A Stereolithography Appearance-Based Ultra-Wideband Wide-Beam Dielectric Resonator Antenna

Abstract

1. Introduction

2. Preparation and Characterization of Dielectric Ceramics via SLA

2.1. SLA-Fabricated Dielectric Ceramics

- (1)

- Formulation of photosensitive ceramic slurry through mixing nano-ceramic powder with photosensitive dispersants and stabilizers.

- (2)

- Mixing nanoalumina ceramic powder, photosensitive resin, photo initiator, and dispersant with the ball mill, stir, and defoam method.

- (3)

- Stereolithographic printing with subsequent cleaning and secondary curing processes.

- (4)

- High-temperature debinding and sintering in a controlled-atmosphere furnace [26].

- (5)

- Precision surface finishing to produce final SLA dielectric ceramics.

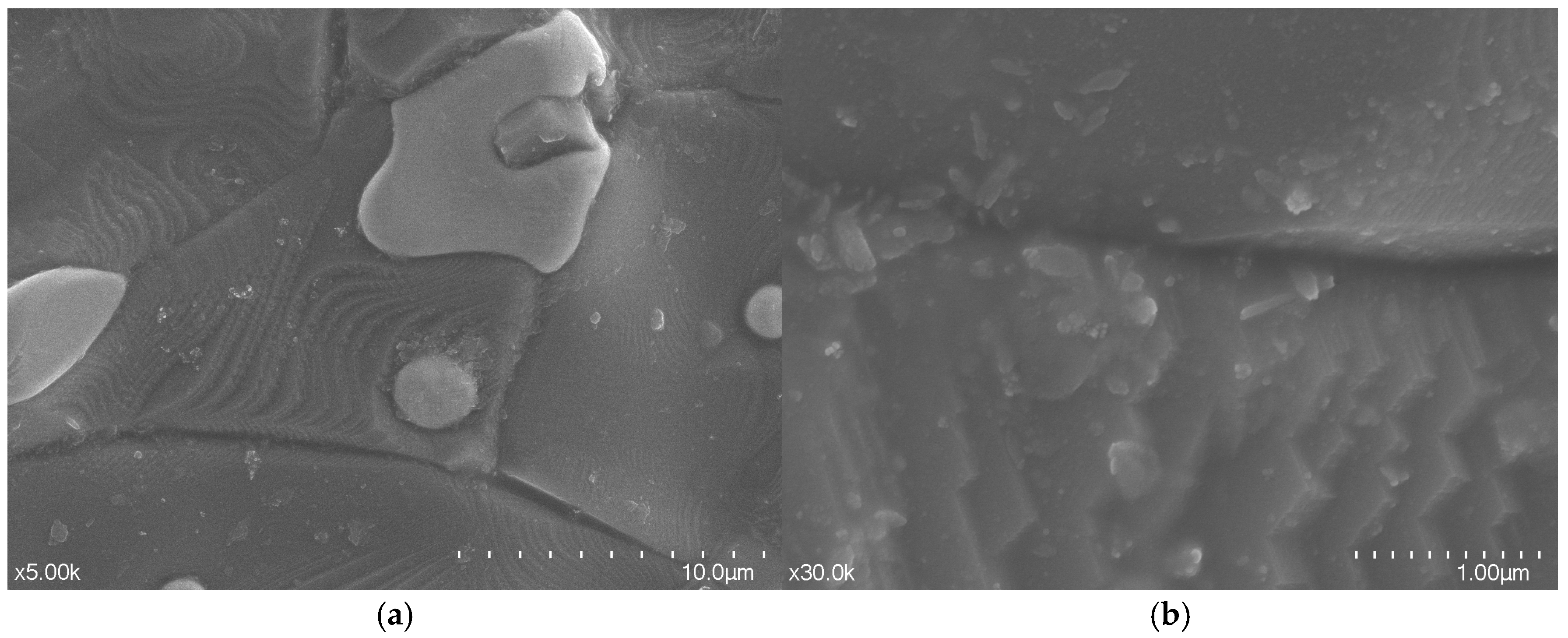

2.2. Characterization of SLA-Fabricated Dielectric Ceramics

3. Design of SLA-Based UWB Wide-Beam DRA

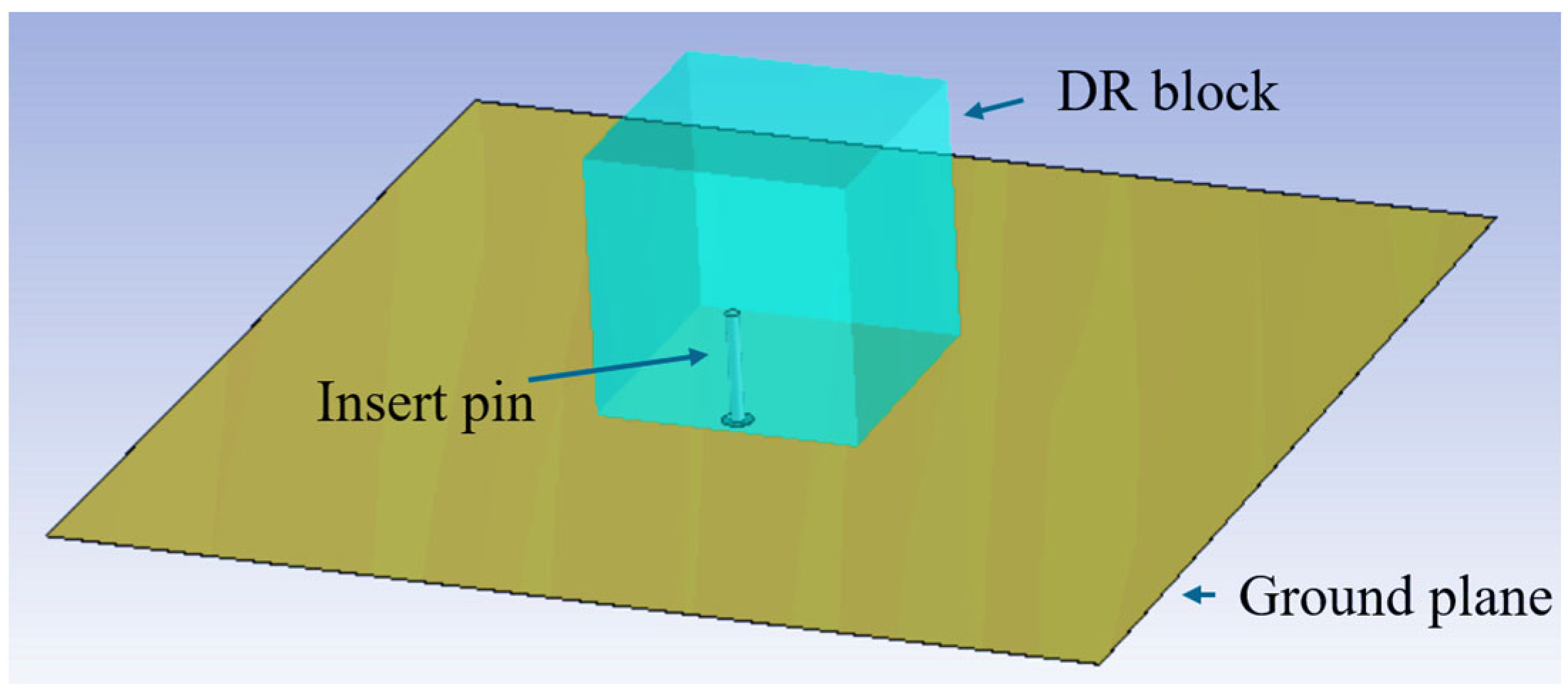

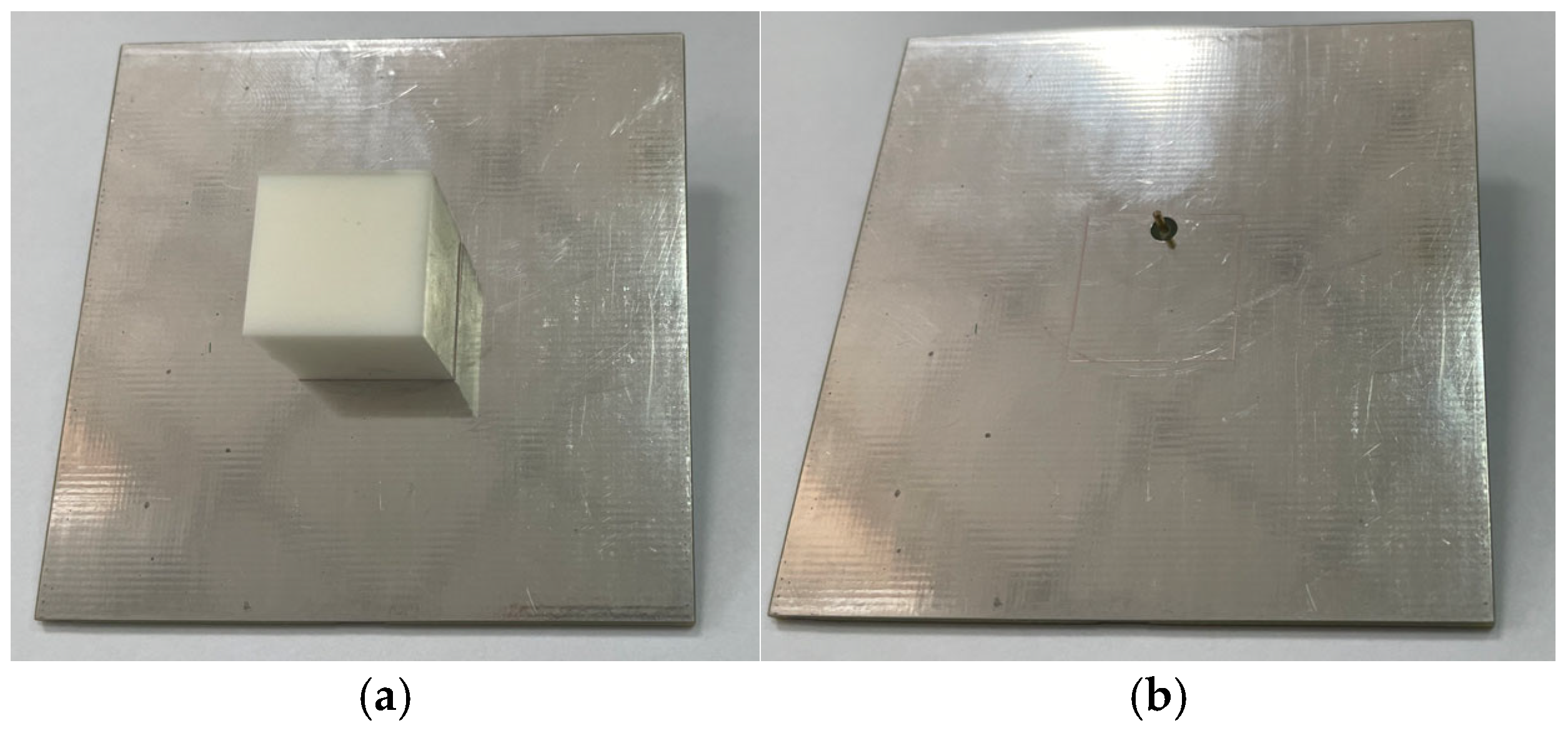

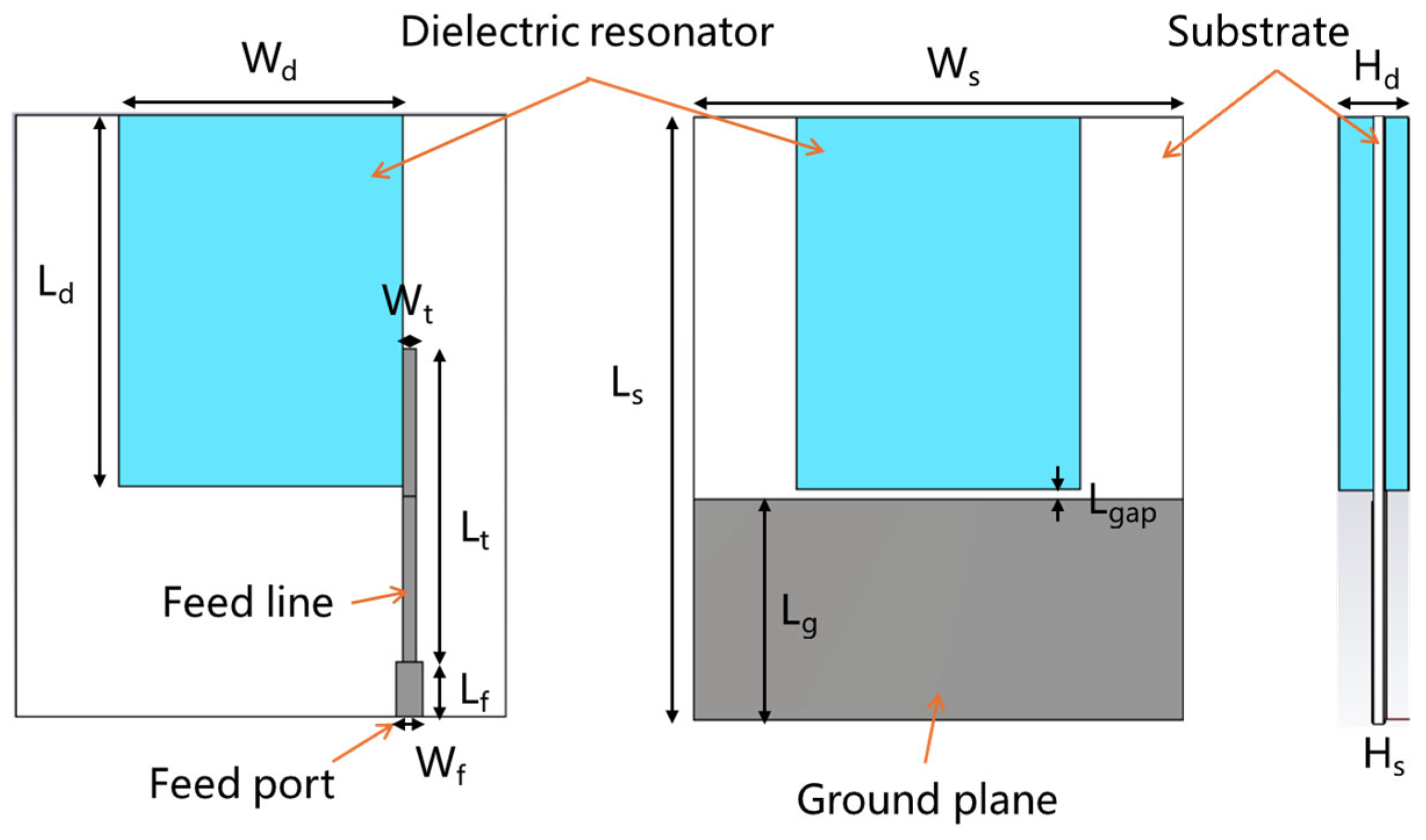

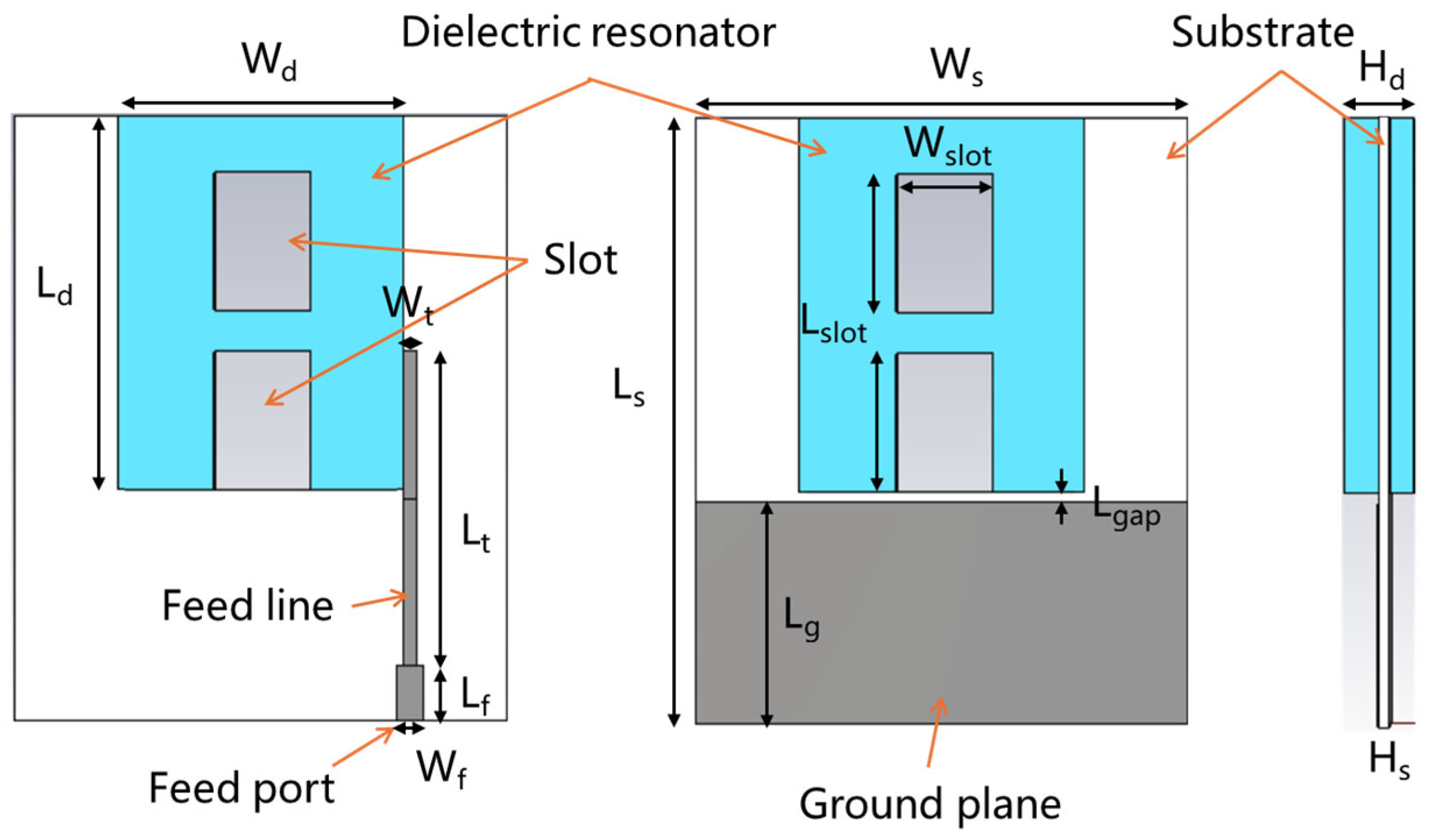

3.1. SLA-Fabricated UWB DRA

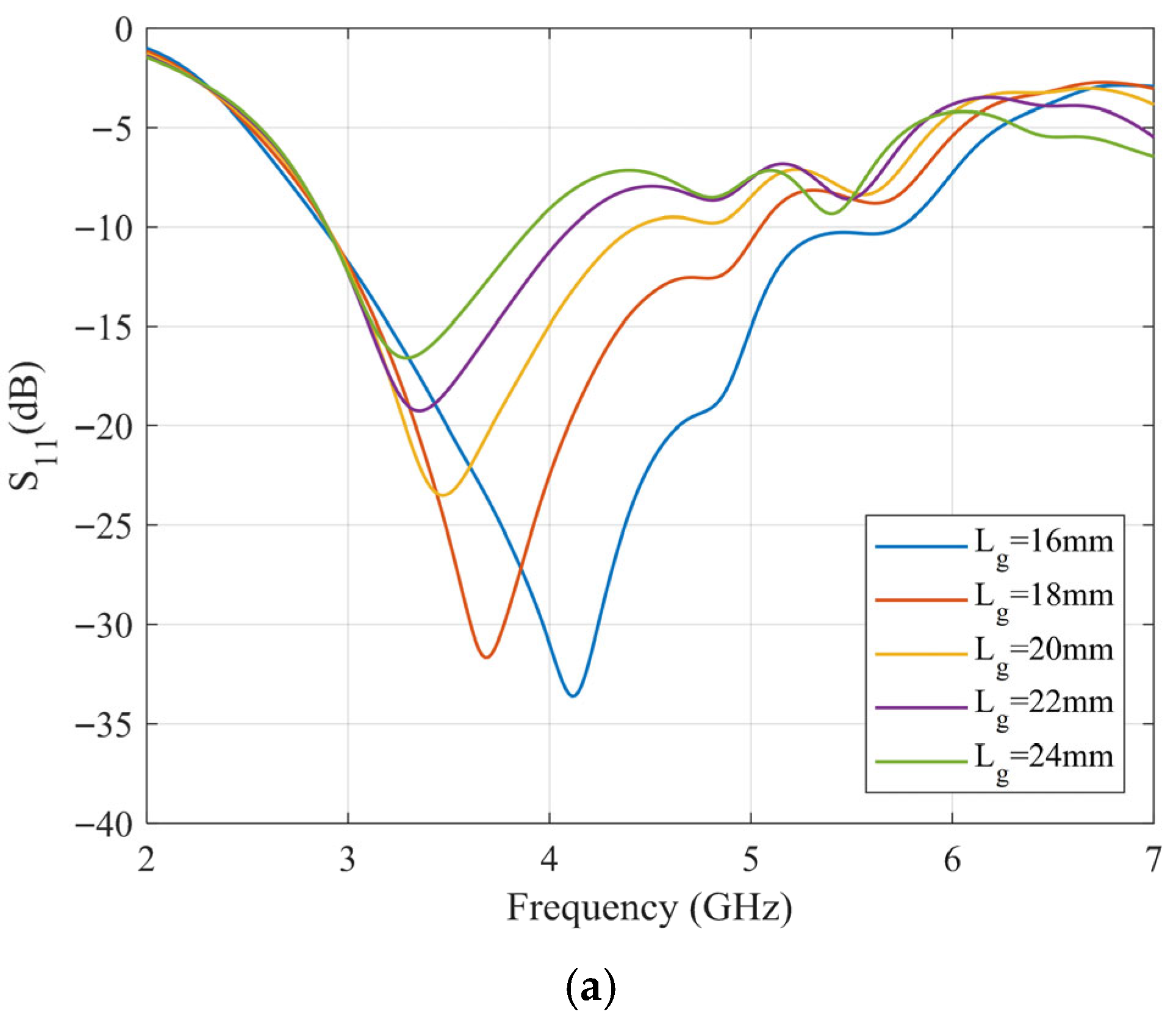

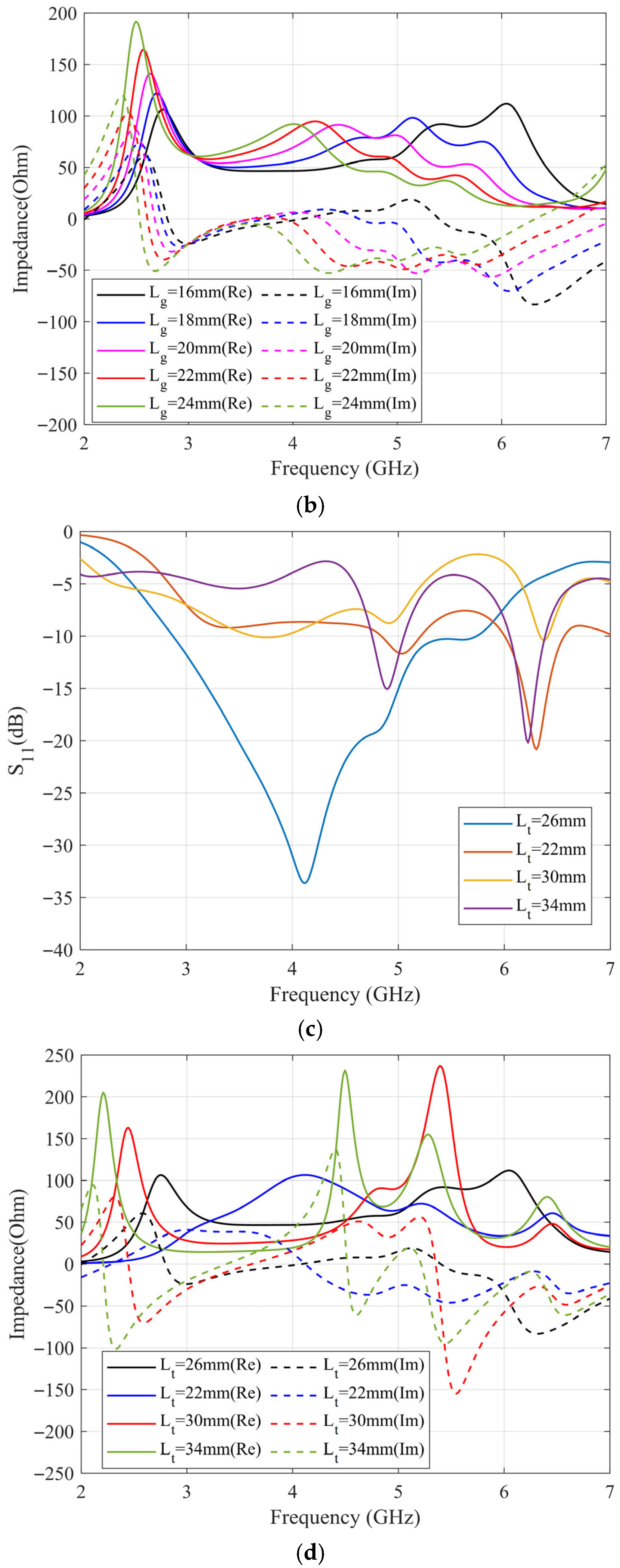

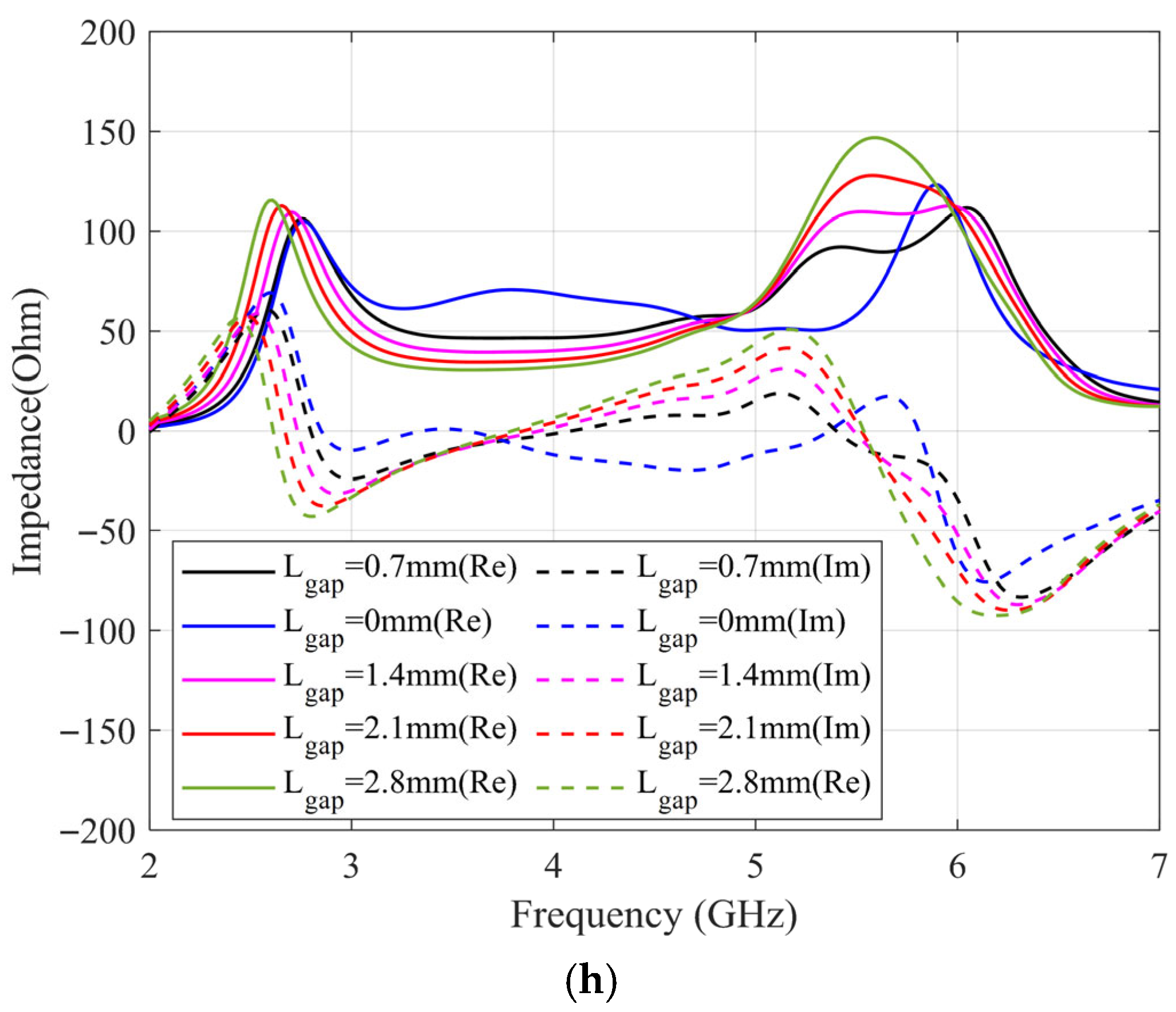

3.2. Paramatric Study

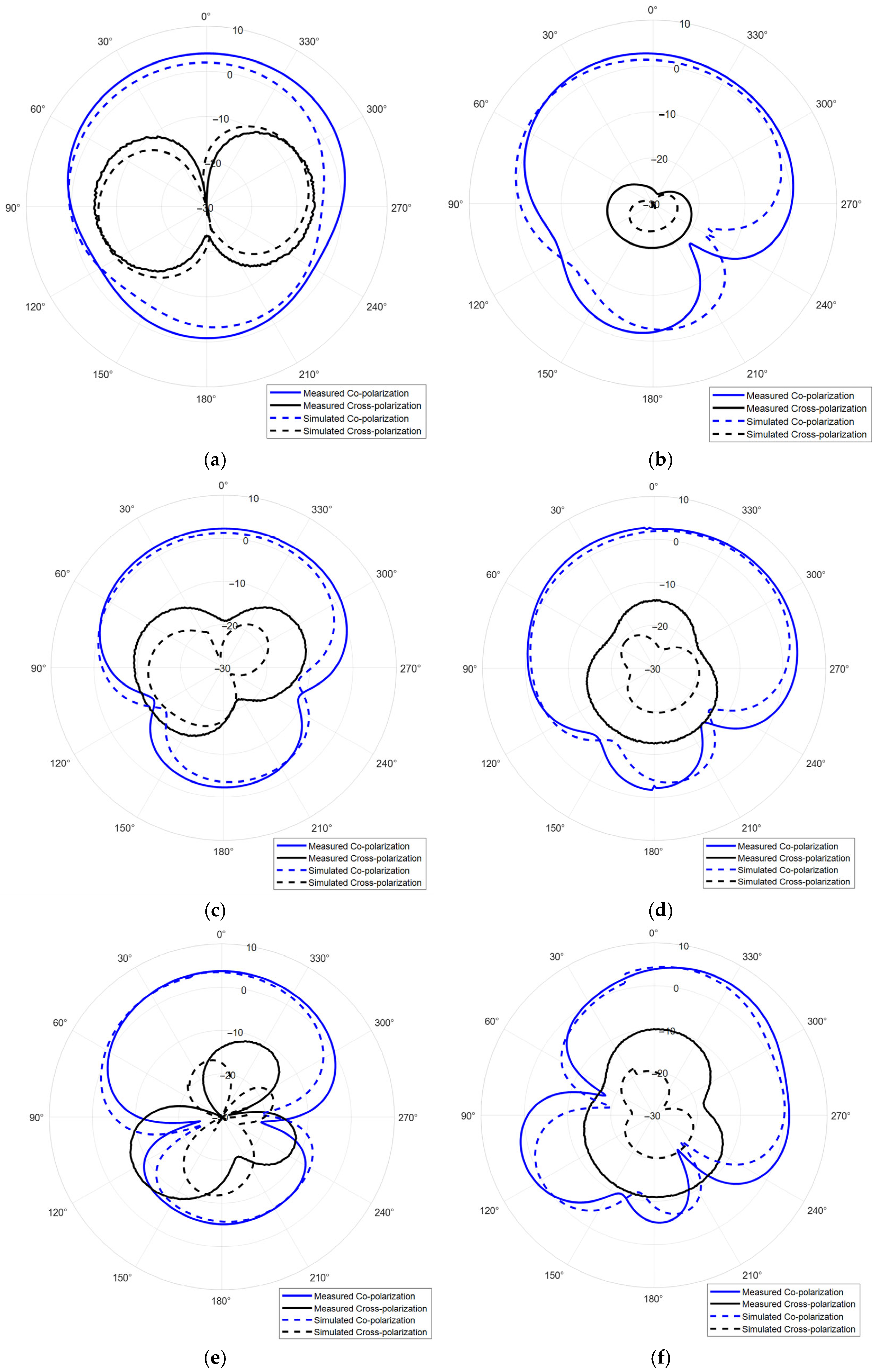

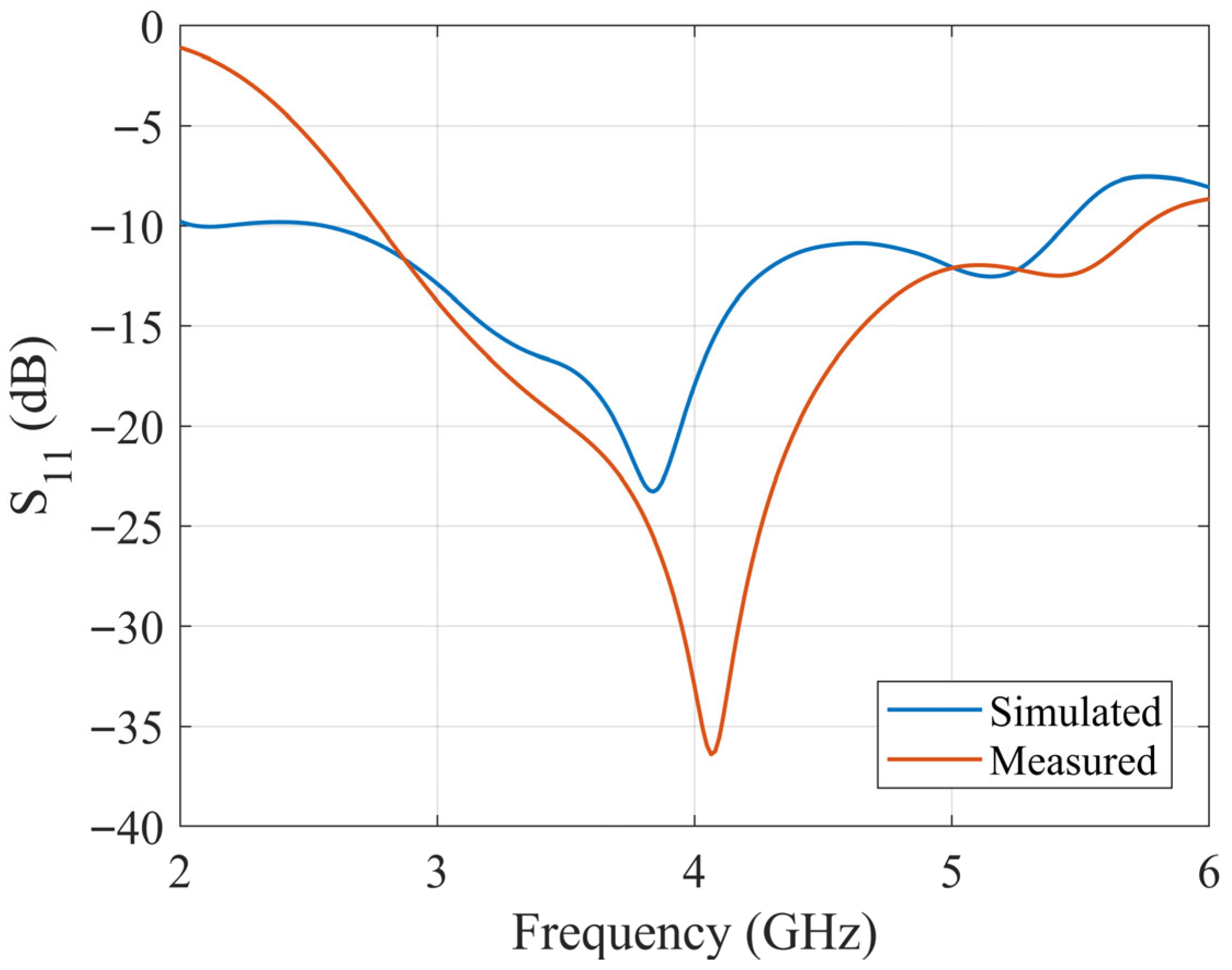

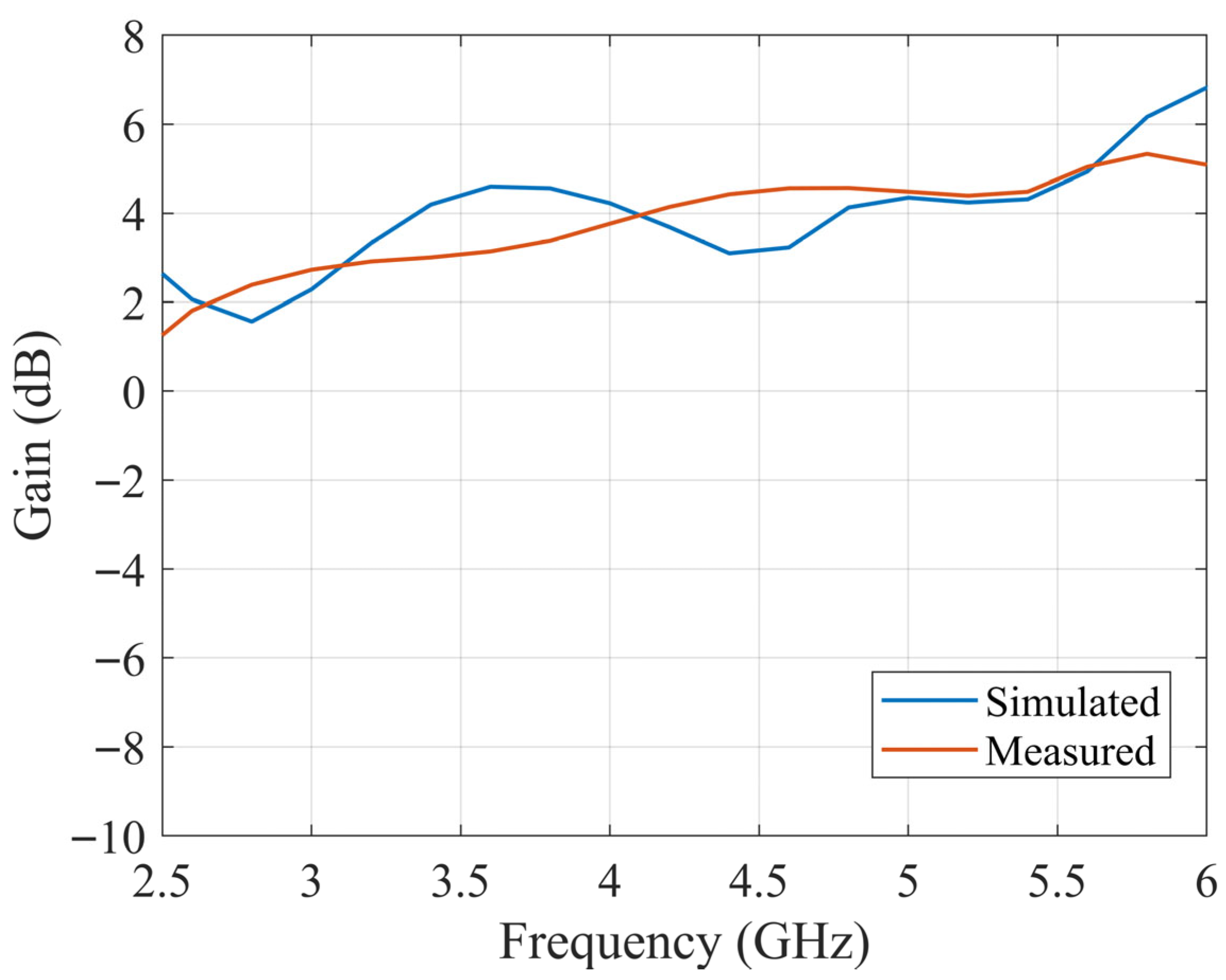

3.3. Simulation and Measurement

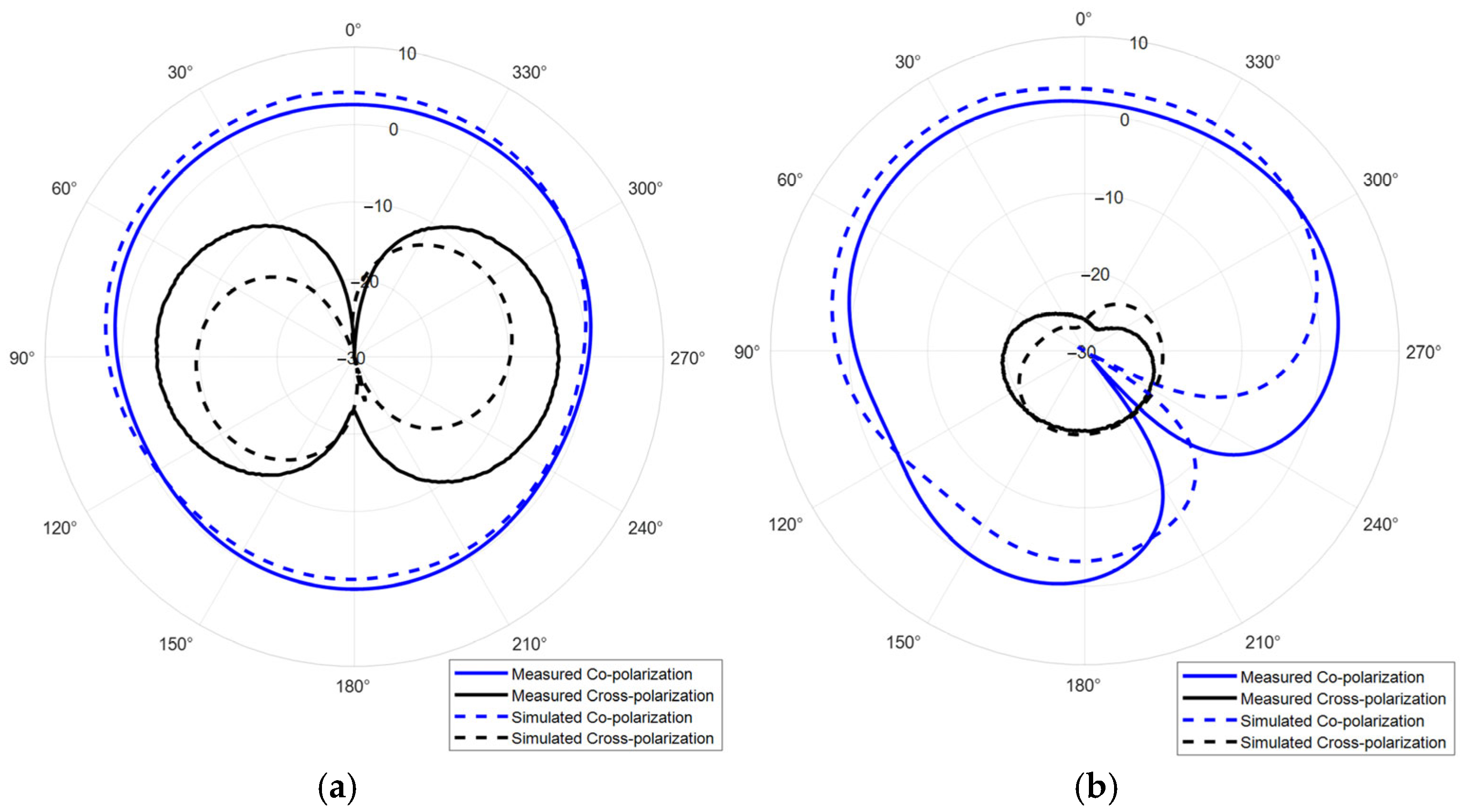

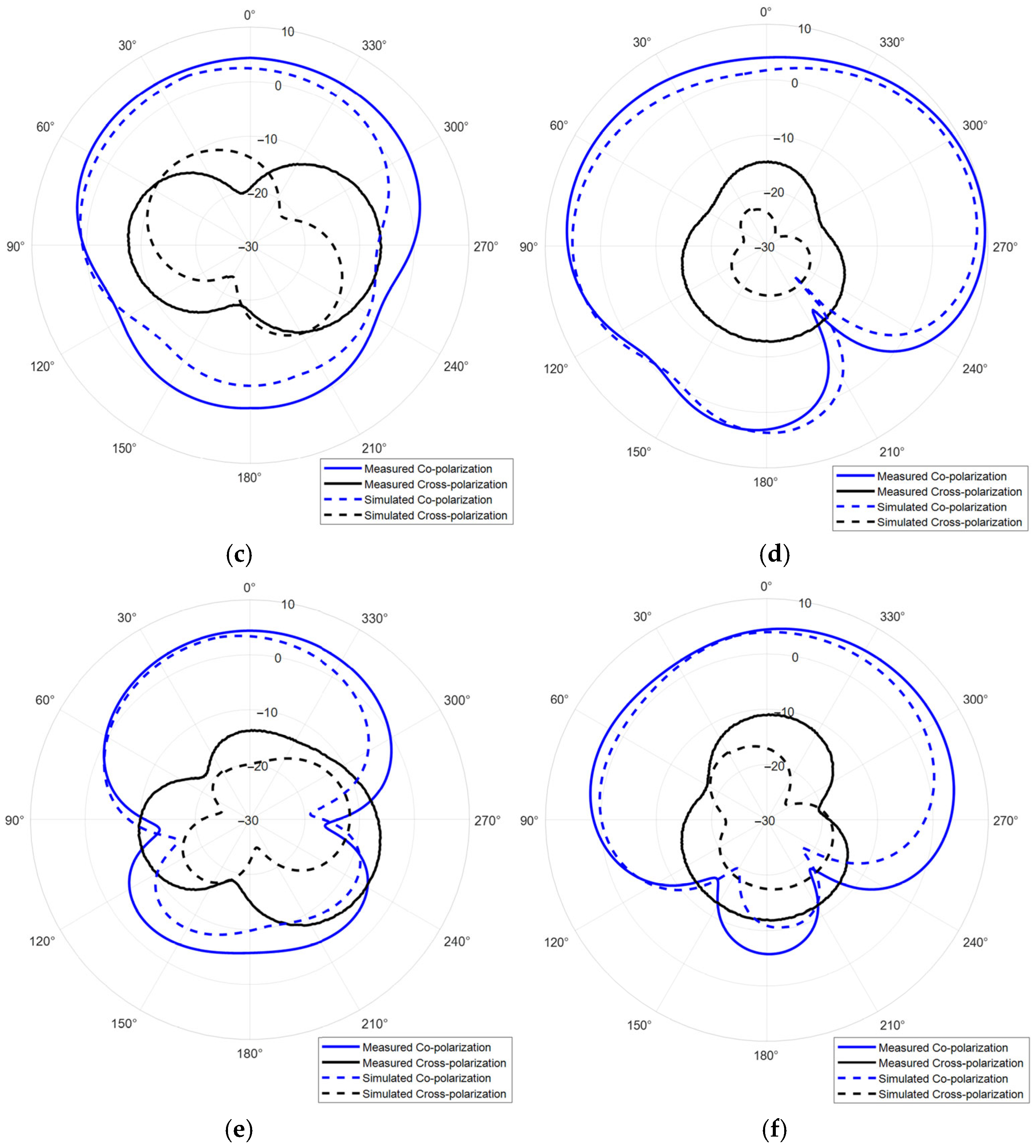

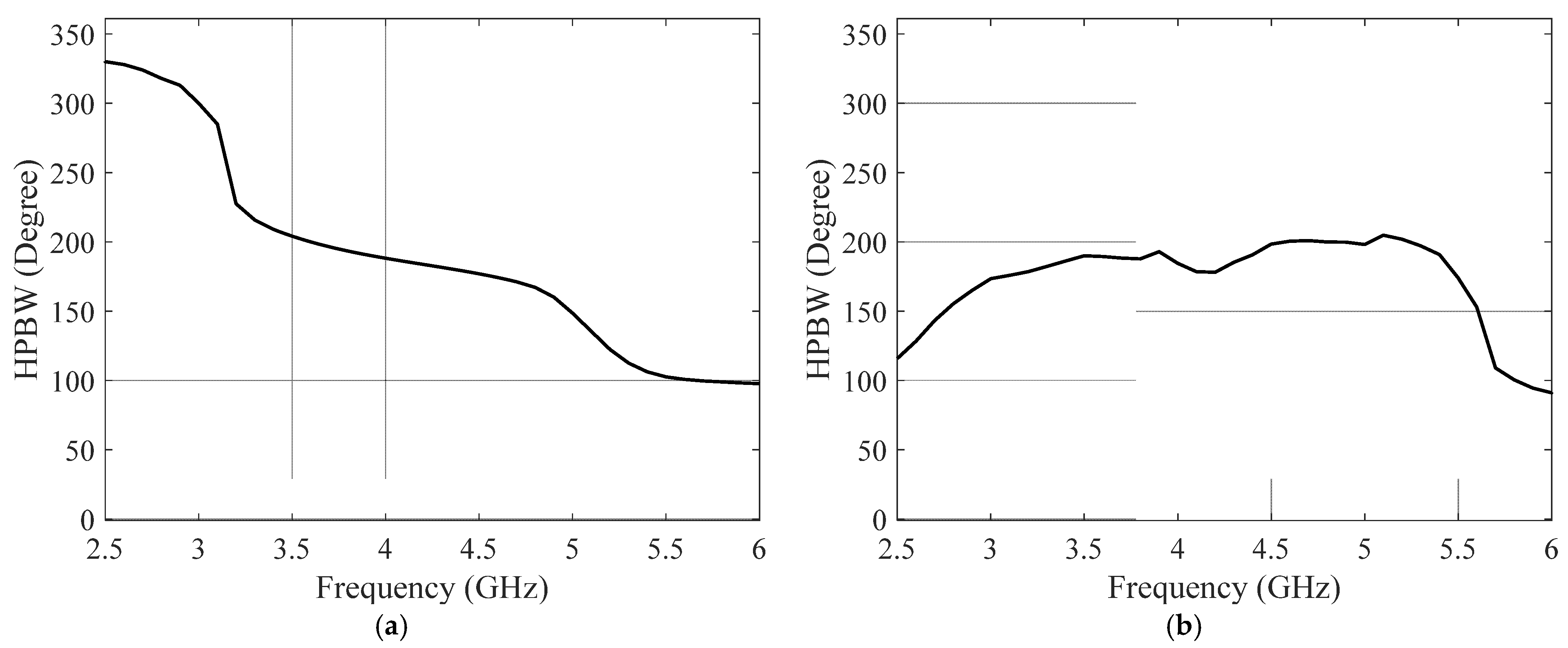

4. UWB Wide-Beam DRA Radiation Pattern Correction

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jamshidi-Zarmehri, H.; Akbari, A.; Labadlia, M.; Kedze, K.E.; Shaker, J.; Xiao, G.; Amaya, R.E. A Review on Through-Wall Communications: Wall Characterization, Applications, Technologies, and Prospects. IEEE Access 2023, 11, 127837–127854. [Google Scholar] [CrossRef]

- New, W.K.; Wong, K.-K.; Xu, H.; Wang, C.; Ghadi, F.R.; Zhang, J.; Rao, J.; Murch, R.; Ramírez-Espinosa, P.; Morales-Jimenez, D.; et al. A Tutorial on Fluid Antenna System for 6G Networks: Encompassing Communication Theory, Optimization Methods and Hardware Designs. IEEE Commun. Surv. Tutor. 2025, 27, 2325–2377. [Google Scholar] [CrossRef]

- Amador, M.; Rouco, A.; Albuquerque, D.; Pinho, P. Overview of Vivaldi Antenna Selection for Through-Wall Radar Applications. Sensors 2024, 24, 6536. [Google Scholar] [CrossRef] [PubMed]

- Arnaoutoglou, D.G.; Empliouk, T.M.; Kaifas, T.N.F.; Chryssomallis, M.T.; Kyriacou, G. A Review of Multifunctional Antenna Designs for Internet of Things. Electronics 2024, 13, 3200. [Google Scholar] [CrossRef]

- Shehbaz, M.; Du, C.; Zhou, D.; Xia, S.; Xu, Z. Recent Progress in Dielectric Resonator Antenna: Materials, Designs, Fabrications, and Their Performance. Appl. Phys. Rev. 2023, 10, 021303. [Google Scholar] [CrossRef]

- Petosa, A.; Ittipiboon, A. Dielectric Resonator Antennas: A Historical Review and the Current State of the Art. IEEE Antennas Propag. Mag. 2010, 52, 91–116. [Google Scholar] [CrossRef]

- Kishk, A.A.; Zhang, X.; Glisson, A.W.; Kajfez, D. Numerical Analysis of Stacked Dielectric Resonator Antennas Excited by a Coaxial Probe for Wideband Applications. IEEE Trans. Antennas Propag. 2003, 51, 1996–2006. [Google Scholar] [CrossRef]

- Kishk, A.A.; Yin, Y.; Glisson, A.W. Conical Dielectric Resonator Antennas for Wide-Band Applications. IEEE Trans. Antennas Propag. 2002, 50, 469–474. [Google Scholar] [CrossRef]

- Rad, M.; Nikkhah, N.; Zakeri, B.; Yazdi, M. Wideband Dielectric Resonator Antenna With Dual Circular Polarization. IEEE Trans. Antennas Propag. 2022, 70, 714–719. [Google Scholar] [CrossRef]

- Li, D.; Shi, L.; Wang, J.; Liu, Y.; Chen, Q. High-Gain Wideband Dielectric Resonator Antenna Based on Semi-Cylindrical Grooved Structure. IEEE Trans. Circuits Syst. II Express Briefs 2024, 71, 1101–1105. [Google Scholar] [CrossRef]

- El Yousfi, A.; Abdalmalak, K.A.; Lamkaddem, A.; Barrera, A.M.; Biscontini, B.; Segovia-Vargas, D. Miniaturized Dual-Polarized, High-Gain, and Wideband Dielectric Resonator Antenna for Low Band Massive MIMO Applications. Prog. Electromagn. Res. 2024, 179, 101–111. [Google Scholar] [CrossRef]

- Roy, A.K.; Basu, S. Broadband, High Gain, Narrow Width Rectangular Dielectric Resonator Antenna with Air Gap. J. Electron. Sci. Technol. 2019, 17, 90–96. [Google Scholar] [CrossRef]

- Gupta, S.; Kshirsagar, P.; Mukherjee, B. A Low-Profile Multilayer Cylindrical Segment Fractal Dielectric Resonator Antenna: Usage for Wideband Applications. IEEE Antennas Propag. Mag. 2019, 61, 55–63. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, S.; Denidni, T.A.; Zeng, Q.; Wei, G. Integrated Ultra-Wideband Plannar Monopole with Cylindrical Dielectric Resonator Antennas. Prog. Electromagn. Res. C 2013, 44, 41–53. [Google Scholar] [CrossRef]

- Liu, N.-W.; Liang, Y.-D.; Zhu, L.; Liu, Z.-X.; Fu, G. A Low-Profile, Wideband, Filtering-Response, Omnidirectional Dielectric Resonator Antenna Without Enlarged Size and Extra Feeding Circuit. IEEE Antennas Wirel. Propag. Lett. 2021, 20, 1120–1124. [Google Scholar] [CrossRef]

- Agrawal, S. A CPW-Fed Super Wideband Dielectric Resonator Antenna. In Proceedings of the 2020 IEEE International Conference on Advanced Networks and Telecommunications Systems (ANTS), New Delhi, India, 14–17 December 2020; IEEE: Washington, DC, USA, 2020; pp. 1–5. [Google Scholar]

- Huda, S.; Saha, A.; Karmakar, A. Ultra Wideband (UWB) Dielectric Resonator Antenna Using Fractal-inspired Feeding Mechanism. Int. J. Commun. Syst. 2023, 36, e5519. [Google Scholar] [CrossRef]

- Omar, M.F.M.; Zubir, I.A.; Kamal, S.; Rajendran, J.A.L.; Mohamed, J.J.; Ahmad, Z.A.; Ain, M.F.; Rahim, S.K.A. A Critical Review on the Development of Multi-Geometrical Stacked Wideband Dielectric Resonator Antenna. Alexandria Eng. J. 2024, 100, 111–141. [Google Scholar] [CrossRef]

- Ullah, U.; Ain, M.F.; Ahmad, Z.A. A Review of Wideband Circularly Polarized Dielectric Resonator Antennas. China Commun. 2017, 14, 65–79. [Google Scholar] [CrossRef]

- Shamsaee Malfajani, R.; Niknam, H.; Bodkhe, S.; Therriault, D.; Laurin, J.-J.; Sharawi, M.S. A 3D-Printed Encapsulated Dual Wide-Band Dielectric Resonator Antenna With Beam Switching Capability. IEEE Open J. Antennas Propag. 2023, 4, 492–505. [Google Scholar] [CrossRef]

- Li, S.; Izquierdo, B.S.; Gao, S.; Chen, Z. FDM 3D-Printed DRA Array for 5G Millimeter Wave and 6G Applications. In Proceedings of the 2024 IEEE International Symposium on Antennas and Propagation and INC/USNC-URSI Radio Science Meeting (AP-S/INC-USNC-URSI), Firenze, Italy, 14–19 July 2024; IEEE: Washington, DC, USA, 2024; pp. 417–418. [Google Scholar]

- Wang, K.; Bao, C.; Zhang, C.; Li, Y.; Liu, R.; Xu, H.; Ma, H.; Man, J.; Song, S. Preparation of High-Strength Si3N4 Antenna Window Using Selective Laser Sintering. Ceram. Int. 2021, 47, 31277–31285. [Google Scholar] [CrossRef]

- Oh, Y.; Bharambe, V.T.; Adams, J.J.; Negro, D.; MacDonald, E. Design of a 3D Printed Gradient Index Lens Using High Permittivity Ceramic. In Proceedings of the 2020 IEEE International Symposium on Antennas and Propagation and North American Radio Science Meeting, Montreal, QC, Canada, 5–10 July 2020; IEEE: Washington, DC, USA, 2020; pp. 1431–1432. [Google Scholar]

- Zhao, K.; Psychogiou, D. Monolithically Integrated Coaxial Resonator-Based Filtennas Using SLA Three-Dimensional Printing. IEEE Antennas Wirel. Propag. Lett. 2023, 22, 189–193. [Google Scholar] [CrossRef]

- Li, J.; Wu, S.; Li, Y.; Chen, X.; Yan, S.; Zhang, X.Y. SLA Printed Dual-Band Conical-Beam Filtering Antenna. IEEE Antennas Wirel. Propag. Lett. 2023, 22, 2462–2466. [Google Scholar] [CrossRef]

- Liu, X.; Zou, B.; Xing, H.; Huang, C. The Preparation of ZrO2-Al2O3 Composite Ceramic by SLA-3D Printing and Sintering Processing. Ceram. Int. 2020, 46, 937–944. [Google Scholar] [CrossRef]

- Huang, C.; Wang, J.; Huang, C. Microwave Dielectric Properties of Sintered Alumina Using Nano-Scaled Powders of α Alumina and TiO2. J. Am. Ceram. Soc. 2007, 90, 1487–1493. [Google Scholar] [CrossRef]

- Fu, Y.; Li, W.; Xu, M.; Wang, C.; Zhang, L.; Zhang, G. Dielectric Properties and 3D-Printing Feasibility of UV-Curable Resin/Micron Ceramic Filler Composites. Adv. Polym. Technol. 2022, 2022, 1–14. [Google Scholar] [CrossRef]

- Bove, A.; Calignano, F.; Galati, M.; Iuliano, L. Photopolymerization of Ceramic Resins by Stereolithography Process: A Review. Appl. Sci. 2022, 12, 3591. [Google Scholar] [CrossRef]

- Petosa, A. Dielectric Resonator Antenna Handbook; Artech: Norwood, MA, USA, 2007. [Google Scholar]

- Mongia, R.K.; Bhartia, P. Accurate Conductor Q-Factor of Dielectric Resonator Placed in an MIC Environment. IEEE Trans. Microw. Theory Tech. 1993, 41, 445–449. [Google Scholar] [CrossRef]

- Costa, F.; Borgese, M.; Degiorgi, M.; Monorchio, A. Electromagnetic Characterisation of Materials by Using Transmission/Reflection (T/R) Devices. Electronics 2017, 6, 95. [Google Scholar] [CrossRef]

- Luukkonen, O.; Maslovski, S.I.; Tretyakov, S.A. A Stepwise Nicolson–Ross–Weir-Based Material Parameter Extraction Method. IEEE Antennas Wirel. Propag. Lett. 2011, 10, 1295–1298. [Google Scholar] [CrossRef]

- Keysight Technologies. Q Factor Measurement of Dielectric Resonators Using the 8720 Network Analyzer; Application Note, Publication Number 5989–2589; Keysight Technologies: Santa Rosa, CA, USA, 1990; Available online: https://www.keysight.com.cn/cn/zh/assets/7018-01284/application-notes/5989-2589.pdf (accessed on 22 May 2024).

- Lim, E.H.; Pan, Y.M.; Leung, K.W. Dielectric Resonator Antennas. Handb. Antenna Technol. 2016, 2, 955–1000. [Google Scholar] [CrossRef]

- Xia, Z.-X.; Leung, K.W. 3-D-Printed Wideband Circularly Polarized Dielectric Resonator Antenna with Two Printing Materials. IEEE Trans. Antennas Propag. 2022, 70, 5971–5976. [Google Scholar] [CrossRef]

- Yang, C.; Leung, K.W. 3-D-Printed Wideband Circularly Polarized MIMO Dielectric Resonator Antenna. IEEE Trans. Antennas Propag. 2023, 71, 5675–5683. [Google Scholar] [CrossRef]

- Hokmabadi, H.R.; Przepiorowski, J.; Nadali, K.; Lemey, S.; Ammann, M.J. 3D-Printed Dual Dielectric Resonator Antennas for Localization in UWB Anchor Nodes. In Proceedings of the 2025 19th European Conference on Antennas and Propagation (EuCAP), Stockholm, Sweden, 30 March–4 April 2025; IEEE: Washington, DC, USA, 2025; pp. 1–4. [Google Scholar]

| Index | Functionality | Molar Mass/(g·mol−1) | Density/(g·cm−3) | Viscosity/(mPa·s) | Refractive Index |

|---|---|---|---|---|---|

| AM | 1 | 71 | 1.32 | Solid | 19.230 |

| 2HEA | 1 | 116 | 1.01 | 8~10 | 1.445~1.450 |

| HEMA | 1 | 130 | 1.07 | 6~11 | 1.453 |

| 4HBA | 1 | 144 | 1.04 | 10~25 | 1.452~1.454 |

| St | 1 | 104 | 0.93 | 0.78 | 1.546 |

| VA | 1 | 86 | 1.04 | 0.43 | 1.395 |

| ACMO | 1 | 141 | 1.12 | 12~15 | 1.512 |

| IBOA | 1 | 208 | 0.98~0.99 | 2~9 | 1.476 |

| IDA | 1 | 212 | 0.88 | 1~10 | 1.440~1.442 |

| PHEA | 1 | 192 | 1.10 | 5~15 | 1.518 |

| MBAM | 2 | 154 | 1.24 | Solid | 1.488 |

| BDDA | 2 | 198 | 1.05 | 8 | 1.456 |

| HDDA | 2 | 226 | 1.01~1.03 | 5~10 | 1.455~1.457 |

| HDEODA + | 2 | 314 | 1.01~1.05 | 10~30 | 1.461 |

| DEGDA | 2 | 214 | 1.12 | 12 | 1.463 |

| TEGMA | 2 | 286 | 1.07~1.09 | 5~30 | 1.461 |

| TTEGDA | 2 | 302 | 1.11 | 5~30 | 1.465 |

| PEGDA + | 2 | 308~508 | 1.11~1.12 | 15~65 | 1.463~1.467 |

| TPGDA | 2 | 300 | 1.03 | 10~15 | 1.450 |

| PPGDMA + | 2 | 536 | 1.00~1.01 | 30~50 | 1.450 |

| NPGPO2DA | 2 | 328 | 1.01 | 10~30 | 1.440~1.447 |

| BPAE2DMA | 2 | 453 | 1.12 | 1800 | 1.542~1.544 |

| UDMA | 2 | 471 | 1.11 | 8500 | 1.485 |

| TMPTA | 3 | 296 | 1.11 | 80~140 | 1.474 |

| TMPETA + | 3 | 693 | 1.10~1.11 | 60~120 | 1.471 |

| Di-TMPTA | 4 | 467 | 1.10~1.15 | 350~800 | 1.479 |

| EPTTA + | 4 | 550~718 | 1.14~1.16 | 100~200 | 1.475 |

| DPHA | 5/6 | 523~579 | 1.16 | 4000~7000 | 1.488~1.490 |

| Parameter | Wd | Ld | Wt | Lt | Lf | Hd |

|---|---|---|---|---|---|---|

| Value (mm) | 20.5 | 27 | 0.7 | 22 | 4 | 5 |

| Parameter | Wf | Ws | Ls | Lg | Lgap | Hs |

| Value (mm) | 1.9 | 35.5 | 43.2 | 16 | 0.7 | 0.762 |

| Parameter | Wd | Ld | Wt | Lt | Lf | Hd | Wslot |

|---|---|---|---|---|---|---|---|

| Value (mm) | 20.5 | 27 | 0.7 | 22 | 4 | 5 | 7 |

| Parameter | Wf | Ws | Ls | Lg | Lgap | Hs | Lslot |

| Value (mm) | 1.9 | 35.5 | 43.2 | 16 | 0.7 | 0.762 | 10 |

| Ref. | Fabrication Method | Bandwidth (MHz) | Antenna Size (mm3) | HPBW (°) | Dielectric Properties | Peak Gain (dB) | ||

|---|---|---|---|---|---|---|---|---|

| E-Plane | H-Plane | Dielectric Constant | Loss Tangent | |||||

| [36] | FDM | 4.80–9.94 GHz (69.7%) | 0.67λ0 × 0.21λ0 × 0.54λ0 | n.a. (~60) | n.a. (~60) | 10 and 3 | n.a. | 8.3 |

| [37] | n.a. | 8.88–11.04 GHz (21.7%) | 0.77λ0 × 0.19λ0 × 0.67λ0 | n.a. (~60) | n.a. | 2.2 | 9 × 10−4 | 4.9 |

| [20] | fused filament fabrication (FFF) | 33% (sub 6G) 27% (mm wave) | 0.87λ0 × 0.87λ0 × 0.35λ0 | 32 | 32 | 9 and 4 | 2.9 × 10−3 | 7.2 at 3.2 GHz 18 at 31.5 GHz |

| [21] | FDM | 21–30 GHz (35.29%) | 2.2λ0 × 2.2λ0 × 0.17λ0 | 57 | 46 | 10 | 3 × 10−3 | 11.8 |

| [38] | FFF | 5.3–8.8 GHz (49.65%) | 0.459λ0 × 0.376λ0 × 0.411λ0 | 90 | 60 | 2.2 and 7.5 | 1 × 10−3 | 5.9 |

| This work | SLA | 2.75–5.75 GHz (70.59%) | 0.598λ0 × 0.491λ0 × 0.069λ0 | 140–210 | 110–320 | 9.2 | 1.6 × 10−3 | 5.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, C.; Yuan, Y.; Ye, S.; Wang, Z.; Zhang, Q.; Liu, X.; Fang, G. A Stereolithography Appearance-Based Ultra-Wideband Wide-Beam Dielectric Resonator Antenna. Sensors 2025, 25, 6989. https://doi.org/10.3390/s25226989

Song C, Yuan Y, Ye S, Wang Z, Zhang Q, Liu X, Fang G. A Stereolithography Appearance-Based Ultra-Wideband Wide-Beam Dielectric Resonator Antenna. Sensors. 2025; 25(22):6989. https://doi.org/10.3390/s25226989

Chicago/Turabian StyleSong, Chenyang, Yubing Yuan, Shengbo Ye, Zihao Wang, Qunying Zhang, Xiaojun Liu, and Guangyou Fang. 2025. "A Stereolithography Appearance-Based Ultra-Wideband Wide-Beam Dielectric Resonator Antenna" Sensors 25, no. 22: 6989. https://doi.org/10.3390/s25226989

APA StyleSong, C., Yuan, Y., Ye, S., Wang, Z., Zhang, Q., Liu, X., & Fang, G. (2025). A Stereolithography Appearance-Based Ultra-Wideband Wide-Beam Dielectric Resonator Antenna. Sensors, 25(22), 6989. https://doi.org/10.3390/s25226989