Development of an Advanced Multi-Layer Digital Twin Conceptual Framework for Underground Mining

Abstract

1. Introduction

1.1. Operational Challenges in Underground Mines

1.2. Why Are Underground Mine Digital Twins Needed? A Growing Simulation Issue

- Real-time monitoring: integrating sensors with digital twins provides constant data on drift stability, hazardous gas levels, and other critical factors.

- Predictive simulations: virtual models can predict adverse events such as structural failures, enabling preventive measures to be implemented before accidents occur.

- Reducing human exposure: by operating equipment remotely through the digital twin, workers can avoid hazardous areas, significantly improving workplace safety.

- Efficient equipment management: they enable real-time monitoring of equipment status, facilitating predictive maintenance and reducing downtime (see Figure 2).

- Simulation of operating processes: with digital twins, it is possible to simulate mining designs and machinery movements to optimize workflow and minimize disruptions (see Figure 2).

- Data-driven decision-making: by consolidating and analyzing operational information in real time, digital twins enable operators to make dynamic adjustments that increase productivity (see Figure 2).

- Reducing energy consumption: by optimizing operations and reducing downtime, digital twins reduce energy consumption, indirectly reducing carbon emissions.

- Efficient water management: simulations of water flow and drainage make it possible to prevent contamination of nearby aquifers and optimize the use of this critical resource.

- Environmental restoration: virtual models help plan land reclamation strategies, aligning with responsible mining principles.

- Process standardization: improves interoperability between existing systems and technologies.

- Advanced predictive capabilities: the combination of AI and digital twins allows for the prediction of long-term trends in operations, improving strategic planning.

- Advanced visualization: augmented reality (AR) and virtual reality (VR) tools integrated with digital twins allow operators to interact with detailed mine models to assess risks and plan operations.

1.3. Why Are Underground Mine Digital Twins and Automation More Cost-Effective and Safer?

1.4. Scope of the Review

- RQ1: What does an underground mine digital twin mean?

- RQ2: What are the components of an underground mine digital twin?

- RQ3: What are the functionalities of an underground mine digital twin?

- RQ4: What is an advanced multi-layered digital twin conceptual framework for underground mining?

- RQ5: Is the advanced multi-layered digital twin conceptual framework valid for an expert panel?

- RQ6: What are the future directions for underground mining digital twins?

2. Literature Review of Digital Twins in Underground Mines

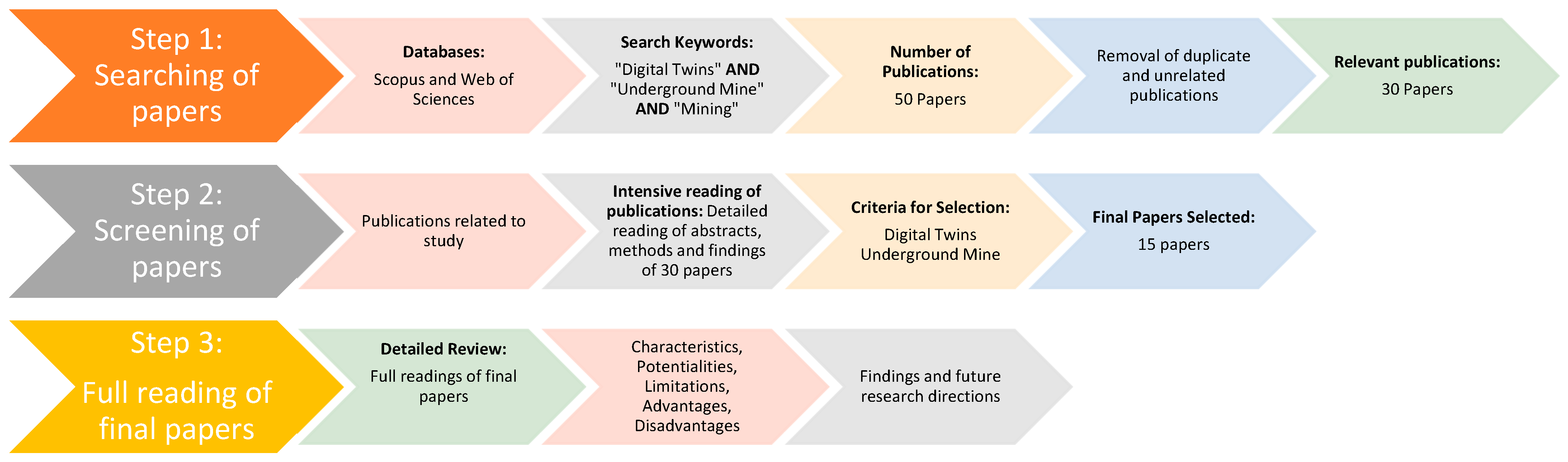

2.1. Research Methodology

2.1.1. Preliminary Search

2.1.2. Literature Screening

2.1.3. Literature Study

2.2. State of the Art

3. Definition of Underground Mine Digital Twins and Components

3.1. Definition of Underground Mine Digital Twins and Related Technologies

3.1.1. Digital Twins

3.1.2. Sensors

- Real-time monitoring: sensors continuously send data to digital models, allowing the current state of operations to be assessed and anomalies to be detected immediately.

- Predictive simulations: historical and real-time data is used to predict failures, optimize processes, and simulate scenarios such as changes in ventilation or extraction configurations.

- Improved safety: geotechnical and environmental sensors provide early warnings in the event of risks, such as structural instabilities or dangerous gas levels.

3.1.3. IoT

- Real-time data collection: IoT devices, such as environmental, geotechnical, and equipment sensors, collect critical information on variables such as temperature, gas concentration, tunnel stability, and machinery performance. This data is transmitted to the digital twin to reflect the status of underground operations.

- Remote monitoring and control: The IoT enables real-time connection between physical systems and their digital representations. This enables operators to monitor underground mine conditions from remote locations and make informed decisions to minimize risks and optimize processes.

- Predictive maintenance optimization: IoT sensors installed on machinery and equipment collect data on their operating status, such as vibrations, temperature, and wear. The digital twin uses this information to predict failures and schedule preventive maintenance, reducing downtime and operating costs.

- Integration with AI algorithms and simulations: Information collected by IoT devices is used in predictive simulations within the digital twin. For example, hypothetical scenarios, such as ventilation adjustments or changes in extraction methods, can be modeled to assess their impact on safety and productivity.

- Sustainability management: IoT devices help monitor the consumption of resources such as energy and water, as well as measure the environmental impact of operations. Digital twins use this information to design more sustainable and efficient strategies.

3.1.4. Artificial Intelligence

- Equipment fault prediction and detection: AI analyzes operational data from heavy machinery collected by sensors to identify patterns that indicate potential failures before they occur. This facilitates predictive maintenance and reduces downtime, improving overall productivity.

- Resource and operations optimization: ML algorithms process energy consumption, ventilation, and production data to optimize resource use. For example, they can automatically adjust airflows in mines to balance safety and energy efficiency.

- Predictive simulations: AI allows multiple operational scenarios to be simulated in the digital twin, such as changes in extraction methods or haulage configurations. These simulations help evaluate the impact of decisions before implementing them in the physical system, reducing risks and costs.

- Risk management: By combining real-time data and predictive modeling techniques, AI-enabled digital twins can identify hazardous conditions, such as geotechnical instabilities, before they become critical issues. This significantly improves safety in the underground environment.

- Automation and intelligent decision-making: AI helps automate complex decisions, such as equipment scheduling or haulage route optimization, based on real-time operational data and conditions.

3.1.5. Machine Learning

- Mining operation optimization: ML algorithms analyze real-time data from operations to identify patterns and trends. This allows for the optimization of processes such as underground ventilation, material transportation, and resource distribution, reducing costs and improving operational efficiency.

- Predictive maintenance: ML is key to predictive models in digital twins, which analyze the condition of mining equipment. By detecting anomalies in operational data, digital twins can predict failures and schedule preventive maintenance, minimizing downtime and extending asset lifespan.

- Geotechnical management: In underground mining, ML enables the analysis of sensor-collected data on deformations, vibrations, and geotechnical stability. Digital twins, powered by ML, identify conditions that could pose risks, offering automated solutions to mitigate problems before they occur.

- Simulation and operational planning: Using ML, digital twins can simulate complex operational scenarios based on vast amounts of historical and real-time data. For example, they can assess the impact of an extraction design before its physical implementation, minimizing risks and maximizing productivity.

- Risk and safety analysis: By analyzing historical and current data, ML algorithms can predict dangerous situations, such as toxic gas concentrations or structural collapses, alerting operators in real time to take preventive measures.

3.1.6. Cloud Computing

- Real-time data processing and storage: Digital twins in underground mining generate and analyze large volumes of data from IoT sensors and other sources. Cloud computing provides the massive storage capacity and processing power needed to handle this data in real time, facilitating the generation of updated models of the physical environment.

- Distributed system integration: Cloud computing enables the integration of data from multiple locations and systems, such as geotechnical sensors, ventilation equipment, and transportation systems. This creates a centralized platform where digital twins can access all the information relevant to their operations.

- Scalable simulation and analysis: Cloud platforms offer advanced simulation and analysis tools, enabling digital twins to run complex calculations and model operational scenarios. For example, extreme geotechnical conditions can be simulated to predict risks or evaluate extraction designs before their physical implementation.

- Remote access and collaboration: Thanks to cloud computing, digital twin data and models are accessible from any location and any internet-connected device. This allows distributed teams to collaborate in real time, optimizing decision-making, even when operators are not physically at the underground mine.

- Predictive maintenance and automation: Using cloud platforms, digital twins can collect and analyze historical and real-time data to predict mining equipment failures. Additionally, the cloud facilitates connection to automation systems, improving response to critical underground mine conditions.

3.1.7. Big Data

- Real-time data integration and management: In underground mining, digital twins rely on a continuous stream of data from IoT sensors, geotechnical monitoring systems, ventilation equipment, and heavy machinery. Big Data facilitates the integration and management of this data, enabling efficient, real-time processing and ensuring an accurate virtual representation of the physical environment.

- Predictive analytics and anomaly detection: Advanced Big Data analytics helps identify hidden patterns in historical and real-time data. This enables digital twins to predict equipment failures, detect anomalies in field conditions, and anticipate risks, improving safety and optimizing operations.

- Process simulation and optimization: Digital twins use Big Data to run complex simulations that evaluate extraction, geotechnical stability, or ventilation design scenarios. This helps optimize operational processes and reduce costs by minimizing planning errors.

- Environmental monitoring and sustainability: In the context of sustainability, Big Data enables the monitoring of environmental parameters such as gas levels, energy consumption, and waste generation. Digital twins can use this information to implement cleaner mining strategies and comply with environmental regulations.

- Data-driven decision-making: The use of Big Data enhances the ability of digital twins to act as decision-support tools, providing operators with detailed, real-time information about mining operations. This is essential for mitigating risks and increasing productivity.

3.1.8. Robotics

- Automation of critical operations: In underground mining, robots play an essential role in performing dangerous tasks such as drilling, loading, and hauling materials. Digital twins integrate these robots as virtual representations that replicate their movements and states in real time, enabling more precise control and monitoring.

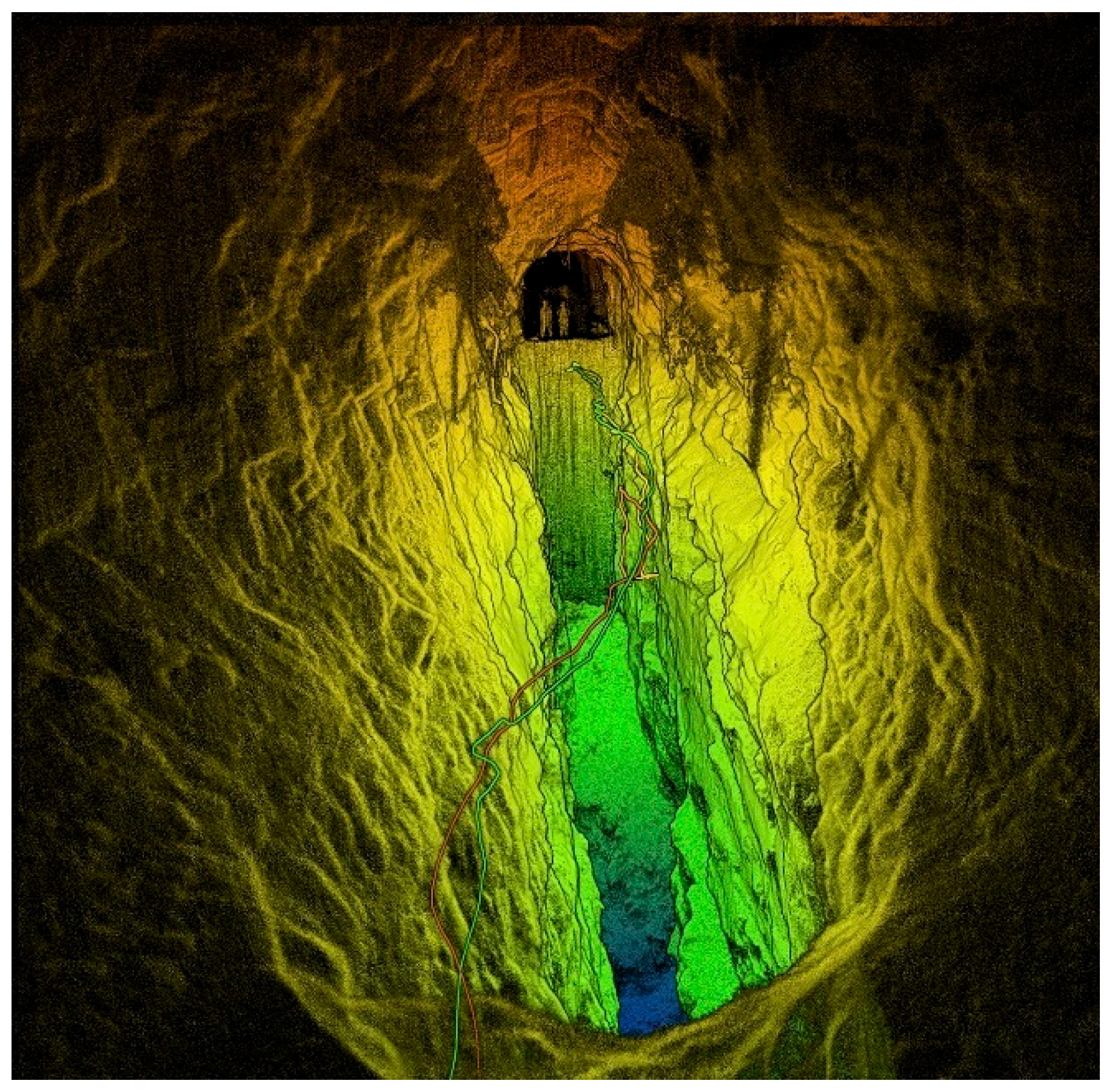

- Inspection and monitoring in high-risk areas: Mobile robots equipped with cameras, sensors, and Light Detection and Ranging (LiDAR) systems can operate in hazardous areas, such as unstable tunnels or zones with high levels of toxic gases. Digital twins use the data generated by these robots to update virtual models, facilitating remote assessment of critical conditions.

- Robotic process optimization through simulation: Digital twins allow robot movements and operations to be simulated and tested in a virtual environment before being deployed in the physical field. This minimizes errors and downtime, increasing operational efficiency.

- Autonomous and predictive maintenance: Maintenance robots, such as those equipped with manipulator arms or drones, can inspect equipment and perform minor repairs. Digital twins integrate the data obtained by these robots to predict failures and plan interventions before serious breakdowns occur.

- Coordination of autonomous teams: Digital twins enable the coordination of multiple autonomous robots in underground environments. For example, material transport routes can be optimized or drilling and loading tasks synchronized to maximize productivity.

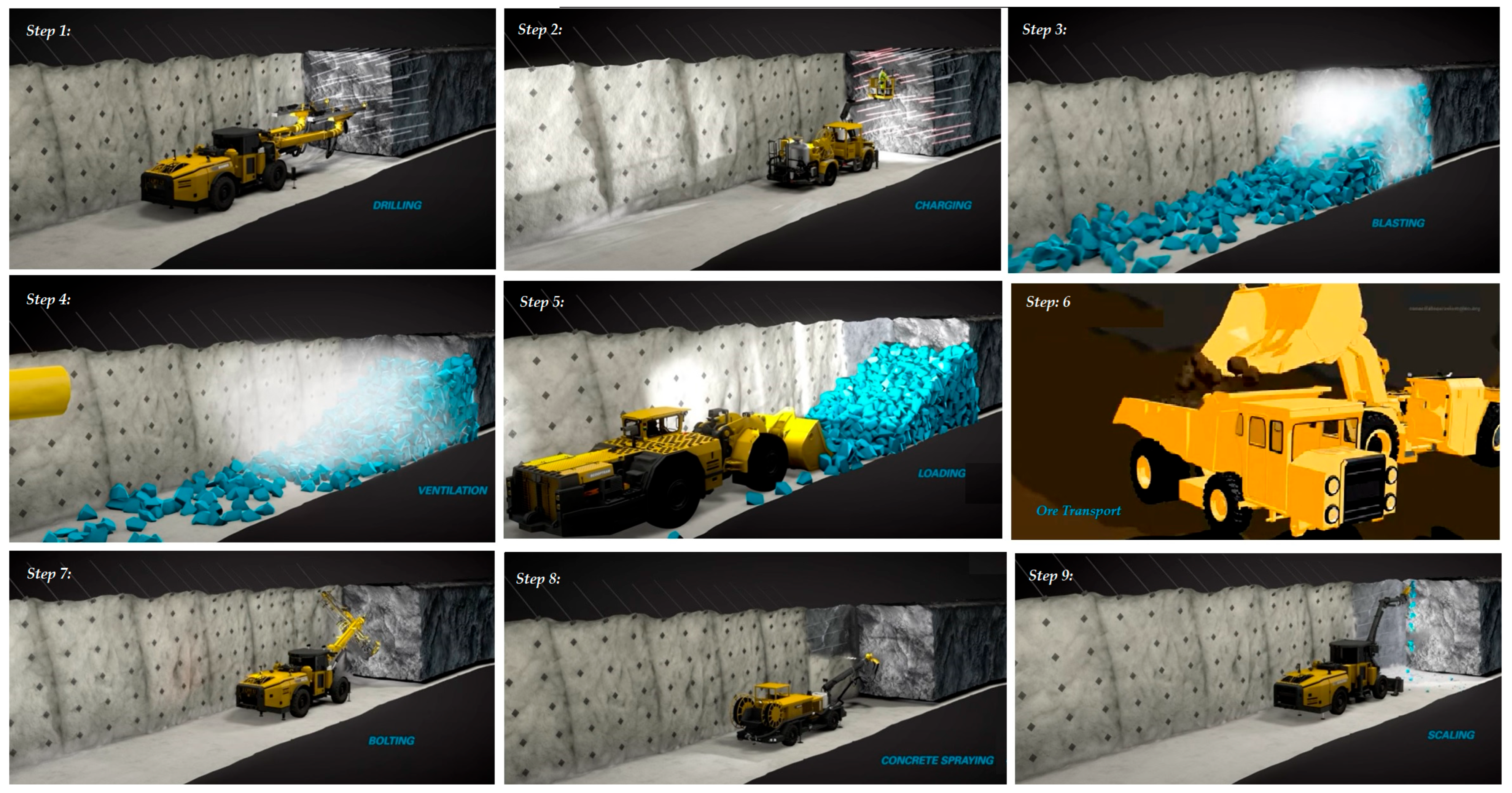

3.1.9. Automation

- Autonomous control of machinery and equipment: Automation in underground mining applies to equipment such as drills, loaders, and autonomous trucks, allowing them to operate without direct intervention. Digital twins replicate these automated systems in a virtual environment, allowing operators to monitor performance, analyze data in real time, and optimize processes.

- Mining operation optimization: Automated systems, integrated with digital twins, can plan and coordinate activities such as drilling, blasting, and material hauling. This ensures a continuous and efficient workflow, minimizing disruptions and downtime.

- Dynamic monitoring and adjustment: Digital twins use data generated by automated systems to model and simulate different operating scenarios. This allows parameters to be adjusted in real time to maximize safety and productivity in complex underground conditions.

- Predictive maintenance automation: Integrating automation with digital twins allows equipment failures to be predicted using predictive analytics algorithms. Systems can automatically schedule machine maintenance before critical failures occur, reducing costs and improving reliability.

- Automated ventilation systems: in underground environments, automated ventilation systems, linked to digital twins, optimize airflow based on the specific needs of each operation, improving environmental conditions and reducing energy consumption.

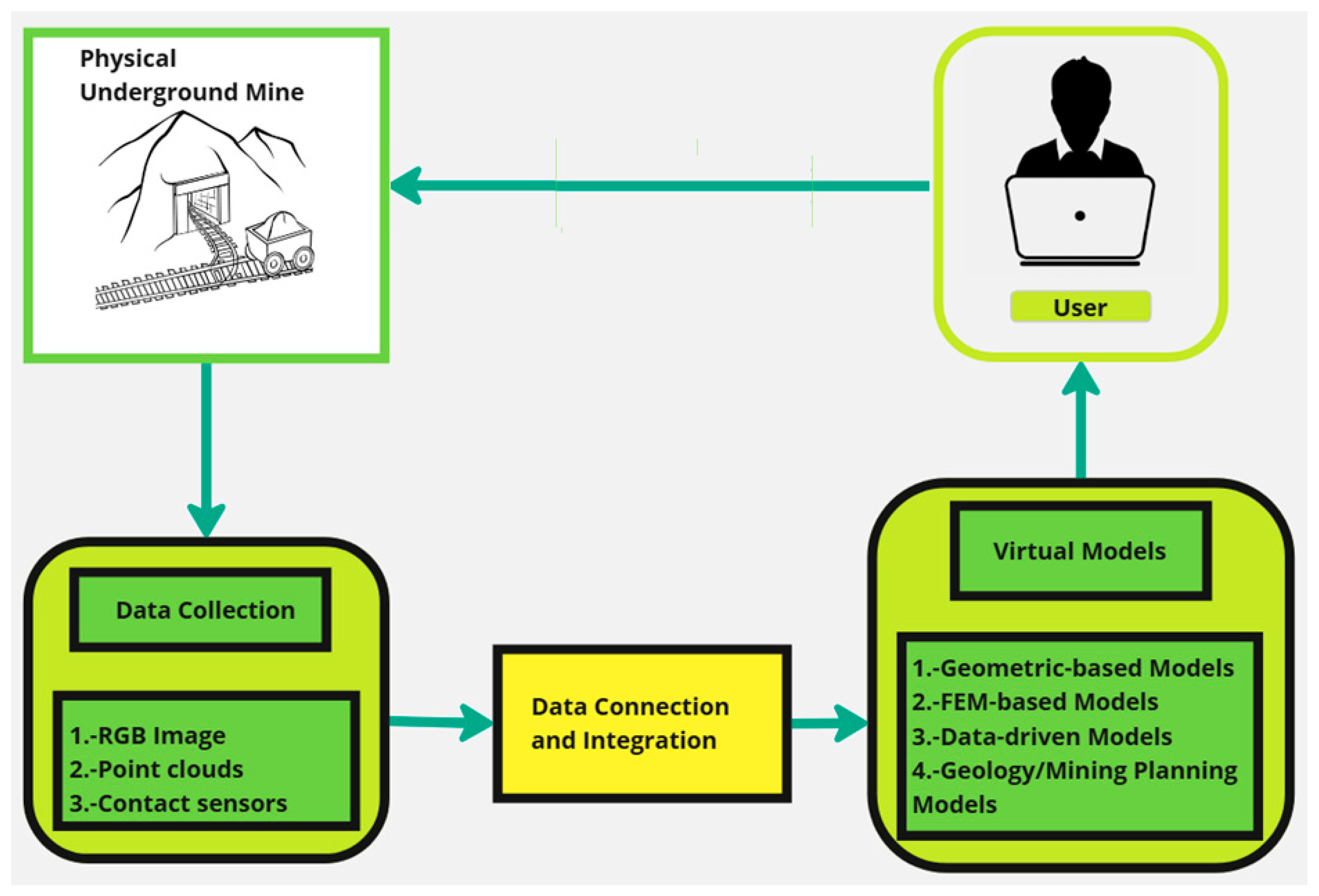

3.2. Components of Underground Mine Digital Twins

3.2.1. Physical Entity (Underground Mine)

- Replication accuracy: the better the physical entity is monitored, the more accurate the digital twin will be.

- Scalability: some digital twins can integrate multiple interconnected physical entities (e.g., a multi-level underground mine connected to conveyor belt extraction systems).

- Full lifecycle: the digital twin can follow the physical entity from design to obsolescence, enabling continuous optimizations.

3.2.2. Data Collection System (Sensors)

- IoT sensors and devices: (i) Physical sensors measure variables such as temperature, pressure, vibration, humidity, electric current, etc. (ii) IoT (Internet of Things) devices allow wireless data transmission. (iii) Actuators not only capture data but can also interact with the physical system (feedback).

- Acquisition hardware (DAQ): (i) data acquisition cards (e.g., NI DAQ from National Instruments), (ii) PLCs (Programmable Logic Controllers) in industrial environments, and (iii) embedded systems (Raspberry Pi, Arduino) for prototypes.

- Capture and preprocessing software: (i) Firmware on devices: initial processing of data before sending it. (ii) Gateways IoT: filter and compress data before sending it to the cloud. (iii) Edge computing: local processing to reduce latency (e.g.: Azure IoT Edge, AWS Greengrass).

3.2.3. Data Connectivity and Data Storage/Processing System (IoT, Cloud Computing, and AI)

- Main functions: (i) data transmission: connects sensors and IoT devices with processing platforms, where they guarantee low latency and high reliability (e.g., for real-time industrial applications).

- Processing and storage: filters, cleans, and structures raw data (e.g., removing noise from vibration signals), stores historical data for trend analysis and AI model training.

- Integration with virtual models: feed processed data into simulation models, dashboards, or prediction algorithms.

3.2.4. Virtual Models

- Geometric models (CAD/3D): 3D visual representation of the physical entity, created with tools such as CAD (Computer-Aided Design) (see Figure 5), where the main uses are the following: (i) visualization of the physical asset; (ii) design and ergonomics analysis, integration of the use of drones with LiDAR technology, RGB images with the use of photogrammetry, and use with AR; (iii) and VR.

- Physical–mathematical models for geological–mining planning: based on equations that describe system behavior (rock mechanics, mining plan, ventilation, etc.) (see Figure 6). Some examples of software packages include Surpac, Vulcan, Datamine, Minesight, and Promine, among others.

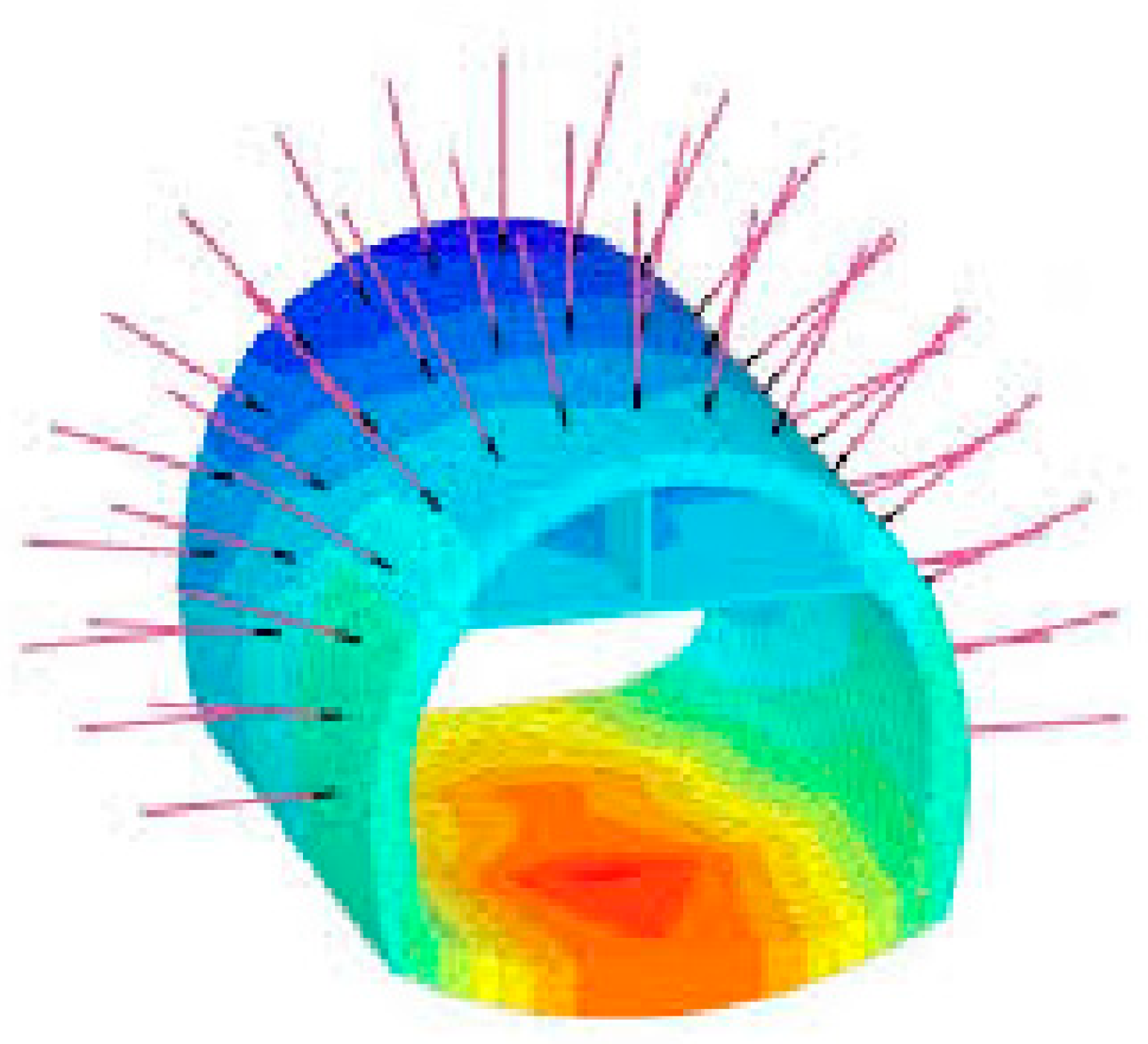

- Dynamic simulation and finite element models (FEMs): It is possible to predict the behavior of the system in different operating conditions (see Figure 7), where the common tools are the following: (i) MATLAB Simulink (control systems), (ii) ANSYS (multidisciplinary engineering), and (iii) Modelica (modeling of complex physical systems). Some other examples of software packages include COMSOL, FLAC3D, PLAXIS, and MIDAS GTS NX.

- Data-driven models: they use ML and AI to learn patterns from historical and real-time data, where some examples are the following: (i) neural networks to predict machinery failures and (ii) clustering algorithms to optimize industrial processes.

- Hybrid models (physical + data-driven): they combine physics-based models with AI techniques for greater accuracy, where they are useful when pure equations do not capture all the complexity of the system.

3.2.5. User

- Operators and technicians: (i) Role: real-time monitoring and maintenance. (ii) Interaction: view alerts and anomalies (e.g., excessive vibrations in a machine), receive predictive maintenance instructions, and use simple interfaces (dashboards, augmented reality).

- Engineers and designers: (i) Role: continuous optimization and improvement. (ii) Interaction: analyze historical data and simulations to redesign components, test “ what-if “ scenarios before implementing changes in the real world, and use advanced tools (CAD, FEM simulators, machine learning models).

- Managers and decision-makers: (i) Role: strategy and resource management. (ii) Interaction: analyze KPIs (performance, costs, energy efficiency), make decisions based on projections (e.g., when to replace an asset), use dashboards with intuitive visualizations (charts, control panels).

- Automated systems (AI/ML and controllers): (i) Role: autonomy and real-time adjustment. (ii) Interaction: AI algorithms that adjust parameters automatically (e.g., smart ventilation system). (iii) Control systems that react to changes without human intervention.

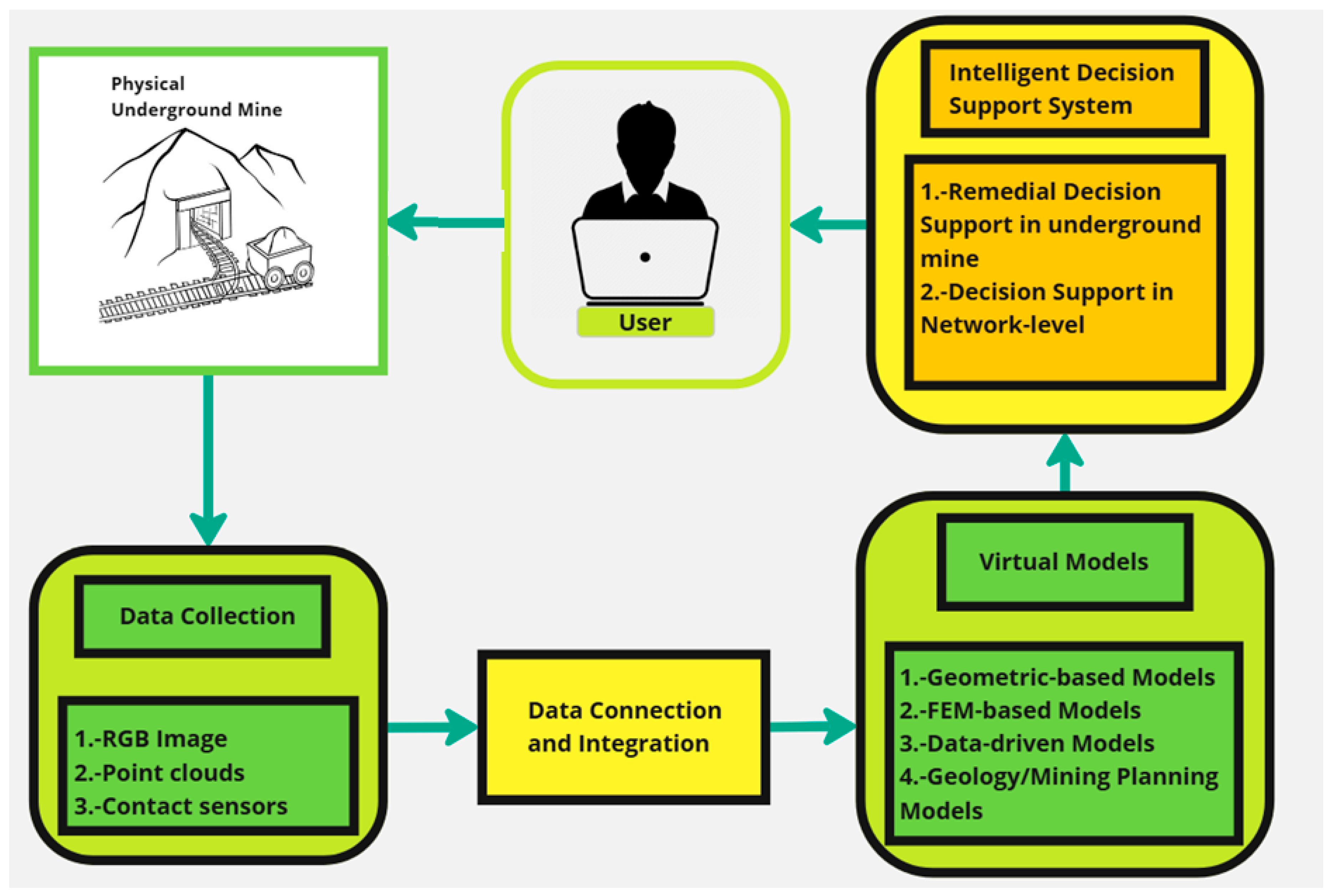

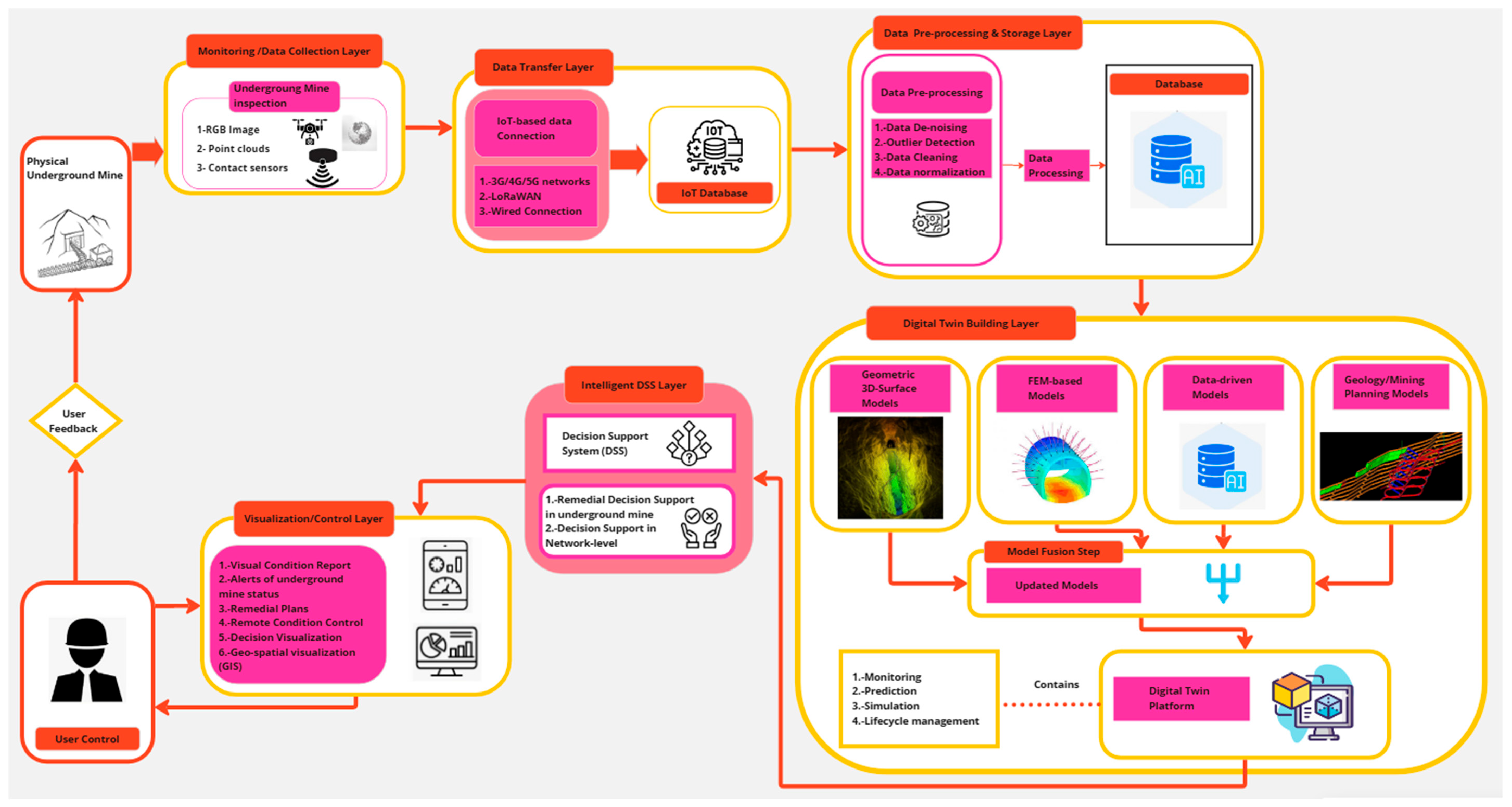

4. Advanced Multilayer Conceptual Framework of Underground Mine Digital Twins

- Physical entity: underground mine.

- Monitoring/data collection layer: This layer starts with the physical underground mine as the data source. Large volumes of data are collected through different types of sensors: RGB images, point clouds, and contact sensors.

- 3.

- Data transfer layer: This layer is responsible for the connection between the monitoring layer and the preprocessing and storage layer. This information is transmitted through different networks (3G/4G/5G, LoRaWAN, wired connection, among others) to an IoT database.

- 4.

- Data preprocessing and storage layer: The collected data is preprocessed to improve its quality and usefulness. This process includes noise removal, outlier detection, data cleaning, and normalization. The processed data is stored in a database which incorporates artificial intelligence (AI) for analysis.

- 5.

- Digital twin construction layer: This layer uses processed data to create various models: 3D geometric surface models, finite element models (FEM), data-driven models (using AI), and geological/mine planning models. These models are then merged to generate updated models that form the digital twin. This layer also contains the core functionalities of the digital twin platform, such as monitoring, prediction, simulation, and lifecycle management.

- 6.

- Intelligent decision support system (DSS) layer: This layer is crucial for data analysis. The decision support system (DSS) provides two important functions: decision support for corrective measures in the underground mine and decision support at the network level.

- 7.

- Visualization/control layer: This layer provides a user interface for visualizing the status of the underground mine, including visual condition reports, alerts, remediation plans, remote condition control, decision visualization, and geospatial visualization (GIS). A representative user interface with graphics and visualizations is shown. For example, results can be viewed through smartphones, tablets, or computer screens.

- 8.

- User feedback: a feedback loop is included that allows the user to interact with the system and provide information that will be used to improve the process.

5. Functionalities of the Underground Mine Advanced Multi-Layered Digital Twin Conceptual Framework

5.1. Monitoring in Real Time

5.2. Prediction of Anomalies

5.3. Simulation of Scenarios

5.4. Lifecycle Management

5.5. Decision Support System

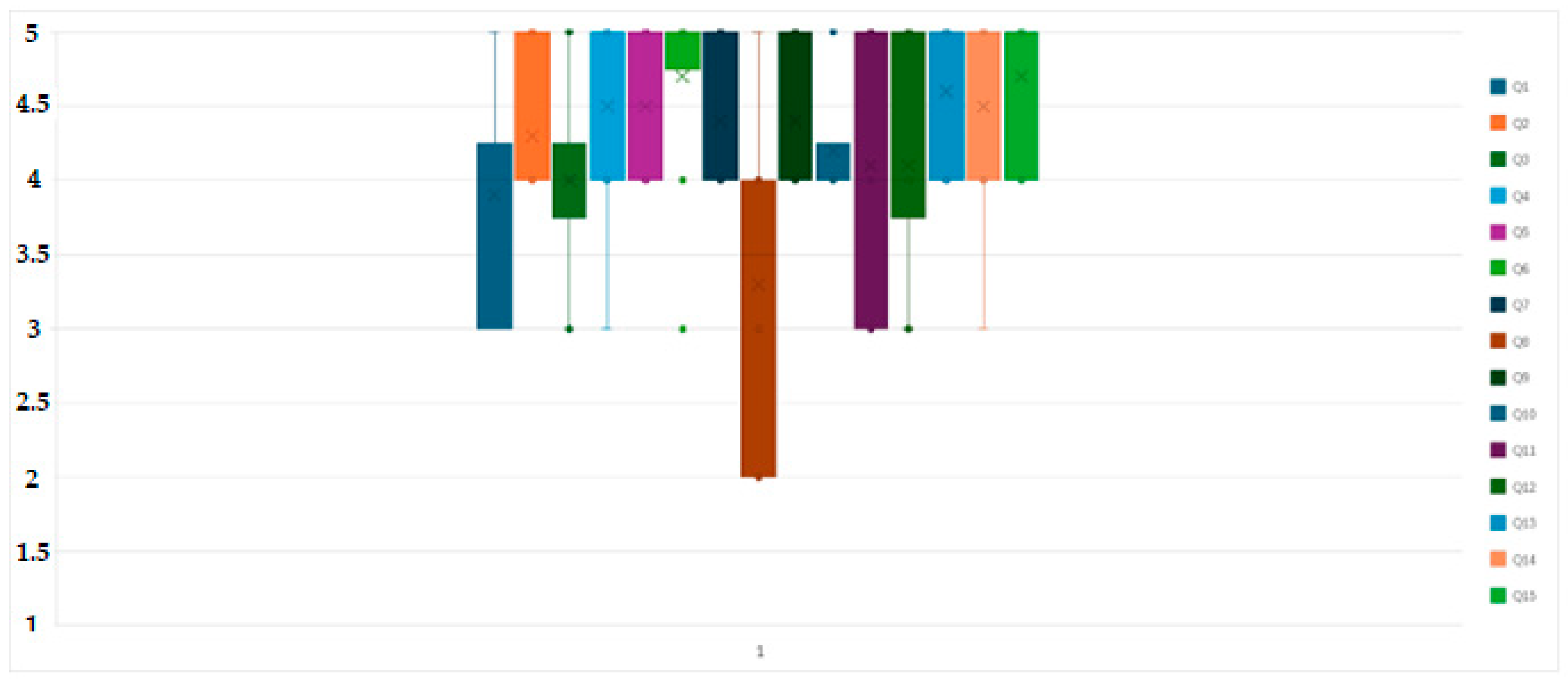

6. Validation by a Panel of Experts

7. Comparative Analysis of the Theoretical Framework Defined in This Study with Existing Research

8. Discussion: Future Directions Related to Underground Mine Digital Twins

8.1. Advanced Integration with IoT and Smart Sensors

- Real-time monitoring of environmental conditions (gases, temperature, humidity).

- Precise tracking of equipment and personnel using wearable sensors.

- Predicting machine failures through vibration and wear analysis.

8.2. Simulation and Optimization of Operations

- Dynamic tunnel and mining planning, adjusting strategies based on updated geological data.

- Virtual testing of new technologies, such as autonomous equipment or ventilation systems, before their physical implementation.

- Modeling risk scenarios, such as landslides or fires, to improve emergency protocols.

8.3. Artificial Intelligence and Machine Learning

- Predictive diagnosis of failures in critical equipment, such as drilling rigs or transportation systems.

- Automated recommendations to improve energy efficiency or mineral logistics.

- Analysis of historical data to identify patterns and optimize long-term processes.

8.4. Augmented Reality and Immersive Visualization

- Three-dimensional visualization of underground mines in control centers, allowing for more intuitive monitoring.

- Virtual training for workers, simulating real-life conditions without exposing them to hazards.

- Remote assistance from experts, who could virtually “enter” the mine to resolve technical issues.

8.5. Interoperability and Global Standards

- Compatibility between software from various vendors, avoiding information silos.

- Cybersecurity protocols, given the increasing digitalization of mining operations.

- Regulations and standards that guide the ethical and efficient implementation of this technology.

8.6. Sustainability and Improved Safety

- Environmental footprint: simulation of strategies to reduce emissions and energy consumption.

- Proactive safety: risk detection through pattern analysis (e.g., gas buildup, pillar instability).

8.7. Pending Challenges

9. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| DT | Digital Twin |

| AI | Artificial Intelligence |

| ML | Machine Learning |

| CC | Cloud Computing |

| IoT | Internet of Things |

| AU | Automation |

| RO | Robotics |

| DSS | Decision Support System |

| ROI | Return On Investment |

| AR | Augmented Reality |

| VR | Virtual Reality |

| LiDAR | Light Detection and Ranging |

| CAD | Computer-Aided Design |

| FEM | Finite Element Model |

| KPI | Key Performance Index |

| PLCs | Programmable Logic Controllers |

| LHD | Load Haul Dump |

| BIM | Building Information Modeling |

| SCADA | Supervisory Control and Data Acquisition |

References

- Cavalcanti, M.d.C.R.; Nahas Ribeiro, W.; Cabral dos Santos Junior, M. Engineering Challenges for Safe and Sustainable Underground Occupation. Infrastructures 2023, 8, 42. [Google Scholar] [CrossRef]

- Li, X.; Ren, Z.; Cao, Z.; Ren, H. Study on coal drawing parameters of deeply buried hard coal seams based on PFC. Sci Rep. 2025, 15, 21934. [Google Scholar]

- Imam, M.; Baïna, K.; Tabii, Y.; Ressami, E.M.; Adlaoui, Y.; Benzakour, I.; Abdelwahed, E.H. The Future of Mine Safety: A Comprehensive Review of Anti-Collision Systems Based on Computer Vision in Underground Mines. Sensors 2023, 23, 4294. [Google Scholar] [CrossRef]

- Wang, Q.; Cheng, T.; Lu, Y.; Liu, H.; Zhang, R.; Huang, J. Underground Mine Safety and Health: A Hybrid MEREC–CoCoSo System for the Selection of Best Sensor. Sensors 2024, 24, 1285. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Atencio, E.; Komarizadehasl, S.; Lozano-Galant, J.A. Internet of Things Long-Range-Wide-Area-Network-Based Wireless Sensors Network for Underground Mine Monitoring: Planning an Efficient, Safe, and Sustainable Labor Environment. Sensors 2024, 24, 6971. [Google Scholar] [CrossRef] [PubMed]

- Hazrathosseini, A.; Moradi Afrapoli, A. The advent of digital twins in surface mining: Its time has finally arrived. Resour. Policy 2023, 80, 103155. [Google Scholar] [CrossRef]

- Agrawal, A.; Thiel, R.; Jain, P.; Singh, V.; Fischer, M. Digital Twin: Where do humans fit in? Autom. Constr. 2023, 148, 104749. [Google Scholar] [CrossRef]

- Florescu, A. Digital Twin for Flexible Manufacturing Systems and Optimization Through Simulation: A Case Study. Machines 2024, 12, 785. [Google Scholar] [CrossRef]

- Ben Amor, S.; Elloumi, N.; Eltaief, A.; Louhichi, B.; Alrasheedi, N.H.; Seibi, A. Digital Twin Implementation in Additive Manufacturing: A Comprehensive Review. Processes 2024, 12, 1062. [Google Scholar] [CrossRef]

- Renard, D.; Saddem, R.; Annebicque, D.; Riera, B. From Sensors to Digital Twins toward an Iterative Approach for Existing Manufacturing Systems. Sensors 2024, 24, 1434. [Google Scholar] [CrossRef]

- Rahmani, R.; Jesus, C.; Lopes, S.I. Implementations of Digital Transformation and Digital Twins: Exploring the Factory of the Future. Processes 2024, 12, 787. [Google Scholar] [CrossRef]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital twin: Enabling technologies, challenges and open research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Wang, J.; Huang, Y.; Zhai, W.; Li, J.; Ouyang, S.; Gao, H.; Liu, Y.; Wang, G. Research on coal mine safety management based on digital twin. Heliyon 2023, 9, e13608. [Google Scholar] [CrossRef] [PubMed]

- Bertoni, A.; MacHchhar, R.J.; Larsson, T.; Frank, B. Digital Twins of Operational Scenarios in Mining for Design of Customized Product-Service Systems Solutions. Procedia CIRP 2022, 109, 532–537. [Google Scholar] [CrossRef]

- Wen, H.; Liu, S.; Zheng, X.; Cai, G.; Zhou, B.; Ding, W.; Ma, Y. The digital twins for mine site rescue environment: Application framework and key technologies. Process Saf. Environ. Prot. 2024, 186, 176–188. [Google Scholar] [CrossRef]

- Nikula, R.P.; Remes, A.; Kaartinen, J.; Kortelainen, J.; Loponen, T.; Ruuska, J.; Ruusunen, M. Autonomous residual monitoring of metallurgical digital twins. Min. Eng. 2025, 220, 109107. [Google Scholar] [CrossRef]

- Servin, M.; Vesterlund, F.; Wallin, E. Digital twins with distributed particle simulation for mine-to-mill material tracking. Minerals 2021, 11, 524. [Google Scholar] [CrossRef]

- Qiang, X.; Li, G.; Hou, J.; Zhang, X.; Liu, Y. Intelligent Safety Risk Analysis and Decision-Making System for Underground Metal Mines Based on Big Data. Sustainability 2023, 15, 10086. [Google Scholar] [CrossRef]

- Wu, X.; Li, H.; Wang, B.; Zhu, M. Review on Improvements to the Safety Level of Coal Mines by Applying Intelligent Coal Mining. Sustainability 2022, 14, 16400. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Guzmán, V.; Catriñir, P.; Atencio, E.; Komarizadehasl, S.; Lozano-Galant, J.A. Low-Cost Sensors Technologies for Monitoring Sustainability and Safety Issues in Mining Activities: Advances, Gaps, and Future Directions in the Digitalization for Smart Mining. Sensors 2023, 23, 6846. [Google Scholar] [CrossRef]

- van Eyk, L.; Heyns, P.S. A framework to define, design and construct digital twins in the mining industry. Comput Ind Eng. 2025, 200, 110805. [Google Scholar] [CrossRef]

- Cranford, R. Conceptual application of digital twins to meet ESG targets in the mining industry. Front. Ind. Eng. 2023, 1, 1223989. [Google Scholar] [CrossRef]

- Nobahar, P.; Xu, C.; Dowd, P.; Shirani Faradonbeh, R. Exploring digital twin systems in mining operations: A review. Green Smart Min. Eng. 2024, 1, 474–492. [Google Scholar] [CrossRef]

- El Bazi, N.; Mabrouki, M.; Laayati, O.; Ouhabi, N.; El Hadraoui, H.; Hammouch, F.E.; Chebak, A. Generic Multi-Layered Digital-Twin-Framework-Enabled Asset Lifecycle Management for the Sustainable Mining Industry. Sustainability 2023, 15, 3470. [Google Scholar] [CrossRef]

- Sharma, A.; Kosasih, E.; Zhang, J.; Brintrup, A.; Calinescu, A. Digital Twins: State of the art theory and practice, challenges, and open research questions. Vol. 30, Journal of Industrial Information Integration. J. Ind. Inf. Integr. 2022, 30, 100383. [Google Scholar]

- VanDerHorn, E.; Mahadevan, S. Digital Twin: Generalization, characterization and implementation. Decis Support Syst. 2021, 145, 113524. [Google Scholar] [CrossRef]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A systematic literature review. CIRP J. Manuf. Sci Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Sun, Z.; Zhang, R.; Zhu, X. The progress and trend of digital twin research over the last 20 years: A bibliometrics-based visualization analysis. J. Manuf. Syst. 2024, 74, 1–15. [Google Scholar] [CrossRef]

- Perno, M.; Hvam, L.; Haug, A. Implementation of digital twins in the process industry: A systematic literature review of enablers and barriers. Comput. Ind. 2022, 134, 103558. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Parekh, H.; Mani, V.; Belhadi, A.; Sharma, R. Digital twin for sustainable manufacturing supply chains: Current trends, future perspectives, and an implementation framework. Technol. Forecast. Soc. Change 2022, 176, 121448. [Google Scholar] [CrossRef]

- Liu, Y.; Feng, J.; Lu, J.; Zhou, S. A review of digital twin capabilities, technologies, and applications based on the maturity model. Adv. Eng. Inform. 2024, 62, 102592. [Google Scholar] [CrossRef]

- Sreedharan, S.; Ramachandran, M.; Ramesh, D. Harnessing digital twins and industrial-IoT for cutting-edge mining automation: A methodological and technology assessment prototype. Comput. Ind. Eng. 2025, 201, 110871. [Google Scholar] [CrossRef]

- Segovia, M.; Garcia-Alfaro, J. Design, Modeling and Implementation of Digital Twins. Sensors 2022, 22, 5396. [Google Scholar] [CrossRef] [PubMed]

- Jeremiah, S.R.; El Azzaoui, A.; Xiong, N.N.; Park, J.H. A comprehensive survey of digital twins: Applications, technologies and security challenges. J. Syst. Archit. 2024, 151, 103120. [Google Scholar] [CrossRef]

- Zhu, H.; Huang, M.; Ji, P.; Xiao, F.; Zhang, Q.B. Transforming the maintenance of underground infrastructure through Digital Twins: State of the art and outlook. Tunn. Undergr. Space Technol. 2025, 161, 106508. [Google Scholar] [CrossRef]

- Resman, M.; Debevec, M.; Herakovič, N. Using Digital Twin Technology to Improve the Organization of the Supply Chain in Piece Type of Production. Systems 2025, 13, 505. [Google Scholar] [CrossRef]

- Rojas, L.; Peña, Á.; Garcia, J. AI-Driven Predictive Maintenance in Mining: A Systematic Literature Review on Fault Detection, Digital Twins, and Intelligent Asset Management. Appl. Sci. 2025, 15, 3337. [Google Scholar] [CrossRef]

- Sharafat, A.; Tanoli, W.A.; Zubair, M.U.; Mazher, K.M. Digital Twin-Driven Stability Optimization Framework for Large Underground Caverns. Appl. Sci. 2025, 15, 4481. [Google Scholar] [CrossRef]

- Yu, C.; Liu, Z.; Wang, H.; Shi, G.; Song, T. Intelligent Analysis of Construction Safety of Large Underground Space Based on Digital Twin. Buildings 2024, 14, 1551. [Google Scholar] [CrossRef]

- Wang, H.; Yu, C.; Zheng, J.; Jia, Y.; Liu, Z.; Yang, K. Digital-Twin-Based Operation and Maintenance Management Method for Large Underground Spaces. Buildings 2024, 14, 2577. [Google Scholar] [CrossRef]

- Botín-Sanabria, D.M.; Mihaita, S.; Peimbert-García, R.E.; Ramírez-Moreno, M.A.; Ramírez-Mendoza, R.A.; Lozoya-Santos Jde, J. Digital Twin Technology Challenges and Applications: A Comprehensive Review. Remote Sens. 2022, 14, 1335. [Google Scholar] [CrossRef]

- Awouda, A.; Traini, E.; Bruno, G.; Chiabert, P. IoT-Based Framework for Digital Twins in the Industry 5.0 Era. Sensors 2024, 24, 594. [Google Scholar] [CrossRef]

- Al-Ali, A.R.; Gupta, R.; Zaman Batool, T.; Landolsi, T.; Aloul, F.; Al Nabulsi, A. Digital twin conceptual model within the context of internet of things. Future Internet 2020, 12, 163. [Google Scholar] [CrossRef]

- Costantini, A.; Di Modica, G.; Ahouangonou, J.C.; Duma, D.C.; Martelli, B.; Galletti, M.; Antonacci, M.; Nehls, D.; Bellavista, P.; Delamarre, C.; et al. IoTwins: Toward Implementation of Distributed Digital Twins in Industry 4.0. Settings. Computer 2022, 11, 67. [Google Scholar] [CrossRef]

- Campana, P.; Censi, R.; Tarola, A.M.; Ruggieri, R. Artificial Intelligence and Digital Twins for Sustainable Waste Management: A Bibliometric and Thematic Review. Appl. Sci. 2025, 15, 6337. [Google Scholar] [CrossRef]

- Mayer, A.; Greif, L.; Häußermann, T.M.; Otto, S.; Kastner, K.; El Bobbou, S.; Chardonnet, J.-R.; Reichwald, J.; Fleischer, J.; Ovtcharova, J. Digital Twins, Extended Reality, and Artificial Intelligence in Manufacturing Reconfiguration: A Systematic Literature Review. Sustainability 2025, 17, 2318. [Google Scholar] [CrossRef]

- Emmert-Streib, F. What Is the Role of AI for Digital Twins? AI 2023, 4, 721–728. [Google Scholar] [CrossRef]

- Biller, B.; Biller, S. Implementing Digital Twins That Learn: AI and Simulation Are at the Core. Machines 2023, 11, 425. [Google Scholar] [CrossRef]

- Mikołajewska, E.; Mikołajewski, D.; Mikołajczyk, T.; Paczkowski, T. Generative AI in AI-Based Digital Twins for Fault Diagnosis for Predictive Maintenance in Industry 4.0/5.0. Appl. Sci. 2025, 15, 3166. [Google Scholar] [CrossRef]

- Karagianni, M.; Benardos, A. Machine Learning Techniques to Model and Predict Airflow Requirements in Underground Mining. Mater. Proc. 2023, 15, 17. [Google Scholar]

- Lehmann, J.; Lober, A.; Häußermann, T.; Rache, A.; Ollinger, L.; Baumgärtel, H.; Reichwald, J. The Anatomy of the Internet of Digital Twins: A Symbiosis of Agent and Digital Twin Paradigms Enhancing Resilience (Not Only) in Manufacturing Environments. Machines 2023, 11, 504. [Google Scholar] [CrossRef]

- Ikeda, H.; Mokhtar, N.E.B.; Sinaice, B.B.; Mahboob, M.A.; Toriya, H.; Adachi, T.; Kawamura, Y. Digital Twin Technology in Data Center Simulations: Evaluating the Feasibility of a Former Mine Site. Sustainability 2023, 15, 16176. [Google Scholar] [CrossRef]

- Wang, Z.; Bi, L.; Li, J.; Wu, Z.; Zhao, Z. Development Status and Trend of Mine Intelligent Mining Technology. Mathematics 2025, 13, 2217. [Google Scholar] [CrossRef]

- Roman, E.A.; Stere, A.S.; Roșca, E.; Radu, A.V.; Codroiu, D.; Anamaria, I. State of the Art of Digital Twins in Improving Supply Chain Resilience. Logistics 2025, 9, 22. [Google Scholar] [CrossRef]

- Alnaser, A.A.; Maxi, M.; Elmousalami, H. AI-Powered Digital Twins and Internet of Things for Smart Cities and Sustainable Building Environment. Appl. Sci. 2024, 14, 12056. [Google Scholar] [CrossRef]

- Alnaser, A.A.; Elmousalami, H. Benefits and Challenges of AI-Based Digital Twin Integration in the Saudi Arabian Construction Industry: A Correspondence Analysis (CA) Approach. Appl. Sci. 2025, 15, 4675. [Google Scholar] [CrossRef]

- Chouridis, I.; Mansour, G.; Chouridis, A.; Papageorgiou, V.; Mansour, M.T.; Tsagaris, A. Digital Twin Driven Four-Dimensional Path Planning of Collaborative Robots for Assembly Tasks in Industry 5.0. Robotics 2025, 14, 97. [Google Scholar] [CrossRef]

- Nagy, M.; Figura, M.; Valaskova, K.; Lăzăroiu, G. Predictive Maintenance Algorithms, Artificial Intelligence Digital Twin Technologies, and Internet of Robotic Things in Big Data-Driven Industry 4.0 Manufacturing Systems. Mathematics 2025, 13, 981. [Google Scholar] [CrossRef]

- Konieczna-Fuławka, M.; Koval, A.; Nikolakopoulos, G.; Fumagalli, M.; Santas Moreu, L.; Vigara-Puche, V.; Müller, J.; Prenner, M. Autonomous Mobile Inspection Robots in Deep Underground Mining—The Current State of the Art and Future Perspectives. Sensors 2025, 25, 3598. [Google Scholar] [CrossRef]

- Park, J.; Lee, J.K.; Son, M.J.; Yu, C.; Lee, J.; Kim, S. Unlocking the Potential of Digital Twins in Construction: A Systematic and Quantitative Review Using Text Mining. Buildings 2024, 14, 702. [Google Scholar] [CrossRef]

- Ortiz, J.S.; Quishpe, E.K.; Sailema, G.X.; Guamán, N.S. Digital Twin-Based Active Learning for Industrial Process Control and Supervision in Industry 4.0. Sensors 2025, 25, 2076. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Ji, P.; Ma, H.; Xing, L. A Comprehensive Review of Digital Twin from the Perspective of Total Process: Data, Models, Networks and Applications. Sensors 2023, 23, 8306. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Lee, Y.; Park, S.; Hong, C. Implementing a Digital Twin of an Underground Utility Tunnel for Geospatial Feature Extraction Using a Multimodal Image Sensor. Appl. Sci. 2023, 13, 9137. [Google Scholar] [CrossRef]

- Komarizadehasl, S.; Mobaraki, B.; Ma, H.; Lozano-Galant, J.A.; Turmo, J. Low-Cost Sensors Accuracy Study and Enhancement Strategy. Appl. Sci. 2022, 12, 3186. [Google Scholar] [CrossRef]

- Komarizadehasl, S.; Lozano, F.; Lozano-Galant, J.A.; Ramos, G.; Turmo, J. Low-Cost Wireless Structural Health Monitoring of Bridges. Sensors 2022, 22, 5725. [Google Scholar] [CrossRef]

- El-Hajj, M. Leveraging Digital Twins and Intrusion Detection Systems for Enhanced Security in IoT-Based Smart City Infrastructures. Electronics 2024, 13, 3941. [Google Scholar] [CrossRef]

- Abdullahi, I.; Longo, S.; Samie, M. Towards a Distributed Digital Twin Framework for Predictive Maintenance in Industrial Internet of Things (IIoT). Sensors 2024, 24, 2663. [Google Scholar] [CrossRef]

- Hananto, A.L.; Tirta, A.; Herawan, S.G.; Idris, M.; Soudagar, M.E.M.; Djamari, D.W.; Veza, I. Digital Twin and 3D Digital Twin: Concepts, Applications, and Challenges in Industry 4.0 for Digital Twin. Computers 2024, 13, 100. [Google Scholar] [CrossRef]

- Empl, P.; Pernul, G. Digital-Twin-Based Security Analytics for the Internet of Things. Information 2023, 14, 95. [Google Scholar] [CrossRef]

- Taber, K.S. The Use of Cronbach’s Alpha When Developing and Reporting Research Instruments in Science Education. Res. Sci. Educ. 2018, 48, 1273–1296. [Google Scholar] [CrossRef]

- Kreuzer, T.; Papapetrou, P.; Zdravkovic, J. Artificial intelligence in digital twins—A systematic literature review. Data Knowl. Eng. 2024, 151, 102304. [Google Scholar] [CrossRef]

- Aragón, A.; Arquier, M.; Tokdemir, O.B.; Enfedaque, A.; Alberti, M.G.; Lieval, F.; Loscos, E.; Pavón, R.M.; Novischi, D.M.; Legazpi, P.V.; et al. Seeking a Definition of Digital Twins for Construction and Infrastructure Management. Appl. Sci. 2025, 15, 1557. [Google Scholar] [CrossRef]

- Tang, M.; Nikolaenko, M.; Alrefai, A.; Kumar, A. Metaverse and Digital Twins in the Age of AI and Extended Reality. Architecture 2025, 5, 36. [Google Scholar] [CrossRef]

- Židek, K.; Pitel’, J.; Adámek, M.; Lazorík, P.; Hošovskỳ, A. Digital twin of experimental smart manufacturing assembly system for industry 4.0 concept. Sustainability 2020, 12, 3658. [Google Scholar] [CrossRef]

| Searching Index | Content |

|---|---|

| Time | 2020 (March)–2025 (July) |

| Database | Scopus and Web of Science |

| Title/Subject-Abstract | “Digital Twins” AND “Underground Mine” AND “Mining” |

| Publication Type | “Article” and “Review Article” |

| Data Extraction Index 1 | Technological advances |

| Data Extraction Index 2 | Integration with Industry 4.0 Concept |

| # | Authors Reference | Technological Advances | Sensors | AI | ML | IoT | Big Data | CC | AU | RO |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | [21] | This paper studies the development of a customized digital twin framework for the mining industry. Also, this research provides model selection tools to aid digital twin construction. | X | X | X | |||||

| 2 | [22] | This research found that digital twin technology can be applied across all mining project phases and can provide added value to improve multiple ESG factors and measure them. | X | |||||||

| 3 | [23] | This study provides valuable insights into fully integrated digital twin mining systems, which will significantly improve mining efficiency and sustainability. | X | X | X | |||||

| 4 | [24] | This paper intends to shed light on the state of art of DT case studies focusing on concept, design, and development. | X | X | X | X | ||||

| 5 | [25] | This article discusses the current state of machine learning and Big Data in digital twins and finds that advancement in these technologies has impacted the adoption and ideal implementation of digital twins. | X | X | ||||||

| 6 | [26] | This paper studies how digital twins can be distinguished from other types of digital modeling and simulation. | X | X | ||||||

| 7 | [27] | Through a systematic literature review and a thematic analysis of 92 digital twin publications from the last ten years, this paper provides a characterization of the digital twin, identification of gaps in knowledge, and required areas of future research. | X | X | ||||||

| 8 | [28] | This paper summarizes the development trends and directions of digital twin research. | X | X | ||||||

| 9 | [29] | At this article challenges to digital twin implementation are identified and categorized. | X | X | ||||||

| 10 | [30] | This paper studies how technologies such as IoT, cloud computing, and blockchain have increased the potential of digital twins and how digital twins should include the “things” and “humans” from the entire supply chain. | X | X | ||||||

| 11 | [31] | This paper catalogs supporting tools aligned with the technical specifications stipulated in DTs’ functional capabilities, aiding developers in devising implementation strategies. | X | X | ||||||

| 12 | [32] | This article outlines an IoT and digital twin prototype for automating large-scale conventional mines, referencing architecture for mining to model, simulate, and control the underground physical world virtually. | X | X | ||||||

| 13 | [33] | In this paper, we focus on the construction of DTs. More specifically, we focus on determining (methodologically) how to design, create, and connect physical objects with their virtual counterpart. We explore the problem into several phases: from functional requirement selection and architecture planning to integration and verification of the final (digital) models. | X | X | X | |||||

| 14 | [34] | This study fills this gap by systematically reviewing DT research, focusing on three interrelated aspects: DT applications, architectural layers, and security. | X | |||||||

| 15 | [35] | This paper studies the incorporation of sensing and machine learning into reflective twins for dynamic updates, describing progress and insights for multi-criteria decision-making for intervention. | X | X |

| No. | Occupation | Profession | Labor Camp | Country of Residence | Experience (Years) |

|---|---|---|---|---|---|

| 1 | Superintendent of Underground Mine | Mining Engineer, MSc | Underground mining operation | Peru | 20 |

| 2 | Underground Mining Engineer | Mining Engineer | Underground mining operation | Chile | 8 |

| 3 | Underground Mining Engineer | Mining Engineer | Underground mining operation | Chile | 10 |

| 4 | Underground Mining Consultant | Mining Engineer, PhD | Design, construction and operation of underground mines | Peru | 25 |

| 5 | Underground Mining Engineer | Mining Engineer, MBA | Underground mining operation | Peru | 12 |

| 6 | Underground Mining Manager | Mining Engineer, MSc | Design, construction and operation of underground mines | Chile | 25 |

| 7 | Underground Mining Engineer | Mining Engineer, MBA | Safety in underground mines | Chile | 14 |

| 8 | Superintendent of Underground Mining | Mining Engineer, MSc | Design, construction and operation of underground mines | Chile | 18 |

| 9 | Underground Mining Engineer | Mining Engineer, MBA | Safety in underground mines | Chile | 10 |

| 10 | Underground Mining Engineer | Mining Engineer | Underground mining operation | Peru | 12 |

| No. | Quality Dimension | Statement |

|---|---|---|

| 1 | Technology | The technological dimension of a digital twin refers to the set of tools, platforms, standards, and software and hardware architectures that enable the creation, maintenance, operation, analysis, and ongoing management of the virtual representation of a physical object or system. |

| 2 | Operation | The operational dimension refers to the practical and applied use of the digital twin to monitor, control, optimize, and automate the operations of a physical system in real time. It is the dimension that connects the data and the virtual model with decision-making and concrete actions in the real world. |

| 3 | Productivity | The productivity dimension refers to the ability of the digital twin to generate measurable improvements in the efficiency, effectiveness, and performance of a process, system, or organization. It involves quantifying how the digital twin enables organizations to achieve more with less: increasing production, improving quality, reducing costs, and optimizing the use of resources (time, materials, energy, and human capital). |

| 4 | Safety | The security dimension refers to the set of protocols, technologies, and practices implemented to protect the safety of mine workers. Its objective is to prevent physical, cyber, and operational risks, ensuring that decisions made based on the digital twin do not compromise the safety of people, equipment, or the environment. |

| 5 | Sustainability | The sustainability dimension refers to the ability of the digital twin to monitor, simulate, optimize, and report on the environmental and social performance of a physical asset or process throughout its entire lifecycle. Its objective is to minimize negative environmental impact (emissions, waste, resource consumption) and maximize positive social impact, all while remaining economically viable. |

| 6 | Economy | The economic dimension refers to the analysis of the costs, benefits, return on investment (ROI), and business models associated with the implementation and use of a digital twin. It evaluates how the digital twin contributes to an organization’s financial viability, profitability, and competitive advantage, whether through cost reduction, asset optimization, or the creation of new revenue streams. |

| ID | Quality Dimension | Ask |

|---|---|---|

| Q1 | Technology | The digital twin in an underground mining context is differentiated from a traditional 3D model. |

| Q2 | Technology | Technologies (IoT, AI, sensors, etc.) are essential to developing a functional digital twin in an underground mine. |

| Q3 | Operation | There may be greater technical and logistical challenges when implementing a digital twin in an underground mining operation. |

| Q4 | Operation | Real-time data from machinery, geology, and personnel, if integrated into a digital twin |

| Q5 | Productivity | Infrastructure requirements (connectivity, hardware, software) may be necessary to maintain an efficient digital twin. |

| Q6 | Productivity | A digital twin could optimize production planning and logistics in underground mining. |

| Q7 | Safety | Decision-making in a digital twin is improved in critical situations, such as structural failures or unexpected geological changes. |

| Q8 | Safety | The digital twin does predict events such as landslides or floods through simulations. |

| Q9 | Safety | The digital twin contributes to worker safety in underground environments |

| Q10 | Sustainability | A digital twin plays an important role in monitoring environmental conditions (air quality, vibrations, temperature). |

| Q11 | Sustainability | A digital twin could offer sustainability benefits (waste reduction, energy efficiency) |

| Q12 | Economy | A digital twin could generate ROI (Return on Investment) in an underground mine. |

| Q13 | Technology | Technological advances (e.g., 5G, edge computing) could power digital twins in the coming years |

| Q14 | Operation | A digital twin considers the training of staff to operate and take advantage of these technological tools. |

| Q15 | Operation | The digital twin could serve as the foundational basis for achieving fully autonomous underground mining operations in the future. |

| Ask | N for the Test | Wilcoxon Statistic | p-Value |

|---|---|---|---|

| Q1 | 7 | 60.0 | 0.001 |

| Q2 | 10 | 103.0 | 0.001 |

| Q3 | 8 | 75.0 | 0.001 |

| Q4 | 9 | 88.0 | 0.001 |

| Q5 | 9 | 88.0 | 0.001 |

| Q6 | 10 | 103.0 | 0.001 |

| Q7 | 10 | 103.0 | 0.001 |

| Q8 | 6 | 52.0 | 0.002 |

| Q9 | 10 | 103.0 | 0.001 |

| Q10 | 8 | 75.0 | 0.001 |

| Q11 | 7 | 60.0 | 0.001 |

| Q12 | 9 | 88.0 | 0.001 |

| Q13 | 10 | 103.0 | 0.001 |

| Q14 | 10 | 103.0 | 0.001 |

| Q1 | Q2 | Q3 | Q4 | Q5 | Q6 | Q7 | Q8 | Q9 | Q10 | Q11 | Q12 | Q13 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q2 | 0.23 | ||||||||||||

| Q3 | −0.53 | 0.20 | |||||||||||

| Q4 | 0.31 | 0.26 | 0.36 | ||||||||||

| Q5 | −0.21 | −0.12 | 0.16 | −0.31 | |||||||||

| Q6 | 0.44 | 0.09 | 0.06 | 0.25 | 0.44 | ||||||||

| Q7 | 0.33 | −0.18 | 0.66 * | 0.44 | 0.37 | 0.22 | |||||||

| Q8 | 0.08 | 0.05 | 0.12 | −0.27 | 0.62 * | 0.25 | 0.59 * | ||||||

| Q9 | 0.21 | −0.30 | 0.36 | 0.79 * | 0.09 | −0.08 | 0.04 | 0.38 | |||||

| Q10 | 0.61 | 0.23 | −0.19 | 0.44 | −0.22 | 0.56 * | 0.26 | 0.10 | 0.08 | ||||

| Q11 | 0.14 | −0.15 | 0.69 * | −0.19 | 0.06 | 0.33 | 0.12 | 0.33 | 0.11 | 0.34 | |||

| Q12 | 0.42 | 0.81 * | 0.12 | 0.08 | −0.07 | −0.15 | −0.20 | 0.80 * | 0.36 | 0.22 | −0.05 | ||

| Q13 | 0.56 | 0.27 | −0.38 | 0.71 * | −0.22 | 0.22 | 0.44 | −0.13 | 0.11 | 0.72 * | 0.21 | 0.16 | |

| Q14 | 0.09 | 0.19 | −0.33 | 0.07 | 0.14 | 0.08 | 0.35 | −0.30 | −0.11 | 0.29 | 0.33 | 0.68 * | −0.05 |

| p-value < 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cacciuttolo, C.; Atencio, E.; Komarizadehasl, S.; Lozano-Galant, J.A. Development of an Advanced Multi-Layer Digital Twin Conceptual Framework for Underground Mining. Sensors 2025, 25, 6650. https://doi.org/10.3390/s25216650

Cacciuttolo C, Atencio E, Komarizadehasl S, Lozano-Galant JA. Development of an Advanced Multi-Layer Digital Twin Conceptual Framework for Underground Mining. Sensors. 2025; 25(21):6650. https://doi.org/10.3390/s25216650

Chicago/Turabian StyleCacciuttolo, Carlos, Edison Atencio, Seyedmilad Komarizadehasl, and Jose Antonio Lozano-Galant. 2025. "Development of an Advanced Multi-Layer Digital Twin Conceptual Framework for Underground Mining" Sensors 25, no. 21: 6650. https://doi.org/10.3390/s25216650

APA StyleCacciuttolo, C., Atencio, E., Komarizadehasl, S., & Lozano-Galant, J. A. (2025). Development of an Advanced Multi-Layer Digital Twin Conceptual Framework for Underground Mining. Sensors, 25(21), 6650. https://doi.org/10.3390/s25216650