A Fault Diagnosis Method for Gas Turbine Rolling Bearings with Variable Speed Based on Dynamic Time-Varying Response and Joint Attention Mechanism

Abstract

1. Introduction

- (1)

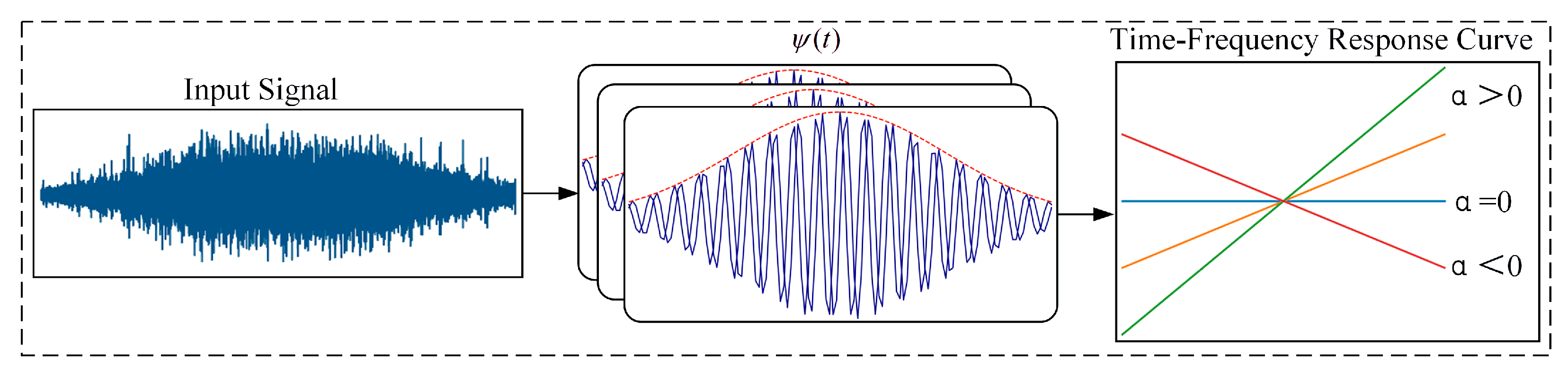

- Due to the variable speed issue, this paper designs a dynamic time-varying response module that effectively captures the changing characteristics of time-varying signals through a dynamically adjusted convolutional neural network.

- (2)

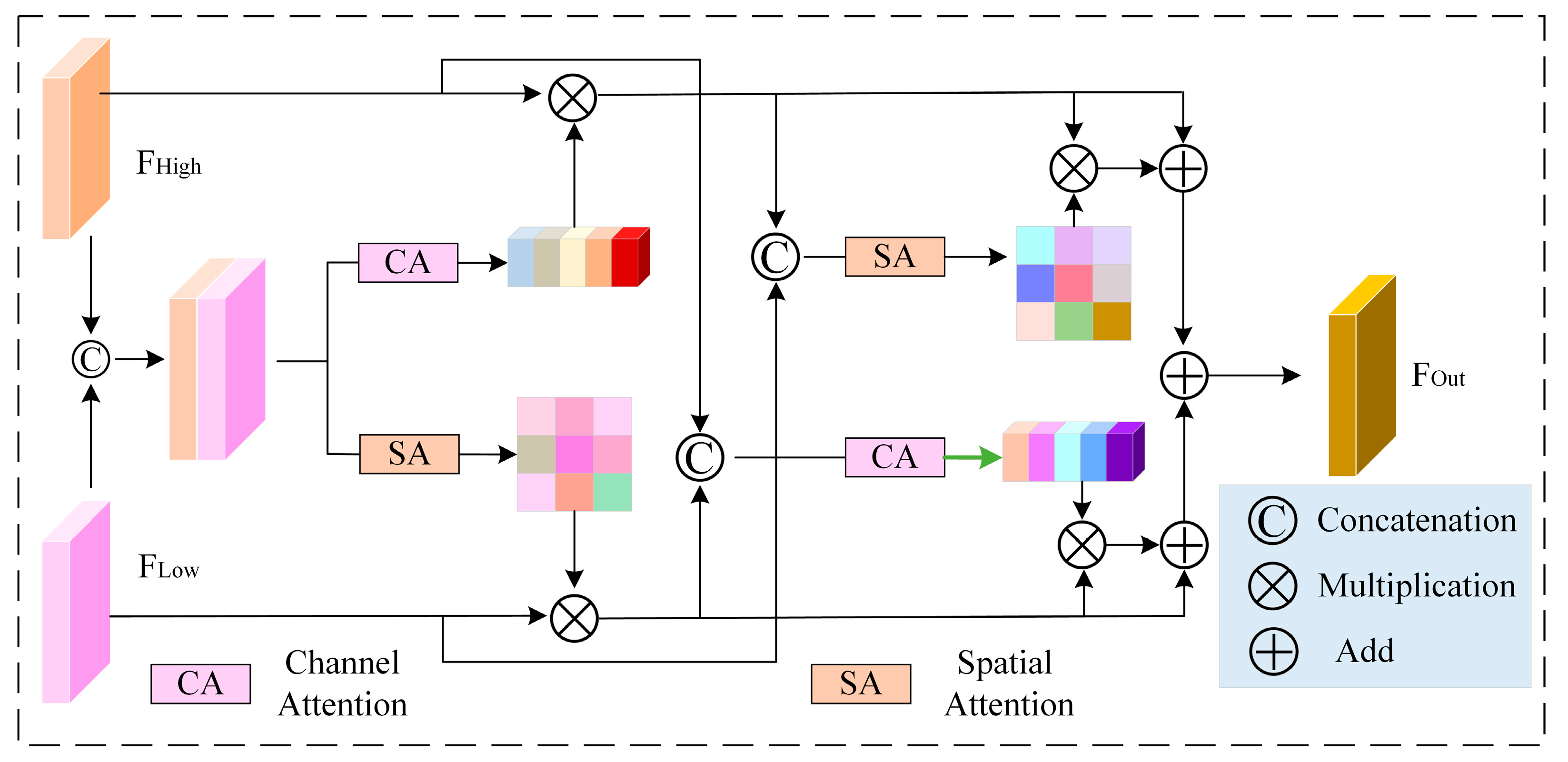

- To address the frequent start-stop problem, this paper combines channel and spatial attention mechanisms to automatically weigh important features, enhancing the model’s adaptability under complex operating conditions. Particularly, in environments with variable speed and frequent start-stop cycles, this significantly improves the robustness of fault diagnosis.

- (3)

- This paper proposes a novel multi-channel variable-speed attention framework, which effectively captures key features in variable speed conditions with three-channel inputs. By integrating channel and spatial attention mechanisms, it adaptively strengthens attention to core features, thereby achieving precise fault diagnosis of bearings under complex operating conditions.

2. Related Work

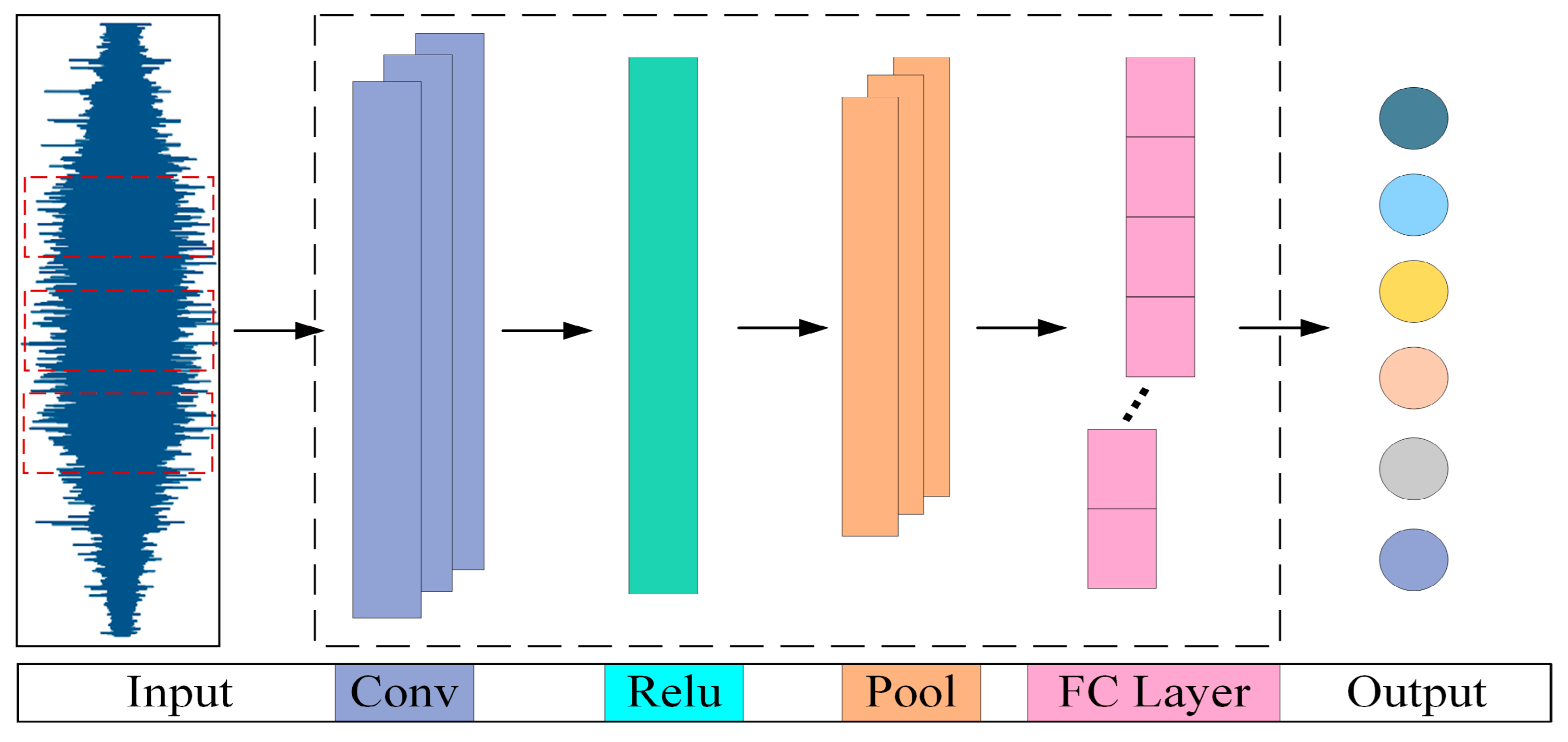

2.1. Convolutional Neural Networks

2.2. Spatial Attention Mechanism

2.3. Channel Attention Mechanism

2.4. Feature Fusion Techniques

3. Method

3.1. Multi-Channel Variable-Speed Attention Framework

- (1)

- Data Acquisition: Collect high-frequency vibration signals of the bearing under various operating conditions, including start-stop cycles, variable speeds, and different load levels, to ensure comprehensive and reliable feature extraction.

- (2)

- Multi-Channel Input Construction: Preprocess the raw vibration signals through denoising, normalization, and time-window segmentation, and construct three-channel inputs to provide rich, multi-dimensional fault information for the convolutional layers.

- (3)

- Dynamic Response Modeling: Extract local features using multiple convolutional layers and employ adaptive time-varying convolution kernels to normalize signals with different lengths and phases, addressing non-stationary characteristics under start-stop and variable-speed conditions and ensuring stable feature representations.

- (4)

- Joint Attention Mechanism: Apply Channel Attention (CAM) and Spatial Attention (SAM) on the convolutional feature maps to emphasize key channels and critical spatial positions, then fuse them to generate highly discriminative features, enhancing the model’s sensitivity and recognition capability for subtle fault signals.

- (5)

- Classification and Evaluation: Feed the fused features into the classifier for fault type identification and rigorously evaluate the recognition results using metrics such as accuracy, F1-score, and confusion matrices to validate the robustness and reliability of the method under complex operating conditions.

3.2. Dynamic Time-Varying Response Module

3.3. Joint Attention Mechanism

4. Experimental Validation

4.1. Tsinghua University Variable-Speed Bearing Dataset

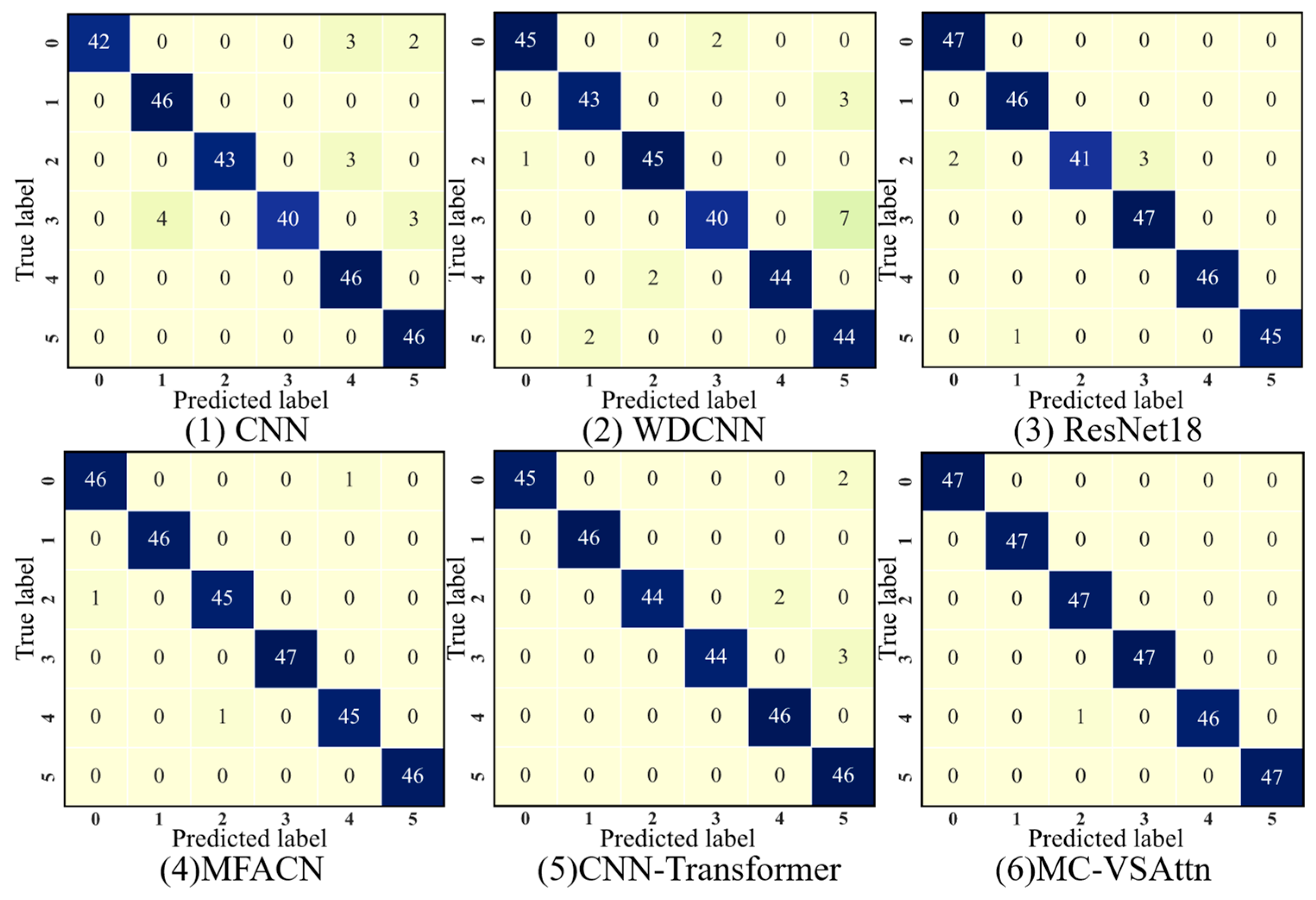

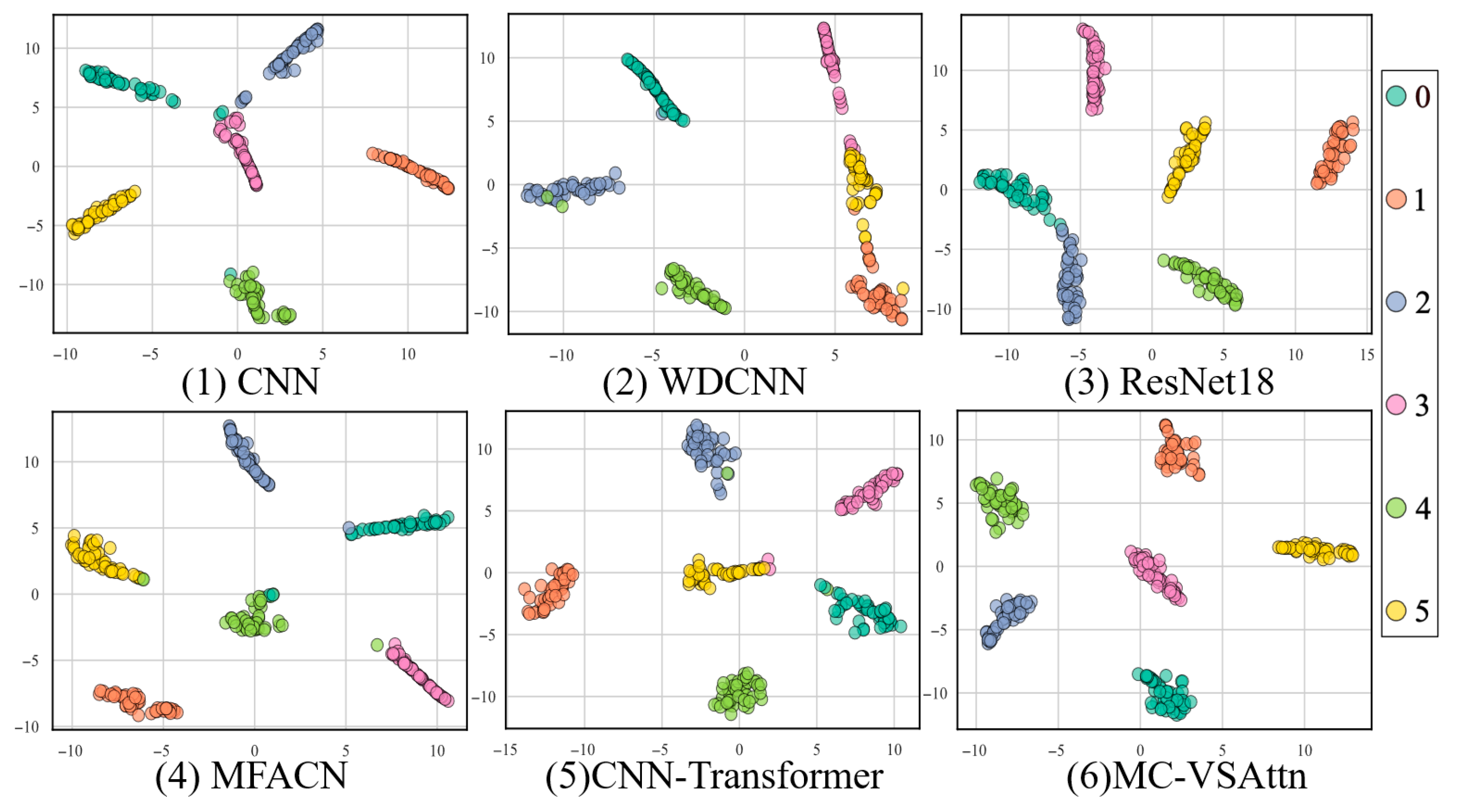

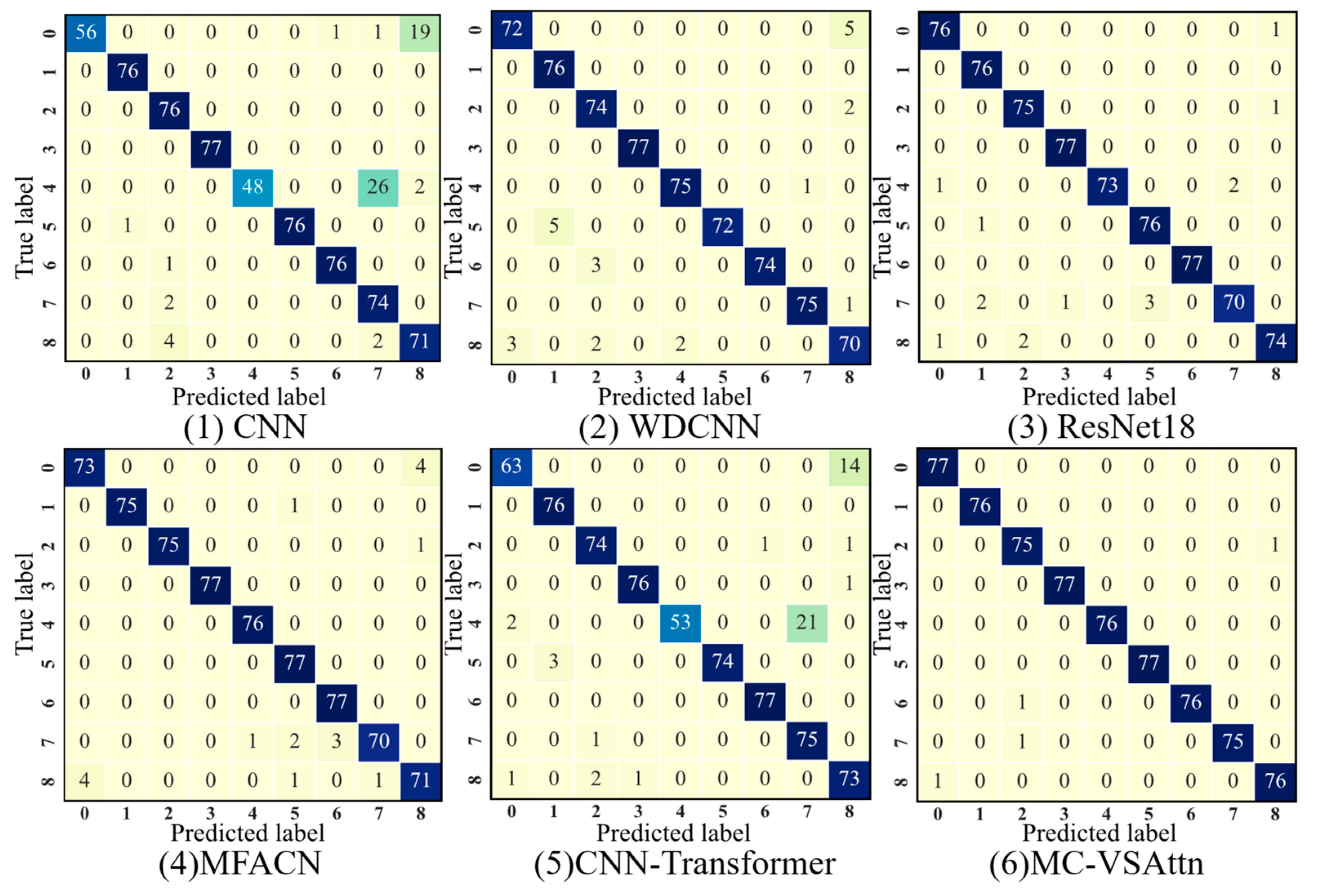

4.1.1. Results and Analysis

4.1.2. Ablation Study

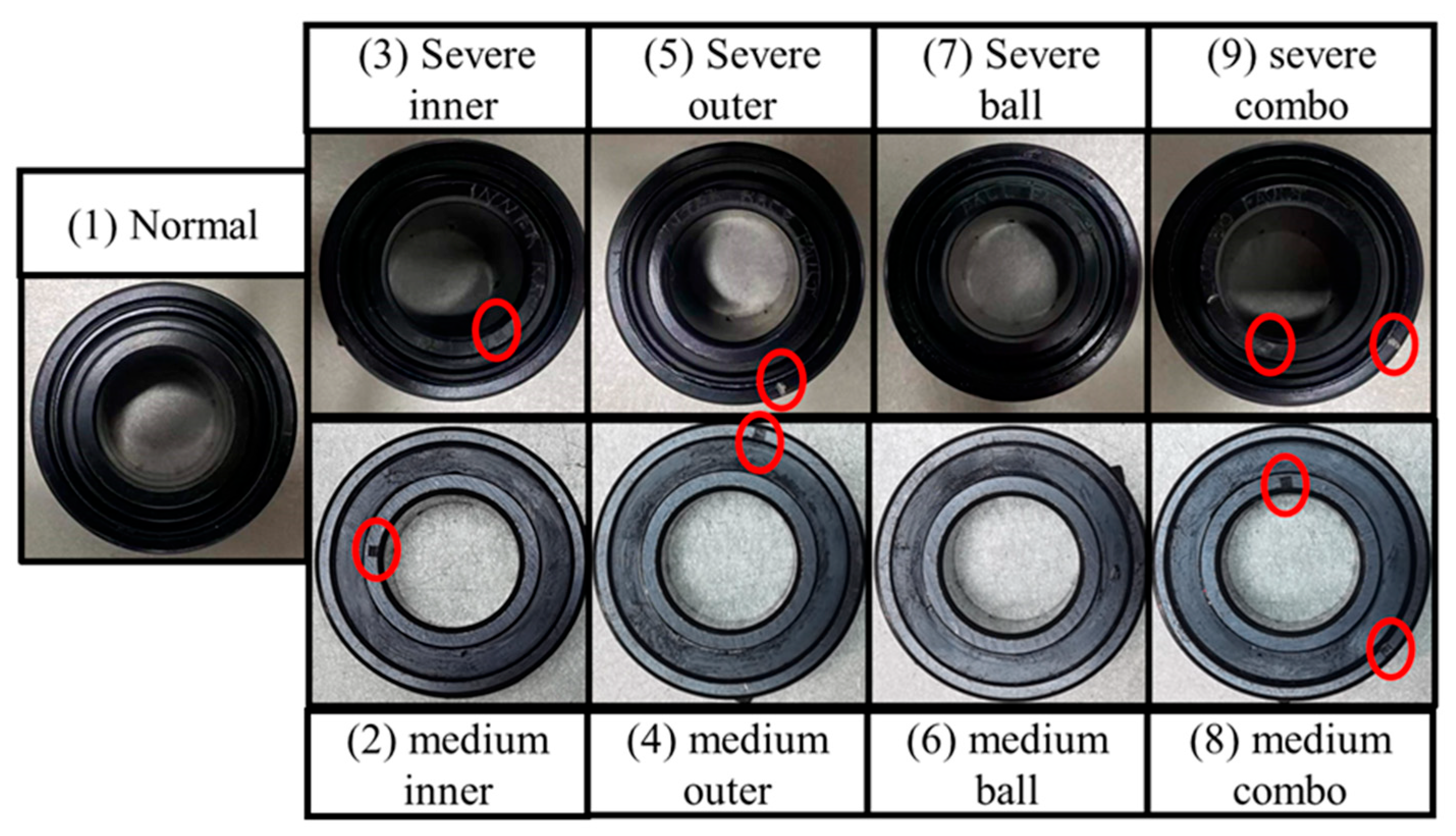

4.2. Huazhong University of Science and Technology Variable-Speed Bearing Dataset

4.2.1. Results and Analysis

4.2.2. Ablation Experiments

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, X.; Xiao, S.; Li, Q.; Zhu, L.; Wang, T.; Chu, F. The bearing multi-sensor fault diagnosis method based on a multi-branch parallel perception network and feature fusion strategy. Reliab. Eng. Syst. Saf. 2025, 261, 111122. [Google Scholar] [CrossRef]

- Li, Q.; Chen, L.; Kong, L.; Wang, D.; Xia, M.; Shen, C.J.R.E.; Safety, S. Cross-domain augmentation diagnosis: An adversarial domain-augmented generalization method for fault diagnosis under unseen working conditions. Reliab. Eng. Syst. Saf. 2023, 234, 109171. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Z.; Jiang, Y.; Gong, D.; Zhou, K. Sparse LPV-ARMA model for non-stationary vibration representation and its application on gearbox tooth crack detection under variable speed conditions. Mech. Syst. Signal Process. 2025, 224, 112161. [Google Scholar] [CrossRef]

- Saucedo-Dorantes, J.J.; Arellano-Espitia, F.; Delgado-Prieto, M.; Osornio-Rios, R.A. Diagnosis Methodology Based on Deep Feature Learning for Fault Identification in Metallic, Hybrid and Ceramic Bearings. Sensors 2021, 21, 5832. [Google Scholar] [CrossRef]

- Su, B.; Lu, C.; Li, C. Current Status of Research on Hybrid Ceramic Ball Bearings. Machines 2024, 12, 510. [Google Scholar] [CrossRef]

- He, D.; He, M.; Yoon, J. Full Ceramic Bearing Fault Diagnosis with Few-Shot Learning Using GPT-2. Comput. Model. Eng. Sci. (CMES) 2025, 143, 1955–1969. [Google Scholar] [CrossRef]

- Wei, Y.; Liu, H.; Wei, M.; Li, M. A fault diagnosis method for dry vacuum pump bearing based on finite element simulation with deep transfer learning. IEEE Access 2025, 13, 138568–138588. [Google Scholar] [CrossRef]

- Zhi, S.; Niu, Y.; Ma, L.; Wu, H.; Shen, H.; Wang, T. Local Entropy Selection Scaling-extracting Chirplet Transform for Enhanced Time-Frequency Analysis and Precise State Estimation in Reliability-Focused Fault Diagnosis of Non-stationary Signals. Eksploat. I Niezawodn. Maint. Reliab. 2025. [Google Scholar] [CrossRef]

- Yu, Z.; Wei, Y.; Niu, B.; Zhang, X. Automatic condition monitoring and fault diagnosis system for power transformers based on voiceprint recognition. IEEE Trans. Instrum. Meas. 2024, 73, 1–11. [Google Scholar] [CrossRef]

- Li, X.; Wu, X.; Wang, T.; Xie, Y.; Chu, F.J. Fault diagnosis method for imbalanced data based on adaptive diffusion models and generative adversarial networks. Eng. Appl. Artif. Intell. 2025, 147, 110410. [Google Scholar] [CrossRef]

- Dong, Y.; Jiang, H.; Yao, R.; Mu, M.; Yang, Q.J.; Safety, S. Rolling bearing intelligent fault diagnosis towards variable speed and imbalanced samples using multiscale dynamic supervised contrast learning. Reliab. Eng. Syst. Saf. 2024, 243, 109805. [Google Scholar] [CrossRef]

- Zhi, S.; Shen, H.; Wang, T. Gearbox localized fault detection based on meshing frequency modulation analysis. Appl. Acoust. 2024, 219, 109943. [Google Scholar] [CrossRef]

- Zhang, C.; Meng, Z.; Wang, Y.; Yang, Z.; Jiang, H.; Li, B. Fault signature extraction of rolling bearings under variable speed via time–frequency overlap group sparse representation. Mech. Syst. Signal Process. 2025, 223, 111823. [Google Scholar] [CrossRef]

- Ma, Z.; Zhao, M.; Ou, S.; Ma, B.; Zhang, Y. Physics-Inspired sparse voiceprint sensing for bearing fault Diagnosis. IEEE Trans. Ind. Inform. 2024, 20, 11273–11284. [Google Scholar] [CrossRef]

- Gong, T.; Wang, Z.; Ma, Q.; Yang, J. Motor Bearing fault diagnosis in an industrial robot under complex variable speed Conditions. J. Comput. Nonlinear Dyn. 2023, 19, 021007. [Google Scholar] [CrossRef]

- Yang, D.; Cai, G.; Yan, Y.; Hu, Y.; Wang, S. Attention-Guided Multi-Feature Fusion Convolutional Network for Machinery Intelligent Fault Diagnosis. IEEE Trans. Instrum. Meas. 2025, 74, 3553114. [Google Scholar] [CrossRef]

- Li, X.; Yu, T.; Zhang, F.; Huang, J.; He, D.; Chu, F. Mixed style network based: A novel rotating machinery fault diagnosis method through batch spectral penalization. Reliab. Eng. Syst. Saf. 2025, 255, 110667. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, Q.; Hu, Y.; Xu, C.; Luo, L. Attention-based two-stage multi-sensor feature fusion method for bearing fault diagnosis. IEEE Trans. Ind. Appl. 2024, 60, 8709–8721. [Google Scholar] [CrossRef]

- Shen, Q.; Zhang, Z. Fault diagnosis method for bearing based on attention mechanism and multi-scale convolutional neural network. IEEE Access 2024, 12, 12940–12952. [Google Scholar] [CrossRef]

- Li, X.; Yu, T.; Wang, X.; Li, D.; Xie, Z.; Kong, X. Fusing joint distribution and adversarial networks: A new transfer learning method for intelligent fault diagnosis. Appl. Acoust. 2024, 216, 109767. [Google Scholar] [CrossRef]

- Li, X.; Wu, X.; Yu, J.; Wang, T.; Shi, C.; Choi, J.-H.; Chu, F. A fault diagnosis data augmentation method integrating multimodal non-Gaussian denoising diffusion generative adversarial network. Adv. Eng. Inform. 2025, 68, 103776. [Google Scholar] [CrossRef]

- Wang, H.; Li, M.; Liu, Z.; Dai, X.; Wang, R.; Shi, L. Rotary machinery fault diagnosis based on split attention mechanism and graph convolutional domain adaptive adversarial network. IEEE Sens. J. 2024, 24, 5399–5413. [Google Scholar] [CrossRef]

- Li, X.; Xiao, S.; Zhang, F.; Huang, J.; Xie, Z.; Kong, X. A fault diagnosis method with AT-ICNN based on a hybrid attention mechanism and improved convolutional layers. Appl. Acoust. 2024, 225, 110191. [Google Scholar] [CrossRef]

- Guo, M.-H.; Xu, T.-X.; Liu, J.-J.; Liu, Z.-N.; Jiang, P.-T.; Mu, T.-J.; Zhang, S.-H.; Martin, R.R.; Cheng, M.-M.; Hu, S.-M. Attention mechanisms in computer vision: A survey. Comput. Vis. Media 2022, 8, 331–368. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, J.; Zhang, X.; Lu, Y. Multiscale channel attention-driven graph dynamic fusion learning method for robust fault diagnosis. IEEE Trans. Ind. Inform. 2024, 20, 11002–11013. [Google Scholar] [CrossRef]

- Zhang, S.; Zhou, H. Transformer fault diagnosis based on Multi-Strategy enhanced Dung beetle algorithm and optimized SVM. Energies 2024, 17, 6296. [Google Scholar] [CrossRef]

- Wu, Y.; Bai, Y.; Yang, S.; Li, C. Extracting random forest features with improved adaptive particle swarm optimization for industrial robot fault diagnosis. Measurement 2024, 229, 114451. [Google Scholar] [CrossRef]

- Anwar, T.; Mu, C.; Yousaf, M.Z.; Khan, W.; Khalid, S.; Hourani, A.O.; Zaitsev, I. Robust fault detection and classification in power transmission lines via ensemble machine learning models. Sci. Rep. 2025, 15, 2549. [Google Scholar] [CrossRef]

- Li, Q.; Li, H.; Hu, W.; Sun, S.; Qin, Z.; Chu, F. Transparent operator network: A fully interpretable network incorporating learnable wavelet operator for intelligent fault diagnosis. IEEE Trans. Ind. Inform. 2024, 20, 8628–8638. [Google Scholar] [CrossRef]

- Wang, H.; Li, C.; Ding, P.; Li, S.; Li, T.; Liu, C.; Zhang, X.; Hong, Z. A novel transformer-based few-shot learning method for intelligent fault diagnosis with noisy labels under varying working conditions. Reliab. Eng. Syst. Saf. 2024, 251, 110400. [Google Scholar] [CrossRef]

- Zhao, D.; Shao, D.; Cui, L. CTNet: A data-driven time-frequency technique for wind turbines fault diagnosis under time-varying speeds. ISA Trans. 2024, 154, 335–351. [Google Scholar]

- Ahmad, I.; Xia, Y.; Cui, H.; Islam, Z.U. DAN-NucNet: A dual attention based framework for nuclei segmentation in cancer histology images under wild clinical conditions. Expert Syst. Appl. 2023, 213, 118945. [Google Scholar] [CrossRef]

- Chen, S.; Liu, Z.; He, X.; Zou, D.; Zhou, D. Multi-mode fault diagnosis datasets of gearbox under variable working conditions. Data Brief 2024, 54, 110453. [Google Scholar] [CrossRef] [PubMed]

- Zhao, B.; Zhang, X.; Li, H.; Yang, Z. Intelligent fault diagnosis of rolling bearings based on normalized CNN considering data imbalance and variable working conditions. Knowl.-Based Syst. 2020, 199, 105971. [Google Scholar] [CrossRef]

- Liu, X.; Chen, J.; Zhang, K.; Liu, S.; He, S.; Zhou, Z. Cross-domain intelligent bearing fault diagnosis under class imbalanced samples via transfer residual network augmented with explicit weight self-assignment strategy based on meta data. Knowl.-Based Syst. 2022, 251, 109272. [Google Scholar] [CrossRef]

- Zhang, W.; Peng, G.; Li, C.; Chen, Y.; Zhang, Z. A new deep learning model for fault diagnosis with good anti-noise and domain adaptation ability on raw vibration signals. Sensors 2017, 17, 425. [Google Scholar] [CrossRef]

- Xu, Y.; Li, S.; Yan, X.; He, J.; Ni, Q.; Sun, Y.; Wang, Y. Multiattention-based feature aggregation convolutional networks with dual focal loss for fault diagnosis of rotating machinery under data imbalance conditions. IEEE Trans. Instrum. Meas. 2024, 73, 3506211. [Google Scholar] [CrossRef]

- Zhi, S.; Su, K.; Yu, J.; Li, X.; Shen, H. An unsupervised transfer learning bearing fault diagnosis method based on multi-channel calibrated Transformer with shiftable window. Struct. Health Monit. 2025. [Google Scholar] [CrossRef]

- Zhao, C.; Zio, E.; Shen, W. Domain generalization for cross-domain fault diagnosis: An application-oriented perspective and a benchmark study. Reliab. Eng. Syst. Saf. 2024, 245, 109964. [Google Scholar] [CrossRef]

| Health Condition | Label |

|---|---|

| Healthy Gear + Healthy Bearing | 0 |

| Gear Tooth Break + Inner Race L | 1 |

| Gear Tooth Break + Inner Race M | 2 |

| Gear Tooth Break + Inner Race H | 3 |

| Gear Tooth Break + Outer Race L | 4 |

| Gear Tooth Break + Outer Race M | 5 |

| Method | F1 | Acc (%) | Pr (%) | Re (%) |

|---|---|---|---|---|

| CNN | 94.74 | 94.85 | 94.15 | 94.85 |

| WDCNN | 94.45 | 94.43 | 94.73 | 94.43 |

| ResNet18 | 96.44 | 96.47 | 96.47 | 96.47 |

| MFACN | 97.56 | 97.59 | 97.56 | 97.54 |

| CNN-Transformer | 97.46 | 97.58 | 97.46 | 97.46 |

| MC-VSAttn | 99.04 | 99.14 | 99.15 | 99.12 |

| Methods | F1 | Acc (%) | Pr (%) | Re (%) |

|---|---|---|---|---|

| MC-VSAttn | 99.04 ± 0.12 | 99.14 ± 0.11 | 99.15 ± 0.07 | 99.12 ± 0.05 |

| A | 96.12 ± 0.33 | 96.25 ± 0.42 | 96.33 ± 0.31 | 96.18 ± 0.22 |

| B | 95.06 ± 0.24 | 95.22 ± 0.31 | 95.34 ± 0.30 | 95.29 ± 0.26 |

| C | 96.35 ± 0.20 | 96.30 ± 0.28 | 96.50 ± 0.23 | 96.20 ± 0.19 |

| D | 95.59 ± 0.44 | 95.51 ± 0.27 | 95.43 ± 0.36 | 95.29 ± 0.41 |

| E | 96.01 ± 0.39 | 96.12 ± 0.31 | 96.23 ± 0.40 | 96.01 ± 0.38 |

| Health Condition | Label | Health Condition | Label |

|---|---|---|---|

| Normal Bearing | 0 | Moderate Rolling Element Fault | 5 |

| Moderate Inner Race Fault | 1 | Severe Rolling Element Fault | 6 |

| Severe Inner Race Fault | 2 | Moderate Combined Fault | 7 |

| Moderate Outer Race Fault | 3 | Severe Combined Fault | 8 |

| Severe Outer Race Fault | 4 |

| Method | F1 | Acc (%) | Pr (%) | Re (%) |

|---|---|---|---|---|

| CNN | 92.74 | 92.85 | 92.65 | 92.85 |

| WDCNN | 94.45 | 94.64 | 94.71 | 94.64 |

| ResNet18 | 95.78 | 95.82 | 96.08 | 95.82 |

| MFACN | 96.83 | 96.83 | 96.97 | 96.83 |

| CNN-Transformer | 94.02 | 94.38 | 94.94 | 94.12 |

| MC-VSAttn | 98.24 | 98.23 | 98.23 | 98.22 |

| Methods | F1 | Acc (%) | Pr (%) | Re (%) |

|---|---|---|---|---|

| MC-VSAttn | 98.24 ± 0.15 | 98.23 ± 0.14 | 98.23 ± 0.11 | 98.22 ± 0.13 |

| A | 95.92 ± 0.27 | 96.05 ± 0.32 | 96.10 ± 0.30 | 95.88 ± 0.29 |

| B | 94.85 ± 0.41 | 94.92 ± 0.40 | 95.30 ± 0.38 | 94.80 ± 0.36 |

| C | 96.08 ± 0.28 | 96.12 ± 0.28 | 96.25 ± 0.31 | 96.01 ± 0.25 |

| D | 95.40 ± 0.37 | 95.48 ± 0.36 | 95.52 ± 0.34 | 95.35 ± 0.33 |

| E | 95.97 ± 0.35 | 96.02 ± 0.33 | 96.12 ± 0.31 | 95.91 ± 0.34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, H.; Dong, Z.; Li, X. A Fault Diagnosis Method for Gas Turbine Rolling Bearings with Variable Speed Based on Dynamic Time-Varying Response and Joint Attention Mechanism. Sensors 2025, 25, 6617. https://doi.org/10.3390/s25216617

Lv H, Dong Z, Li X. A Fault Diagnosis Method for Gas Turbine Rolling Bearings with Variable Speed Based on Dynamic Time-Varying Response and Joint Attention Mechanism. Sensors. 2025; 25(21):6617. https://doi.org/10.3390/s25216617

Chicago/Turabian StyleLv, Hongxun, Zhilin Dong, and Xueyi Li. 2025. "A Fault Diagnosis Method for Gas Turbine Rolling Bearings with Variable Speed Based on Dynamic Time-Varying Response and Joint Attention Mechanism" Sensors 25, no. 21: 6617. https://doi.org/10.3390/s25216617

APA StyleLv, H., Dong, Z., & Li, X. (2025). A Fault Diagnosis Method for Gas Turbine Rolling Bearings with Variable Speed Based on Dynamic Time-Varying Response and Joint Attention Mechanism. Sensors, 25(21), 6617. https://doi.org/10.3390/s25216617