Broken Rotor Bar Fault Detection for Inverter-Fed Induction Motor with Negative-Sequence Current Analysis

Abstract

1. Introduction

- Development of the ST-HAEKF to extract fault-associated NSC components at fundamental and sideband frequencies, while efficiently suppressing inverter harmonics and other non-characteristic components.

- Development of a Fault Detection Index (FDI) by deducting the healthy NSC baseline from defective motor circumstances, hence facilitating a more precise measurement of BRB fault signals across various load and speed conditions.

- Thorough experimental validation of the NSC-based diagnostic methodology on both healthy and faulty motors, showcasing enhanced sensitivity, resilience to disturbances, suitability for real-time fault monitoring and their potential for incipient BRB fault detection.

2. Methodology

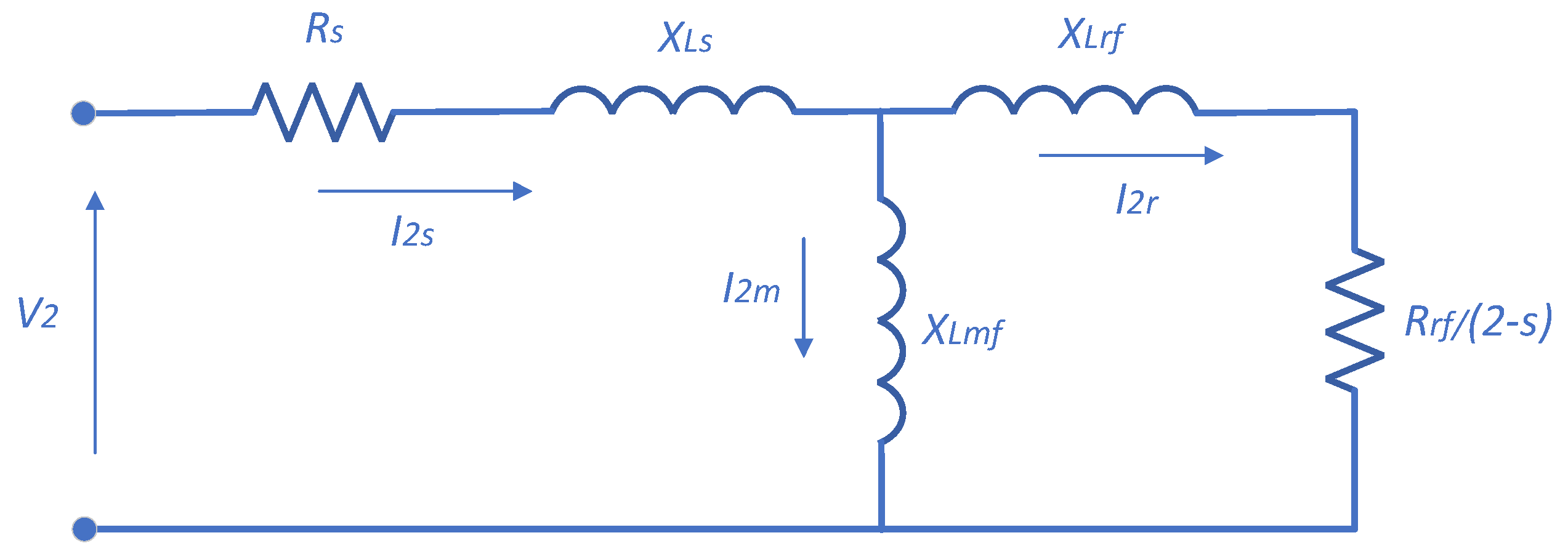

2.1. Analytical Model of the IM with BRB Fault

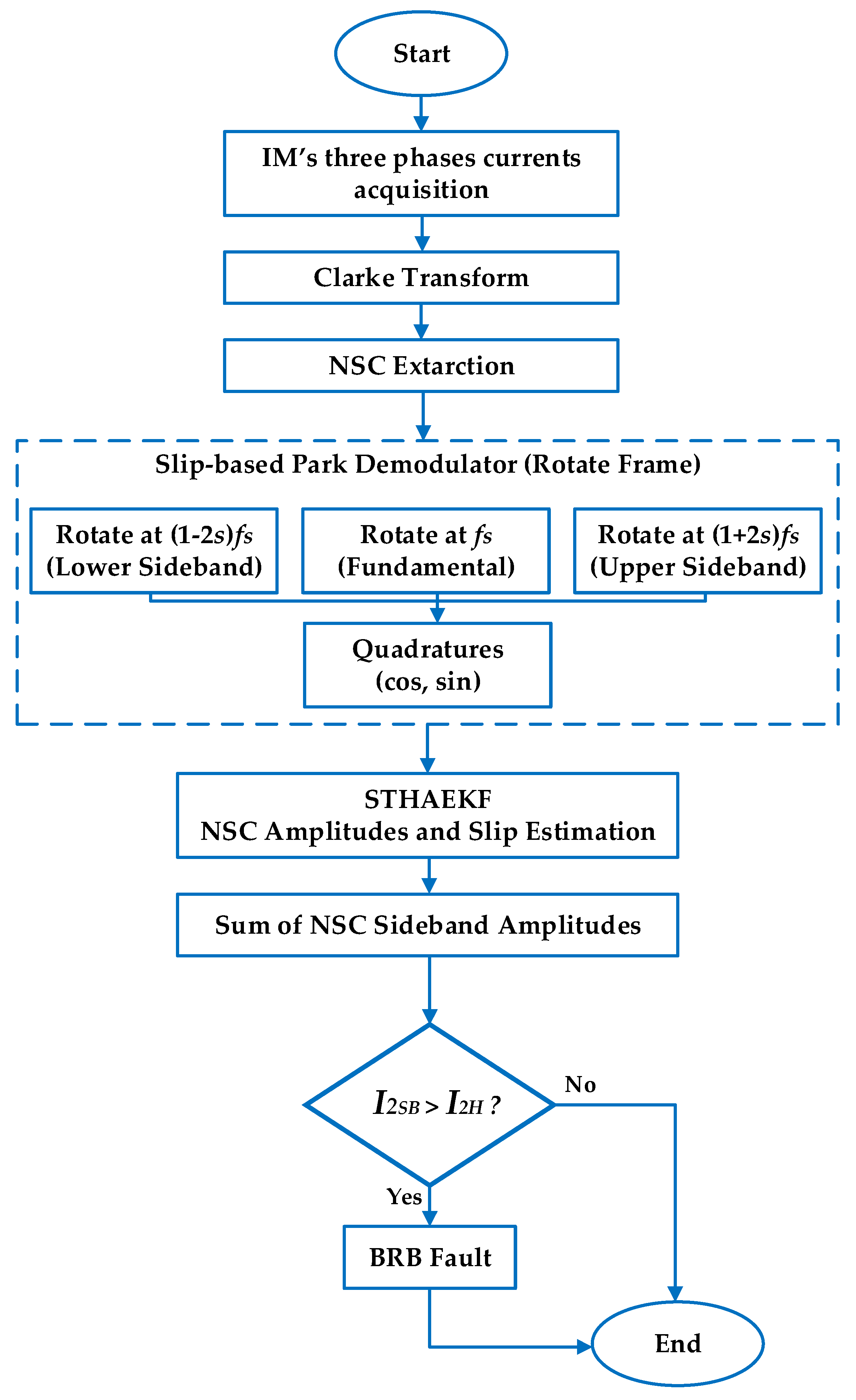

2.2. Signal Proccesing

2.2.1. Spectrum Tracking–Hybrid Adaptive Extended Kalman Filter

- Initialization

- Time Update:

- Measurement Update:

2.2.2. Framework

3. Experimental Setup and Data Acquisition

3.1. Experimental Setup

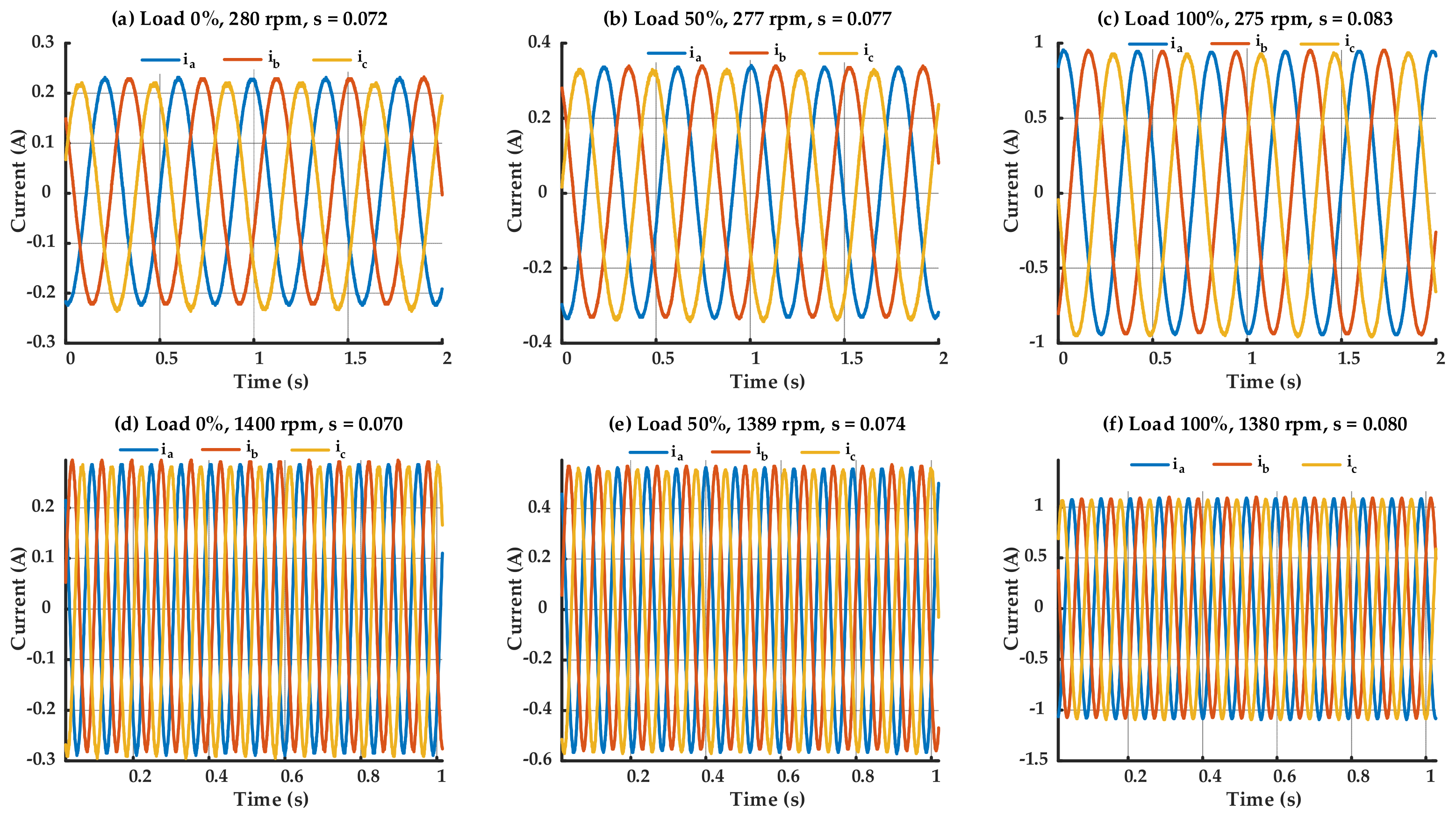

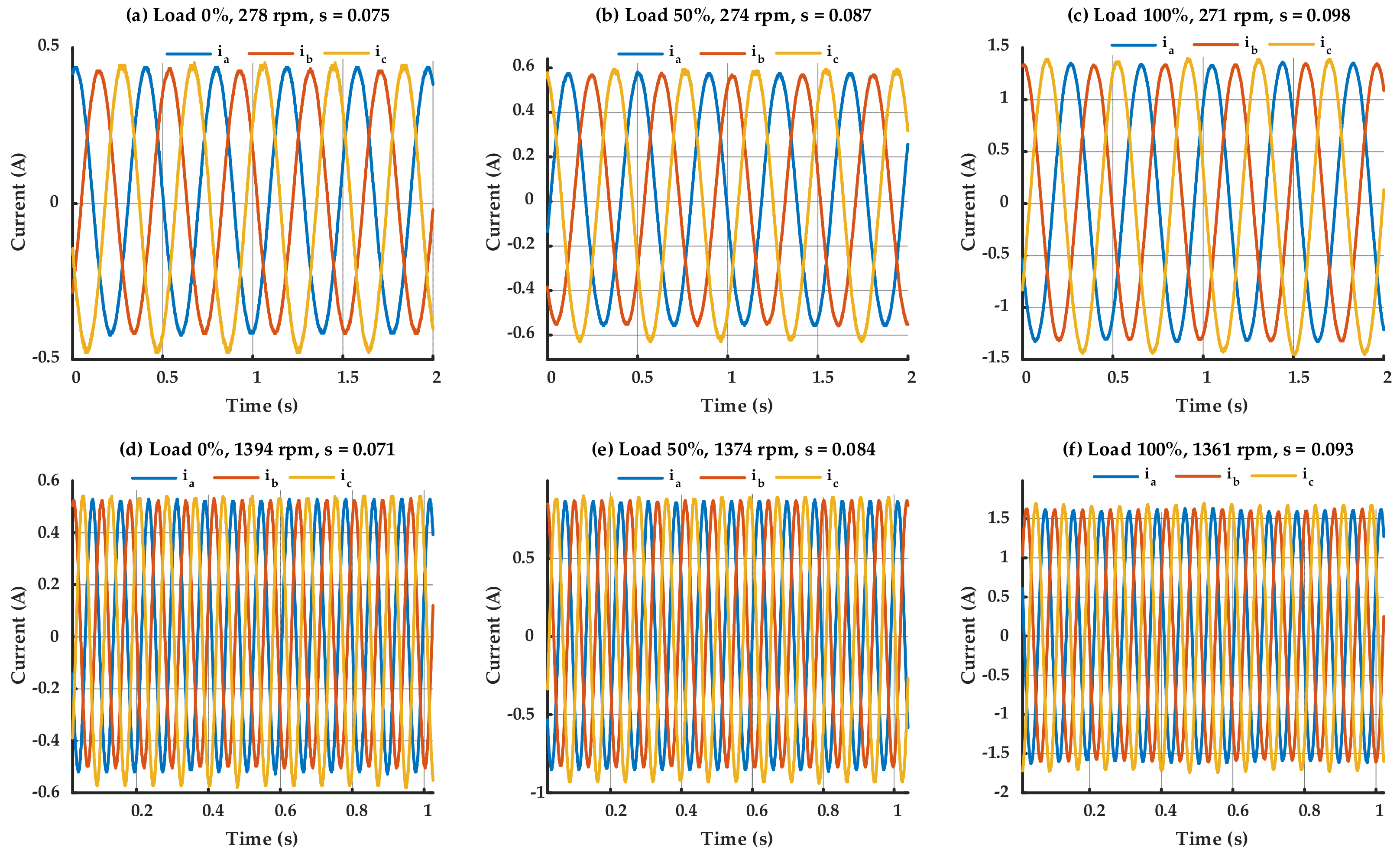

3.2. Data Acquisition

4. Results and Discussions

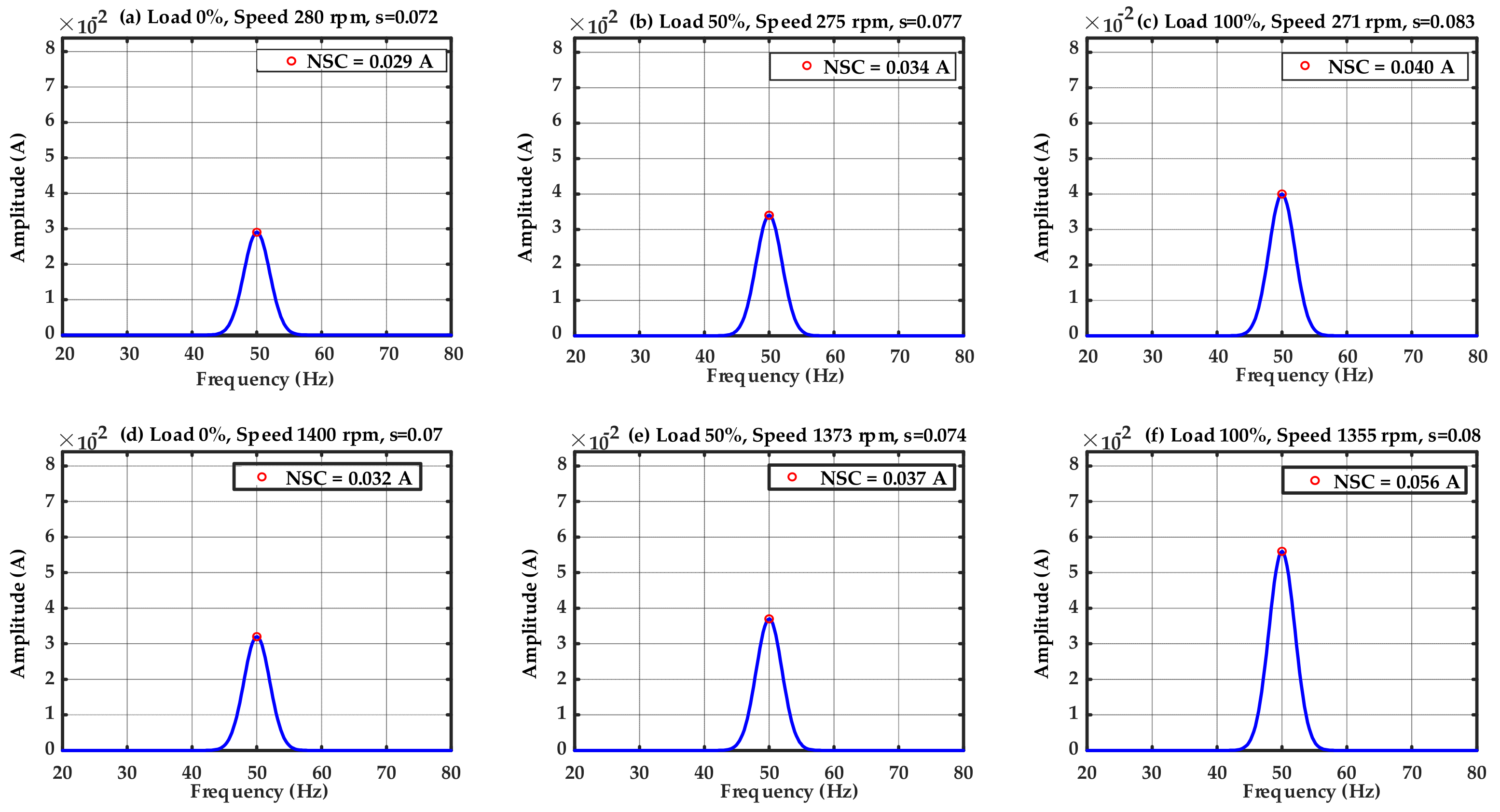

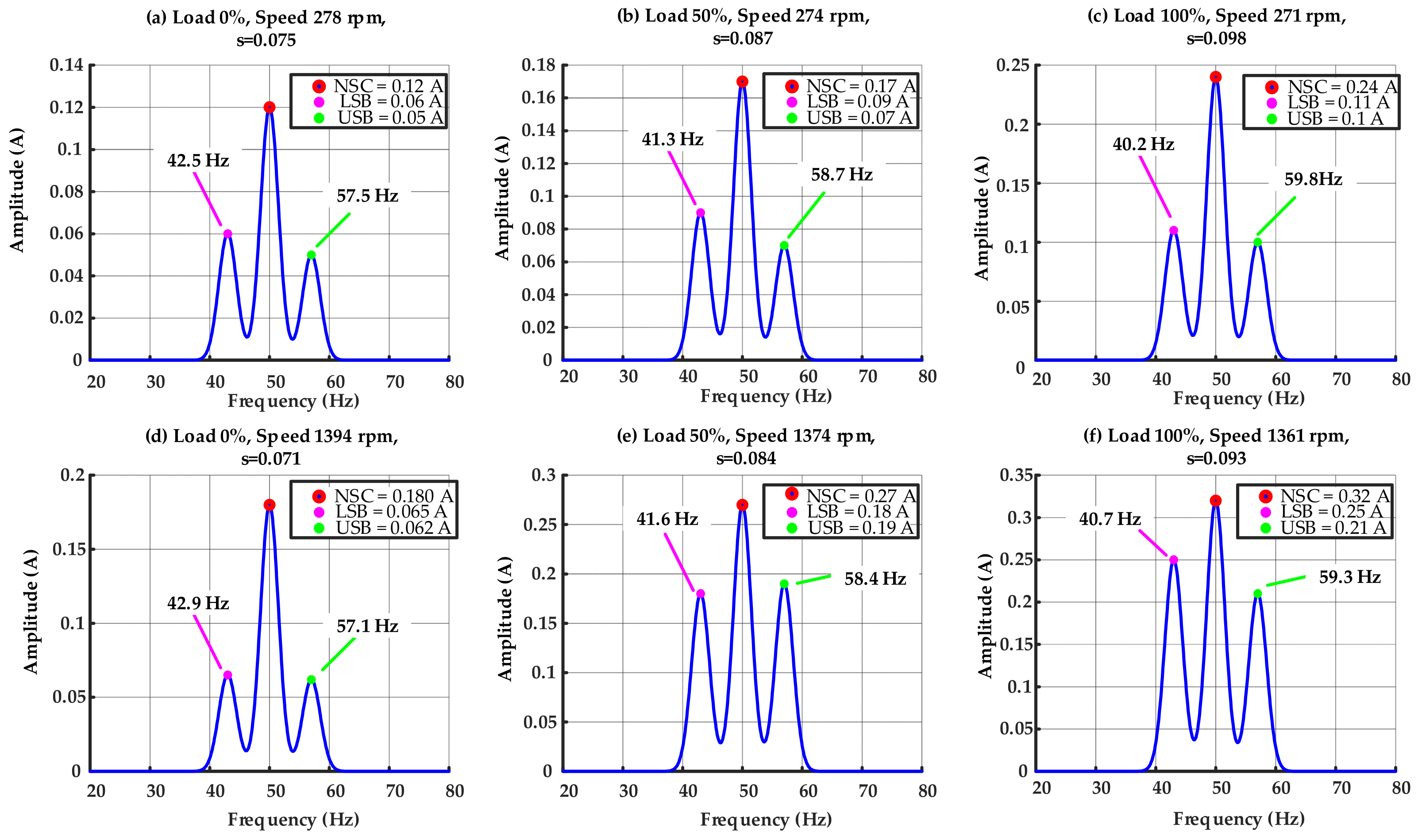

4.1. Negative Sequence Current Signal Analaysis

4.2. Fault Detection Accuarcy Analyis and Sensitivity Evaluation

4.3. Key Contributions of the Proposed Method

- In contrast to Hilbert- or wavelet-based decomposition methods that passively extract fault-related frequencies, the proposed method continuously tracks the NSC components via a state-space model. The ST-HAEKF concurrently estimates the fundamental and sideband NSC components while adjusting to load-dependent slip fluctuations in real time. This spectrum-tracking capacity guarantees that the sideband frequencies linked to BRBs remain accurately aligned despite variations in speed and load, which are unattainable with fixed-frame Hilbert or Fourier methods.

- A significant practical constraint of Hilbert spectrum and time-frequency analysis is their susceptibility to inverter harmonics in inverter-driven IMs. Our proposed framework directly represents these harmonics as unmodeled dynamics in the covariance adaption process of the Kalman filter. Consequently, the harmonics associated with the inverter are statistically mitigated, resulting in a more refined and fault-centric NSC representation. This is the initial NSC-based diagnostic system that exhibits harmonic-resilient estimate in inverter-fed drives via adaptive Kalman filtering, to the greatest of our knowledge.

- While several present investigations depend exclusively on amplitude thresholds or classification methods, our approach incorporates a baseline subtraction technique. This baseline-referenced comparison obviously improves sensitivity to early-stage BRB defects by offsetting intrinsic machine asymmetries and supply discrepancies. The method attains a consistent detection accuracy exceeding 96.5%, even in no-load and low-speed scenarios, where other existing techniques frequently suffer from diminished fault signs.

- The ST-HAEKF necessitates merely a limited number of recursive state changes, eliminating the requirement for massive training datasets or elaborate feature extraction processes commonly found in intelligent classifiers. Consequently, it is ideally suited for real-time deployment in condition-monitoring systems.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ruzimov, S.; Jianzhong, Z.; Latipov, S.; Shahzad, M.A. Fault Detection in Induction Motors: Recent Advances and Future Prospects. In Proceedings of the IEEE 3rd International Conference on Problems of Informatics, Electronics and Radio Engineering (PIERE), Novosibirsk, Russia, 15–17 November 2024; pp. 1420–1427. [Google Scholar] [CrossRef]

- Ruzimov, S.; Zhang, J.; Huang, X.; Aziz, M.S. Detection of Inter-Turn Short-Circuit Faults for Inverter-Fed Induction Motors Based on Negative-Sequence Current Analysis. Sensors 2025, 25, 4844. [Google Scholar] [CrossRef]

- Hassan, O.E.; Amer, M.; Abdelsalam, A.K.; Barry, W.W. Induction motor broken rotor bar fault detection techniques based on fault signature analysis—A review. IET Electr. Power Appl. 2018, 12, 895–907. [Google Scholar] [CrossRef]

- Nandi, S.; Ahmed, S.; Toliyat, H.A. Detection of rotor slot and other eccentricity related harmonics in a three-phase induction motor with different rotor cages. IEEE Trans. Energy Convers. 2001, 16, 253–260. [Google Scholar] [CrossRef]

- Niu, G.; Chen, Y. Motor Fault Diagnostics Based on Current Signatures: A Review. IEEE Trans. Instrum. Meas. 2023, 72, 3520919. [Google Scholar] [CrossRef]

- Wang, T.; Wen, S.; Sheng, S.; Ma, H. Multi-Signal Induction Motor Broken Rotor Bar Detection Based on Merged Convolutional Neural Network. Actuators 2025, 14, 113. [Google Scholar] [CrossRef]

- Taghiyarrenani, Z.; Berenji, A. An Analysis of Vibrations and Currents for Broken Rotor Bar Detection in Three-phase Induction Motors. PHM Soc. Eur. Conf. 2022, 7, 43–48. [Google Scholar] [CrossRef]

- Zubčić, M.; Pavić, I.; Matić, P.; Polak, A. Broken Rotor Bar Detection Based on Steady-State Stray Flux Signals Using Triaxial Sensor with Random Positioning. Sensors 2024, 24, 3080. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, J.; Cheng, M. Fault detection of servo motor bearing based on speed signal under variable-speed conditions. IEEE Trans. Instrum. Meas. 2024, 73, 3517012. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, J.; Wu, Y.; Xu, Z.; Cheng, M. Speed Signature Analysis for Servo Motor Bearing Fault Detection Under Dynamic Load Conditions. IEEE Trans. Power Electron. 2024, 40, 7275–7285. [Google Scholar]

- Arifin, M.S.; Wang, W.; Uddin, M.N. A Modified EMD Technique for Broken Rotor Bar Fault Detection in Induction Machines. Sensors 2024, 24, 5186. [Google Scholar] [CrossRef]

- Choudhary, A.; Goyal, D.; Shimi, S.L.; Akula, A. Condition Monitoring and Fault Diagnosis of Induction Motors: A Review. Springer Nat. 2018, 26, 1221–1238. [Google Scholar]

- Bahgat, H.; Elhay, E.A.; Elkholy, M.M. Advanced fault detection technique of three phase induction motor: Comprehensive review. Springer Nat. Link 2024, 1, 9. [Google Scholar] [CrossRef]

- He, Y.; Qiao, Z.; Xie, B.; Ning, S.; Li, Z.; Kumar, A.; Lai, Z. Two-stage benefits of internal and external noise to enhance early fault detection of machinery by exciting fractional SR. Chaos Solitons Fractals 2024, 182, 114749. [Google Scholar] [CrossRef]

- Liu, T.; Huang, K.-C.; Liao, J.-J. Effects of frequency and signal-to-noise ratio on accuracy of target sound detection with varied inferences among Taiwanese hearing-impaired individuals. Appl. Acoust. 2020, 161, 107176. [Google Scholar] [CrossRef]

- Milles, A.; Benbouhenni, H.; Debdouche, N.; Yessef, M. An Innovative MRAS-Based Technique for Online Detection of Short-Circuit Faults in Induction Motors Using Hilbert and Kalman Methods. Electr. Eng. 2025, 107, 301–312. [Google Scholar] [CrossRef]

- Khan, M.A.; Asad, B.; Vaimann, T.; Kallaste, A. Improved Diagnostic Approach for BRB Detection and Classification in Inverter-Driven Induction Motors Employing Sparse Stacked Autoencoder (SSAE) and LightGBM. Electronics 2024, 13, 1292. [Google Scholar] [CrossRef]

- Zolfaghari, S.; Noor, S.B.M.; Mehrjou, M.R.; Marhaban, M.H.; Mariun, N. Broken Rotor Bar Fault Detection and Classification Using Wavelet Packet Signature Analysis Based on Fourier Transform and Multi-Layer Perceptron Neural Network. Appl. Sci. 2018, 8, 25. [Google Scholar] [CrossRef]

- Martin-Diaz, I.; Garcia-Calva, T.; Duque-Perez, Ó.; Morinigo-Sotelo, D. Imbalanced Diagnosis Scheme for Incipient Rotor Faults in Inverter-Fed Induction Motors. Appl. Sci. 2024, 14, 7237. [Google Scholar] [CrossRef]

- Wang, W.; Song, X.; Liu, G.; Chen, Q.; Zhao, W.; Zhu, H. Induction Motor Broken Rotor Bar Fault Diagnosis Based on Third-Order Energy Operator Demodulated Current Signal. IEEE Trans. Energy Convers. 2021, 37, 1052–1059. [Google Scholar] [CrossRef]

- Beguenane, R.; Benbouzid, M.E.H. Induction motors thermal monitoring by means of rotor resistance identification. IEEE Trans. Energy Convers. 1999, 14, 566–570. [Google Scholar] [CrossRef]

- Benbouzid, M.E.H.; Vieira, M.; Theys, C. Induction motors faults detection and localization using stator current advanced signal processing techniques. IEEE Trans. Power Electron. 1999, 14, 14–22. [Google Scholar] [CrossRef]

- Cho, K.R.; Lang, J.H.; Umans, S.D. Detection of broken rotor bars in induction motors using state and parameter estimation. IEEE Trans. Ind. Appl. 1992, 28, 702–709. [Google Scholar] [CrossRef]

- Naït-Saïd, M.-S.; Benbouzid, M.; Benchaib, A. Detection of Broken Bars in Induction Motors Using an Extended Kalman Filter for Rotor Resistance Sensorless Estimation. IEEE Trans. Energy Convers. 2000, 15, 66–70. [Google Scholar] [CrossRef]

- Li, H.; Zhu, Z.Q.; Azar, Z.; Clark, R.; Wu, Z. Fault Detection of Permanent Magnet Synchronous Machines: An Overview. Energies 2025, 18, 534. [Google Scholar] [CrossRef]

- Montin, E.; Lattanzi, R. Seeking a widely adoptable practical standard to estimate signal-to-noise ratio in magnetic resonance imaging for multiple-coil reconstructions. J. Magn. Reson. Imaging 2021, 54, 1952–1964. [Google Scholar] [CrossRef]

- Shobayo, O.; Saatchi, R. Developments in Deep Learning Artificial Neural Network Techniques for Medical Image Analysis and Interpretation. Diagnostics 2025, 15, 1072. [Google Scholar] [CrossRef] [PubMed]

- Quiroz, J.C.; Mariun, N.; Mehrjou, M.R.; Izadi, M.; Misron, N.; Radzi, M.A.M. Fault detection of broken rotor bar in LS-PMSM using random forests. Measurement 2018, 116, 273–280. [Google Scholar] [CrossRef]

- Filippetti, F.; Franceschini, G.; Tassoni, C. AI techniques in induction machines diagnosis including the speed ripple effect. IEEE Trans. Ind. Appl. 1998, 34, 98–108. [Google Scholar] [CrossRef]

- Jung, H.-S.; Hwang, C.-E.; Kim, H.-S. Minimum torque ripple pulse width modulation with reduced switching frequency for medium-voltage motor drive. IEEE Trans. Ind. Appl. 2018, 54, 3315–3325. [Google Scholar] [CrossRef]

- Lee, K.; Shen, G.; Yao, W. Performance characterization of random pulse width modulation algorithms in industrial and commercial adjustable speed drives. IEEE Trans. Ind. Appl. 2017, 53, 1078–1087. [Google Scholar] [CrossRef]

- Ozkurt, G.; Zerdali, E. Design and Implemenetation of Hybrid Adaptive Extened Kalman Filter for State Estimation of Inducton Motor. IEEE Trans. Instrum. Meas. 2022, 71, 7500212. [Google Scholar] [CrossRef]

- Kim, K.-H.; Jee, G.-I.; Park, C.-G.; Lee, J.-G. The stability analysis of the adaptive fading extended Kalman filter using the innovation covariance. Int. J. Control Autom. Syst. 2009, 7, 49–56. [Google Scholar] [CrossRef]

- Zerdali, E. Adaptive extended Kalman filter for speed-sensorless control of induction motors. IEEE Trans. Energy Convers. 2019, 34, 789–800. [Google Scholar] [CrossRef]

| Parameter | Symbol | Typical Value | Unit |

|---|---|---|---|

| Induction motor | YS-7124 | - | - |

| Motor rated power | P | 0.37 | kW |

| Rated rotor speed | nr | 1400 | rpm |

| Rated current | Ir | 1.12 | A |

| Voltage | U | 380 | V |

| Stator resistance | Rs | 0.5 | Ohm |

| Rotor resistance | Rr | 0.3 | Ohm |

| Stator inductance | Ls | 25 | mH |

| Rotor inductance | Lr | 20 | mH |

| Mutual inductance (stator–rotor) | Lm | 15 | mH |

| Number of rotor bars | Nbars | 18 | - |

| Operational Conditions | Amplitude of the NSC [A] | Threshold | ||

|---|---|---|---|---|

| Speed | Load | Healthy (I2H) | Faulty (I2SB) | |

| Low | 0% | 0.029 | 0.11 | I2SB > I2H |

| 50% | 0.034 | 0.16 | ||

| 100% | 0.04 | 0.21 | ||

| High | 0% | 0.032 | 0.13 | |

| 50% | 0.037 | 0.37 | ||

| 100% | 0.056 | 0.46 | ||

| Operational Conditions | Amplitude of the NSC [A] | Fault Severity | ||

|---|---|---|---|---|

| Speed | Load | Healthy I2H by Experiment | Faulty (I2SB) by Simulation | |

| Low | 0% | 0.029 | 0.06 | δ = 0.25 |

| 50% | 0.034 | 0.07 | ||

| 100% | 0.04 | 0.09 | ||

| High | 0% | 0.032 | 0.08 | |

| 50% | 0.037 | 0.10 | ||

| 100% | 0.056 | 0.14 | ||

| Operational Conditions | Amplitude of the NSC (I2SB) [A] at Switching Frequency | |||

|---|---|---|---|---|

| Speed [rpm] | Load [%] | 3 kHz | 6 kHz | 10 kHz |

| 280 | 0 | 0.113 | 0.11 | 0.106 |

| 50 | 0.168 | 0.16 | 0.158 | |

| 100 | 0.216 | 0.21 | 0.203 | |

| 1400 | 0 | 0.134 | 0.13 | 0.127 |

| 50 | 0.375 | 0.37 | 0.362 | |

| 100 | 0.467 | 0.46 | 0.453 | |

| Ref. | Method | Sensitivity | High Load | Low Load | High Speed | Low Speed |

|---|---|---|---|---|---|---|

| [6] | Multi-signal fusion with merged convolutional neural network | High | Strong | Good (multi-signal helps) | Strong | Moderate (low speed performance depends on training data) |

| [11] | Improved empirical mode decomposition for current signals | High | Reliable | Good (EMD extracts weak low load features) | Reliable | Moderate (better than FFT at low speed but still limited) |

| [18] | Wavelet packet + Fourier features + MLP classifier | High | Good | Limited | Reliable | Weak (MLP needs strong features) |

| [19] | Focused on inverter-fed IM with imbalanced data | High for incipient faults | Good | Good | Reliable | Reliable |

| [17] | Sparse Stacked Autoencoder (SSAE) + Light-GBM | High | High | Good | Good | Good |

| [20] | Demodulated current signal using higher-order energy operator | High (sensitive to incipient faults) | High | Reliable | Reliable | Reliable (better than FFT/HT at low speed) |

| [28] | Random forest with flux/current features | High | Reliable | Limited | Reliable | Weak (incipient faults masked) |

| Proposed method | High (validated experimentally) | High | High (validated with no load) | High | High (validated at low speed) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruzimov, S.; Zhang, J.; Huang, X.; Aziz, M.S. Broken Rotor Bar Fault Detection for Inverter-Fed Induction Motor with Negative-Sequence Current Analysis. Sensors 2025, 25, 7045. https://doi.org/10.3390/s25227045

Ruzimov S, Zhang J, Huang X, Aziz MS. Broken Rotor Bar Fault Detection for Inverter-Fed Induction Motor with Negative-Sequence Current Analysis. Sensors. 2025; 25(22):7045. https://doi.org/10.3390/s25227045

Chicago/Turabian StyleRuzimov, Sarvarbek, Jianzhong Zhang, Xu Huang, and Muhammad Shahzad Aziz. 2025. "Broken Rotor Bar Fault Detection for Inverter-Fed Induction Motor with Negative-Sequence Current Analysis" Sensors 25, no. 22: 7045. https://doi.org/10.3390/s25227045

APA StyleRuzimov, S., Zhang, J., Huang, X., & Aziz, M. S. (2025). Broken Rotor Bar Fault Detection for Inverter-Fed Induction Motor with Negative-Sequence Current Analysis. Sensors, 25(22), 7045. https://doi.org/10.3390/s25227045