Effect of Embroidery Style on the Bandwidth of Textronic RFID UHF Transponder Antenna

Abstract

1. Introduction

1.1. Purpose of the Work

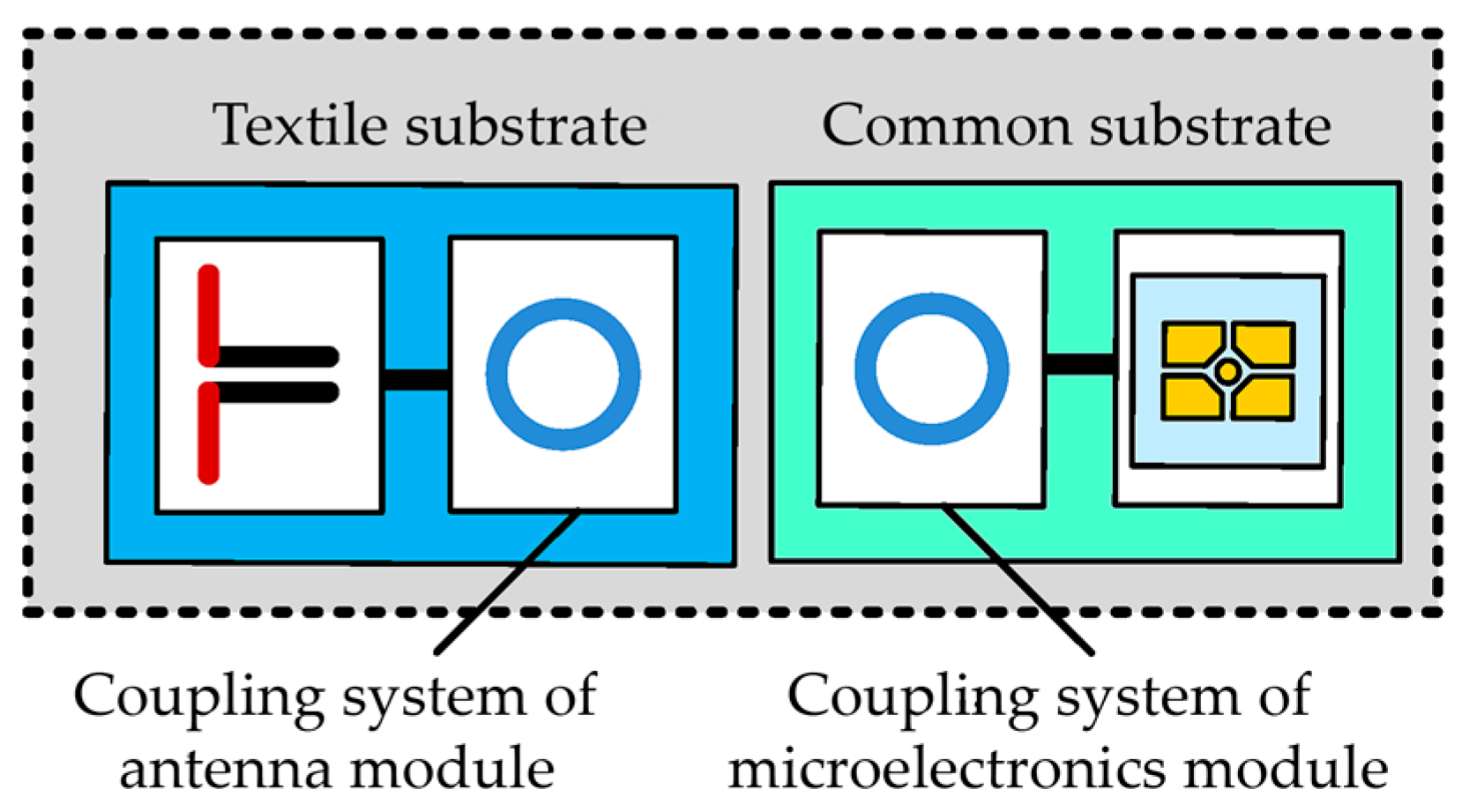

1.2. Textile UHF RFID Transponder Antenna

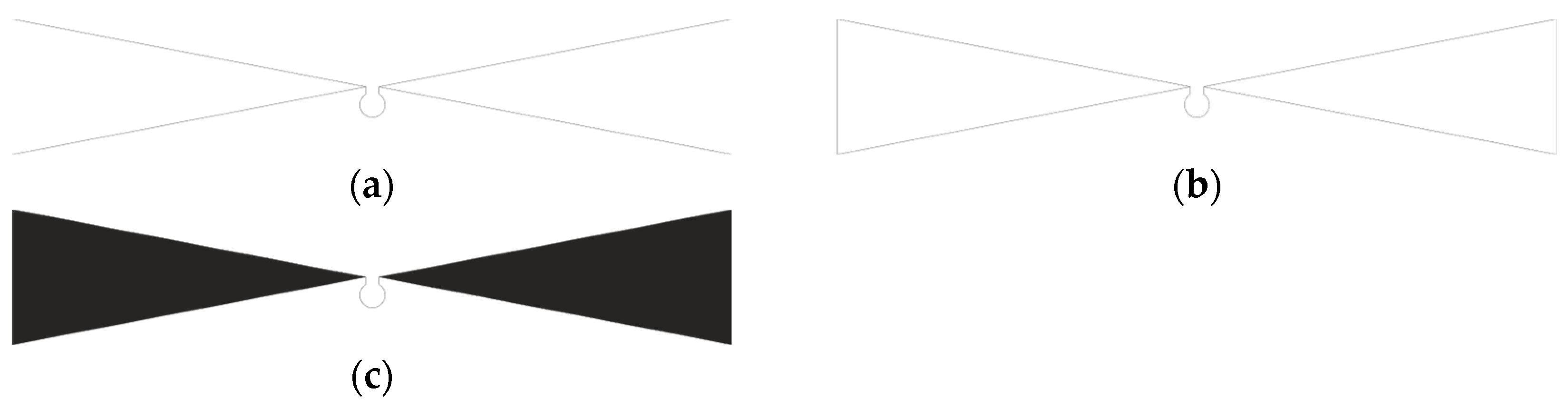

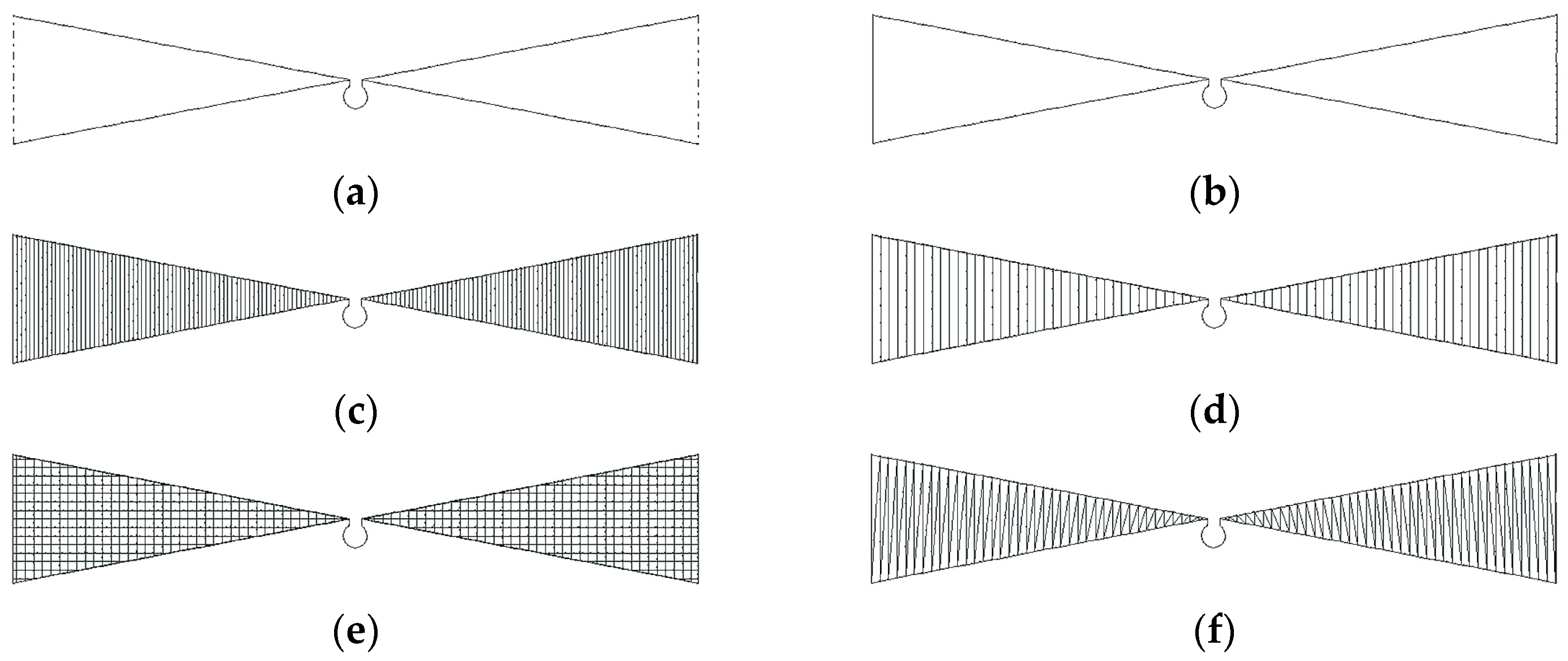

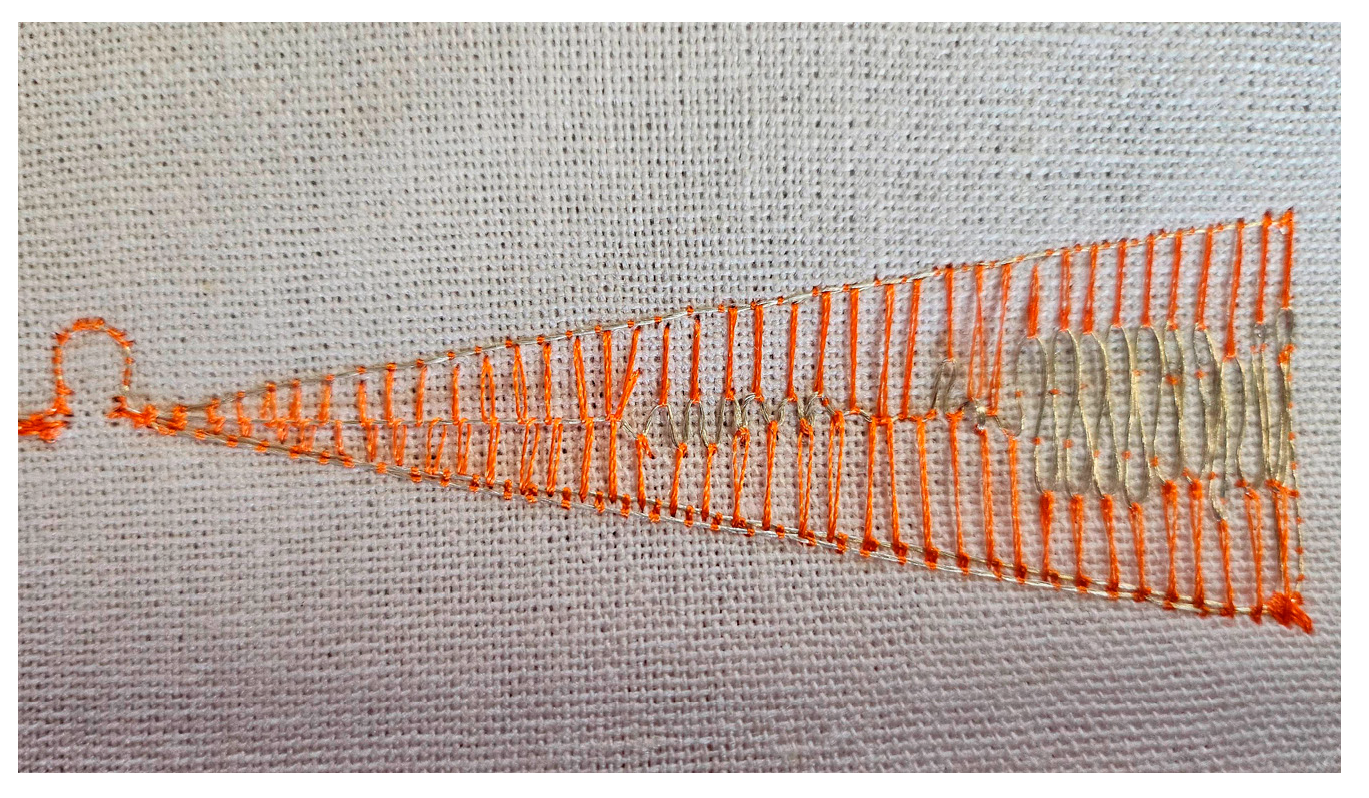

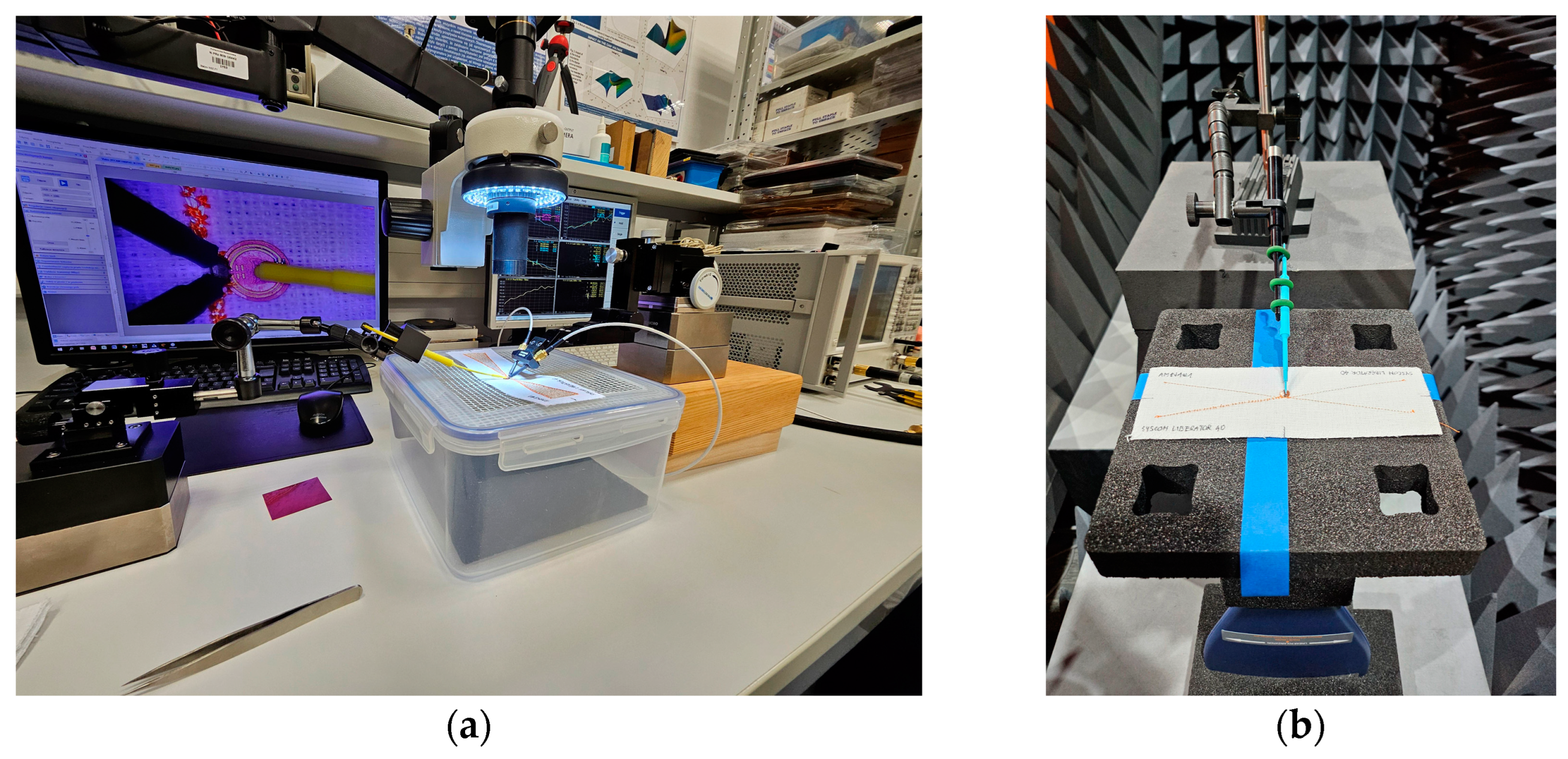

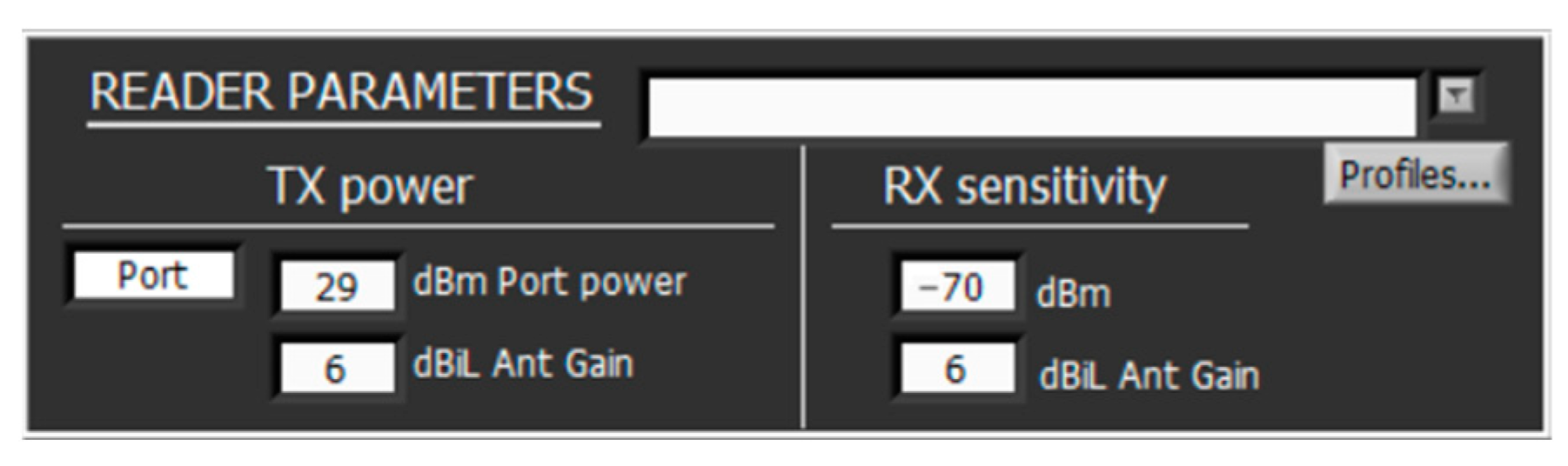

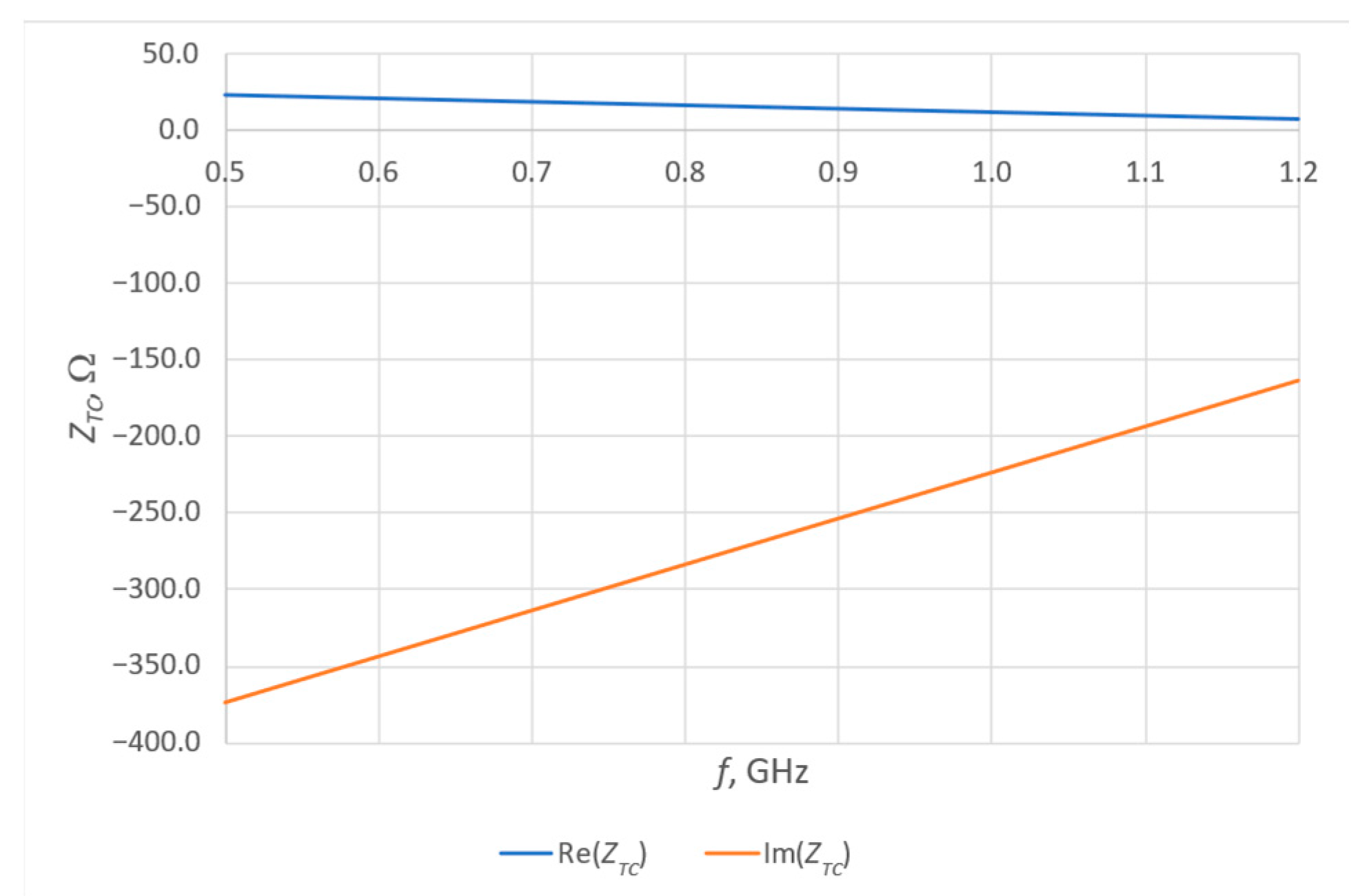

2. Materials and Methods

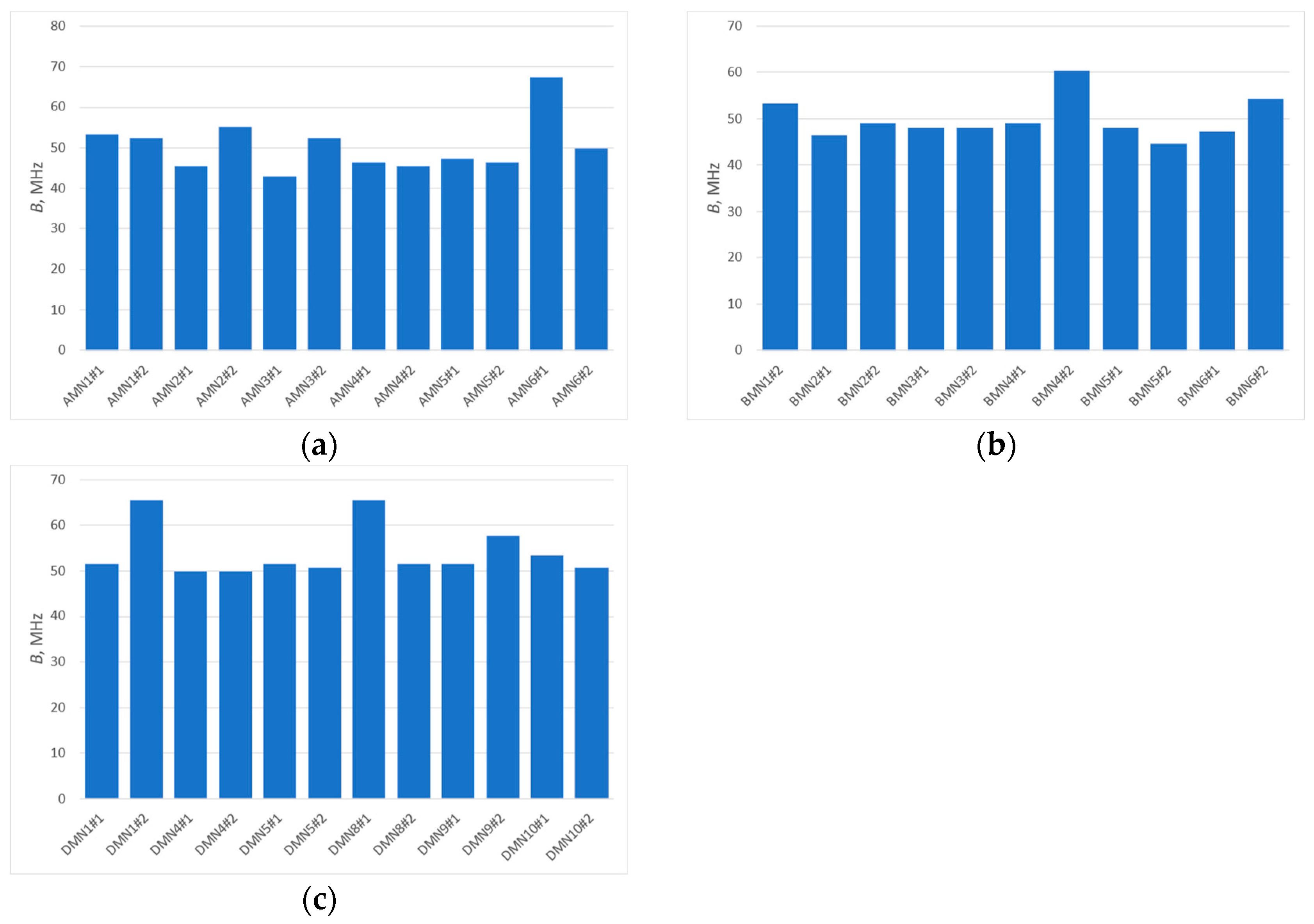

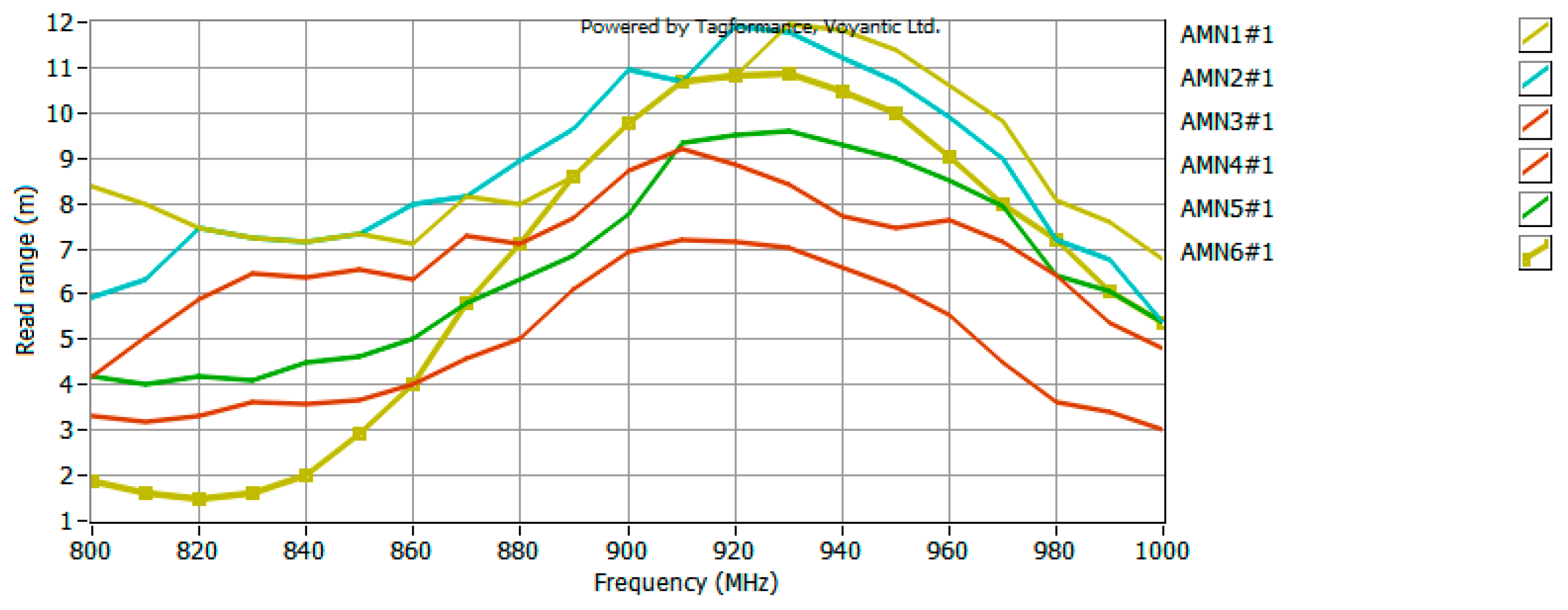

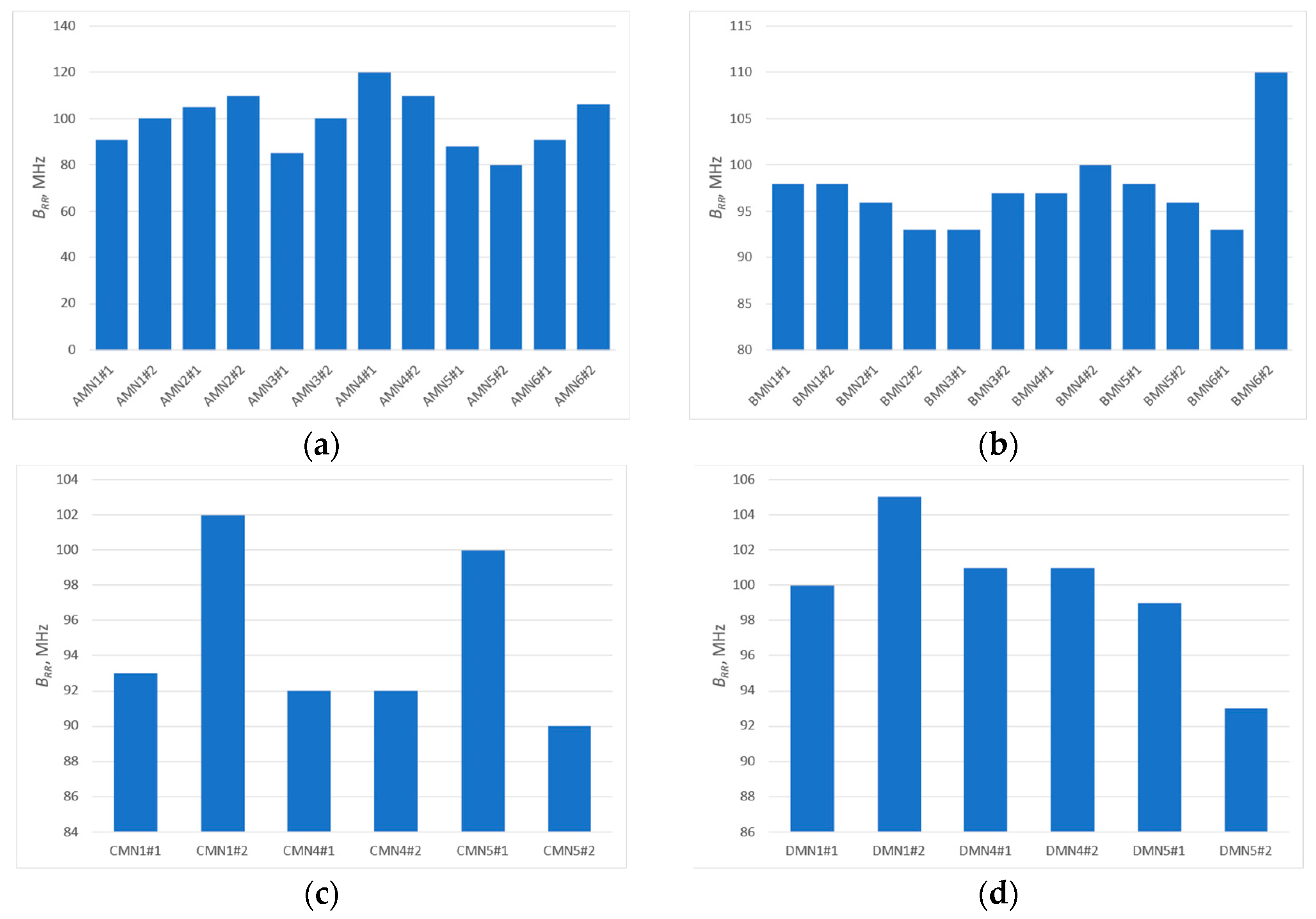

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Younes, B. Textronics: A Review of Their Technological Aspects and Applications. J. Text. Inst. 2024, 115, 1509–1525. [Google Scholar] [CrossRef]

- Younes, B. Smart E-Textiles: A Review of Their Aspects and Applications. J. Ind. Text. 2023, 53, 15280837231215493. [Google Scholar] [CrossRef]

- Choudhry, N.A.; Arnold, L.; Rasheed, A.; Khan, I.A.; Wang, L. Textronics—A Review of Textile-Based Wearable Electronics. Adv. Eng. Mater. 2021, 23, 2100469. [Google Scholar] [CrossRef]

- Meena, J.S.; Choi, S.B.; Jung, S.B.; Kim, J.W. Electronic Textiles: New Age of Wearable Technology for Healthcare and Fitness Solutions. Mater. Today Bio 2023, 19, 100565. [Google Scholar] [CrossRef] [PubMed]

- Qu, Z.; Zhu, Z.; Liu, Y.; Yu, M.; Ye, T.T. Parasitic Capacitance Modeling and Measurements of Conductive Yarns for E-Textile Devices. Nat. Commun. 2023, 14, 2785. [Google Scholar] [CrossRef] [PubMed]

- Lemey, S.; Rogier, H. SIW Textile Antennas as a Novel Technology for UWB RFID Tags. In Proceedings of the 2014 IEEE RFID Technology and Applications Conference (RFID-TA), Tampere, Finland, 8–9 September 2014. [Google Scholar]

- Bouamra, W.; Osman, L. On-Body Investigation of Textile Antenna for Wearable RFID Applications. In Proceedings of the International Conference on Microelectronics (ICM), Sousse, Tunisia, 16–19 December 2018; Volume 2018. [Google Scholar]

- Shah, A.A.S.A.; Abd Rahman, N.H.; Ali, M.T.; Ahmad, M.R.; Nordin, S.A.; Zaidi, N.I.; Abdul Aziz, N.H.; Yamada, Y. Design of Electro-Textile UHF RFID Tag through T-Match Network. In Proceedings of the 2018 IEEE International RF and Microwave Conference, Penang, Malaysia, 17–19 December 2018. [Google Scholar]

- Jiang, Y.; Xu, L.; Pan, K.; Leng, T.; Li, Y.; Danoon, L.; Hu, Z. E-Textile Embroidered Wearable near-Field Communication RFID Antennas. IET Microw. Antennas Propag. 2019, 13, 99–104. [Google Scholar] [CrossRef]

- Virkki, J.; Wei, Z.; Liu, A.; Ukkonen, L.; Björninen, T. Wearable Passive E-Textile UHF RFID Tag Based on a Slotted Patch Antenna with Sewn Ground and Microchip Interconnections. Int. J. Antennas Propag. 2017, 2017, 3476017. [Google Scholar] [CrossRef]

- Lundquist, J.; Linkous, L.; Piper, M.E.; Sickey, Z.; Zimmet, K.; Mendoza, I.; Suresh, S.; Topsakal, E. Textile-Based Inkjet-Printed RFIDs: Exploring Wearable Antennas in the Real World [Bioelectromagnetics]. IEEE Antennas Propag. Mag. 2024, 66, 50–62. [Google Scholar] [CrossRef]

- Dang, Q.H.; Chen, S.J.; Ranasinghe, D.C.; Fumeaux, C. Modular Integration of a Passive RFID Sensor with Wearable Textile Antennas for Patient Monitoring. IEEE Trans. Compon. Packaging Manuf. Technol. 2020, 10, 1979–1988. [Google Scholar] [CrossRef]

- Luo, C.; Gil, I.; Fernandez-Garcia, R. Textile UHF-RFID Antenna Embroidered on Surgical Masks for Future Textile Sensing Applications. IEEE Trans. Antennas Propag. 2022, 70, 5246–5253. [Google Scholar] [CrossRef]

- Luo, C.; Gil, I.; Fernandez-Garcia, R. Electro-Textile UHF-RFID Compression Sensor for Health-Caring Applications. IEEE Sens. J. 2022, 22, 12332–12338. [Google Scholar] [CrossRef]

- Lee, H.; Tak, J.; Choi, J. Wearable Antenna Integrated into Military Berets for Indoor/Outdoor Positioning System. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 1919–1922. [Google Scholar] [CrossRef]

- Sathishkannan, P.; Singh, R.K.; Ray, K.P.; Singh, M. A Compact and Flexible Dipole Antenna to Be Integrated into Military Berets. In Proceedings of the 2022 IEEE Microwaves, Antennas, and Propagation Conference (MAPCON), Bangalore, India, 12–16 December 2022. [Google Scholar]

- Chung, Y.; Berhe, T.H. Long-Range Uhf Rfid Tag for Automotive License Plate. Sensors 2021, 21, 2521. [Google Scholar] [CrossRef]

- Wang, S.; Liu, Y.; Ye, T.T. “Unconventionally Shaped” Antenna Design for UHF RFID Tags. Int. J. Antennas Propag. 2021, 2021, 9965252. [Google Scholar] [CrossRef]

- Kommey, B.; Addo, E.O.; Tamakloe, E. Systematic Design and Prototyping of a Low-Cost Passive UHF-RFID Transponder. Eng. Rep. 2023, 5, e12636. [Google Scholar] [CrossRef]

- Hossain, S.S.; Karmakar, N. An Overview on RFID Frequency Regulations and Antennas. In Proceedings of the 4th International Conference on Electrical and Computer Engineering (ICECE), Dhaka, Bangladesh, 19–21 December 2006. [Google Scholar]

- Kamili, J.B.; Bhattacharya, A. Design and Investigation of Cavity Backed Bowtie Antenna with Unidirectional Radiation Pattern Using Characteristic Mode Analysis. Frequenz 2024, 78, 323–334. [Google Scholar] [CrossRef]

- Iliadis, L.A.; Boursianis, A.D.; Rekkas, V.P.; Zaharis, Z.D.; Koulouridis, S.; Goudos, S.K. Aperture-Coupled Bowtie Patch Antenna Design for Autonomous Driving Applications. In Proceedings of the 2023 International Workshop on Antenna Technology, Aalborg, Denmark, 15–17 May 2023. [Google Scholar]

- Kumar, T.; Harish, A.R. A Modified Bow-Tie Antenna for Universal UHF RFID Application. In Proceedings of the ISAP 2018—2018 International Symposium on Antennas and Propagation, Busan, Republic of Korea, 23–26 October 2018. [Google Scholar]

- Aoues, B.; Zaid, J.; Denidni, T.A. A Miniaturized Printed Bow-Tie Antenna for Passive RFID Applications. In Proceedings of the 2020 IEEE International Symposium on Antennas and Propagation and North American Radio Science Meeting, Montreal, QC, Canada, 5–10 July 2020. [Google Scholar]

- Chopra, R.; Agarwal, A.; Lakhmani, R. A Broadband Planar Bow-Tie Antenna with Quasi-Isotropic Coverage. In Proceedings of the 2021 IEEE Indian Conference on Antennas and Propagation, Jaipur, India, 13–16 December 2021. [Google Scholar]

- Kumari, S.; Awasthi, Y.K.; Bansal, D. Design a Bow-Tie Antenna for Multiband Applications. In Proceedings of the 17th INDIACom; 2023 10th International Conference on Computing for Sustainable Global Development, New Delhi, India, 15–17 March 2023. [Google Scholar]

- Senapati, H.S.; Chongder, P.; Ajith, K.K.; Maiti, S. Design Of UWB Bow Tie Antenna For GPR Object Detection. In Proceedings of the 2021 Advanced Communication Technologies and Signal Processing (ACTS), Rourkela, India, 15–17 December 2021. [Google Scholar]

- Gonçalves Licursi de Mello, R.; Lepage, A.C.; Begaud, X. The Bow-Tie Antenna: Performance Limitations and Improvements. IET Microw. Antennas Propag. 2022, 16, 283–294. [Google Scholar] [CrossRef]

- Vital, D.; Zhong, J.; Bhardwaj, S.; Volakis, J.L. Loss-Characterization and Guidelines for Embroidery of Conductive Textiles. In Proceedings of the 2018 IEEE Antennas and Propagation Society International Symposium and USNC/URSI National Radio Science Meeting (APSURSI), Boston, MA, USA, 8–13 July 2018. [Google Scholar]

- Maleszka, T.; Kabacik, P. Bandwidth Properties of Embroidered Loop Antenna for Wearable Applications. In Proceedings of the European Microwave Week 2010, EuMW2010: Connecting the World, Conference Proceedings—European Wireless Technology Conference (EuWiT), Paris, France, 27–28 September 2010. [Google Scholar]

- Chen, X.; Liu, A.; Wei, Z.; Ukkonen, L.; Virkki, J. Experimental Study on Strain Reliability of Embroidered Passive UHF RFID Textile Tag Antennas and Interconnections. J. Eng. 2017, 2017, 8493405. [Google Scholar] [CrossRef]

- Moradi, E.; Björninen, T.; Ukkonen, L.; Rahmat-Samii, Y. Effects of Sewing Pattern on the Performance of Embroidered Dipole-Type RFID Tag Antennas. IEEE Antennas Wirel. Propag. Lett. 2012, 11, 1482–1485. [Google Scholar] [CrossRef]

- Vuohijoki, T.; Shaikh, A.; Merilampi, S.; Ihalainen, T.; Virkki, J. Punch-Needled Passive UHF RFID Tag Dipole Antennas—Design, Fabrication, and Initial Wireless Evaluation. In Proceedings of the 2023 8th International Conference on Smart and Sustainable Technologies (SpliTech), Split, Croatia, 20–23 June 2023. [Google Scholar]

- Liu, Y.; Xu, L.; Li, Y.; Ye, T.T. Textile Based Embroidery-Friendly RFID Antenna Design Techniques. In Proceedings of the 2019 IEEE International Conference on RFID, Phoenix, AZ, USA, 2–4 April 2019. [Google Scholar]

- Brechet, N.; Ginestet, G.; Torres, J.; Moradi, E.; Ukkonen, L.; Bjorninen, T.; Virkki, J. Cost- and Time-Effective Sewing Patterns for Embroidered Passive UHF RFID Tags. In Proceedings of the 2017 International Workshop on Antenna Technology: Small Antennas, Innovative Structures, and Applications, Athens, Greece, 1–3 March 2017. [Google Scholar]

- Song, L.; Zhang, D.; Rahmat-Samii, Y. Towards Embroidered Textile Antenna Systematic Design and Accurate Modeling: Investigation of Stitch Density. In Proceedings of the 2019 United States National Committee of URSI National Radio Science Meeting (USNC-URSI NRSM), Boulder, CO, USA, 9–12 January 2019. [Google Scholar]

- Simorangkir, R.B.V.B.; Yang, Y.; Esselle, K.P. Performance of Embroidered Higher-Order Mode Antennas with Different Stitching Patterns. In Proceedings of the 2017 11th European Conference on Antennas and Propagation (EUCAP), Paris, France, 19–24 March 2017. [Google Scholar]

- Song, L.; Zhang, B.; Zhang, D.; Rahmat-Samii, Y. Embroidery Electro-Textile Patch Antenna Modeling and Optimization Strategies With Improved Accuracy and Efficiency. IEEE Trans. Antennas Propag. 2022, 70, 6388–6400. [Google Scholar] [CrossRef]

- Seager, R.; Zhang, S.; Chauraya, A.; Whittow, W.; Vardaxoglou, Y.; Acti, T.; Dias, T. Effect of the Fabrication Parameters on the Performance of Embroidered Antennas. IET Microw. Antennas Propag. 2013, 7, 1174–1181. [Google Scholar] [CrossRef]

- Pinapati, S.P.; Chen, S.J.; Brittain, J.; Caldow, A.; Fumeaux, C. Embroidered Ground Planes for Wearable Antennas. IEEE Trans. Compon. Packaging Manuf. Technol. 2022, 12, 1029–1039. [Google Scholar] [CrossRef]

- Jankowski-Mihułowicz, P.; Węglarski, M.; Chamera, M.; Pyt, P. Textronic Uhf Rfid Transponder. Sensors 2021, 21, 1093. [Google Scholar] [CrossRef] [PubMed]

- Ziobro, A.; Jankowski-Mihułowicz, P.; Węglarski, M.; Pyt, P. Investigation of Factors Affecting the Performance of Textronic UHF RFID Transponders. Sensors 2023, 23, 9703. [Google Scholar] [CrossRef] [PubMed]

- Jankowski-Mihułowicz, P.; Węglarski, M.; Wilczkiewicz, B.; Chamera, M.; Laskowski, G. The Influence of Textile Substrates on the Performance of Textronic RFID Transponders. Materials 2022, 15, 7060. [Google Scholar] [CrossRef] [PubMed]

- Jankowski-Mihułowicz, P.; Węglarski, M.; Pyt, P.; Skrobacz, K.; Karpiński, K. UHF Textronic RFID Transponder with Bead-Shaped Microelectronic Module. Electronics 2023, 12, 4873. [Google Scholar] [CrossRef]

| Model | Stitch Style | Density | Stitching Direction |

|---|---|---|---|

| MN1 | Running Stitch | 2 mm | - |

| MN2 | Running Stitch | 2 mm | - |

| MN3 | Fill Stitch | 1.0 line/mm | 90 deg |

| MN4 | Fill Stitch | 0.5 line/mm | 90 deg |

| MN5 | Net Fill Stitch | 2 mm | 0 deg |

| MN6 | Satin Stitch | 1 line/mm | 90 deg |

| Symbol | Manufacturer | Brand Name | Material | Thread Resistivity, Ω/m |

|---|---|---|---|---|

| A | Syscom Advanced Materials, Inc., Columbus, OH, USA | Liberator 40 | Silver coated vectran | 3.28 |

| B | Plug&Wear, Florence, Italy | PW018A | Silver plated nylon | 300 |

| C | Sparkfun Electronics, Niwot, CO, USA | DEV-11791 | Stainless steel | 91.86 |

| D | AMANN Group, Bönnigheim, Germany | Silver-tech 30 tex 96 | Silver coated polyamide/polyester | 85 |

| Group of Samples | s, MHz | srel |

|---|---|---|

| A | 6.57 | 13.05% |

| B | 4.46 | 8.95% |

| D | 5.74 | 10.59% |

| Group of Samples | s, MHz | srel |

|---|---|---|

| A | 11.97 | 12.11% |

| B | 4.56 | 4.68% |

| C | 4.92 | 5.18% |

| D | 3.92 | 3.93% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nizioł, M.; Jankowski-Mihułowicz, P.; Węglarski, M. Effect of Embroidery Style on the Bandwidth of Textronic RFID UHF Transponder Antenna. Sensors 2025, 25, 371. https://doi.org/10.3390/s25020371

Nizioł M, Jankowski-Mihułowicz P, Węglarski M. Effect of Embroidery Style on the Bandwidth of Textronic RFID UHF Transponder Antenna. Sensors. 2025; 25(2):371. https://doi.org/10.3390/s25020371

Chicago/Turabian StyleNizioł, Magdalena, Piotr Jankowski-Mihułowicz, and Mariusz Węglarski. 2025. "Effect of Embroidery Style on the Bandwidth of Textronic RFID UHF Transponder Antenna" Sensors 25, no. 2: 371. https://doi.org/10.3390/s25020371

APA StyleNizioł, M., Jankowski-Mihułowicz, P., & Węglarski, M. (2025). Effect of Embroidery Style on the Bandwidth of Textronic RFID UHF Transponder Antenna. Sensors, 25(2), 371. https://doi.org/10.3390/s25020371