1. Introduction

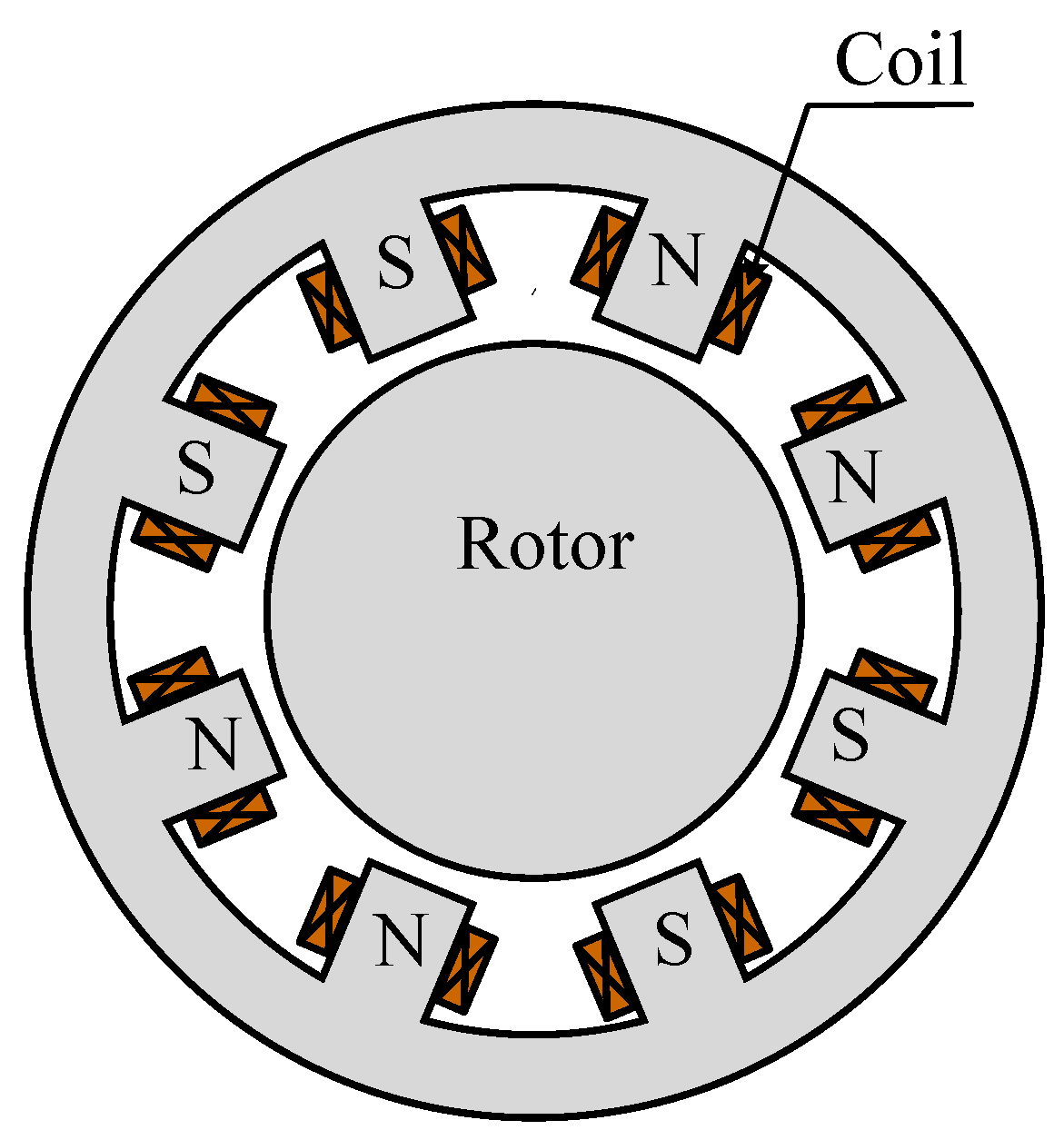

With increasingly stringent energy-efficiency targets, active magnetic bearings (AMBs) have emerged as a prevalent and promising technology, demonstrating outstanding performance and potential in multiple industrial rotating machines, such as compressors, turbines, and generators [

1,

2]. AMBs offer significant advantages over other contact and non-contact bearing technologies, including adjustable dynamics, high load capacity, and the omission of lubricants. Additionally, they can operate in extreme environments such as a vacuum and high-temperature conditions. Traditional AMB systems rely on displacement sensors to measure rotor displacement and achieve feedback control. However, AMB systems equipped with displacement sensors have the following shortcomings in practical applications:

Cost and reliability: Displacement sensors used in magnetic bearing systems include inductive displacement sensors and eddy current displacement sensors. In high-precision applications, eddy current sensors are often preferred due to their high resolution and fast response characteristics. However, eddy current sensors are costly, which increases manufacturing costs, and they can reduce the reliability of the system.

Failure of position detection in bending mode: When the rotor speed approaches the bending critical speed, the system may exhibit the flexible mode [

3,

4]. Due to the non-collocation arrangement between axial sensors and actuators, deriving the accurate displacements through a linear transformation is impossible. This non-collocation significantly increases the complexity and uncertainty under ultra-high rotating speed.

Integration limitations: Displacement sensors are typically arranged along the rotor’s axial or radial direction, thereby increasing axial length or occupying radial space, which increases volume and limits the high integration design of the system.

Displacement self-sensing technology provides a novel approach that does not require displacement sensors by directly estimating rotor displacements by processing signals within the actuators. Compared to traditional sensor-equipped systems, self-sensing offers significant advantages in terms of improving reliability, reducing manufacturing costs, minimizing size, and enhancing integration [

5,

6,

7]. As a result, self-sensing technology has become an important research direction in AMBs and has attracted widespread attention.

The displacement self-sensing technology for active magnetic levitation bearings was first proposed by Vischer, a scholar from the Swiss Federal Institute of Technology in Zurich (ETH Zurich), in 1988 [

8]. Vischer’s method was based on the Luenberger observer scheme for the linearized state-space model of the equilibrium point in a single-degree-of-freedom (1-DOF) magnetic levitation system (MagLev) [

8,

9]. Subsequently, Mizuno et al. investigated the stability of magnetic levitation systems without displacement sensors [

10], and provided an analysis of the stability differences between self-sensing systems using full-dimensional observers and reduced-dimensional observers [

10,

11,

12]. Morse et al. compared the upper bounds of the compensating sensitivity functions for two magnetic levitation control systems—one equipped with displacement sensors and the other based on a linear observer—using the small gain theorem and insensitivity function robustness theory. They concluded that the robustness and stability of the MagLev system based on a linear observer are significantly lower than those of the system equipped with displacement sensors [

13].

As numerous experimental studies found that the robustness estimates above were overly conservative [

14,

15,

16], Maslen and Montie from the University of Virginia revised the aforementioned view using a linear periodic model and analyzed the robustness limits of self-sensing AMB systems, with conclusions closely aligned with experimental results [

14,

17]. The LP model accounts for the switching ripple effects of the PWM power amplifier itself, indicating that utilizing the periodic ripple components in voltage and current can enhance the robustness of self-sensing technology. This is also one of the foundational theoretical studies for AMB self-sensing schemes based on demodulation methods. In recent years, various displacement estimation methods based on advanced control system theories such as nonlinear observers and adaptive filters have been proposed [

18,

19]. Since the single-degree-of-freedom MagLev system is inherently a third-order, nonlinear, highly uncertain system with multiple mismatched disturbances, the design of nonlinear observers must prioritize performance metrics such as convergence and robustness. Mystkowski et al. designed a sliding mode observer that leverages the insensitivity of sliding mode control to matched disturbances to address model uncertainty, and incorporated a magnetic circuit nonlinearity correction mechanism [

18], but the experimental results were unsatisfactory. The Kalman filter displacement estimator optimized using a particle swarm algorithm proposed by scholars from Jiangsu University was successfully applied in a laboratory setting for a three-pole, five-degree-of-freedom AMB. However, the Kalman filter algorithm for the state transition model of a high-order (15th-order) AMB poses significant computational challenges for digital controllers [

19].

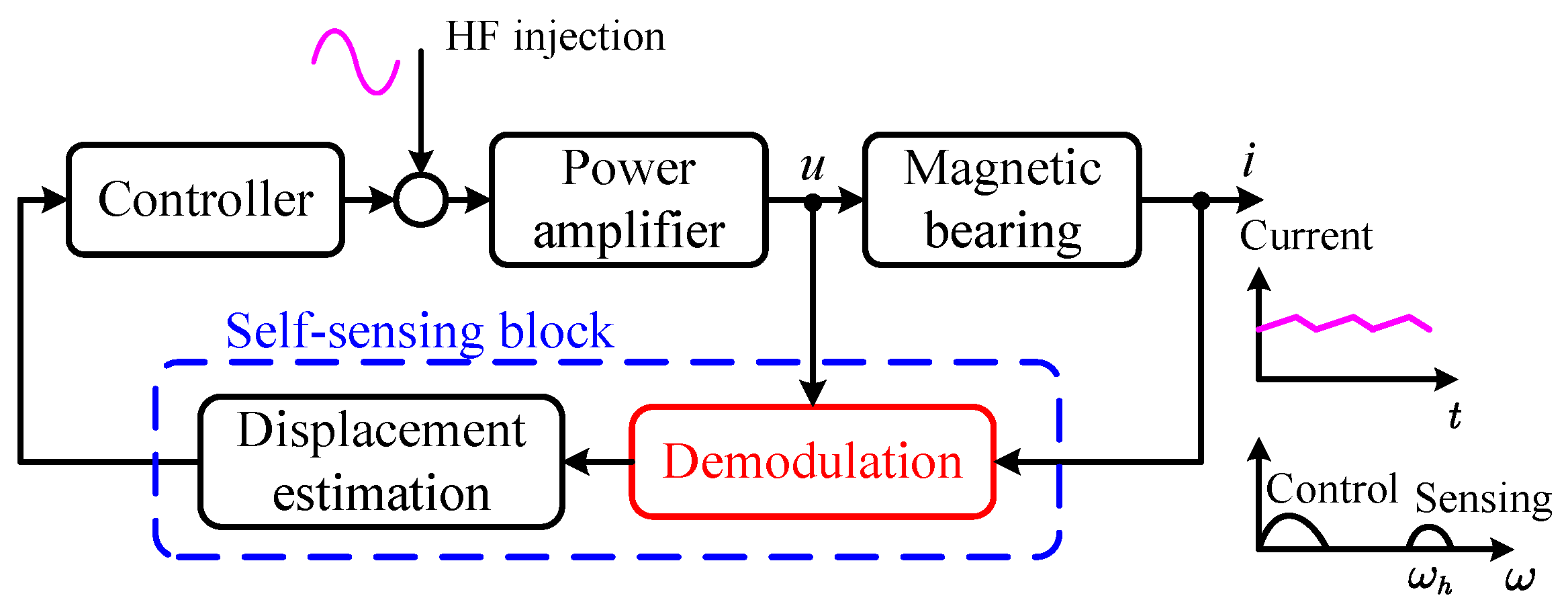

Another technical approach for self-sensing AMBs is parameter estimation, which involves deriving displacement through signal detection or system identification algorithms using the physical model of electromagnet inductance–displacement. Parameter identification methods emerged in the early 1990s and can be categorized into demodulation methods based on signal analysis and parameter identification methods based on dynamic models [

20,

21]. These methods generally rely on high-frequency (HF) signals. If a linear power amplifier is used, an additional high-frequency power supply is required to generate the injection signal. Conversely, the maturity of modern power electronics technology has enabled the widespread use of PWM switch amplifiers. By utilizing the switching ripple inherent in PWM, rotor displacement information can be obtained without applying an injection signal.

Depending on the type of information being analyzed, demodulation methods can be categorized into amplitude demodulation [

6,

22,

23,

24], frequency demodulation [

20,

25,

26,

27], and phase demodulation [

28]. Displacement self-sensing based on amplitude demodulation typically involves three signal processing stages: bandpass filtering, peak detection, and low-pass filtering. Early researchers used analog circuits to implement signal demodulation [

22,

29,

30,

31]. With the improvement in digital microcontroller processing capabilities, digital signal frequency analysis techniques, including Fourier transform [

32], digital phase-locked amplifiers [

24], current change rate detection, wavelet transform [

33,

34], Hilbert transform, etc., have gradually replaced the rectification and low-pass filtering stages of analog circuits, and together with analog anti-aliasing filters, form a mixed analog–digital demodulation scheme. Compared to pure analog schemes, mixed analog–digital schemes have higher hardware complexity, but they require higher processor computational capabilities, consume more computational resources, and have higher software complexity, though they offer more flexible configuration and implementation options. To address the dependence of PWM ripple amplitude on the duty cycle and the PWM sideband effects caused by the dynamic duty cycle [

35,

36], Zhu and Tang et al. proposed a compensation strategy using Butterworth wideband bandpass filters (BPFs) and eCAP real-time duty cycle detection [

23].

In [

34], a dual orthogonal spline wavelet algorithm to replace the traditional BPF is employed, addressing the issue of non-uniform convergence caused by the Gibbs effect in non-stationary characteristics of non-periodic waveforms. Reference [

25] utilizes a hysteresis PWM power amplifier to achieve detection based on the relationship between inductance and PWM ripple frequency under fixed current ripple magnitude conditions; however, such methods exhibit poor dynamic performance during current reference transients and are difficult to resolve. The phase demodulation method based on orthogonal injection signals proposed in [

28] has too low sensitivity and high parameter dependency, making it difficult to apply in practice. Additionally, some scholars have proposed a nonlinear parameter estimation method that uses an inductance model to estimate the current, then constructs a closed-loop inductance estimator using the current estimation error, and applies the Popov circle criterion to select parameters to ensure algorithm stability [

21,

29,

37,

38]. Parameter estimation methods based on system identification typically involve collecting PWM current ripple, constructing parameter estimation formats using discrete dynamic models driven by switching voltages, and identifying unknown inductance using the least squares method [

39,

40].

In addition to the development trend of digital alternatives for demodulation schemes, the refinement of inductance models is also a key research focus in demodulation-based AMB displacement self-sensing. Traditional inductance–displacement estimation models are based on the assumption of a linear magnetic circuit, ignoring the effects of magnetic field saturation, eddy current effects, and cross-coupling between radial displacements. To account for magnetic saturation in displacement self-sensing strategies, existing methods include magnetic circuit polynomial fitting [

22,

31,

41], FEM-based precise numerical optimization of magnetic network analysis [

42,

43], weight-based magnetic saturation avoidance methods [

44], and data-driven and machine learning approaches [

45]. Meeker et al. studied the magnetic bearing pole model, considering eddy current effects, and proposed a complex permeability and equivalent cascaded RL network model [

46]. Methods for compensating eddy current effects include the complex permeability lookup table method [

42], RL network inversion method [

47], dynamic compensator method [

48], and current offset correction method [

49], among others.

In addition, some studies have incorporated similar physical sensors into power amplifiers by improving their structure. In [

36], a dedicated sensing winding to the magnetic bearing core is added to amplify ripple current, and an RLC passive filter is incorporated to improve PWM noise. In [

50], the middle tap of the electromagnet coil is extracted as an independent sensing subsystem separate from the power section, and a resonant network is designed to enhance the sensitivity of displacement self-sensing. This paper focuses on the theory and algorithms of displacement self-sensing based on general amplifier topologies, so such structure-inherent displacement sensors are not discussed here.

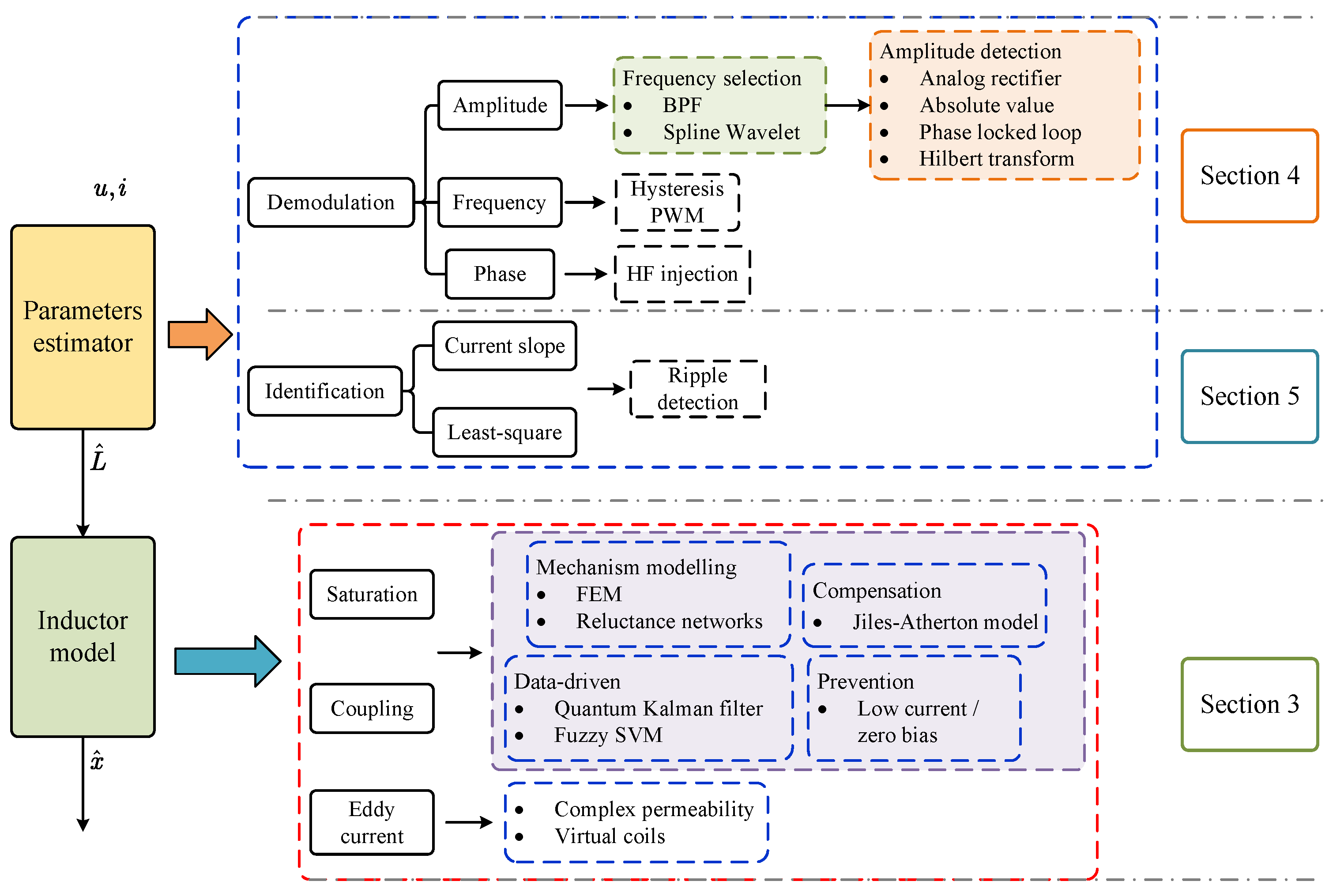

As displacement self-sensing schemes become more diverse and research deepens, there are still some questions that need to be answered. First, regarding the relationship between various magnetic bearing displacement self-sensing methods—whether they are formally opposed or compatible, and whether their theoretical analyses converge—there is currently a lack of clear discussion on how to integrate them into a comprehensive research framework. Additionally, the performance differences between these methods in terms of their fundamental principles and practical applications have not yet been uniformly evaluated within a single system model. Therefore, this paper aims to address these issues through a technical review. The remainder of this paper is structured as follows:

Section 2 outlines the comprehensive research framework for displacement self-sensing and summarizes the basic research approach;

Section 3 discusses the first part of the research framework, namely how to establish a physical model of the electromagnetic coil inductance and air gap;

Section 4 and

Section 5, respectively, discuss inductance parameter estimation algorithms from the perspectives of demodulation methods and least squares parameter identification; and

Section 6 provides a summary of existing methods and an outlook on future trends.

4. Inductance Estimation Based on Amplitude Demodulation

4.1. Structures of Demodulator

Sensing signals can originate from the actuator itself—PWM ripple of the switching power amplifier or from an active injected high-frequency voltage signal. The PWM ripple scheme faces dynamic compensation issues, meaning that when the control component changes, the amplitude of the PWM ripple also changes. Changes in ripple amplitude result in sideband components at the sensing frequency, necessitating appropriate duty cycle compensation strategies [

23,

36]. Actively injecting high-frequency signals can avoid the issue of varying sensing component amplitude during system dynamics, eliminating the need for duty cycle compensation.

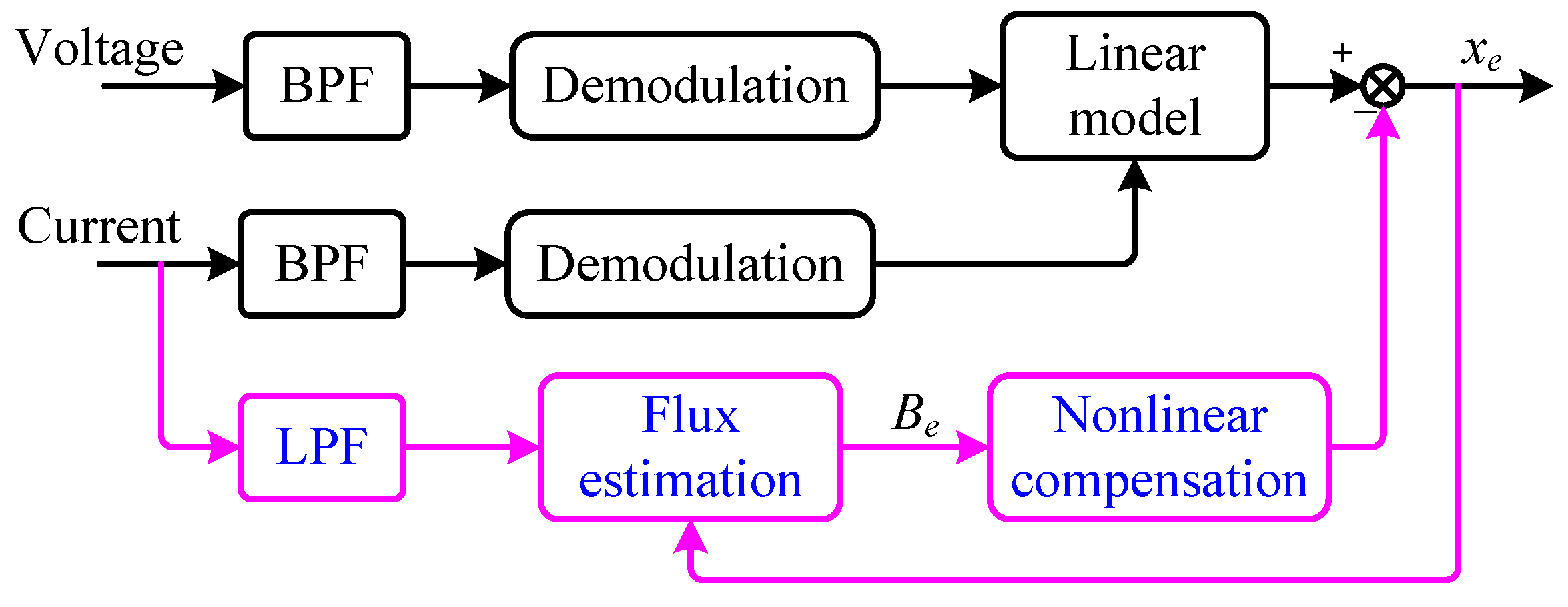

Amplitude demodulators are generally divided into two parts: the first part extracts the single-frequency sensing component from the current and voltage, functioning as a frequency-selective network, while the second part extracts the amplitude of the sensing component. For both of these stages, there are various analog or digital implementation schemes available. The general block diagram of the amplitude demodulator can be represented by

Figure 7.

The frequency selection stage can employ an analog bandpass filter, which combines a filtering function with signal amplification. In PWM ripple demodulation, considering the spectral changes caused by dynamic processes, the amplitude demodulator should extract the components of the PWM frequency and its primary sideband frequencies. This requires the BPF to have a wide and flat passband, making the Butterworth filter more suitable for amplitude demodulation. If a digital form of the filter is used, lower-order infinite impulse response (IIR) filters are preferred for real-time control to reduce computational burden. It is worth noting that detecting high-frequency micro signals poses a challenge for limited ADC resolution. Therefore, an appropriate analog front-end amplifier should be used to amplify the high-frequency components before detecting them.

The amplitude detection can be implemented using a precise rectifier circuit. To obtain a smooth signal amplitude, it must also pass through a low-pass filter. This method directly maps to the digital domain as an absolute value function and digital low-pass filter (LPF). The output of this configuration is the periodic average value of the rectified signal, which is of the actual amplitude.

Analog demodulators achieve demodulation through an analog circuit, which helps alleviate computational load, thereby freeing up processor resources for executing magnetic levitation control algorithms. Despite this advantage, analog demodulators suffer from several notable drawbacks compared to their digital counterparts. Firstly, they substantially increase hardware cost and complexity while reducing overall system reliability. Moreover, their performance is constrained by inherent non-idealities, such as component parameter drift and the forward voltage drop in diodes, which ultimately limit estimation accuracy. In contrast, digital demodulators are implemented in software, offering fully configurable parameters and structures. This programmability significantly enhances the flexibility of the displacement estimation stage, making digital approaches the prevailing trend.

Other digital implementations like Hilbert transformation and complex Morlet wavelet transformation are also mentioned by articles [

33]. The essence of the Hilbert transform is an all-pass filter, which constructs the imaginary part of the signal through an orthogonal transform to achieve a complete representation in the complex domain. An

Nth-order finite impulse response (FIR) filter can be used to approximate the ideal Hilbert transformation. Additionally, the input signal must be delayed by

cycles to compensate the fixed group delay introduced by the linear phase.

The complex Morlet wavelet defines filtering behavior from a convolution perspective and can be analogized as a series of BPFs. However, the convolution kernel varies with the translation parameter and is essentially a time-varying system. Therefore, it cannot be expressed as a transfer function like an LTI filter. The analysis of its filtering characteristics should be based on time-domain waveform similarity rather than a fixed frequency-domain response.

Figure 8 shows the block diagram of several amplitude demodulators based on digital algorithms. Hilbert transform and wavelet transform adopt high-order FIR filters or convolution operations, which are difficult to implement on a DSP platform and require a higher-performance hardware platform such as the FPGA.

4.2. Parametric Amplitude-Phase Extraction Algorithms

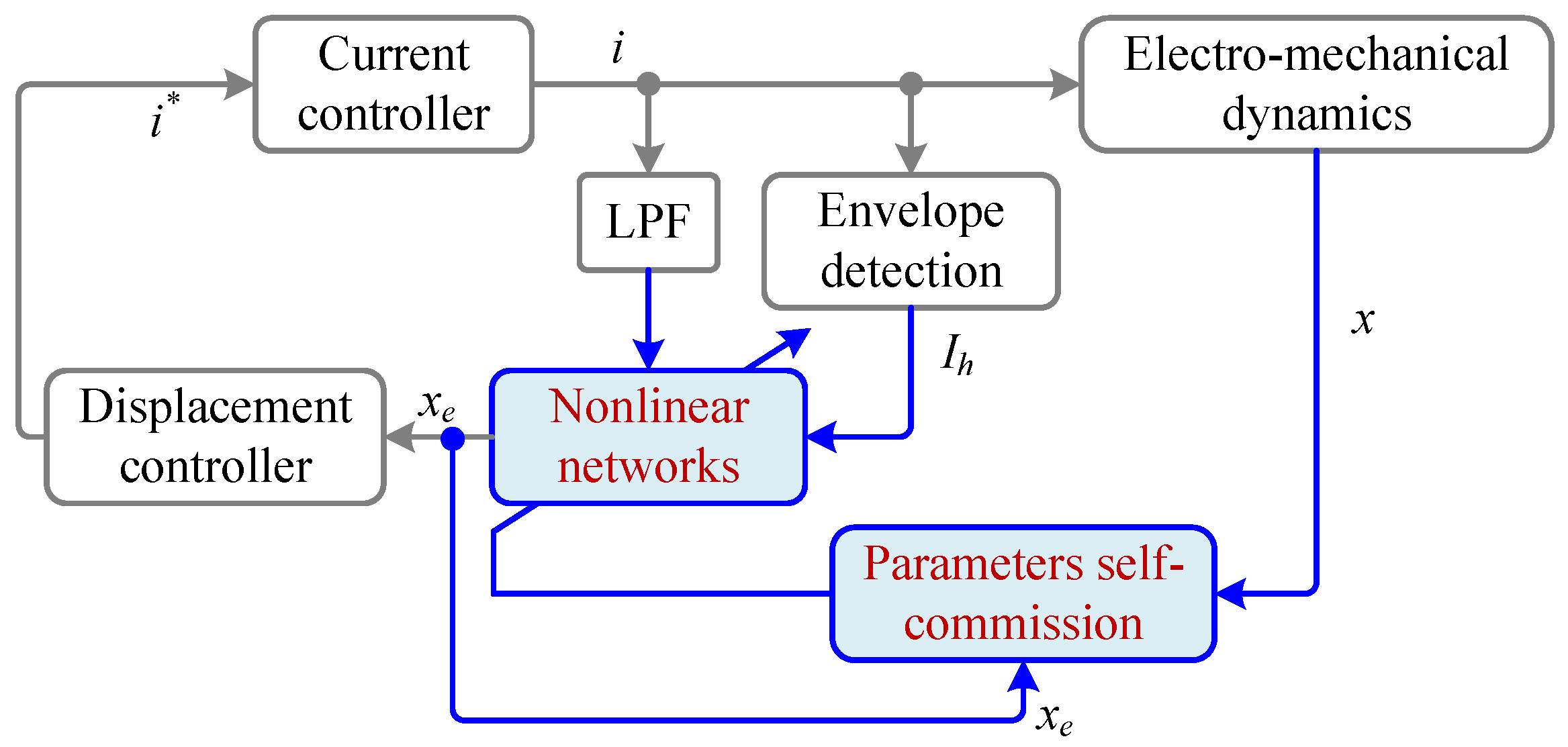

Besides the two-step implementation mentioned above, there are also algorithms that can precisely analyze and decompose the signal into various frequency components. Then, the amplitude and phase of the desired frequency component, such as phase-locked loops and frequency-domain LMS filters, can be directly calculated. These algorithms do not require the configuration of BPF, as the algorithms themselves have the filtering capability. Additionally, the amplitude is contained in the parameters, eliminating the necessity for the LPF at the output. Therefore, theoretically, this reduces digital complexity and minimizes the delay introduced by filters.

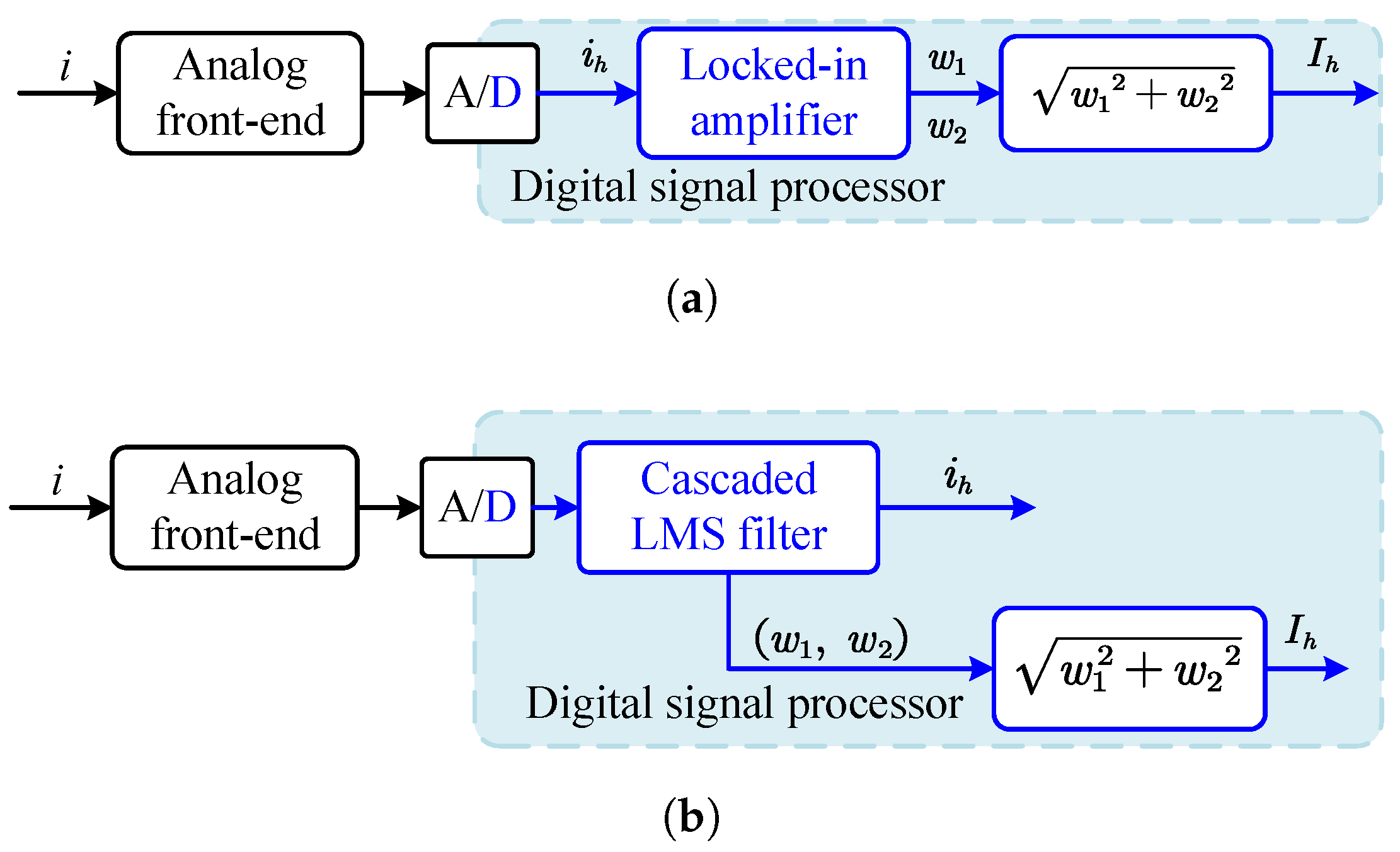

The locked-in amplifier (LIA) operates based on the principle of orthogonality between trigonometric functions at different frequencies. The input signal is multiplied by a reference signal at the target frequency, whereby only the component at this specific frequency contributes to the DC portion of the resulting product. Therefore, by applying a low-pass filter subsequently, the amplitude of the target frequency component can be extracted. Since the multiplication (mixing) of signals generates both sum and difference frequency components, the suppression capability of the LPF at twice the sensing frequency requires particular attention. The schematic block diagram of the lock-in amplifier is shown in

Figure 9. Using the Fourier transform, the frequency response characteristics of the LIA can be derived as

where

is the transfer function of the LPF and

is the sensing frequency. As the cutoff frequency of the LPF decreases, the filtering performance improves, but the phase shift increases. Meanwhile, the group delay at the center frequency of the passband also increases, indicating a decline in dynamic performance. The amplitude of the sensing signal is

, while this result is not equal but half of the amplitude.

The frequency-domain LMS filter, serving as an enhanced variant of adaptive filters, has found extensive application in real-time signal processing since its introduction by Widrow in 1976 [

61]. The LMS filter updates its parameters based on the minimum mean square error principle, thereby reconstructing the desired frequency signal. The schematic diagram of the LMS adaptive filter is illustrated in

Figure 10, and its state-space representation can be formulated as

The discrete impulse transfer function can be derived as

Among these, the parameter

influences the frequency characteristics and the dynamic performance. The smaller the

, the narrower the passband and the stronger the frequency selection capability, but the dynamic response decreases. Therefore, it is necessary to balance the performance of both aspects and select the parameters reasonably. The block diagrams of demodulators based on the LIA and the LMS filter are shown in

Figure 11.

Table 2 presents the key parameters of various digital demodulation algorithms and their impact on demodulator performance.

4.3. Performance Evaluation and Comparison

Some performance metrics of self-sensing AMBs utilizing different demodulation approaches described in the presented articles can be seen in

Table 3. Then, simulations were conducted to compare the performance of the displacement self-sensing systems. For all the demodulators discussed, the high-frequency signal is uniformly injected to avoid the influence of the dynamic duty cycle. The parameters of the system are shown in

Table 4. Several representative demodulator types were selected for evaluation:

- (1)

Analog BPF + absolute value + digital LPF.

- (2)

Digital locked-in amplifier.

- (3)

Frequency LMS filter.

In configuration (1), a Butterworth BPF is used. In configurations (2) and (3), to avoid the sampling distortion of small high-frequency signals due to insufficient AD resolution, a high-pass filter is added to amplify high-frequency signals and suppress low-frequency control signals. To conduct an optimal dynamic performance, for designing each demodulator, this paper chooses the structure that confirms the fastest dynamic response to the displacement variation, under the constraint that the noise signal in the estimated displacement is confined to a specific threshold.

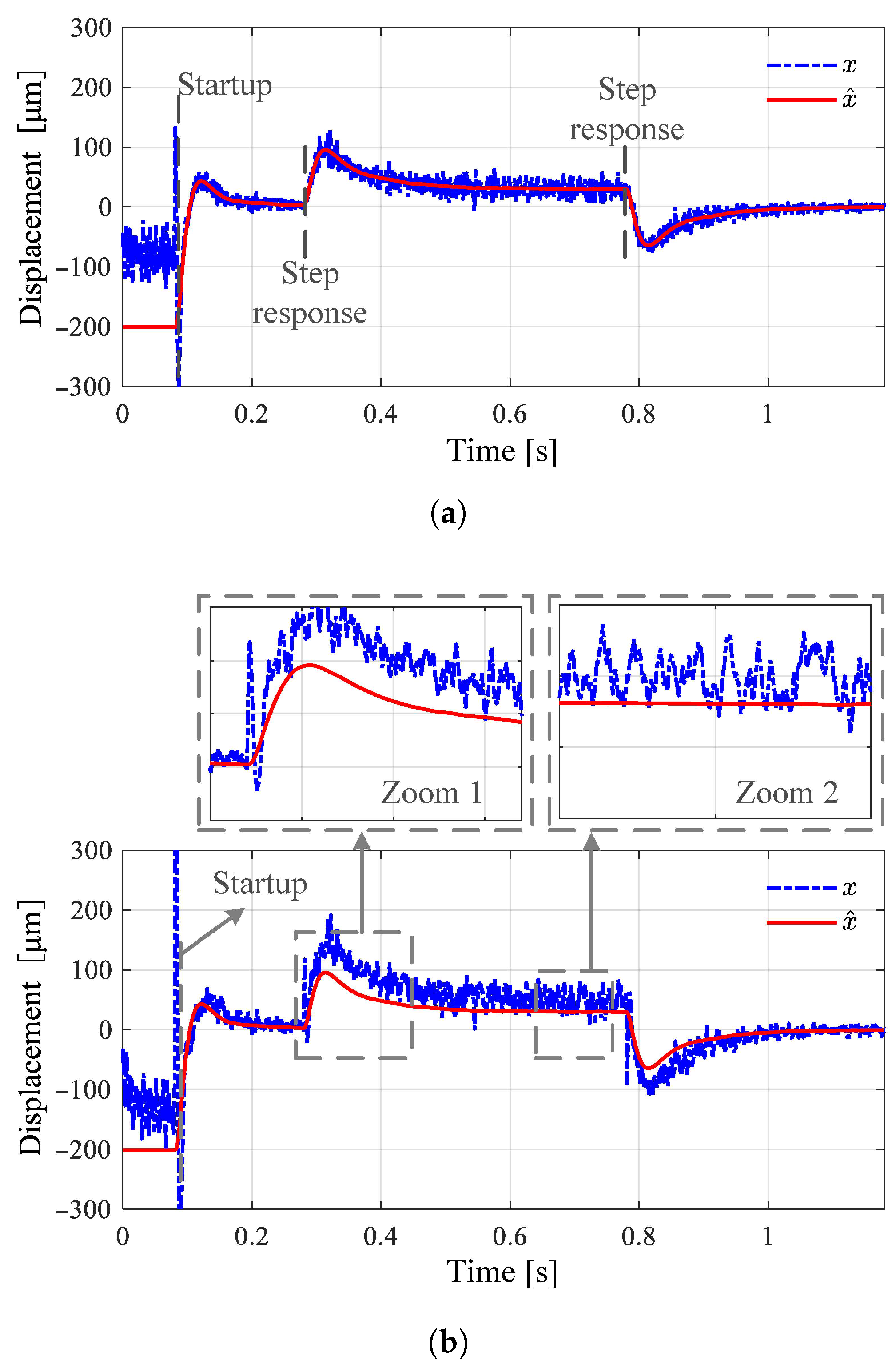

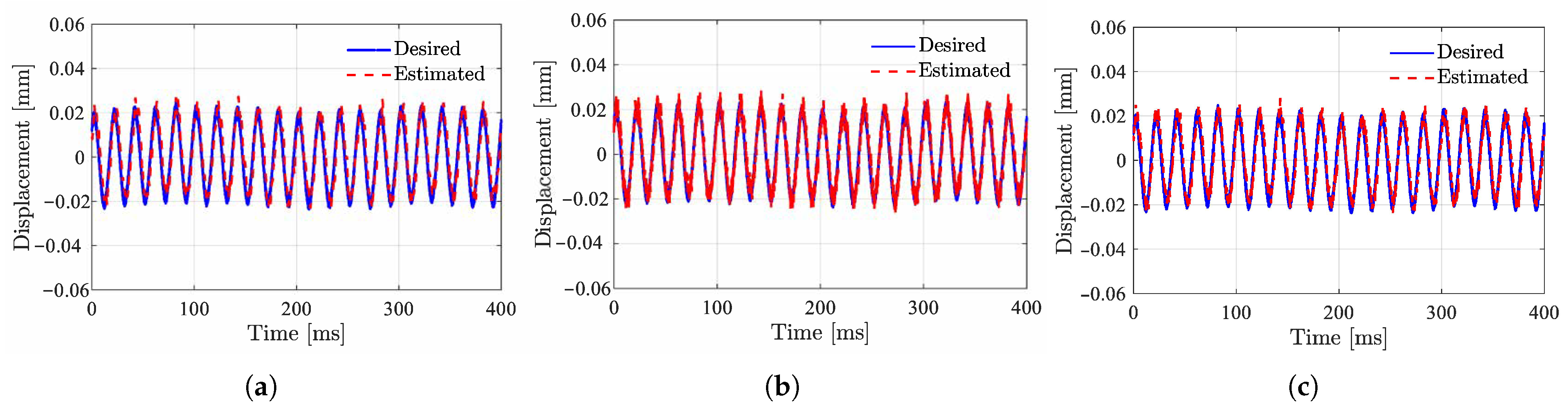

Figure 12 shows the waveforms of the estimated displacement and actual displacement by simulations. The system is subjected to an external disturbance of 50 Hz, corresponding to the excitation by mass unbalance at a speed of 3000 rpm. From this, the accuracy of the displacement estimation values is satisfactory with small errors and high signal-to-noise ratios.

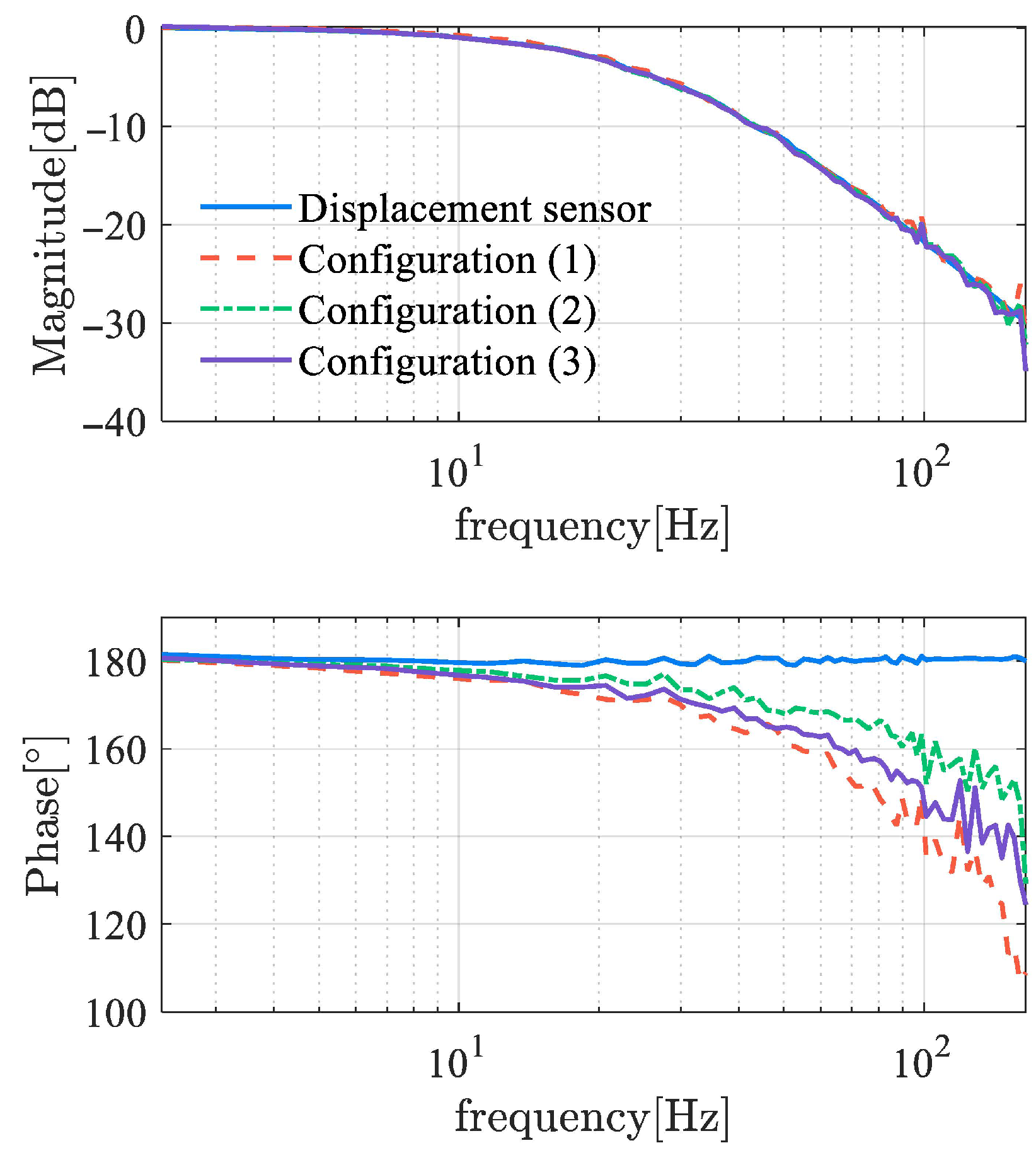

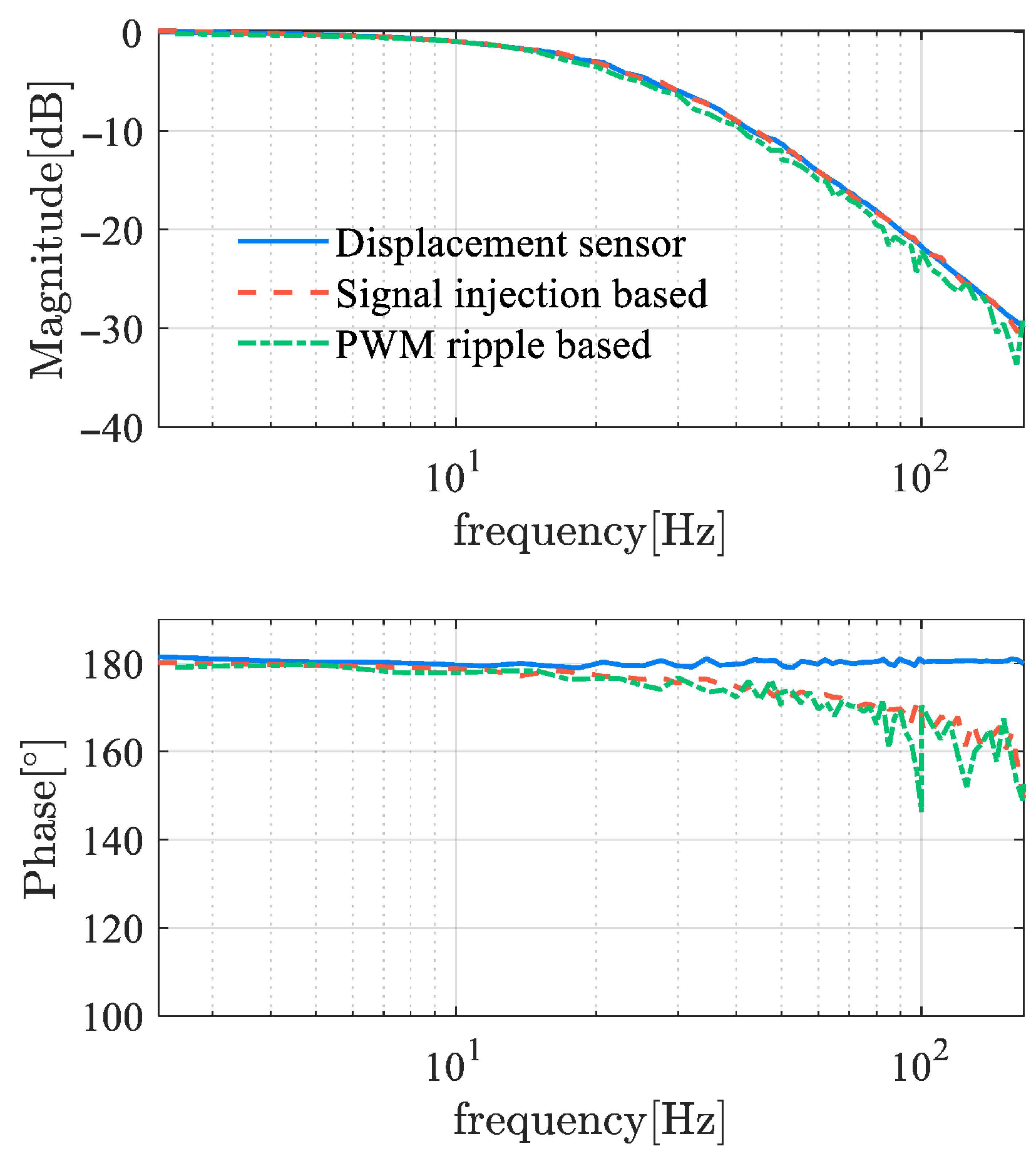

The evaluation of the dynamic response time of the demodulator is conducted from multiple aspects. As shown in

Figure 13, it is an offline test of the demodulators that examines the response time of the demodulators to track the step amplitude. The step setting times of several demodulators are all in the ms range, indicating a fast response speed. Using frequency domain identification theory,

Figure 14 shows the frequency response function (FRF) of self-sensing AMBs, where the input of the tested object is the control current

, and the output is the estimated displacement. An AMB with displacement sensors has a constant 180° phase, while the phases of self-sensing systems have a certain delay. The phase delay of the self-sensed AMB plant increases with frequency, while the amplitude of that is basically consistent with the original sensor-based system. This indicates that since the cutoff frequency of the self-sensing system remains the same as the sensor-equipped system, phase lag can lead to a reduction in phase margin and may even cause instability. Obviously, the phase margin loss achieved using the demodulation-based method is significantly improved compared to the observer method, resulting in enhanced stability.

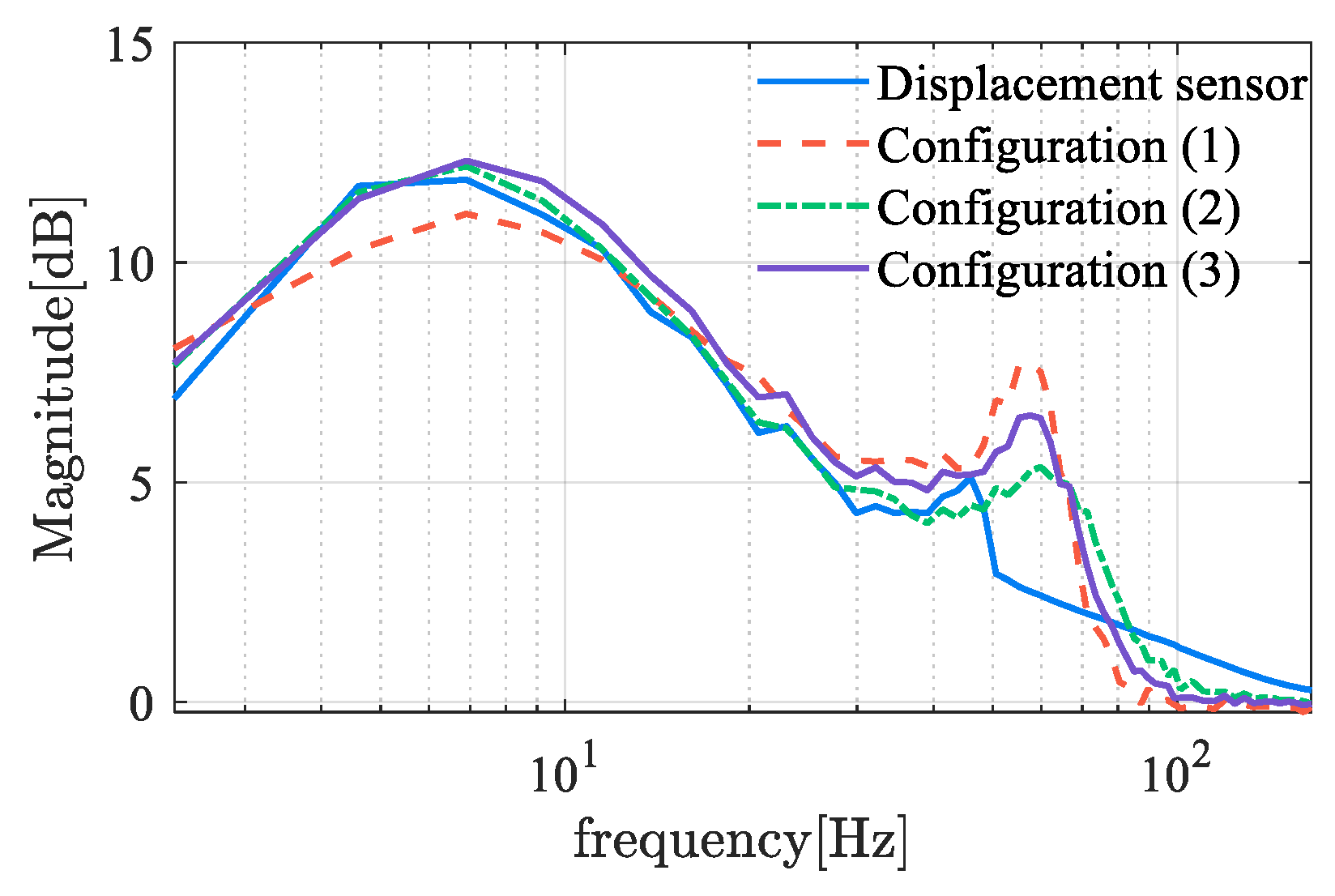

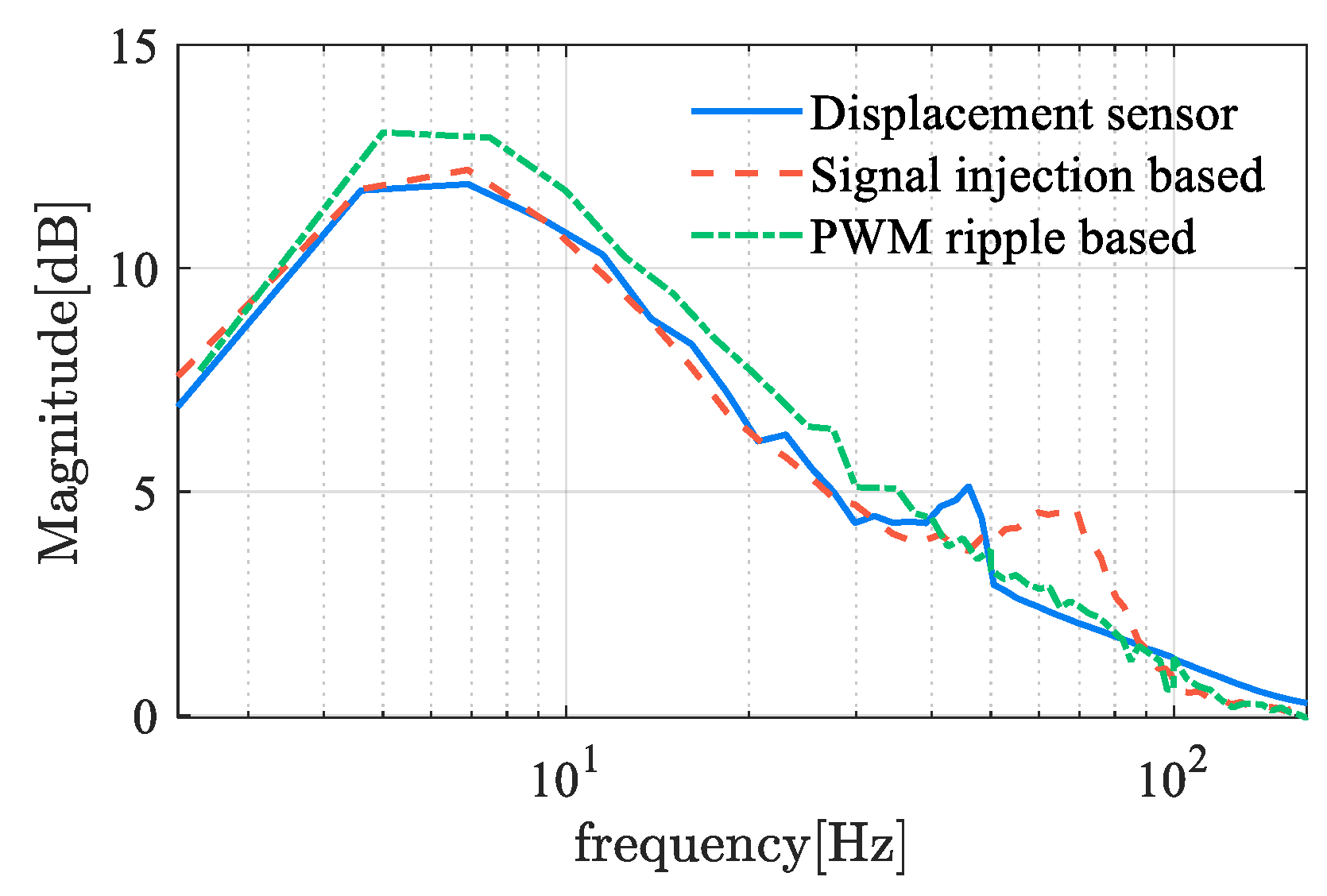

Examine the sensitivity function, which is defined as

where

represents the open-loop transfer function. The sensitivity function reflects the system’s sensitivity to disturbances and model perturbations. A smaller amplitude-frequency characteristic indicates stronger robustness.

Figure 15 shows the frequency characteristics of the sensitivity functions for self-sensing AMBs. The amplitude reaches the sensitivity peak at approximately 7 Hz, with a peak value of about 11–13, which indicates the robustness of B and C classes. However, magnetic bearings typically operate at a high frequency, where the amplitude of sensitivity is relatively small. There is an evident difference between self-sensing systems and sensor-equipped systems at the range of 50 to 80 Hz, where the sensor-equipped system exhibits better robustness. This distinction between 50 Hz to 80 Hz is primarily attributable to the time delay inherent in the displacement estimation process. As the delayed time increases, the second amplitude peak is observed to shift toward a lower frequency domain, accompanied by an increase in peak value. This demonstrates the significant deterioration in performance that occurred when utilizing displacement self-sensing in comparison with the displacement sensor.

In

Table 5, the phase margin under the PID controller and the

norm of the sensitivity function at typical operating frequencies are listed. The robustness of displacement self-sensing systems dominated by three demodulation algorithms is similar in terms of sensitivity metrics. However, the stability and time delay show some differences, with performance ranked as follows: locked-in amplifier, LMS filter, and absolute value detection algorithm.

To provide a comprehensive comparison, the relative merits and limitations of various digital demodulation algorithms are discussed herein, with the critical premise that all are designed for equivalent noise suppression and filtering performance. The BPF combined with absolute value detection and LPF is characterized by its implementation simplicity; however, this comes at the expense of significant phase delay and a consequently reduced stability margin. In contrast, the Hilbert transform achieves superior demodulation accuracy, yet it inherently introduces a large group delay due to its high filter order, a limitation that can only be mitigated by implementing a high sampling rate. Similarly, the Morlet wavelet transform offers exceptional time–frequency localization and thus very high precision, but its demanding computational load from continuous convolution also necessitates both high processing power and a high sampling rate for dynamic applications. Meanwhile, the locked-in amplifier stands out for its excellent accuracy, minimal data storage, straightforward implementation, and fast dynamic response, although its performance is contingent upon the effective design of the output low-pass filter to suppress components at twice the carrier frequency. Conversely, the LMS filter features rapid dynamic response, high accuracy, and a simple structure, but a single LMS filter struggles to simultaneously achieve satisfactory noise rejection and dynamic performance, often requiring a more complex cascaded design.

Consequently, for general-purpose control platforms, the locked-in amplifier and LMS filter present a favorable balance, enhancing dynamic performance without sacrificing noise immunity. On advanced hardware platforms that support high sampling rates and substantial computational throughput, the Hilbert and Morlet wavelet transforms emerge as viable alternatives where utmost precision is required.

5. Inductance Estimation Based on Least Squares Identification

Parameter identification relies on continuous-time sampling to construct the identification equation. For the system in a steady state, there exists a rank deficiency in the identification equation. The rank deficiency means that there are multiple linearly correlated rows in the regression matrix, resulting in the rank of the regression matrix being less than the number of parameters to be identified, and there are infinite solutions. Typically, the dynamics of the excitation system are required to ensure the identifiability of the parameters. The excitation signal can still be generated using PWM switching harmonics and additional high-frequency voltage injection.

5.1. Construction and Solution of Identification Equations

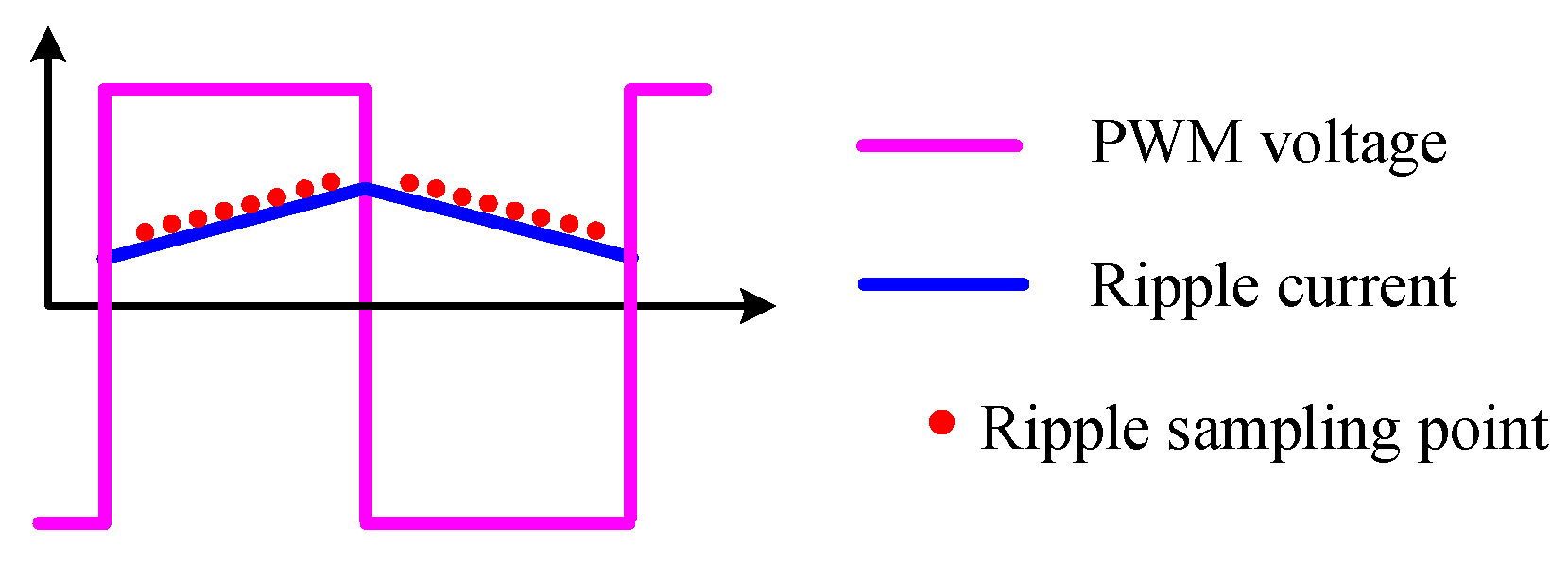

The voltage of a PWM amplifier is in the form of pulses with variable width. If bipolar modulation is used, the output voltage and current waveforms are as shown in

Figure 16. It can be seen that within a PWM cycle, the current exhibits exponential rise and fall phases. Considering some reasonable simplification, the current waveform can be approximated as linear. During the rise and fall phases of the current within a PWM cycle, ripple current is sampled at specific time points, with the sampling time and value recorded as

where the subscript

r represents the rising phase,

f is the falling phase, and

m and

n are sampling numbers during the rising and falling phases, respectively. The sampling time should avoid overlapping with the switching instances and maintain a certain interval from them. The reason is that the EMI is strongest at the switch instances, which can easily affect the reliability of current sampling. Moreover, eddy currents can cause severe distortion of the current waveform near the switching instances.

The identification function can be derived from the discrete form of the flux equation, which is given as

where

contains the parameters to be estimated, and

and

are the regression matrix and measurement vector.

is the change in flux, given as

and the solution in the least squares sense is given by the pseudo-inverse as

Since the dimension of the equation is relatively low, the above equation can lead to the solution given as

which is the direct estimation equation. This is efficient in reducing the numerical errors introduced by solving the linear equation. There is also a method that takes into account two types of errors: resistance mismatch and changes in inductance values within a PWM cycle. By combining the currents from the rising and falling segments, improved estimation has been proposed [

39].

The design of a digital program for PWM ripple detection seems quite challenging. This challenge manifests in two aspects. First, the PWM switching frequency and the current sampling frequency are inconsistent. Second, as the duty cycle changes, the current sampling instances also need to be adjusted. One solution to deal with the ripple sampling under dynamic duty cycles is to set alternating control and measurement cycles [

31], with the digital implementation as shown in

Figure 17.

If high-frequency voltage injection is adopted, the control voltage is represented as , where is the current controller outputs, and and are the amplitude and angular frequency of the injected signal. Compared with the ripple detection method, the sensing signal frequency of the high-frequency injection method is constant and not affected by dynamic duty cycles. Therefore, the sensing component can be separated and amplified first, and then sampled, reducing the impact of ADC resolution and sampling noise. In addition, the switching frequency and sampling frequency are equal, which allows the current sampling to be triggered by hardware, making software implementation more convenient.

5.2. Performance Evaluation and Comparison

The PWM frequency and injection frequency of the high-frequency injection method are the same as those in the previous section. Since the sensing signal has a fixed frequency, it is amplified by the analog front-end. The PWM ripple detection method uses a switching frequency of 5 kHz and the bipolar modulation strategy, and the DC-link voltage is increased to 100 V.

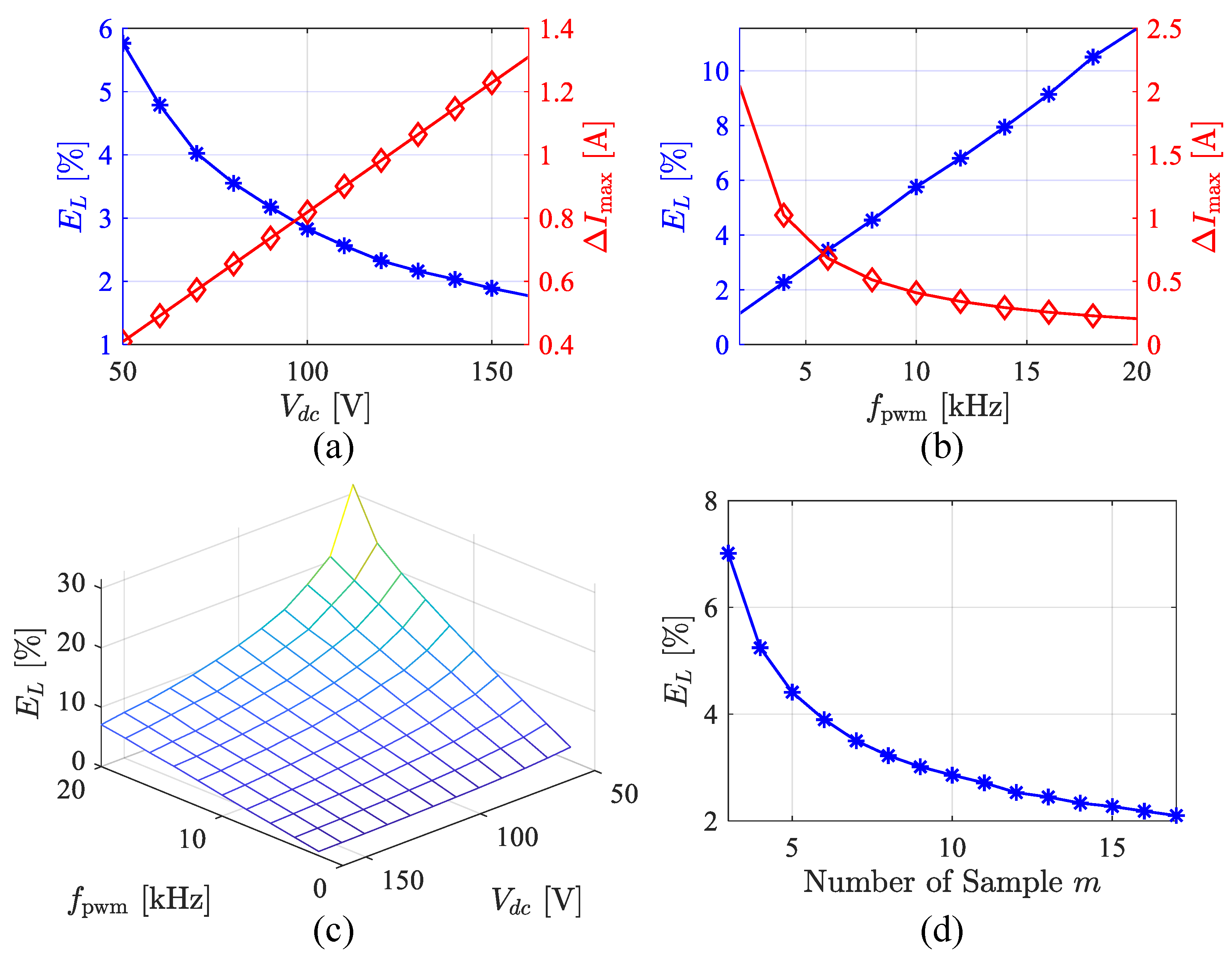

In the ripple detection method, there are parameters that significantly affect the precision of estimation results. These include the DC voltage

, the PWM frequency

, and the number of samples during the current rise and fall phases. The sampling noise is set as a Gaussian white noise sequence with a mean of 0. The standard deviation

is given in the form of the integer value of 12-bit AD conversion noise. The noise of the parameter identification results is defined as

The above equation represents the mathematical expectation of the relative error, with the mean value replacing it in a statistical sense.

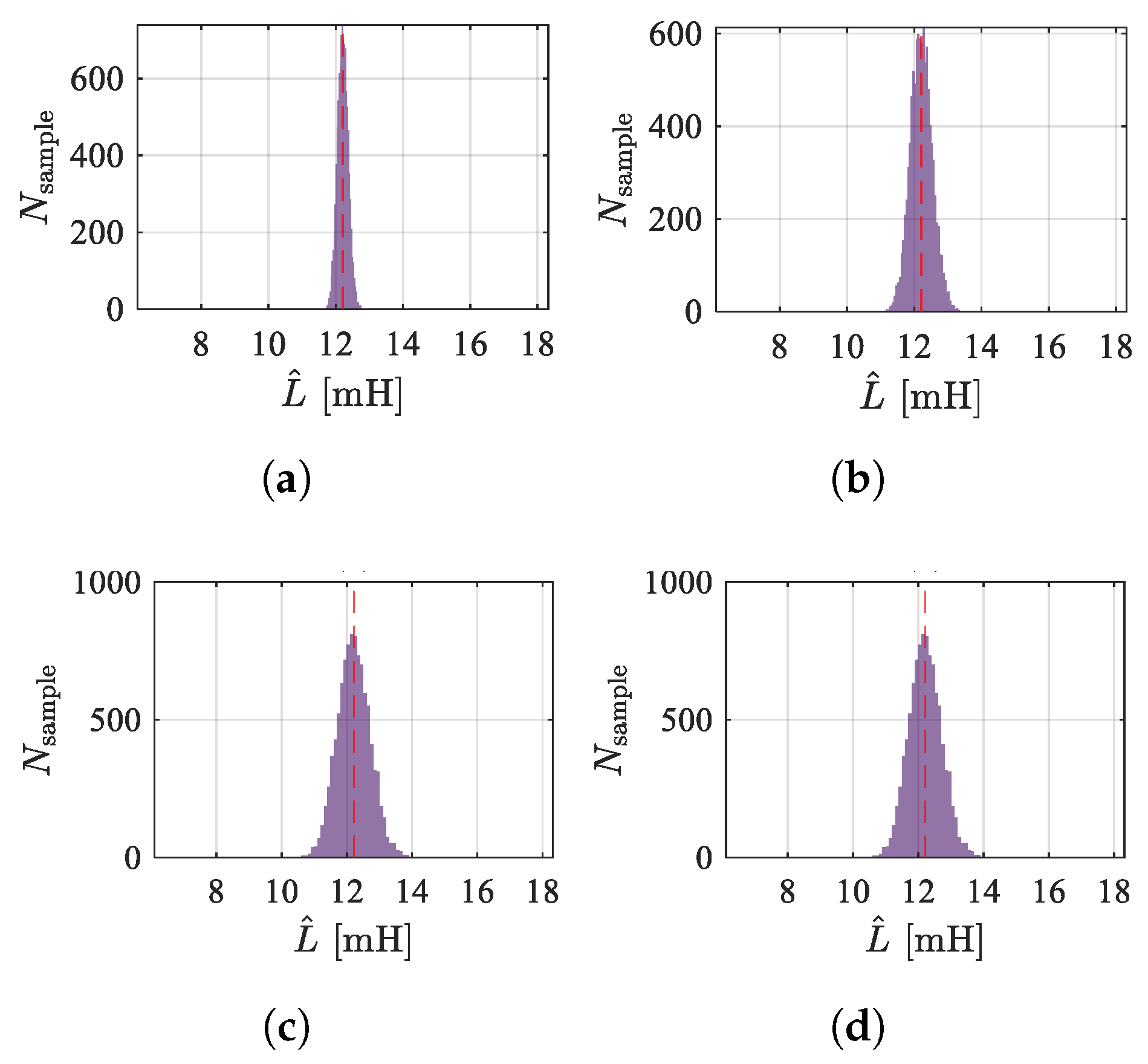

Figure 18 illustrates the influence of these parameters on the inductance estimation error.

Figure 18a shows the variation in ripple amplitude and noise with respect to the DC voltage. Obviously, as the DC voltage increases, the mean error decreases. The relationship between noise and PWM frequency is shown in (b). Noise generally increases linearly with PWM frequency. Considering the combined effects of Vdc and fpwm on EL, (c) shows the variation in the form of a surface. (d) illustrates the impact of the number of samples on EL. It is evident that as m and n increase, EL decreases, indicating that the SNR improves. These results provide guidance for parameter selection.

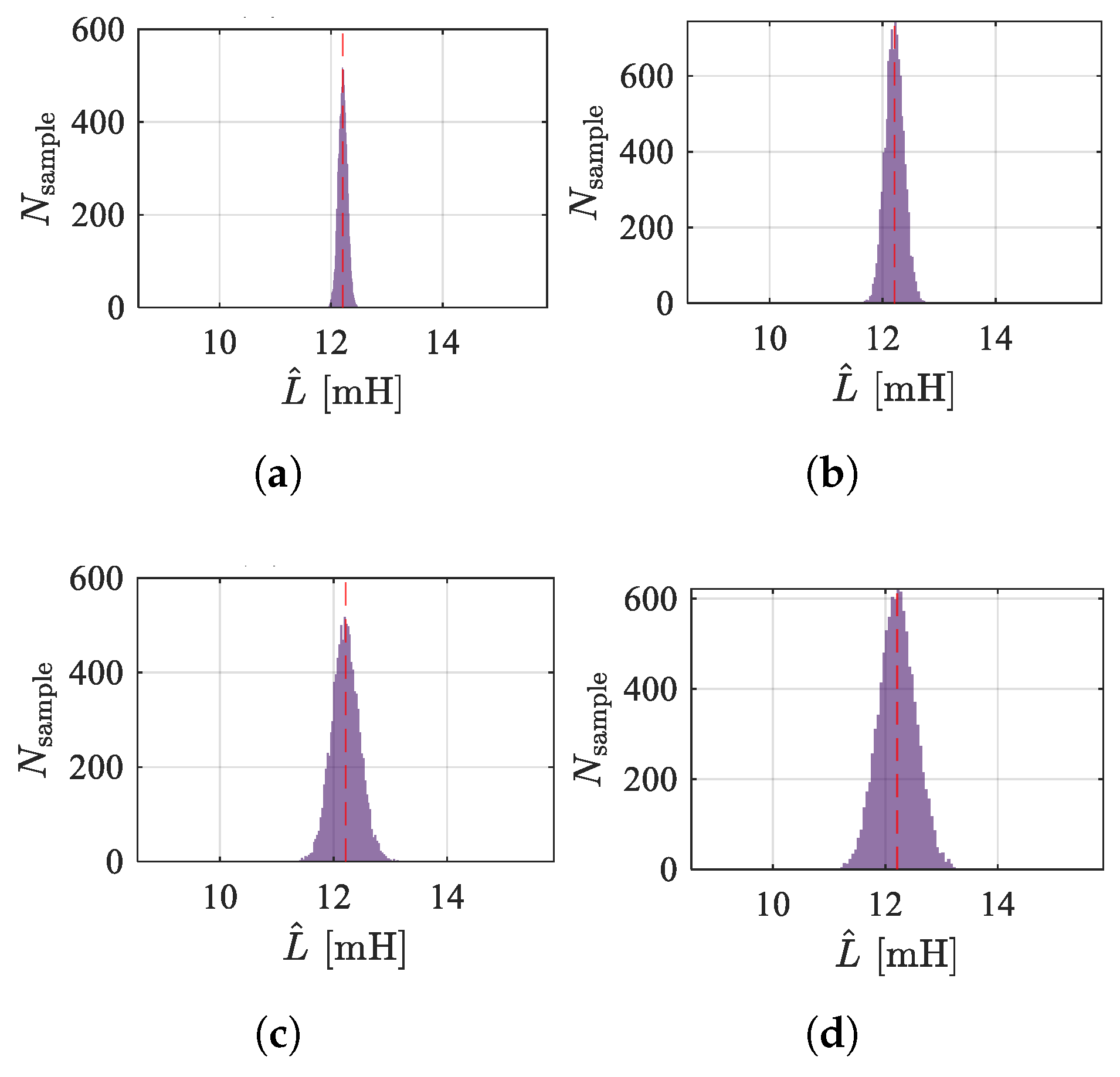

Set the standard deviation of sampling noise from 5 to 20.

Figure 19 and

Figure 20 show the frequency distribution histograms of the inductance estimates for the two methods. As the noise increases, the distribution of inductance estimates becomes more dispersed, and the SNR decreases. Due to the amplification of high-frequency signals, the high-frequency injection method is less affected by sampling noise. However, in terms of the mean value, the PWM ripple method is closer to unbiased estimation, which is related to the sampling rate and the accuracy of the discretization model.

Figure 21 shows the estimated displacement waveforms under a 50 Hz disturbance (3000 rpm speed).

Robustness and stability are evaluated based on the FRF and sensitivity function of the controlled system. The FRF of the controlled plant is illustrated in

Figure 22. The phase lag of the PWM ripple-based method is more pronounced, which can be attributed to the following rationale. Theoretically, the ripple detection approach completes the estimation within two PWM cycles, thereby achieving a very high bandwidth. However, the introduction of a low-pass filter to enhance the signal-to-noise ratio introduces additional phase delay. This reflects a fundamental trade-off between signal-to-noise ratio and dynamic response speed, necessitating a balanced design in practice. Typically, the parameter estimation value is processed through an LPF to achieve a smoother waveform. The LPF plays an essential role in the trade-off between SNR and dynamic performance. The cutoff frequency of the LPF is generally selected as the maximum value that still satisfies the SNR requirement, as this configuration ensures the fastest possible dynamic response under the given SNR constraint. The phase stability margin of the displacement self-sensing system is computed and summarized in the accompanying table. Furthermore, the robustness metric, defined in terms of the sensitivity function, is provided in

Figure 23 and

Table 6.

In summary, the high-frequency injection method demonstrates lower sensitivity to sampling noise than the PWM ripple method. When the noise level in the estimation output is constrained to a comparable range through a post-processing LPF, the high-frequency injection approach still achieves a larger phase margin and superior dynamic performance. In contrast, the PWM ripple method is subject to several practical limitations. For example, excessively high electromagnet inductance can attenuate the current ripple amplitude to an unmeasurable level. Additionally, in the absence of laminated cores, eddy currents can severely distort the PWM current waveform, making the ripple-based estimation impractical. Therefore, this study concludes that the high-frequency injection method exhibits better overall performance and wider applicability than the PWM ripple method.

Based on simulation analysis between the demodulation method and the parameter identification method, the following conclusions can be drawn. When the noise levels in the estimation results are comparable, the least squares parameter identification approach exhibits superior dynamic performance over the demodulation method. This advantage is reflected in its smaller phase lag, larger stability margin, and lower upper bound of the sensitivity function. It should be noted, however, that the parameter identification method shows higher sensitivity to disturbances such as resistance mismatch, PWM dead-time effects, and current sampling noise. In practice, demodulation remains a more mature and widely adopted solution. Nevertheless, for applications requiring high dynamic performance, parameter identification represents a promising direction for future development.

6. Tendency Discussion

6.1. Improvements in Dynamic Performance

Existing research indicates that the phase lag of self-sensing AMB systems increases significantly with frequency, which severely limits the performance of high-speed rotor systems. To overcome this, solutions can be sought from two dimensions: hardware optimization and algorithm improvement. On the hardware aspect, system bandwidth can be expanded by optimizing the demodulator design or adopting higher-frequency sensing signals. However, analog circuits are constrained by the structure of the filter and rectifier circuit, facing inherent limitations. Future trends may involve the deep integration of high-speed data detection technology (such as high-precision ADCs) with high-performance computing platforms (DSP+FPGA architectures). By the extraction of the sensing signal and combining advanced digital demodulation algorithms like adaptive filter and wavelet analysis, the dynamic response of the system can be enhanced.

6.2. Robustness and Disturbance Attenuation

The self-sensing technology faces several challenges in enhancing robustness and attenuating disturbance. Research indicates that the eddy current causes distortion of the triangular current ripple, thereby narrowing the effective detection window. Further research requires solutions from two dimensions: material optimization and algorithm compensation. From the first perspective, the use of low eddy current loss materials, such as optimally designed laminated core, can effectively suppress eddy current effects. At the algorithm level, advanced compensation algorithms can improve displacement estimation quality.

Additionally, refining the inductance model is another key point to improve displacement sensing accuracy, requiring comprehensive consideration of nonlinear factors such as saturation and temperature drift. Development trends will focus on developing adaptive algorithms that adjust inductance model parameters in real time to achieve continuous optimization of accuracy. This technical approach, which integrates both material and algorithmic innovation, holds promise for enhancing the robustness of displacement self-sensing systems under complex operating conditions.

6.3. Integration with Intelligent Algorithms

AMB displacement self-sensing technology is showing a trend toward the integration of intelligent algorithms. Cutting-edge research is actively exploring innovative applications of machine learning algorithms: by constructing nonlinear input–output models of actuators using machine learning methods (such as support vector machine and multi-layer neural networks), features can be directly extracted from raw current and voltage signals, effectively avoiding nonlinear errors introduced by simplifying assumptions in traditional analytical models. Another breakthrough is that data-driven algorithms can achieve adaptive fusion of parameters, updating key variables in real time through online learning mechanisms, thereby addressing model mismatch issues. This intelligent solution is providing a new technical paradigm for achieving high-precision, robust displacement self-sensing systems.

6.4. Innovation in Hardware

The hardware integration trend suggests that integrating sensing coils as redundant calibration units within self-sensing systems can enhance system reliability and robustness under extreme operating conditions.

Additionally, the high-frequency characteristics (up to MHz level) of wide bandgap semiconductor devices, including SiC and GaN, not only significantly reduce power consumption and temperature rise but also generate current ripple signals with superior spectral characteristics. Meanwhile, new power converter topologies, such as two-phase-three-arm configurations, can provide structural redundancy and fault-tolerant capabilities for self-sensing systems.

7. Conclusions

Driven by the demands for cost-effectiveness, high integration, and reliability in magnetic bearings, the development of high-precision displacement self-sensing AMBs with enhanced robustness has garnered increasing attention. This paper comprehensively examines the state of the art in displacement self-sensing technologies. A unified framework is first established to systematically categorize existing research efforts in this domain, elucidating the connections and distinctions among various approaches. Regarding the modeling, the linear magnetic circuit model is introduced, followed by nonlinear modeling strategies and online compensation techniques addressing critical nonlinearities including saturation and eddy current effects. The analysis procedure for displacement estimators based on demodulation and parameter identification methods is elaborated, with comparative simulations demonstrating their interrelationships.

Specifically, parameter identification schemes achieve a faster dynamic response, which contributes to improved closed-loop stability margins; however, they are more susceptible to noise in the sampled signals, necessitating a careful design trade-off between the signal-to-noise ratio and dynamic performance. In contrast, digital demodulation algorithms based on parametric amplitude-phase extraction can provide superior phase stability margins compared to traditional demodulators.

Building upon these findings, the paper discusses future trends, highlighting that intelligent algorithms are promising in addressing nonlinearities inherent in electromagnetic actuator models. Furthermore, hardware–software co-optimization—enabled by processors with higher sampling rates and enhanced computational capacity—will facilitate the adoption of more advanced frequency-domain analysis algorithms, thereby significantly improving the performance of displacement self-sensing systems.