Abstract

An innovative solution for real-time monitoring of reactions within confined spaces, optimized for Raman spectroscopy applications, is presented. This approach involves the utilization of a hollow-core waveguide configured as a compact flow cell, serving both as a conduit for Raman excitation and scattering and seamlessly integrating into the effluent stream of a cracking catalytic reactor. The analytical technique, encompassing device and optical design, ensures robustness, compactness, and cost-effectiveness for implementation into process facilities. Notably, the modularity of the approach empowers customization for diverse gas monitoring needs, as it readily adapts to the specific requirements of various sensing scenarios. As a proof of concept, the efficacy of a spectroscopic approach is shown by monitoring two catalytic processes: CO2 methanation (CO2 + 4H2 → CH4 + 2H2O) and ammonia cracking (2NH3 → N2 + 3H2). Leveraging chemometric data processing techniques, spectral signatures of the individual components involved in these reactions are effectively disentangled and the results are compared to mass spectrometry data. This robust methodology underscores the versatility and reliability of this monitoring system in complex chemical environments.

1. Introduction

Recognized for its broad applicability, Raman spectroscopy offers significant advantages in terms of specificity, speed, accuracy, simplicity, and stability. One of the major weaknesses of the analytical approach is the inherent weakness of Raman scattering, resulting in poor sensitivity. However, there are several techniques that enhance the Raman signal (e.g., surface plasmons, resonance enhancement, and multi-pass/cavity-based techniques) and there are systematic improvements that have been recently demonstrated and developed [1,2,3,4]. In the 1970s, thin film-coated optical fibers were demonstrated as a waveguide enhancement approach for liquid samples [5]. However, recent work in fiber-based approaches has expanded as a sensor for gaseous species (i.e., CO, CO2, H2, D2, N2, O2, SO2, NH3, CH4, and other small hydrocarbons) [6,7,8,9,10,11,12,13].

The first of two catalytic processes monitored here is carbon dioxide methanation (CO2 + 4H2 → CH4 + 2H2O) in which the spectral features of each component have been reported to navigate performance conditions [14,15,16]. Analytical techniques commonly used for monitoring gas-phase reactions include mass spectrometry and infrared spectroscopy (diffuse reflectance infrared Fourier transform spectroscopy or DRIFTS) [17,18]. For this reaction, features in mass spectra can be compromised by mass coincidence (N2 and CO have m/z ~28) and inactive vibrations in the infrared spectra prevent detection of H2 and N2. In contrast, Raman spectroscopy provides a single analytical approach to track all the involved gases simultaneously and thus more completely assess the performance of the catalyst in real time [11]. Flow rates, temperatures, and molar ratios are all modified to determine key kinetic properties. Robust data acquisition is required to adjust these parameters for optimal catalytic performance.

The second of two catalytic processes demonstrated is ammonia cracking or the chemical process where NH3 is decomposed into its diatomic constituent elements, N2 and H2 [19,20,21,22]. The most common cracking techniques rely on catalyst iron oxide (Fe3O4) [23]; however, catalytic efficiency can be further optimized by introducing elements like potassium or aluminum for synthesis and incorporating nickel or ruthenium for decomposition [24,25,26]. Monitoring reactants and products in real time plays a role in computing reaction rates in relation to the composition of the catalyst under consideration. Raman spectroscopy provides a noninvasive approach for observing relative and absolute concentrations for samples in gas, liquid or solid forms and is ideal for interrogating small molecular species [27,28].

In this work, two catalytic processes are monitored via real-time Raman spectroscopy for the activity of catalysts on Al2O3 support [29,30]. The primary focus of this work is the demonstration of real-time monitoring of gas cracking and synthesis by Raman spectroscopy. The primary aim is to demonstrate the analytical capabilities of this experimental design and gain insight into the feasibility of quantitative measurements utilizing a hollow-core waveguide as a flow cell in addition to the signal enhancement [31].

2. Materials and Methods

Experiments for monitoring HD by mixing H2 and D2 across platinum-coated alumina pellets have been previously reported in the literature by Telle and coworkers. In brief, Raman spectra are collected by flowing gases through a hollow-core waveguide [11]. A backward Raman configuration is used for the analysis of gaseous samples flowing through a waveguide to accomplish enhanced collection of Raman scattering. Raman spectroscopic measurements were carried out with a Horiba iHR320 spectrometer (0.318 m; 600 lines/mm grating) equipped with a Syncerity cooled CCD detector (–60 °C) [32]. Spectra were collected in the 180° backscattering geometry using 532 nm excitation (532 nm 1500 mW Green DPSS, Civil Laser Supplier. NaKu Technology Co., Ltd., Hangzhou, China). The reflective waveguide is a commercially available silver-lined, glass capillary with an inner diameter of 1 mm and a length of 500 mm (Guiding Photonics, Torrance, CA, USA). The waveguide is held in nested stainless-steel tubes with matched inner and outer diameters. These tubes support the waveguide and facilitate connection to the gas handling systems. Restricted flow outside the tubes, due to the matched diameters, ensures gas flow through the waveguide [33].

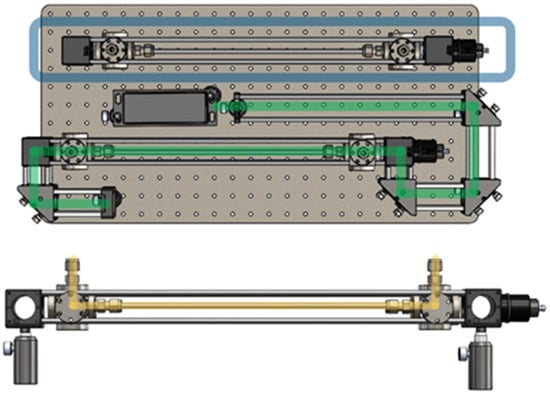

Stainless-steel pinhole (800 micron) endcaps cover the endcaps of the waveguide to remove background scattering from the annular silica surface that would otherwise be illuminated. Data were collected and presented in real time (Horiba LabSpec6 software, Solo Model Exporter 9.2.1, PLS toolbox, Eigenvector Research) to control the detector, grating position, and acquire data. Data analysis was performed offline using a chemometric pre-processing software package (PLS toolbox, Eigenvector Research, Wenatchee, DC, USA) for background subtraction, smoothing, and peak fitting. Optical lenses and mounts were purchased through Thorlabs Inc., including a narrowband pass filter, 532 nm dichroic filter, mounts, posts, silver mirrors and focusing lenses. Figure 1 shows a schematic with optical elements for sampling and collection of Raman spectra.

Figure 1.

Experimental design of optical elements for sampling and collection of Raman spectra by workstation, (top) laser path in green and extra waveguide in blue. The (bottom) sample flow through the waveguide is highlighted in yellow.

For CO2 methanation reactions, the catalytic reactor bed was packed with 500 mg of a nickel-based (Ni/Yb/K/Al2O3) catalyst and was activated under a 20% H2 (10 mL min−1 H2 and 40 mL min−1 Ar) atmosphere at 600 °C for three hours. The flow was then purged of H2 by flowing pure Ar for 30 min before reagent gases were added to ensure any H2 detected was that from CO2 methanation. Then, the reaction took place under varying amounts of CO2 in H2 at 450 °C. CO2 (>99.98) was obtained from Sigma Aldrich (St. Louis, MO, USA). Nickel nitrate (99.9%), ytterbium nitrate (99.9%), and potassium nitrate (99.9%) were all obtained from ThermoFisher (Waltham, MA, USA) and utilized for the catalyst synthesis without further purification. γ-Al2O3 was obtained from Sasol (Johannesburg, South Africa) (lot# TK2347) and used without further purification.

For ammonia cracking, the catalytic reactor bed was packed with 500 mg of a trimetallic ruthenium (Ru/Y/K/Al2O3) catalyst and was activated under a 20% H2 (10 mL min−1 H2 and 40 mL min−1 Ar) atmosphere at 450 °C for three hours. The flow was then purged of H2 by flowing pure Ar for 30 min before ammonia was added to ensure any H2 detected was that from ammonia decomposition. Then, the reaction took place under either 10% NH3 in Ar or 100% NH3 atmospheres at temperatures ranging from 250 to 450 °C. NH3 (>99.98) was obtained from Sigma Aldrich. The exhaust was connected to the Raman spectrometer and a mass spectrometer (Cirrus 2, MKS, Andover, MA, USA). Ruthenium nitrosylnitrate (99.9%) and yttrium nitrate (99.9%) were both obtained from ThermoFisher.

3. Results and Discussion

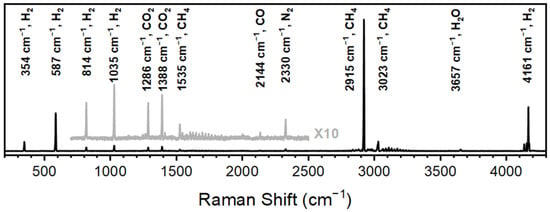

While catalysts are developed based on efficiency, performance, deactivation, cost of materials, and effectiveness, the analytical measurement technique for each of these criteria has yet to be standardized across the community. The results shown here demonstrate the versatility of Raman spectroscopy in CO2 methanation for detecting reactants, products, and environmental components. Figure 2 is a Raman spectrum of the effluent from a reactor with CO2 and H2 flowed at optimized ratios (concentrations) and speeds in the presence of a nickel-based catalyst. The CO2 features centered at 1286 and 1388 cm−1 and CO feature at 2144 cm−1 have been previously reported and are used to monitor effective catalysis (CO2 conversion) and breakthrough. The H2 features at 354, 587, 814, 1035 and 4161 cm−1 are also in agreement with previously reported values and provide insight into the stoichiometric conditions of the catalyst. The dominating methane features at 2915 cm−1 allow for methane to be detected under poor conditions for catalysis.

Figure 2.

Raman spectra of CO2 methanation acquired over 10 s spectral accumulations.

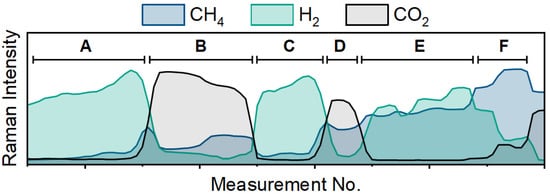

The temporal selectivity for CO2 methanation can be best represented through extracting the reactants and products of the reaction using multivariate curve resolution (MCR). Here, Raman spectra of known concentrations as well as sample data are batch processed by baseline subtraction and signal averaging. The known concentrations serve as an external calibration with a minor nitrogen feature at 2330 cm−1 serving as the internal standard. Figure 3 is separated into six distinct regions of interest and shows the three major components from the MCR loading plots generated from 120 Raman spectra. The CH4 component (blue) is the product of the reaction and is monitored along with the reactants (H2 in green and CO2 in black). In Regions A, B, and C, the flow rates of H2 and CO2 are recorded at 50:0, 0:50, 50:0 mL min−1, respectively. Low amounts of methane were observed in Region B, most likely due to lingering hydrogen from the catalyst activation reacting to form CH4. The flow rates in Region D are 50:20 and continuous CO2 methanation is observed. Region E shows the increase in H2 flow from 100 to 150 to 200 mL min−1 and shows that the additional hydrogen flow improves the conversion of the catalyst as CO2 decreases. Lastly, Region F shows that increasing the CO2 flow from 20 to 30 to 50 mL min−1 decreases the rate of reaction. Additionally, it is important to note that as the CO2 increases, the H2 decreases due to its being consumed in the reaction. Thus, the Raman spectrometer can be utilized to identify products in the gas effluent stream and to track changes in the reactivity of the system in real time.

Figure 3.

Traces from Raman spectra of CH4 (blue), H2 (green) and CO2 (black) with changes to the flow rate conditions of the feed gases to the reactor.

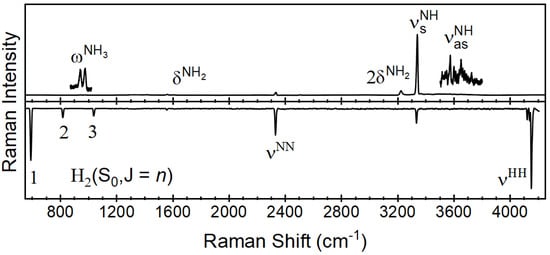

The Raman spectra of hydrogen isotopes have been previously reported by employing metal-coated hollow glass fibers in the application of passing H2 and D2 gases through a catalytic reactor to produce HD [11]. Here, a similar process is demonstrated known as ammonia cracking or 2NH3 → N2 + 3H2. Figure 4 (top) shows the Raman spectrum of 100% ammonia gas flowing through the catalytic reactor at 50 mL min−1 at a reactor temperature of 250 °C. The primary feature observed for ammonia is centered at 3337 cm−1. This is in agreement with previous reports [34], in which it has been characterized as the symmetric stretch (νs). In addition to the primary feature, minor features include the out-of-plane bend (δ), the asymmetric stretch (νas) and the asymmetric bending (ω).

Figure 4.

Raman spectra of ammonia reactant (top) and hydrogen/nitrogen product (bottom) flowing at 50 mL min and acquired over 10 s spectral accumulations.

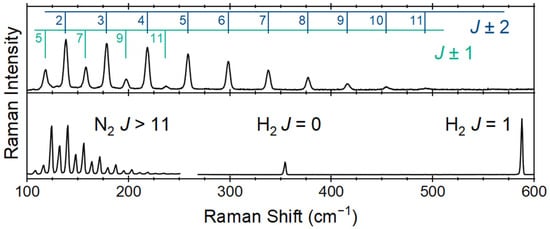

The features observed for hydrogen and nitrogen have been previously reported in the spectral range of Figure 5 [35]. In addition to the fundamental Q-branches of the diatomic species (N2 2330 cm−1 and H2 4161 cm−1), there are rotational features observed across the spectral range from 100 to 4250 cm−1 [36,37]. Of these, the nitrogen rotational features are observed and can be compared to previously reported spectra in a similar Raman spectrum for ammonia to the nitrogen and hydrogen features in the spectral range of 100 to 600 cm−1. These features can be used as confirmatory or even primary indicators of process control at higher concentrations. Lewis and Houston previously reported these low-wavenumber features of the Raman spectrum of ammonia and assigned them to the ΔJ = ± 1 and 2 pure rotational states [38]. These results agree with the previously reported rotational constants for ammonia when considering the spectral range from 100 to 500 cm−1.

Figure 5.

Low-wavenumber Raman spectra of ammonia (top) and hydrogen and nitrogen (bottom) flowing at 50 mL min and acquired over 30 s spectral accumulations.

While some features overlap (completely or partially), standard chemometric approaches can be employed for deconvolution to include partial least-squares (PLS) modeling, first derivative (second-order polynomial) baseline correction, normalizing spectra to the area of a feature, and mean centering data to equally weight the data. Recent work by Lines and coworkers demonstrates the improvements by leveraging chemometric analyses for applications across multiple systems [39]. The combination of online monitoring, robust calibration methods and chemometrics provides a nondestructive analytical approach for gas processes, transfers, and separations [40,41]. This type of less common, spectroscopic approach can be directly compared to other analytical platforms (i.e., mass spectrometry).

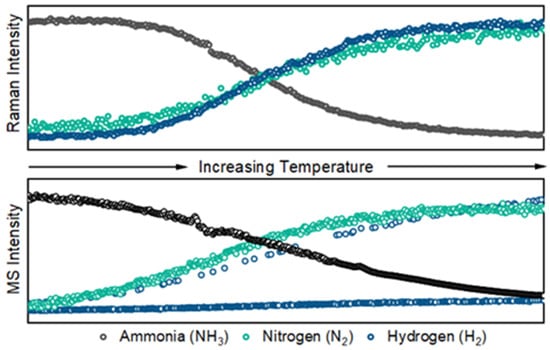

The side-by-side comparison of Raman signals (counts at peak height) and selective ion monitoring signals (mass-to-charge ratio counts) is shown in Figure 6. These data were acquired with 10% ammonia in argon gas flowing through the catalytic reactor at a rate of 50 mL min−1. The initial temperature was 200 °C and the final temperature was 450 °C. The temperature was increased at a rate of 10 °C min−1. Both sets of data were processed in Eigenvector Research PLS-Toolbox (Solo+Model Exporter version 9.2). The Raman and mass spectra were processed with baseline corrections (Whittaker filter, λ = 100 and p = 0.001) and normalization of each of the largest features. Subtle differences in the curvature of the Raman and mass spectra are expected as a result of the heated transfer capillary and low flow to the mass spectrometer in addition to the location of the sampling position.

Figure 6.

Peak heights of select Raman features of ammonia reactant (top) and hydrogen/nitrogen product (bottom) flowing at 50 mL min and acquired over 10 s spectral accumulations.

A major concern for Raman spectroscopy for online monitoring is providing defensible data in terms of intensity-to-concentration conversion. While canonical Raman experiments rely on stable laser power and spectrometer drift correction, fiber or waveguide enhancement techniques are significantly impacted by the sampling and collection efficiency. Minor misalignments for the laser excitation can significantly increase background scattering, and minor misalignment of the collection can decrease the observed Raman signal for a given concentration of gas. This work demonstrates the feasibility of monitoring reactive systems by waveguide-enhanced Raman scattering and does not aim to be a comprehensive study on quantifying limits of detection or other figures of merit for a validated analytical method. Further development of instrumental and procedural controls to facilitate operations by more quantitative approaches will lead to the employment of real-time monitoring by Raman spectroscopy.

4. Conclusions

Using a hollow-core waveguide for Raman spectroscopy provides significant scattering enhancement for gaseous samples flowing through the waveguide. While the advantages are obvious, there are several considerations to evaluate for future directions for this work to include sample compatibility, fluorescence, memory effects, and accessibility for alignment. Here, a Raman spectroscopy platform can provide real-time analytical support for catalytic reactions, specifically CO2 methanation and ammonia cracking. The low-wavenumber-region Raman spectrum of ammonia has been observed in this work but can be further explored for mixed isotope contributions. Compared to conventional Raman scattering geometries, the waveguide enhancement has been shown to provide sensitivity enhancements of at least 50× for hydrogen [11,32].

The chemometric techniques applied to the data support eventual implementation for real-time quantification of reactive species [42]. Chemometric tools were leveraged for post-processing data for calibration curves though mass flow-controlled dilution of target species in argon. A more acceptable approach for acquiring reliable data would be to devise a sample sequence that measures external calibration samples, quality control samples, and instrument blank samples. In addition to devising a reporting scheme for uploading to a laboratory information management system, a more robust approach for clustering and classifying unknown spectral features is projected for real-time analyses using Raman spectroscopy.

Here, a Raman spectroscopy platform is shown to provide real-time analytical support for catalytic reactions, specifically CO2 methanation and ammonia cracking. The low-wavenumber-region Raman spectrum of ammonia has been observed in this work but can be further explored for mixed isotope contributions. Future applications include tracking hydrogen isotope exchange in ammonia and methane, first in a “cold” environment using H2 and D2, then eventually in a radiological or “hot” glovebox in the Tritium Instrument Demonstration System at the Savannah River Site [43]. This specific application extends widely to radiological measurements to the accountancy in deuterium-tritium (DT) fusion energy as a non-invasive gas measurement technique [44]. An extra challenge to this work is that there is little literature of the vibrational spectroscopy of the multiple mixed isotopologue species for ammonia (four) and methane (five). The immediate next direction is focusing on generating these species using cracking methods, detecting the mixed isotopologues in real time, and using chemometric methods to extract the spectra of individual species from the inevitable mixtures that result. These results, confirmed by calculations of Raman intensity, will allow for an accurate concentration measurement of species that are difficult to isolate.

Author Contributions

J.T.K. and C.J.K. contributed equally to the collection and analysis of data; J.T.K., C.J.K., R.L. and T.G. conceived and designed the experiments. J.T.K., C.J.K. and T.G. contributed infrastructure and materials; J.T.K., C.J.K., R.L. and T.G. wrote the article. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Tritium Modernization Program, sponsored by the National Nuclear Security Administration (NNSA) of the U.S. Department of Energy (DOE) through the Office of Strategic Materials Production Modernization. This work was produced by Battelle Savannah River Alliance, LLC under Contract No. 89303321CEM000080 with the U.S. Department of Energy. Publisher acknowledges the U.S. Government license to provide public access under the DOE Public Access Plan (http://energy.gov/downloads/doe-public-access-plan, accessed on 16 October 2024).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Different catalysts were characterized and tested, including ruthenium on alumina and nickel on alumina (Ni/Al). Select catalysts on alumina may be the most compatible for use in tritiated environments. The specific synthesis is proprietary; however, the corresponding author can be contacted directly for additional information or discussion. In addition, inquiries on the detection limitations and sensitivity of the spectroscopic approach can also be sent to the corresponding author.

Acknowledgments

The authors are grateful to Mary Leslie Whitehead for her instructions, guidance, and safety protocols relevant to the tritium handling and measurements.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Niklas, C.; Wackerbarth, H.; Ctistis, G. A Short Review of Cavity-Enhanced Raman Spectroscopy for Gas Analysis. Sensors 2021, 21, 1698. [Google Scholar] [CrossRef] [PubMed]

- Allsop, T.; Neal, R. A Review: Application and Implementation of Optic Fibre Sensors for Gas Detection. Sensors 2021, 21, 6755. [Google Scholar] [CrossRef] [PubMed]

- Ettabib, M.A.; Liu, Z.; Zervas, M.N.; Bartlett, P.N.; Wilkinson, J.S. Waveguide-enhanced Raman spectroscopy. Nat. Rev. Methods Primers 2024, 4, 5. [Google Scholar] [CrossRef]

- Le Ru, E.C.; Auguié, B. Enhancement Factors: A Central Concept During 50 Years of Surface-Enhanced Raman Spectroscopy. ACS Nano 2024, 18, 9773–9783. [Google Scholar] [CrossRef]

- Walrafen, G.; Stone, J. Intensification of Spontaneous Raman Spectra by Use of Liquid Core Optical Fibers. Appl. Spectrosc. 1972, 26, 585–589. [Google Scholar] [CrossRef]

- Blohm, A.; Domes, C.; Frosch, T. Isotopomeric Peak Assignment for N2O in Cross-Labeling Experiments by Fiber-Enhanced Raman Multigas Spectroscopy. Anal. Chem. 2024, 96, 2883–2892. [Google Scholar] [CrossRef]

- Blohm, A.; Domes, C.; Merian, A.; Wolf, S.; Popp, J.; Frosch, T. Comprehensive Multi-gas Study by Means of Fiber-enhanced Raman Spectroscopy for the Investigation of nitrogen Cycle Processes. Analyst 2024, 149, 1885–1894. [Google Scholar] [CrossRef] [PubMed]

- Buric, M.; Woodruff, S.; Chorpening, B.; Tucker, D. Fuel Flexibility via Real-time Raman Fuel-gas Analysis for Turbine System Control. In Proceedings of the Next-Generation Spectroscopic Technologies VIII, Baltimore, MD, USA, 20–22 April 2015; pp. 148–157. [Google Scholar]

- Buric, M.P. Gas Phase Raman Spectroscopy using Hollow Waveguides. Ph.D. Thesis, University of Pittsburgh, Pittsburgh, PA, USA, 2011. [Google Scholar]

- Ettabib, M.A.; Marti, A.; Liu, Z.; Bowden, B.M.; Zervas, M.N.; Bartlett, P.N.; Wilkinson, J.S. Waveguide Enhanced Raman Spectroscopy for Biosensing: A Review. ACS Sens. 2021, 6, 2025–2045. [Google Scholar] [CrossRef]

- James, T.M.; Rupp, S.; Telle, H.H. Trace Gas and Dynamic Process Monitoring by Raman Spectroscopy in Metal-coated Hollow Glass Fibres. Anal. Methods 2015, 7, 2568–2576. [Google Scholar] [CrossRef]

- Petrov, D.V.; Matrosov, I.I. Raman Gas Analyzer (RGA): Natural Gas Measurements. Appl. Spectrosc. 2016, 70, 1770–1776. [Google Scholar] [CrossRef]

- Zhao, J.; Cao, X.; Xu, W.; Xu, S. Waveguide-based Raman Enhancement Strategies. J. Raman Spectrosc. 2024, 55, 355–376. [Google Scholar] [CrossRef]

- Bai, Y.; Xiong, D.; Yao, Z.; Wang, X.; Zuo, D. Analysis of CH4, C2H6, C2H4, C2H2, H2, CO, and H2S by Forward Raman Scattering with a Hollow-core Anti-resonant Fiber. J. Raman Spectrosc. 2022, 53, 1023–1031. [Google Scholar] [CrossRef]

- Fang, J.; Chou, I.M.; Chen, Y. Quantitative Raman Spectroscopic Study of the H2─CH4 Gaseous System. J. Raman Spectrosc. 2018, 49, 710–720. [Google Scholar] [CrossRef]

- Fouche, D.; Chang, R. Relative Raman Cross Section for O3, CH4, C3H8, NO, N2O, and H2. Appl. Phys. Lett. 1972, 20, 256–257. [Google Scholar] [CrossRef]

- Ashok, J.; Pati, S.; Hongmanorom, P.; Tianxi, Z.; Junmei, C.; Kawi, S. A Review of Recent Catalyst Advances in CO2 Methanation Processes. Catal. Today 2020, 356, 471–489. [Google Scholar] [CrossRef]

- Zhao, K.; Zhang, J.; Luo, W.; Li, M.; Moioli, E.; Spodaryk, M.; Züttel, A. A Combined Diffuse Reflectance Infrared Fourier Transform Spectroscopy–Mass Spectroscopy–Gas Chromatography for the Operando Study of the Heterogeneously Catalyzed CO2 Hydrogenation Over Transition Metal-based Catalysts. Rev. Sci. Instrum. 2020, 91, 074102. [Google Scholar] [CrossRef] [PubMed]

- Chai, W.S.; Bao, Y.; Jin, P.; Tang, G.; Zhou, L. A Review on Ammonia, Ammonia-Hydrogen and Ammonia-methane Fuels. Renew. Sustain. Energy Rev. 2021, 147, 111254. [Google Scholar] [CrossRef]

- Klerke, A.; Christensen, C.H.; Nørskov, J.K.; Vegge, T. Ammonia for Hydrogen Storage: Challenges and Opportunities. J. Mater. Chem. 2008, 18, 2304–2310. [Google Scholar] [CrossRef]

- Lamb, K.E.; Dolan, M.D.; Kennedy, D.F. Ammonia for Hydrogen Storage; A Review of Catalytic Ammonia Decomposition and Hydrogen Separation and Purification. Int. J. Hydrogen Energy 2019, 44, 3580–3593. [Google Scholar] [CrossRef]

- Schüth, F.; Palkovits, R.; Schlögl, R.; Su, D.S. Ammonia as a Possible Element in an Energy Infrastructure: Catalysts for Ammonia Decomposition. Energy Environ. Sci. 2012, 5, 6278–6289. [Google Scholar] [CrossRef]

- Song, X.; Basheer, C.; Zare, R.N. Making Ammonia from Nitrogen and Water Microdroplets. Proc. Natl. Acad. Sci. USA 2023, 120, e2301206120. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.D.; Gluhoi, A.C.; Nieuwenhuys, B.E. Ammonia Oxidation over Au/MOx/γ-Al2O3—Activity, Selectivity and FTIR Measurements. Catal. Today 2004, 90, 3–14. [Google Scholar] [CrossRef]

- Miyazaki, A.; Balint, I.; Aika, K.-i.; Nakano, Y. Preparation of Ru Nanoparticles Supported on γ-Al2O3 and its Novel Catalytic Activity for Ammonia Synthesis. J. Catal. 2001, 204, 364–371. [Google Scholar] [CrossRef]

- Yin, S.; Xu, B.; Zhou, X.; Au, C. A Mini-review on Ammonia Decomposition Catalysts for On-site Generation of Hydrogen for Fuel Cell Applications. Appl. Catal. A Gen. 2004, 277, 1–9. [Google Scholar] [CrossRef]

- Fenner, W.R.; Hyatt, H.A.; Kellam, J.M.; Porto, S. Raman Cross Section of Some Simple Gases. JOSA 1973, 63, 73–77. [Google Scholar] [CrossRef]

- Schrötter, H.; Klöckner, H. Raman scattering Cross Sections in Gases and Liquids. In Raman Spectroscopy of Gases and Liquids; Springer: Berline/Heidelberg, Germany, 1979; pp. 123–166. [Google Scholar]

- Kowalczyk, Z.; Sentek, J.; Jodzis, S.; Muhler, M.; Hinrichsen, O. Effect of Potassium on the Kinetics of Ammonia Synthesis and Decomposition Over Fused Iron Catalyst at Atmospheric Pressure. J. Catal. 1997, 169, 407–414. [Google Scholar] [CrossRef]

- McCullough, K.; Chiang, P.-H.; Jimenez, J.D.; Lauterbach, J.A. Material Discovery and High Throughput Exploration of Ru Based Catalysts for Low Temperature Ammonia Decomposition. Materials 2020, 13, 1869. [Google Scholar] [CrossRef]

- Pearman, W.F.; Carter, J.C.; Angel, S.M.; Chan, J.W.-J. Multipass Capillary Cell for Enhanced Raman Measurements of Gases. Appl. Spectrosc. 2008, 62, 285–289. [Google Scholar] [CrossRef]

- Lascola, R.; O’Rourke, P.E.; Immel, D.M. Development of a Nuclear Fuel Dissolution Monitor Based on Raman Spectroscopy. Sensors 2024, 24, 607. [Google Scholar] [CrossRef]

- Kelly, J.T.; Lascola, R. Online Monitoring of Hydrogen Processing Using Hollow-core Waveguide-based Raman Spectroscopy. In Proceedings of the Optical Waveguide and Laser Sensors III, National Habor, MD, USA, 21–25 April 2024; pp. 40–44. [Google Scholar]

- Yang, C.; Ezendeeva, D.; Yu, T.; Magnotti, G. Temperature Dependent Raman Spectra of Ammonia Ranging from 3150 cm−1 to 3810 cm−1 for Combustion Applications. Opt. Express 2021, 29, 33234–33244. [Google Scholar] [CrossRef]

- Knebl, A.; Yan, D.; Popp, J.; Frosch, T. Fiber Enhanced Raman Gas Spectroscopy. TrAC Trends Anal. Chem. 2018, 103, 230–238. [Google Scholar] [CrossRef]

- Okajima, H.; Hamaguchi, H.o. Accurate Intensity Calibration for Low Wavenumber (−150 to 150 cm−1) Raman Spectroscopy using the Pure Rotational Spectrum of N2. J. Raman Spectrosc. 2015, 46, 1140–1144. [Google Scholar] [CrossRef]

- Raj, A.; Kato, C.; Witek, H.A.; Hamaguchi, H.o. Toward Standardization of Raman Spectroscopy: Accurate Wavenumber and Intensity Calibration using Rotational Raman Spectra of H2, HD, D2, and Vibration–Rotation Spectrum of O2. J. Raman Spectrosc. 2020, 51, 2066–2082. [Google Scholar] [CrossRef]

- Lewis, C.M.; Houston, W.V. The Raman Effect in Ammonia and Some Other Gases. Phys. Rev. 1933, 44, 903. [Google Scholar] [CrossRef]

- Felmy, H.M.; Cox, R.M.; Espley, A.F.; Campbell, E.L.; Kersten, B.R.; Lackey, H.E.; Branch, S.D.; Bryan, S.A.; Lines, A.M. Quantification of Hydrogen Isotopes Utilizing Raman Spectroscopy Paired with Chemometric Analysis for Application across Multiple Systems. Anal. Chem. 2024, 96, 7220–7230. [Google Scholar] [CrossRef] [PubMed]

- Sadergaski, L.R.; Andrews, H.B.; Wilson, B.A. Comparing Sensor Fusion and Multimodal Chemometric Models for Monitoring U(VI) in Complex Environments Representative of Irradiated Nuclear Fuel. Anal. Chem. 2024, 96, 1759–1766. [Google Scholar] [CrossRef]

- Sadergaski, L.R.; Hager, T.J.; Andrews, H.B. Design of Experiments, Chemometrics, and Raman Spectroscopy for the Quantification of Hydroxylammonium, Nitrate, and Nitric acid. ACS Omega 2022, 7, 7287–7296. [Google Scholar] [CrossRef]

- Andrews, H.B.; Sadergaski, L.R. Automated Calibration for Rapid Optical Spectroscopy Sensor Development for Online Monitoring. ACS Sens. 2024, 9, 6257–6264. [Google Scholar] [CrossRef]

- Wright, J.; Torres, R.; Peters, B.; Hope, D.; Tovo, L. In-line Chemical Sensor Deployment in a Tritium Plant. Fusion Sci. Technol. 2015, 67, 639–642. [Google Scholar] [CrossRef][Green Version]

- Garcia-Diaz, B.L.; Babineau, D.; Klein, J.; Allgood, R.; Larsen, G.; Flynn, H.B.; Hitchcock, D.; Krentz, T.; Dandeneau, C.; Angelette, L. Technology Development and Materials Research to Enable a Sustainable DT Fusion Energy Fuel Cycle. J. S. Carol. Acad. Sci. 2024, 22, 2. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).