Design and Implementation of a Cost-Effective IoT-Based Monitoring and Alerting System for Recirculating Aquaculture Systems (RAS)

Highlights

- The developed IoT monitoring system is highly accurate and reliable.

- The system’s integrated alerting function proved critical for operational reliability.

- The system enables proactive aquaculture management.

- It provides a validated, scalable blueprint for precision aquaculture.

Abstract

1. Introduction

2. Materials and Methods

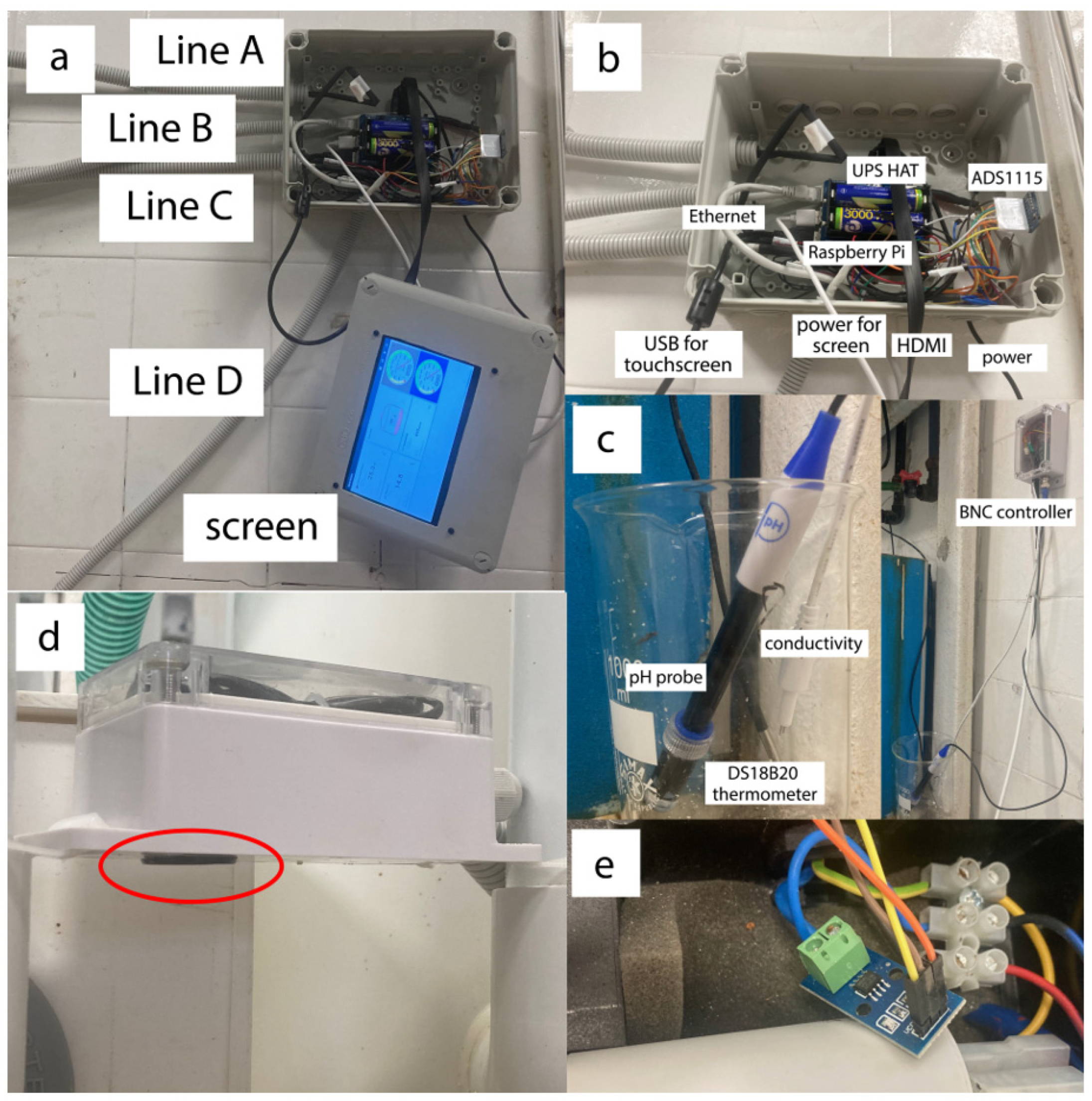

2.1. Hardware

2.2. Operational Workflow and Error Handling

2.3. Experimental Implementation

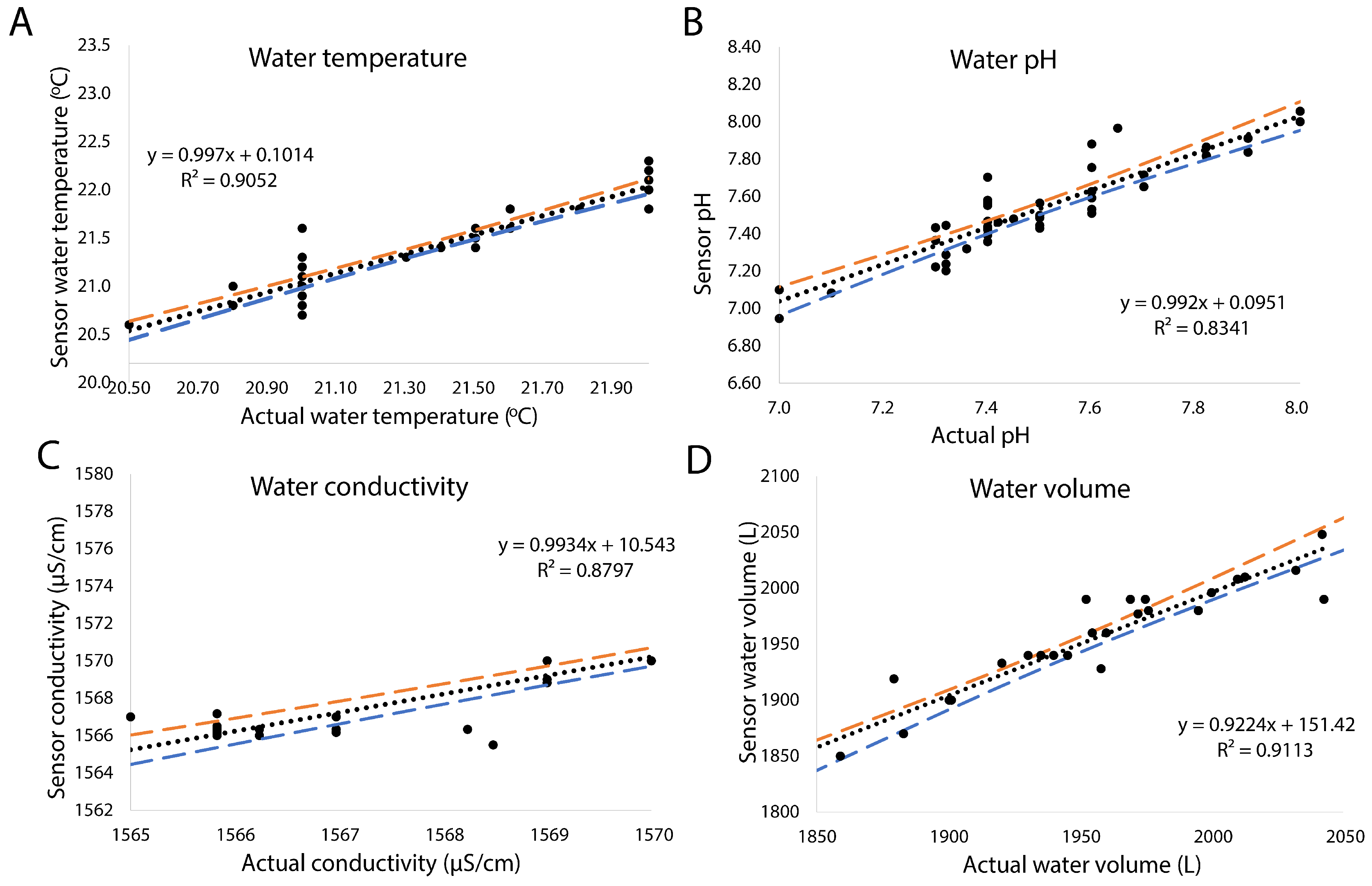

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ADC | Analog-to-Digital Converter |

| API | Application Programming Interface |

| CSV | Comma-Separated Value |

| DO | Dissolved Oxygen |

| GPIO | General Purpose Input/Output |

| GUI | Graphical User Interface |

| IoT | Internet of Things |

| MAE | Mean Absolute Error |

| HTTPS | Hypertext Transfer Protocol Secure |

| ORP | Oxidation–Reduction Potential |

| RAS | Recirculating Aquaculture System |

| RMSE | Root Mean Square Error |

| RPM | Revolutions Per Minute |

| UI | User Interface |

| UPS HAT | Uninterruptible Power Supply Hardware Attached on Top |

| USB | Universal Serial Bus |

| VNC | Virtual Network Computing |

References

- FAO. The State of World Fisheries and Aquaculture 2022; FAO: Rome, Italy, 2022; ISBN 978-92-5-136364-5. [Google Scholar]

- Martins, C.I.M.; Eding, E.H.; Verdegem, M.C.J.; Heinsbroek, L.T.N.; Schneider, O.; Blancheton, J.P.; d’Orbcastel, E.R.; Verreth, J.A.J. New Developments in Recirculating Aquaculture Systems in Europe: A Perspective on Environmental Sustainability. Aquac. Eng. 2010, 43, 83–93. [Google Scholar] [CrossRef]

- Ebeling, J.M.; Timmons, M.B. Recirculating Aquaculture; Cayuga Aqua Ventures: Ithaca, NY, USA, 2010. [Google Scholar]

- Flores-Iwasaki, M.; Guadalupe, G.A.; Pachas-Caycho, M.; Chapa-Gonza, S.; Mori-Zabarburú, R.C.; Guerrero-Abad, J.C. Internet of Things (IoT) Sensors for Water Quality Monitoring in Aquaculture Systems: A Systematic Review and Bibliometric Analysis. AgriEngineering 2025, 7, 78. [Google Scholar] [CrossRef]

- Boyd, C.E.; Tucker, C.S. Pond Aquaculture Water Quality Management; Springer Science & Business Media: New York, NY, USA, 2012; ISBN 978-1-4615-5407-3. [Google Scholar]

- Liu, Y.; Ma, X.; Shu, L.; Hancke, G.P.; Abu-Mahfouz, A.M. From Industry 4.0 to Agriculture 4.0: Current Status, Enabling Technologies, and Research Challenges. IEEE Trans. Ind. Inform. 2021, 17, 4322–4334. [Google Scholar] [CrossRef]

- Shete, R.P.; Bongale, A.M.; Dharrao, D. IoT-Enabled Effective Real-Time Water Quality Monitoring Method for Aquaculture. MethodsX 2024, 13, 102906. [Google Scholar] [CrossRef] [PubMed]

- Muangprathub, J.; Boonnam, N.; Kajornkasirat, S.; Lekbangpong, N.; Wanichsombat, A.; Nillaor, P. IoT and Agriculture Data Analysis for Smart Farm. Comput. Electron. Agric. 2019, 156, 467–474. [Google Scholar] [CrossRef]

- Salehin, S.; Meem, T.A.; Islam, A.J.; Al Islam, N. Design and Development of a Low-Cost IoT-Based Water Quality Monitoring System. In Proceedings of the Fourth Industrial Revolution and Beyond; Hossain, M.S., Majumder, S.P., Siddique, N., Hossain, M.S., Eds.; Springer Nature: Singapore, 2023; pp. 709–721. [Google Scholar]

- Design of IoT-Based Monitoring System for Temperature and Dissolved Oxygen Levels in Catfish Aquaculture Pond Water. Available online: https://www.researchgate.net/publication/382741741_Design_of_IoT-based_monitoring_system_for_temperature_and_dissolved_oxygen_levels_in_catfish_aquaculture_pond_water (accessed on 28 August 2025).

- Islam, M.M.; Kashem, M.A.; Alyami, S.A.; Moni, M.A. Monitoring Water Quality Metrics of Ponds with IoT Sensors and Machine Learning to Predict Fish Species Survival. Microprocess. Microsyst. 2023, 102, 104930. [Google Scholar] [CrossRef]

- Al Mamun, M.R.; Ashik-E-Rabbani, M.; Haque, M.M.; Upoma, S.M. IoT-Based Real-Time Biofloc Monitoring and Controlling System. Smart Agric. Technol. 2024, 9, 100598. [Google Scholar] [CrossRef]

- Bórquez López, R.A.; Martinez Cordova, L.R.; Gil Nuñez, J.C.; Gonzalez Galaviz, J.R.; Ibarra Gamez, J.C.; Casillas Hernandez, R. Implementation and Evaluation of Open-Source Hardware to Monitor Water Quality in Precision Aquaculture. Sensors 2020, 20, 6112. [Google Scholar] [CrossRef]

- Pasika, S.; Gandla, S.T. Smart Water Quality Monitoring System with Cost-Effective Using IoT. Heliyon 2020, 6, e04096. [Google Scholar] [CrossRef]

- Mohd Jais, N.A.; Abdullah, A.F.; Mohd Kassim, M.S.; Abd Karim, M.M.; M, A.; Muhadi, N. ‘Atirah Improved Accuracy in IoT-Based Water Quality Monitoring for Aquaculture Tanks Using Low-Cost Sensors: Asian Seabass Fish Farming. Heliyon 2024, 10, e29022. [Google Scholar] [CrossRef]

- Palconit, M.G.B.; Concepcion, R.S.; Tobias, R.R.; Alejandrino, J.; Almero, V.J.D.; Bandala, A.A.; Vicerra, R.R.P.; Sybingco, E.; Dadios, E.P. Development of IoT-Based Fish Tank Monitoring System. In Proceedings of the 2021 IEEE 13th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Manila, Philippines, 28–30 November 2021; pp. 1–6. [Google Scholar]

- Chen, C.-H.; Wu, Y.-C.; Zhang, J.-X.; Chen, Y.-H. IoT-Based Fish Farm Water Quality Monitoring System. Sensors 2022, 22, 6700. [Google Scholar] [CrossRef]

- Parra, L.; Sendra, S.; García, L.; Lloret, J. Design and Deployment of Low-Cost Sensors for Monitoring the Water Quality and Fish Behavior in Aquaculture Tanks during the Feeding Process. Sensors 2018, 18, 750. [Google Scholar] [CrossRef]

- Fu, S.; Xing, W.; Wu, J.; Chen, J.; Liu, S. Research and Design of an Intelligent Fish Tank System. PLoS ONE 2023, 18, e0285105. [Google Scholar] [CrossRef]

- Lin, J.-Y.; Tsai, H.-L.; Lyu, W.-H. An Integrated Wireless Multi-Sensor System for Monitoring the Water Quality of Aquaculture. Sensors 2021, 21, 8179. [Google Scholar] [CrossRef]

- Lafont, M.; Dupont, S.; Cousin, P.; Vallauri, A.; Dupont, C. Back to the Future: IoT to Improve Aquaculture: Real-Time Monitoring and Algorithmic Prediction of Water Parameters for Aquaculture Needs. In Proceedings of the 2019 Global IoT Summit (GIoTS), Aarhus, Denmark, 17–21 June 2019; pp. 1–6. [Google Scholar]

- Lee, J.; Angani, A.; Thalluri, T.; Shin, K.J. Realization of Water Process Control for Smart Fish Farm. In Proceedings of the 2020 International Conference on Electronics, Information, and Communication (ICEIC), Barcelona, Spain, 19–22 January 2020; pp. 1–5. [Google Scholar]

- De Paolis, L.T.; De Luca, V.; Paiano, R. Sensor Data Collection and Analytics with Thingsboard and Spark Streaming. In Proceedings of the 2018 IEEE Workshop on Environmental, Energy, and Structural Monitoring Systems (EESMS), Salerno, Italy, 21–22 June 2018; pp. 1–6. [Google Scholar]

- Zuhaer, A.; Khandoker, A.; Enayet, N.; Partha, P.K.P.; Awal, M.A. Sustainable Aquaculture: An IoT-Integrated System for Real-Time Water Quality Monitoring Featuring Advanced DO and Ammonia Sensors. Aquac. Eng. 2025, 112, 102620. [Google Scholar] [CrossRef]

- Biazi, V.; Marques, C. Industry 4.0-Based Smart Systems in Aquaculture: A Comprehensive Review. Aquac. Eng. 2023, 103, 102360. [Google Scholar] [CrossRef]

- Saad, A.; Baikas, A.; Remen, M.; Bjørnson, F.O. Optimizing Feeding Strategies in Aquaculture Using Machine Learning: Ensuring Sustainable and Economically Viable Fish Farming Practices. Procedia Comput. Sci. 2024, 246, 4712–4721. [Google Scholar] [CrossRef]

- Li, W.Y.; Li, T.K.; Liao, Z.H.; Wu, Q.X.; Lin, J.Q.; Wu, T.; Lin, L.; Xu, H.X.; Yang, L.; Zou, J. Multi-Model Fusion Method for Detecting the Feeding Behavior of Sea Bass. Int. J. Mach. Learn. Cybern. 2025. [Google Scholar] [CrossRef]

- Mustapha, U.F.; Alhassan, A.-W.; Jiang, D.-N.; Li, G.-L. Sustainable Aquaculture Development: A Review on the Roles of Cloud Computing, Internet of Things and Artificial Intelligence (CIA). Rev. Aquac. 2021, 13, 2076–2091. [Google Scholar] [CrossRef]

- Wang, C.; Li, Z.; Wang, T.; Xu, X.; Zhang, X.; Li, D. Intelligent Fish Farm—The Future of Aquaculture. Aquac. Int. 2021, 29, 2681–2711. [Google Scholar] [CrossRef] [PubMed]

- Ahmad dar, S.; Kumar, S.; Saini, V.P. Smart Fish Feeding System in Aquaculture. In Information Technology in Fisheries and Aquaculture; Ganie, P.A., Posti, R., Pandey, P.K., Eds.; Springer Nature: Singapore, 2025; pp. 123–133. ISBN 978-981-97-8553-7. [Google Scholar]

- Kassem, T.; Shahrour, I.; El Khattabi, J.; Raslan, A. Smart and Sustainable Aquaculture Farms. Sustainability 2021, 13, 10685. [Google Scholar] [CrossRef]

- Brown, A.R.; Wilson, R.W.; Tyler, C.R. Assessing the Benefits and Challenges of Recirculating Aquaculture Systems (RAS) for Atlantic Salmon Production. Rev. Fish. Sci. Aquac. 2025, 33, 380–401. [Google Scholar] [CrossRef]

| Parameter | Sensor Mean | Reference Mean | Expanded Uncertainty (U) (k = 2) | Mean Absolute Error (MAE) | Root Mean Square Error (RMSE) | R2 |

|---|---|---|---|---|---|---|

| Temperature | 21.43 ± 0.49 °C | 21.36 ± 0.46 °C | 0.096 °C | 0.12 °C | 0.15 °C | 0.91 |

| pH | 7.46 ± 0.21 | 7.50 ± 0.23 | 0.058 | 0.08 | 0.11 | 0.83 |

| Conductivity | 1570.3 ± 3.2 µS/cm | 1569.8 ± 3.8 µS/cm | 0.60 µS/cm | 0.84 µS/cm | 1.44 µS/cm | 0.88 |

| Water volume | 1970 ± 77 L | 1947 ± 56 L | 11.54 L | 11.7 L | 17.4 L | 0.91 |

| Recirculation pump | 2800 ± 783 RPM | 2800 RPM (set) | ||||

| Dispensing pump | 1897 ± 217 RPM | 1900 RPM (set) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malandrakis, E.E. Design and Implementation of a Cost-Effective IoT-Based Monitoring and Alerting System for Recirculating Aquaculture Systems (RAS). Sensors 2025, 25, 6692. https://doi.org/10.3390/s25216692

Malandrakis EE. Design and Implementation of a Cost-Effective IoT-Based Monitoring and Alerting System for Recirculating Aquaculture Systems (RAS). Sensors. 2025; 25(21):6692. https://doi.org/10.3390/s25216692

Chicago/Turabian StyleMalandrakis, Emmanouil E. 2025. "Design and Implementation of a Cost-Effective IoT-Based Monitoring and Alerting System for Recirculating Aquaculture Systems (RAS)" Sensors 25, no. 21: 6692. https://doi.org/10.3390/s25216692

APA StyleMalandrakis, E. E. (2025). Design and Implementation of a Cost-Effective IoT-Based Monitoring and Alerting System for Recirculating Aquaculture Systems (RAS). Sensors, 25(21), 6692. https://doi.org/10.3390/s25216692