A Data-Driven Gaussian Process Regression Model for Concrete Complex Dielectric Permittivity Characterization

Abstract

1. Introduction

2. Materials and Methods

2.1. The Jonscher Universal Model

2.2. Gaussian Process Regression

2.3. Hyperparameters Selection

2.4. Error Metrics

3. Numerical Results

| Algorithm 1 Matlab GPR concrete permittivity modeling pseudocode. |

| 1: Input: , ; 2: Output: , 3: []= , ; 4: ; 5: ; 6: ; 7: ; 8: []=; 9: []=; 10: |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| GPR | Gaussian Process Regression; |

| MSE | Mean-Squared Error; |

| MAPE | Mean Absolute Percentage Error; |

| MAE | Mean Absolute Error |

References

- Kanagaraj, B.; Anand, N.; Raj, R.S.; Lubloy, E. Techno-socio-economic aspects of portland cement, geopolymer, and limestone calcined clay cement (LC3) composite systems: A-state-of-art-review. Constr. Build. Mater. 2023, 398, 132484. [Google Scholar] [CrossRef]

- Angiulli, G.; Burrascano, P.; Ricci, M.; Versaci, M. Advances in the Integration of Artificial Intelligence and Ultrasonic Techniques for Monitoring Concrete Structures: A Comprehensive Review. J. Compos. Sci. 2024, 8, 531. [Google Scholar] [CrossRef]

- Bouzaffour, K.; Lescop, B.; Talbot, P.; Gallee, F.; Rioual, S. Development of an embedded UHF-RFID corrosion sensor for monitoring corrosion of steel in concrete. IEEE Sens. J. 2021, 21, 12306–12312. [Google Scholar] [CrossRef]

- Angiulli, G.; Calcagno, S.; La Foresta, F.; Versaci, M. Concrete Compressive Strength Prediction Using Combined Non-Destructive Methods: A Calibration Procedure Using Preexisting Conversion Models Based on Gaussian Process Regression. J. Compos. Sci. 2024, 8, 300. [Google Scholar] [CrossRef]

- Mair, D.; Fischer, M.; Konzilia, J.; Renzler, M.; Ussmueller, T. Evolutionary optimization of antennas for structural health monitoring. IEEE Access 2023, 11, 4905–4913. [Google Scholar] [CrossRef]

- Tenório Filho, J.R.; Goethals, J.; Aminzadeh, R.; Abbas, Y.; Valdez Madrid, D.E.; Cnudde, V.; Vermeeren, G.; Plets, D.; Matthys, S. An automated wireless system for monitoring concrete structures based on embedded electrical resistivity sensors: Data transmission and effects on concrete properties. Sensors 2023, 23, 8775. [Google Scholar] [CrossRef] [PubMed]

- Prattico, D.; Laganá, F.; Oliva, G.; Fiorillo, A.S.; Pullano, S.A.; Calcagno, S.; De Carlo, D.; La Foresta, F. Sensors and Integrated Electronic Circuits for Monitoring Machinery On Wastewater Treatment: Artificial Intelligence Approach. In Proceedings of the IEEE Sensors Applications Symposium (SAS), Napoli, Italy, 23–24 July 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Shilar, F.A.; Ganachari, S.V.; Patil, V.; Yunus Khan, T.M.; Saddique Shaik, A.; Azam Ali, M. Exploring the potential of promising sensor technologies for concrete structural health monitoring. Materials 2024, 17, 2410. [Google Scholar] [CrossRef]

- Telfah, D.; Al-Mattarneh, H.; Ismail, R.; Rawashdeh, A.; Aljamal, M.; Dahim, M. Development of permittivity sensor for advanced in situ testing and evaluation of building material. In Proceedings of the 21st IEEE International Multi-Conference on Systems, Signals & Devices, Erbil, Iraq, 22–25 April 2024; pp. 164–169. [Google Scholar]

- Bouzaffour, K.; Lescop, B.; Talbot, P.; Nguyen-Vien, G.; Gallée, F.; Rioual, S. Decoupling free chloride and water ingress in concrete by a dielectric resonant sensor. Constr. Build. Mater. 2023, 372, 130806. [Google Scholar] [CrossRef]

- Gao, S.; Chung, K.L.; Cui, A.; Ghannam, M.; Luo, J.; Wang, L.; Ma, M.; Liao, Z. Accurate strength prediction models of ordinary concrete using early-age complex permittivity. Mater. Struct. 2021, 54, 172. [Google Scholar] [CrossRef]

- Oliveira, J.G.; Junior, J.G.D.; Pinto, E.; Neto, V.P.S.; D’Assunção, A.G. A new planar microwave sensor for building materials complex permittivity characterization. Sensors 2020, 20, 6328. [Google Scholar] [CrossRef]

- Cataldo, A.; Schiavoni, R.; Masciullo, A.; Cannazza, G.; Micelli, F.; De Benedetto, E. Combined punctual and diffused monitoring of concrete structures based on dielectric measurements. Sensors 2021, 21, 4872. [Google Scholar] [CrossRef]

- Pereira, R.N.; Júnior, J.G.D.; Praxedes, M.E.T.S.; Cabral, K.C.; da Silva Neto, V.P.; D’Assunção, A.G. A planar DGS sensor for moisture analysis in civil construction aggregates. Sens. Actuators A Phys. 2024, 367, 115042. [Google Scholar] [CrossRef]

- Suchorab, Z.; Szczepaniak, Z.; Tabiś, K.; Łagód, G.; Brzyski, P.; Rogala, T. Comparison of reflectometric and microwave moisture detection techniques. Aip Conf. Proc. 2023, 2801, 030029. [Google Scholar]

- González-López, G.; Blanch, S.; Romeu, J.; Jofre, L. Debye frequency-extended waveguide permittivity extraction for high complex permittivity materials: Concrete setting process characterization. IEEE Trans. Instrum. Meas. 2019, 69, 5604–5613. [Google Scholar] [CrossRef]

- Zhang, B.; Ni, Y.; Zhong, Y. Theoretical derivation of and experimental investigations into the dielectric properties modeling of concrete. J. Mater. Civ. Eng. 2023, 35, 04022445. [Google Scholar] [CrossRef]

- Chung, K.L.; Yuan, L.; Ji, S.; Sun, L.; Qu, C.; Zhang, C. Dielectric characterization of Chinese standard concrete for compressive strength evaluation. Appl. Sci. 2017, 7, 177. [Google Scholar] [CrossRef]

- Angiulli, G.; Versaci, M. Electromagnetic Characterization of Concrete by Jonscher Universal Dielectric Model: Numerical Validation of Different Nonlinear Optimization Algorithms. IEEE Access 2025, 13, 142635–142650. [Google Scholar] [CrossRef]

- Jo, S.; Cho, K.; Noh, V.; Lee, N.; Kim, S.; Yook, J.G. Electromagnetic shielding effectiveness of the concrete composite as a function of structural parameters of steel fibers. J. Korean Inst. Electromagn. Eng. Sci. 2021, 32, 517–526. [Google Scholar] [CrossRef]

- Chen, L.; Kim, C.; Batra, R.; Lightstone, J.P.; Wu, C.; Li, Z.; Deshmukh, A.A.; Wang, Y.; Tran, H.D.; Vashishta, P.; et al. Frequency-dependent dielectric constant prediction of polymers using machine learning. NPJ Comput. Mater. 2020, 6, 61. [Google Scholar] [CrossRef]

- Guo, H.; Song, Y.; Yin, J.; Li, J.; Liu, X. Predicting Dielectric Constant of Polyimide Composites Using Data-Driven Wavelet Kernel Deep Gaussian Process. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 1045–1052. [Google Scholar] [CrossRef]

- Güneşer, M.T.; Atasoy, F. Extracting complex permittivity of materials by Gaussian process regression using the transmission parameter at sub-THz. J. Electron. Mater. 2020, 49, 681–688. [Google Scholar] [CrossRef]

- Gramacy, R.B. Surrogates: Gaussian Process Modeling, Design, and Optimization for the Applied Sciences; Chapman and Hall/CRC: Boca Raton, FL, USA, 2020. [Google Scholar]

- Huang, S.; Chung, K.L.; Zheng, K.; Liu, X. An Improved Jonscher Model for Broadband Dielectric Characterization of Cement Composites. In Proceedings of the 2023 IEEE International Symposium On Antennas And Propagation (ISAP), Kuala Lumpur, Malaysia, 30 October–2 November 2023; pp. 1–2. [Google Scholar]

- Jonscher, A.K. Dielectric relaxation in solids. J. Phys. D Appl. Phys. 1999, 32, R57. [Google Scholar] [CrossRef]

- Bourdi, T.; Rhazi, J.E.; Boone, F.; Ballivy, G. Application of Jonscher model for the characterization of the dielectric permittivity of concrete. J. Phys. D Appl. Phys. 2008, 41, 205410. [Google Scholar] [CrossRef]

- Wong, E. Introduction to Random Processes; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- MATLAB Team. Statistics and Machine Learning Toolbox; The Mathworks Inc.: Natick, MA, USA, 2019. [Google Scholar]

- Lee, K.Y.; Phua, Y.N.; Lim, S.K.; You, K.Y.; Cheng, E.M. Determination of density and compressive strength of lightweight foamed concrete using frequency domain approach. Microw. Opt. Technol. Lett. 2021, 63, 2153–2159. [Google Scholar] [CrossRef]

| Concrete | n | (GHz) | ||

|---|---|---|---|---|

| B1 | 0.2266 | |||

| B2 | 0.2266 | |||

| LFC | 0.2129 | |||

| ULCC | 0.0321 |

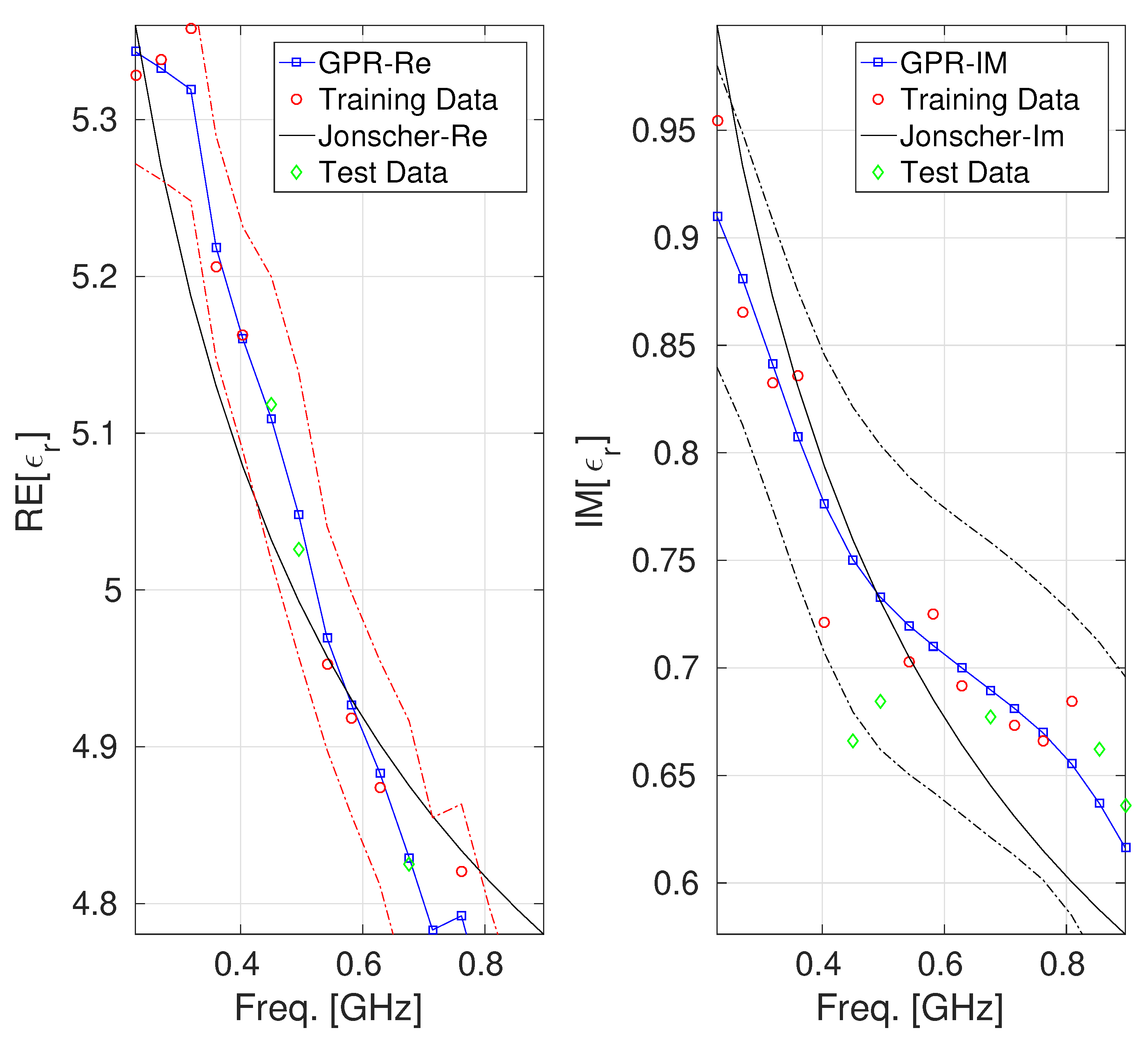

| B1 | MSE | MAE | MAPE |

|---|---|---|---|

| Jonscher(Re) | |||

| GPR(Re) | |||

| Jonscher(Im) | |||

| GPR(Im) |

| B2 | MSE | MAE | MAPE |

|---|---|---|---|

| Jonscher(Re) | |||

| GPR(Re) | |||

| Jonscher(Im) | |||

| GPR(Im) |

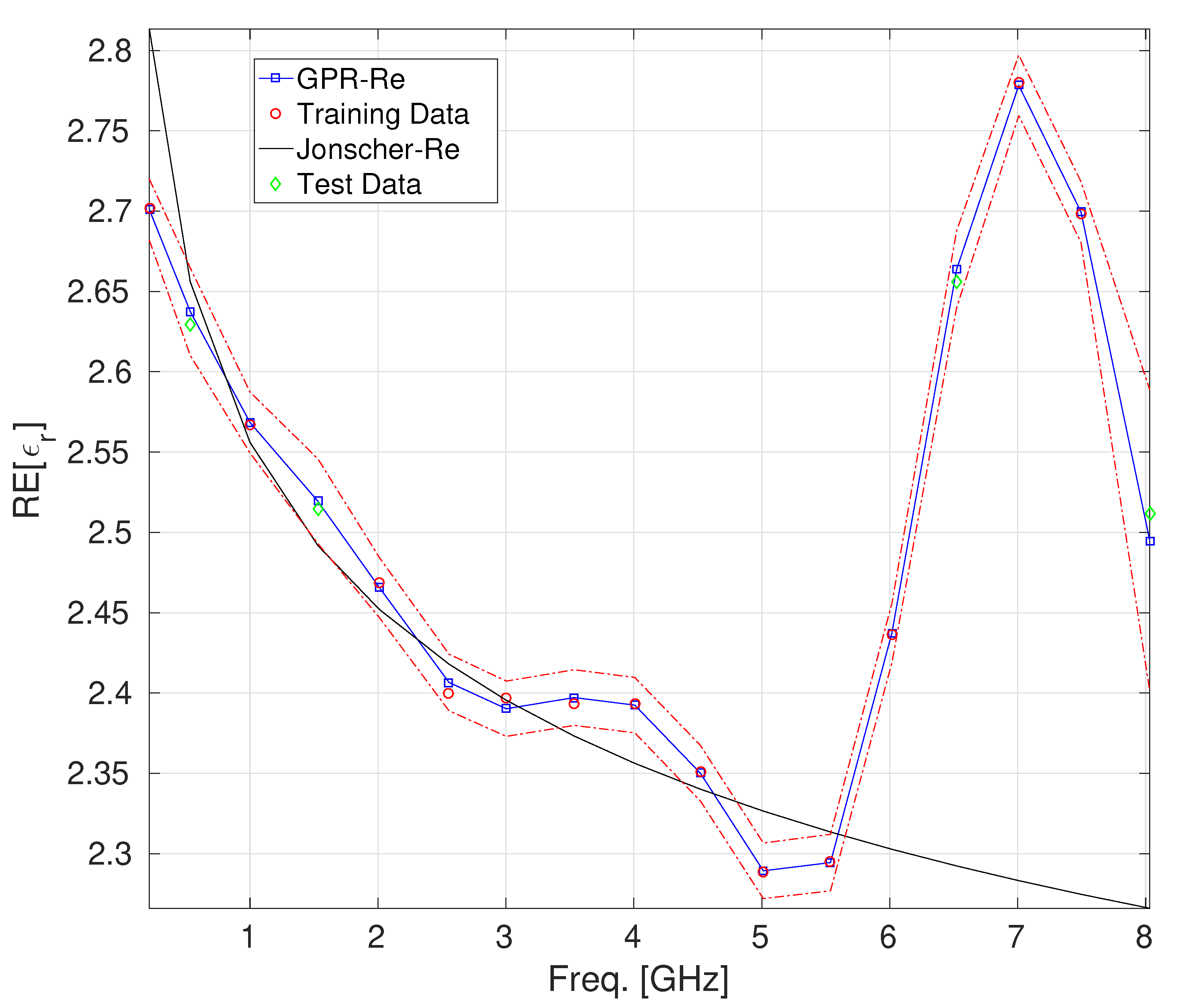

| LFC | MSE | MAE | MAPE |

|---|---|---|---|

| Jonscher(Re) | |||

| GPR(Re) |

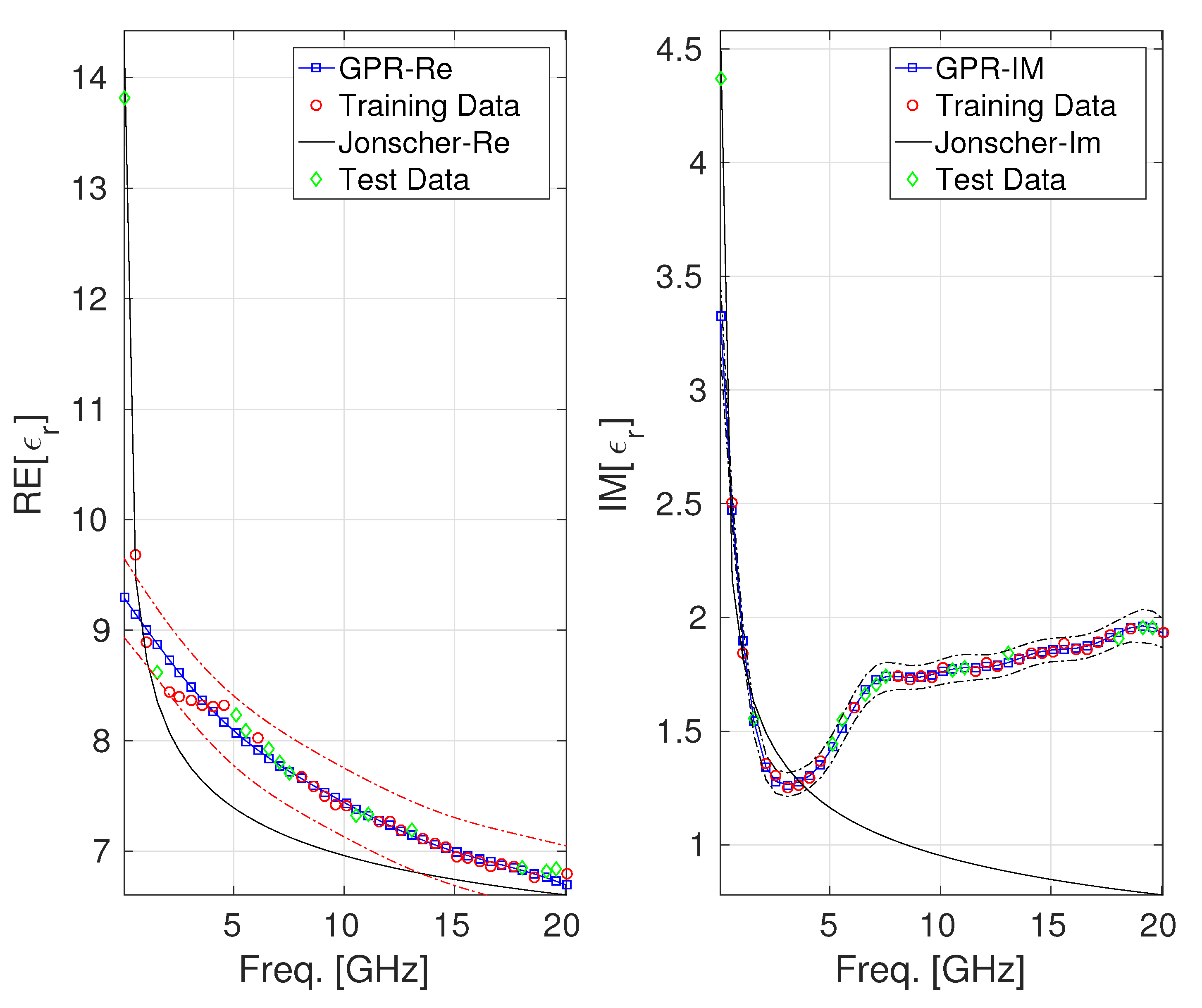

| ULCC | MSE | MAE | MAPE |

|---|---|---|---|

| Jonscher(Re) | |||

| GPR(Re) | |||

| Jonscher(Im) | |||

| GPR(Im) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Angiulli, G.; Versaci, M.; Burrascano, P.; Laganá, F. A Data-Driven Gaussian Process Regression Model for Concrete Complex Dielectric Permittivity Characterization. Sensors 2025, 25, 6350. https://doi.org/10.3390/s25206350

Angiulli G, Versaci M, Burrascano P, Laganá F. A Data-Driven Gaussian Process Regression Model for Concrete Complex Dielectric Permittivity Characterization. Sensors. 2025; 25(20):6350. https://doi.org/10.3390/s25206350

Chicago/Turabian StyleAngiulli, Giovanni, Mario Versaci, Pietro Burrascano, and Filippo Laganá. 2025. "A Data-Driven Gaussian Process Regression Model for Concrete Complex Dielectric Permittivity Characterization" Sensors 25, no. 20: 6350. https://doi.org/10.3390/s25206350

APA StyleAngiulli, G., Versaci, M., Burrascano, P., & Laganá, F. (2025). A Data-Driven Gaussian Process Regression Model for Concrete Complex Dielectric Permittivity Characterization. Sensors, 25(20), 6350. https://doi.org/10.3390/s25206350