Optical–Structural Optimization for Condensation Suppression in Automotive Camera Modules

Abstract

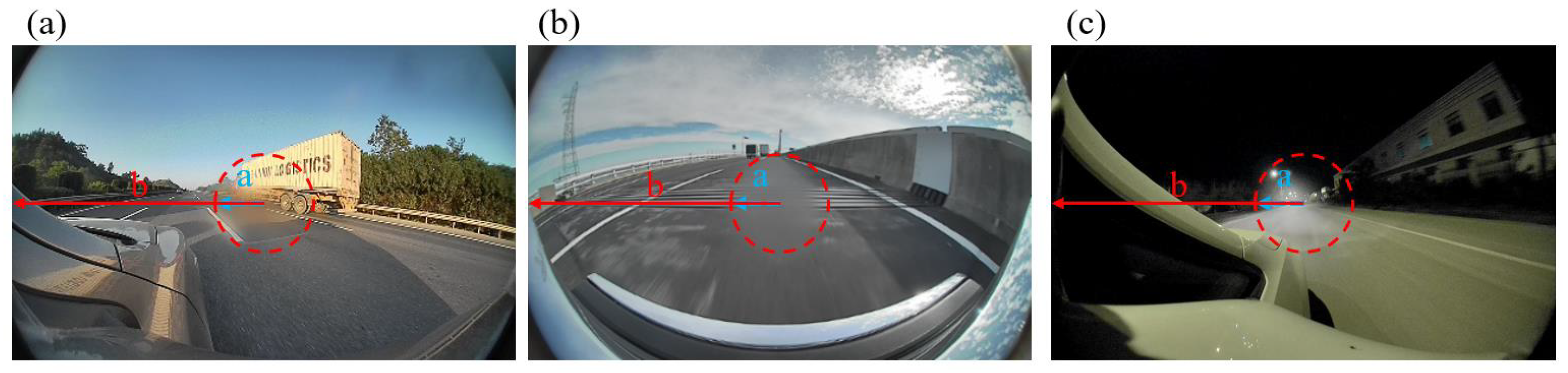

1. Introduction

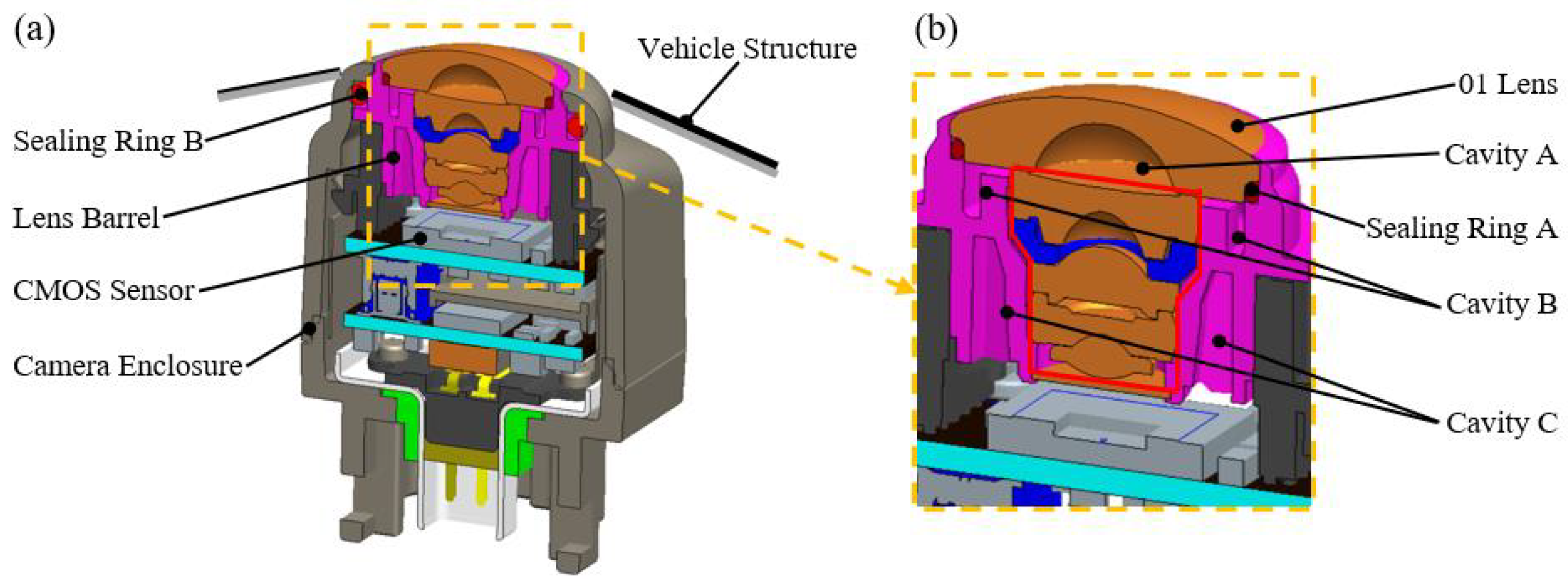

2. Simulation of Condensation in ACM

2.1. Materials and Methods

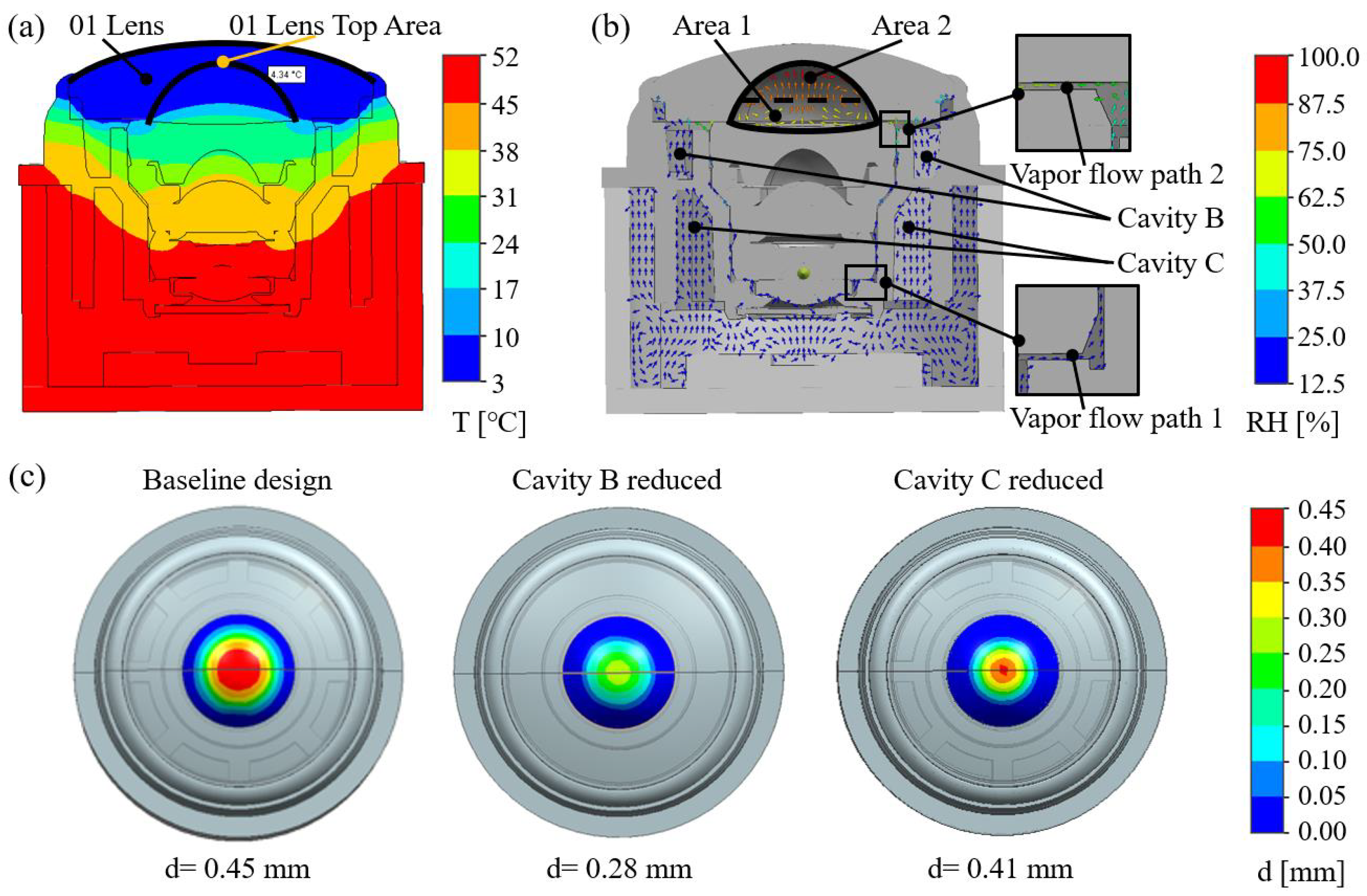

2.2. Simulation Analysis of Condensation-Induced Optical Imaging Degradation

3. Optical–Structural Optimization Design and Simulation Verification

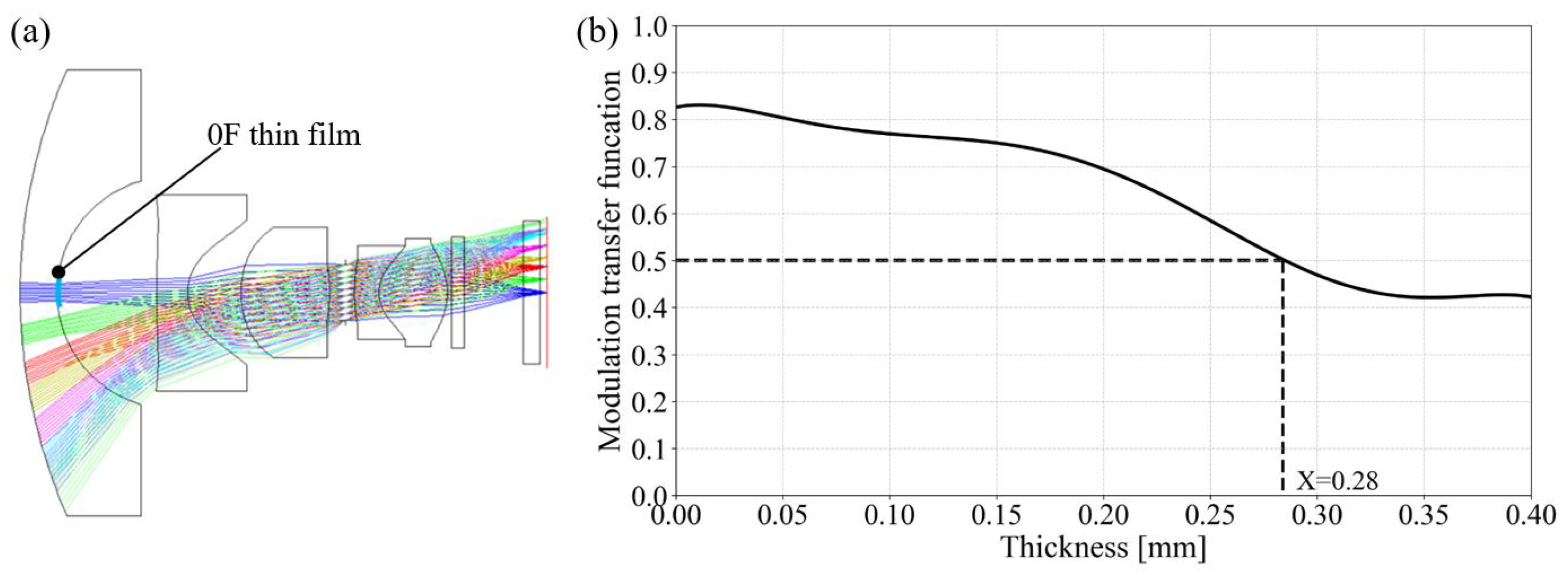

3.1. Optical–Structural Optimization Design

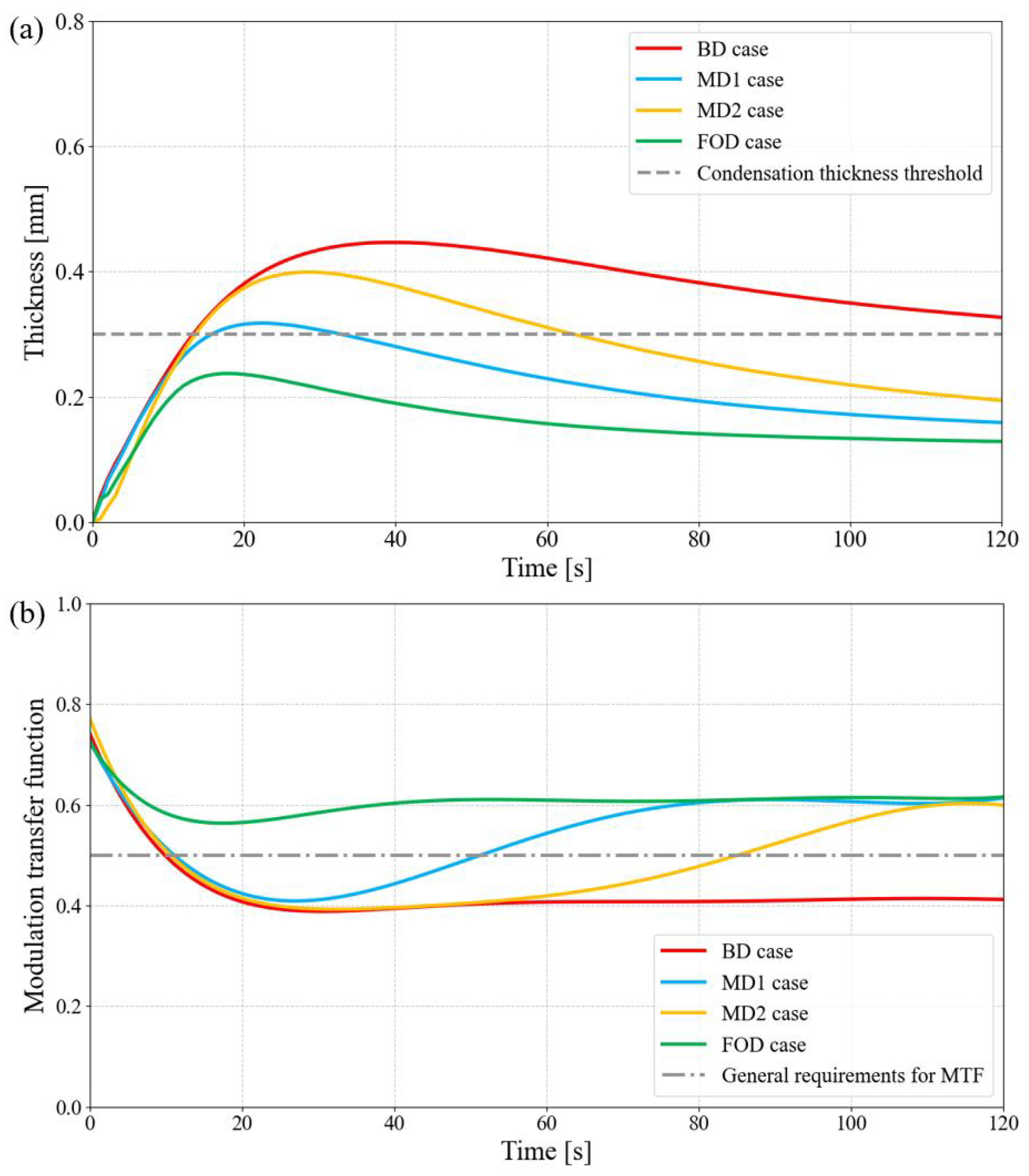

3.2. Comparison Analysis of ACM Before and After Optimization

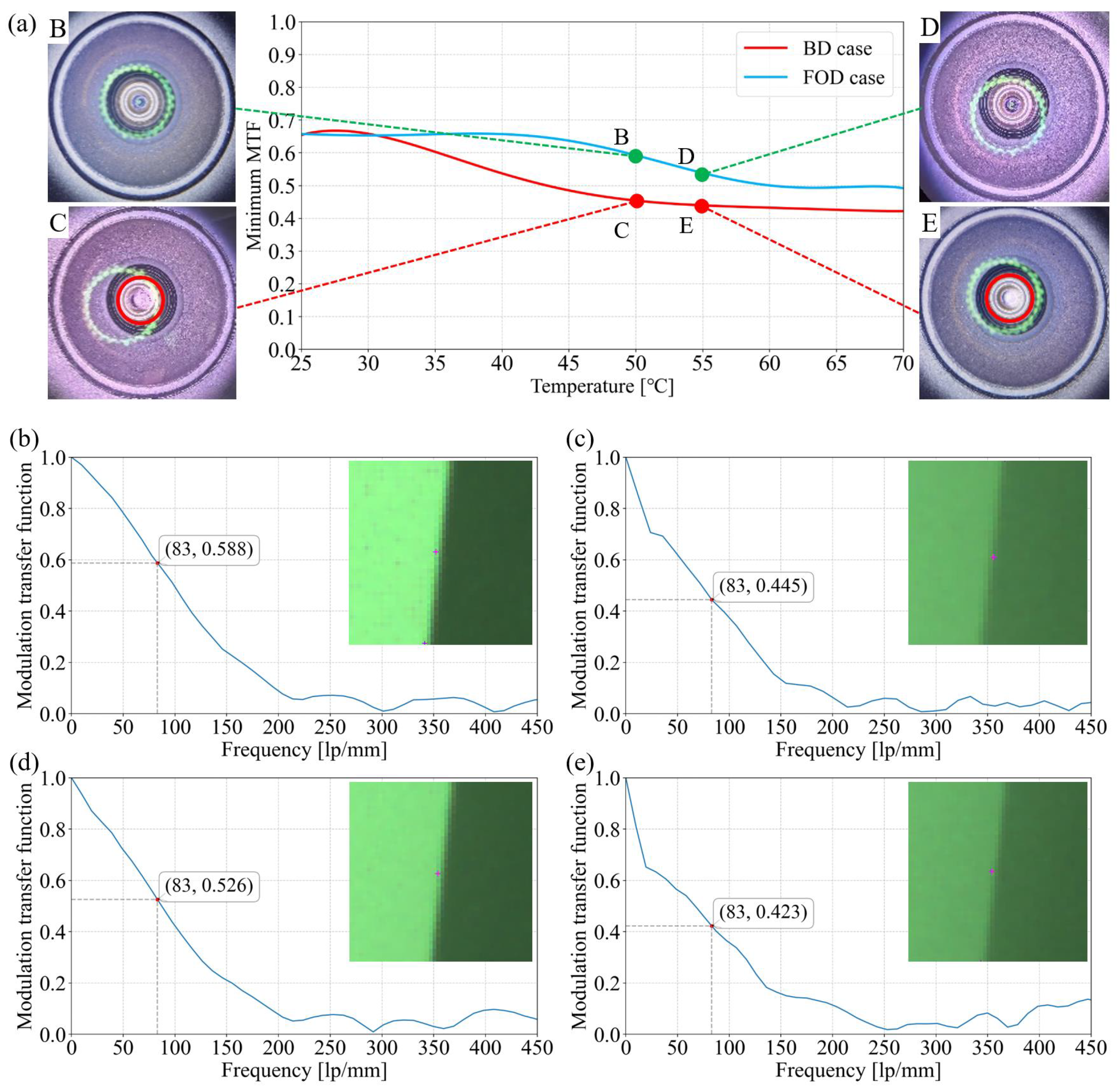

4. Experiment Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ADS | Autonomous Driving Systems |

| ACM | Automotive Camera Module |

| MTF | Modulation Transfer Function |

| RH | Relative Humidity |

| FOV | Field of View |

| BD | Baseline Design |

| MD1 | Modified Design 1 |

| MD2 | Modified Design 2 |

| FOD | Fully Optimized Design |

References

- Dong, X.; Cappuccio, M.; Al Jassmi, H.; Alnajjar, F.; Debie, E.; Ghasrikhouzani, M.; Lanteri, A.; Luqman, A.; McGregor, T.; Molloy, O.; et al. Why Autonomous Vehicles Are Not Ready Yet: A Multi-Disciplinary Review of Problems, Attempted Solutions, and Future Directions. arXiv 2023, arXiv:2311.09093. [Google Scholar]

- Van Brummelen, J.; O’Brien, M.; Gruyer, D.; Najjaran, H. Autonomous vehicle perception: The technology of today and tomorrow. Transport. Res. Part C Emerg. Technol. 2018, 89, 384–406. [Google Scholar] [CrossRef]

- Zhu, H.; Yuen, K.-V.; Mihaylova, L.; Leung, H. Overview of Environment Perception for Intelligent Vehicles. IEEE Trans. Intell. Transport. Syst. 2017, 18, 2584–2601. [Google Scholar] [CrossRef]

- Behere, S.; Törngren, M. A functional reference architecture for autonomous driving. Inf. Softw. Technol. 2016, 73, 136–150. [Google Scholar] [CrossRef]

- Yeong, D.J.; Velasco-Hernandez, G.; Barry, J.; Walsh, J. Sensor and Sensor Fusion Technology in Autonomous Vehicles: A Review. Sensors 2021, 21, 2140. [Google Scholar] [CrossRef] [PubMed]

- Rosique, F.; Navarro, P.J.; Fernández, C.; Padilla, A. A Systematic Review of Perception System and Simulators for Autonomous Vehicles Research. Sensors 2019, 19, 648. [Google Scholar] [CrossRef]

- Heng, L.; Choi, B.; Cui, Z.; Geppert, M.; Hu, S.; Kuan, B.; Liu, P.; Nguyen, R.; Yeo, Y.C.; Geiger, A.; et al. Project AutoVision: Localization and 3D Scene Perception for an Autonomous Vehicle with a Multi-Camera System. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 4695–4702. [Google Scholar]

- Li, Y.; Ibanez-Guzman, J. Lidar for Autonomous Driving: The Principles, Challenges, and Trends for Automotive Lidar and Perception Systems. IEEE Signal Process. Mag. 2020, 37, 50–61. [Google Scholar] [CrossRef]

- Alaba, S.Y.; Ball, J.E. A Survey on Deep-Learning-Based LiDAR 3D Object Detection for Autonomous Driving. Sensors 2022, 22, 9577. [Google Scholar] [CrossRef] [PubMed]

- Baek, S.; Kim, J.; Yi, K. Robust Tracking and Detection Based on Radar Camera Fusion Filtering in Urban Autonomous Driving. Intell. Serv. Robot. 2024, 17, 1125–1141. [Google Scholar] [CrossRef]

- Yao, S.; Guan, R.; Huang, X.; Li, Z.; Sha, X.; Yue, Y.; Lim, E.G.; Seo, H.; Man, K.L.; Zhu, X.; et al. Radar-Camera Fusion for Object Detection and Semantic Segmentation in Autonomous Driving: A Comprehensive Review. IEEE Trans. Intell. Veh. 2024, 9, 2094–2128. [Google Scholar] [CrossRef]

- Rhee, J.H.; Seo, J. Low-Cost Curb Detection and Localization System Using Multiple Ultrasonic Sensors. Sensors 2019, 19, 1389. [Google Scholar] [CrossRef]

- Wang, C.; Wang, X.; Hu, H.; Liang, Y.; Shen, G. On the Application of Cameras Used in Autonomous Vehicles. Arch. Comput. Methods Eng. 2022, 29, 4319–4339. [Google Scholar] [CrossRef]

- Matos, F.; Bernardino, J.; Durães, J.; Cunha, J. A Survey on Sensor Failures in Autonomous Vehicles: Challenges and Solutions. Sensors 2024, 24, 5108. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Carballo, A.; Yang, H.; Takeda, K. Perception and sensing for autonomous vehicles under adverse weather conditions: A survey. ISPRS J. Photogramm. Remote Sens. 2023, 196, 146–177. [Google Scholar] [CrossRef]

- Cicchino, J.B. Effects of rearview cameras and rear parking sensors on police-reported backing crashes. Traffic Inj. Prev. 2017, 18, 859–865. [Google Scholar] [CrossRef]

- Li, C. Waterproof Structure of Monitoring Camera. Chinese Patent CN201083940, 9 July 2008. [Google Scholar]

- Liu, Q.; Cui, J.; Kaneko, T.; Dong, W.; Chen, M.; Luo, J.; Shi, D. High and long-lasting antifogging performance of silane based hydrophilic polymer coating. Prog. Org. Coat. 2024, 196, 108690. [Google Scholar] [CrossRef]

- Kaveh, R.; Alijani, H.; Falletta, E.; Bianchi, C.L.; Mokhtarifar, M.; Boffito, D.C. Advancements in superhydrophilic titanium dioxide/graphene oxide composites coatings for self-cleaning applications on glass substrates: A comprehensive review. Prog. Org. Coat. 2024, 190, 108347. [Google Scholar] [CrossRef]

- Peng, J.; Ye, P.; Bu, X.; Zhang, Y.; Zhu, Y.; Wang, R.; Bao, D.; Wang, H. Dynamically omniphobic and highly transparent polyurethane coating towards efficient self-cleaning on photovoltaic modules. Prog. Org. Coat. 2025, 207, 109394. [Google Scholar] [CrossRef]

- Calhoun, J.T.; Redan, J.A. Elimination of laparoscopic lens fogging using directional flow of CO2. JSLS J. Soc. Laparoendosc. Surg. 2014, 18, 55–61. [Google Scholar] [CrossRef]

- Van Deurzen, D.F.P.; Mannaerts, G.H.H.; Jakimowicz, J.J.; Cuschieri, A. Prevention of Lens Condensation in Laparoscopic Surgery by Lens Heating with a Thermos Flask. Surg. Endosc. 2005, 19, 299–300. [Google Scholar] [CrossRef] [PubMed]

- Runia, A.J.; Zengerink, J.F.; Mannaerts, G.H.H. Easy Cleaning of the Scope’s Lens in a Syringe to Prevent Condensation During Laparoscopic Surgery. Surg. Endosc. 2009, 23, 2849–2850. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z. Vehicle-Mounted Camera and Vehicle. Chinese Patent CN220359240U, 16 January 2024. [Google Scholar]

- Xiao, W.; Shi, S.; Zhang, Y.; Zhang, G.; Yuan, R.; Lai, X. Study on the Technology of Removing Fog From Lens Glass Heated By Chip Waste Heat. Environ. Technol. 2023, 41, 118–125. [Google Scholar]

- Cao, J. A Camera with Anti-Fogging Function. Chinese Patent CN104618630A, 13 May 2015. [Google Scholar]

- Lu, H. Research Progress of Anti-Fogging Technology of Glass. China Ceram. 2004, 6, 49–52. [Google Scholar]

| Component | Material | Thermal Condition (W/m·K) | Density (g/cm3) | Specific Heat Conductivity (KJ/Kg·K) |

|---|---|---|---|---|

| Lens barrel | Plastic | 0.13 | 1.65 | 1.15 |

| 01 Lens | Glass | 0.91 | 4.24 | 0.5 |

| Other lens | Plastic | 0.17 | 1.08 | 2.5 |

| Upper Shell | Plastic | 0.13 | 1.56 | 1.1 |

| Lower Shell | Plastic | 0.13 | 1.56 | 1.1 |

| O-ring | Rubber | 0.25 | 1.13 | 0.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, K.; Xu, Y.; Xu, S.; Lin, X.; Zhou, J.; Liu, Z.; Li, Y.; Wei, H. Optical–Structural Optimization for Condensation Suppression in Automotive Camera Modules. Sensors 2025, 25, 6515. https://doi.org/10.3390/s25216515

Zhang K, Xu Y, Xu S, Lin X, Zhou J, Liu Z, Li Y, Wei H. Optical–Structural Optimization for Condensation Suppression in Automotive Camera Modules. Sensors. 2025; 25(21):6515. https://doi.org/10.3390/s25216515

Chicago/Turabian StyleZhang, Kouwen, Yike Xu, Shenwei Xu, Xiaoyang Lin, Junyu Zhou, Zhaoqing Liu, Yan Li, and Haoyun Wei. 2025. "Optical–Structural Optimization for Condensation Suppression in Automotive Camera Modules" Sensors 25, no. 21: 6515. https://doi.org/10.3390/s25216515

APA StyleZhang, K., Xu, Y., Xu, S., Lin, X., Zhou, J., Liu, Z., Li, Y., & Wei, H. (2025). Optical–Structural Optimization for Condensation Suppression in Automotive Camera Modules. Sensors, 25(21), 6515. https://doi.org/10.3390/s25216515