Calibration of Digital Holographic Camera for Bubble Gas Volumetric Flux Measurements

Highlights

- A method that allows determining the volumetric flux of the bubble gas flow based on the analysis of histograms of the cross-sectional areas of bubbles and their velocities measured on the basis of the holographic images of bubbles was developed.

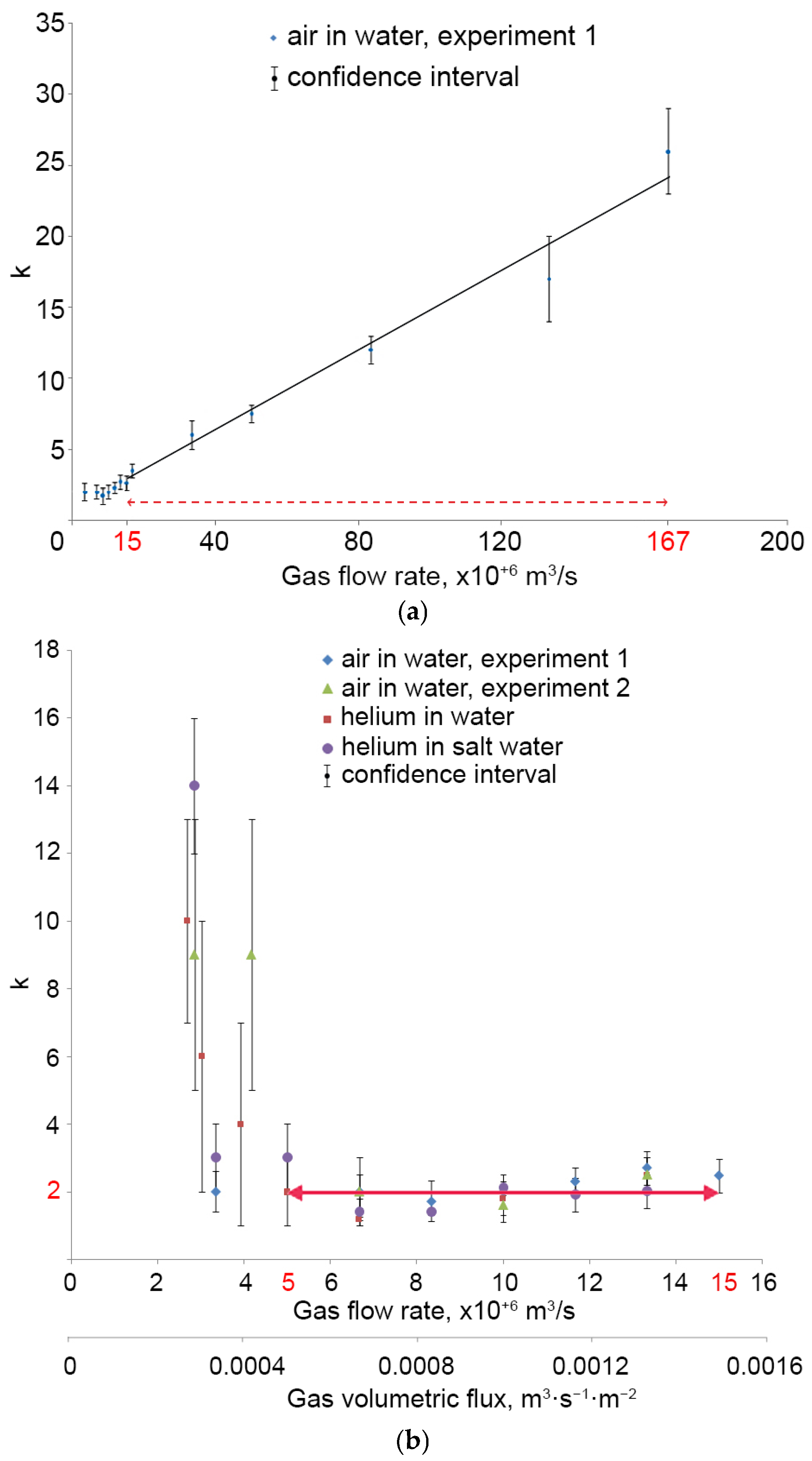

- A calibration procedure for a digital holographic camera with calibration coefficient k = 2 in the gas volumetric flux range from 5 × 10−4 m3·m−2·s−1 to 15 × 10−4 m3·m−2·s−1 was described.

- The method can be applied to monitor weak gas emissions, including methane in the Arctic seas, and may be used for the calibration of acoustic sounding systems.

- The obtained results are confirmed by field data, which demonstrates the promising application of the method for environmental studies.

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Unit and Software

2.2. Bubble Gas Volumetric Flux Measuring Theory and Mathematical Tools

- How constant is k and what is this coefficient for bubbles with different formation conditions (formed by different gases, at different volumetric flux and for different water salinity)?

- In what range of the volumetric flux (gas flow rates) does Formula (7) apply?

2.3. Measurement Technique

- Setting a specified gas flow rate through the bubble generator

- Recording a series of holograms (at least 100 dual holograms in each bubble generator mode)

- Reconstructing bubble images from holograms

- Determining for each bubble:

- Area of a vertical bubble cross-section—(Si)

- Speed vi—according to a shift on superimposed holograms

- Calculating the total gas flow from DHC data

- Comparing with the specified gas flow rate to determine the calibration factor using Formula (10).

2.4. Natural Measurements

3. Results

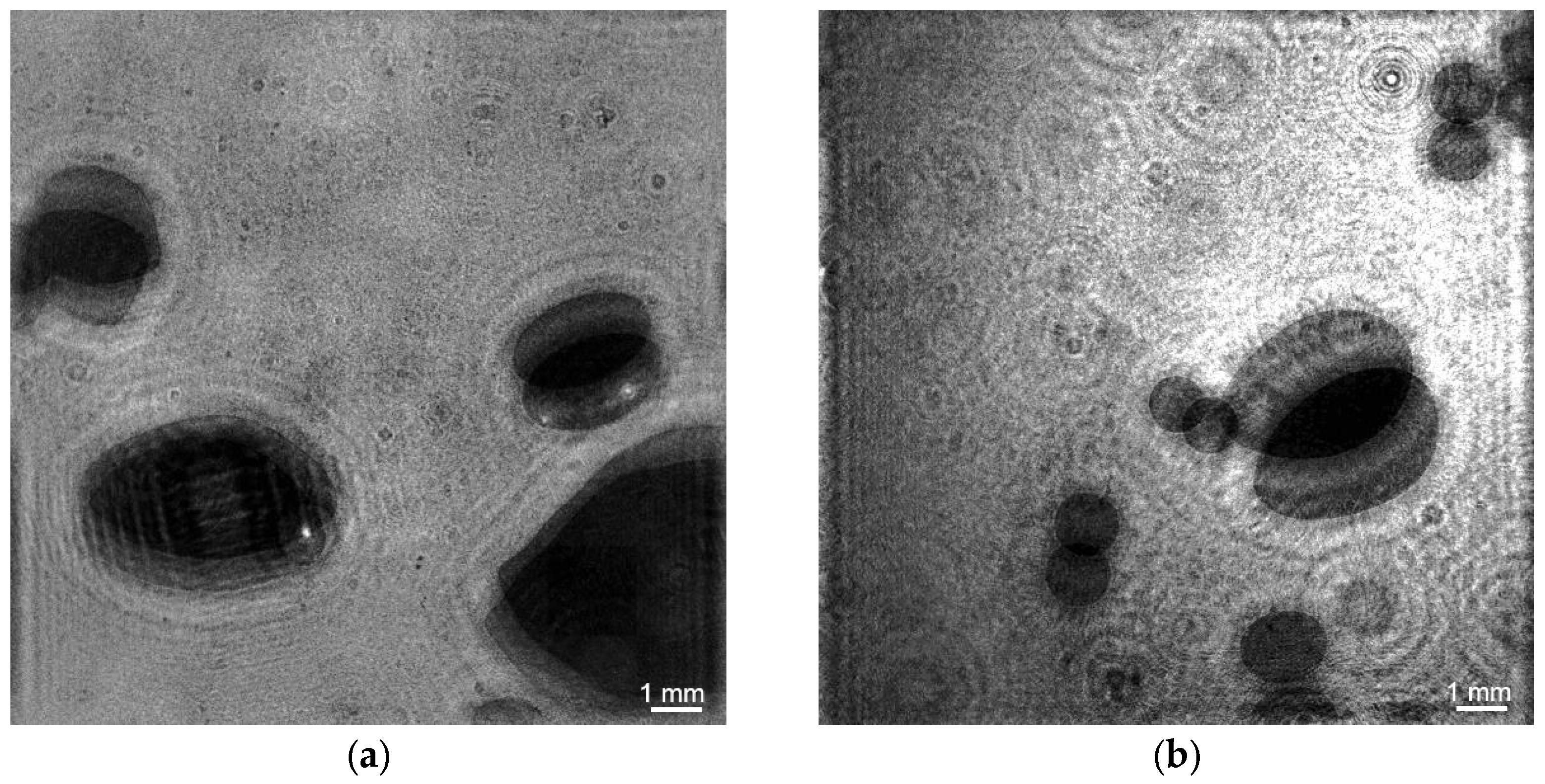

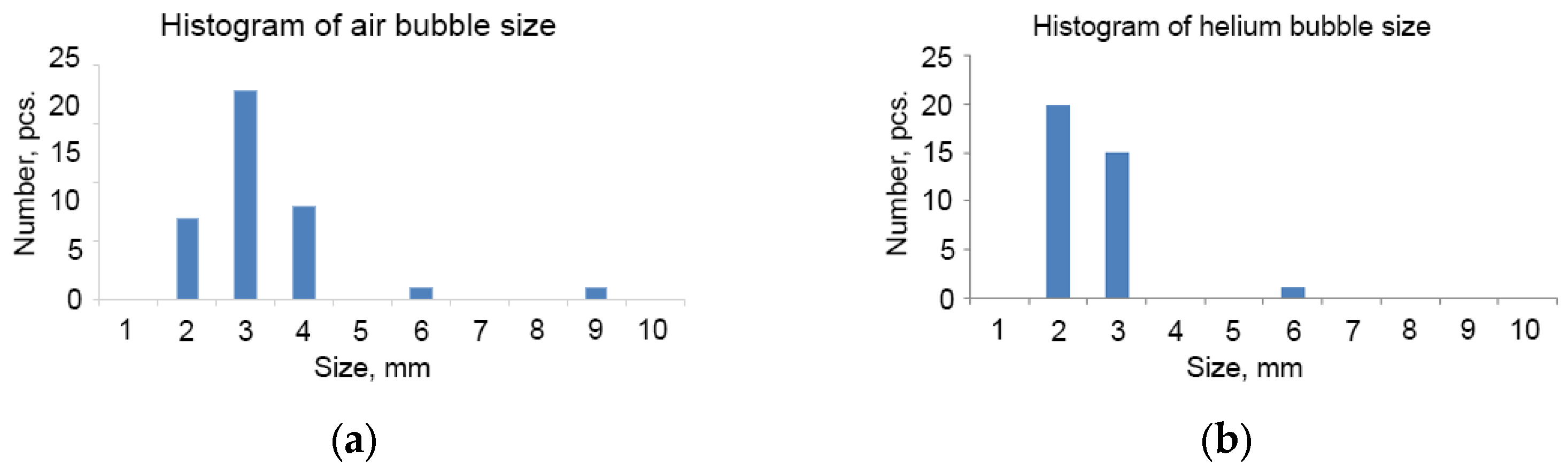

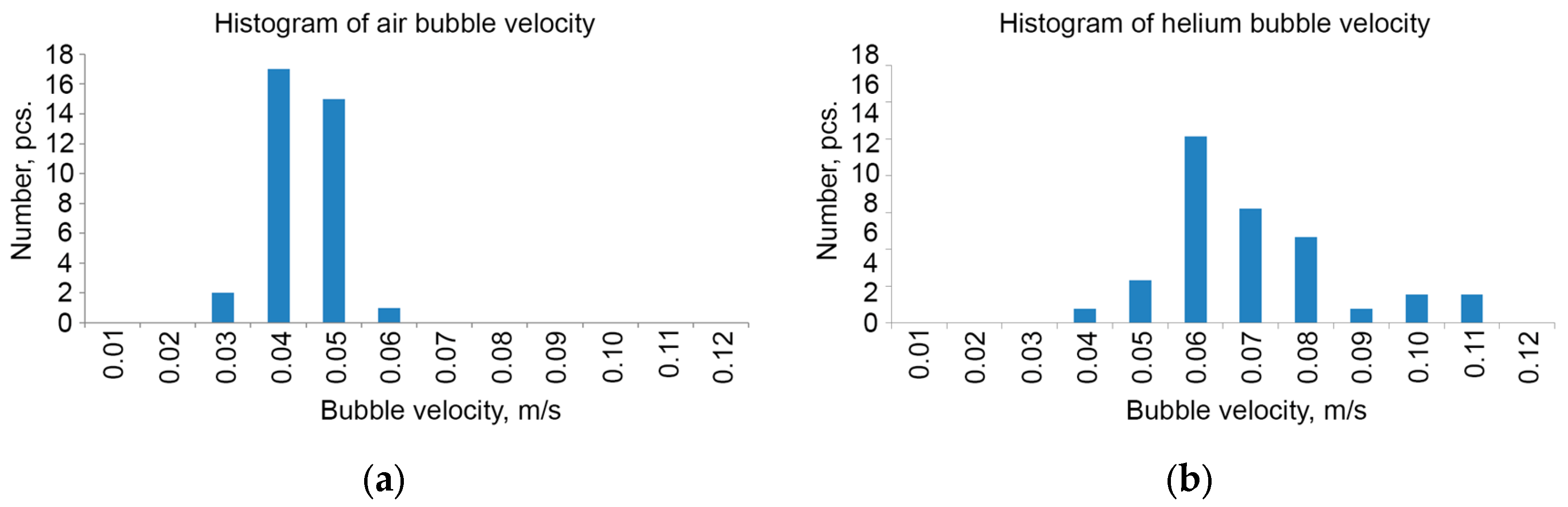

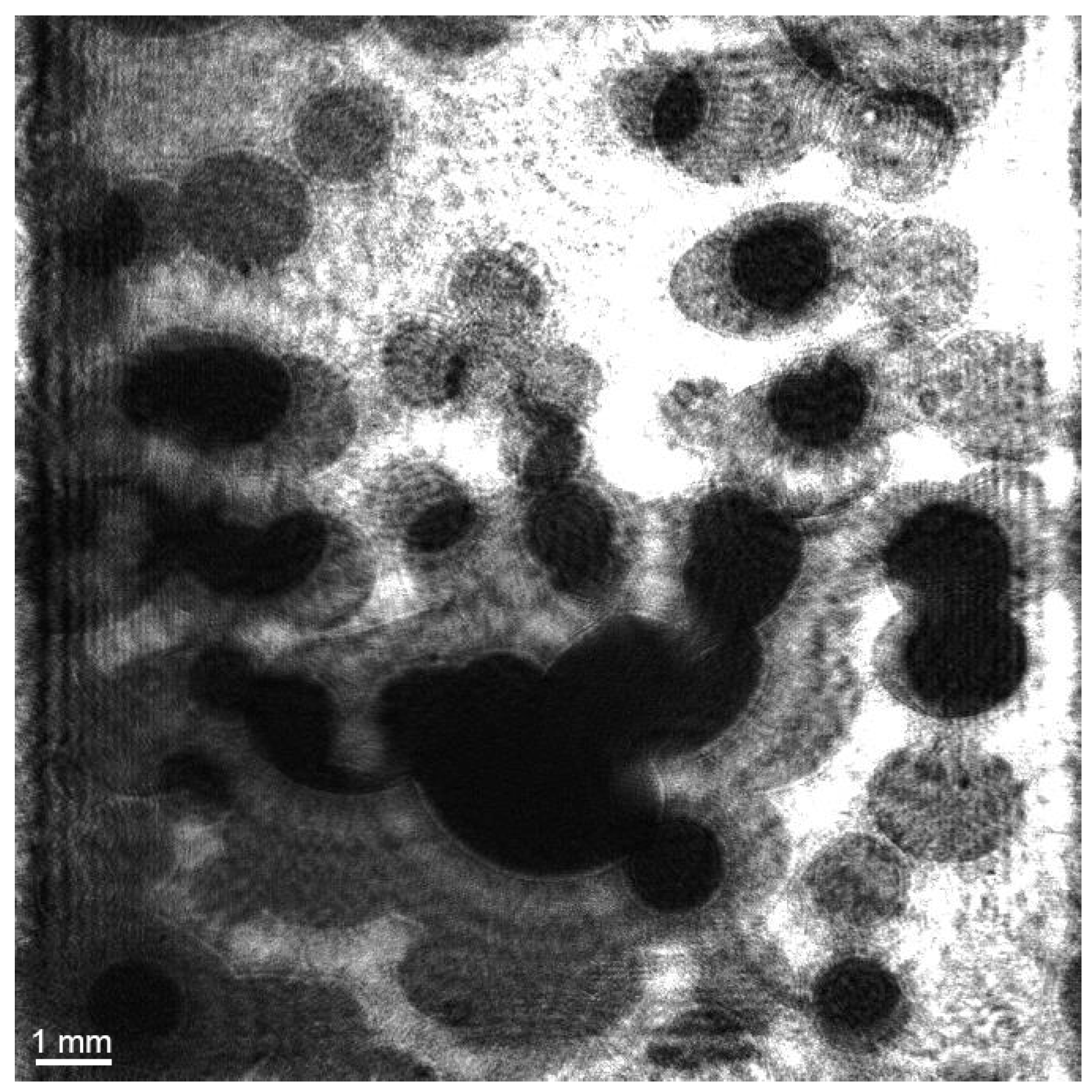

3.1. Bubble Flow Characteristics

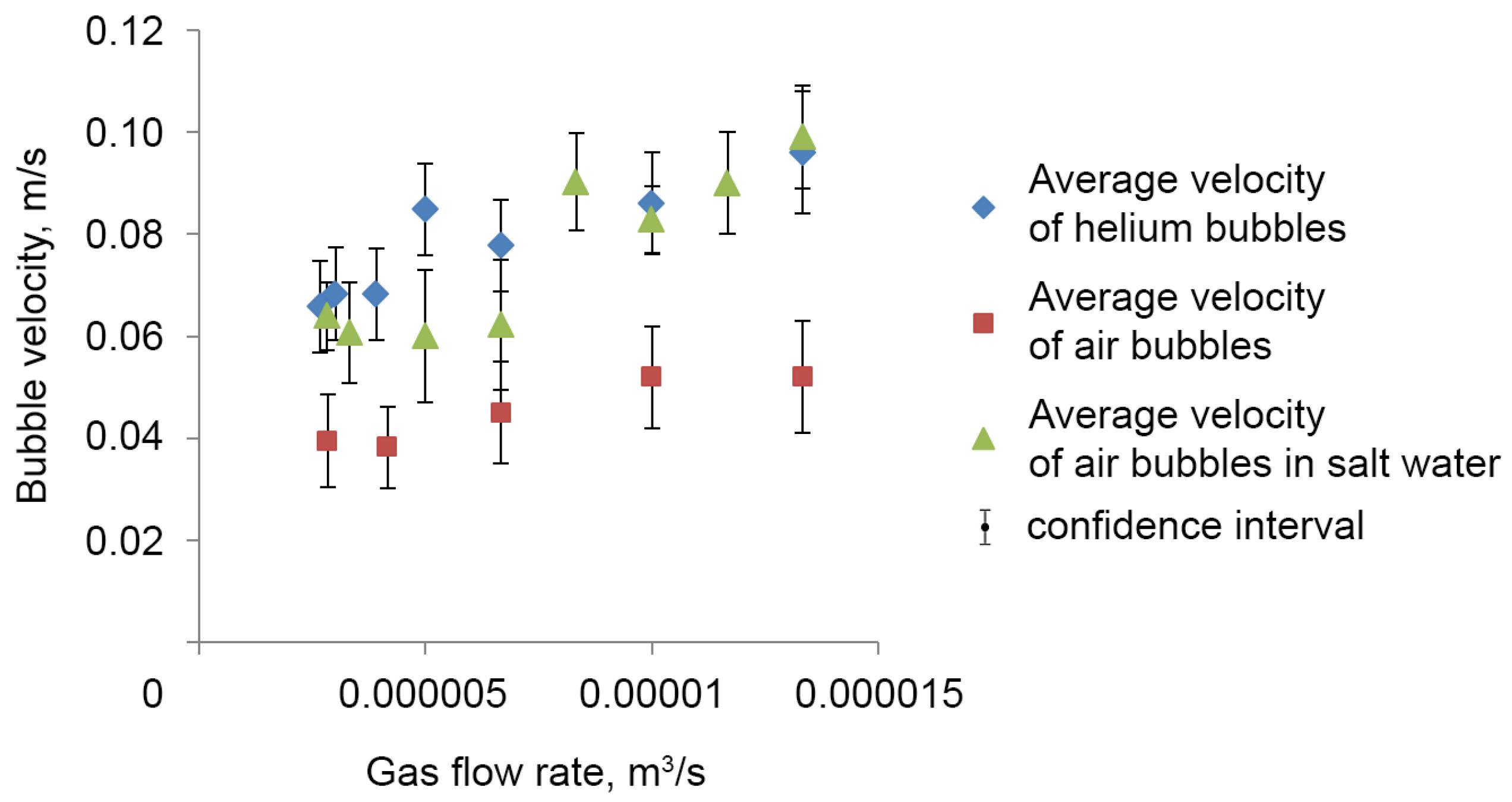

3.2. Calibration Dependencies

3.3. Comparison with Natural Data

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DHC | Digital Holographic Camera |

| AMK-82 | 82nd Arctic expedition on the research vessel Akademik Mstislav Keldysh |

References

- Shakhova, N.; Semiletov, I.; Leifer, I.; Sergienko, V.; Salyuk, A.; Kosmach, D.; Chernykh, D.; Stubbs, C.; Nicolsky, D.; Tumskoy, V.; et al. Ebullition and storm-induced methane release from the East Siberian Arctic Shelf. Nat. Geosci. 2014, 7, 64–70. [Google Scholar] [CrossRef]

- Thornton, B.F.; Geibel, M.C.; Crill, P.M.; Humborg, C.; Mörth, C. Methane fluxes from the sea to the atmosphere across the Siberian shelf seas. Geophys. Res. Lett. 2016, 43, 5869–5877. [Google Scholar] [CrossRef]

- Krylov, A.A.; Ananiev, R.A.; Chernykh, D.V.; Alekseev, D.A.; Balikhin, E.I.; Dmitrevsky, N.N.; Novikov, M.A.; Radiuk, E.A.; Domaniuk, A.V.; Kovachev, S.A.; et al. A Complex of Marine Geophysical Methods for Studying Gas Emission Process on the Arctic Shelf. Sensors 2023, 23, 3872. [Google Scholar] [CrossRef]

- Chernykh, D.V.; Kosmach, D.A.; Shakhova, N.E.; Salomatin, A.S.; Salyuk, A.N.; Domaniuk, A.V.; Spivak, E.A.; Gershelis, E.V.; Dudarev, O.V.; Krasikov, V.A.; et al. Quantification of bubble methane reaching atmosphere in the Arctic. Bull. Tomsk Polytech. Univ. Geo Assets Eng. 2024, 335, 184–197. [Google Scholar] [CrossRef]

- Reeburgh, W.S. Oceanic Methane Biogeochemistry. Chem. Rev. 2007, 107, 486–513. [Google Scholar] [CrossRef]

- Boulart, C.; Connelly, D.P.; Mowlem, M.C. Sensors and technologies for in situ dissolved methane measurements and their evaluation using Technology Readiness Levels. TrAC Trends Anal. Chem. 2010, 29, 186–195. [Google Scholar] [CrossRef]

- Sun, K.; Cui, W.; Chen, C. Review of underwater sensing technologies and applications. Sensors 2021, 21, 7849. [Google Scholar] [CrossRef] [PubMed]

- Walter, K.M.; Zimov, S.A.; Chanton, J.P.; Verbyla, D.; Chapin, F.S. Methane bubbling from Siberian thaw lakes as a positive feedback to climate warming. Nature 2006, 443, 71–75. [Google Scholar] [CrossRef] [PubMed]

- Weber, T.C.; De Robertis, A.; Greenaway, S.F.; Smith, S.; Mayer, L.; Rice, G. Estimating oil concentration and flow rate with calibrated vessel-mounted acoustic echo sounders. Proc. Natl. Acad. Sci. USA 2012, 109, 20240–20245. [Google Scholar] [CrossRef]

- Ananiev, R.A.; Dmitrevsky, N.N.; Roslyakov, A.G.; Chernykh, D.V.; Moroz, E.A.; Zarayskaya, Y.A.; Semiletov, I.P. Acoustic Monitoring of Gas Emission Processes in the Arctic Shelf Seas. Oceanology 2022, 62, 127–132. [Google Scholar] [CrossRef]

- Leifer, I.; Tang, D. The acoustic signature of marine seep bubbles. J. Acoust. Soc. Am. 2007, 121, EL35–EL40. [Google Scholar] [CrossRef]

- Chernykh, D.; Yusupov, V.; Salomatin, A.; Kosmach, D.; Shakhova, N.; Gershelis, E.; Konstantinov, A.; Grinko, A.; Chuvilin, E.; Dudarev, O.; et al. Sonar estimation of methane bubble flux from thawing subsea permafrost: A case study from the Laptev Sea Shelf. Geosci. 2020, 10, 411. [Google Scholar] [CrossRef]

- Shakhova, N.; Semiletov, I.; Salyuk, A.; Yusupov, V.; Kosmach, D.; Gustafsson, Ö. Extensive methane venting to the atmosphere from sediments of the East Siberian Arctic Shelf. Science 2010, 327, 1246–1250. [Google Scholar] [CrossRef] [PubMed]

- Shakhova, N.; Semiletov, I.; Sergienko, V.; Lobkovsky, L.; Yusupov, V.; Salyuk, A.; Salomatin, A.; Chernykh, D.; Kosmach, D.; Panteleev, G.; et al. The East Siberian Arctic Shelf: Towards further assessment of permafrost-related methane fluxes and role of sea ice. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2015, 373, 20140451. [Google Scholar] [CrossRef] [PubMed]

- Shakhova, N.; Semiletov, I.; Chuvilin, E. Understanding the Permafrost–Hydrate System and Associated Methane Releases in the East Siberian Arctic Shelf. Geosciences 2019, 9, 251. [Google Scholar] [CrossRef]

- Blanchard, D.C.; Woodcock, A.H. Bubble Formation and Modification in the Sea and Its Meteorological Significance. Tellus 1957, 9, 145–158. [Google Scholar] [CrossRef]

- Katz, J.; Sheng, J. Applications of Holography in Fluid Mechanics and Particle Dynamics. Annu. Rev. Fluid Mech. 2009, 42, 531–555. [Google Scholar] [CrossRef]

- Nayak, A.R.; Malkiel, E.; McFarland, M.N.; Twardowski, M.S.; Sullivan, J.M. A Review of Holography in the Aquatic Sciences: In Situ Characterization of Particles, Plankton, and Small Scale Biophysical Interactions. Front. Mar. Sci. 2021, 7, 572147. [Google Scholar] [CrossRef]

- Al-Lashi, R.S.; Gunn, S.R.; Webb, E.G.; Czerski, H. A Novel High-Resolution Optical Instrument for Imaging Oceanic Bubbles. IEEE J. Ocean. Eng. 2018, 43, 72–82. [Google Scholar] [CrossRef]

- Chernykh, D.; Shakhova, N.; Yusupov, V.; Gershelis, E.; Morgunov, B.; Semiletov, I. First Calibrated Methane Bubble Wintertime Observations in the Siberian Arctic Seas: Selected Results from the Fast Ice. Geosciences 2023, 13, 228. [Google Scholar] [CrossRef]

- Dyomin, V.; Semiletov, I.; Chernykh, D.; Chertoprud, E.; Davydova, A.; Kirillov, N.; Konovalova, O.; Olshukov, A.; Osadchiev, A.; Polovtsev, I. Study of Marine Particles Using Submersible Digital Holographic Camera During the Arctic Expedition. Appl. Sci. 2022, 12, 11266. [Google Scholar] [CrossRef]

- Collier, R.J.; Burckhardt, C.B.; Lin, L.H. Optical Holography; Academic Press: New York, NY, USA, 1971; ISBN 9780121810504. [Google Scholar]

- Schnars, U.; Juptner, W.P.O. Digital recording and numerical reconstruction of holograms. Meas. Sci. Technol. 2002, 13, R85–R101. [Google Scholar] [CrossRef]

- Yaroslavsky, L. Digital Holography and Digital Image Processing; Springer: Boston, MA, USA, 2004; ISBN 978-1-4419-5397-1. [Google Scholar]

- Poon, T.-C.; Liu, J.-P. Introduction to Modern Digital Holography; Cambridge University Press: New York, NY, USA, 2014; ISBN 9781139061346. [Google Scholar]

- Mudanyali, O.; Tseng, D.; Oh, C.; Isikman, S.O.; Sencan, I.; Bishara, W.; Oztoprak, C.; Seo, S.; Khademhosseini, B.; Ozcan, A. Compact, light-weight and cost-effective microscope based on lensless incoherent holography for telemedicine applications. Lab Chip 2010, 10, 1417–1428. [Google Scholar] [CrossRef]

- Wu, Y.-C.; Shiledar, A.; Li, Y.-C.; Wong, J.; Feng, S.; Chen, X.; Chen, C.; Jin, K.; Janamian, S.; Yang, Z.; et al. Air quality monitoring using mobile microscopy and machine learning. Light Sci. Appl. 2017, 6, e17046. [Google Scholar] [CrossRef]

- Garcia-Sucerquia, J.; Xu, W.; Jericho, S.K.; Klages, P.; Jericho, M.H.; Kreuzer, H.J. Digital in-line holographic microscopy. Appl. Opt. 2006, 45, 836–850. [Google Scholar] [CrossRef]

- Di, J.; Zhao, J.; Jiang, H.; Zhang, P.; Fan, Q.; Sun, W. High resolution digital holographic microscopy with a wide field of view based on a synthetic aperture technique and use of linear CCD scanning. Appl. Opt. 2008, 47, 5654–5659. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Cadalso, D.; Furlong, C. High-resolution imaging for in-situ non-destructive testing by quantitative lensless digital holography. Front. Photonics 2024, 5, 1351744. [Google Scholar] [CrossRef]

- Barua, R.; Sanborn, D.; Nyman, L.; McFarland, M.; Moore, T.; Hong, J.; Garrett, M.; Nayak, A.R. In situ digital holographic microscopy for rapid detection and monitoring of the harmful dinoflagellate, Karenia brevis. Harmful Algae 2023, 123, 102401. [Google Scholar] [CrossRef]

- Guo, B.; Nyman, L.; Nayak, A.R.; Milmore, D.; McFarland, M.; Twardowski, M.S.; Sullivan, J.M.; Yu, J.; Hong, J. Automated plankton classification from holographic imagery with deep convolutional neural networks. Limnol. Oceanogr. Methods 2021, 19, 21–36. [Google Scholar] [CrossRef]

- Saito, M.; Kitamura, M.; Ide, Y.; Nguyen, M.H.; Le, B.D.; Mai, A.T.; Miyashiro, D.; Mayama, S.; Umemura, K. An Efficient Method of Observing Diatom Frustules via Digital Holographic Microscopy. Microsc. Microanal. 2022, 28, 2172–2176. [Google Scholar] [CrossRef]

- Orenstein, E.C.; Ratelle, D.; Briseño-Avena, C.; Carter, M.L.; Franks, P.J.S.; Jaffe, J.S.; Roberts, P.L.D. The Scripps Plankton Camera system: A framework and platform for in situ microscopy. Limnol. Oceanogr. Methods 2020, 18, 681–695. [Google Scholar] [CrossRef]

- Giering, S.L.C.; Cavan, E.L.; Basedow, S.L.; Briggs, N.; Burd, A.B.; Darroch, L.J.; Guidi, L.; Irisson, J.-O.; Iversen, M.H.; Kiko, R.; et al. Sinking Organic Particles in the Ocean—Flux Estimates from in situ Optical Devices. Front. Mar. Sci. 2020, 6, 834. [Google Scholar] [CrossRef]

- Walcutt, N.L.; Knörlein, B.; Cetinić, I.; Ljubesic, Z.; Bosak, S.; Sgouros, T.; Montalbano, A.L.; Neeley, A.; Menden-Deuer, S.; Omand, M.M. Assessment of holographic microscopy for quantifying marine particle size and concentration. Limnol. Oceanogr. Methods 2020, 18, 516–530. [Google Scholar] [CrossRef] [PubMed]

- Memmolo, P.; Carcagnì, P.; Bianco, V.; Merola, F.; Goncalves da Silva Junior, A.; Garcia Goncalves, L.M.; Ferraro, P.; Distante, C. Learning Diatoms Classification from a Dry Test Slide by Holographic Microscopy. Sensors 2020, 20, 6353. [Google Scholar] [CrossRef]

- Graham, G.W.; Nimmo Smith, W.A.M. The application of holography to the analysis of size and settling velocity of suspended cohesive sediments. Limnol. Oceanogr. Methods 2010, 8, 1–15. [Google Scholar] [CrossRef]

- Zhu, Y.; Hang Yeung, C.; Lam, E.Y. Digital holographic imaging and classification of microplastics using deep transfer learning. Appl. Opt. 2021, 60, A38. [Google Scholar] [CrossRef]

- Bianco, V.; Memmolo, P.; Carcagnì, P.; Merola, F.; Paturzo, M.; Distante, C.; Ferraro, P. Microplastic Identification via Holographic Imaging and Machine Learning. Adv. Intell. Syst. 2020, 2, 1900153. [Google Scholar] [CrossRef]

- Shao, S.; Li, C.; Hong, J. A hybrid image processing method for measuring 3D bubble distribution using digital inline holography. Chem. Eng. Sci. 2019, 207, 929–941. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, H.; Wu, X.; Cen, K. Quantifying bubble size and 3D velocity in a vortex with digital holographic particle tracking velocimetry (DHPTV). Flow Meas. Instrum. 2020, 76, 101826. [Google Scholar] [CrossRef]

- Talapatra, S.; Sullivan, J.; Katz, J.; Twardowski, M.; Czerski, H.; Donaghay, P.; Hong, J.; Rines, J.; McFarland, M.; Nayak, A.R.; et al. Application of in-situ digital holography in the study of particles, organisms and bubbles within their natural environment. In Proceedings of the SPIE—The International Society for Optical Engineering, Baltimore, MD, USA, 12 June 2012; Hou, W.W., Arnone, R., Eds.; SPIE: Bellingham, WA, USA, 2012; Volume 8372, pp. 837205-1–837205-17. [Google Scholar]

- Scherrer, R.; Govan, R.; Quiniou, T.; Jauffrais, T.; Lemonnier, H.; Bonnet, S.; Selmaoui-Folcher, N. Automatic Plankton Detection and Classification on Raw Hologram with a Single Deep Learning Architecture. In Proceedings of the CIBB 2021 Computational Intelligence Methods for Bioinformatics and Biostatistics, Online, 15–17 November 2021; pp. 1–6. [Google Scholar]

- Zhang, Y.; Lu, Y.; Wang, H.; Chen, P.; Liang, R. Automatic Classification of Marine Plankton with Digital Holography Using Convolutional Neural Network. Opt. Laser Technol. 2021, 139, 106979. [Google Scholar] [CrossRef]

- Scherrer, R.; Govan, R.; Quiniou, T.; Jauffrais, T.; Lemonnier, H.; Bonnet, S.; Selmaoui-Folcher, N. Real-Time Automatic Plankton Detection, Tracking and Classification on Raw Hologram. In Computational Intelligence Methods for Bioinformatics and Biostatistics; Springer: Cham, Switzerland, 2022; pp. 25–39. [Google Scholar]

- Shrestha, P.; Kuang, N.; Yu, J. Efficient end-to-end learning for cell segmentation with machine generated weak annotations. Commun. Biol. 2023, 6, 232. [Google Scholar] [CrossRef] [PubMed]

- Xiong, Z.; Yu, L.; An, S.; Zheng, J.; Ma, Y.; Micó, V.; Gao, P. Automatic identification and analysis of cells using digital holographic microscopy and Sobel segmentation. Front. Photonics 2024, 5, 1359595. [Google Scholar] [CrossRef]

- Dyomin, V.V.; Davydova, A.Y.; Polovtsev, I.G.; Yudin, N.N.; Zinoviev, M.M. Accuracy of Determination of Longitudinal Coordinates of Particles by Digital Holography. Atmos. Ocean. Opt. 2023, 36, 113–120. [Google Scholar] [CrossRef]

- Dyomin, V.; Polovtsev, I.; Davydova, A. Calibration for the magnification of a submersible digital holographic camera during the study of particles in natural conditions. Appl. Opt. 2025, 64, B49–B57. [Google Scholar] [CrossRef]

- Ghiglia, D.C.; Mark, P.D. Two-Dimensional Phase Unwrapping: Theory, Algorithms, and Software; Wiley: Hoboken, NJ, USA, 1998. [Google Scholar]

- Juarez-Salazar, R.; Robledo-Sanchez, C.; Guerrero-Sanchez, F. Phase-unwrapping algorithm by a rounding-least-squares approach. Opt. Eng. 2014, 53, 024102. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, X.; Xu, M.; Zhang, H.; Jiang, X. Phase unwrapping in digital holography based on non-subsampled contourlet transform. Opt. Commun. 2018, 407, 367–374. [Google Scholar] [CrossRef]

- Park, S.; Kim, Y.; Moon, I. Automated phase unwrapping in digital holography with deep learning. Biomed. Opt. Express 2021, 12, 7064–7081. [Google Scholar] [CrossRef]

- Dyomin, V.; Olshukov, A.S.; Davydova, A. Data acquisition from digital holograms of particles. In Proceedings of the Unconventional Optical Imaging, Strasbourg, France, 22–26 April 2018; Fournier, C., Georges, M.P., Popescu, G., Eds.; Volume 10677, p. 123. [Google Scholar]

- Degterev, A.K. Influence of gas hydrate formation on methane seeps at the bottom of water reservoirs. Russ. Geol. Geophys. 2017, 58, 1101–1105. [Google Scholar] [CrossRef]

- Liu, L.; Yan, H.; Zhao, G. Experimental studies on the shape and motion of air bubbles in viscous liquids. Exp. Therm. Fluid Sci. 2015, 62, 109–121. [Google Scholar] [CrossRef]

- Michel, A.P.M.; Preston, V.L.; Fauria, K.E.; Nicholson, D.P. Observations of Shallow Methane Bubble Emissions from Cascadia Margin. Front. Earth Sci. 2021, 9, 613234. [Google Scholar] [CrossRef]

| Parameter | Laboratory DHC Data, Air | Laboratory DHC Data, Helium | Field Data, Methane, Trap Method, Weak Release, Station 6964 | Field Data, Methane, Strong Release, Station 6975 | |

|---|---|---|---|---|---|

| DHC | Trap Method | ||||

| Volumetric flux, m3·m−2·s−1 | 2.5 × 10−4–15 × 10−4 | 2.5 × 10−4–15 × 10−4 | 0.13 × 10−6–1.5 × 10−6 | 9.8 × 10−4 | 10 × 10−4 |

| Mean bubble diameter, mm | 2.7 ± 0.4 | 2.1 ± 0.2 | N/A | 2.2 ± 0.6 | N/A |

| Mean bubble velocity, m/s | 0.039 ± 0.008 | 0.068 ± 0.009 | N/A | 0.05 ± 0.01 | N/A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dyomin, V.; Davydova, A.; Kirillov, N.; Polovtsev, I. Calibration of Digital Holographic Camera for Bubble Gas Volumetric Flux Measurements. Sensors 2025, 25, 6969. https://doi.org/10.3390/s25226969

Dyomin V, Davydova A, Kirillov N, Polovtsev I. Calibration of Digital Holographic Camera for Bubble Gas Volumetric Flux Measurements. Sensors. 2025; 25(22):6969. https://doi.org/10.3390/s25226969

Chicago/Turabian StyleDyomin, Victor, Alexandra Davydova, Nikolay Kirillov, and Igor Polovtsev. 2025. "Calibration of Digital Holographic Camera for Bubble Gas Volumetric Flux Measurements" Sensors 25, no. 22: 6969. https://doi.org/10.3390/s25226969

APA StyleDyomin, V., Davydova, A., Kirillov, N., & Polovtsev, I. (2025). Calibration of Digital Holographic Camera for Bubble Gas Volumetric Flux Measurements. Sensors, 25(22), 6969. https://doi.org/10.3390/s25226969