Bias Calibration of Optically Pumped Magnetometers Based on Variable Sensitivity

Abstract

1. Introduction

2. Principle

2.1. Operating Principle of the SERF-OPM

2.2. Calculation of the Bias

2.3. Magnetic Field Compensation with Bias

3. Experiment Setup

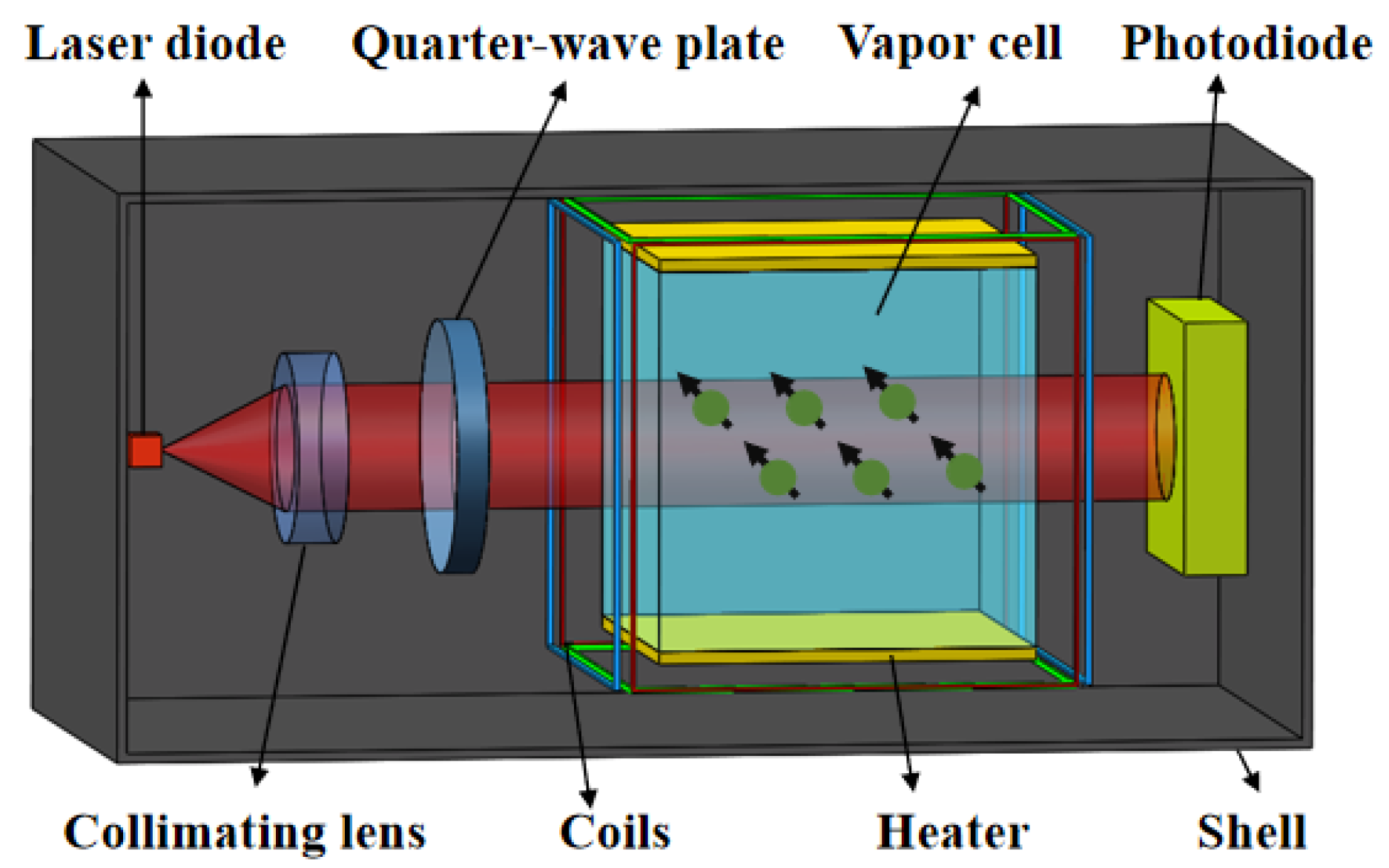

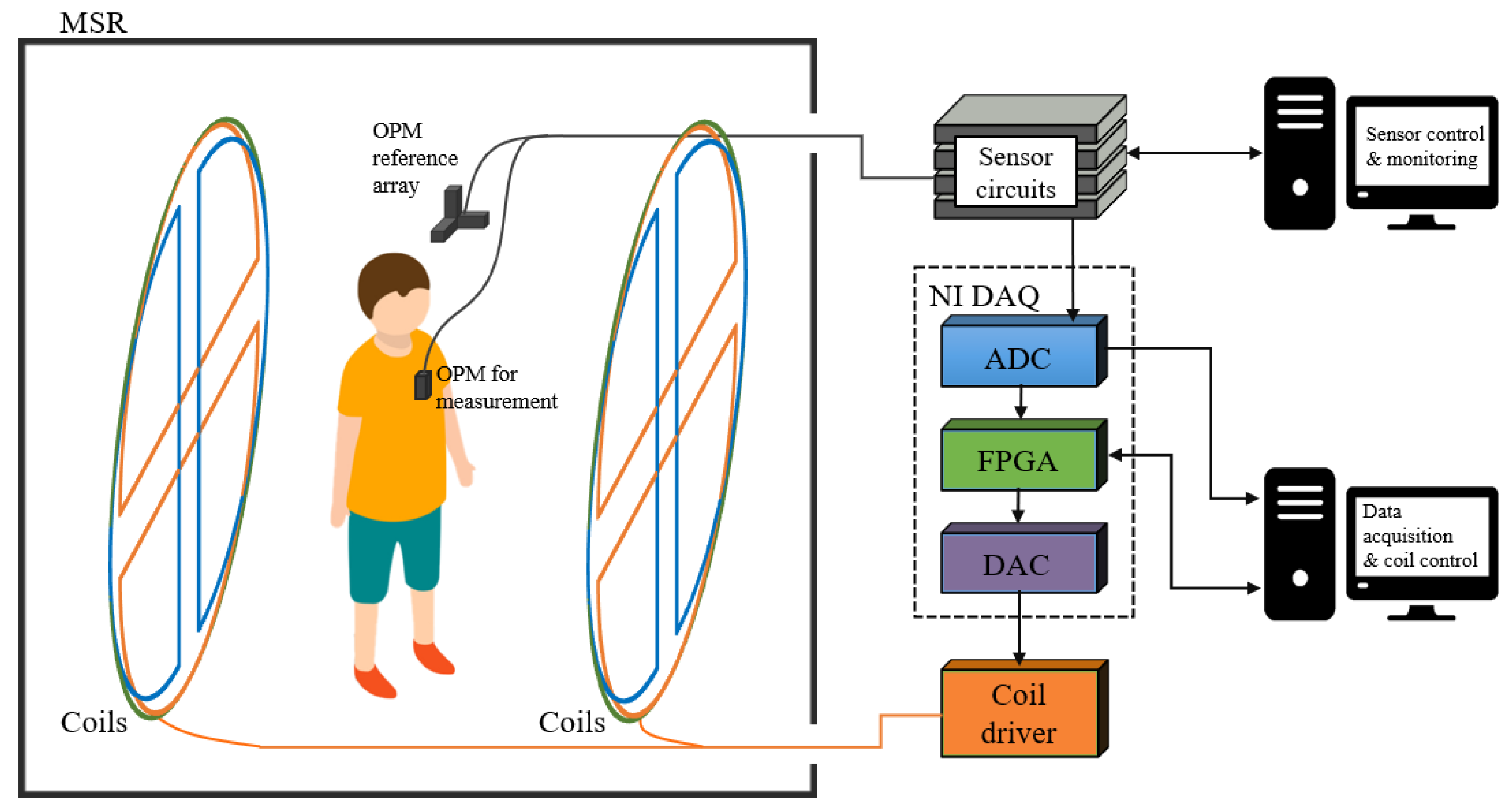

3.1. System Diagram

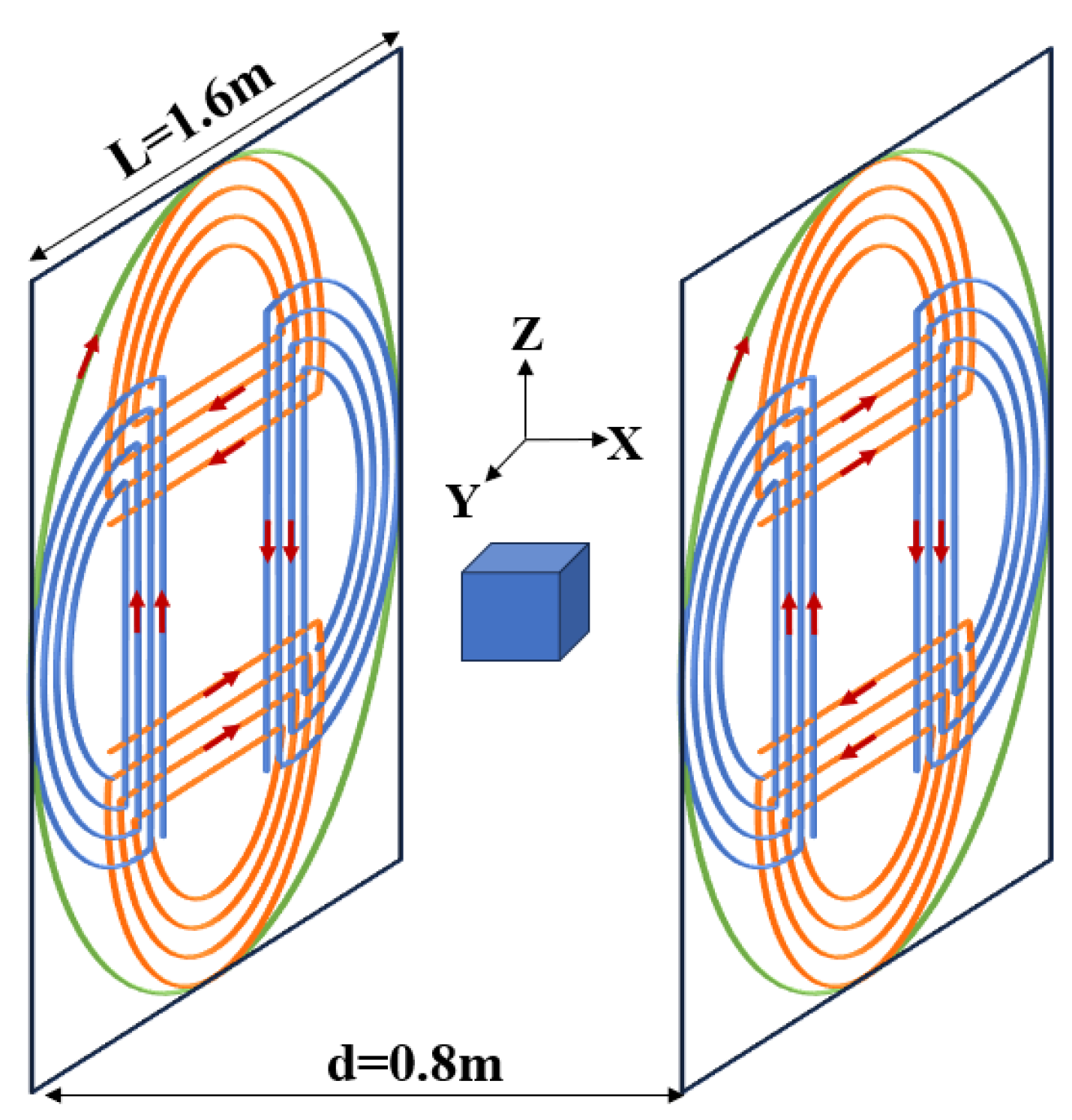

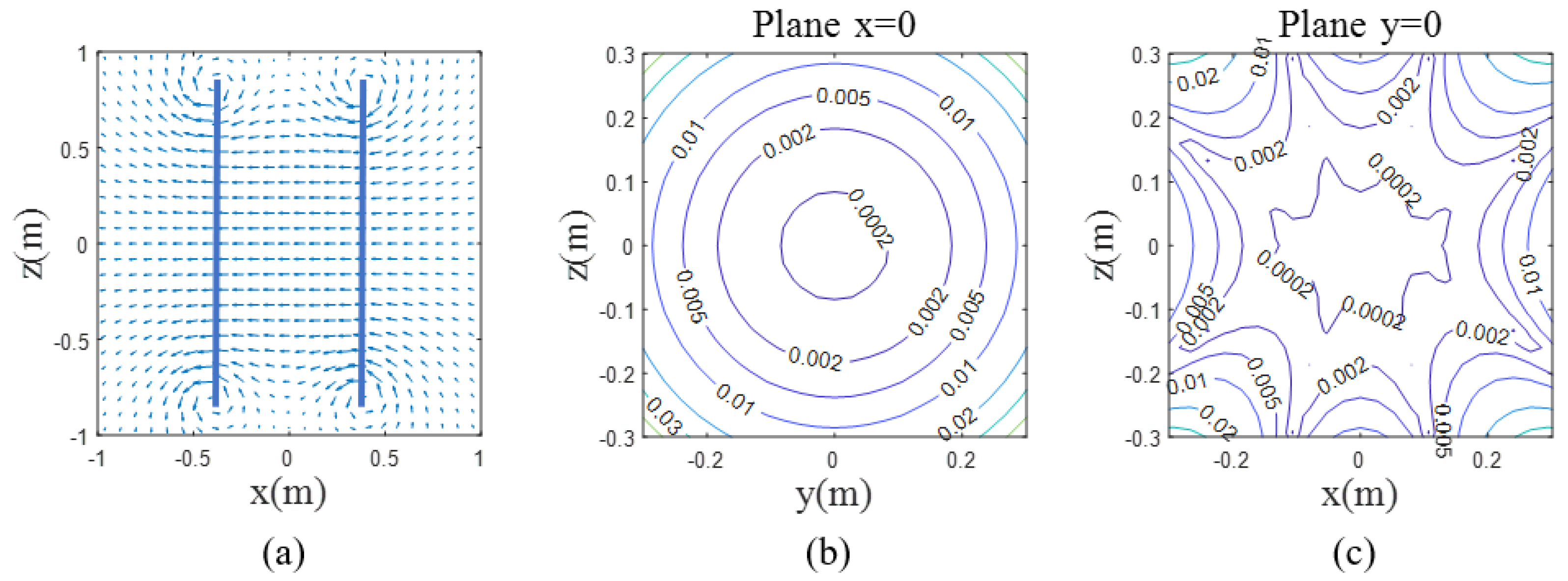

3.2. Compensation Coils

3.3. Control and Data Acquisition

4. Experimental Results and Discussion

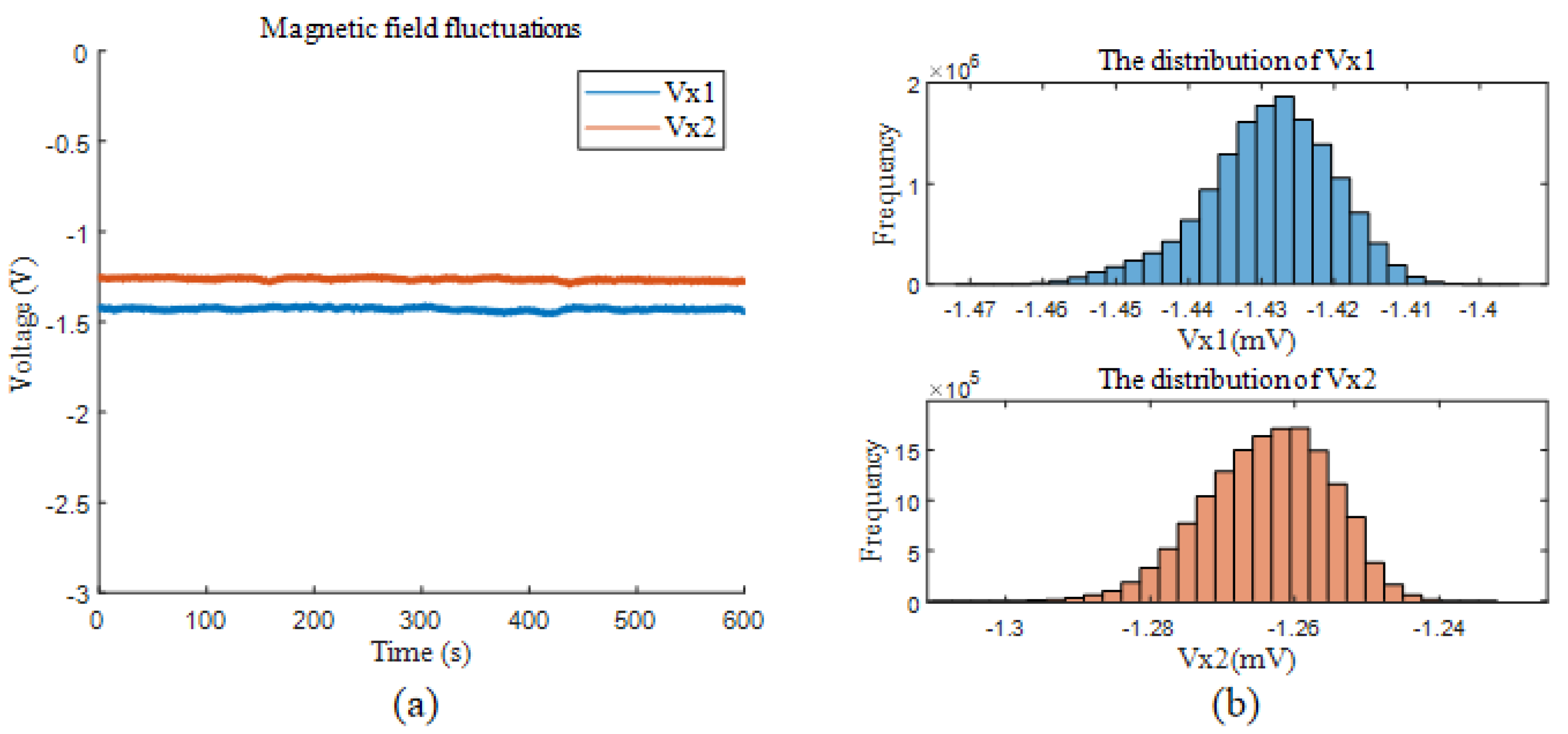

4.1. Parameters Estimation

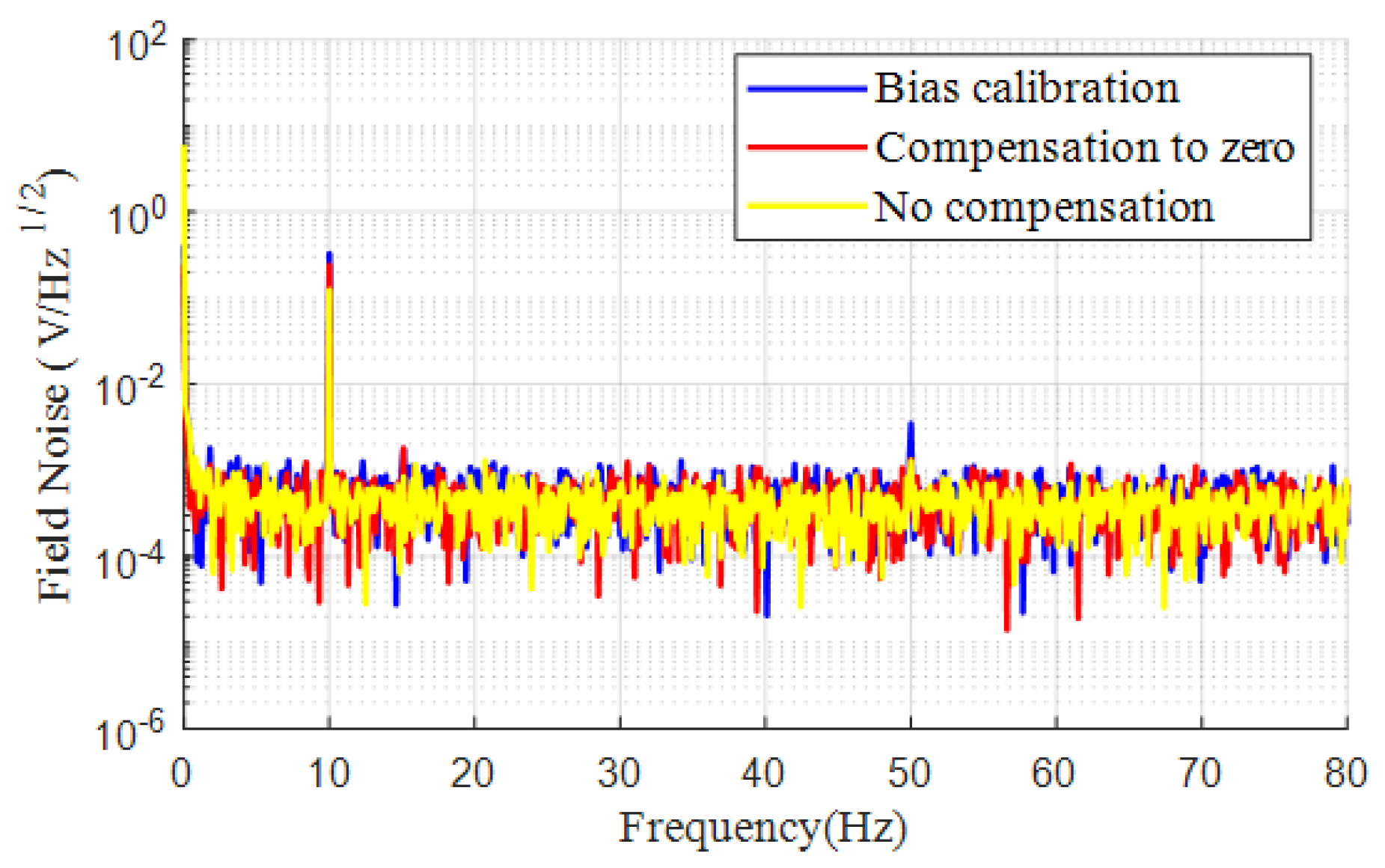

4.2. Magnetic Field Fluctuation Suppression Experiment

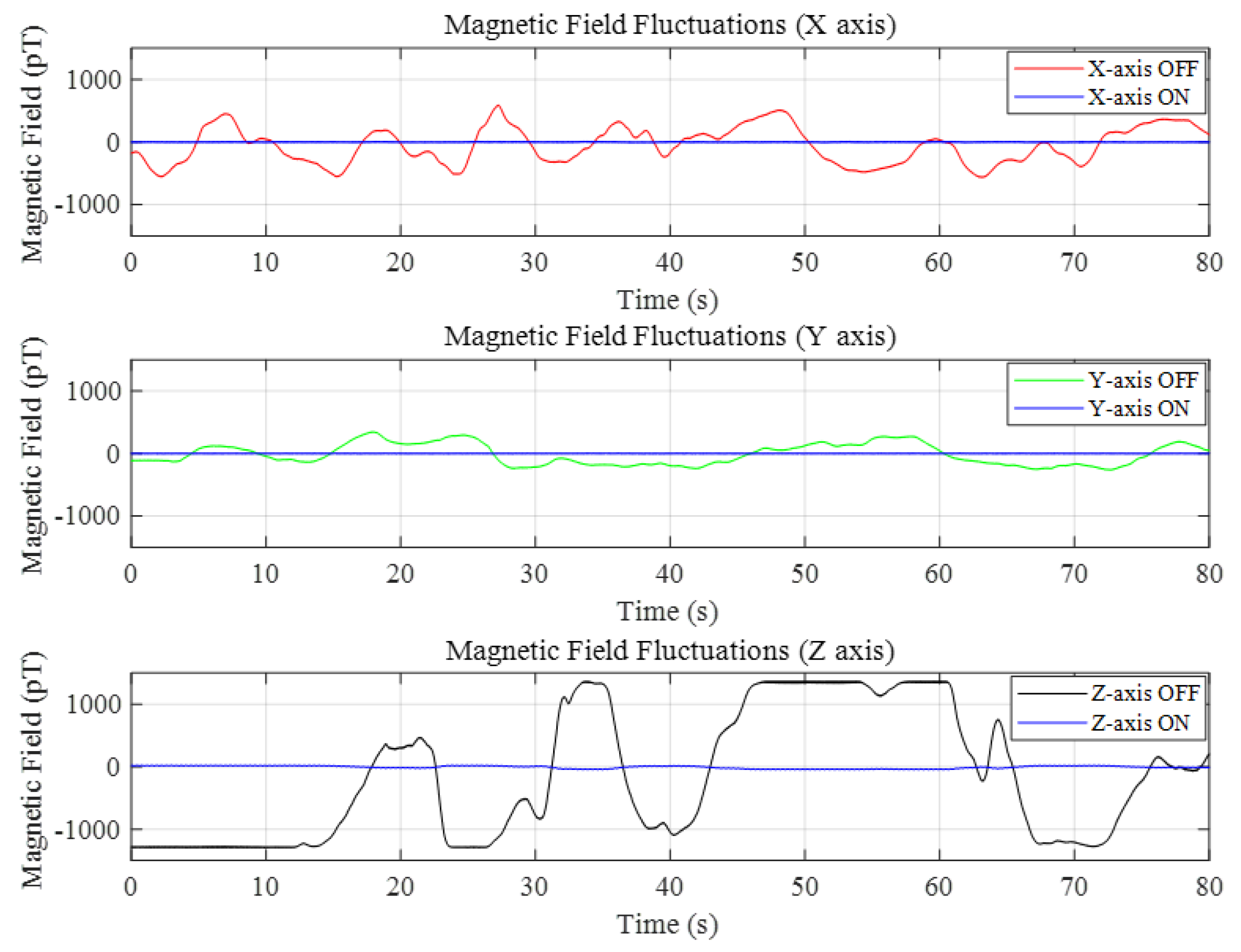

4.3. Magnetocardiography Measurement

4.4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Boto, E.; Holmes, N.; Leggett, J.; Roberts, G.; Shah, V.; Meyer, S.S.; Muñoz, L.D.; Mullinger, K.J.; Tierney, T.M.; Bestmann, S.; et al. Moving magnetoencephalography towards real-world applications with a wearable system. Nature 2018, 555, 657–661. [Google Scholar] [CrossRef] [PubMed]

- Akaza, M.; Kawabata, S.; Ozaki, I.; Miyano, Y.; Watanabe, T.; Adachi, Y.; Sekihara, K.; Sumi, Y.; Yokota, T. Noninvasive measurement of sensory action currents in the cervical cord by magnetospinography. Clin. Neurophysiol. 2021, 132, 382–391. [Google Scholar] [CrossRef] [PubMed]

- Wyllie, R.; Kauer, M.; Wakai, R.T.; Walker, T.G. Optical magnetometer array for fetal magnetocardiography. Opt. Lett. 2012, 37, 2247–2249. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.J.; Savukov, I.; Newman, S. Magnetocardiography with a 16-channel fiber-coupled single-cell Rb optically pumped magnetometer. Appl. Phys. Lett. 2019, 114, 143702. [Google Scholar] [CrossRef]

- Broser, P.J.; Middelmann, T.; Sometti, D.; Braun, C. Optically pumped magnetometers disclose magnetic field components of the muscular action potential. J. Electromyogr. Kinesiol. 2021, 56, 102490. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, M.; Liang, A.; Yin, Y.; Ma, X.; Gao, Y.; Ning, X. A new wearable multichannel magnetocardiogram system with a SERF atomic magnetometer array. Sci. Rep. 2021, 11, 5564. [Google Scholar] [CrossRef]

- Han, X.; Xue, X.; Yang, Y.; Liang, X.; Gao, Y.; Xiang, M.; Sun, J.; Ning, X. Magnetocardiography using optically pumped magnetometers array to detect acute myocardial infarction and premature ventricular contractions in dogs. Phys. Med. Biol. 2023, 68, 165006. [Google Scholar] [CrossRef]

- Rhodes, N.; Rea, M.; Boto, E.; Rier, L.; Shah, V.; Hill, R.M.; Osborne, J.; Doyle, C.; Holmes, N.; Coleman, S.C.; et al. Measurement of frontal midline theta oscillations using OPM-MEG. NeuroImage 2023, 271, 120024. [Google Scholar] [CrossRef]

- Boto, E.; Hill, R.M.; Rea, M.; Holmes, N.; Seedat, Z.A.; Leggett, J.; Shah, V.; Osborne, J.; Bowtell, R.; Brookes, M.J. Measuring functional connectivity with wearable MEG. NeuroImage 2021, 230, 117815. [Google Scholar] [CrossRef]

- Tierney, T.M.; Levy, A.; Barry, D.N.; Meyer, S.S.; Shigihara, Y.; Everatt, M.; Mellor, S.; Lopez, J.D.; Bestmann, S.; Holmes, N.; et al. Mouth magnetoencephalography: A unique perspective on the human hippocampus. NeuroImage 2021, 225, 117443. [Google Scholar] [CrossRef]

- Marhl, U.; Jodko-Wladzinska, A.; Brühl, R.; Sander, T.; Jazbinšek, V. Comparison between conventional SQUID based and novel OPM based measuring systems in MEG. In Proceedings of the 8th European Medical and Biological Engineering Conference: Proceedings of the EMBEC 2020, Portorož, Slovenia, 29 November–3 December 2020; Springer: Berlin/Heidelberg, Germany, 2021; pp. 254–261. [Google Scholar]

- Zhang, S.; Zhou, Y.; Lu, F.; Yan, Y.; Wang, W.; Zhou, B.; Zhai, Y.; Lu, J.; Ye, M. Temperature characteristics of Rb-N2 single-beam magnetometer with different buffer gas pressures. Measurement 2023, 215, 112860. [Google Scholar] [CrossRef]

- Kominis, I.K.; Kornack, T.W.; Allred, J.C.; Romalis, M.V. A subfemtotesla multichannel atomic magnetometer. Nature 2003, 422, 596–599. [Google Scholar] [CrossRef] [PubMed]

- Allred, J.; Lyman, R.; Kornack, T.; Romalis, M.V. High-sensitivity atomic magnetometer unaffected by spin-exchange relaxation. Phys. Rev. Lett. 2002, 89, 130801. [Google Scholar] [CrossRef] [PubMed]

- Lu, F.; Lu, J.; Li, B.; Yan, Y.; Zhang, S.; Yin, K.; Ye, M.; Han, B. Triaxial vector operation in near-zero field of atomic magnetometer with femtotesla sensitivity. IEEE Trans. Instrum. Meas. 2022, 71, 1–10. [Google Scholar] [CrossRef]

- Brookes, M.J.; Leggett, J.; Rea, M.; Hill, R.M.; Holmes, N.; Boto, E.; Bowtell, R. Magnetoencephalography with optically pumped magnetometers (OPM-MEG): The next generation of functional neuroimaging. Trends Neurosci. 2022, 45, 621–634. [Google Scholar] [CrossRef]

- Happer, W.; Tang, H. Spin-exchange shift and narrowing of magnetic resonance lines in optically pumped alkali vapors. Phys. Rev. Lett. 1973, 31, 273. [Google Scholar] [CrossRef]

- Niu, Y.; Zou, Z.; Cheng, L.; Ye, C. Compact optically pumped magnetometer light source stabilization with regulated feedbacks. Sens. Actuators A Phys. 2024, 365, 114869. [Google Scholar] [CrossRef]

- Long, T.; Han, B.; Song, X.; Suo, Y.; Jia, L. Fast in-situ triaxial remanent magnetic field measurement for single-beam SERF atomic magnetometer based on trisection algorithm. Photonic Sens. 2023, 13, 230311. [Google Scholar] [CrossRef]

- Yang, K.; Lu, J.; Ma, Y.; Wang, Z.; Sun, B.; Wang, Y.; Han, B. In situ compensation of triaxial magnetic field gradient for atomic magnetometers. IEEE Trans. Instrum. Meas. 2022, 71, 1–8. [Google Scholar]

- Long, T.; Song, X.; Han, B.; Suo, Y.; Jia, L. In-situ Magnetic Field Compensation Method for Optically Pumped Magnetometers under Three-axis Non-orthogonality. IEEE Trans. Instrum. Meas. 2023, 73, 9502112. [Google Scholar]

- Wang, J.; Zhou, B.; Liu, X.; Wu, W.; Chen, L.; Han, B.; Fang, J. An improved target-field method for the design of uniform magnetic field coils in miniature atomic sensors. IEEE Access 2019, 7, 74800–74810. [Google Scholar] [CrossRef]

- Wang, K.; Sun, J.; Ma, D.; Li, S.; Gao, Y.; Lu, J.; Zhang, J. Octagonal three-dimensional shim coils structure and design in atomic sensors for magnetic field detection. IEEE Sens. J. 2022, 22, 5596–5605. [Google Scholar] [CrossRef]

- Niu, Y.; Ye, C. In situ triaxial magnetic field compensation for the spin-exchange-relaxation-free optically pumped magnetometer. IEEE Sens. J. 2023, 23, 21137–21146. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, K.; Zhou, B.; Lu, F.; Zhang, S.; Yan, Y.; Wang, W.; Lu, J. Triaxial closed-loop measurement based on a single-beam zero-field optically pumped magnetometer. Front. Phys. 2022, 10, 1059487. [Google Scholar] [CrossRef]

- Li, L.; Tang, J.; Zhao, B.; Cao, L.; Zhou, B.; Zhai, Y. Single-beam triaxial spin-exchange relaxation-free atomic magnetometer utilizing transverse modulation fields. J. Phys. D Appl. Phys. 2022, 55, 505001. [Google Scholar] [CrossRef]

- Yan, Y.; Lu, J.; Zhang, S.; Lu, F.; Yin, K.; Wang, K.; Zhou, B.; Liu, G. Three-axis closed-loop optically pumped magnetometer operated in the SERF regime. Opt. Express 2022, 30, 18300–18309. [Google Scholar] [CrossRef]

- Long, T.; Song, X.; Duan, Z.; Dai, Y.; Suo, Y.; Jia, L.; Han, B. Analysis and suppression of cross-axis modulation coupling errors in optically pumped magnetometers. Measurement 2025, 242, 115824. [Google Scholar] [CrossRef]

- Wang, K.; Ma, D.; Li, S.; Gao, Y.; Sun, J. Simultaneous in-situ compensation method of residual magnetic fields for the dual-beam SERF atomic magnetometer. Sens. Actuators A Phys. 2023, 349, 114055. [Google Scholar] [CrossRef]

- Fang, J.; Wang, T.; Quan, W.; Yuan, H.; Zhang, H.; Li, Y.; Zou, S. In situ magnetic compensation for potassium spin-exchange relaxation-free magnetometer considering probe beam pumping effect. Rev. Sci. Instrum. 2014, 85, 063108. [Google Scholar] [CrossRef]

- Liang, S.; Zhu, Y.; He, J.; Qi, J.; Jia, Y.; Wang, A.; Zhao, T.; Wei, C.; Jiao, H.; Feng, L.; et al. Optical pump magnetometers parametric correction method based on three-axis coil arrays. Measurement 2025, 242, 115909. [Google Scholar] [CrossRef]

- Holmes, N.; Leggett, J.; Boto, E.; Roberts, G.; Hill, R.M.; Tierney, T.M.; Shah, V.; Barnes, G.R.; Brookes, M.J.; Bowtell, R. A bi-planar coil system for nulling background magnetic fields in scalp mounted magnetoencephalography. NeuroImage 2018, 181, 760–774. [Google Scholar] [CrossRef] [PubMed]

- Holmes, N.; Tierney, T.M.; Leggett, J.; Boto, E.; Mellor, S.; Roberts, G.; Hill, R.M.; Shah, V.; Barnes, G.R.; Brookes, M.J.; et al. Balanced, bi-planar magnetic field and field gradient coils for field compensation in wearable magnetoencephalography. Sci. Rep. 2019, 9, 14196. [Google Scholar] [CrossRef]

- Tierney, T.M.; Holmes, N.; Mellor, S.; López, J.D.; Roberts, G.; Hill, R.M.; Boto, E.; Leggett, J.; Shah, V.; Brookes, M.J.; et al. Optically pumped magnetometers: From quantum origins to multi-channel magnetoencephalography. NeuroImage 2019, 199, 598–608. [Google Scholar] [CrossRef] [PubMed]

- Jia, L.; Song, X.; Suo, Y.; Li, J.; Long, T.; Ning, X. Magnetic field interference suppression for minimized SERF atomic magnetometer. Sens. Actuators A Phys. 2023, 351, 114188. [Google Scholar] [CrossRef]

- Zhang, S.; Lu, J.; Ye, M.; Zhou, Y.; Yin, K.; Lu, F.; Yan, Y.; Zhai, Y. Optimal operating temperature of miniaturized optically pumped magnetometers. IEEE Trans. Instrum. Meas. 2022, 71, 1–7. [Google Scholar] [CrossRef]

- Kelha, V.; Pukki, J.; Peltonen, R.; Penttinen, A.; Ilmoniemi, R.; Heino, J. Design, construction, and performance of a large-volume magnetic shield. IEEE Trans. Magn. 1982, 18, 260–270. [Google Scholar] [CrossRef]

- Holmes, N.; Rea, M.; Chalmers, J.; Leggett, J.; Edwards, L.J.; Nell, P.; Pink, S.; Patel, P.; Wood, J.; Murby, N.; et al. A lightweight magnetically shielded room with active shielding. Sci. Rep. 2022, 12, 13561. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Ye, C.; Hou, X.; Niu, Y.; Sun, L. Bias Calibration of Optically Pumped Magnetometers Based on Variable Sensitivity. Sensors 2025, 25, 433. https://doi.org/10.3390/s25020433

Chen J, Ye C, Hou X, Niu Y, Sun L. Bias Calibration of Optically Pumped Magnetometers Based on Variable Sensitivity. Sensors. 2025; 25(2):433. https://doi.org/10.3390/s25020433

Chicago/Turabian StyleChen, Jieya, Chaofeng Ye, Xingshen Hou, Yaqiong Niu, and Limin Sun. 2025. "Bias Calibration of Optically Pumped Magnetometers Based on Variable Sensitivity" Sensors 25, no. 2: 433. https://doi.org/10.3390/s25020433

APA StyleChen, J., Ye, C., Hou, X., Niu, Y., & Sun, L. (2025). Bias Calibration of Optically Pumped Magnetometers Based on Variable Sensitivity. Sensors, 25(2), 433. https://doi.org/10.3390/s25020433