Application of Multi-Sensor Data Fusion and Machine Learning for Early Warning of Cambrian Limestone Water Hazards

Abstract

1. Introduction

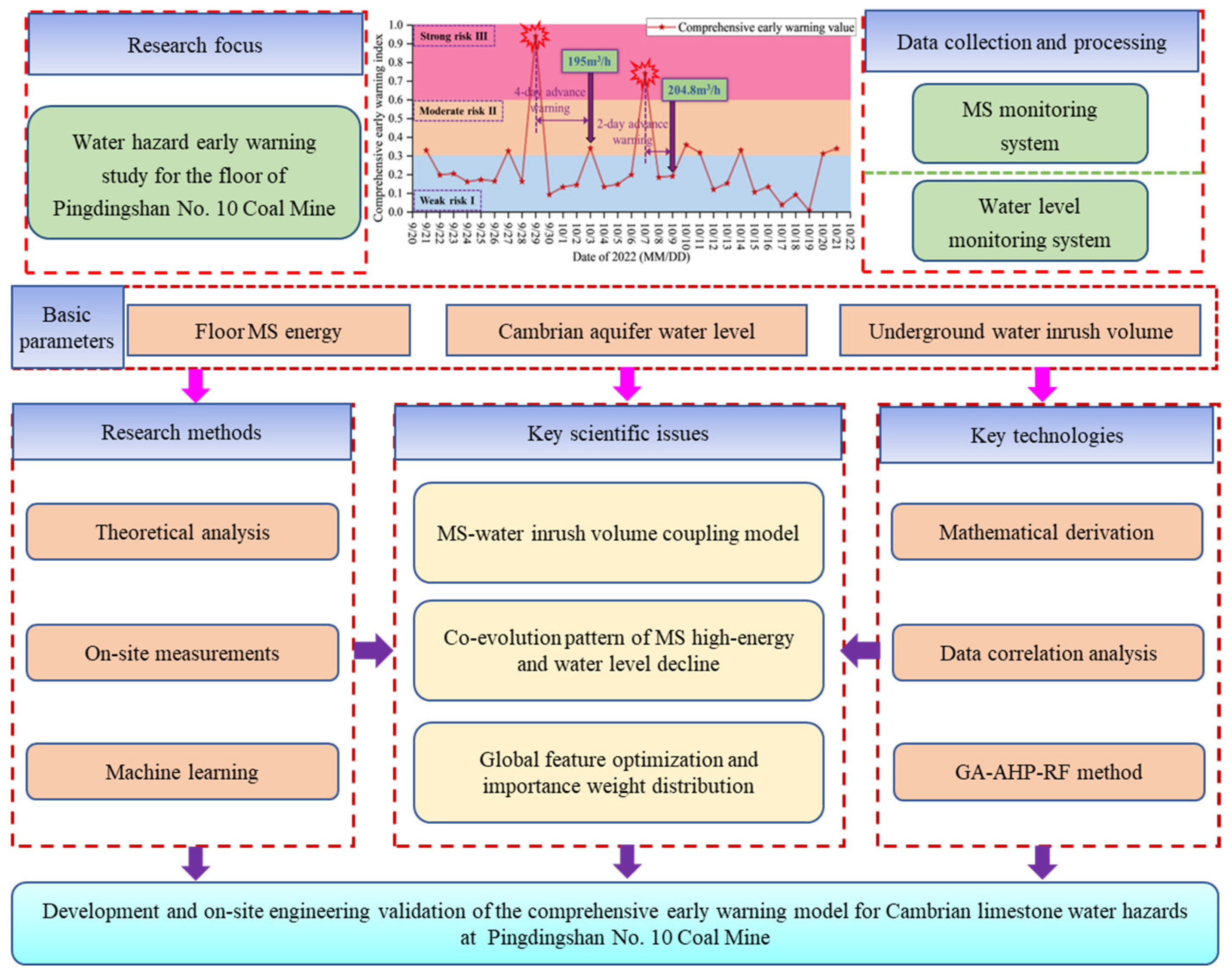

2. Methodology

- (1)

- Theoretical model development: Based on the MS source damage characteristics, the geometric features of the water inrush channels are derived, and an MS-water inrush volume correlation model is established to provide a theoretical basis for subsequent analyses.

- (2)

- Feature correlation analysis: Representative MS energy indicators (single high-energy events and high daily cumulative energy) and water level change indicators are extracted to identify significant correlation response patterns before water inrush events.

- (3)

- Indicator optimization and weight distribution: GA is used for global optimization of multi-source feature combinations to select the optimal indicator set. The integration of AHP and RF models is used to assign weights to indicators through a combination of subjective and objective methods.

- (4)

- Comprehensive early warning system validation: A water hazard early warning system is constructed based on the GA-AHP-RF fusion algorithm. The model is validated using actual measurement data from the working face of Pingdingshan No. 10 Coal Mine to evaluate its accuracy and timeliness.

3. Engineering Conditions and Integrated Monitoring System

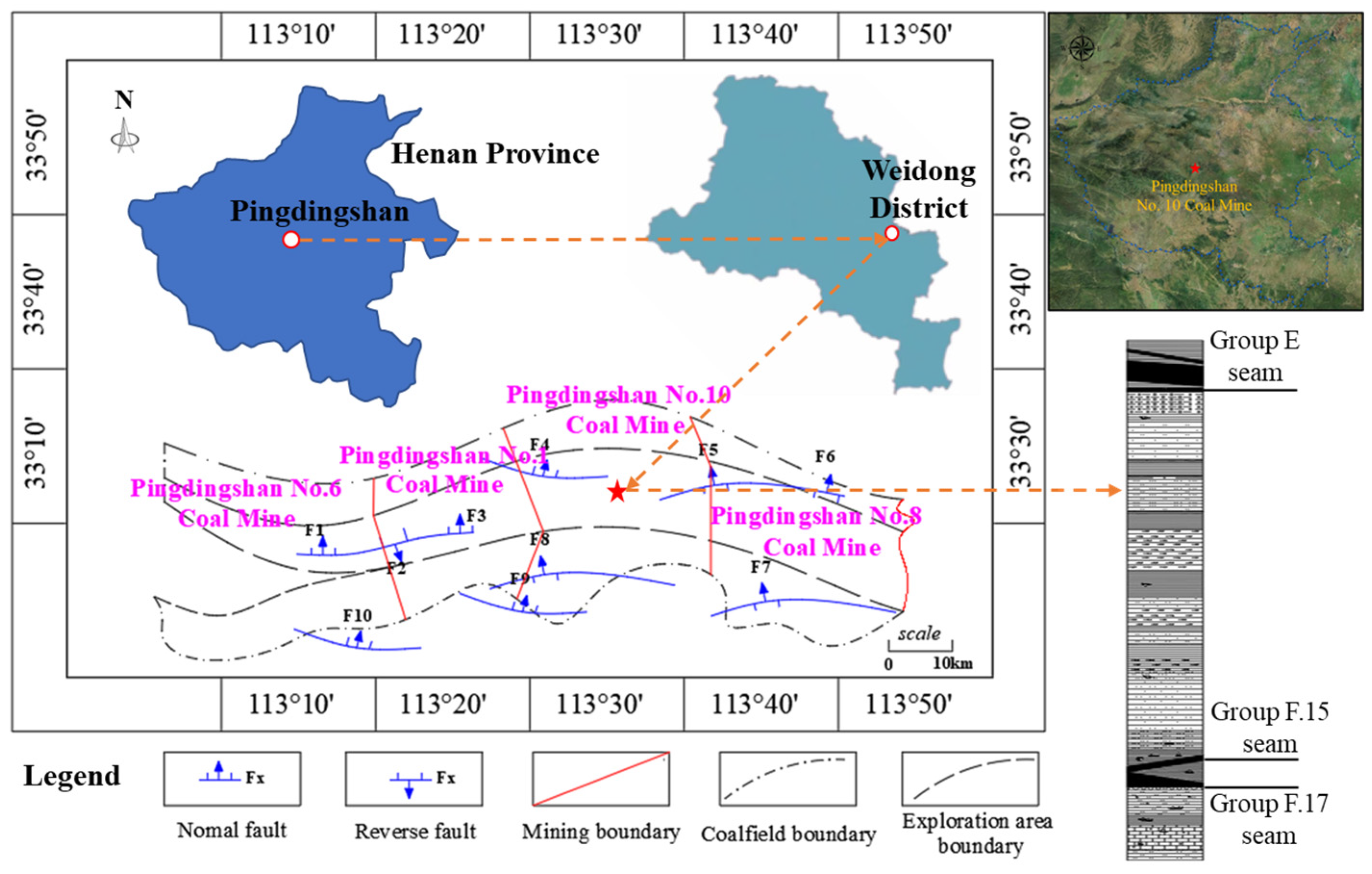

3.1. Geological Overview

3.2. Working Face Overview and Monitoring System Layout

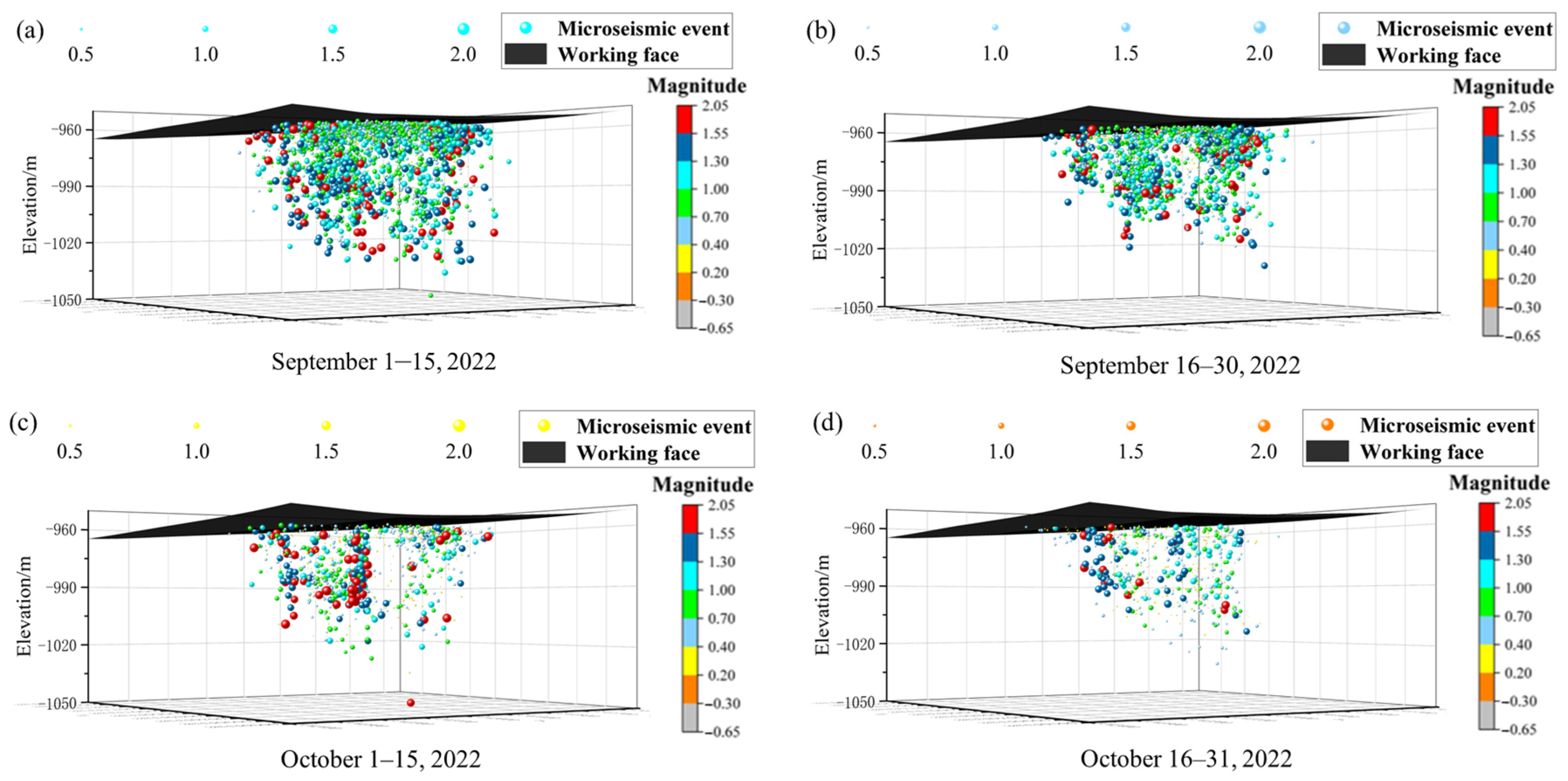

3.3. MS Monitoring Analysis of Coal Seam Floor

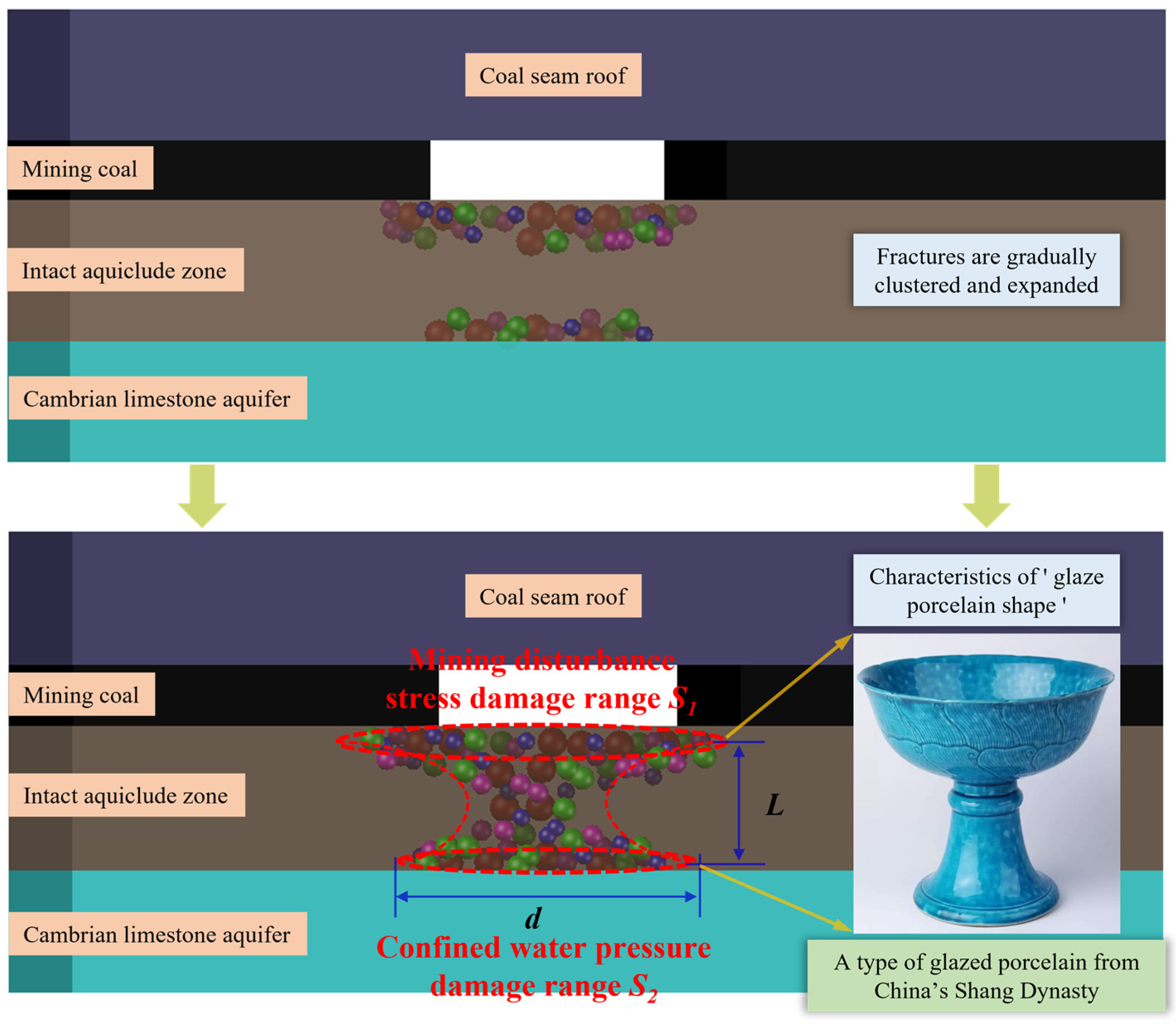

4. Correlation Theoretical Model of MS-Water Inrush Volume

5. Synergistic Effects of Precursory Indicators for Floor Water Inrush

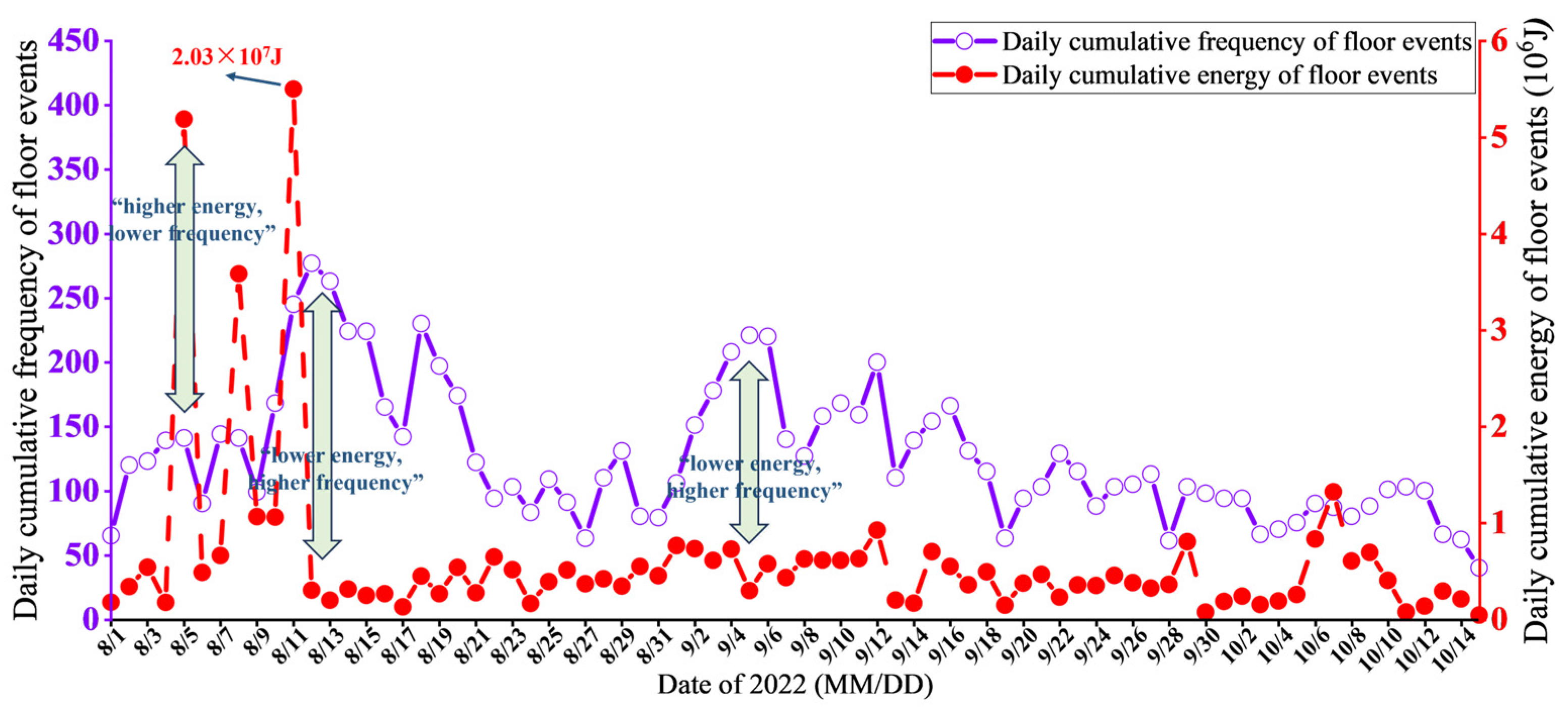

5.1. Statistical Analysis of Floor MS Data

5.2. Correlation Analysis of Single High-Energy Events and Water Level

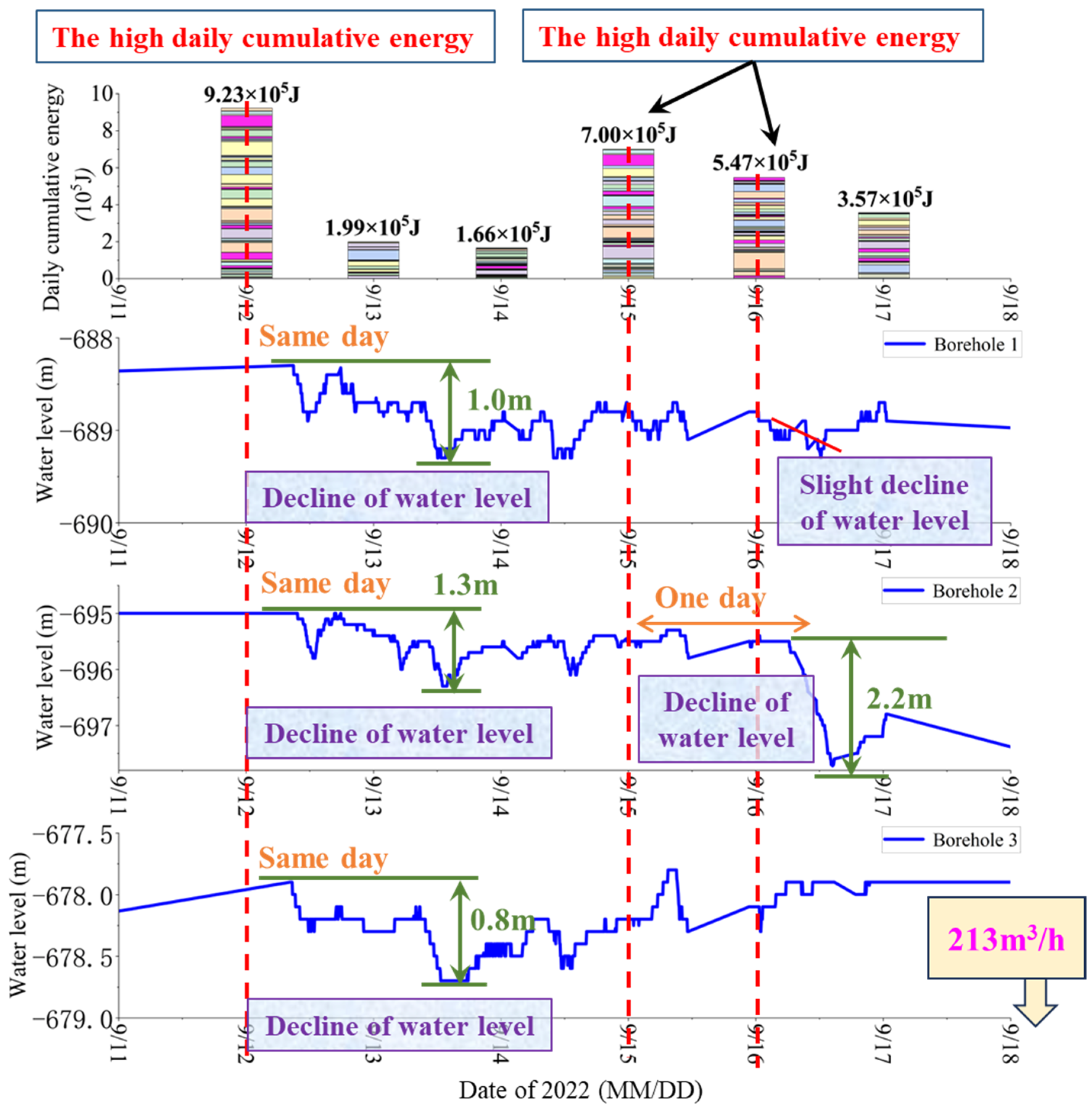

5.3. Correlation Analysis of High Daily Cumulative Energy and Water Level

6. Construction and Field Verification of the Integrated Early Warning Model

6.1. Indicator Optimization Based on GA

6.2. Importance Weight Allocation Based on AHP and RF

6.2.1. Construction of the Hierarchical Model

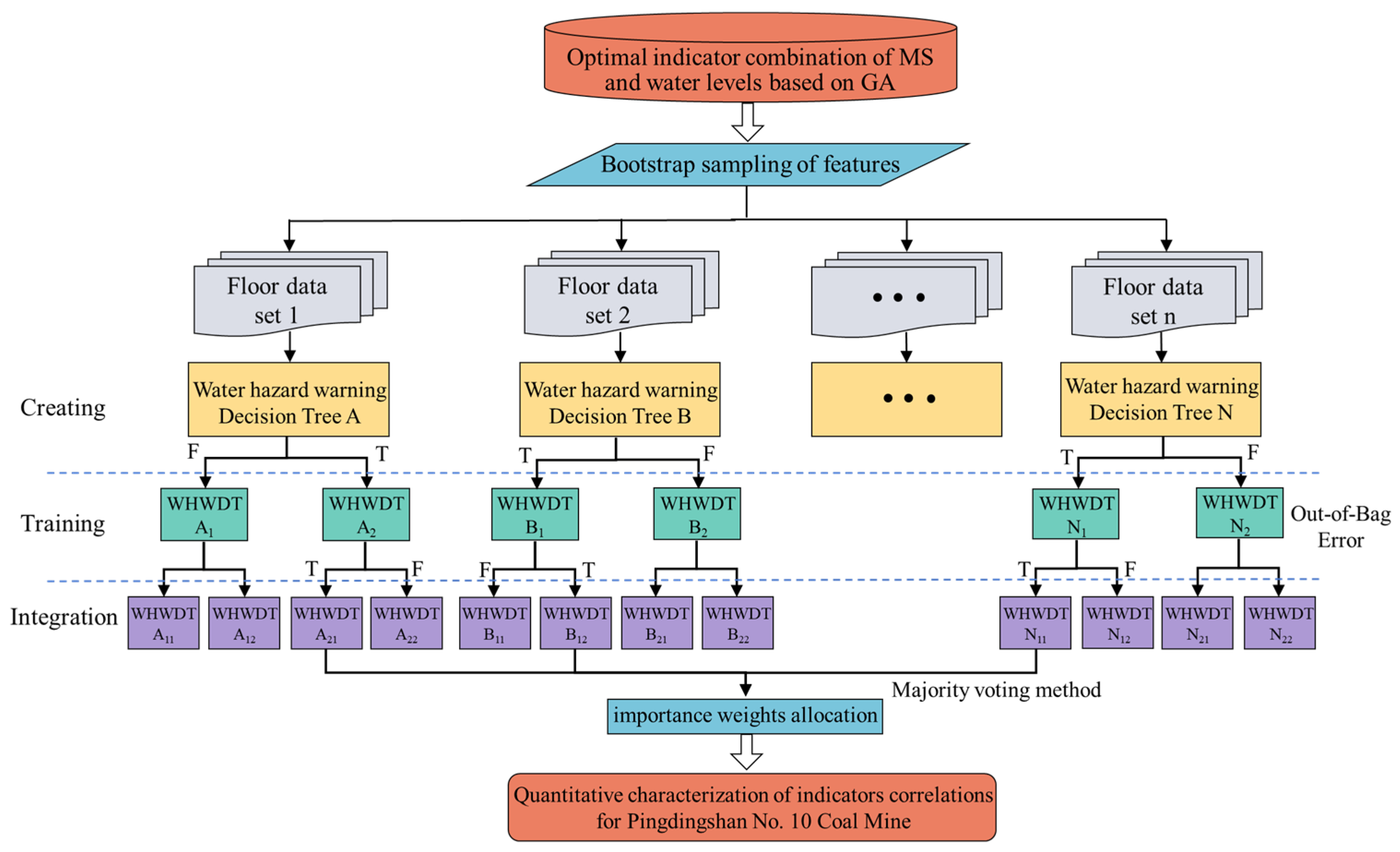

6.2.2. RF Model Construction

6.3. Field Engineering Validation

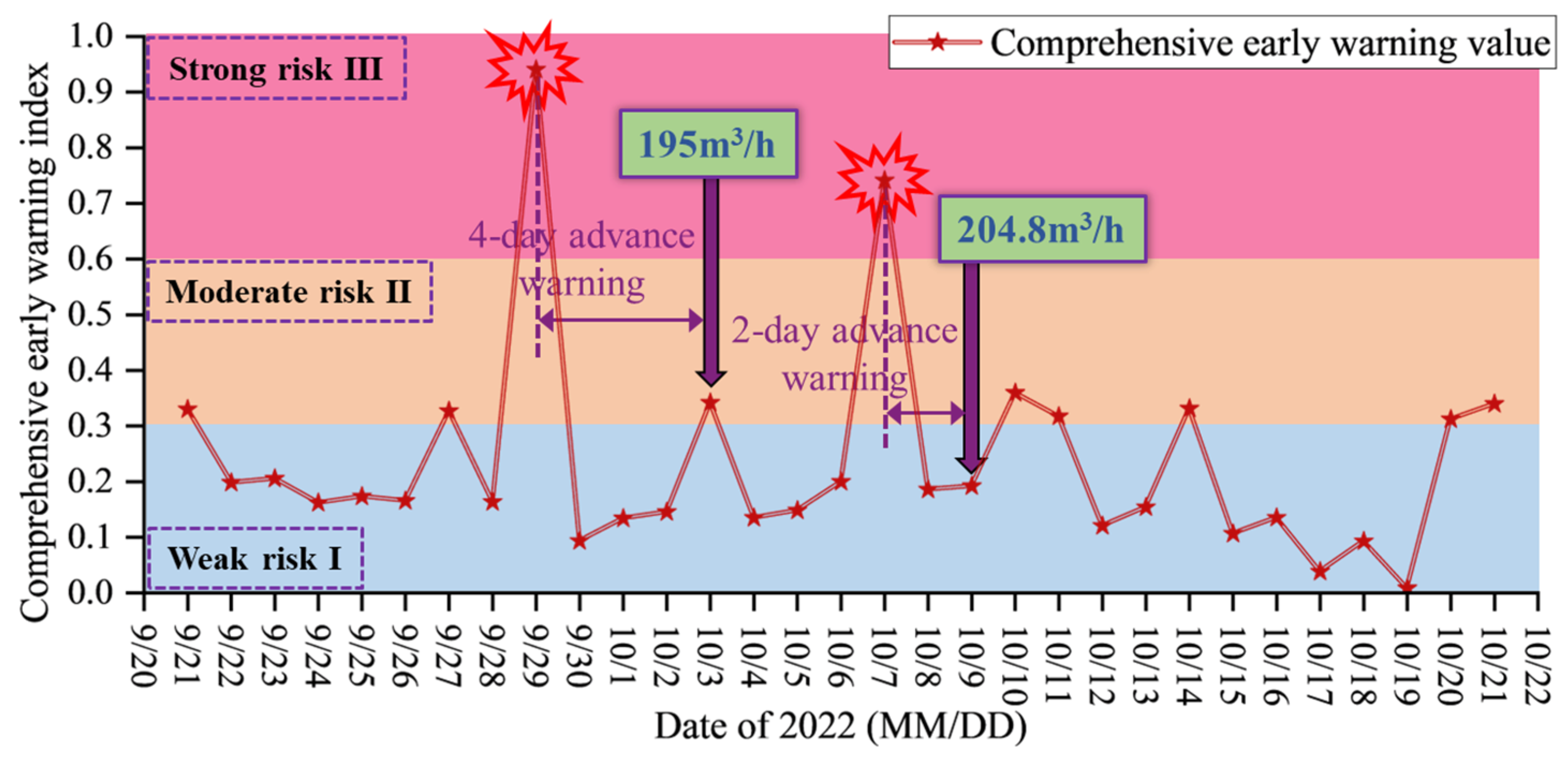

6.3.1. Classification of Water Inrush Risk Levels

6.3.2. Engineering Application Effect Analysis

7. Conclusions

- (1)

- Among the MS events recorded in the floor of the F.17-33200 working face, a total of 5456 events had magnitudes less than 1.30, accounting for 89.27% of all events. The frequency of MS events decreases vertically with increasing depth, with fracture events mainly concentrated within 0–40 m of the floor, and the deepest occurrence reaching 84.78 m.

- (2)

- Two events are used as examples to characterize the intrinsic relationship between MS activity and fractures. By integrating the “glazed porcelain shape” feature of floor rock failure that forms water inrush channels, a theoretical expression of aquifer water inrush volume based on MS activity is derived. It is also shown that a certain correlation exists between MS activity and water level variations.

- (3)

- Analysis of field monitoring data shows that significant sensitivity response characteristics exist prior to floor water inrush: single high-energy events and high daily cumulative energy of MS activity are found to be strongly correlated with water level decline. Based on this, a method that combines MS energy with water level dynamics is proposed, by which effective early warning of floor water inrush disasters can be achieved.

- (4)

- The GA-AHP-RF model quantifies the relationships among sensitive indices, with CR, MAE, and RMSE values of 0.024, 0.027, and 0.046, respectively. The weights for floor MS energy and water levels in Boreholes 1, 2, and 3 are 22%, 52%, 9%, and 17%. Field results confirm that the comprehensive index can provide an accurate early warning up to four days before high water inrush events.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Q.; Guo, J.; Lu, X.; Ding, K.; Yuan, R.; Wang, D. Simulation and On-Site Detection of the Failure Characteristics of Overlying Strata under the Mining Disturbance of Coal Seams with Thin Bedrock and Thick Alluvium. Sensors 2024, 24, 1748. [Google Scholar] [CrossRef] [PubMed]

- Quan, L.; Jin, S.; Zhang, J.; Chen, J.; He, J. Subsidence characteristics in North Anhui coal mining areas using Space-Air-Ground collaborative observations. Sensors 2024, 24, 3869. [Google Scholar] [CrossRef] [PubMed]

- Ilić, M.Č.; Popović, M.P.; Bajić, D.; Matović, V.; Abramović, F.; Alimpić, F. Monitoring the Impact of Artificial Structure on Hydrogeological Environment: A Case Study of Hydraulic Tunnel at Pirot Hydropower Plant. Sensors 2024, 24, 6578. [Google Scholar] [CrossRef]

- Aghababaei, S.; Saeedi, G.; Jalalifar, H. Risk analysis and prediction of floor failure mechanisms at longwall face in Parvadeh-I coal mine using rock engineering system (RES). Rock Mech. Rock Eng. 2015, 49, 1889–1901. [Google Scholar] [CrossRef]

- Wang, D.; Sui, W.; Ji, Z.; Cheng, Y. Dynamic hazard analysis and mechanism of groundwater inrush under complex geological structures. Tunn. Undergr. Space Technol. 2025, 165, 106884. [Google Scholar] [CrossRef]

- Wang, K.K.; Ma, K.; Tang, C.A.; Liu, H.; Wang, X.; Li, Q. Study on deep mining-induced strata behavior based on the evolutional laws of multiple indices from microseismic monitoring. Rock Mech. Rock Eng. 2023, 56, 6481–6501. [Google Scholar] [CrossRef]

- Cao, W.Z.; Durucan, S.; Cai, W.; Shi, J.-Q.; Korre, A.; Jamnikar, S.; Rošer, J.; Lurka, A.; Siata, R. The role of mining intensity and pre-existing fracture attributes on spatial, temporal and magnitude characteristics of microseismicity in longwall coal mining. Rock Mech. Rock Eng. 2020, 53, 4139–4162. [Google Scholar] [CrossRef]

- Gai, Q.; He, M.; Gao, Y.; Li, S. Mechanism of floor damage reduction in non-pillar mining with automatically formed roadway: A model test study. Rock Mech. Rock Eng. 2025, 58, 9573–9600. [Google Scholar] [CrossRef]

- Tong, X.; Zheng, X.; Jin, Y.; Dong, B.; Liu, Q.; Li, Y. Prevention and control strategy of coal mine water inrush accident based on case-driven and Bow-Tie-Bayesian model. Energy 2025, 320, 135312. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, X.; Gai, Q.; Han, D.; He, M. An integrated method to prevent confined floor water inrush based on no pillar mining with pressure relief and grouting reinforcement. Geomech. Geophys. Geo-Energy Geo-Resour. 2025, 11, 85. [Google Scholar] [CrossRef]

- Liu, X.Z.; Tang, C.A.; Li, L.C.; Lv, P.; Liu, H. Microseismic monitoring and 3D finite element analysis of the right bank slope, Dagangshan hydropower station, during reservoir impounding. Rock Mech. Rock Eng. 2017, 50, 1901–1917. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, Y.; Wang, Q.; Zhao, J.; Zhu, J.; Li, X.; Yang, Y. The propagation laws of hydraulic fractures under the influence of natural fracture zones. Phys. Fluids 2025, 37, 016616. [Google Scholar] [CrossRef]

- Li, J.; Chen, D.; Wang, E.; Yang, H.; Zhao, S.; Jia, H.; Sun, W.; Song, Y.; Fan, X. Enhanced convolutional neural network-based prediction and source mechanism interpretation of high-energy microseismic events in coal mines. Phys. Fluids 2025, 37, 046606. [Google Scholar] [CrossRef]

- Zhang, J.C. Investigations of water inrushes from aquifers under coal seams. Int. J. Rock Mech. Min. Sci. 2005, 42, 350–360. [Google Scholar] [CrossRef]

- Tang, S.; Tang, C. Numerical studies on tunnel floor heave in swelling ground under humid conditions. Int. J. Rock Mech. Min. Sci. 2012, 55, 139–150. [Google Scholar] [CrossRef]

- Li, J.; Tang, S.; Li, T.; Zhang, S.; Tang, L.; Sun, K. Study on rockburst control of deep-buried tunnel by combining advanced stress release borehole and hydraulic fracturing. Tunn. Undergr. Space Technol. 2025, 160, 106517. [Google Scholar] [CrossRef]

- Zhang, X.; Li, W.; Li, A.; Gao, F.; Zhang, N.; Li, X.; Chen, Y.; Liu, C.; Shi, C.; Han, F.; et al. Study on mine earthquake prediction based on numerical simulation of rock fracture evolution. Energy Sci. Eng. 2025, 13, 2082–2097. [Google Scholar] [CrossRef]

- Zhou, J.R.; Wei, J.; Yang, T.H.; Zhang, P.; Liu, F.; Chen, J. Seepage channel development in the crown pillar: Insights from induced microseismicity. Int. J. Rock Mech. Min. Sci. 2021, 145, 104851. [Google Scholar] [CrossRef]

- Gabry, M.A.; Gharieb, A.; Soliman, M.Y.; Eltaleb, I.; Farouq-Ali, S.; Cipolla, C. Advanced deep learning for microseismic events prediction for hydraulic fracture treatment via continuous wavelet transform. Geoenergy Sci. Eng. 2024, 239, 212983. [Google Scholar] [CrossRef]

- Cheng, J.Y.; Wang, P.; Nan, S.H.; Qin, S. Rapidly locating a water-inrush collapse column in a seam floor: A case study. Mine Water Environ. 2021, 40, 389–397. [Google Scholar] [CrossRef]

- Cheng, X.; Qiao, W.; Dou, L.; He, H.; Ju, W.; Zhang, J.; Song, S.; Cui, H.; Fang, H. In-situ stress field inversion and its impact on mining-induced seismicity. Geomatics Nat. Hazards Risk 2022, 14, 176–195. [Google Scholar] [CrossRef]

- Zuo, J.P.; Wu, G.S.; Du, J.; Lei, B.; Li, Y. Rock strata failure behavior of deep Ordovician limestone aquifer and multi-level control technology of water inrush based on microseismic monitoring and numerical methods. Rock Mech. Rock Eng. 2022, 55, 4591–4614. [Google Scholar] [CrossRef]

- Cheng, A.P.; Gao, Y.T.; Liu, C.; Chai, J.F. Microseismic monitoring and numerical simulation research of floor failure depth in extra-thick coal seam. Adv. Mater. Res. 2014, 881–883, 1799–1804. [Google Scholar] [CrossRef]

- Huang, L.; Xu, Y.; Liu, S.; Gai, Q.; Miao, W.; Li, Y.; Zhao, L. Research on the development law of pre-mining microseisms and risk assessment of floor water inrush: A case study of the Wutongzhuang coal mine in China. Sustainability 2022, 14, 9774. [Google Scholar] [CrossRef]

- Zhuang, D.; Ma, K.; Tang, C.; Cui, X.; Yang, G. Study on crack formation and propagation in the galleries of the Dagangshan high arch dam in Southwest China based on microseismic monitoring and numerical simulation. Int. J. Rock Mech. Min. Sci. 2018, 115, 157–172. [Google Scholar] [CrossRef]

- Cheng, S.; Li, S.; Li, L.; Shi, S.; Zhou, Z.; Wang, J. Study on energy band characteristic of microseismic signals in water inrush channel. J. Geophys. Eng. 2018, 15, 1826–1834. [Google Scholar] [CrossRef]

- Li, L.; Jin, H.; Chen, Y.; Cheng, S.; Hu, H.; Wang, S. Noise reduction method of microseismic signal of water inrush in tunnel based on variational mode method. Bull. Eng. Geol. Environ. 2021, 80, 6497–6512. [Google Scholar] [CrossRef]

- Xiong, W. Application of micro-seismic monitoring technology in fracturing and water injection development of horizontal wells with low permeability and thin layer. IOP Conf. Ser. Earth Environ. Sci. 2019, 252, 052018. [Google Scholar] [CrossRef]

- Xu, S.; Peng, Z.; Zheng, Q. Research on data-driven prediction of inrush probability in coal mines under the mechanism of feature reconstruction in information interconnectivity. Water 2025, 17, 843. [Google Scholar] [CrossRef]

- Cui, M.; Hou, E.; Feng, D.; Che, X.; Xie, X.; Hou, P. Identification of the water inrush source based on the deep learning model for mines in Shaanxi, China. Mine Water Environ. 2025, 44, 133–148. [Google Scholar] [CrossRef]

- Ye, Z.; Tang, S.; Ke, S.; Tang, X. An evaluation of the mine water inrush based on the deep learning of ISMOTE. Nat. Hazards 2023, 117, 1475–1491. [Google Scholar] [CrossRef]

- Konicek, P.; Waclawik, P. Stress changes and seismicity monitoring of hard coal longwall mining in high rockburst risk areas. Tunn. Undergr. Space Technol. 2018, 81, 237–251. [Google Scholar] [CrossRef]

- Duan, H.F.; Zhao, L.J. New evaluation and prediction method to determine the risk of water inrush from mining coal seam floor. Environ. Earth Sci. 2021, 80, 30. [Google Scholar] [CrossRef]

- Gao, R.; Yan, H.; Ju, F.; Mei, X.; Wang, X. Influential factors and control of water inrush in a coal seam as the main aquifer. Int. J. Min. Sci. Technol. 2018, 28, 187–193. [Google Scholar] [CrossRef]

- Gao, X.; Hao, X.; Ji, J.; Lü, W.; Yang, H.; Li, H.; Chu, F.; Li, Y. Study on the structural evolution model and pressure relief effect of whole-layer pre-fracture in high-level key strata. J. China Coal Soc. 2025, 49, 1–13. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, L.; Cong, P. The predication of No.16 coal seam water inflow of Hegang coal mine. Shandong Coal Sci. Technol. 2016, 3, 140–142. [Google Scholar]

- Mu, W.; Li, L.; Zhang, Y.; Yu, G.; Ren, B. Failure mechanism of grouted floor with confined aquifer based on mining-induced data. Rock Mech. Rock Eng. 2023, 56, 2897–2922. [Google Scholar] [CrossRef]

- Hao, X.; Li, H.; Zhao, Y.; Yang, H.; Yang, B.; Liu, K.; Li, Y. An early warning method and application of water inrush from coal mining floor based on the correlation effect between daily cumulative micro-seismic indicators and water level. Chin. J. Rock Mech. Eng. 2024, 43, 2125–2139. [Google Scholar] [CrossRef]

- Shi, H.; Jin, Z. Multi-condition magnetic core loss prediction and magnetic component performance optimization based on improved deep forest. IEEE Access. 2025, 13, 82261–82277. [Google Scholar] [CrossRef]

- Mathew, M.; Chakrabortty, R.K.; Ryan, M.J. A novel approach integrating AHP and TOPSIS under spherical fuzzy sets for advanced manufacturing system selection. Eng. Appl. Artif. Intell. 2020, 96, 103988. [Google Scholar] [CrossRef]

- Ma, H.; Peng, T.; Zhang, C.; Ji, C.; Li, Y.; Nazir, M.S. Developing an evolutionary deep learning framework with random forest feature selection and improved flow direction algorithm for NOx concentration prediction. Eng. Appl. Artif. Intell. 2023, 123, 106367. [Google Scholar] [CrossRef]

| Indicator Combination | F-Value | Indicator Combination | F-Value |

|---|---|---|---|

| MS energy, Borehole 1, Borehole 2, Borehole 3 | 0.6860 | MS energy, MS frequency, Borehole 3 | 0.5109 |

| MS energy, Borehole 1, Borehole 3 | 0.6763 | MS energy, Borehole 3 | 0.4636 |

| MS energy, MS frequency, Borehole 1, Borehole 3 | 0.6757 | Borehole 1, Borehole 3 | 0.4551 |

| MS energy, MS frequency, Borehole 1, Borehole 2, Borehole 3 | 0.6399 | MS frequency, Borehole 1, Borehole 2, Borehole 3 | 0.4541 |

| MS energy, Borehole 1, Borehole 2 | 0.5134 | MS frequency, Borehole 1, Borehole 3 | 0.4322 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Li, Y.; Lin, W.; Yang, H.; Liu, K. Application of Multi-Sensor Data Fusion and Machine Learning for Early Warning of Cambrian Limestone Water Hazards. Sensors 2025, 25, 6854. https://doi.org/10.3390/s25226854

Li H, Li Y, Lin W, Yang H, Liu K. Application of Multi-Sensor Data Fusion and Machine Learning for Early Warning of Cambrian Limestone Water Hazards. Sensors. 2025; 25(22):6854. https://doi.org/10.3390/s25226854

Chicago/Turabian StyleLi, Hang, Yijia Li, Wantong Lin, Huaixiang Yang, and Kefeng Liu. 2025. "Application of Multi-Sensor Data Fusion and Machine Learning for Early Warning of Cambrian Limestone Water Hazards" Sensors 25, no. 22: 6854. https://doi.org/10.3390/s25226854

APA StyleLi, H., Li, Y., Lin, W., Yang, H., & Liu, K. (2025). Application of Multi-Sensor Data Fusion and Machine Learning for Early Warning of Cambrian Limestone Water Hazards. Sensors, 25(22), 6854. https://doi.org/10.3390/s25226854