1. Introduction

One of the primary objectives of teleoperation systems is to extend human manipulation capabilities across different scales, facilitating interaction in remote or hazardous tasks [

1]. As a remote operation carrier for humans, mobile robots have seen widespread development and application across various fields with the continuous advancement of robot technology, computer science, and control theory. Within these, unmanned aerial manipulators (UAMs), typically comprising an unmanned aerial vehicle (UAV) and a robotic manipulator, enable agile three-dimensional motion [

2] attributable to their remarkable maneuverability and versatility, which have received considerable attention in physical interaction tasks, including drawer operation [

3], door opening [

4], glass-wall inspection [

5], aerial writing [

6], and outdoor industrial inspection and maintenance [

7]. While autonomous approaches leverage machine intelligence to perform these tasks, full autonomy is often neither feasible nor desirable due to safety concerns and the complexity of operational environments. The teleoperated UAM scheme, which employs the “human-in-the-loop” control architecture, facilitates the accomplishment of tasks in complex operational conditions under human superior cognitive capabilities and skills.

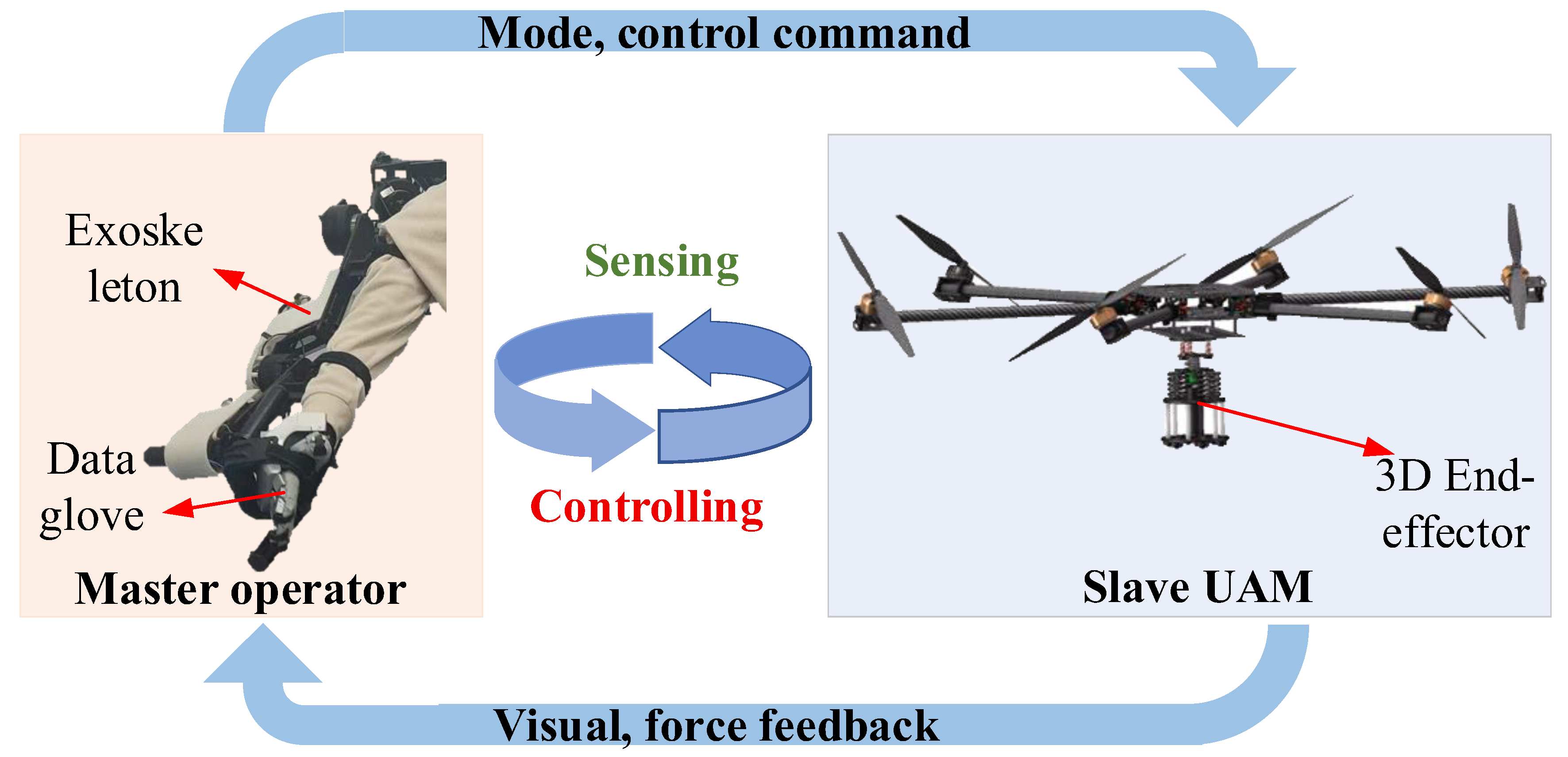

In a UAM teleoperation system, the operator employs a master robot to articulate specific intentions, including position and velocity inputs. These commands are conveyed through a communication channel to the slave UAMs, facilitating precise remote interaction with the operational environment [

8]. Concurrently, force feedback and visual information perceived by the UAMs can be transported back to the human operator to assist the decision making and enhance the immersion of the teleoperation. This has garnered significant attention in research on the control of UAMs under a bilateral teleoperation scheme [

9,

10,

11].

However, due to master–slave heterogeneity, the workspace for UAMs is not proportionally aligned with the operator inevitably. The teleoperation of UAMs predominantly employs single-mapping modes, mainly the rate control strategy, which greatly limits the application of UAMs in practical scenarios. From the literature, several studies have concentrated on hybrid teleoperation mapping schemes of ground mobile manipulators. A hybrid position–position and position–velocity control algorithm was introduced for the teleoperation of generic mobile manipulators [

12]. The current progress of teleoperation mapping of mobile manipulators is summarized in [

13], with consideration given to time delay and stability analysis. Such a variable mapping strategy is also extensively employed in the field of robotic arm teleoperation [

14,

15]. For UAV/UAM teleoperation, a variable kinetic scrolling-based mapping scheme was proposed to overcome master workspace limitations and enable teleoperation of the aerial vehicle in an unbounded workspace [

16]. Additionally, a user-defined variable scale mapping controller was also presented [

9]. Nevertheless, the existing UAV teleoperation mapping modes primarily focus on free movement, i.e., rate mode and position mode, neglecting contact operation modes. It is noteworthy that the transition between operational modes can potentially introduce the risk of misoperation due to complexity and potential operator errors. Therefore, developing intuitive and efficient conversion transitions between different modes based on user intention in teleoperation is crucial for advancing practical UAM applications.

Furthermore, physical contact tasks represent a significant area of focus for the future advancement of UAMs [

2,

17]. Implementing force feedback to perceive forces exerted by UAMs during contact tasks is recognized as an effective control approach. Shared control of path planning with integral haptic feedback was presented in [

18]. Macchini et al. presented a hand-worn haptic interface to enable users to control UAV trajectories and enhance environmental awareness [

19]. Meanwhile, haptic bilateral teleoperation is sophisticatedly employed in advanced UAV applications, including evaluation of obstacle avoidance [

20], environmental perception [

21], and nuclear sources detection [

22]. Several studies have explored the bilateral teleoperation of UAMs in scenarios involving environmental interaction. Schill. et al. investigated the use of a haptic teleoperation joystick with limited workspace in admittance mode [

23]. A force-based bilateral teleoperation framework was proposed both in contact-free flight and in physical contact with the environment [

24]. Haptic-based shared control, incorporating artificial and virtual impedance for interaction force reflection, was designed for the telemanipulation of micro aerial vehicle (MAV) systems [

25]. A team of UAMs employing a force-feedback bilateral teleoperation scheme was proposed [

26], capable of cooperatively grasping objects and performing Vertical Take-Off and Landing (VTOL). A fully decoupled six DOFs bilateral teleoperation framework for omnidirectional micro aerial vehicles (OMAVs) was developed to support aerial physical interaction [

10]. Byun et al. addressed the abrupt reduction in interaction force during the extraction of a wedge-shaped object (e.g., plug pulling) from a static structure, proposing a haptic-based bilateral teleoperation strategy that compensates for reaction time [

11].

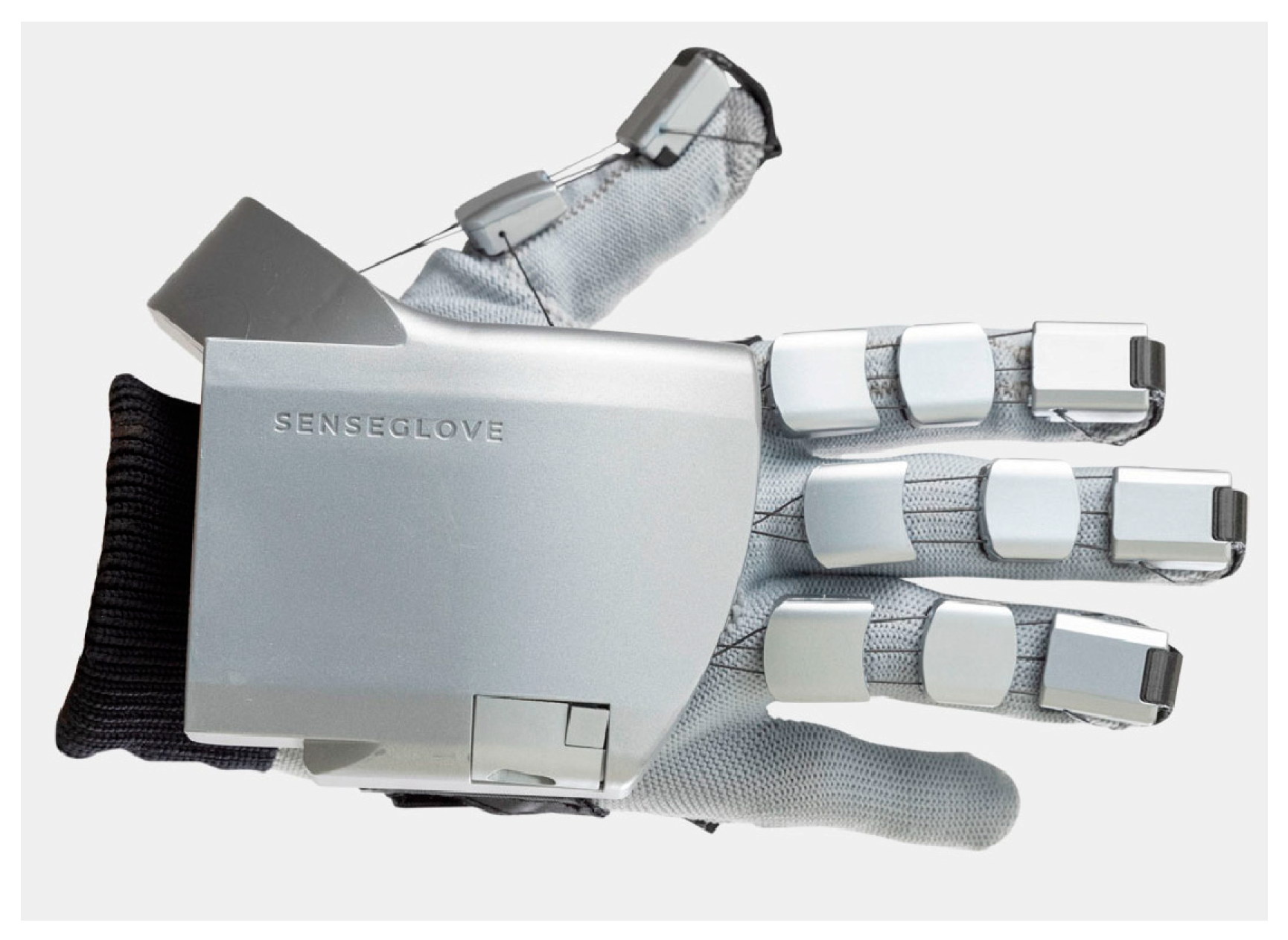

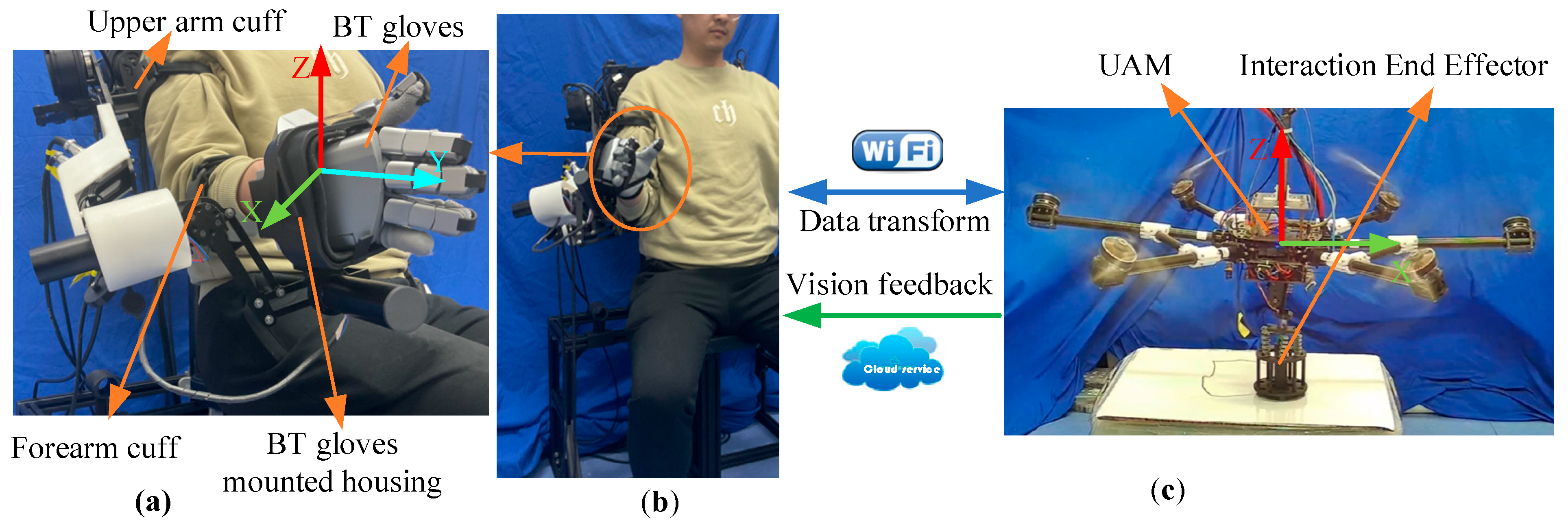

To improve the applicability of UAMs in physical contact tasks and ensure the stability and seamlessness of mode transitions, this paper proposes a haptic-based bilateral teleoperation scheme of a UAM for the aerial writing task. To this end, we develop an upper-limb exoskeleton as the master haptic device, configured with data glove from SenseGlove. The upper arm exoskeleton, utilized as the input device for pose control, simultaneously provides intuitive haptic feedback of the remote environment to the operator, while the application of a data glove for gesture-based switching in UAM control modes is intuitive and effective compared to traditional key-based operation [

27].

Because the fully actuated UAV possesses independent control over its position and orientation, it is capable of applying force and torque in any direction with precise control over both the direction and magnitude without adjusting the fuselage posture like traditional UAVs [

28]. Such UAVs are more suitable for applications such as indoor exploration in a narrow space, or as a stable platform for other air operation equipment [

29]. Thus, a fully actuated UAV equipped with a 3D end-effector is utilized in this work as a teleoperation slave robot for aerial writing tasks. Based on the actual task situation, the aerial writing task was divided into free movement and contact working phases.

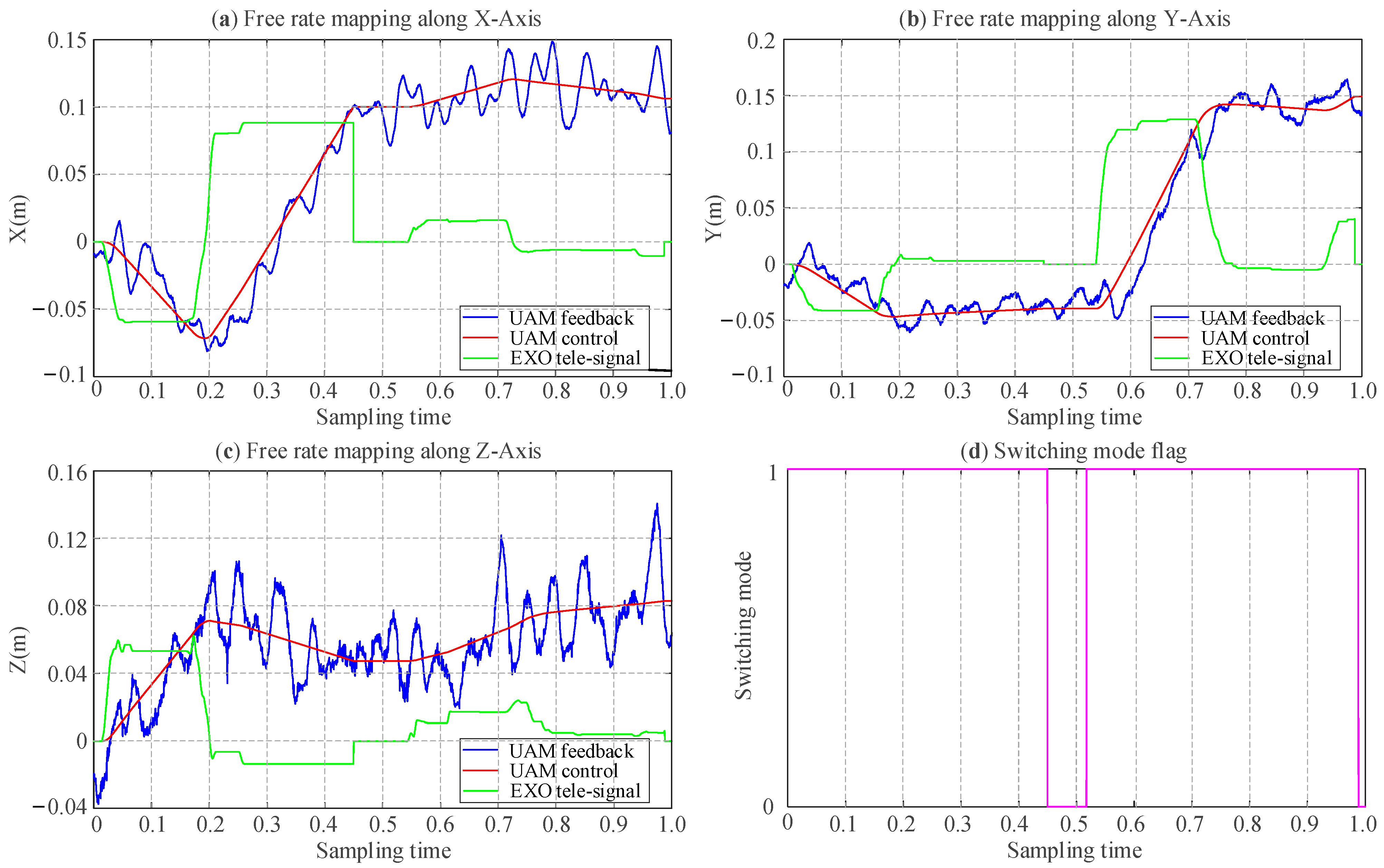

When in the free movement phase, the UAM is controlled in the rate mode and the pose of the master is mapped to a possibly scaled velocity reference of the slave. In this mode, UAM possesses a theoretically infinite operational space, enabling approach of the target position expeditiously and effectively. Subsequently, during the contact phase, haptic feedback is proposed as cues to indicate the teleoperated state of the slave. Also, a transition algorithm between the above two mapping methods for the master haptic device is developed to achieve smoothing switches. As a case study for the aerial writing task, two sets of experiments were conducted with the teleoperation structure. The experimental results demonstrate that the teleoperation method incorporating mapping switching enables rapid execution of contact operations. Overall, the key contributions are as follows:

- (1)

The development of a novel UAM teleoperation framework utilizing an exoskeleton as the master control robot.

- (2)

Proposing a mode-switching teleoperation mapping algorithm, with mode transitions facilitated by gestures captured through data gloves.

- (3)

Experimental validations on the aerial writing teleoperation experiment based on the theoretical framework.

The rest of the article is organized as follows: The system structure is presented and defined in

Section 2.

Section 3 provides a comprehensive examination of the two mapping modes and transition algorithms, in addition to a discussion on the passivity of the control method.

Section 4 presents the validation of simulation and experimental results, demonstrating the efficacy and performance of the proposed UAM teleoperation structure. Finally,

Section 5 concludes this article.

3. Model and Method

To enhance the remote operability of UAMs, intuitive and accessible human–robot mapping strategies are critical for achieving superior maneuverability. Harnessing human intelligence for mapping transformations enables effective control within the constrained workspace of the master robot. A dynamic mapping approach is proposed, integrating free-rate and position-based modes, effectively addressing the challenges of mapping between constrained and unconstrained spaces. Furthermore, the incorporation of force feedback is under consideration to augment operational flexibility, precision, and efficiency in complex task execution.

3.1. Free Rate Mode

Rate control has proven suitable for UAMs during unconstrained motion. Within the remote manipulation framework of this study, the free rate mode of UAM operation is employed at the prepare position, typically remote from the operational area, to enable swift transit to the designated target location. However, when the slave UAM is operated in the rate control mode, significant stability and transparency issues are experienced upon contacting the environment [

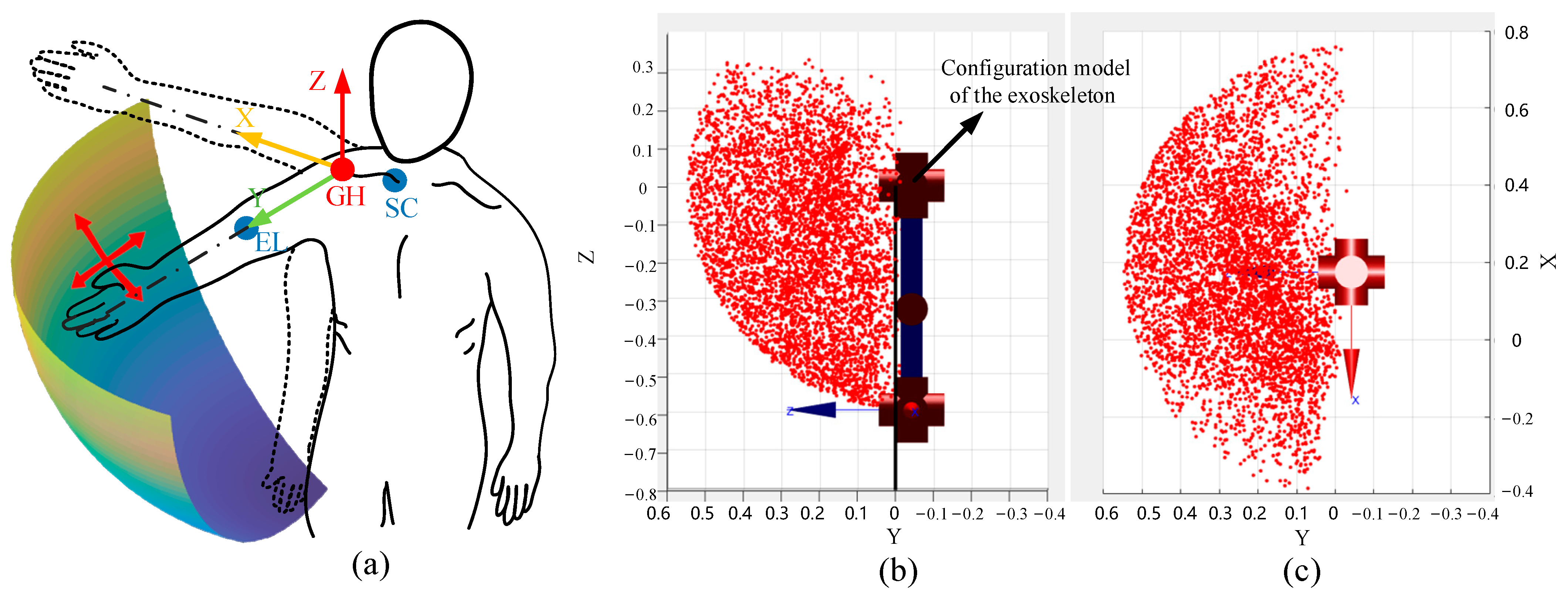

35]. Notably, due to the serial configuration of the exoskeleton master robot, changes in the position of the end-effector also influence its orientation and the attitude adjustment range of the UAM is limited during operations. Consequently, we employ a decoupled mapping strategy for teleoperation: the UAM positional movements are mapped through the shoulder and elbow joint position illustrated in

Figure 2, while the orientation is directly controlled by three wrist joints. This decoupled attitude–position mapping approach also effectively mitigates singularities in robotic control systems and ensures that the UAM orientation will not change along with the variation in the end position. This decoupling may increase control complexity and limit the system’s overall flexibility. Nevertheless, these trade-offs are effectively counterbalanced by the significantly enhanced precision of UAM control and the expanded effective operational range achieved through mode switching.

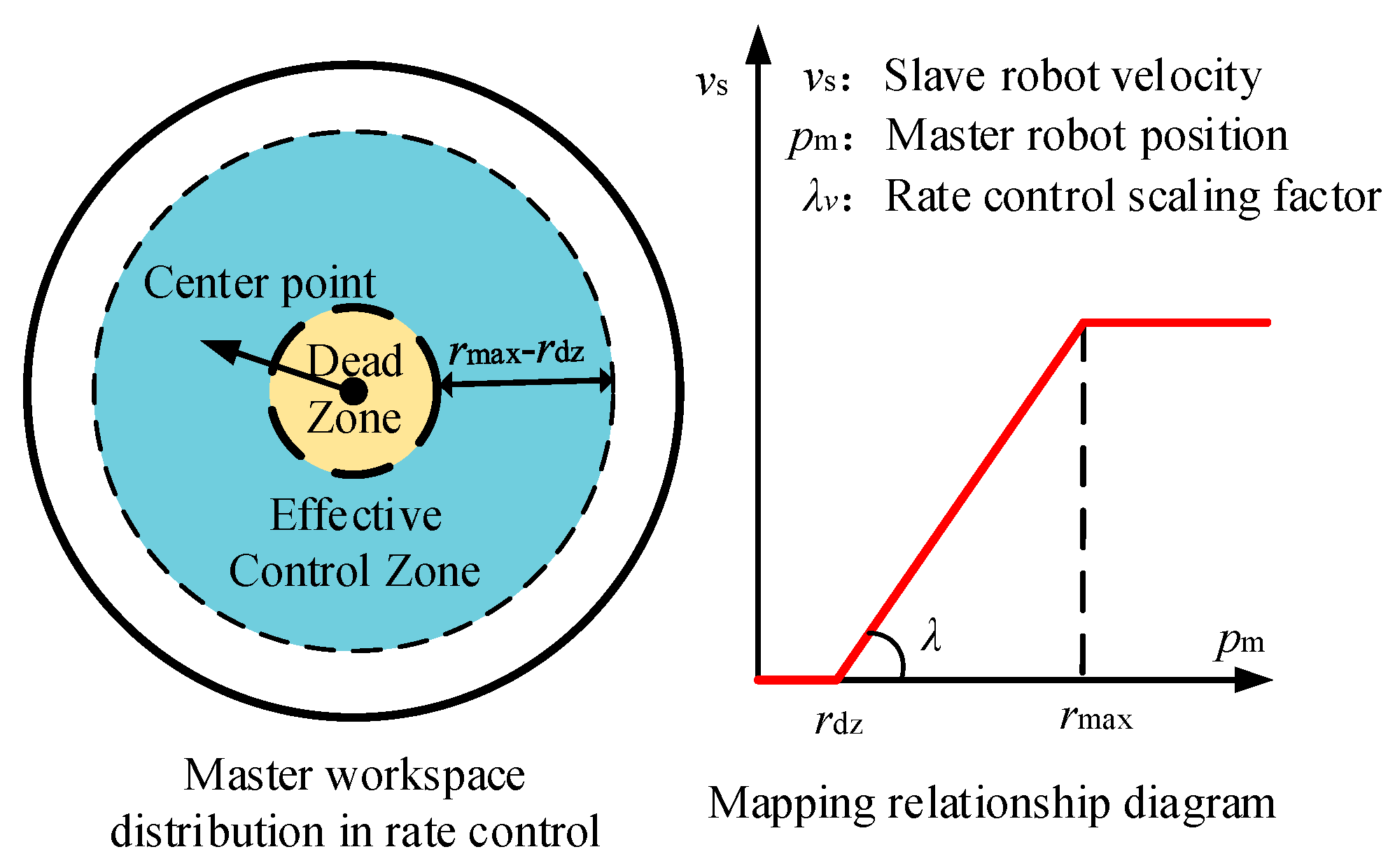

To avoid misoperation by the operator’s input, a dead zone is defined around the center of wrist joint

pee, as illustrated in

Figure 8. The velocity of the UAM is characterized as a vector with a magnitude directed outward from the central point. A maximum operational region

rmax is defined, and when the input from the master robot surpasses the boundary, the slave robot is instructed to maximum velocity. In the free rate mode, the position and wrist joint angle denoted as

is mapped to a scaled twist reference for the slave manipulator as follows:

with

where

λ = [

λvθx,

λvθy,

λvθz,

λvx,

λvy,

λvz]

T is the scaling factor of angle and position of end-effector. In the free rate mode, position commands are transmitted to control velocity via scaling factors

λv, as illustrated in

Figure 8; whereas in the position mode, the scaling factors

λp serve as workspace mapping adjustment parameters.

αn−1 = [

αθx,

αθy,

αθz,

αx,

αy,

αz]

T is a vector representing the desired pose offset between the center point of the master end-effector and UAM, respectively.

θee and

pee denote the wrist joint angles and central position of the end-effector. Similarly,

θdz and

pdz denote the sphere center of position and rotation and

rθ and

rt denote the coordinate range of the designated dead zone.

To enhance the efficiency and intuitiveness of UAM teleoperation, we integrate reset and normal modes within the mapping framework. Under optimal conditions in the normal mode, the operator initiates teleoperation from a neutral pose, where the effective control zone resides within the master robot’s workspace, and effective control of the UAM becomes infeasible. Therefore, inspired by the computer mouse, the cursor remains stationary when the mouse is lifted from the surface, regardless of its position. Meanwhile, contact with the surface sets a new zero-point for control. The reset mode in this study suspends teleoperation to recalibrate the neutral center of the mapping between the master and slave workspaces, ensuring precise alignment and effective control. In reset mode, the master robot’s neutral pose is redefined to align with the UAM’s current position, recentering the effective control zone within the master’s workspace while the UAM maintains its position and orientation. Once recalibration is complete, the operator resumes control in normal mode with an adjusted workspace, enabling seamless and intuitive operation in challenging environments.

In this research, we establish two mapping submodes by altering the offset α of the pose of the master when instruction is issued at n-th switching time. In the reset mode, the desired offset α represents the pose at the time of switching (

tn), as shown in Equation (4). When switching from position mode to reset mode at

tn, the system records the instantaneous pose data. While in reset mode, the dead zone center dynamically tracks the motion trajectory, whereas UAM control commands remain constant. Upon transitioning back to position mode, the system redefines the dead zone center by leveraging the positional data recorded at the time of mode transition

tn+1, thereby effectively repositioning the center of the dead zone to match the normal mode perceived pose. The alpha values for the two submodes are denoted as follows:

with

3.2. Pose Mode

Rate mapping enables teleoperation across unbounded spaces but lacks the precision necessary for operational tasks. In contrast, pose mapping provides enhanced precision for contact tasks within a constrained workspace. In the pose mode, the end-effector’s pose of the master robot is mapped to the central pose of the UAM through a scaling factor. Specify the homogeneous matrix representations for the orientation of the master exoskeleton’s end-effector, with the mapping function defined as follows:

with

where

c(.) and

s(.) represent the cosine and sine functions.

Rms0(

t) and

pms0(

t) denote the rotation matrix and position vector relative to the

X,

Y,

Z axes. Noting that, the rotation matrix adheres to the ZYX Euler angle convention, where rotations are performed sequentially about the

Z-axis (yaw,

ψ),

Y-axis (pitch,

θ), and

X-axis (roll,

φ) with respect to the master wrist joint 7, 6, 5. A dead zone is also implemented in the pose mode to minimize vibrations during teleoperation both for position and orientation. The mapped waist angle, denoted as

θt, aligns with the angular representation provided in Equation (1).

with

In pose mode, a larger scaling factor λp can obtain a greater position range but also diminish the control accuracy. A significant challenge in the other research lies in achieving an optimal balance between control accuracy and spatial extent. A dual-submode switching approach, analogous to speed mapping, is employed to enhance precision. In normal mode, the effective control zone is directly confined to the master workspace. The discrepancy between the master and the dead zone, as specified by the operator, represents the desired offset relative to the zero pose of slave UAM.

Similarly to the reset mode in free rate mode, through the pose reset mode, the origin of the master and slave workspaces is recalibrated. This recalibration aligns the slave’s posture, as perceived by the operator during mode switching, with a neutral posture that serves as the desired reinitialized reference between the master and slave workspace. Effectively, this process recenters the achievable workspace of the slave to this posture when the operator perceives it. In this state, the teleoperation workspaces of the master and slave are asymmetric. We designate this sub-mode as the pose reset submode, where the offset α in the two sub-modes of the posture mode can be expressed as follows:

with

3.3. Mode Transformation

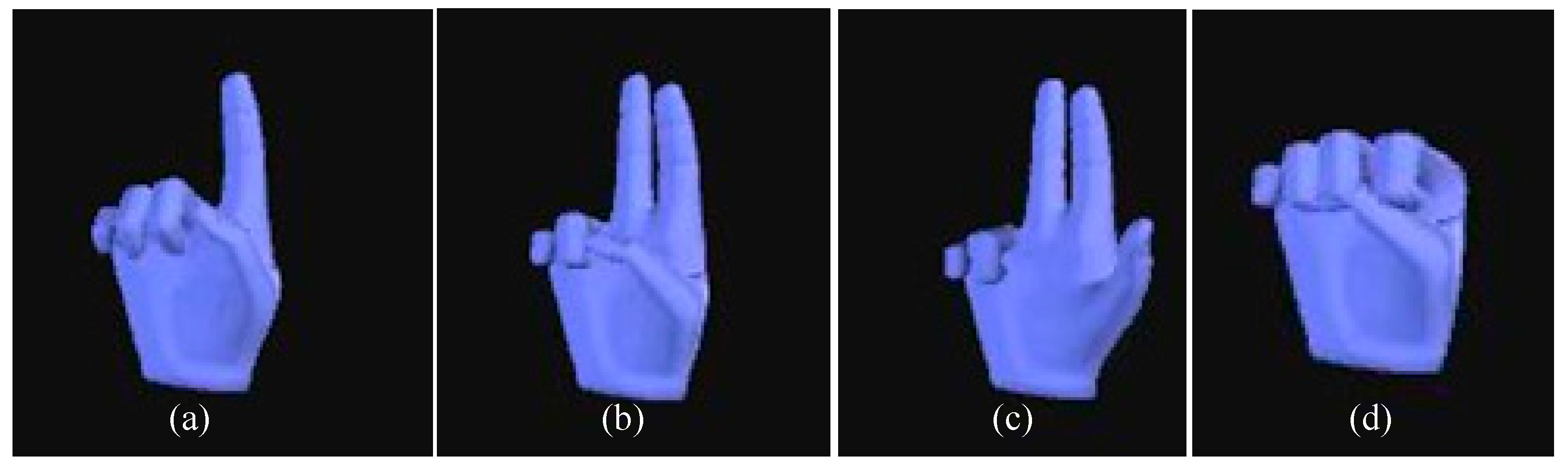

In this section, the transition algorithm for switching between the two workspace mapping methods is developed and described in detail. The Novasense Bluetooth data glove is utilized as the mode switching device capable of sensing and receiving hand command information from the operator intuitively. Gesture one depicted in

Figure 9a serves as the control signal for the rate mode, and gesture two shown in

Figure 9b acts as the switching signal for the position mode. The gesture illustrated in

Figure 9d represents the reset mode, while the gesture depicted in

Figure 9c denotes force feedback mode which is described in detail in the next section. The switch controlled by the operator can be performed when mode transformation is necessary. Compared to conventional button-based switching modes, the data glove enhances the flexibility of the mapping algorithm and offers diverse switching options. By enabling direct operator control over mode switching, the teleoperation mapping achieves greater transparency.

To prevent conflicts between the speed mode and position control mode, a binary logical input

s is introduced to denote the operational mode, where

s = 0 corresponds to the position control mode and

s = 1 corresponds to the speed mode. To ensure the safety of the teleoperation process, transitions between the speed control mode and the rate control mode are restricted, requiring passage through the reset mode. Conversely, the pose control mode and the force feedback mode may be interchanged freely during operation. Upon switching to force feedback mode, it is postulated that the UAM is in contact with the whiteboard surface, thereby fixing the

Z-axis position at the height established during the mode switch, with no teleoperation control applied to the

Z-axis. Furthermore, force feedback mode incorporates haptic feedback, while the

X,

Y-axis teleoperation mapping algorithm remains consistent with that employed in position mode. The mapping function is expressed by the following equation:

The proposed mapping strategy allows for continuous and seamless switching between two sub-modes. Switching transformation signals are sent under the operator’s control whenever necessary, enhancing the flexibility of the mapping algorithm. In contrast to button-based switching, the data glove utilized in this research offers an intuitive approach and minimizes the probability of operational errors due to mode switching.

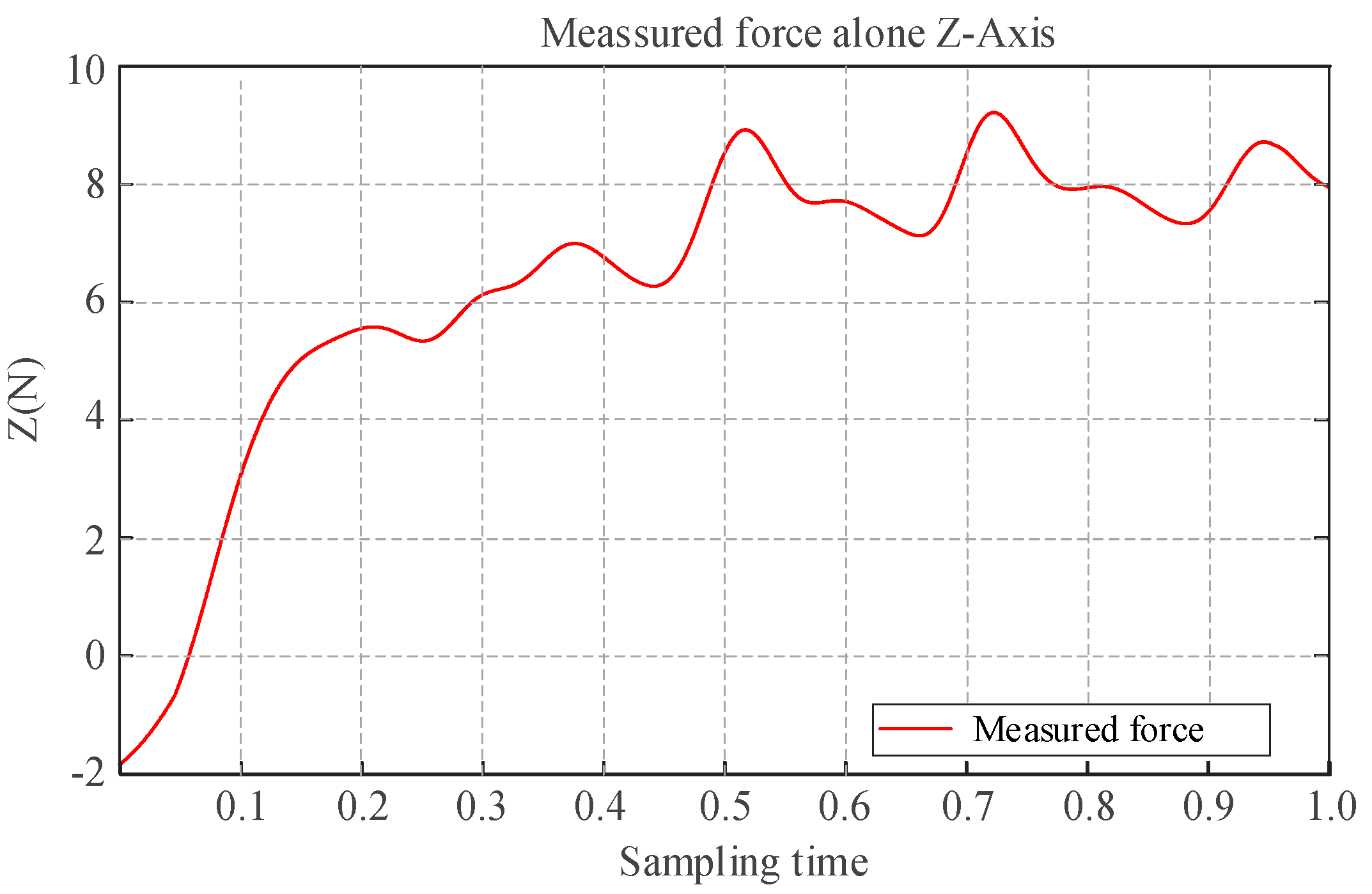

3.4. Force Feedback in Physical Contact Tasks

The present research proposes a haptic feedback framework aimed at enhancing performance and operator immersion in human–robot interaction systems. Within the established position-mode teleoperation framework, pose commands from the master are directly mapped and transmitted to the contact end of the unmanned autonomous manipulator (UAM).

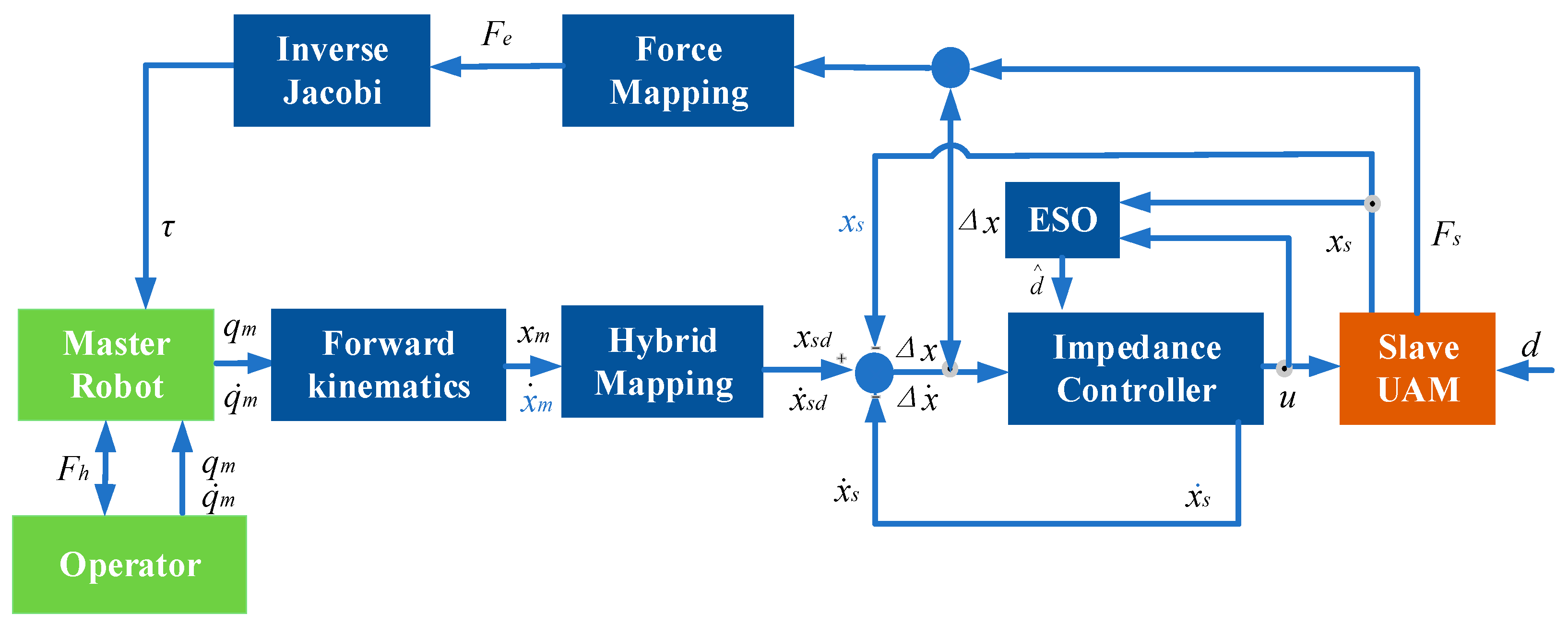

When the end-effector of the slave UAM encounters a rigid object, minor positional errors may generate substantial contact forces, potentially undermining the stability and safety of the teleoperation system. To mitigate this, a force feedback framework based on impedance control, as depicted in

Figure 10, is introduced.

Through the master–slave pose mapping algorithm, the position commands of the master device

xm are transformed into the desired position of the slave device

xs. The characteristics of a spring-damper second-order system are integrated into the impedance model of UAM, and the impedance controller is formulated as follows:

The dynamics model of the slave UAM can be represented as follows:

where

Fs indicates the detect force from the force sensor.

Kd is the stiffness parameter;

Dd is the damping parameter;

Md is the inertia parameter;

Ms is the inertia matrix.

is the Kohl force matrix;

Gs(

q) is the gravity matrix of UAM and

Tfs represents the conversion matrix that transforms the external force into a control value. The term u

d represents the control input for the UAM generated by the control framework to regulate the UAM’s dynamic. Conversely, u

s denotes the external control value transmitted to the UAM, which accounts for external forces or disturbance. In addition, the UAV is subject to external disturbances

d, such as wind, during task execution. To address this issue, an extended state observer (ESO) is incorporated into the control system of the UAM to enhance stability [

36]. Finally, the following impedance control calculation can be obtained as follows:

Feedback force

Ff comprising the contact force

Fs from the slave environment and the difference

pe between the desired and actual positions of the UAM are transmitted to the master robot through the force mapping channel as follows:

where

Ks and

Ke denote the coefficient of the contact force and impedance force because of position error. Meanwhile,

Kf denotes the force feedback mapping coefficient, which scales the combined impedance forces and contact force to the force feedback output. In the experiment,

Ks and

Kf were set as 1 to ensure the transparency of force feedback, while

Ke was set as 50 N/m. The teleoperation framework presented in this paper is decoupled for position and orientation. Specifically, the first four joints of the master exoskeleton are responsible for position control and feedback three-dimensional contact forces, while the three motors in the wrist joint control the orientation. The end-effector is equipped with a 1-D force sensor, which detects the contact force in the vertical direction between the UAM and the operating environment. The relationship between the feedback force

Ff and the exoskeleton motor torque

τm can be represented as follows:

where

Jm denotes the Jacobian matrix of the exoskeleton. The inverse kinematics solution for the 7-DOF robotic system involves redundancy, resulting in multiple feasible configurations. To address this, the present study incorporates an additional constraint, as defined in Equation (17), which minimizes joint torque output to identify the optimal solution. The term

τi specifically represents the force feedback applied to the shoulder and elbow joints of the exoskeleton, excluding the total output torque, as it also accounts for gravity compensation within the exoskeleton.

The teleoperation system typically consists of the operator, the master robot and controller, the communication channel, the slave robot and controller, and the operating environment. Accordingly, establishing the theoretical stability of the teleoperation system is complicated and challenging. Alternatively, passivity theory presents an approach to establish system stability from the energy perspective [

37]. The total energy is dissipated but not increased in a passive system [

38]. In the passive system, the stored energy remains bounded by the sum of the initial energy storage and the energy supplied to the system which is expressed as follows [

39]:

where

W(t) represents the real-valued rate of energy, corresponding to the input power supplied to the system.

V(0) is the initial energy, while

V(t) is the stored energy function. The stability of the interconnected systems can be rigorously established through passivity theory.

In the teleoperation system, the operator refrains from deliberately compromising system stability and adopts a passive response to external inputs. Concurrently, both the human operator and the environment can be modeled as passive systems [

40]. Consequently, both the master and slave robots demonstrate passivity with respect to the human operator and the environment. Additionally, a cloud server is incorporated into the master–slave system to facilitate data transmission. The data stream is transmitted independently of the video stream, with a time delay not exceeding 10 ms. As such, the time delay between the master and slave in this study is deemed negligible. In conclusion, passivity provides sufficient conditions to ensure the stability of the teleoperated robotic control system.

5. Discussion

Compared to traditional teleoperation systems based on serial or parallel master robots, this study employs a 7 DOF wearable upper-limb exoskeleton, which aligns naturally with the operator joint angles, offering intuitive control logic and a significantly expanded operational workspace of the master device. Additionally, in contrast to conventional button-based mode switching, this work utilizes Bluetooth data gloves as mode-switching sensors, providing a broader, clearer, and intuitive interaction framework according to the operational task that effectively minimizes the risk of erroneous operations. Combined with the hybrid mapping framework we proposed, the operator can leverage velocity mapping to rapidly approach the target, subsequently transitioning seamlessly to either a heterogeneous position mode or a force feedback mode to perform interactive tasks with enhanced precision control. By wearing the exoskeleton arm and configuring appropriate mapping parameters, operators achieved velocity mapping and interactive aerial writing modes. Experimental findings not only verify the feasibility and stability of the entire system but also demonstrate that the mode-switching algorithm facilitates efficient teleoperation processes. Furthermore, the algorithm proposed herein is not only applicable to UAM teleoperation but, with appropriate parameter adjustments, is equally suitable for mobile manipulator platform.

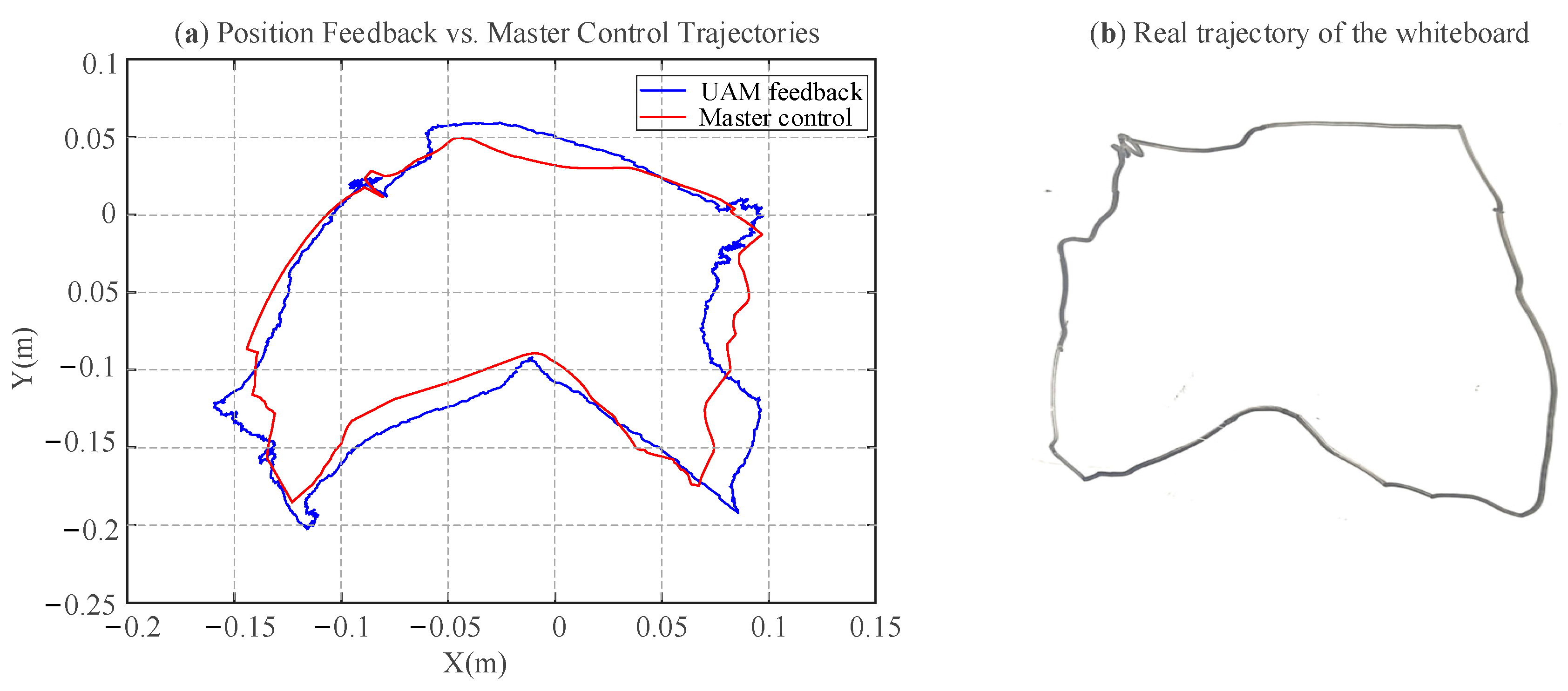

To quantitatively evaluate the system’s usability, focusing on the intuitiveness and operator comfort, a System Usability Scale (SUS) survey, as is shown in

Appendix A, was conducted. The results based on responses from ten participants (nine males and one female) provide a comprehensive evaluation of the exoskeleton for teleoperating the UAM. The mean SUS score was 86.3 (SD = 8.2), surpassing the industry benchmark of 68, indicating above-average usability. Analysis revealed strengths in specific usability dimensions: the statement “The wearable exoskeleton offers enhanced comfort” received a mean score of 4.3, suggesting high user satisfaction with physical ergonomics. Similarly, “The teleoperation mode switching is intuitive and user-friendly” scored 4.8, reflecting intuitive mode transitions, and “The data gloves did not exhibit mode-switching errors during operation” averaged 5.0, confirming reliable performance of mode switching interface. Additionally, “The teleoperation process is free from dizziness or discomfort” scored 4.8, indicating minimal adverse physical effects. However, the statement “The teleoperation process does not exhibit noticeable jitter and unexpected movements” received a lower mean score of 3.9, highlighting a critical area for improvement in control stability. Finally, “The UAM’s trajectory aligns consistently with the master control trajectory” scored 3.1, suggesting generally accurate trajectory tracking but with potential for refinement. These findings validate the system’s intuitive design and comfort while identifying jitter and minor trajectory inconsistencies as priorities for future optimization.

Due to the limited control precision of the UAM, which is significantly lower than the millimeter-level accuracy achievable by robotic manipulators, and the visual localization based on the T265 sensor, constrained to centimeter-level accuracy, experimental trajectories exhibit deviations from actual trajectories, as illustrated in

Figure 14. Nevertheless, the aerial writing experiments have comprehensively validated the efficacy of the hybrid mapping algorithm.

6. Conclusions

This paper describes a generic haptic teleoperation control architecture for a UAM contact task. Firstly, this paper employs an upper arm exoskeleton as the user-friendly master robot, offering superior human adaptability and a broader workspace compared to conventional desktop level haptic devices. Then, to address the requirements of workspace and accuracy in UAM contact tasks, this work introduces a continuous rate and position control mode that innovatively employs a bluetooth data glove as the command-switching device. The proposed control architecture adeptly addresses challenges in teleoperation, including misoperations arising from non-intuitive mode switching, oscillations triggered by mode switching, and limitations in the workspace of master devices, thereby significantly enhancing system stability and operational efficacy. Finally, a comprehensive experimental platform was established, and an aerial writing experiment was conducted. The results showed that the trajectory tracking error of the areal writing experiment achieved a position tracking RMSE of 7.7% and 5.2% in the X,Y-axis, respectively. Additionally, the smooth UAM motion observed during the experiments, with no abrupt feedback force variations, further highlights the excellent stability of the control framework, which has potential applications in autonomous aerial vehicles and human–machine interaction. The SUS survey effectively validates the intuitive and comfort design of the teleoperation master system.

In the future, we plan to implement the teleoperation system in a six-dimensional workspace and on a broader spectrum of robotic platforms to further evaluate its universality.