Response and Flow Characteristics of an Angular Momentum Flowmeter

Abstract

1. Introduction

2. Experimental Schemes and Mathematical Models

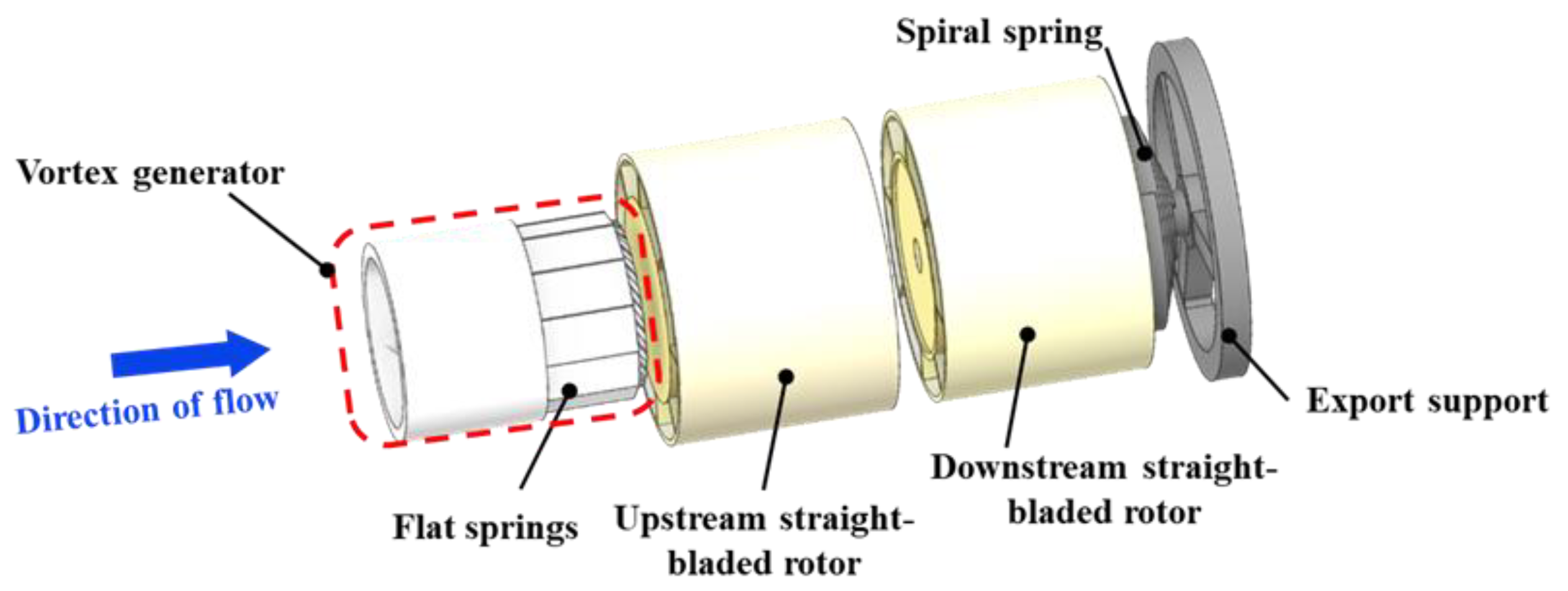

2.1. Structure of the Angular Momentum Flowmeter

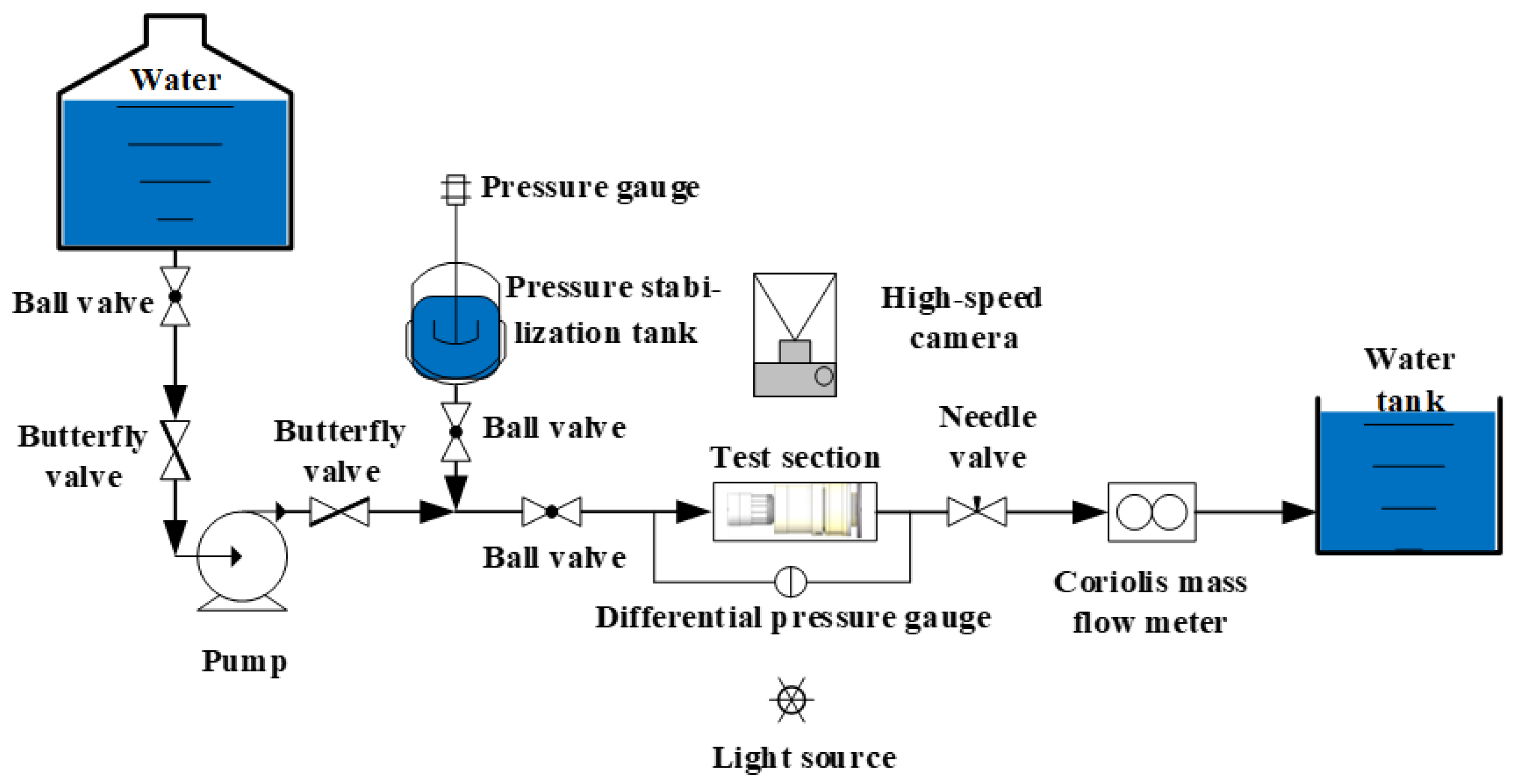

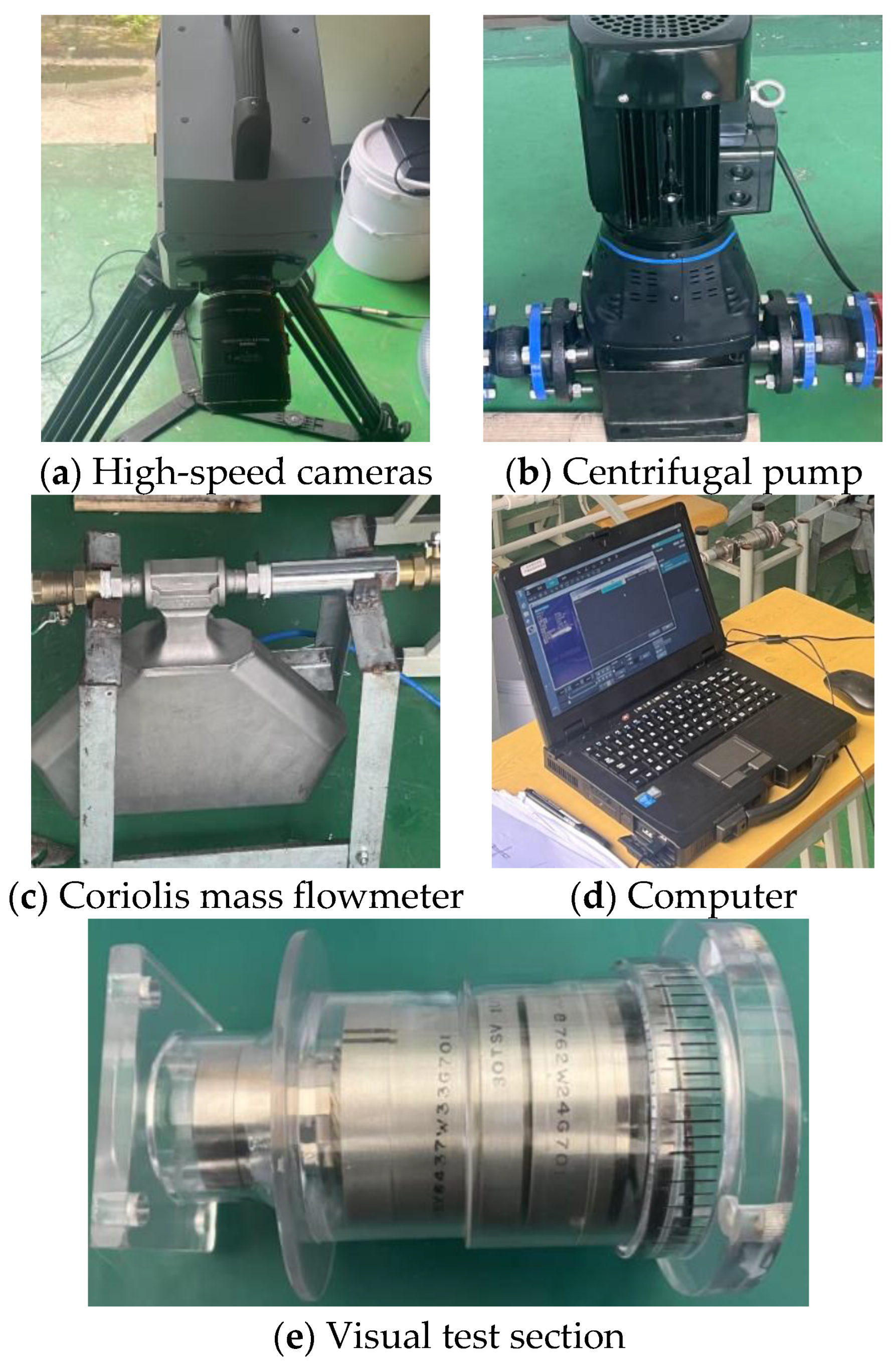

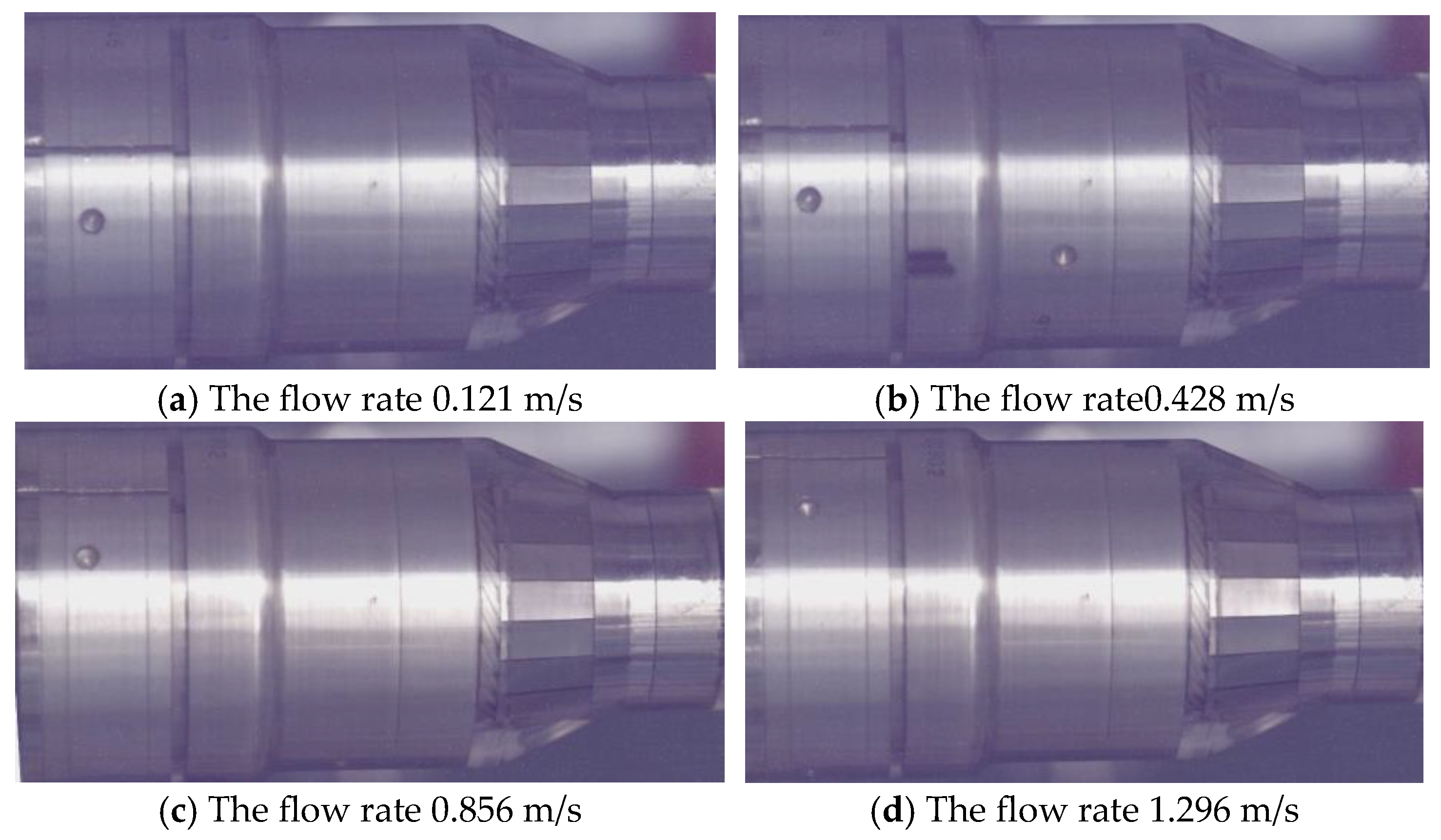

2.2. Experimental Schemes

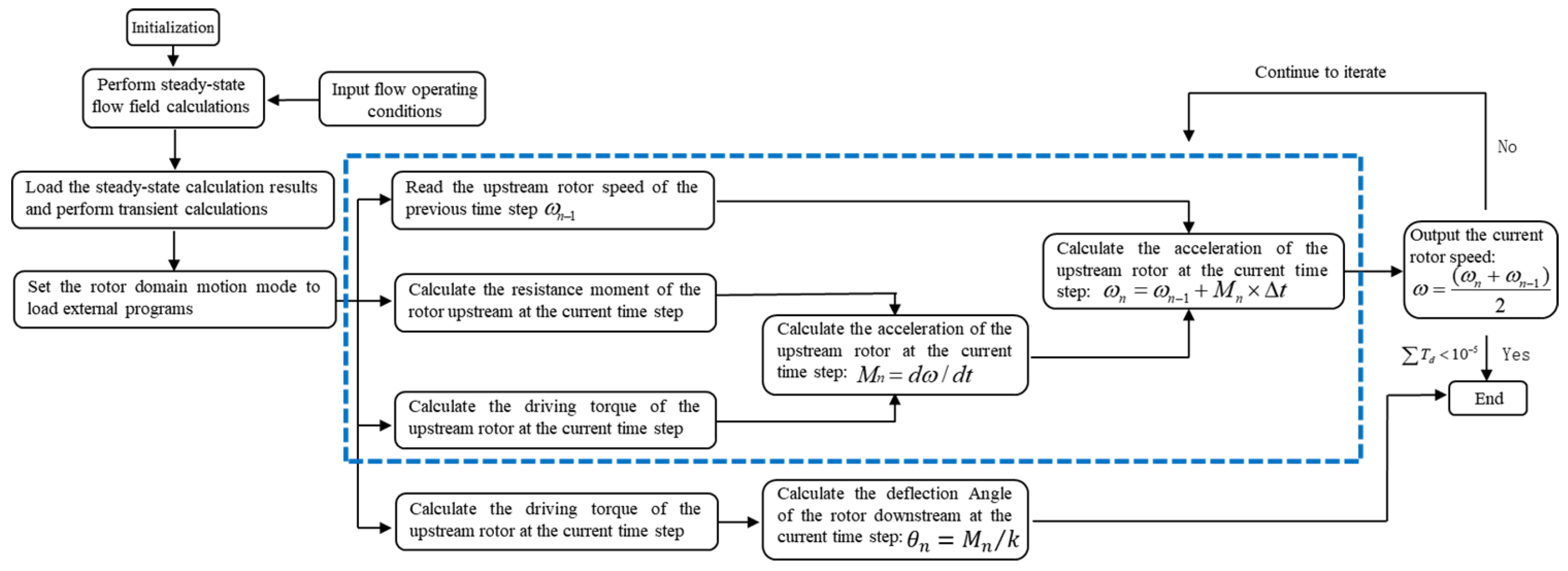

2.3. Mathematical Model

3. Numerical Modeling

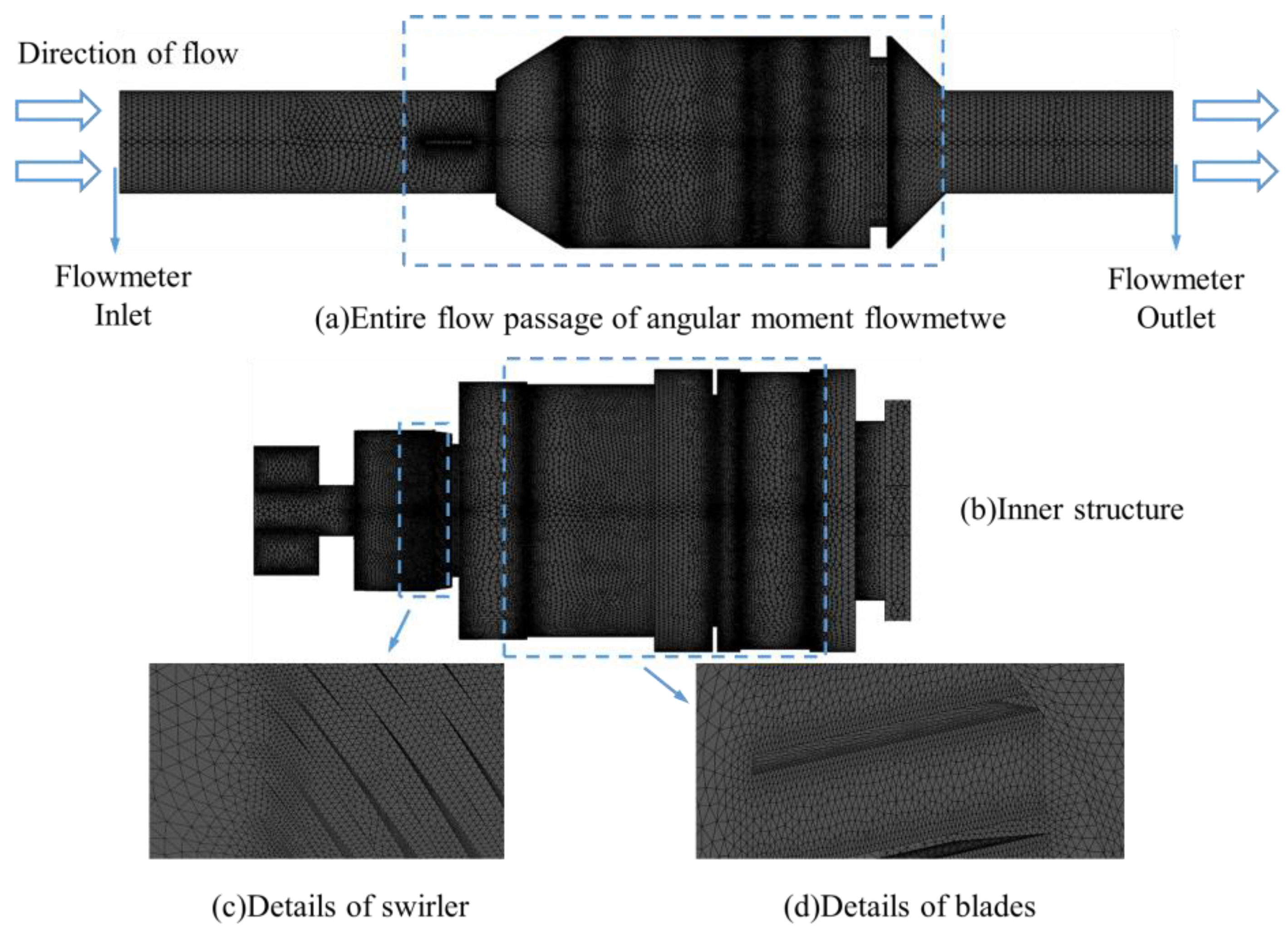

3.1. Computational Model and Grid

3.2. Turbulence Model

3.3. Numerical Methods and Boundary Conditions

3.4. Grid Independence Test

4. Results and Discussion

4.1. Response of the Angular Moment Flowmeter

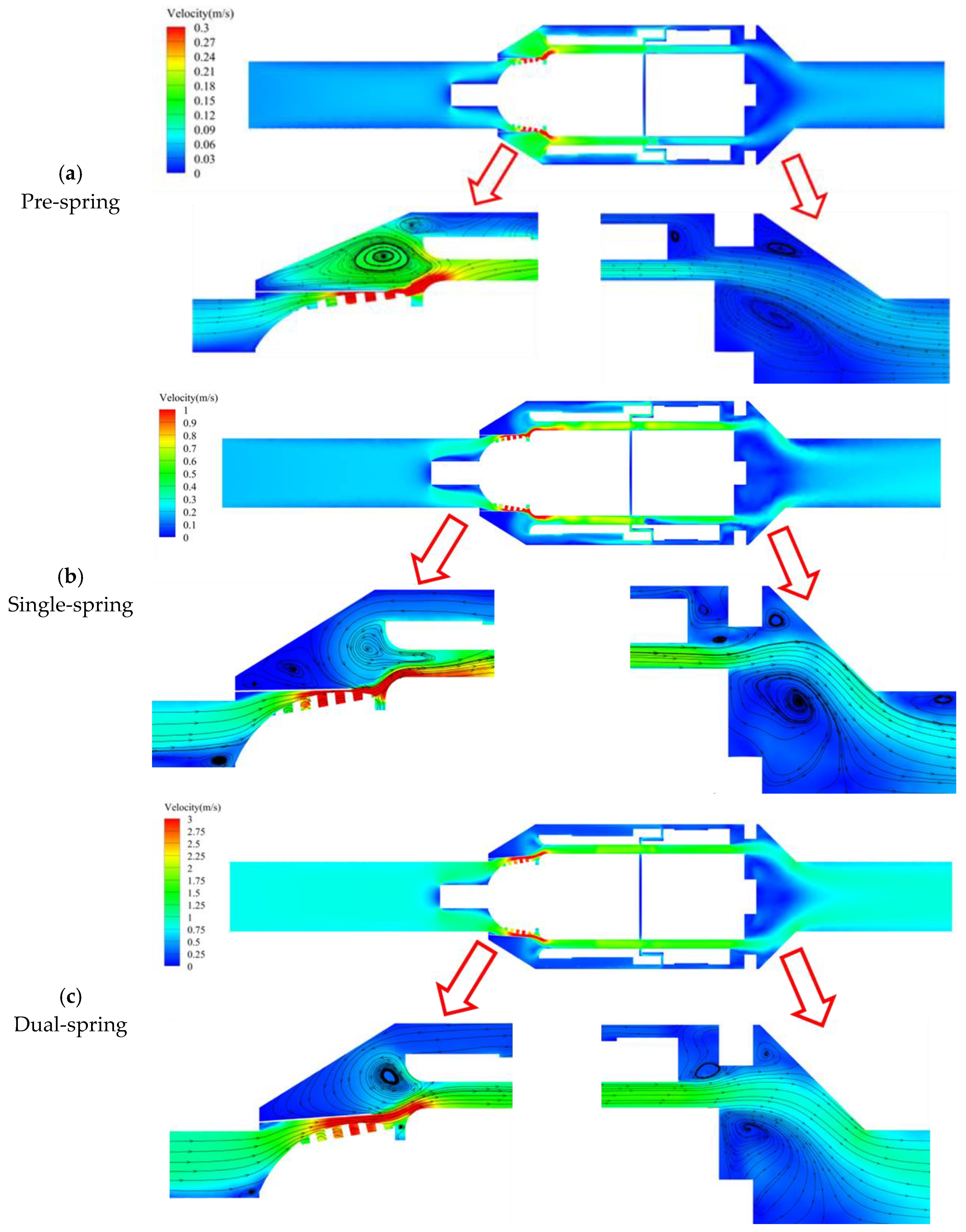

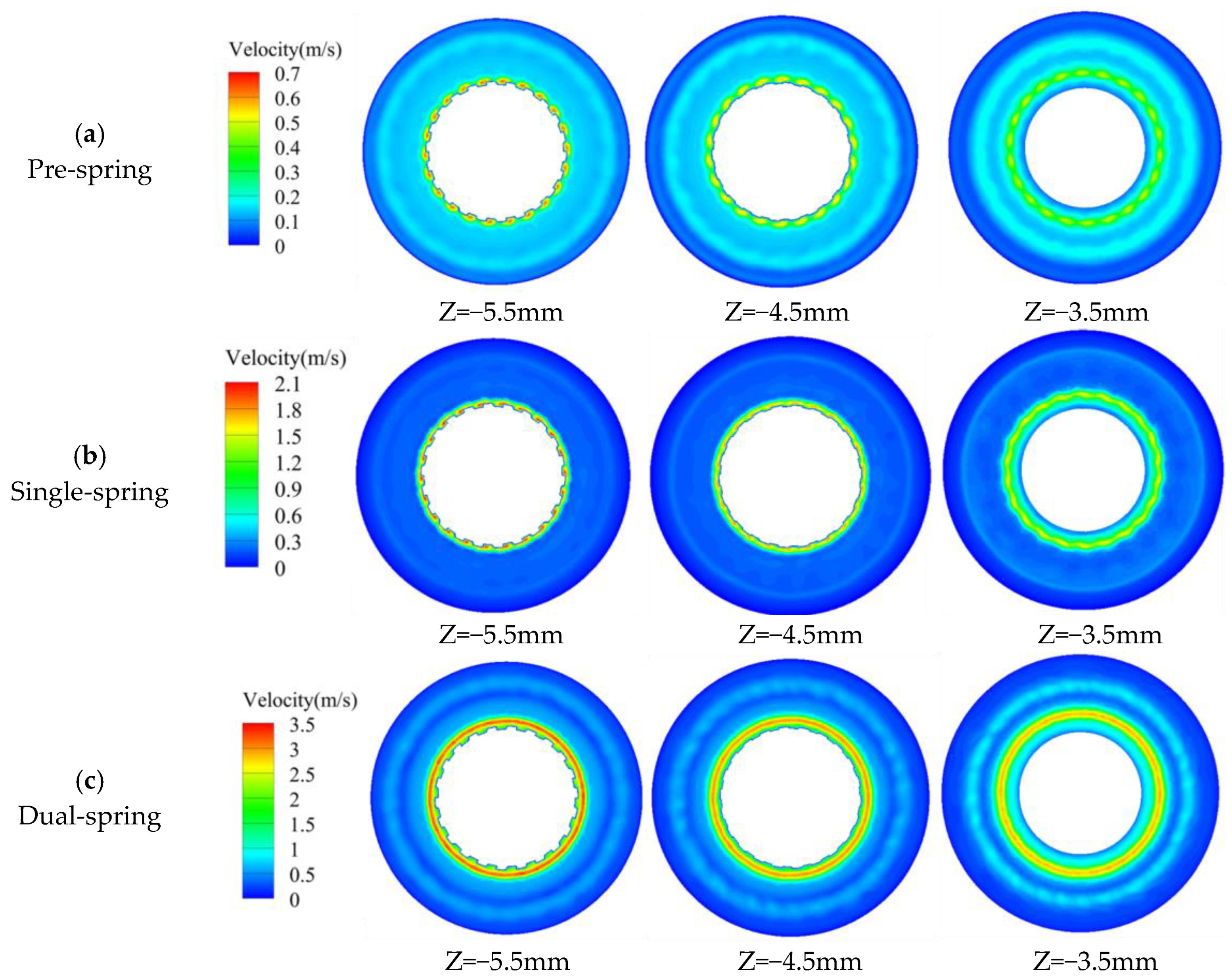

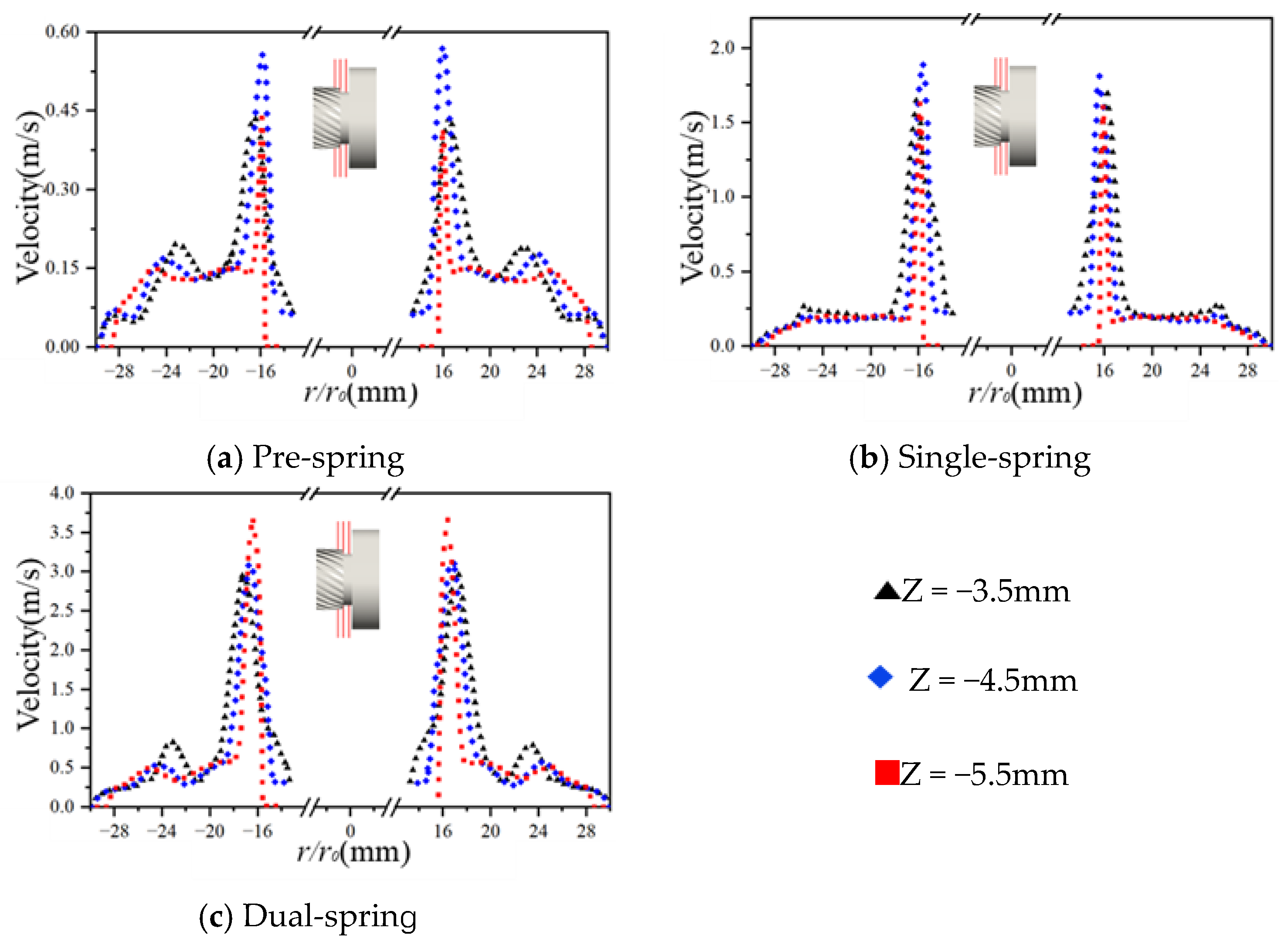

4.2. Comparative Analysis of Three Distinct Operational Regimes

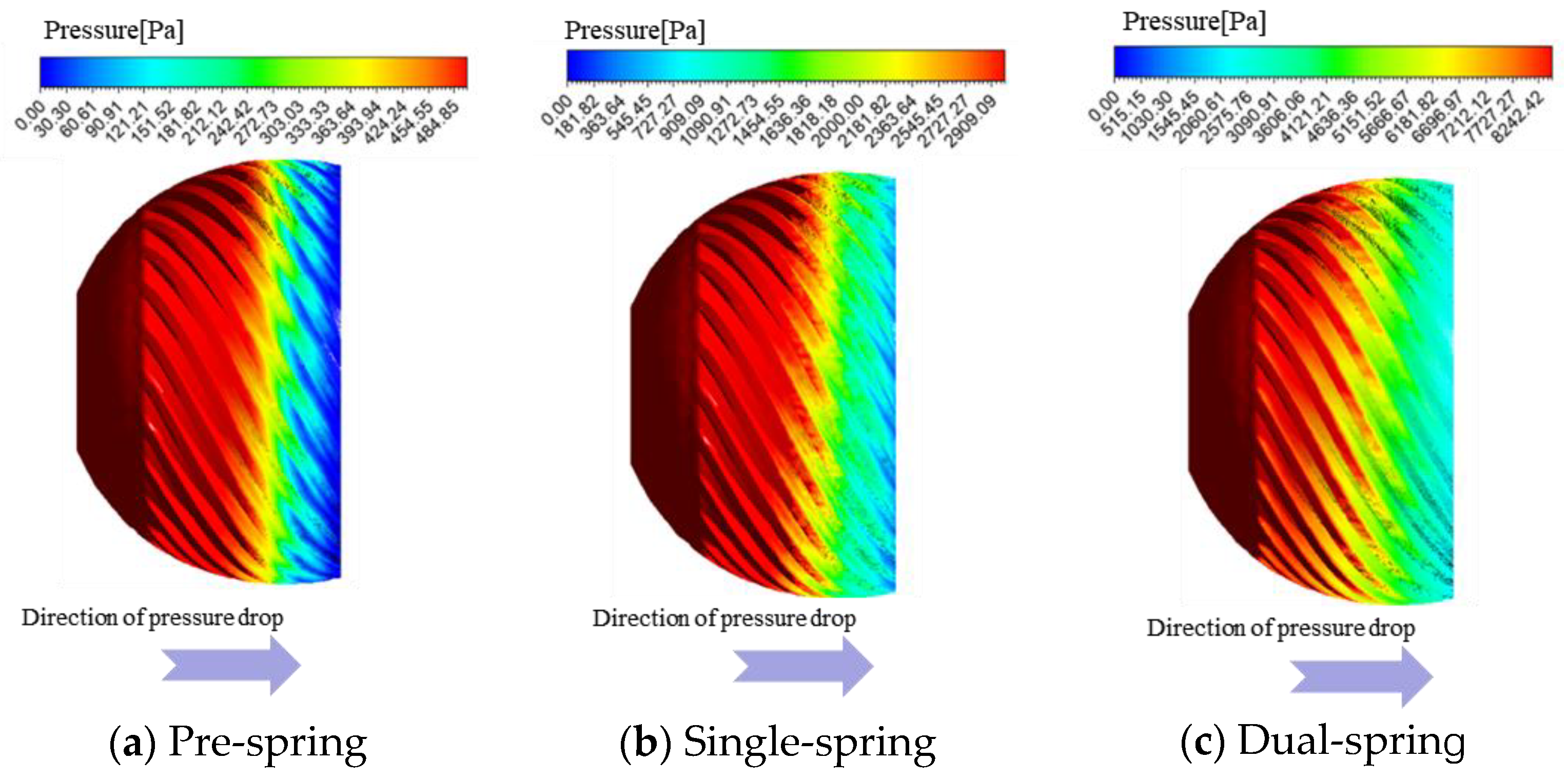

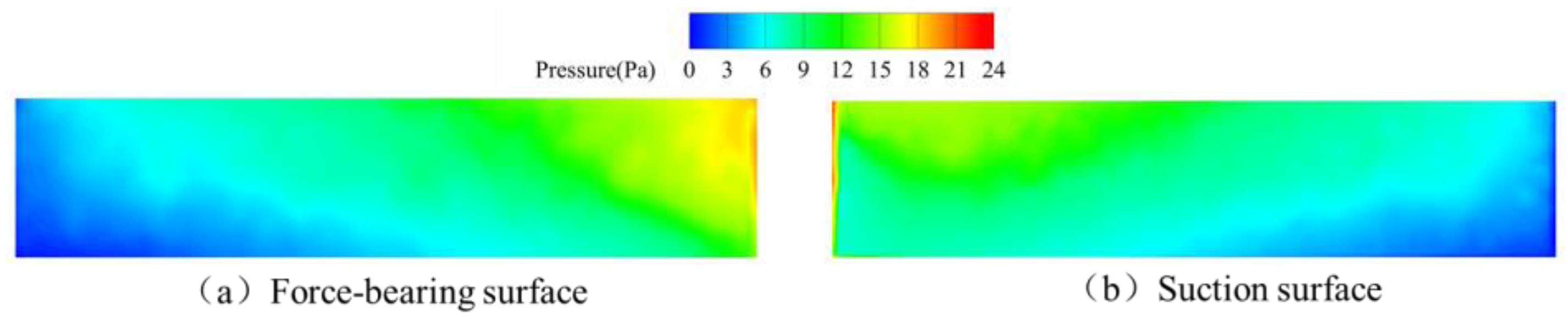

4.3. Comparative Analysis of Angular Moment Flowmeter

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, Y.; Hou, M.J.; Chen, M.; Guo, J. Design and Verification of an In-Situ Calibration System for Aero-Engine Fuel Flow Rate Measurement in Altitude Simulation Test. Gas Turbine Exp. Res. 2013, 26, 5–8+39. [Google Scholar]

- Chun-Yu, S. Measurement Technology of Fuel Flow under Low Temperature Starting in Semi-physical Test. Aeroengine 2016, 42, 1–8. [Google Scholar]

- Chen, B.; Li, C.; Li, Y.; Wang, A. Reliability Analysis Method of an Aircraft Engine FADEC System. In Proceedings of the 8th International Conference on Reliability, Maintainability and Safety (ICRMS 2009), Chengdu, China, 20–24 July 2009. [Google Scholar]

- Bazazzade, M.; Shahriari, A.; Badihi, H. Improved Turbine Engine Hierarchical Modeling and Simulation Based on Engine Fuel Control System. In Proceedings of the 45th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Denver, CO, USA, 2–5 August 2009. [Google Scholar]

- Weeks, R.W.; Moskwa, J.J. Automotive Engine Modeling for Real-Time Control Using MATLAB/SIMULINK. In Proceedings of the 1995 SAE International Congress and Exposition, Detroit, MI, USA, 27 February–2 March 1995. [Google Scholar]

- Bennett, E.J. Accurate measurement of flow by turbine flowmeters. Meas. Control 1979, 12, 49–54. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhang, T. Research on the dynamic characteristics of a turbine flow meter. Flow Meas. Instrum. 2017, 55, 59–66. [Google Scholar] [CrossRef]

- Guo, S.; Sun, L.; Zhang, T.; Yang, W.; Yang, Z. Analysis of viscosity effect on turbine flowmeter performance based on experiments and CFD simulations. Flow Meas. Instrum. 2013, 34, 42–52. [Google Scholar] [CrossRef]

- Stoltenkamp, P.W.; Araujo, S.B.; Riezebos, H.J.; Mulder, J.; Hirschberg, A. Spurious counts in gas volume flow measurements by means of turbine meters. J. Fluids Struct. 2003, 18, 771–781. [Google Scholar] [CrossRef]

- Vemulapalli, S.; Venkata, S.K. Parametric analysis of orifice plates on measurement of flow: A review. Ain Shams Eng. J. 2022, 13, 101639. [Google Scholar] [CrossRef]

- Tomaszewska-Wach, B. Numerical Analysis of the Differential Flowmeter: Standard Orifice and Slotted Orifices. Energies 2023, 16, 5573. [Google Scholar] [CrossRef]

- Campos, S.R.V.; Baliño, J.L.; Slobodcicov, I.; Filho, D.; Paz, E. Orifice plate meter field performance: Formulation and validation in multiphase flow conditions. Exp. Therm. Fluid Sci. 2014, 58, 93–104. [Google Scholar] [CrossRef]

- Weise, J.; Baliño, J.L.; Paladino, E.E. CFD study of the transient wet gas flow behavior through orifice plate flow meters. Flow Meas. Instrum. 2021, 82, 102077. [Google Scholar] [CrossRef]

- Afandi, A.; Catrawedarma, I.; Wijayanta, S. The development of the ultrasonic flowmeter sensors for mass flow rate measurement: A comprehensive review. Flow Meas. Instrum. 2024, 97, 102614. [Google Scholar] [CrossRef]

- Willatzen, M. Ultrasonic flowmeters: Temperature gradients and transducer geometry effects. Ultrasonics 2003, 41, 105–114. [Google Scholar] [CrossRef]

- Leontidis, V.; Cuvier, C.; Caignaert, G.; Dupont, P.; Roussette, O.; Fammery, S.; Nivet, P.; Dazin, A. Experimental validation of an ultrasonic flowmeter for unsteady flows. Meas. Sci. Technol. 2018, 29, 045303. [Google Scholar] [CrossRef]

- Rincón, M.; Reclari, M.; Abkar, M. Turbulent flow in small-diameter ultrasonic flow meters: A numerical and experimental study. Flow Meas. Instrum. 2022, 87, 102227. [Google Scholar] [CrossRef]

- Zhai, H.; Song, X.; Wang, X.; Liu, G. Design of a Flow Automatic Calibration System Based on the Master Meter and Dynamic Weighing Methods. IEEE Access 2024, 12, 37141–37151. [Google Scholar] [CrossRef]

- Bobovnik, G.; Kutin, J.; Bajsić, I. The effect of flow conditions on the sensitivity of the Coriolis flowmeter. Flow Meas. Instrum. 2004, 15, 69–76. [Google Scholar] [CrossRef]

- Shavrina, E.; Nguyen, V.T.; Yan, Z.; Khoo, B.C. Fluid-solid interaction simulation methodology for coriolis flowmeter operation analysis. Sensors 2021, 21, 8105. [Google Scholar] [CrossRef] [PubMed]

- Romanov, V.A. Effects of dissipative forces on Coriolis flowmeter readings. Flow Meas. Instrum. 2022, 86, 102202. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, H.; Lyu, M.; Lai, Y.; Dong, Z. Experimental and numerical study on a novel thermal mass flowmeter that is insensitive to radial flow velocity distribution. Flow Meas. Instrum. 2023, 90, 102315. [Google Scholar] [CrossRef]

- Bekraoui, A.; Hadjadj, A. Thermal flow sensor used for thermal mass flowmeter. Microelectron. J. 2020, 103, 104871. [Google Scholar] [CrossRef]

- Yu, Y.M.; He, Z.H.; Roesler, H.; Solano, C.; Zhang, Z. Design and application of thermal mass flow meter in space. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2020, 950, 163003. [Google Scholar] [CrossRef]

- Wang, T.; Xuan, Y.; Han, X. Investigation on hybrid thermal features of aero-engines from combustor to turbine. Int. J. Heat Mass Transf. 2023, 200, 123559. [Google Scholar] [CrossRef]

- Chen, M.; Jiang, W.; Liu, W.; Zhang, T.; Wang, J. Research on V cone flowmeter used for jet fuel flowrate measurement. J. Electron. Meas. Instrum. 2016, 30, 1167–1174. [Google Scholar]

- Ren, Z.; Zhou, W.; Li, D.J.F.M. Instrumentation. Response and flow characteristics of a dual-rotor turbine flowmeter. Flow Meas. Instrum. 2022, 83, 102120. [Google Scholar] [CrossRef]

- Menter, F.R.; Garbaruk, A.V.; Egorov, Y. Explicit algebraic Reynolds stress models for anisotropic wall-bounded flows. Prog. Flight Phys. 2012, 3, 89–104. [Google Scholar]

| Name | Moving Reference Frame | Dynamic Mesh | Sliding Mesh | |

|---|---|---|---|---|

| Feature | ||||

| Time form | Steady state | Transient | Transient | |

| Form of movement | Simple rotation/translation | Arbitrary deformation/fluid–structure coupling | Complex rotation/translation | |

| Computational efficiency | High (second-level convergence) | Low (Sky level) | Medium (hourly level) | |

| Grid processing | Do not deform | Deformation or reconstruction | Sliding without deformation | |

| Title 1 | Set1 | Set2 | Set3 | Set4 | Set5 |

|---|---|---|---|---|---|

| Number of elements | 3.47 | 4.78 | 5.25 | 6.89 | 7.92 |

| Flow [kg/s] | Velocity [m/s] | Flat Spring Opening Degree [°] | Rotor Speed [rpm] | The Deflection Angle of the Spiral Spring [°] |

|---|---|---|---|---|

| 0.050 | 0. 027 | -- | -- | -- |

| 0.062 | 0.041 | -- | 9.98 | -- |

| 0.091 | 0.121 | -- | 41.9 | -- |

| 0.104 | 0.428 | -- | 197.4 | 13.20 |

| 0.208 | 0.856 | 2.8 | 242 | 30.64 |

| 0.315 | 1.296 | 3.9 | 250 | 46.40 |

| 0.401 | 1.645 | 4.7 | 250.3 | 58.92 |

| 0.504 | 2.074 | 5.4 | 249.9 | 74.24 |

| 0.601 | 2.469 | 6.3 | 242.2 | 88.38 |

| 0.718 | 2.954 | 6.9 | 250 | 105.76 |

| 0.810 | 3.313 | 7.6 | 242 | 119.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zan, H.; Jia, Q.; Liu, C.; Liu, J.; Huang, F.; Zhou, S. Response and Flow Characteristics of an Angular Momentum Flowmeter. Sensors 2025, 25, 6728. https://doi.org/10.3390/s25216728

Zan H, Jia Q, Liu C, Liu J, Huang F, Zhou S. Response and Flow Characteristics of an Angular Momentum Flowmeter. Sensors. 2025; 25(21):6728. https://doi.org/10.3390/s25216728

Chicago/Turabian StyleZan, Hao, Qiusheng Jia, Chengli Liu, Jiabao Liu, Fuji Huang, and Shenmei Zhou. 2025. "Response and Flow Characteristics of an Angular Momentum Flowmeter" Sensors 25, no. 21: 6728. https://doi.org/10.3390/s25216728

APA StyleZan, H., Jia, Q., Liu, C., Liu, J., Huang, F., & Zhou, S. (2025). Response and Flow Characteristics of an Angular Momentum Flowmeter. Sensors, 25(21), 6728. https://doi.org/10.3390/s25216728