Enhancing the Output Performance of Fiber-TENG Through Graphite Doping and Its Application in Human Motion Sensing

Abstract

1. Introduction

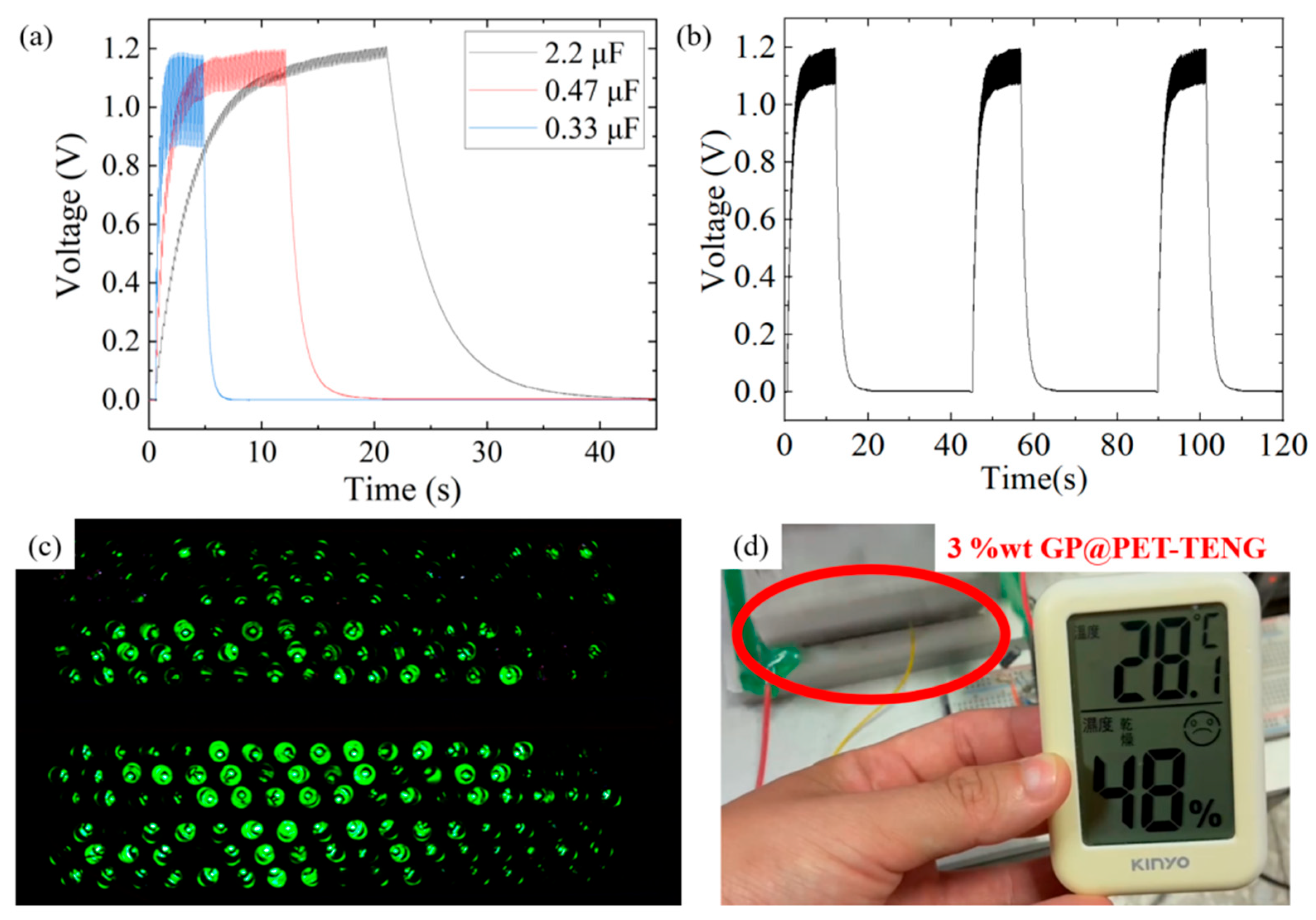

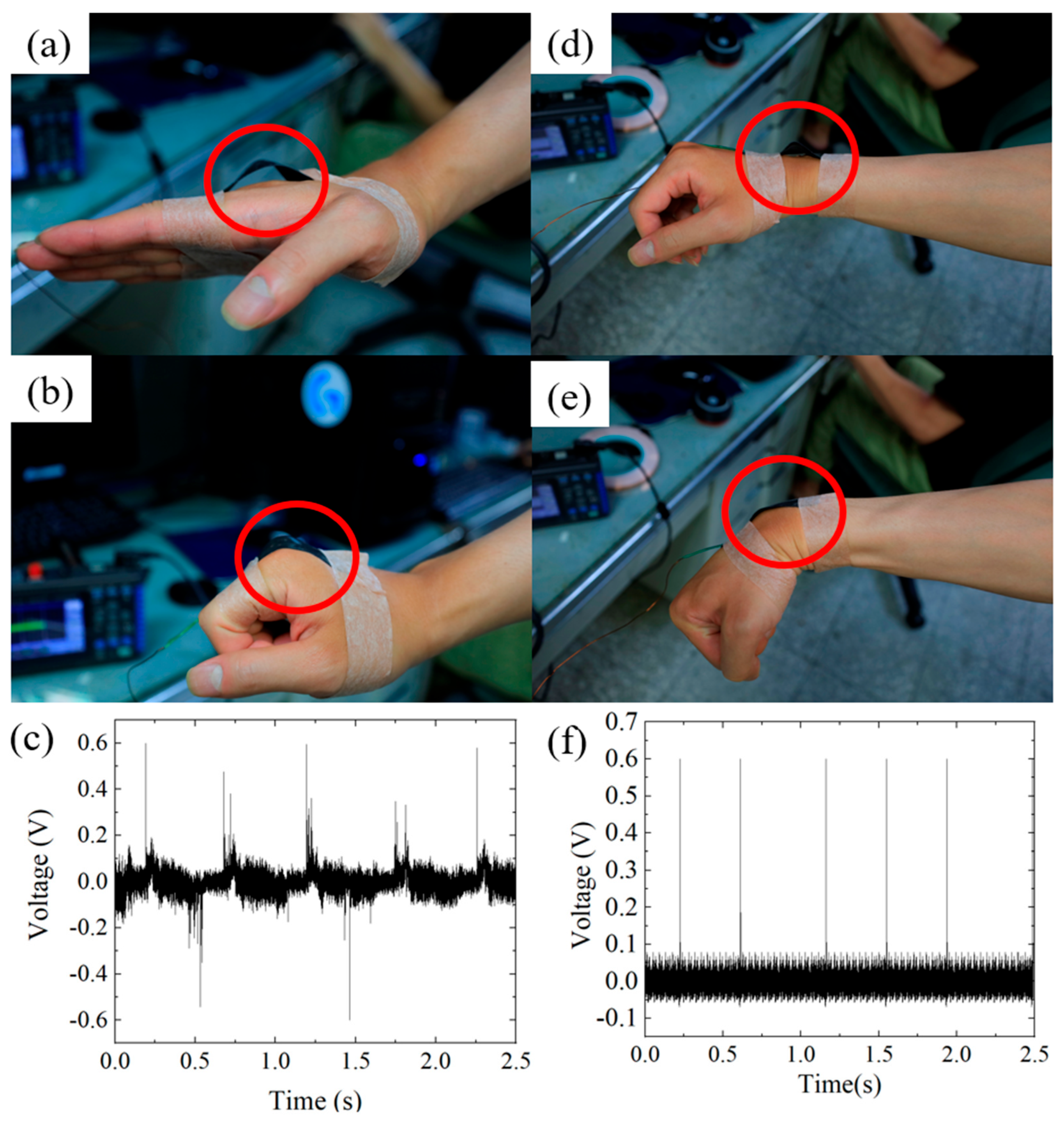

2. Experimental Procedures

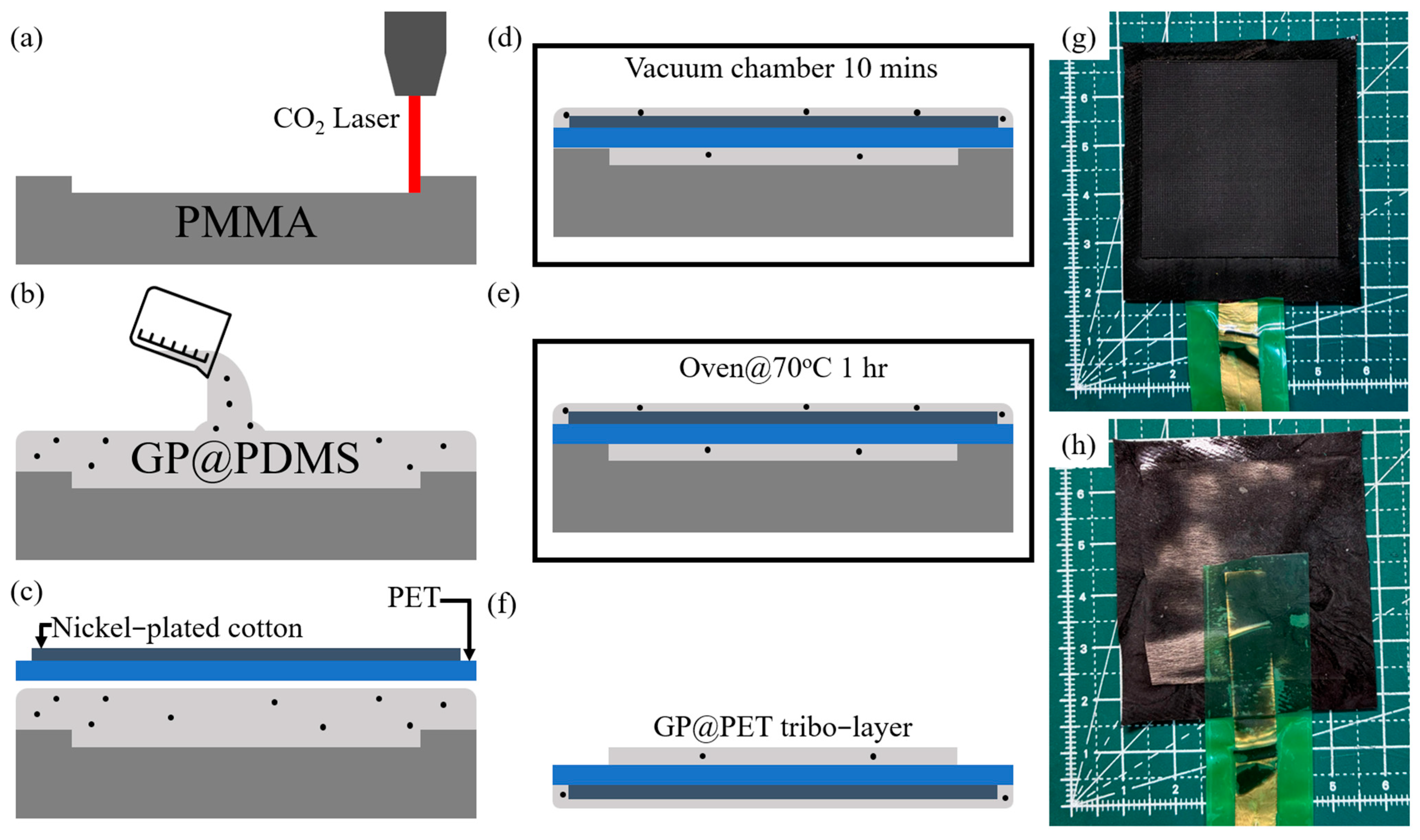

2.1. Fabrication of GP@PET-TENG

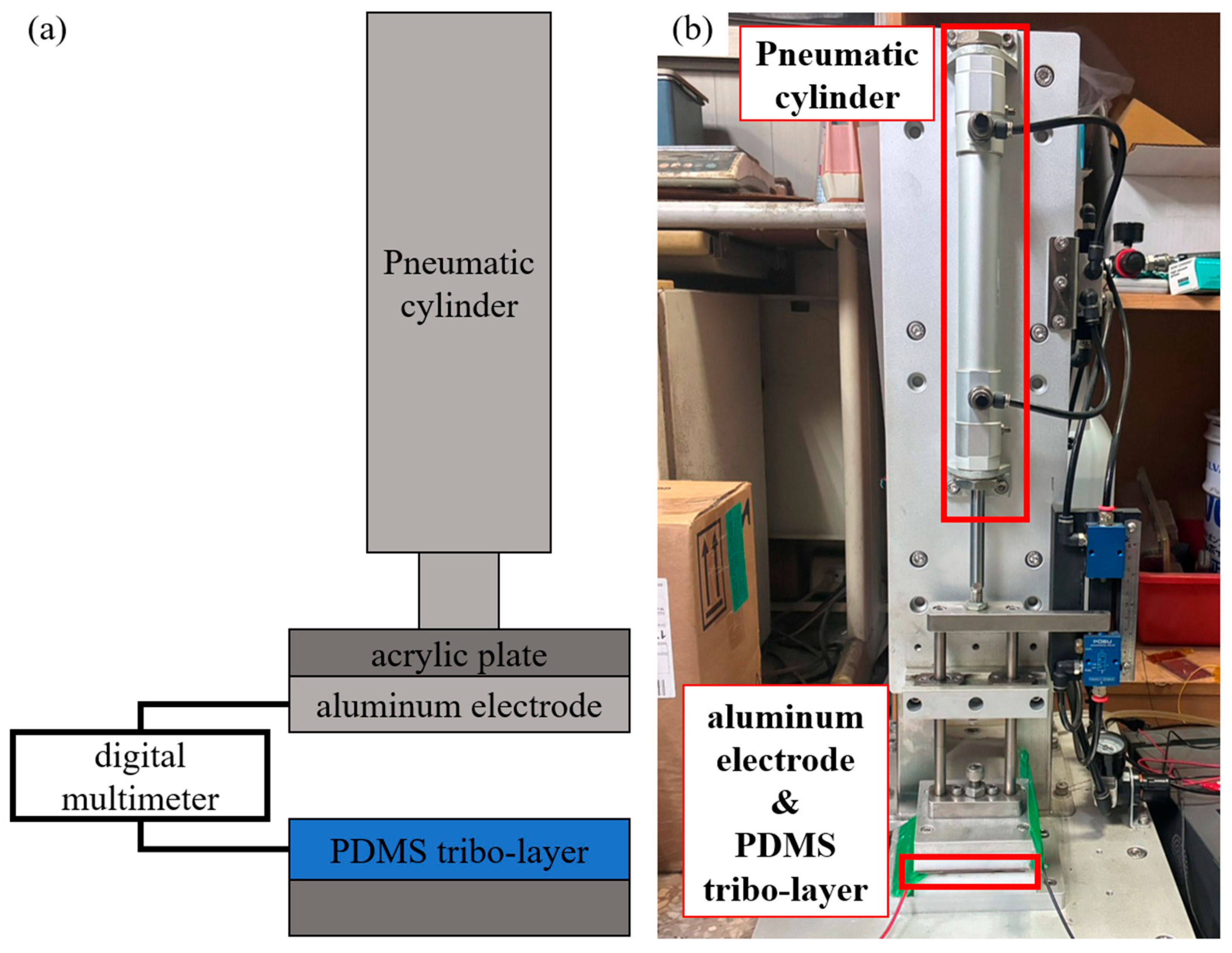

2.2. The Experiment and Measurement of Various PET-TENG

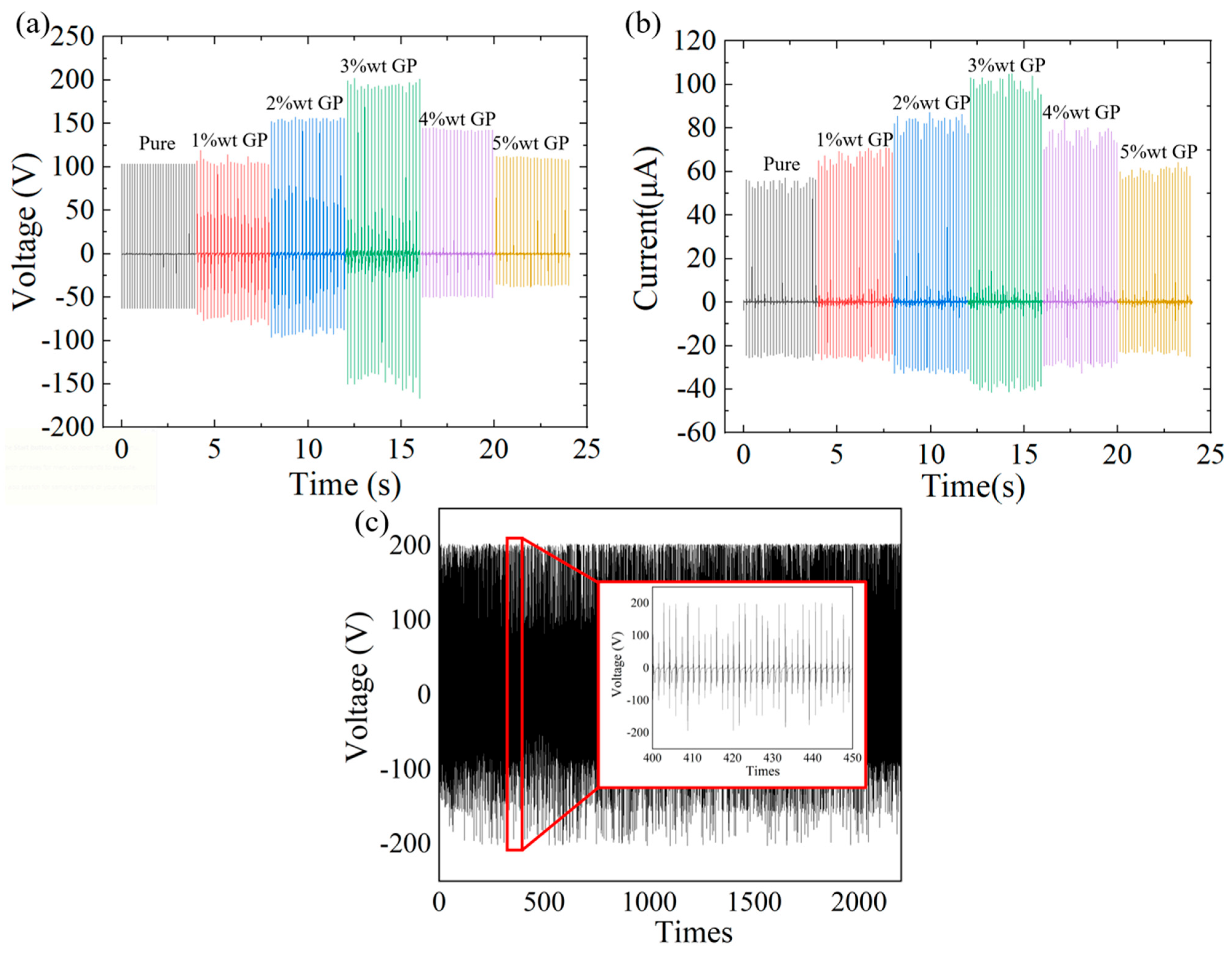

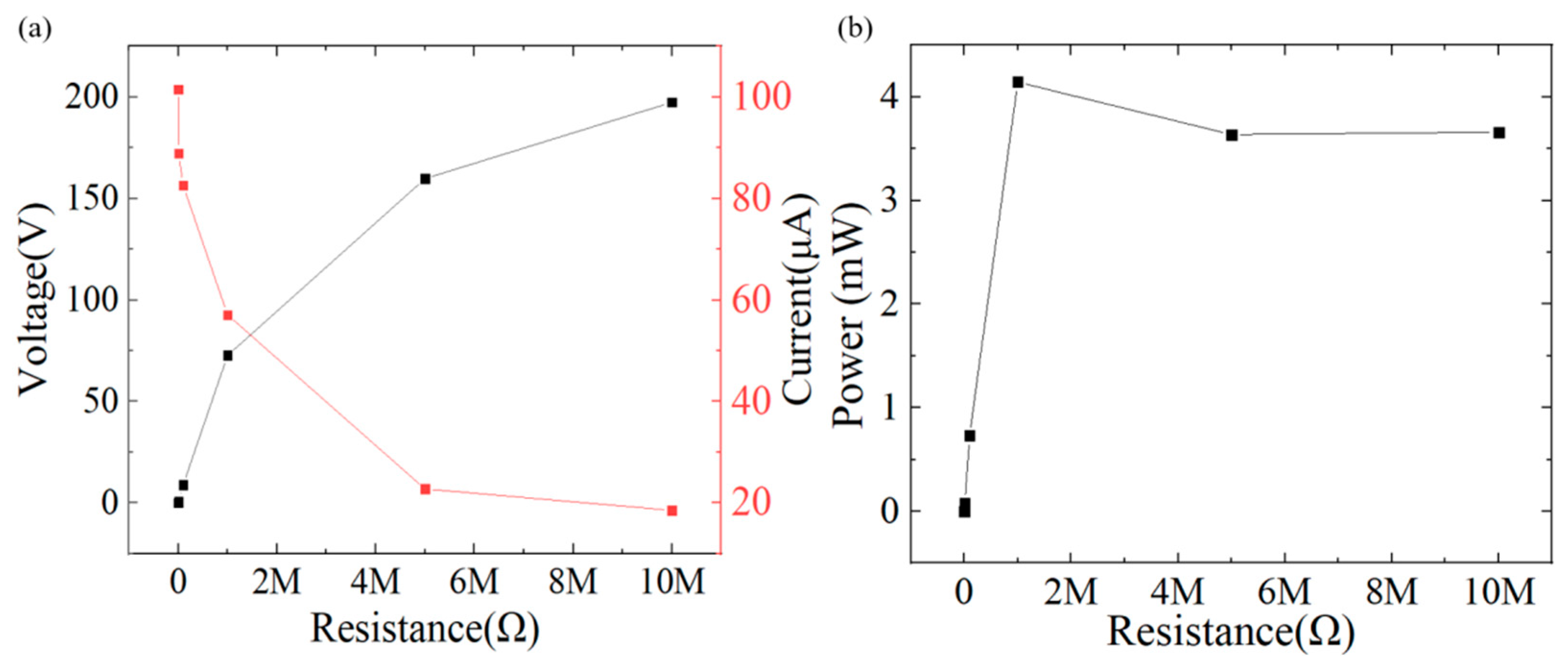

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Porciuncula, F.; Roto, A.V.; Kumar, D.; Davis, I.; Roy, S.; Walsh, C.J.; Awad, L.N. Wearable movement sensors for rehabilitation: A focused review of technological and clinical advances. PM&R 2018, 10, 220–232. [Google Scholar] [CrossRef]

- Mayetin, U.; Kucuk, S. A low cost 3-DOF force sensing unit design for wrist rehabilitation robot. Mechatronics 2021, 78, 102623. [Google Scholar] [CrossRef]

- Cheng, M.; Zhu, G.; Zhang, F.; Tang, W.L.; Jianping, S.; Yang, J.Q.; Zhu, L.Y. A review of flexible force sensors for human health monitoring. J. Adv. Res. 2020, 26, 53–68. [Google Scholar] [CrossRef] [PubMed]

- Hribernik, M.; Umek, A.; Tomažič, S.; Kos, A. Review of real-time biomechanical feedback systems in sport and rehabilitation. Sensors 2022, 22, 3006. [Google Scholar] [CrossRef]

- Cisnal, A.; Pérez-Turiel, J.; Fraile, J.C.; Sierra, D.; de la Fuente, E. Robhand: A hand exoskeleton with real-time emg-driven embedded control quantifying hand gesture recognition delays for bilateral rehabilitation. IEEE Access 2021, 9, 137809–137823. [Google Scholar] [CrossRef]

- Giovanelli, D.; Farella, E. Force sensing resistor and evaluation of technology for wearable body pressure sensing. J. Sens. 2016, 2016, 9391850. [Google Scholar] [CrossRef]

- Muro-De-La-Herran, A.; Garcia-Zapirain, B.; Mendez-Zorrilla, A. Gait analysis methods: An overview of wearable and non-wearable systems, highlighting clinical applications. Sensors 2014, 14, 3362–3394. [Google Scholar] [CrossRef]

- Wang, H.; Wu, T.; Zeng, Q.; Lee, C. A review and perspective for the development of triboelectric nanogenerator (TENG)-based self-powered neuroprosthetics. Micromachines 2020, 11, 865. [Google Scholar] [CrossRef]

- Xiao, X.; Chen, G.; Libanori, A.; Chen, J. Wearable triboelectric nanogenerators for therapeutics. Trends Chem. 2021, 3, 279–290. [Google Scholar] [CrossRef]

- Dassanayaka, D.G.; Alves, T.M.; Wanasekara, N.D.; Dharmasena, I.G.; Ventura, J. Recent progresses in wearable triboelectric nanogenerators. Adv. Funct. Mater. 2022, 32, 2205438. [Google Scholar] [CrossRef]

- Mateu, L.; Moll, F. Review of energy harvesting techniques and applications for microelectronics. In VLSI Circuits and Systems II, Proceedings of SPIE, Sevilla, Spain, 9–11 May 2005; SPIE: Washington, DC, USA, 2005; Volume 5837, pp. 359–373. [Google Scholar]

- Wu, C.; Wang, A.C.; Ding, W.; Guo, H.; Wang, Z.L. Triboelectric nanogenerator: A foundation of the energy for the new era. Adv. Energy Mater. 2019, 9, 1802906. [Google Scholar] [CrossRef]

- Wen, Z.; Fu, J.; Han, L.; Liu, Y.; Peng, M.; Zheng, L.; Zhu, Y.; Sun, X.; Zi, Y. Toward self-powered photodetection enabled by triboelectric nanogenerators. J. Mater. Chem. C 2018, 6, 11893–11902. [Google Scholar] [CrossRef]

- Wang, Z.L.; Lin, L.; Chen, J.; Niu, S.; Zi, Y. Triboelectric nanogenerator: Vertical contact-separation mode. In Triboelectric Nanogenerators; Springer: Cham, Switzerland, 2016; pp. 23–47. [Google Scholar]

- Jin, C.; Kia, D.S.; Jones, M.; Towfighian, S. On the contact behavior of micro-/nano-structured interface used in vertical-contact-mode triboelectric nanogenerators. Nano Energy 2016, 27, 68–77. [Google Scholar] [CrossRef]

- Wang, Z.L.; Lin, L.; Chen, J.; Niu, S.; Zi, Y. Triboelectric nanogenerator: Single-electrode mode. In Triboelectric Nanogenerators; Springer: Cham, Switzerland, 2016; pp. 91–107. [Google Scholar]

- Fan, F.R.; Tian, Z.Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Xu, Y.; Min, G.; Gadegaard, N.; Dahiya, R.; Mulvihill, D.M. A unified contact force-dependent model for triboelectric nanogenerators accounting for surface roughness. Nano Energy 2020, 76, 105067. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, G.; Liu, M.; Wei, C.; Yu, B.; Huang, T.; Yu, H. Advanced electrospun fiber-based triboelectric nanogenerators: From diversified designs to customized applications. Chem. Eng. J. 2025, 503, 158636. [Google Scholar] [CrossRef]

- Xu, J.; Del Río Saez, J.S.; Vázquez-López, A.; Cruz, C.; de la Vega, J.; Collado, I.; Wang, D.Y. Fully Fabric Triboelectric Nanogenerators Based on SWCNH-Coated Cotton Fabric/UHMWPE: IoT Sensing. ACS Appl. Electron. Mater. 2025, 7, 5442–5450. [Google Scholar] [CrossRef]

- Kim, H.; Nguyen, D.C.; Luu, T.T.; Ding, Z.; Lin, Z.H.; Choi, D. Recent advances in functional fiber-based wearable triboelectric nanogenerators. Nanomaterials 2023, 13, 2718. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Cai, J.; Yu, J.; Li, Z.; Ding, B. The rising of fiber constructed piezo/triboelectric nanogenerators: From material selections, fabrication techniques to emerging applications. Adv. Funct. Mater. 2023, 33, 2303249. [Google Scholar] [CrossRef]

- Arica, T.A.; Isık, T.; Guner, T.; Horzum, N.; Demir, M.M. Advances in Electrospun Fiber-Based Flexible Nanogenerators for Wearable Applications. Macromol. Mater. Eng. 2021, 306, 2100143. [Google Scholar] [CrossRef]

- Duo, H.; Wang, H.; Shima, S.; Takamura, E.; Sakamoto, H. Hydrogen-bond enhanced interior charge transport and trapping in all-fiber triboelectric nanogenerators for human motion sensing and communication. Nano Energy 2024, 131, 110297. [Google Scholar] [CrossRef]

- Rana, S.; Sharma, H.; Bokolia, R.; Bhatt, K.; Singh, R.; Meena, R.; Singh, B. PVDF/N-rGO nanofibers based sustainable triboelectric nanogenerator for self-powered wireless motion sensor. Carbon 2025, 234, 119926. [Google Scholar] [CrossRef]

- Barras, R.; dos Santos, A.; Calmeiro, T.; Fortunato, E.; Martins, R.; Águas, H.; Pereira, L. Porous PDMS conformable coating for high power output carbon fibers/ZnO nanorod-based triboelectric energy harvesters. Nano Energy 2021, 90, 106582. [Google Scholar] [CrossRef]

- Dong, K.; Deng, J.; Zi, Y.; Wang, Y.C.; Xu, C.; Zou, H.; Wang, Z.L. 3D orthogonal woven triboelectric nanogenerator for effective biomechanical energy harvesting and as self-powered active motion sensors. Adv. Mater. 2017, 29, 1702648. [Google Scholar] [CrossRef]

- Chung, C.K.; Huang, Y.J.; Wang, T.K.; Lo, Y.L. Fiber-Based Triboelectric Nanogenerator for Mechanical Energy Harvesting and Its Application to a Human–Machine Interface. Sensors 2022, 22, 9632. [Google Scholar] [CrossRef]

- Pace, G.; Serri, M.; del Rio Castillo, A.E.; Ansaldo, A.; Lauciello, S.; Prato, M.; Pasquale, L.; Luxa, J.; Mazánek, V.; Sofer, Z.; et al. Nitrogen-doped graphene based triboelectric nanogenerators. Nano Energy 2021, 87, 106173. [Google Scholar] [CrossRef]

- Huang, Y.J.; Ke, K.H.; Chung, C.K. Effect of commercial P25 TiO2 doping in polydimethylsiloxane tribo-film on the output performance of triboelectric nanogenerator and its application. Surf. Coat. Technol. 2024, 482, 130721. [Google Scholar] [CrossRef]

- Li, C.; Luo, R.; Bai, Y.; Shao, J.; Ji, J.; Wang, E.; Li, Z. Molecular doped biodegradable triboelectric nanogenerator with optimal output performance. Adv. Funct. Mater. 2024, 34, 2400277. [Google Scholar] [CrossRef]

- Song, Z.; Li, W.; Kong, H.; Bao, Y.; Wang, N.; Wang, W.; Niu, L. Enhanced energy harvesting performance of triboelectric nanogenerator via efficient dielectric modulation dominated by interfacial interaction. Nano Energy 2022, 92, 106759. [Google Scholar] [CrossRef]

- Ke, K.H.; Lin, L.; Chung, C.K. Low-cost micro-graphite doped polydimethylsiloxane composite film for enhancement of mechanical-to-electrical energy conversion with aluminum and its application. J. Taiwan Inst. Chem. Eng. 2022, 135, 104388. [Google Scholar] [CrossRef]

- Hatta, F.F.; Mohammad Haniff, M.A.S.; Mohamed, M.A. A review on applications of graphene in triboelectric nanogenerators. Int. J. Energy Res. 2022, 46, 544–576. [Google Scholar] [CrossRef]

- Yang, S.; Goncharenko, D.V.; Ji, P.; Grozova, N.A.; Semencha, A.V.; Larionova, T.V.; Tolochko, O.V. A Carbon Nanotube-Doped Polyurethane Nanocomposite-Based Triboelectric Nanogenerator: A Platform for Efficient Mechanical Energy Harvesting and Self-Powered Motion Sensing. ACS Appl. Mater. Interfaces 2025, 17, 38469–38480. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.; Yu, M.; Zhang, H.; Li, N.; Du, J.; Xu, L.; Xu, J. Triboelectric nanogenerator based on well-dispersed and oxide-free liquid metal-doped conductive hydrogel as self-powered wearable sensor for respiratory and thyroid cartilage signal monitoring. Nano Energy 2025, 134, 110530. [Google Scholar] [CrossRef]

- Niu, S.; Wang, S.; Lin, L.; Liu, Y.; Zhou, Y.S.; Hu, Y.; Wang, Z.L. Theoretical study of contact-mode triboelectric nanogenerators as an effective power source. Energy Environ. Sci. 2013, 6, 3576–3583. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.-J.; Chuang, J.-I.; Chung, C.-K. Enhancing the Output Performance of Fiber-TENG Through Graphite Doping and Its Application in Human Motion Sensing. Sensors 2025, 25, 6409. https://doi.org/10.3390/s25206409

Huang Y-J, Chuang J-I, Chung C-K. Enhancing the Output Performance of Fiber-TENG Through Graphite Doping and Its Application in Human Motion Sensing. Sensors. 2025; 25(20):6409. https://doi.org/10.3390/s25206409

Chicago/Turabian StyleHuang, You-Jun, Jen-I Chuang, and Chen-Kuei Chung. 2025. "Enhancing the Output Performance of Fiber-TENG Through Graphite Doping and Its Application in Human Motion Sensing" Sensors 25, no. 20: 6409. https://doi.org/10.3390/s25206409

APA StyleHuang, Y.-J., Chuang, J.-I., & Chung, C.-K. (2025). Enhancing the Output Performance of Fiber-TENG Through Graphite Doping and Its Application in Human Motion Sensing. Sensors, 25(20), 6409. https://doi.org/10.3390/s25206409