Experimental Investigation of the Evaluation of the Cement Hydration Process in the Annular Space Using Distributed Fiber Optic Temperature Sensing

Abstract

1. Introduction

2. Experiment Setup and Methodology

2.1. Experiment Apparatus and Materials

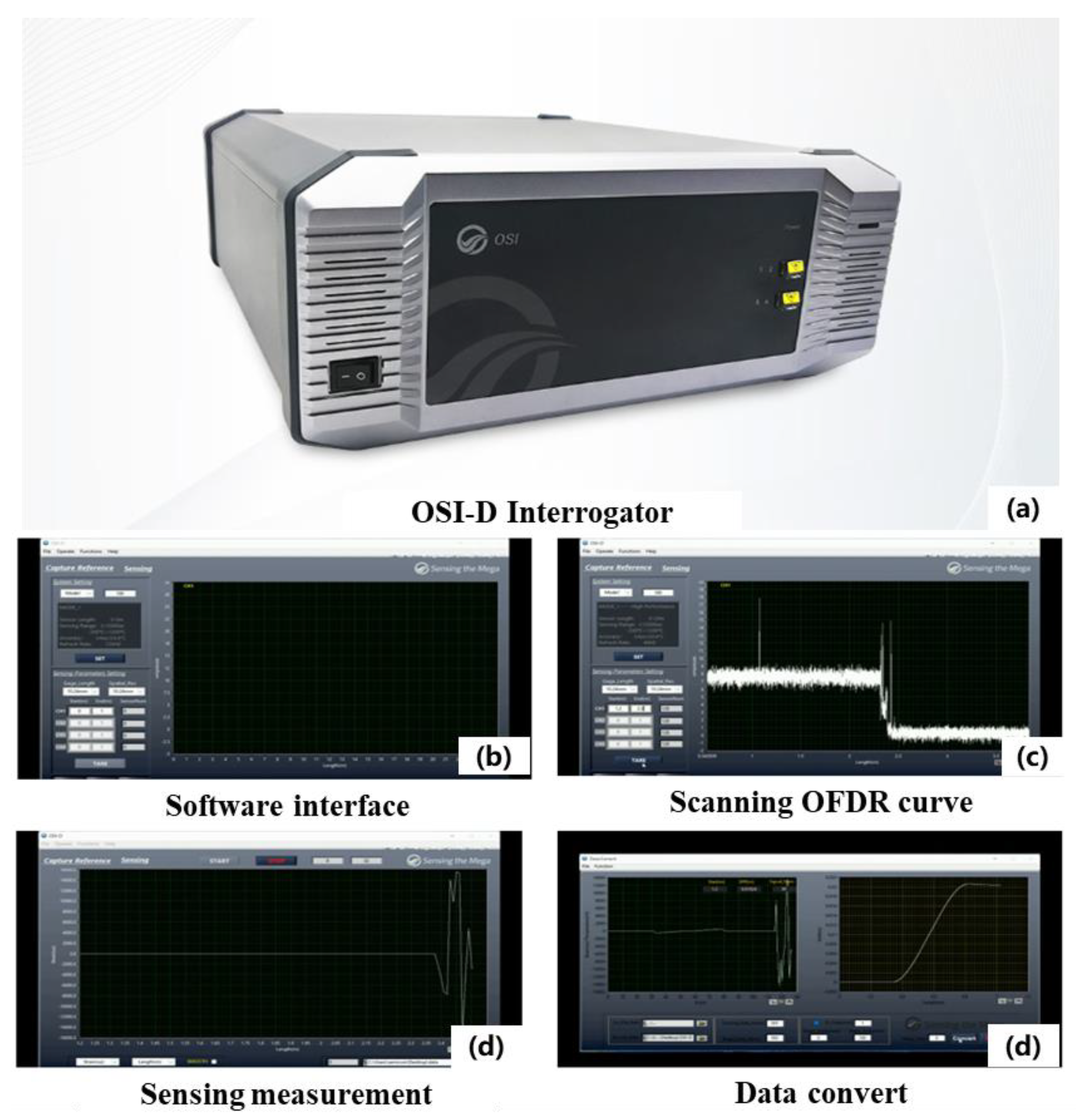

2.1.1. High-Precision Distributed Fiber Optic Temperature/Strain Measurement System

2.1.2. Full-Scale Cement Sheath Sealing Performance Evaluation Apparatus

2.1.3. Experiment Materials

2.2. Experiment Design

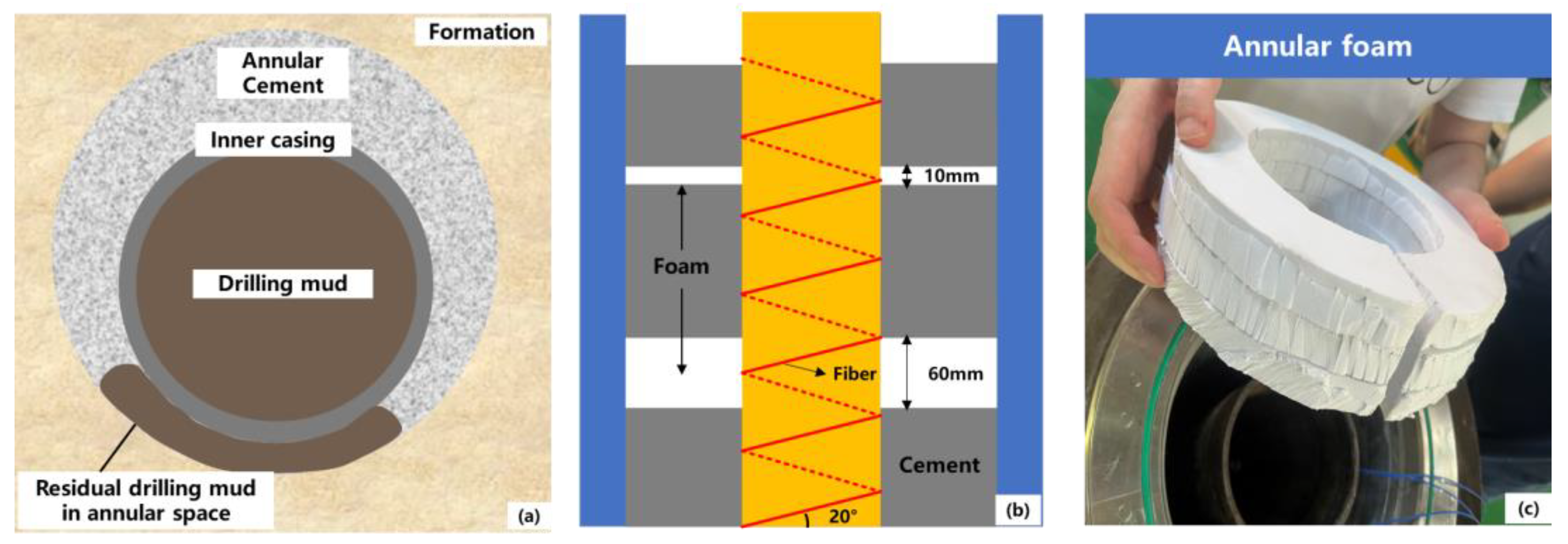

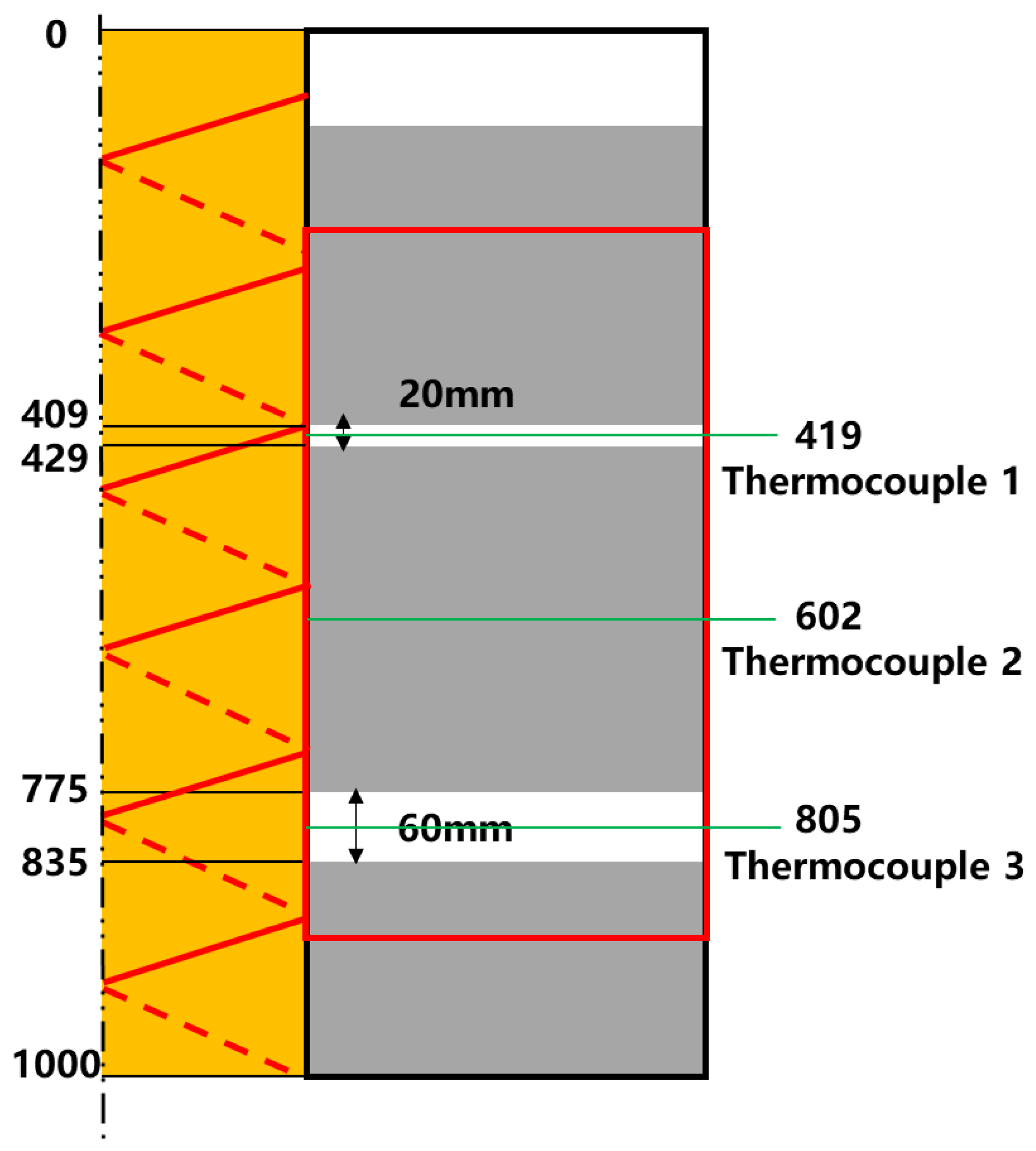

2.2.1. Temperature Change Monitoring of Cement Hydration Under Annular Deficiency

2.2.2. Temperature Change Monitoring of Cement Hydration Under Bond Interface Deficiency

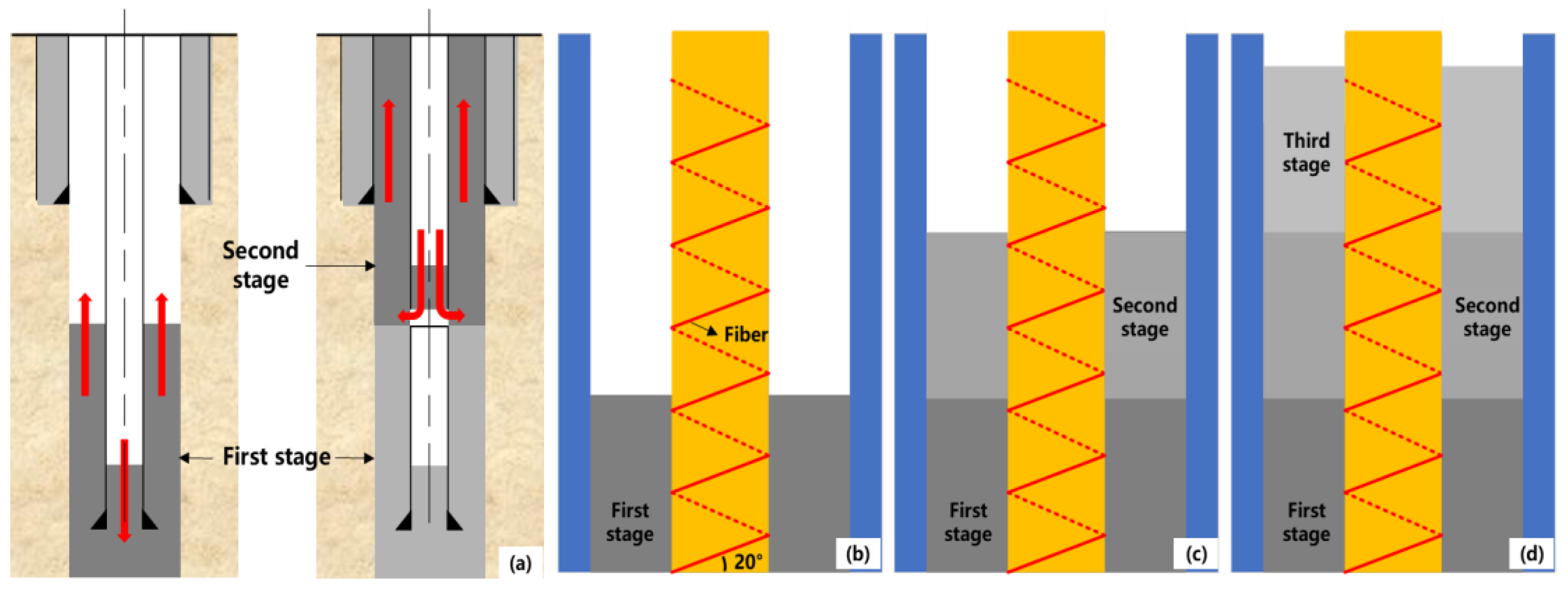

2.2.3. Temperature Change Monitoring of Annular Segmented Cement Hydration

2.3. Experimental Data Processing

3. Experimental Results and Analysis

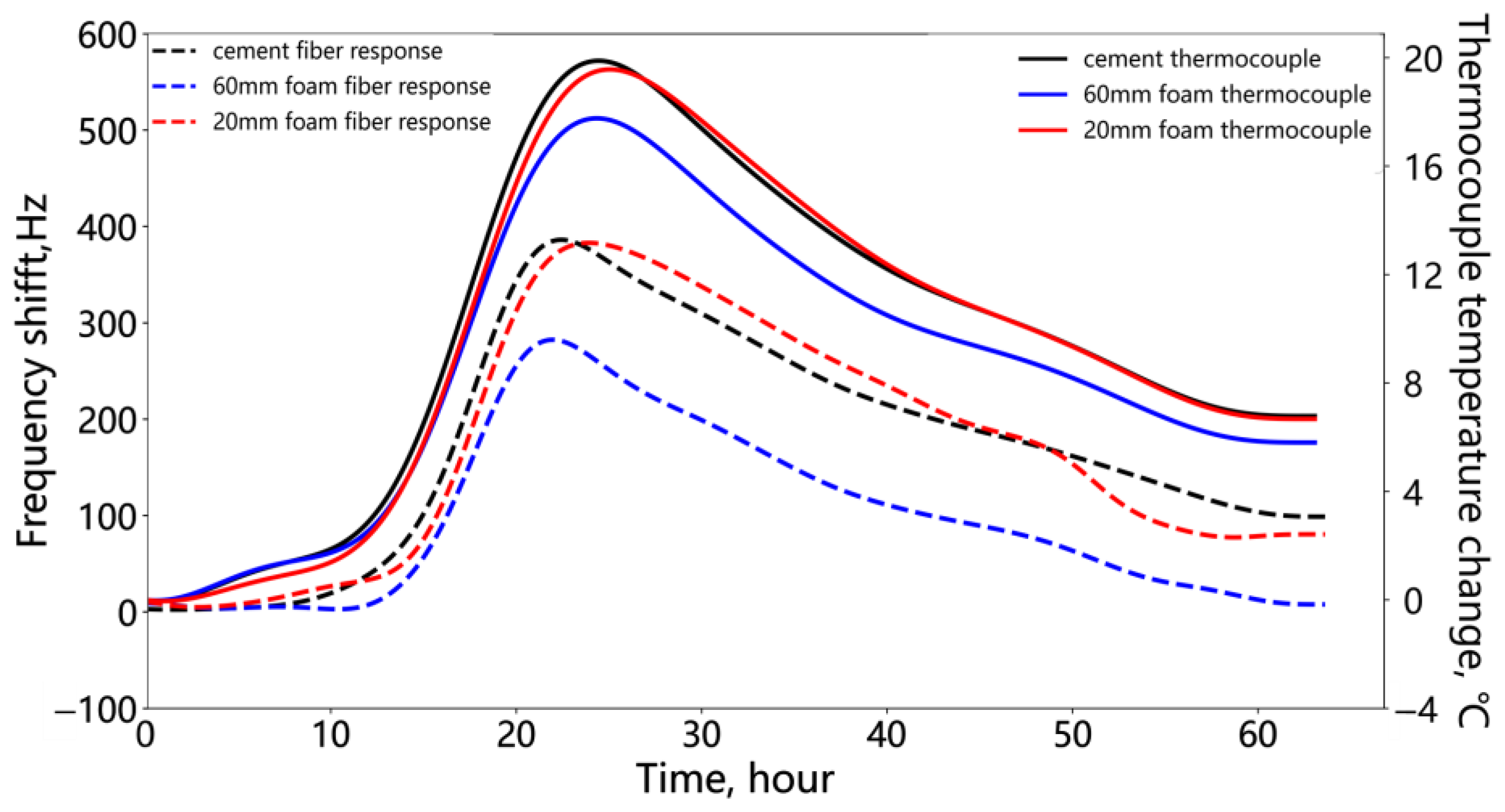

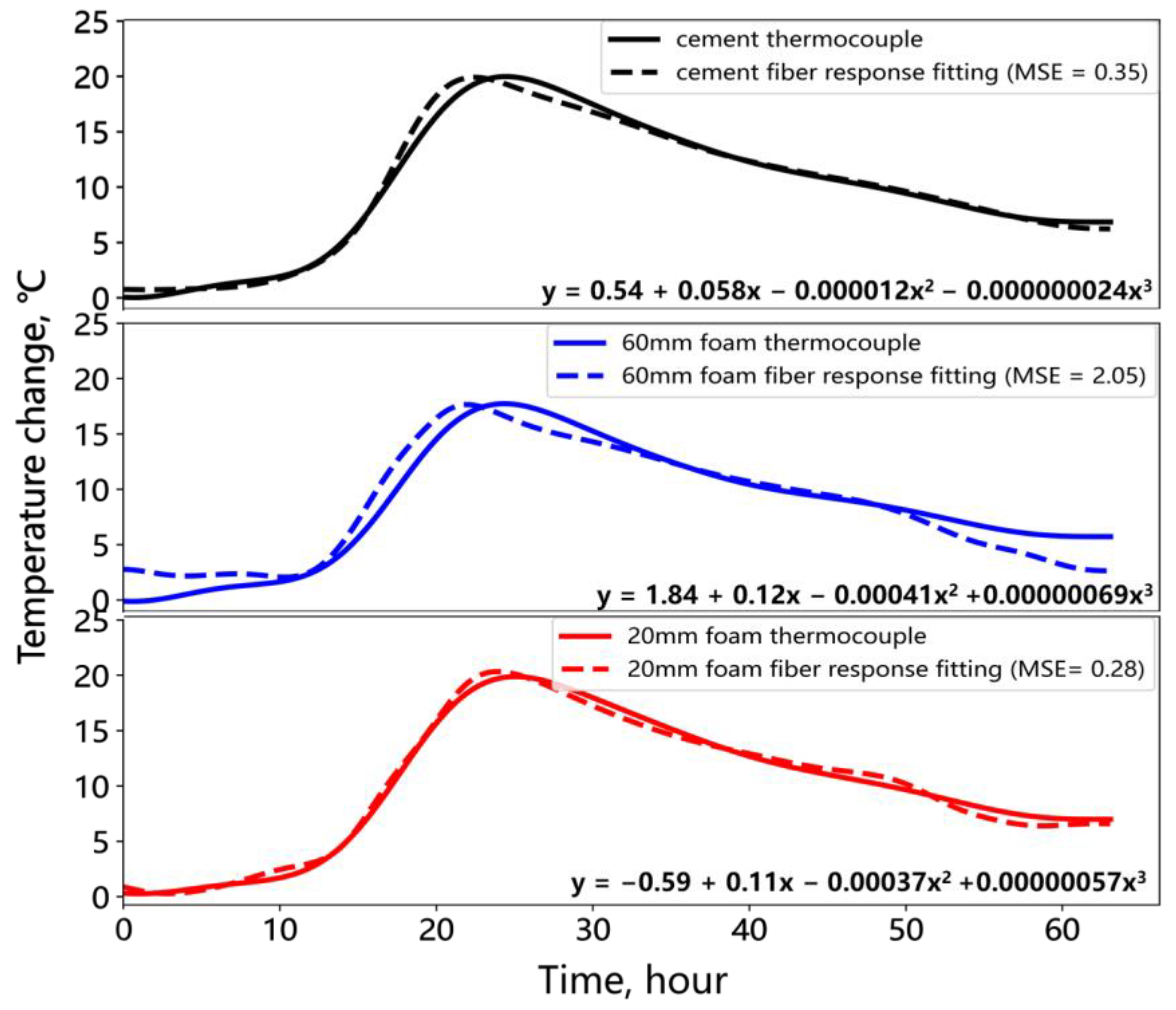

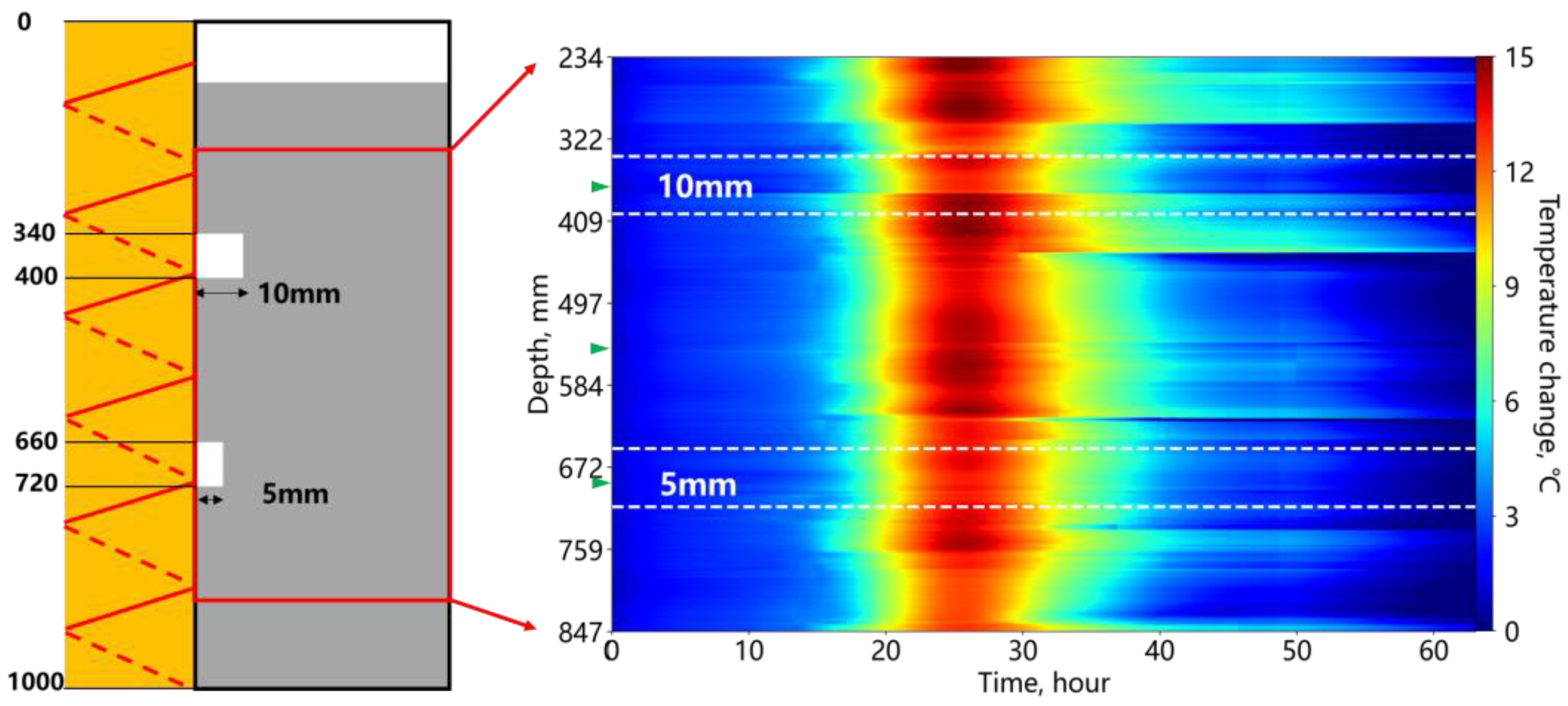

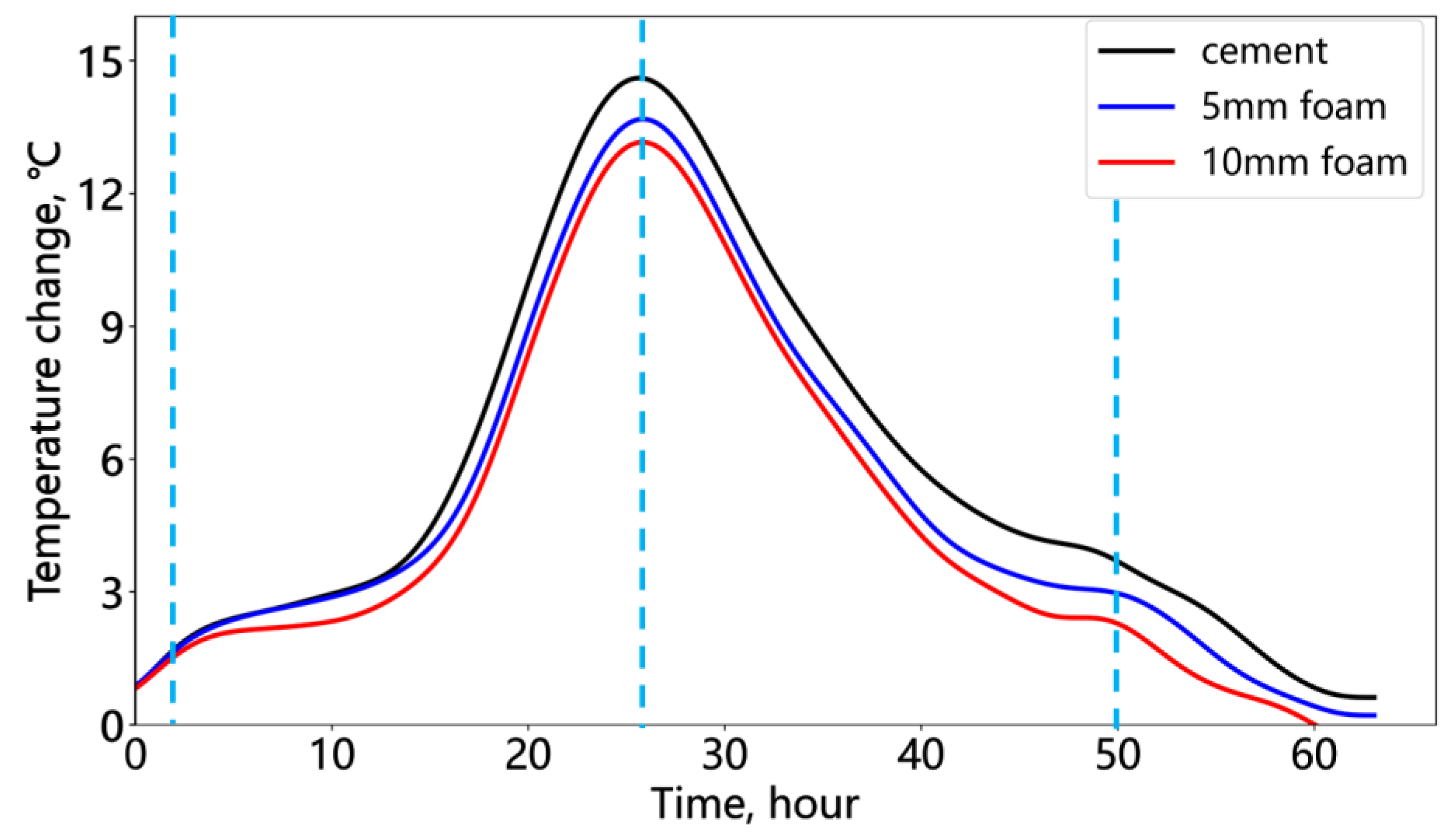

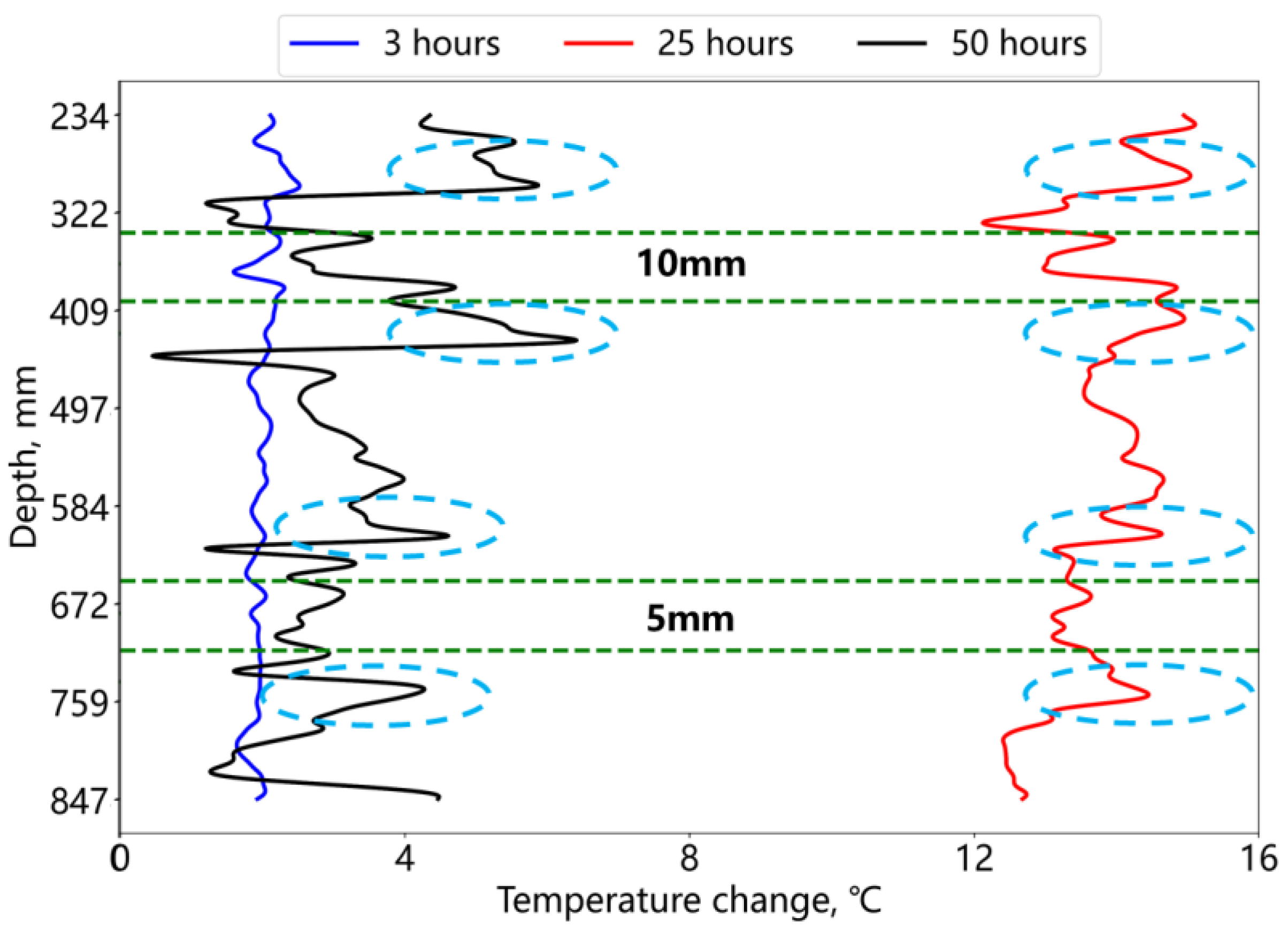

3.1. Analysis of the Temperature Change for Cement Hydration Under Annular Deficiency

3.2. Analysis of the Temperature Change for Cement Hydration Under a Bond Interface Deficiency

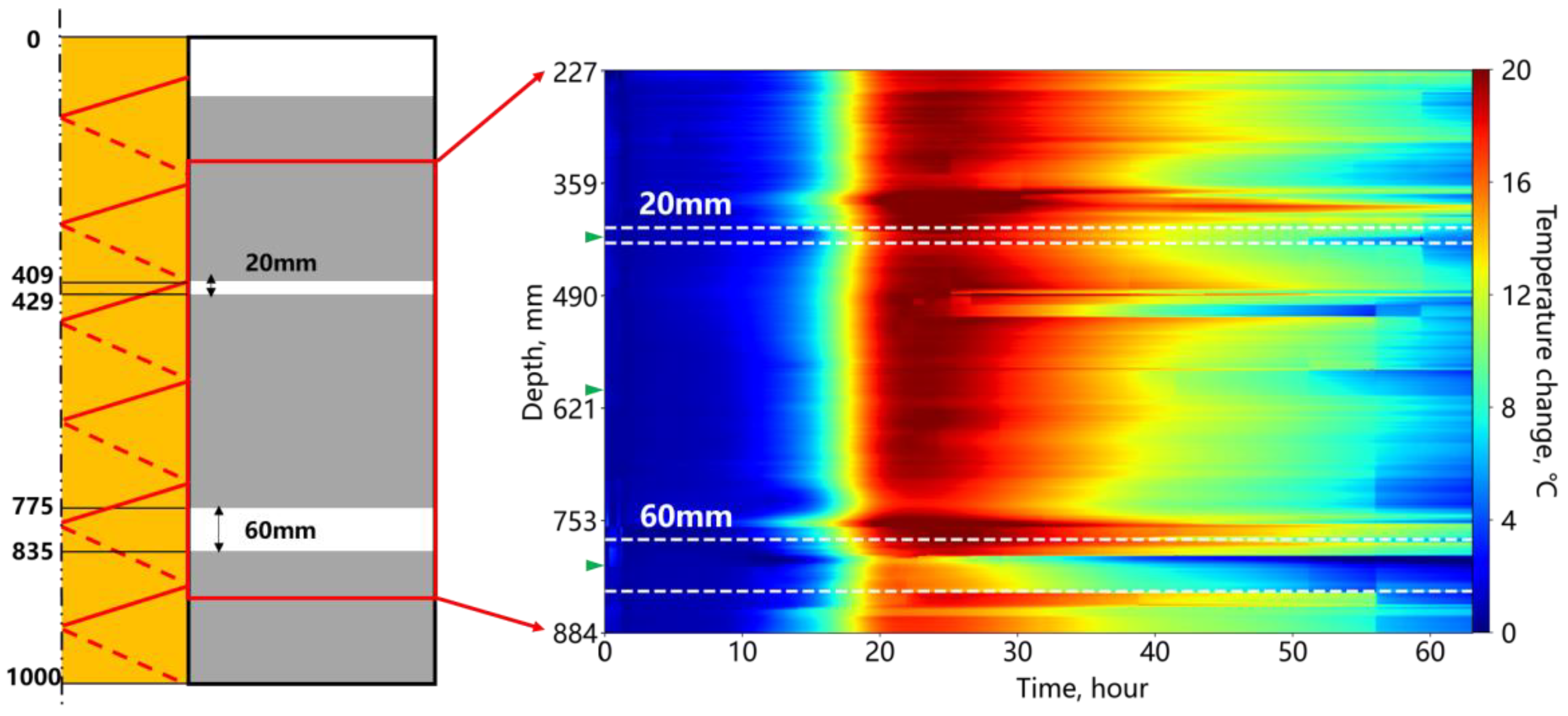

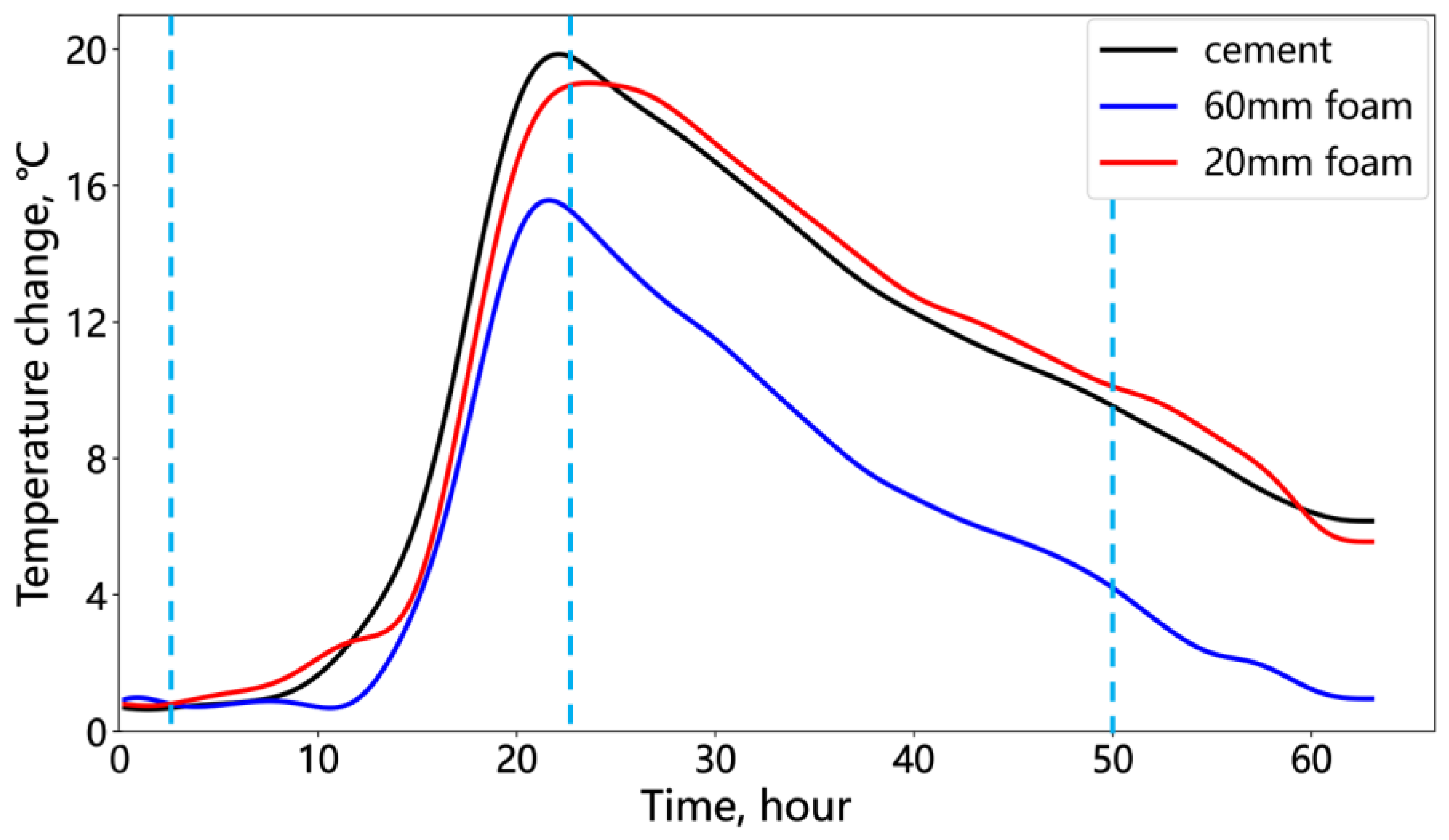

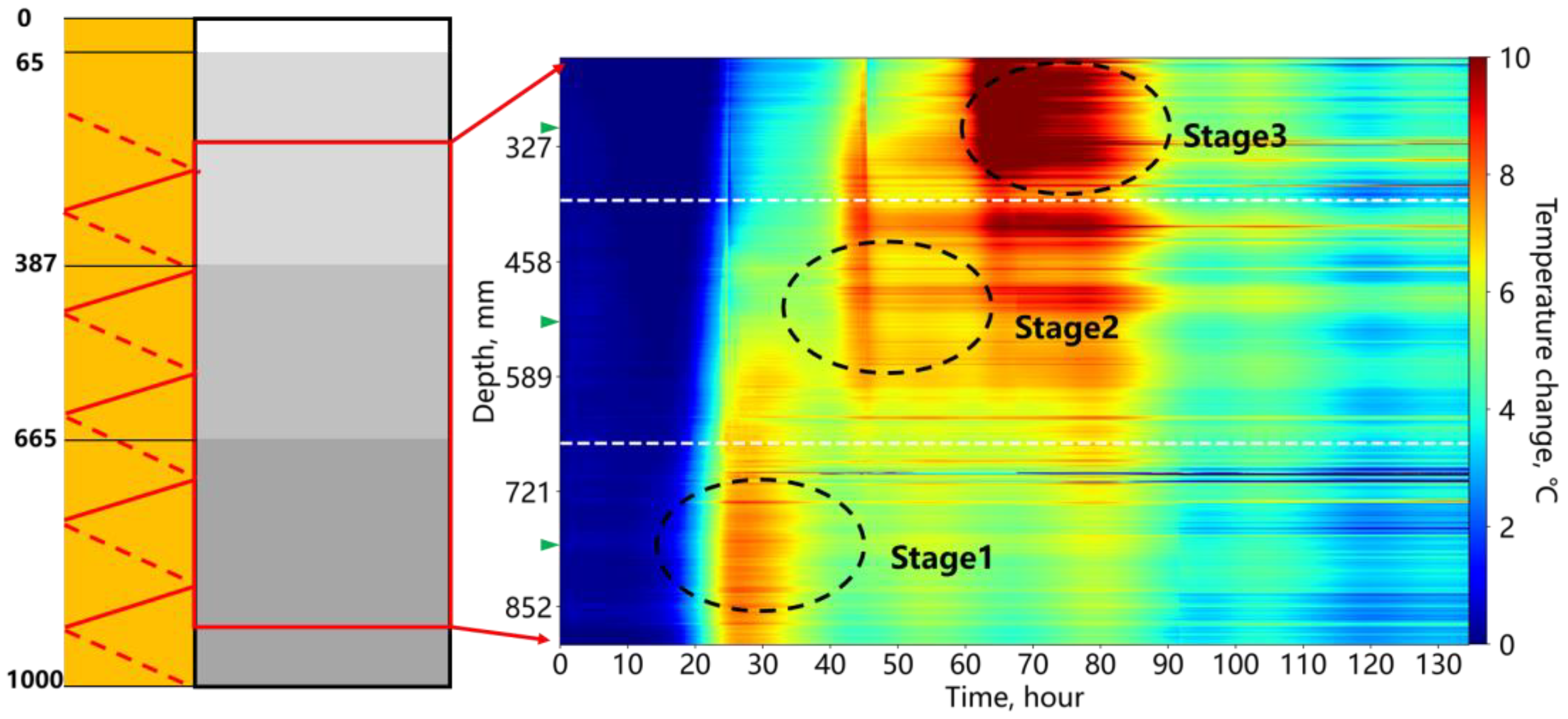

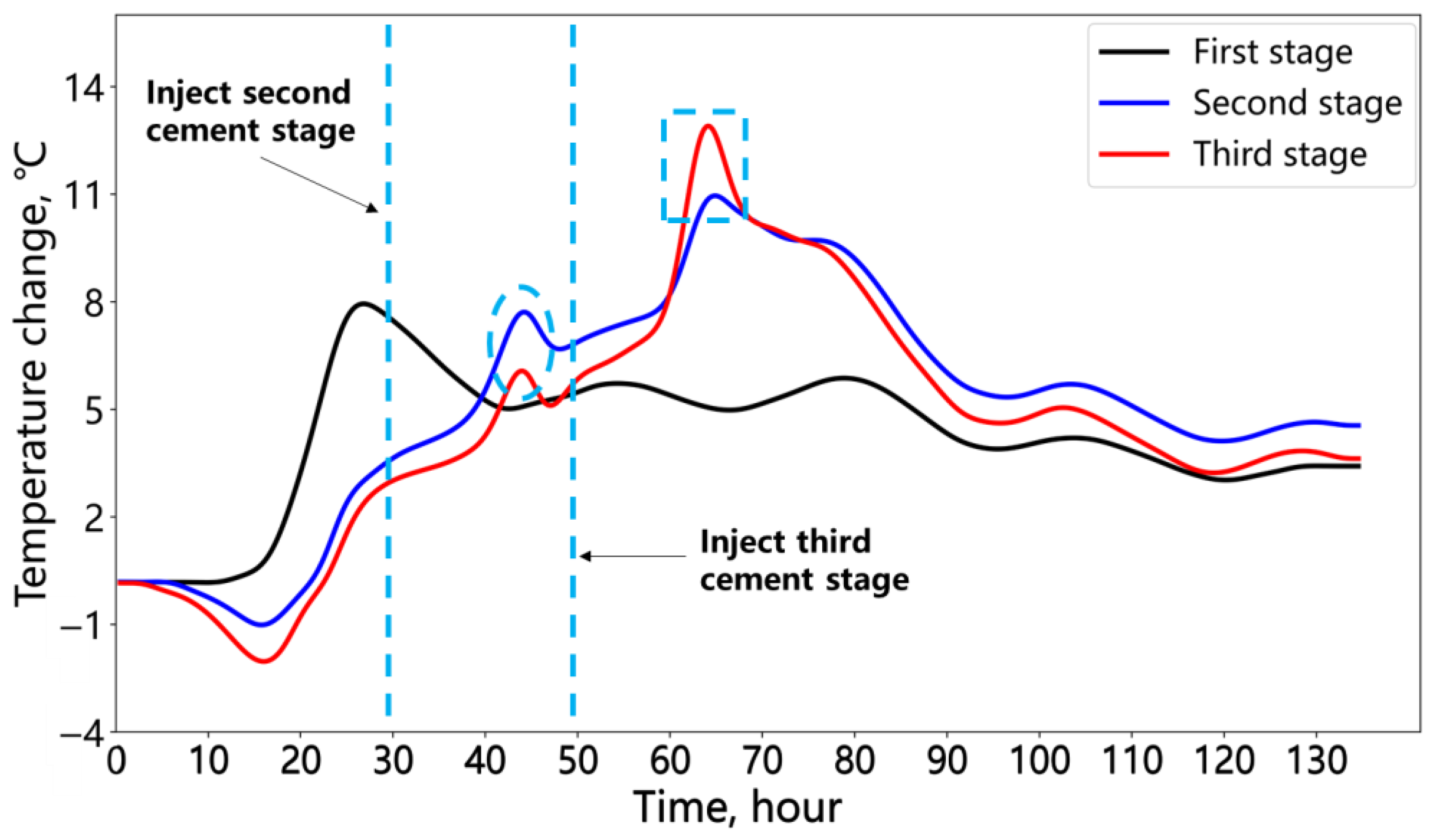

3.3. Analysis of the Temperature Change for Annular Segmented Cement Hydration

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Erik, B.; Nelson, D.G. Well Cementing, 2nd ed.; Schlumberger: Houston, TX, USA, 2006. [Google Scholar]

- Guan, Z.; Deng, K.; Wu, Y.; Lin, Z.; Lin, Y. Experimental Evaluation on the Cement Sheath Integrity of Unconventional Oil and Gas Well During Large-scale Hydraulic Fracturing. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2023, 45, 121–132. [Google Scholar]

- Rocha-Valadez, T.; Hasan, A.R.R.; Mannan, S.; Kabir, C.S.S. Assessing Wellbore Integrity in Sustained-Casing-Pressure Annulus. SPE Drill. Complet. 2014, 29, 131–138. [Google Scholar] [CrossRef]

- Tiku, S.; Veneruso, A.F.; Etchells, R.; Pecht, M.G. Risk Factors in Oil and Gas Well Electronics Compared to Other Electronic Industries. Oil Gas Sci. Technol.-Rev. De L Inst. Fr. Du Pet. 2005, 60, 721–730. [Google Scholar] [CrossRef][Green Version]

- Zhang, H.; Wu, W.; Song, X. Improved cement sheath thickness measurement and its application in cement sheath variation monitoring. Geoenergy Sci. Eng. 2024, 233, 212515. [Google Scholar] [CrossRef]

- Gowida, A.H.; Ahmad, Z.; Elkatatny, S.; Mahmoud, M. Cement Evaluation Challenges. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 23–26 April 2018; p. SPE-192360-MS. [Google Scholar]

- Ashry, I.; Mao, Y.; Wang, B.W.; Hveding, F.; Bukhamsin, A.; Ng, T.K.; Ooi, B.S. A Review of Distributed Fiber-Optic Sensing in the Oil and Gas Industry. J. Light. Technol. 2022, 40, 1407–1431. [Google Scholar] [CrossRef]

- Lu, P.; Lalam, N.; Badar, M.; Liu, B.; Chorpening, B.T.; Buric, M.P.; Ohodnicki, P.R. Distributed optical fiber sensing: Review and perspective. Appl. Phys. Rev. 2019, 6, 041302. [Google Scholar] [CrossRef]

- Gholizadeh Doonechaly, N.; Reinicke, A.; Hertrich, M.; Plenkers, K.; Obermann, A.; Fischli, F.; Maurer, H.; Wiemer, S.; Giardini, D. Multiphysics monitoring of cementation operation: Implications for wellbore integrity and hydrogeological characterization. Environ. Earth Sci. 2024, 83, 146. [Google Scholar] [CrossRef]

- Ricard, L.P. Using Distributed Temperature Sensing to Inform the Quality of Cementing Operations. In Proceedings of the SPE Asia Pacific Oil & Gas Conference and Exhibition, Virtual, 19 November 2020; p. D013S101R011. [Google Scholar]

- Lee, D.S.; Park, K.G.; Lee, C.; Choi, S.-J. Distributed Temperature Sensing Monitoring of Well Completion Processes in a CO2 Geological Storage Demonstration Site. Sensors 2018, 18, 4239. [Google Scholar] [CrossRef]

- Lipus, M.P.; Reinsch, T.; Weisenberger, T.B.; Kragset, S.; Stefánsson, A.; Bogason, S.G. Monitoring of a reverse cement job in a high-temperature geothermal environment. Geotherm. Energy 2021, 9, 5. [Google Scholar] [CrossRef]

- Wu, Q.; Nair, S.; Shuck, M.; van Oort, E.; Guzik, A.; Kishida, K. Advanced Distributed Fiber Optic Sensors to Monitor Cement Hydration and Detect Annular Hydrocarbon Migration for Enhanced Zonal Isolation. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dubai, United Arab Emirates, 26–28 September 2016; p. D021S023R002. [Google Scholar]

- Chen, S.; Wang, L.L. Experimental study on the integrity of cement sheath under cyclic loading. China Pet. Mach. 2024, 52, 107–113. [Google Scholar] [CrossRef]

- Wuhan Haoheng Technology Co. Ltd. OSI-D Dynamic Distributed Optical Fiber Sensing System [EB/OL]. Available online: https://mega-sense.com/?list_8/36.html (accessed on 31 January 2025). (In Chinese).

- Liang, C.; Bai, Q.; Yan, M.; Wang, Y.; Zhang, H.; Jin, B. A Comprehensive Study of Optical Frequency Domain Reflectometry. IEEE Access 2021, 9, 41647–41668. [Google Scholar] [CrossRef]

- Eickhoff, W.; Ulrich, R. Optical frequency-domain reflectometry in single-mode fibers. In Proceedings of the Integrated Optics and Optical Fiber Communication, San Francisco, CA, USA, 27 April 1981. [Google Scholar]

- Haustveit, K.; Haffener, J.; Young, S.; Dwyer, J.; Glaze, G.; Green, B.; Ketter, C.; Williams, T.; Brinkley, K.; Elliott, B. Cementing: The Good, the Bad, and the Isolated—Techniques to Measure Cement Quality and its Impact on Well Performance. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 6–8 February 2024; p. D011S001R002. [Google Scholar]

- Yousuf, N.; Olayiwola, O.; Guo, B.; Liu, N. A comprehensive review on the loss of wellbore integrity due to cement failure and available remedial methods. J. Pet. Sci. Eng. 2021, 207, 109123. [Google Scholar] [CrossRef]

- Tao, C.; Rosenbaum, E.; Kutchko, B.G.; Massoudi, M. A Brief Review of Gas Migration in Oilwell Cement Slurries. Energies 2021, 14, 2369. [Google Scholar] [CrossRef]

- Foroushan, H.K.; Lund, B.; Ytrehus, J.D.; Saasen, A. Cement Placement: An Overview of Fluid Displacement Techniques and Modelling. Energies 2021, 14, 573. [Google Scholar] [CrossRef]

- Alberdi-Pagola, P.; Fischer, G. Review of Integrity Loss Detection and Quantification Due to Cracking in Cemented Wells. SPE J. 2023, 28, 965–982. [Google Scholar] [CrossRef]

- Author, A.O.; Author, M.S.; Author, N.F.; Author, N.L.; Author, O.C. A Deep Dive on Stage Cementing Operations in Sub-Saharan Africa: A Case Study. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 5–7 August 2024; p. D021S002R001. [Google Scholar]

- Guo, Y.; Li, X.; Feng, S.; Zhang, C.; Liu, R.; Zhang, Z.; Li, T.; Guo, P.; Wang, R.; Taoutaou, S.; et al. Cementing Practices to Solve Well Integrity Challenges of Ultra Deep High Temperature Wells in Western China. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 7–10 November 2016; p. D011S019R002. [Google Scholar]

- Hussain, M.Q.; ALRashdi, A.A.; ELMahdy, M.M.; Mwansa, P.L.; Amorocho, A.; Ibrahim, A.M.; Naga, H.; Kaddoura, I. Positive Impact of V0 Multi-Stage Cementing Tool on the Long Term Well Integrity. In Proceedings of the SPE/IADC Middle East Drilling Technology Conference and Exhibition, Abu Dhabi, United Arab Emirates, 23–25 May 2023; p. D031S023R005. [Google Scholar]

| Equipment Specifications | Technical Specifications |

|---|---|

| Measurement Length | 20 m |

| Spatial Resolution | 0.6410.24 mm |

| Sampling Rate | 0120 hz |

| Strain Repeatability Accuracy | ±1.0±8.0 |

| Temperature Repeatability Accuracy | ±0.1±0.8 °C |

| Strain Measurement Range | ±12,000 |

| Temperature Measurement Range | −2001200 °C |

| Storage Temperature | 050 °C |

| Operating Temperature | 1040 °C |

| Operating Humidity | <90% RH |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Li, M.; Guo, H.; Wu, Y.; Sheng, L.; Jiao, J.; Li, Z.; Sui, W. Experimental Investigation of the Evaluation of the Cement Hydration Process in the Annular Space Using Distributed Fiber Optic Temperature Sensing. Sensors 2025, 25, 958. https://doi.org/10.3390/s25030958

Li Z, Li M, Guo H, Wu Y, Sheng L, Jiao J, Li Z, Sui W. Experimental Investigation of the Evaluation of the Cement Hydration Process in the Annular Space Using Distributed Fiber Optic Temperature Sensing. Sensors. 2025; 25(3):958. https://doi.org/10.3390/s25030958

Chicago/Turabian StyleLi, Zhong, Mengbo Li, Huan Guo, Yi Wu, Leixiang Sheng, Jingang Jiao, Zhenbo Li, and Weibo Sui. 2025. "Experimental Investigation of the Evaluation of the Cement Hydration Process in the Annular Space Using Distributed Fiber Optic Temperature Sensing" Sensors 25, no. 3: 958. https://doi.org/10.3390/s25030958

APA StyleLi, Z., Li, M., Guo, H., Wu, Y., Sheng, L., Jiao, J., Li, Z., & Sui, W. (2025). Experimental Investigation of the Evaluation of the Cement Hydration Process in the Annular Space Using Distributed Fiber Optic Temperature Sensing. Sensors, 25(3), 958. https://doi.org/10.3390/s25030958