On-Ground Calibration of a Nano-G Accelerometer for Micro-Vibration Monitoring in Space on a Dual-Axis Indexing Device

Abstract

1. Introduction

2. Accelerometer and Model Equation

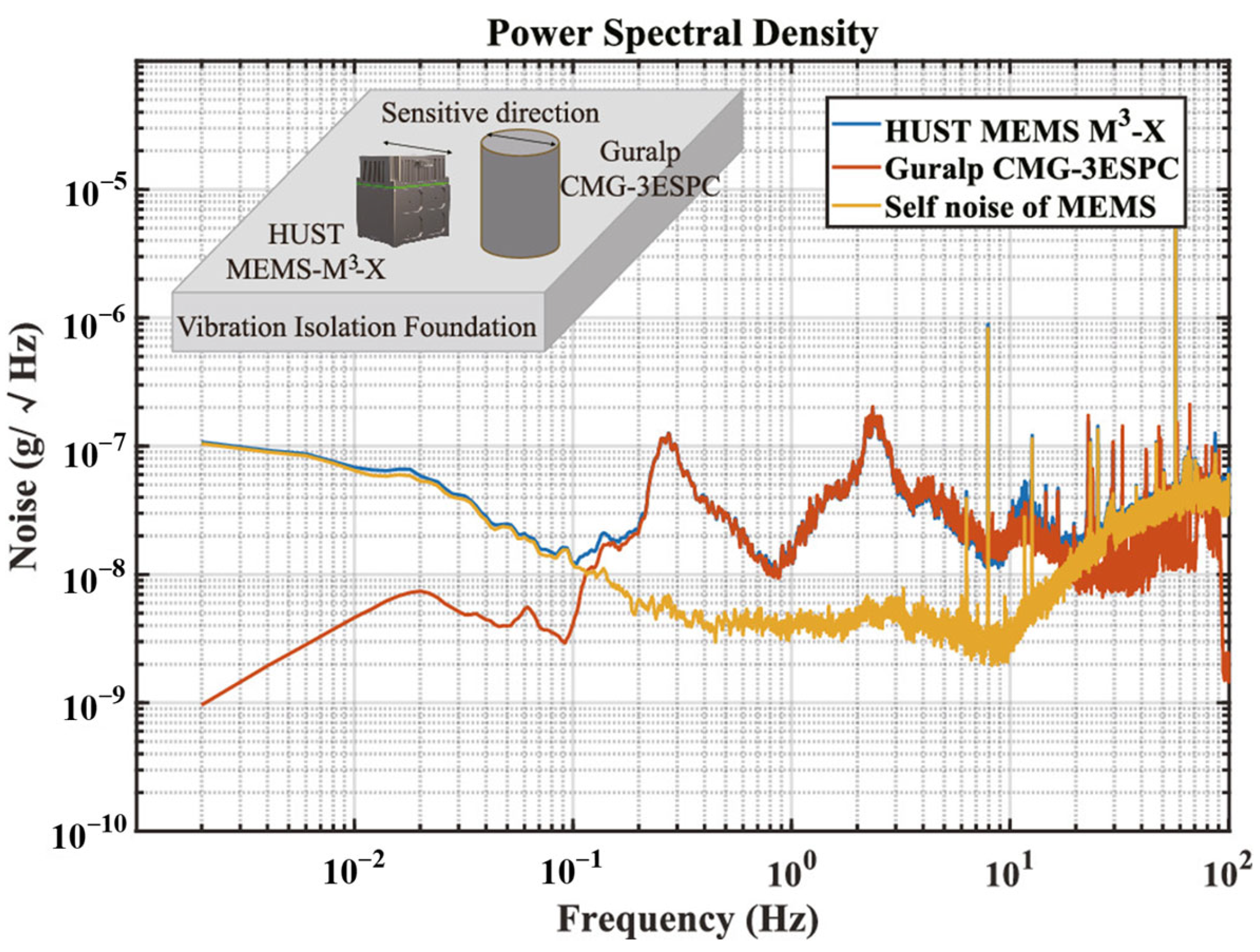

2.1. Description of the Accelerometer to Be Tested

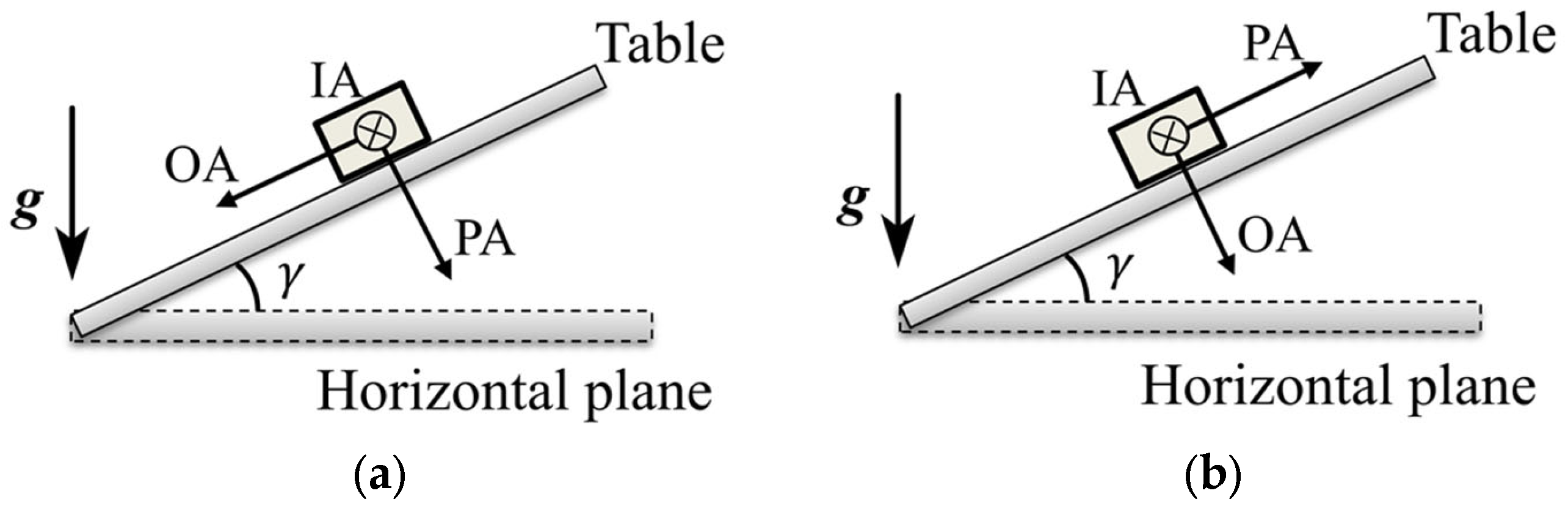

2.2. Model Equation of Accelerometer

3. Calibration Method of High-Precision Tri-Axial Accelerometer

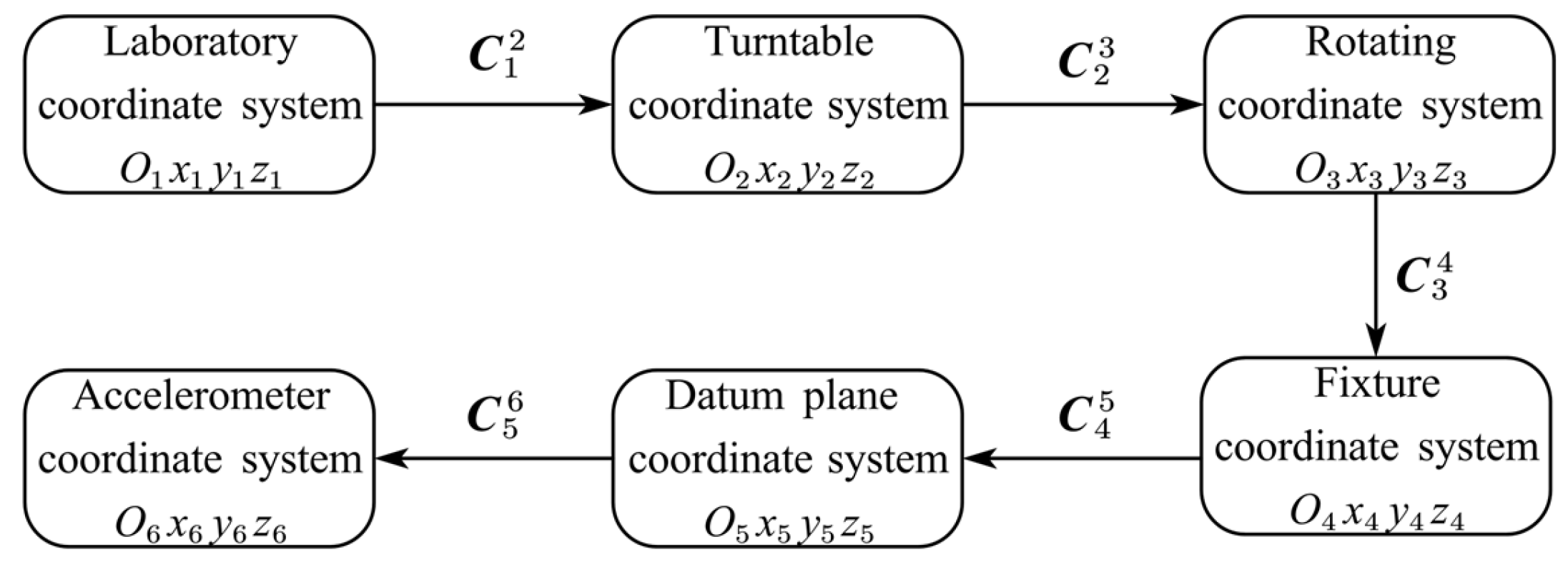

3.1. Test Setup and Coordinate Systems

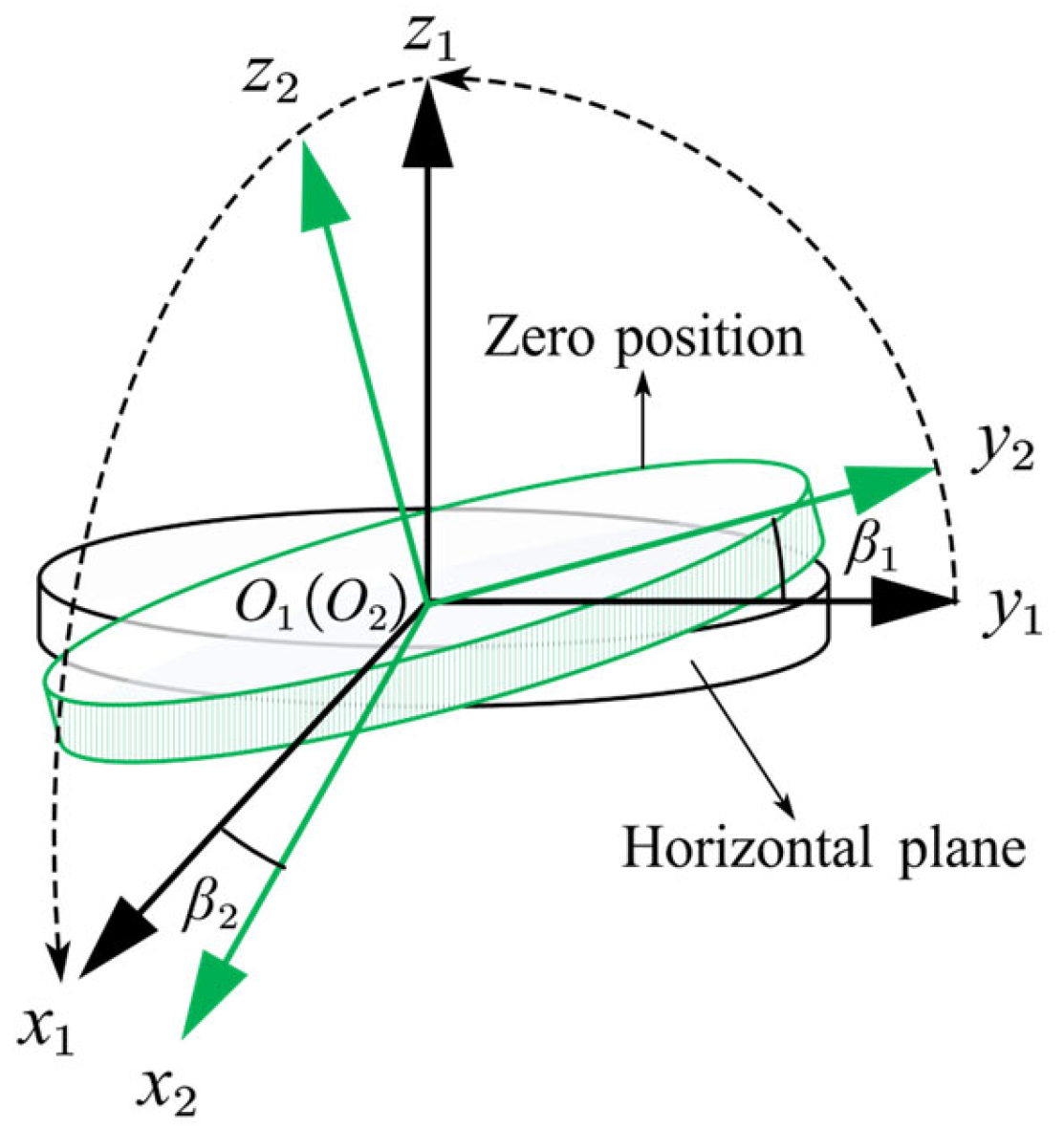

- The laboratory coordinate system is , where the -plane is horizontal and the axis is along the direction of gravity.

- The turntable coordinate system is , where the axis is overlapped with the tilt axis of the turntable and the is orthogonal to the within the rotation surface when the tilt angle is set to the nominal zero position. Therefore, the misalignment between the coordinate systems and is fixed and mainly caused by the installation error of the turntable.

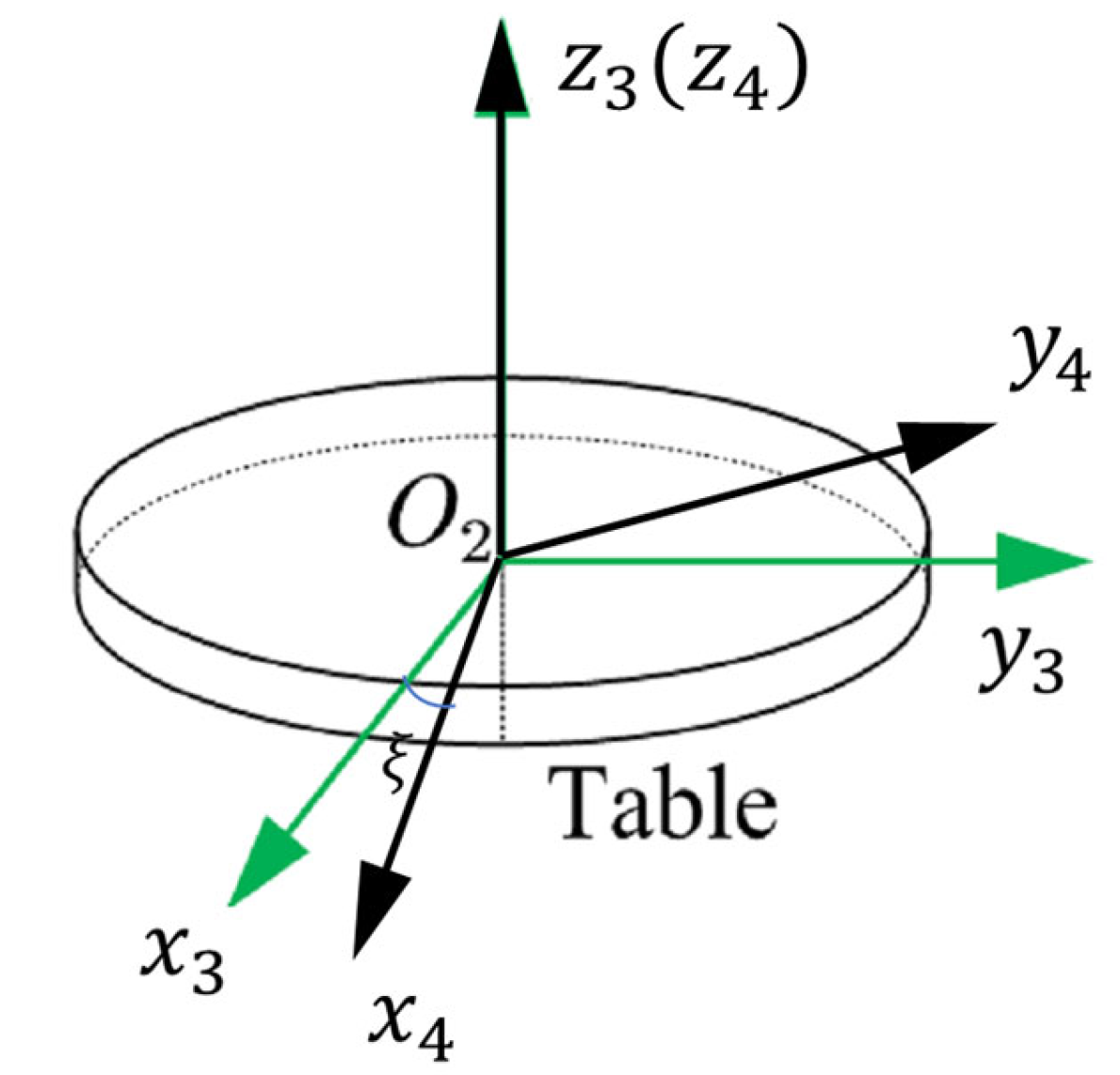

- The rotating coordinate system is , which is fixed to the mounting surface of the turntable and moves together with the accelerometer as the turntable rotates. Figure 6 shows how the turntable coordinate system is transformed to the rotating coordinate system .

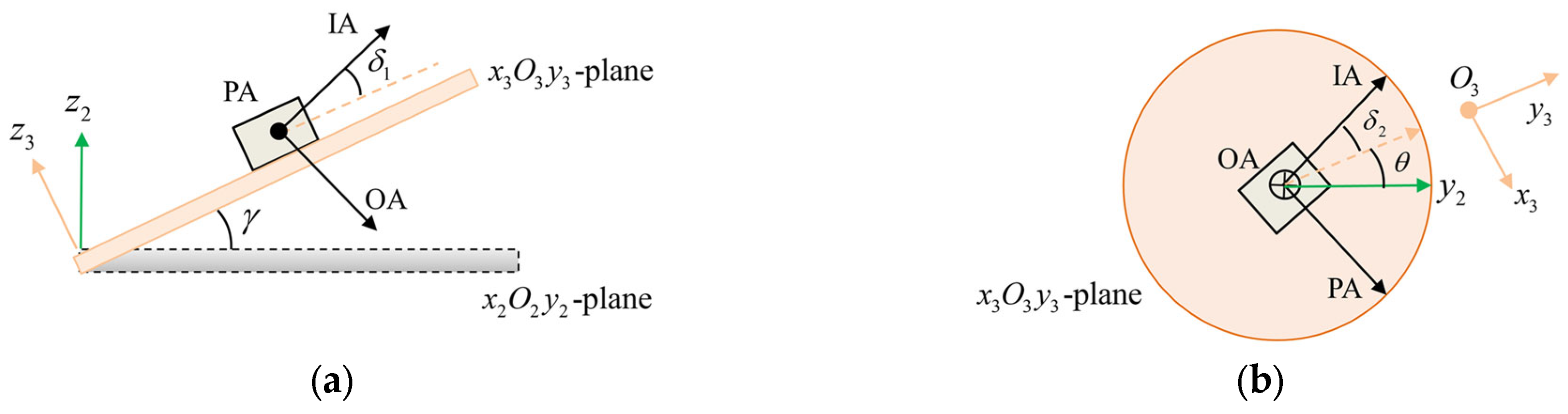

- The fixture coordinate system is , which is realized by rotating the system about the axis with an angle , and where is the mounting error of the fixture relative to the turntable platform, as shown in Figure 7. The accelerometer can be mounted with different configurations through the fixture.

- The datum plane coordinate system is , where the axes are defined by the accelerometer housing the datum plane and bottom surface, as shown in Figure 2. The attitudes of every sensitive axis separately measured in the fixture coordinate system have to be unified in the datum plane coordinate system .

- The accelerometer coordinate system is determined by the IAs of the three units of the tri-axial accelerometer. The difference between and is the accelerometer misalignment of its three sensitive axes.

3.2. Traditional Multi-Position Calibration Method

3.3. Improved Scheme Based on Separately Rotating Along Each of the Three Reference Axes of a Single-Axis Accelerometer Unit

3.4. Unified Misalignment Calibration of the Three Accelerometer Units

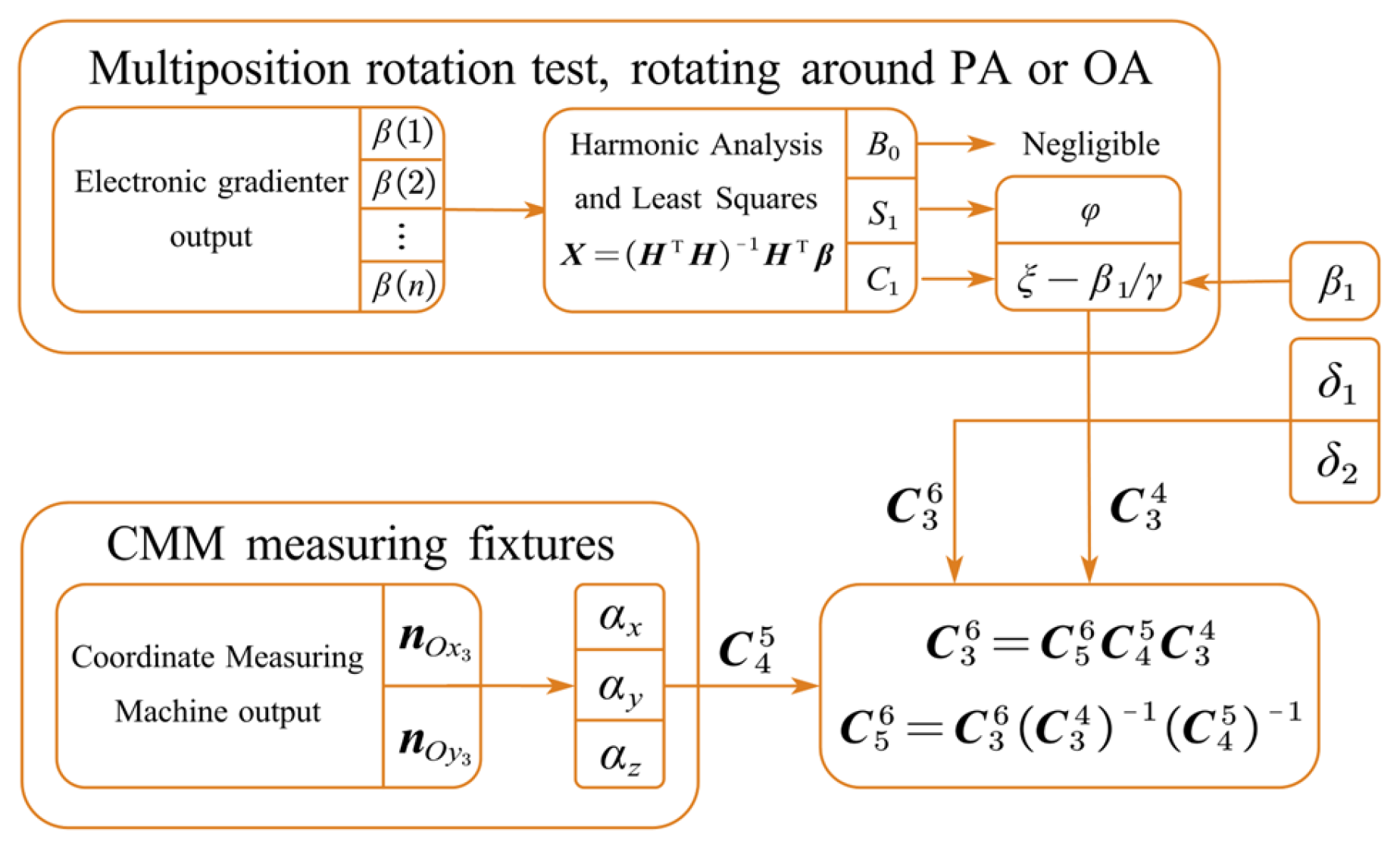

3.5. Data Processing Procedures

4. Experiments and Discussion

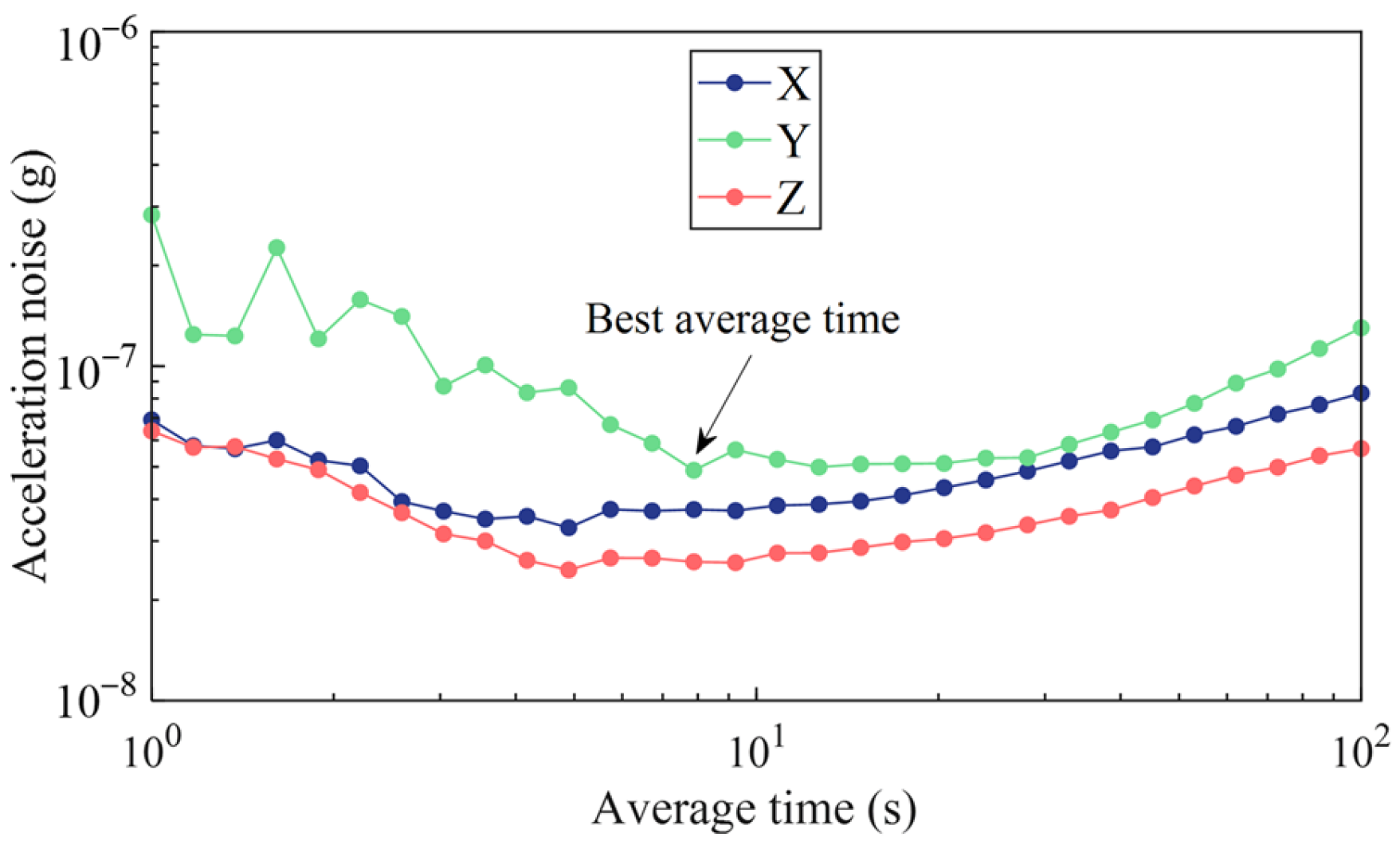

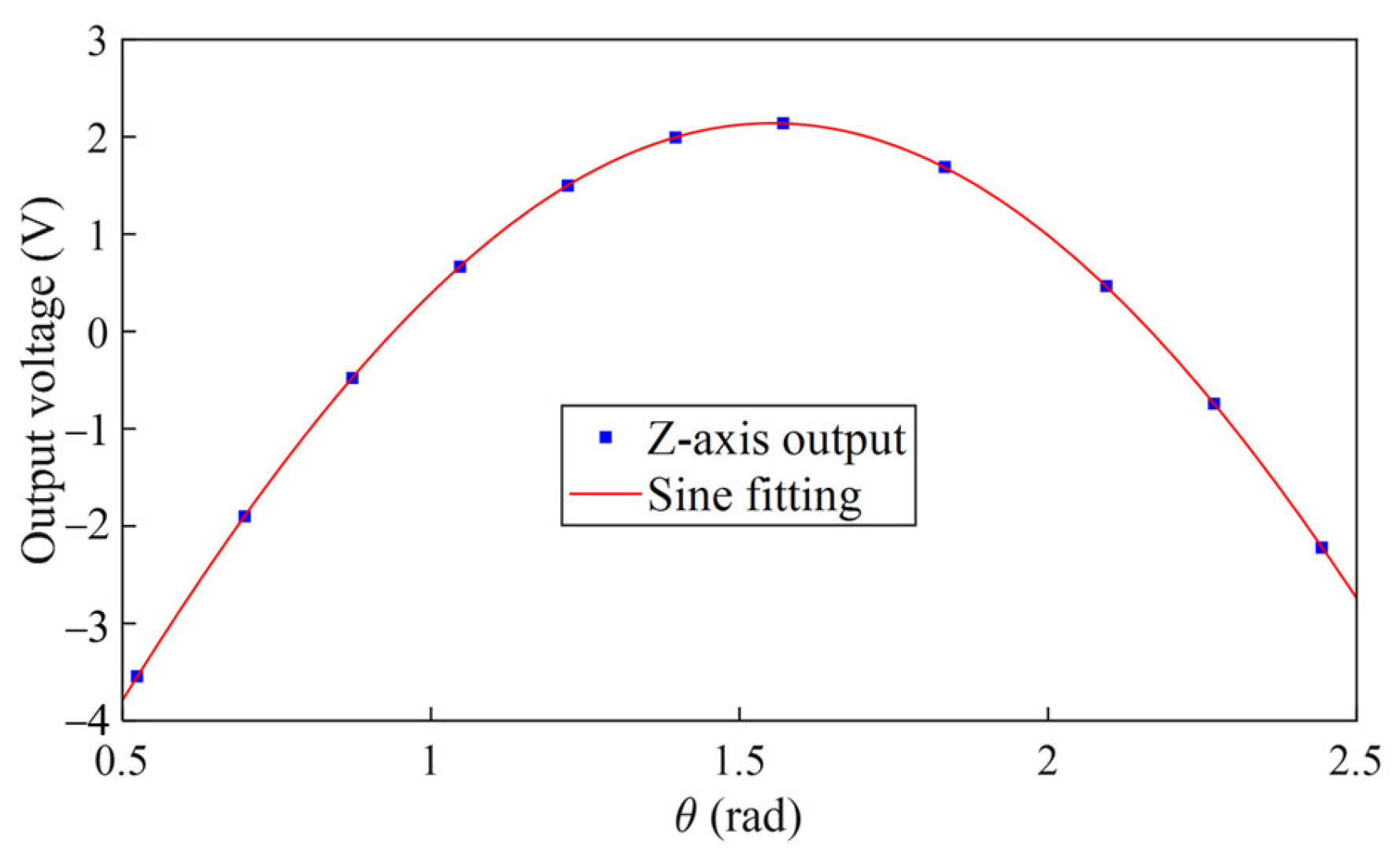

4.1. Testing at Input Range of ±2 mg

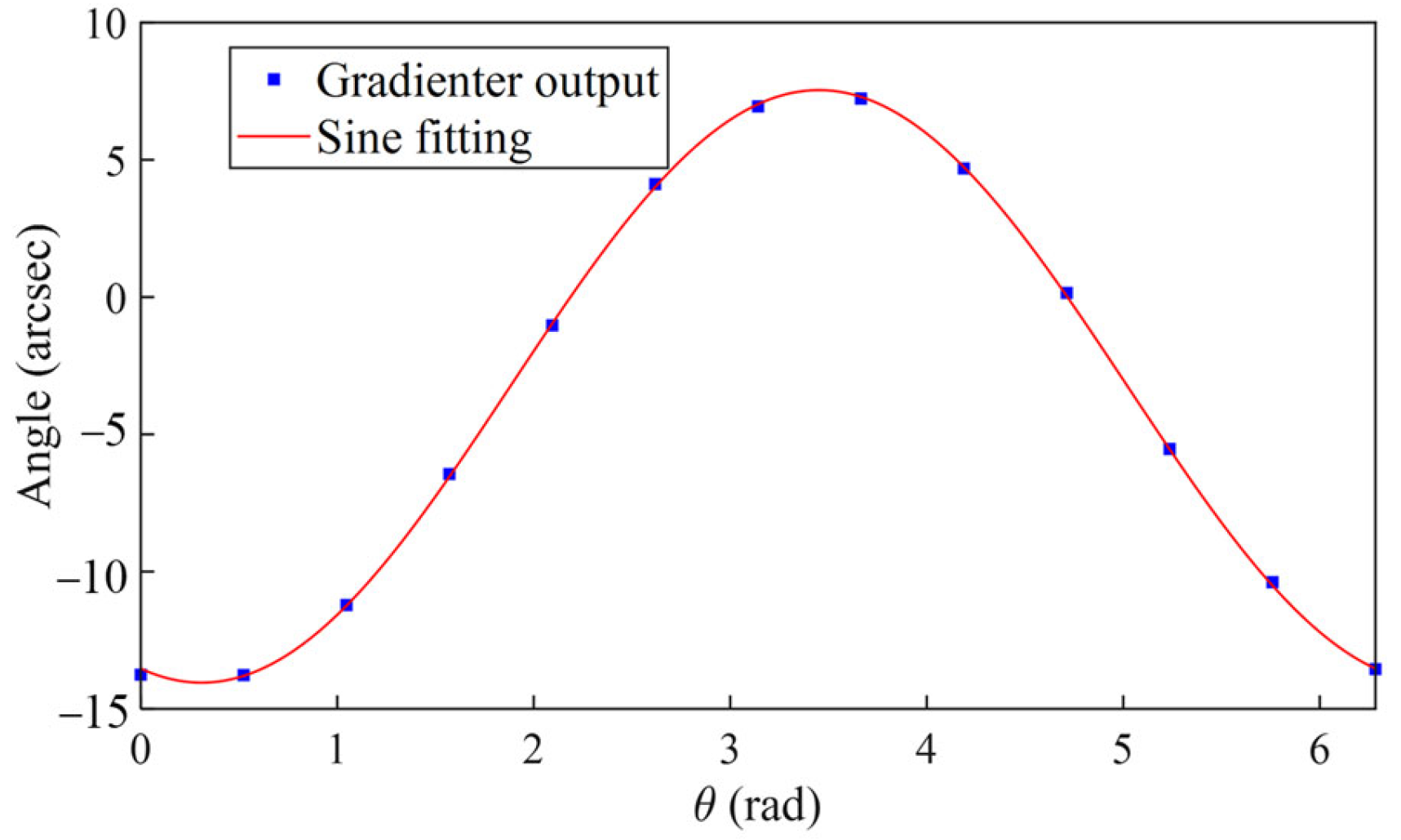

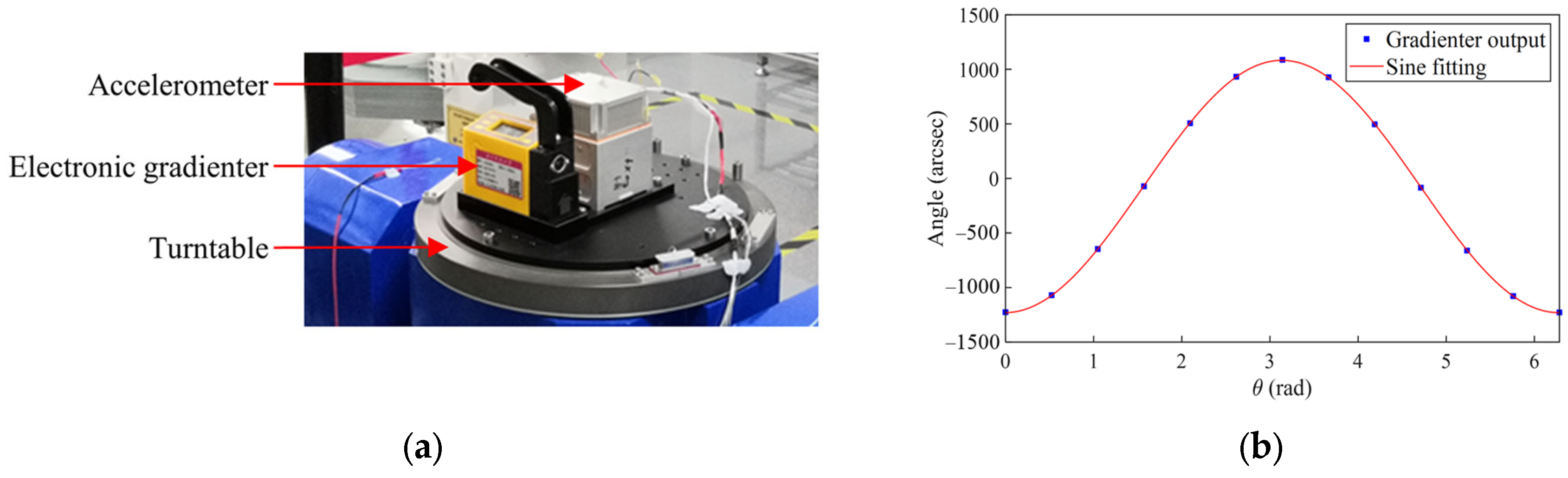

4.2. Calibration of Turntable Installation Error

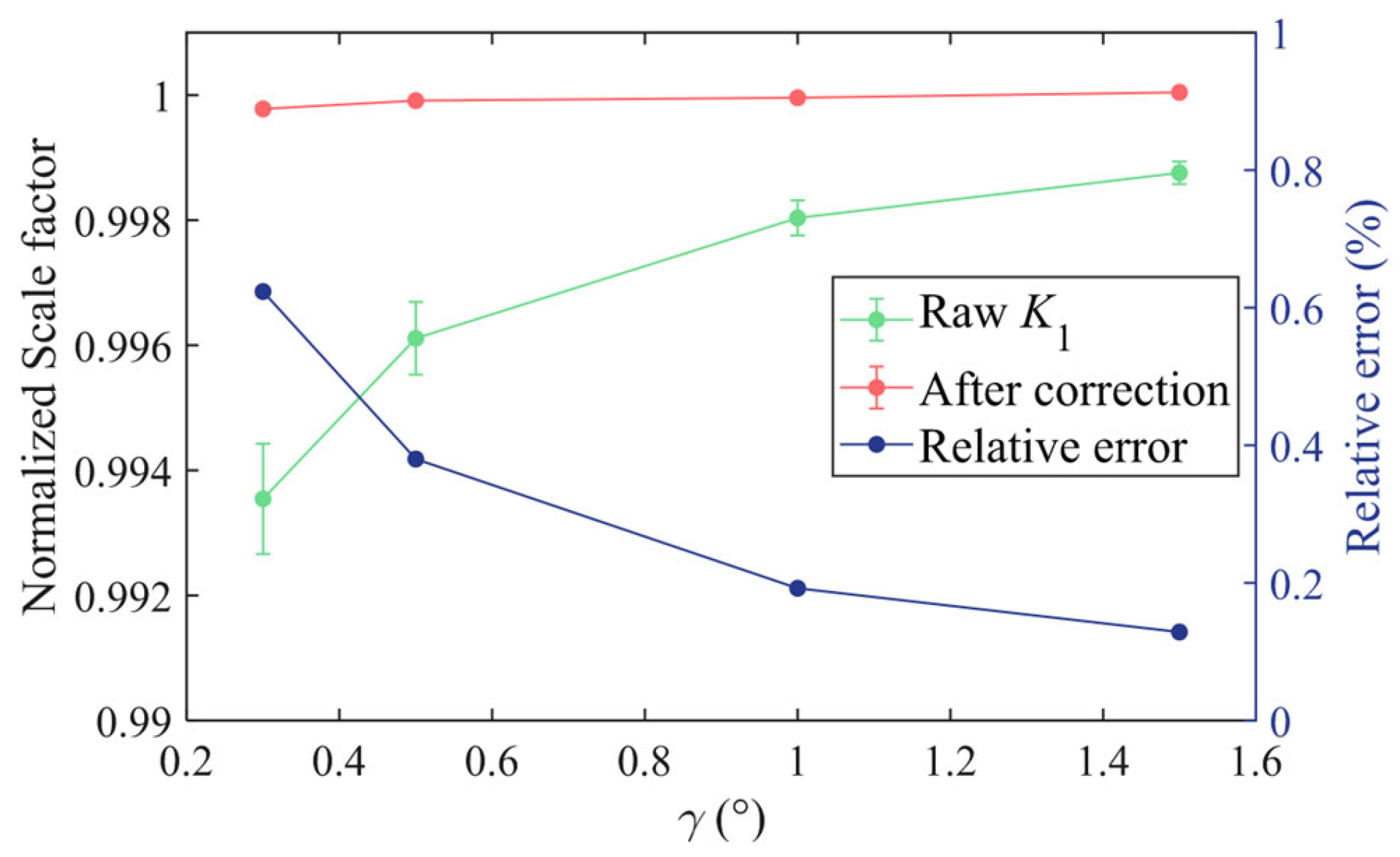

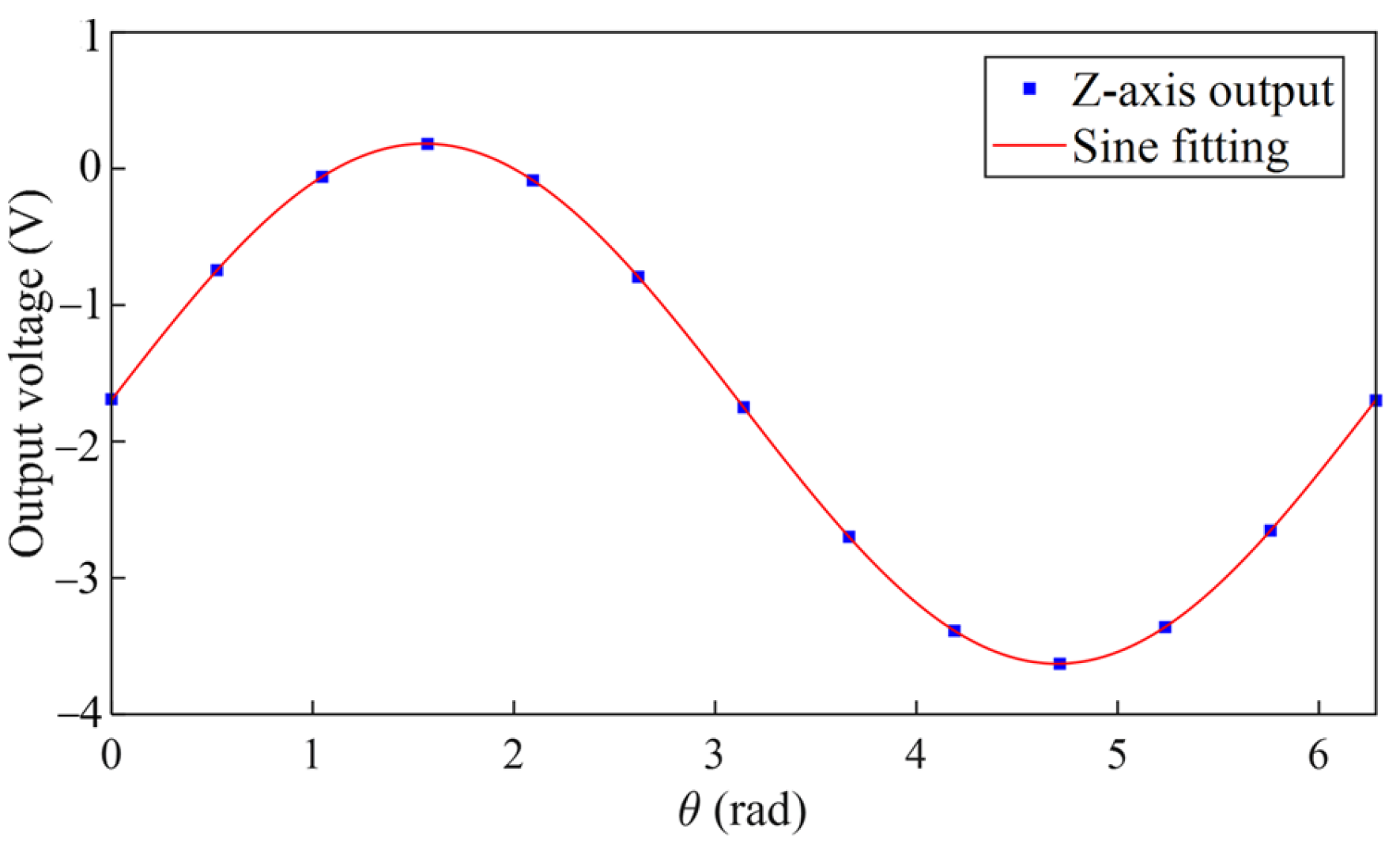

4.3. Testing at Input Range of ±13 mg

4.4. Misalignment Test

4.5. Results and Uncertainty Analysis

4.6. On-Orbit Data Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Middlemiss, R.P.; Samarelli, A.; Paul, D.J.; Hough, J.; Rowan, S.; Hammond, G.D. Measurement of the Earth Tides with a MEMS Gravimeter. Nature 2016, 531, 614–617. [Google Scholar] [CrossRef]

- Liu, H.; Pike, W.T. A Micromachined Angular-Acceleration Sensor for Geophysical Applications. Appl. Phys. Lett. 2016, 109, 173506. [Google Scholar] [CrossRef]

- Crisp, N.H.; Roberts, P.C.E.; Romano, F.; Smith, K.L.; Oiko, V.T.A.; Sulliotti-Linner, V.; Hanessian, V.; Herdrich, G.H.; García-Almiñana, D.; Kataria, D.; et al. System Modelling of Very Low Earth Orbit Satellites for Earth Observation. Acta Astronaut. 2021, 187, 475–491. [Google Scholar] [CrossRef]

- Pike, W.T.; Standley, I.M.; Calcutt, S.B.; Mukherjee, A.G. A Broad-Band Silicon Microseismometer with 0.25 NG/rtHz Performance. In Proceedings of the 2018 IEEE Micro Electro Mechanical Systems (MEMS), Belfast, Ireland, 21–25 January 2018; pp. 113–116. [Google Scholar]

- Liu, H.-F.; Luo, Z.-C.; Hu, Z.-K.; Yang, S.-Q.; Tu, L.-C.; Zhou, Z.-B.; Kraft, M. A Review of High-Performance MEMS Sensors for Resource Exploration and Geophysical Applications. Pet. Sci. 2022, 19, 2631–2648. [Google Scholar] [CrossRef]

- Ma, X.; Fang, J.; Ning, X. An Overview of the Autonomous Navigation for a Gravity-Assist Interplanetary Spacecraft. Prog. Aerosp. Sci. 2013, 63, 56–66. [Google Scholar] [CrossRef]

- Hui, L.; Lin, W.; Lifeng, B.; Qianqian, L.; Panpan, Z.; Menghan, X. Comprehensive Features Matching Algorithm for Gravity Aided Navigation. IEEE Geosci. Remote Sens. Lett. 2022, 19, 1–5. [Google Scholar] [CrossRef]

- Schiermeier, Q. Gravity Mission to Launch. Nature 2009, 458, 133. [Google Scholar] [CrossRef]

- Chen, J.; Cazenave, A.; Dahle, C.; Llovel, W.; Panet, I.; Pfeffer, J.; Moreira, L. Applications and Challenges of GRACE and GRACE Follow-On Satellite Gravimetry. Surv. Geophys. 2022, 43, 305–345. [Google Scholar] [CrossRef]

- Hines, A.; Nelson, A.; Zhang, Y.; Valdes, G.; Sanjuan, J.; Guzman, F. Compact Optomechanical Accelerometers for Use in Gravitational Wave Detectors. Appl. Phys. Lett. 2023, 122, 094101. [Google Scholar] [CrossRef]

- Arun, K.G.; Belgacem, E.; Benkel, R.; Bernard, L.; Berti, E.; Bertone, G.; Besancon, M.; Blas, D.; Böhmer, C.G.; Brito, R.; et al. New Horizons for Fundamental Physics with LISA. Living Rev. Relativ. 2022, 25, 4. [Google Scholar] [CrossRef]

- Gong, Y.; Luo, J.; Wang, B. Concepts and Status of Chinese Space Gravitational Wave Detection Projects. Nat. Astron. 2021, 5, 881–889. [Google Scholar] [CrossRef]

- Khan, A.; Ceylan, S.; van Driel, M.; Giardini, D.; Lognonné, P.; Samuel, H.; Schmerr, N.C.; Stähler, S.C.; Duran, A.C.; Huang, Q.; et al. Upper Mantle Structure of Mars from InSight Seismic Data. Science 2021, 373, 434–438. [Google Scholar] [CrossRef]

- Garcia, R.F.; Daubar, I.J.; Beucler, É.; Posiolova, L.V.; Collins, G.S.; Lognonné, P.; Rolland, L.; Xu, Z.; Wójcicka, N.; Spiga, A.; et al. Newly Formed Craters on Mars Located Using Seismic and Acoustic Wave Data from InSight. Nat. Geosci. 2022, 15, 774–780. [Google Scholar] [CrossRef]

- Du, B.; Shi, Z.; Ding, M.; Han, L.; Song, J. The Calibration Method for Accelerometers in the Redundant MEMS Inertial Navigation System. Meas. Sci. Technol. 2021, 32, 095004. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Z.; Wang, Q.; Yang, Y.; Wang, Y.; He, W.; Liu, J.; Tu, L.; Liu, H. Analysis of the Frequency-Dependent Vibration Rectification Error in Area-Variation-Based Capacitive MEMS Accelerometers. Micromachines 2024, 15, 65. [Google Scholar] [CrossRef]

- Wei, Y.; Yang, J.; Li, P.; Zhang, X.; Liang, P. Analysis and Optimization Method of the Vibration Rectification Error of a Pendulous Accelerometer. IEEE Sens. J. 2021, 21, 19847–19856. [Google Scholar] [CrossRef]

- Santoli, F.; Fiorenza, E.; Lefevre, C.; Lucchesi, D.M.; Lucente, M.; Magnafico, C.; Morbidini, A.; Peron, R.; Iafolla, V. ISA, a High Sensitivity Accelerometer in the Interplanetary Space. Space Sci. Rev. 2020, 216, 145. [Google Scholar] [CrossRef]

- Pou, L.; Mimoun, D.; Lognonne, P.; Garcia, R.F.; Karatekin, O.; Nonon-Latapie, M.; Llorca-Cejudo, R. High Precision SEIS Calibration for the InSight Mission and Its Applications. Space Sci. Rev. 2018, 215, 6. [Google Scholar] [CrossRef]

- Yu, M.; Cai, T. Generation of a Multifrequency Gravitational-Gradient Excitation and Extraction of the Gravitational Gradient with a Rotating Accelerometer Gravity Gradiometer. Rev. Sci. Instrum. 2018, 89, 104501. [Google Scholar] [CrossRef]

- Pi, J.; Yu, X.; Chen, P.; Yu, M.; Yu, L.; Fan, J.; Liu, J.; Hu, C.; Tu, L. Implementation of Effective Scale Factor Matching and Axial Centripetal Error Compensation for a Rotating Accelerometer Gravity Gradiometer. IEEE Trans. Instrum. Meas. 2023, 72, 1–11. [Google Scholar] [CrossRef]

- IEEE. IEEE Recommended Practice for Precision Centrifuge Testing of Linear Accelerometers. In IEEE Std 836-2009 (Revision of IEEE Std 836-2001); IEEE: Piscataway, NJ, USA, 2009; pp. 1–152. [Google Scholar] [CrossRef]

- IEEE. IEEE Standard Specification Format Guide and Test Procedure for Linear Single-Axis, Nongyroscopic Accelerometers. In IEEE Std 1293-2018 (Revision of IEEE Std 1293-1998); IEEE: Piscataway, NJ, USA, 2019; pp. 1–271. [Google Scholar] [CrossRef]

- Cai, Q.; Song, N.; Yang, G.; Liu, Y. Accelerometer Calibration with Nonlinear Scale Factor Based on Multi-Position Observation. Meas. Sci. Technol. 2013, 24, 105002. [Google Scholar] [CrossRef]

- Wang, Z.; Cheng, X.; Fu, J. Optimized Multi-Position Calibration Method with Nonlinear Scale Factor for Inertial Measurement Units. Sensors 2019, 19, 3568. [Google Scholar] [CrossRef]

- Chiominto, L.; D’Emilia, G.; Gaspari, A.; Natale, E. Dynamic Multi-Axis Calibration of MEMS Accelerometers for Sensitivity and Linearity Assessment. Sensors 2025, 25, 2120. [Google Scholar] [CrossRef] [PubMed]

- Mattoo, F.A.; Nawaz, T.; Saleem, M.M.; Khan, U.S.; Hamza, A. Deep Learning Based Multiresponse Optimization Methodology for Dual-Axis MEMS Accelerometer. Micromachines 2023, 14, 817. [Google Scholar] [CrossRef]

- Zhang, M.; Yan, S.; Deng, Z.; Chen, P.; Li, Z.; Fan, J.; Liu, H.; Liu, J.; Tu, L. Cross-Coupling Coefficient Estimation of a Nano-g Accelerometer by Continuous Rotation Modulation on a Tilted Rate Table. IEEE Trans. Instrum. Meas. 2021, 70, 1–12. [Google Scholar] [CrossRef]

- Wielandt, E.; Zumberge, M. Measuring Seismometer Nonlinearity on a Shake Table. Bull. Seismol. Soc. Am. 2013, 103, 2247–2256. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, S.; Zhou, Y.; Wu, W.; Tu, L.; Liu, J. Calibrating Nonlinearity Coefficients of a Nano-g Accelerometer by Dual-Frequency Excitation on a Shaker. Measurement 2024, 225, 114016. [Google Scholar] [CrossRef]

- MEMS Microgravity Measurement Module with Nano-g/Hz Noise Floor for Spaceborne Higher-Level Microgravity Scientific Experiment Applications | ACS Applied Electronic Materials. Available online: https://pubs.acs.org/doi/10.1021/acsaelm.1c00359 (accessed on 31 August 2025).

- Sun, X.; Lai, J.; Lyu, P.; Liu, R.; Gao, W. A Fast Self-Calibration Method for Dual-Axis Rotational Inertial Navigation Systems Based on Invariant Errors. Sensors 2024, 24, 597. [Google Scholar] [CrossRef]

- Gaitan, M.; Geist, J. Calibration of Triaxial Accelerometers by Constant Rotation Rate in the Gravitational Field. Measurement 2022, 189, 110528. [Google Scholar] [CrossRef] [PubMed]

- Yuan, B.; Tang, Z.; Zhang, P.; Lv, F. Thermal Calibration of Triaxial Accelerometer for Tilt Measurement. Sensors 2023, 23, 2105. [Google Scholar] [CrossRef] [PubMed]

- Soto, H.L. Calibrating a 3-Axis Accelerometer Instrument with a Less Accurate Calibration Device Part 1: Mathematical Methodology; NASA: Washington, DC, USA, 2020. [Google Scholar]

- Galetto, M.; Schiavi, A.; Genta, G.; Prato, A.; Mazzoleni, F. Uncertainty Evaluation in Calibration of Low-Cost Digital MEMS Accelerometers for Advanced Manufacturing Applications. CIRP Ann. 2019, 68, 535–538. [Google Scholar] [CrossRef]

- Cai, Q.; Yang, G.; Song, N.; Liu, Y. Systematic Calibration for Ultra-High Accuracy Inertial Measurement Units. Sensors 2016, 16, 940. [Google Scholar] [CrossRef] [PubMed]

- Dong, C.; Ren, S.; Chen, X.; Wang, Z. A Separated Calibration Method for Inertial Measurement Units Mounted on Three-Axis Turntables. Sensors 2018, 18, 2846. [Google Scholar] [CrossRef]

- Ma, Y.; Bai, Y.-Z.; Li, H.-Y.; Zhou, Z.-B.; Zhou, Z. Identification and Compensation of Quadratic Terms of a Space Electrostatic Accelerometer. Rev. Sci. Instrum. 2018, 89, 114502. [Google Scholar] [CrossRef] [PubMed]

| Parameters | Meaning | Typical Values |

|---|---|---|

| , | Installation error of IA | ±5 mrad |

| Tilt angle of the turntable | ±5 mrad | |

| Bias of accelerometers | ±1 mg | |

| , , | Second-order term coefficients related to IA | ±0.1 g/g2 |

| , , | Second-order term coefficients unrelated to IA | ±0.1 mg/g2 |

| Parameters | Results | |

|---|---|---|

| Multi-position PA rotation | 0.22 ± 0.02 g/g2 | |

| 0.15 ± 0.03 g/g2 | ||

| Multi-position IA tilt | −2.31 ± 0.01 mrad | |

| 5.98 ± 0.01 mrad | ||

| 0.12 ± 0.01 mg/g2 | ||

| 0.11 ± 0.02 mg/g2 |

| Transformation Matrix | Parameters | Values (mrad) |

|---|---|---|

| −2.31 ± 0.01 | ||

| 5.98 ± 0.01 | ||

| −3.1 ± 0.3 | ||

| −1.1 ± 0.1 | ||

| 1.6 ± 0.1 | ||

| 6.7 ± 0.1 | ||

| −6.6 ± 0.3 | ||

| 5.2 ± 0.3 |

| Parameters | X Axis | Y Axis | Z Axis |

|---|---|---|---|

| (V/g) | 2119 ± 6 | 2029 ± 6 | 2048 ± 8 |

| (mg) | −2.49 ± 0.01 | −4.66 ± 0.01 | −2.27 ± 0.01 |

| (g/g2) | 0.23 ± 0.02 | 0.27 ± 0.02 | 0.22 ± 0.02 |

| (g/g2) | 0.29 ± 0.02 | 0.15 ± 0.03 | 0.15 ± 0.03 |

| (g/g2) | 0.012 ± 0.003 | 0.009 ± 0.003 | 0.023 ± 0.003 |

| (mg/g2) | 0.043 ± 0.004 | 0.108 ± 0.006 | 0.11 ± 0.02 |

| (mg/g2) | 0.288 ± 0.008 | 0.093 ± 0.003 | 0.12 ± 0.01 |

| (mrad) | 1.0 ± 0.3 | 0.9 ± 0.3 | −6.6 ± 0.3 |

| (mrad) | 6.5 ± 0.3 | 3.3 ± 0.3 | 5.2 ± 0.3 |

| Parameters | Error Sources | Values | Synthetic Uncertainties |

|---|---|---|---|

| Uncertainty of | 0.05″ | 0.1% | |

| Accelerometer drift | 10 μg | ||

| Uncertainty of or | 0.02 g/g2 | 2% | |

| Accelerometer drift | 10 μg | 0.01 mg | |

| Uncertainty of | 0.01 mrad | ||

| ,, | Accelerometer drift | 2 μg | 0.02 g/g2 |

| , | Fitting error | 13 μg | 0.01 mg/g2 |

| , | Fitting error | 13 μg | 0.01 mrad |

| , | Small-angle approximation | 50 ppm | 0.3 mrad |

| Uncertainty of , | 0.01 mrad | ||

| Accuracy of CMM | 1 μm | ||

| Uncertainty of | 0.3 mrad | ||

| Uncertainty of | 0.05″ | 0.3 mrad | |

| Electronic gradienter drift | 1″ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Li, Z.; Xu, Q.; Li, X. On-Ground Calibration of a Nano-G Accelerometer for Micro-Vibration Monitoring in Space on a Dual-Axis Indexing Device. Sensors 2025, 25, 6289. https://doi.org/10.3390/s25206289

Zhou Y, Li Z, Xu Q, Li X. On-Ground Calibration of a Nano-G Accelerometer for Micro-Vibration Monitoring in Space on a Dual-Axis Indexing Device. Sensors. 2025; 25(20):6289. https://doi.org/10.3390/s25206289

Chicago/Turabian StyleZhou, Yang, Zhi Li, Qiangwei Xu, and Xiangchun Li. 2025. "On-Ground Calibration of a Nano-G Accelerometer for Micro-Vibration Monitoring in Space on a Dual-Axis Indexing Device" Sensors 25, no. 20: 6289. https://doi.org/10.3390/s25206289

APA StyleZhou, Y., Li, Z., Xu, Q., & Li, X. (2025). On-Ground Calibration of a Nano-G Accelerometer for Micro-Vibration Monitoring in Space on a Dual-Axis Indexing Device. Sensors, 25(20), 6289. https://doi.org/10.3390/s25206289