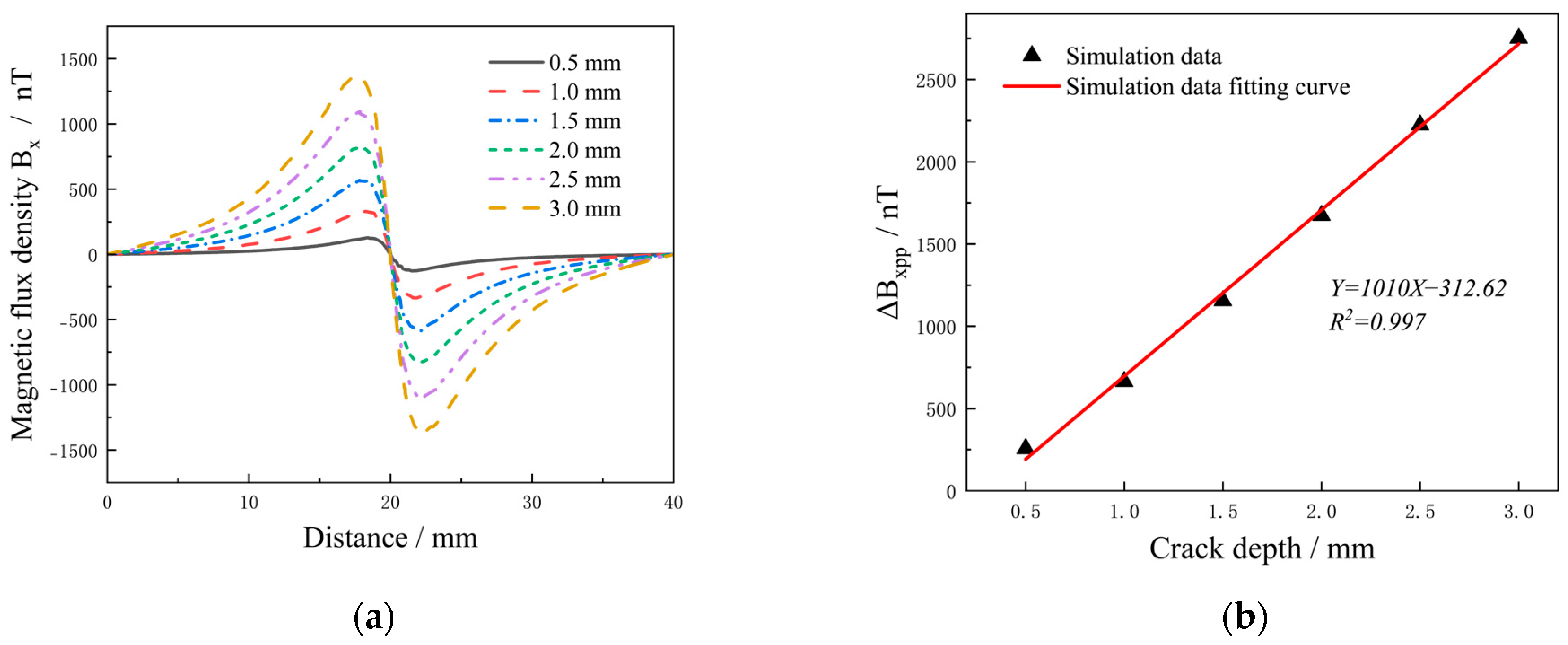

3.3.3. Influence of Crack Depth on ΔBxpp

4. Experimental

4.1. Experimental Setup

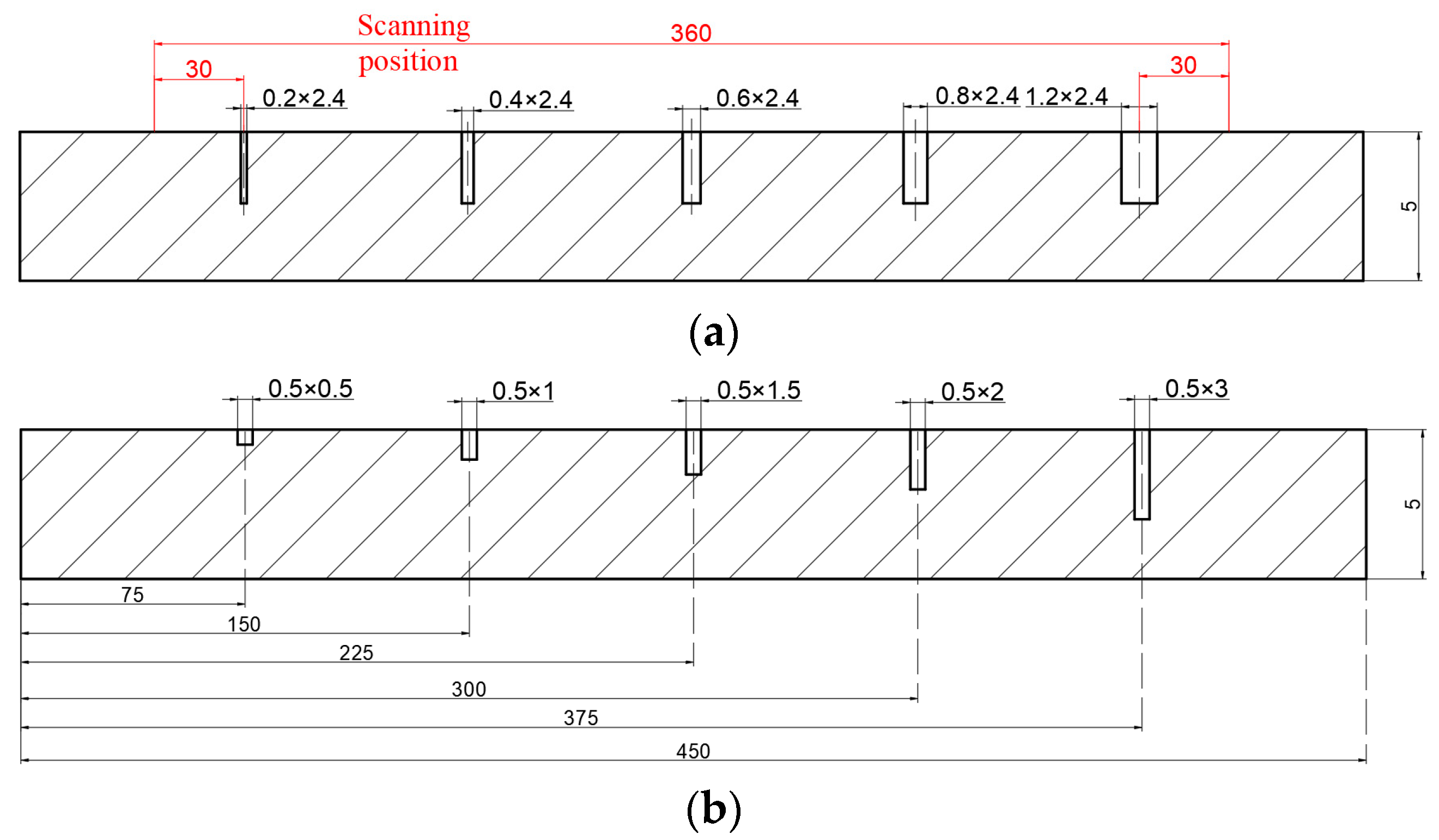

4.1.1. Specimens

4.1.2. Instruments

4.1.3. Experimental Arrangement

5. Results

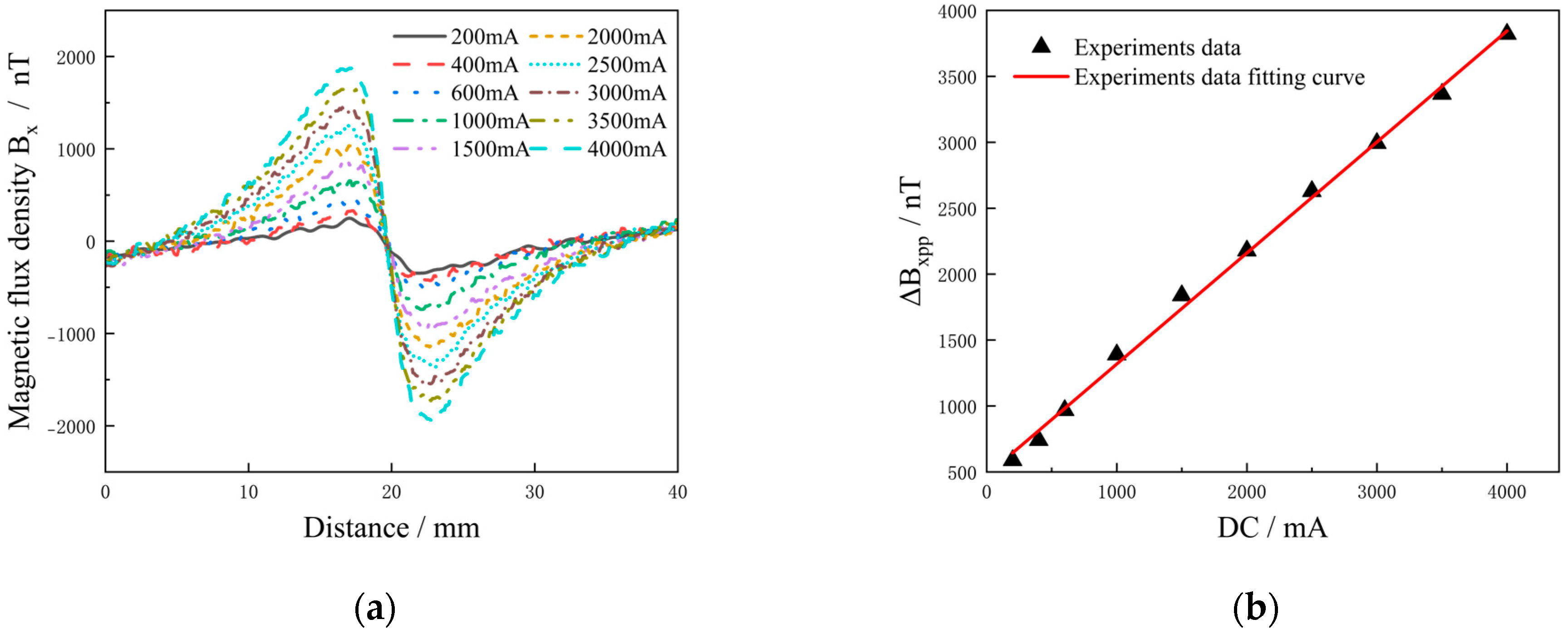

5.1. Detection Results of Different Current Intensities

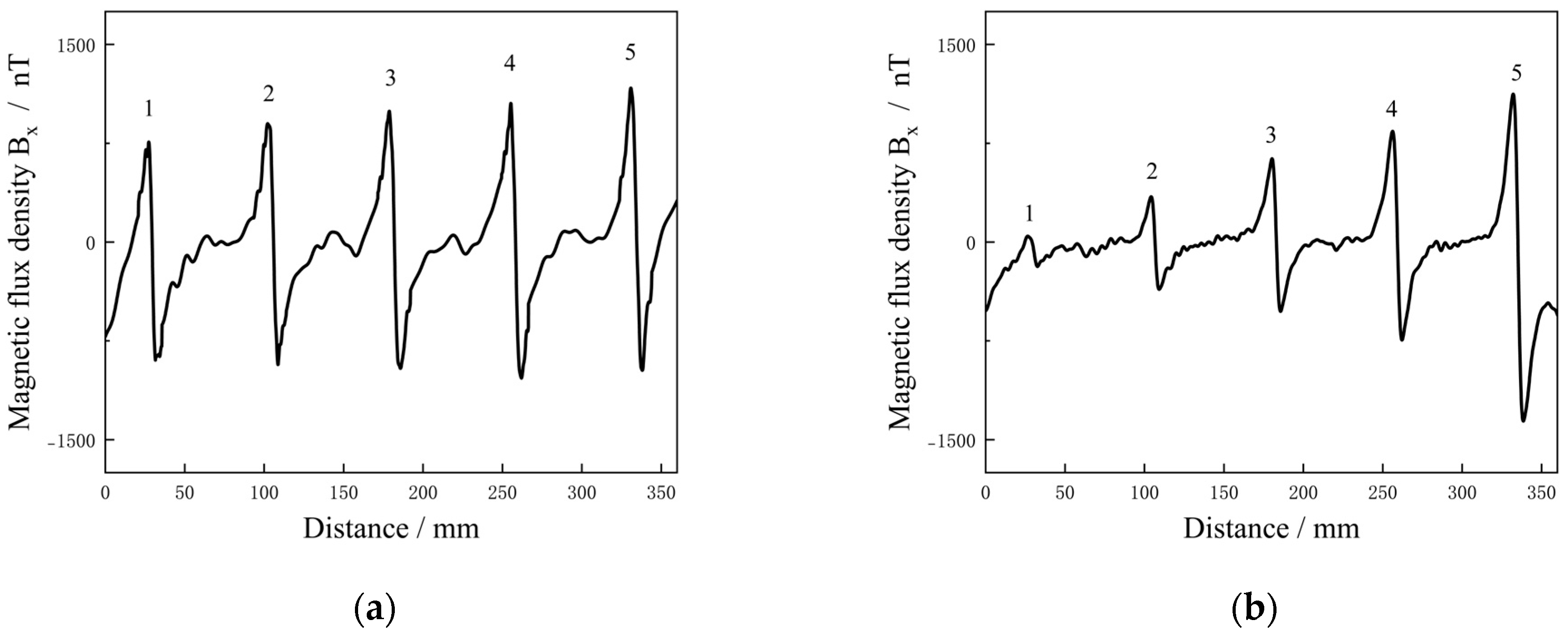

5.2. Detection Results of Cracks with Different Widths and Depths

6. Analysis and Discussion

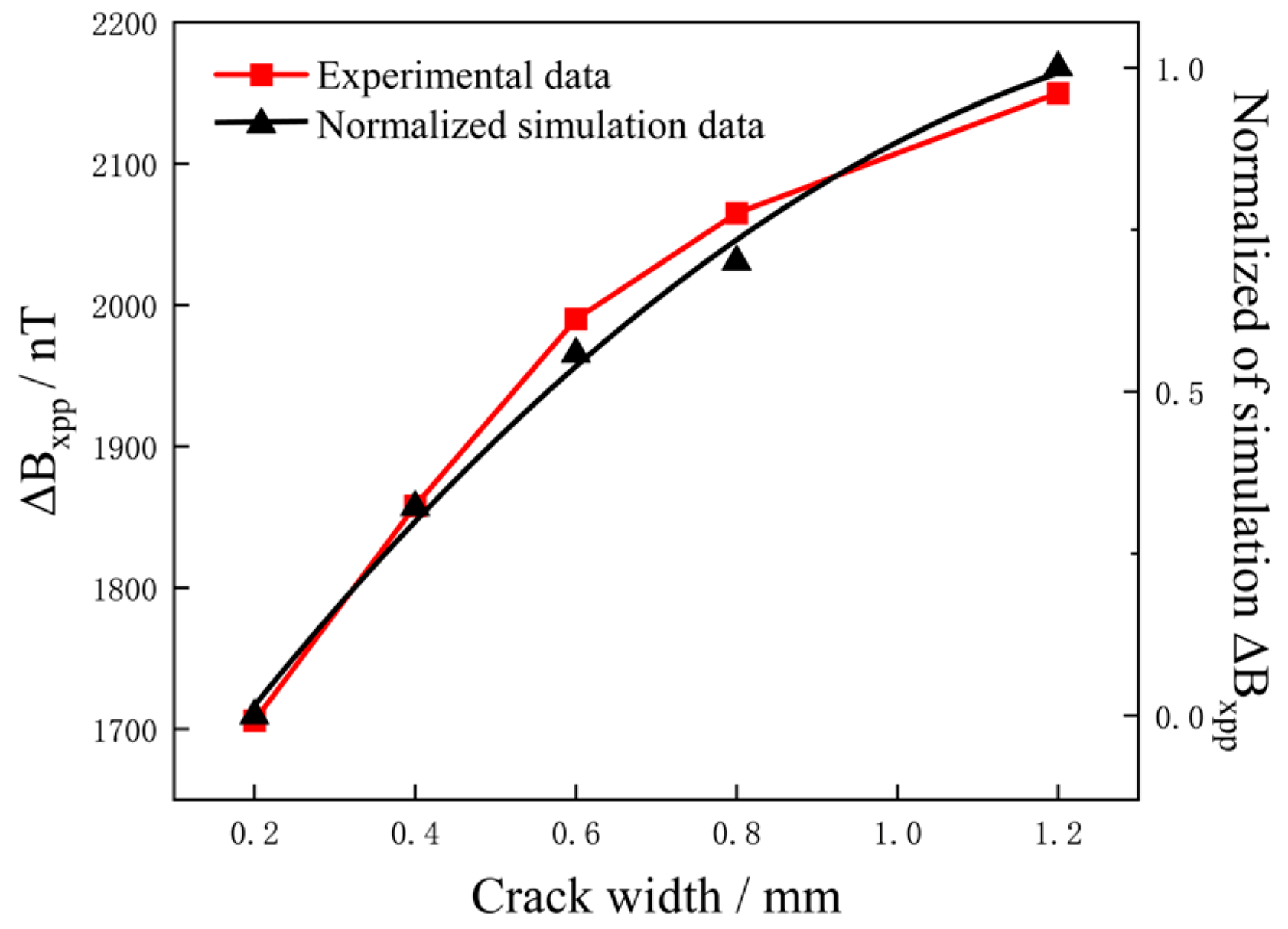

6.1. Characterization of Different Crack Widths

6.2. Characterization of Different Crack Depths

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, Y. The use of aluminum alloys in structures: Review and outlook. Structures 2023, 57, 105290. [Google Scholar] [CrossRef]

- You, X.; Xing, Z.; Jiang, S.; Zhu, Y.; Lin, Y.; Qiu, H.; Nie, R.; Yang, J.; Hui, D.; Chen, W.; et al. A review of research on aluminum alloy materials in structural engineering. Dev. Built Environ. 2024, 17, 100319. [Google Scholar] [CrossRef]

- Zheng, J.; Yang, G.; Shao, C.W.; Li, H.; Hogan, J.D. Impact of alternating corrosion and fatigue on the fatigue life of a 7475-T7351 aluminum alloy in an aircraft beam structure. Int. J. Fract. 2024, 246, 333–344. [Google Scholar] [CrossRef]

- Zhu, S.P.; Ai, Y.; Liao, D.; Correia, J.A.F.O.; De Jesus, A.M.P.; Wang, Q. Recent advances on size effect in metal fatigue under defects: A review. Int. J. Fract. 2021, 234, 21–43. [Google Scholar] [CrossRef]

- Gharehbaghi, V.R.; Noroozinejad Farsangi, E.; Noori, M.; Yang, T.Y.; Li, S.; Nguyen, A.; Málaga-Chuquitaype, C.; Gardoni, P.; Mirjalili, S. A critical review on structural health monitoring: Definitions, methods, and perspectives. Arch. Comput. Method. Eng. 2022, 29, 2209–2235. [Google Scholar] [CrossRef]

- Zhong, J.; Ma, Y.; Zhang, M.; Xiao, R.; Cheng, G.; Huang, B. A Pavement Crack Translator for Data Augmentation and Pixel-Level Detection Based on Weakly Supervised Learning. IEEE Trans. Intell. Transp. Syst. 2024, 25, 13350–13363. [Google Scholar] [CrossRef]

- Zhang, K.; Kang, Y.; Li, D.; Deng, Z. Feasibility study of non-ferrous metal defect inspection by electrified magnetic measuring. Transducer Microsyst. Technol. 2016, 35, 47–50. (In Chinese) [Google Scholar]

- Li, D.; Kang, Y.; Sun, Y.; Ye, Z. A Nondestructive Testing Method Based on Electric Field Measurement. China Mech. Eng. 2015, 26, 1810. [Google Scholar]

- Corcoran, J.; Davies, C.M.; Cawley, P.; Nagy, P.B. A quasi-DC potential drop measurement system for material testing. IEEE Trans. Instrum. Meas. 2019, 69, 1313–1326. [Google Scholar] [CrossRef]

- Yin, X.; Hutchins, D.A.; Chen, G.; Li, W. Detecting surface features on conducting specimens through an insulation layer using a capacitive imaging technique. NDT E Int. 2012, 52, 157–166. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, S.; Deng, Z.; Gu, M.; Liu, C.; He, L.; Kang, Y. New discoveries on electromagnetic action and signal presentation in magnetic flux leakage testing. J. Nondestr Eval. 2019, 38, 93. [Google Scholar] [CrossRef]

- Kehayias, P.; Walraven, J.; Rodarte, A.L.; Mounce, A. High-Resolution Short-Circuit Fault Localization in a Multilayer Integrated Circuit Using a Quantum Diamond Microscope. Phys. Rev. Appl. 2023, 20, 014036. [Google Scholar] [CrossRef]

- Palm, M.L.; Huxter, W.S.; Welter, P.; Ernst, S.; Scheidegger, P.; Diesch, S.; Chang, K.; Rickhaus, P.; Taniguchi, T.; Watanabe, K.; et al. Imaging of submicroampere currents in bilayer graphene using a scanning diamond magnetometer. Phys. Rev. Appl. 2022, 17, 054008. [Google Scholar] [CrossRef]

- Wikswo, J.P.; Sepulveda, N.G.; Ma, Y.P.; Henry, W.P.; Staton, D.J.; Crum, D. An improved method for magnetic identification and localization of cracks in conductors. J. Nondestr Eval. 1993, 12, 109–119. [Google Scholar] [CrossRef]

- Sebestyen, I.; Pavo, J. Flaw detection using dc magnetic field measurement. Int. J. Appl. Electromagn. Mech. 2002, 15, 53–60. [Google Scholar] [CrossRef]

- Inoue, M.; Abiru, K.; Honda, Y.; Kiss, T.; Iijima, Y.; Kakimoto, K.; Shiohara, Y.; Nakao, K.; Saitoh, T. Observation of Current Distribution in High-Tc Superconducting Tape Using Scanning Hall-Probe Microscope. IEEE Trans. Appl. Supercond. 2009, 19, 2847–2850. [Google Scholar] [CrossRef]

- Hafiz, S.K.; Adly, A.A. Three-Dimensional Identification of Crack Location in Conducting Slabs Using Wavelets. IEEE Trans. Magn. 2013, 49, 3472–3475. [Google Scholar] [CrossRef]

- Li, D.; Kang, Y.; Sun, Y.; Ye, Z.; Ding, Y. Nondestructive Evaluation of Conducting Materials Using a Direct Current Perturbation Method. In International Workshop on Electromagnetic Non-Destructive Evaluation; IOS Press: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Li, D.; Sun, Y.; Ye, Z.; Kang, Y. Electric field leakage nondestructive testing principle and its simulation. Mater. Eval. 2015, 73, 1438–1445. [Google Scholar]

- Guru, B.S.; Hiziroglu, H.R. Electromagnetic Field Theory Fundamentals; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Sepúlveda, N.G.; Wikswo, J.P. A numerical study of the use of magnetometers to detect hidden flaws in conducting objects. J. Appl. Phys. 1996, 79, 2122–2135. [Google Scholar] [CrossRef]

- Hu, B.; Yu, R.; Zou, H. Magnetic non-destructive testing method for thin-plate aluminum alloys. NDT E Int. 2012, 47, 66–69. [Google Scholar]

- Zhang, Q.; Pang, H.; Wan, C. Magnetic interference compensation method for geomagnetic field vector measurement. Measurement 2016, 91, 628. [Google Scholar] [CrossRef]

- Sheng, H.; Wang, P.; Tang, C. Predicting Mechanical Properties of Cold-Rolled Steel Strips Using Micro-Magnetic NDT Technologies. Materials 2022, 15, 2151. [Google Scholar] [CrossRef] [PubMed]

- Shkatov, P.N. A Model of the Magnetic Field of a Crack Surrounded by a Uniform Eddy Current. Kontrol. Diagn. 2024, 27, 15–28. [Google Scholar] [CrossRef]

| Brand | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti |

|---|---|---|---|---|---|---|---|---|

| 7075 aluminum alloy | 0.4 | 0.5 | 1.2–2.0 | 0.3 | 2.1–2.9 | 0.18–0.28 | 5.1–6.1 | 0.2 |

| Brand | Conductivity [m/Ω·mm2] | Coefficient of Thermal Expansion [K−1·10−6] | Thermal Conductivity [W/m·K] |

|---|---|---|---|

| 7075 aluminum alloy | 19–23 | 23.4 | 196 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Shi, J.; Wang, Q.; Dong, L.; Liu, H. Surface Crack Detection of Aluminum Alloy Using Injected Direct Current-Magnetic Field Measurement Method. Sensors 2025, 25, 1800. https://doi.org/10.3390/s25061800

Wang H, Shi J, Wang Q, Dong L, Liu H. Surface Crack Detection of Aluminum Alloy Using Injected Direct Current-Magnetic Field Measurement Method. Sensors. 2025; 25(6):1800. https://doi.org/10.3390/s25061800

Chicago/Turabian StyleWang, Huipeng, Jialong Shi, Qiaogen Wang, Lihong Dong, and Huizhong Liu. 2025. "Surface Crack Detection of Aluminum Alloy Using Injected Direct Current-Magnetic Field Measurement Method" Sensors 25, no. 6: 1800. https://doi.org/10.3390/s25061800

APA StyleWang, H., Shi, J., Wang, Q., Dong, L., & Liu, H. (2025). Surface Crack Detection of Aluminum Alloy Using Injected Direct Current-Magnetic Field Measurement Method. Sensors, 25(6), 1800. https://doi.org/10.3390/s25061800