Real-Time Structural Health Monitoring of Reinforced Concrete Under Seismic Loading Using Dynamic OFDR

Abstract

1. Introduction

2. Performance Test

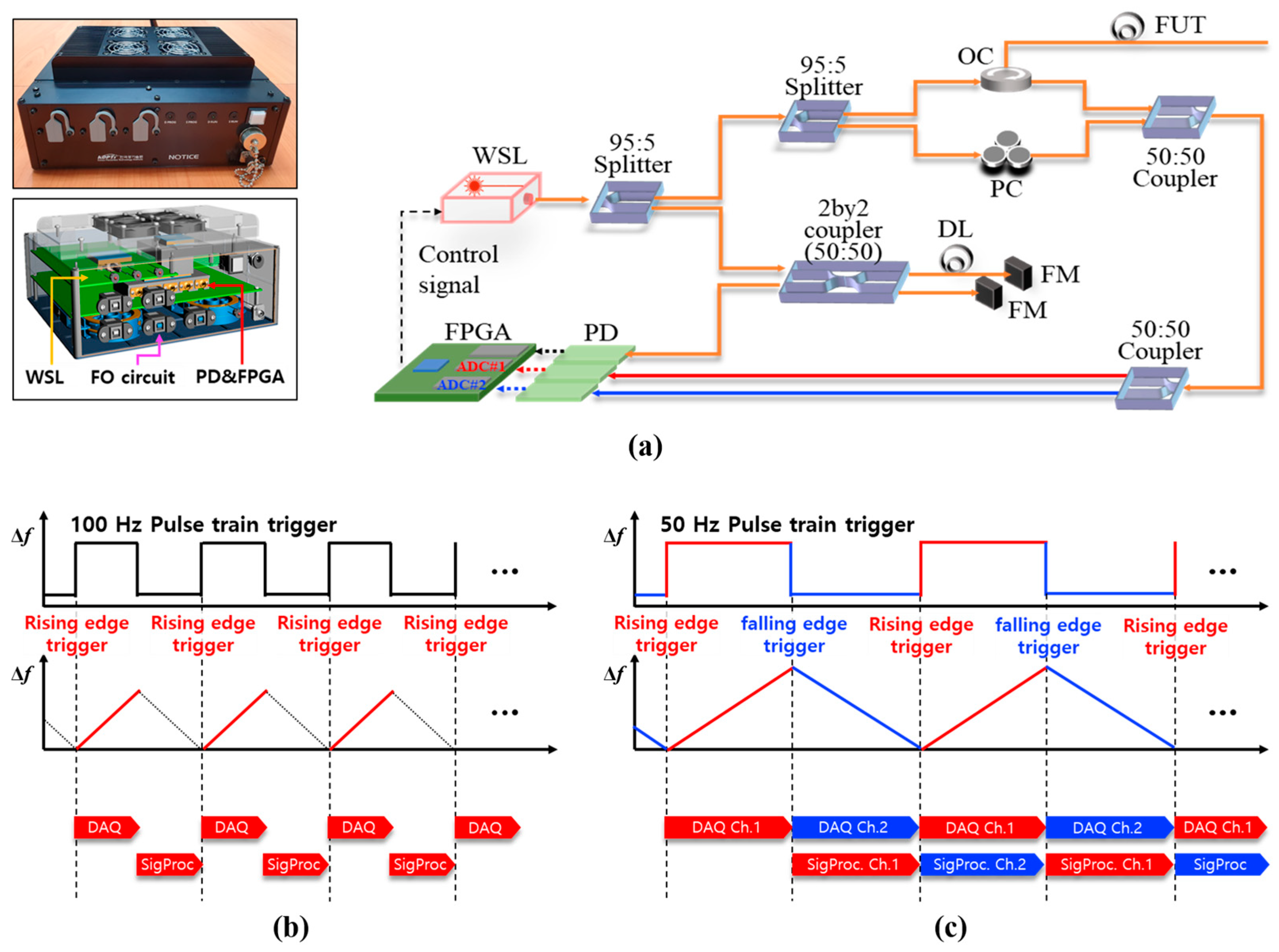

2.1. D-OFDR Interrogator Architecture and Dual-Edge Timing Scheme

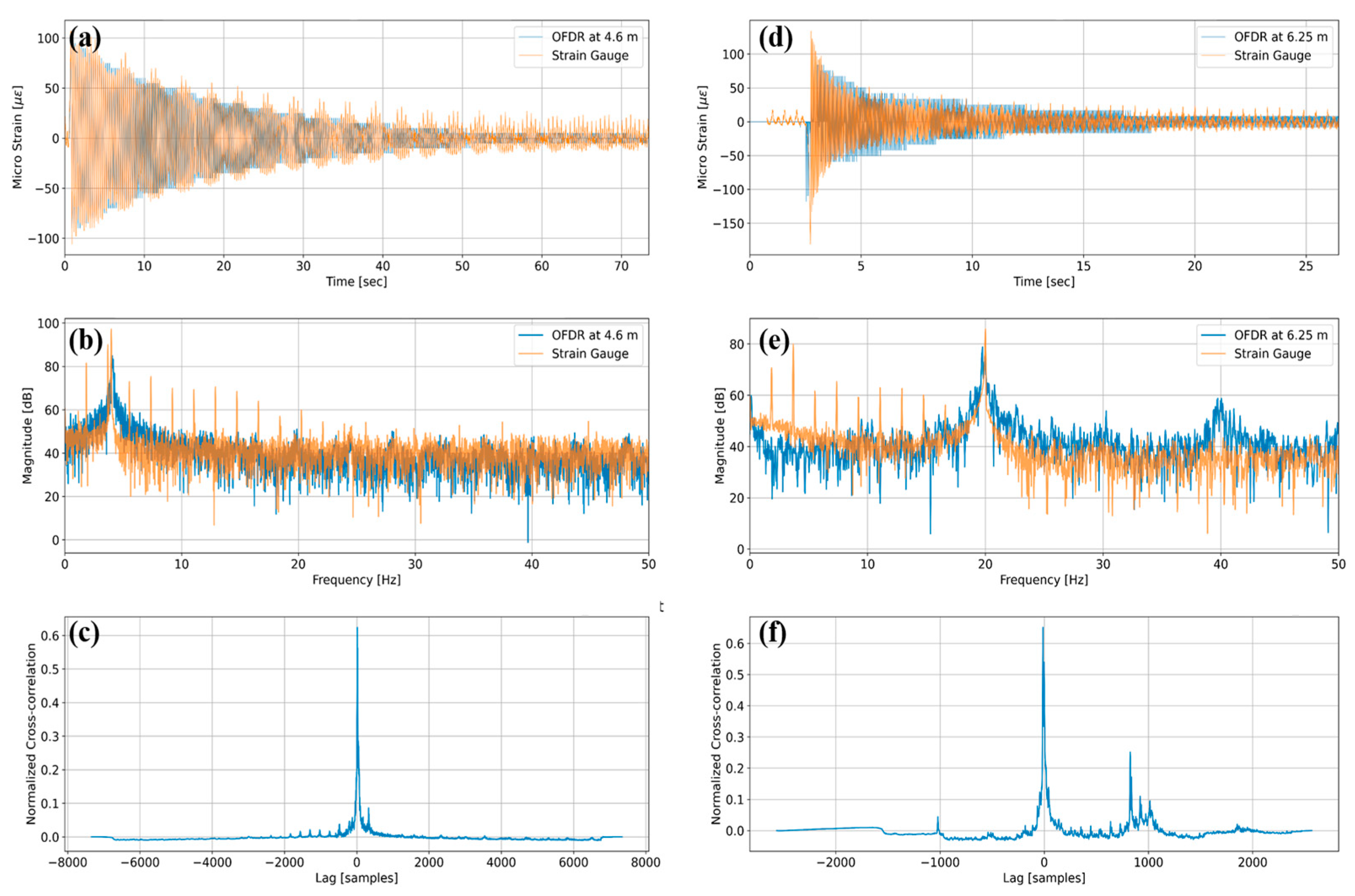

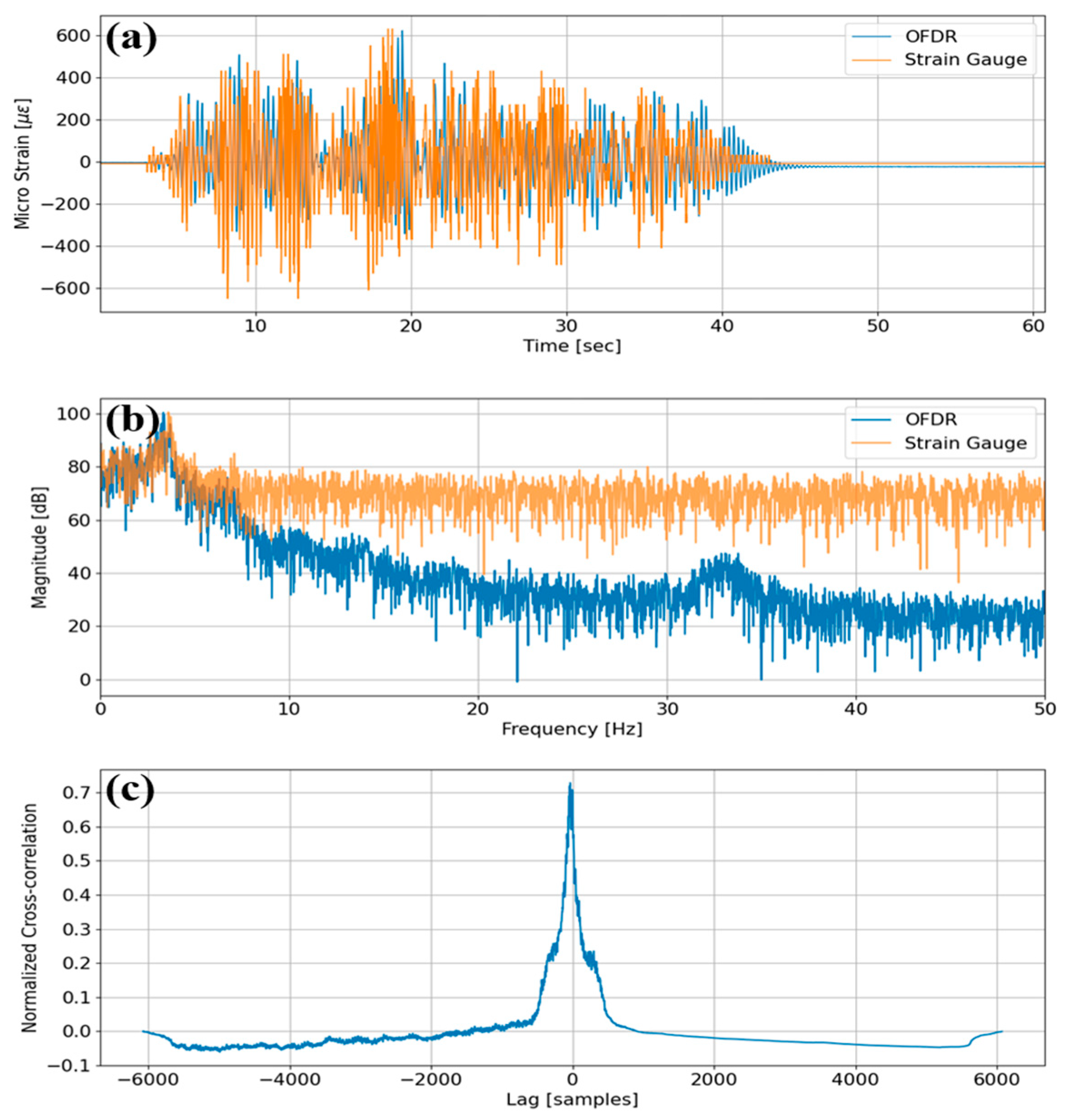

2.2. Real-Time Strain Measurement Test

3. Experimental Investigation on Reinforced Concrete Monitoring

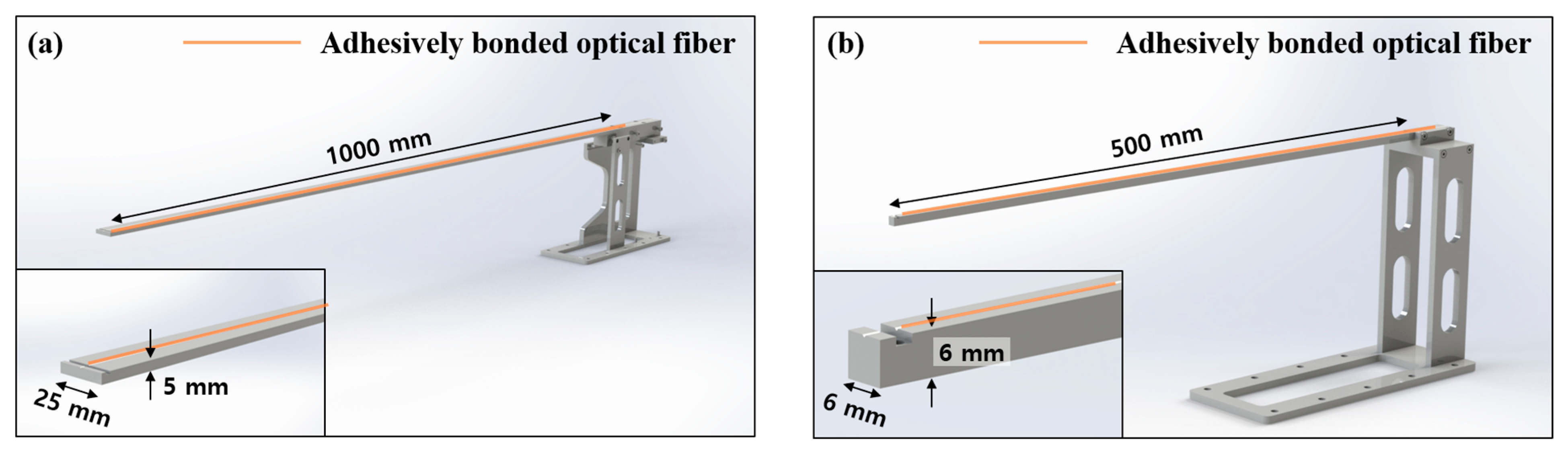

3.1. Specimen Preparation and Sensor Deployment

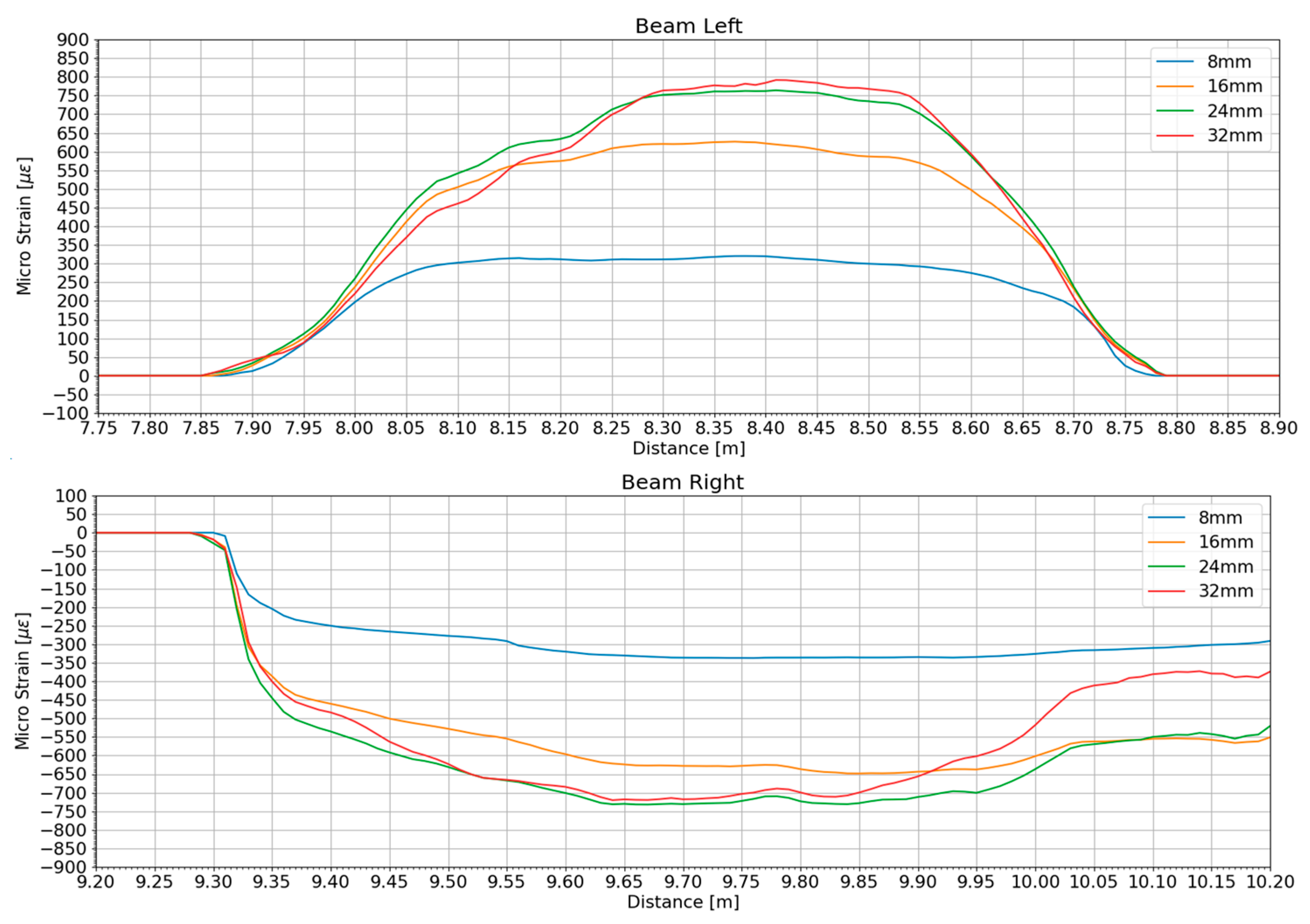

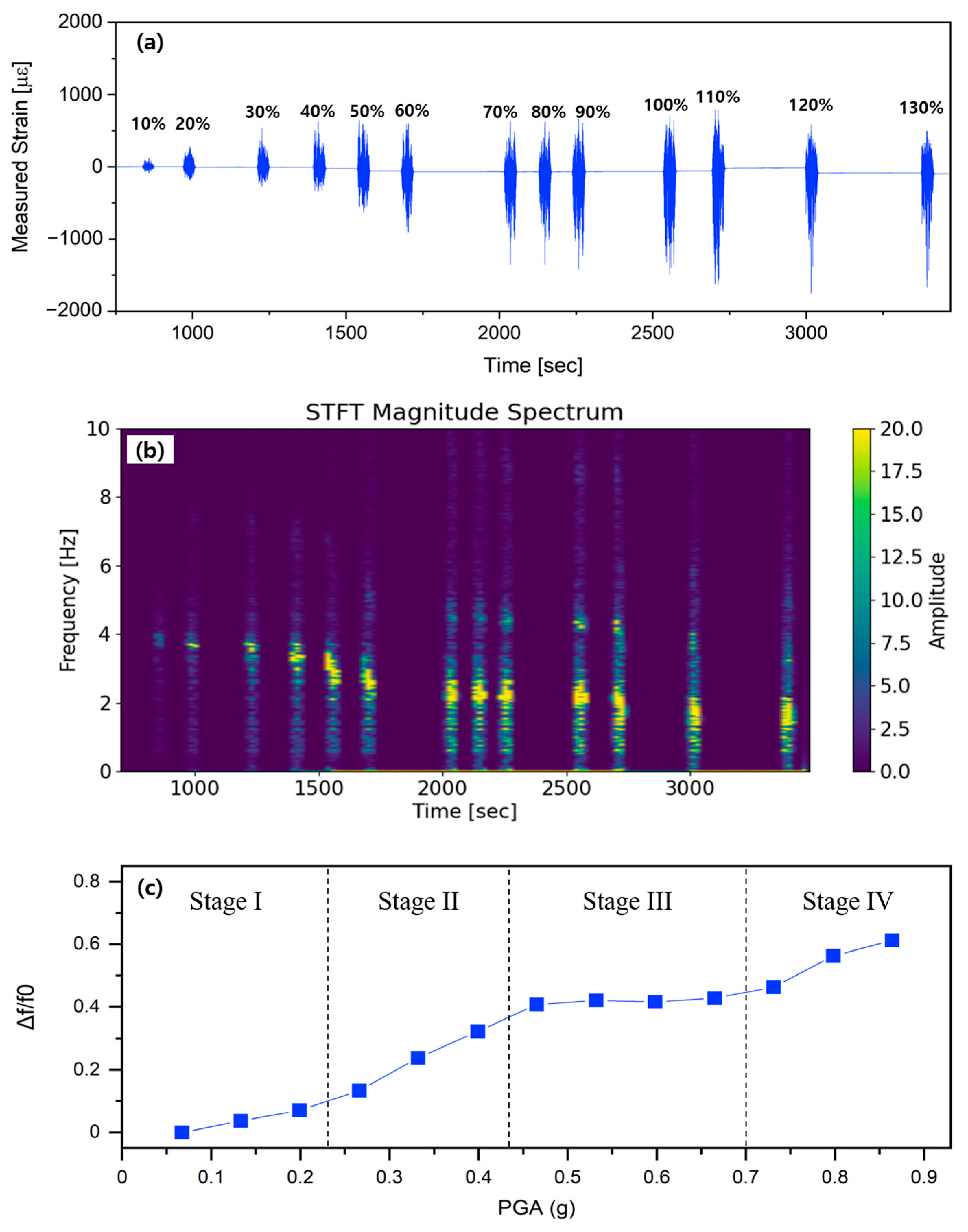

3.2. Artificial Seismic-Wave Excitation Test

4. Discussion: Practical On-Site Application of D-OFDR

4.1. Real-Time Diagnostics and Post-Event Screening Scenarios

4.2. Installation, Routing, and Commissioning Guidelines

4.3. Method Applicability and Trade-Offs for Real-Time RC Monitoring

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, B.; Cho, S. Automated Vision-Based Detection of Cracks on Concrete Surfaces Using a Deep Learning Technique. Sensors 2018, 18, 3452. [Google Scholar] [CrossRef] [PubMed]

- Zhao, G.; Zhang, D.; Zhang, L.; Wang, B. Detection of Defects in Reinforced Concrete Structures Using Ultrasonic Non-Destructive Evaluation with Piezoceramic Transducers and the Time Reversal Method. Sensors 2018, 18, 4176. [Google Scholar] [CrossRef] [PubMed]

- Kaklauskas, G.; Sokolov, A.; Ramanauskas, R.; Jakubovskis, R. Reinforcement Strains in Reinforced Concrete Tensile Members Recorded by Strain Gauges and FBG Sensors: Experimental and Numerical Analysis. Sensors 2019, 19, 200. [Google Scholar] [CrossRef] [PubMed]

- Barrias, A.; Casas, J.R.; Villalba, S. A Review of Distributed Optical Fiber Sensors for Civil Engineering Applications. Sensors 2016, 16, 748. [Google Scholar] [CrossRef] [PubMed]

- Bado, M.F.; Casas, J.R. A Review of Recent Distributed Optical Fiber Sensors Applications for Civil Engineering Structural Health Monitoring. Sensors 2021, 21, 1818. [Google Scholar] [CrossRef] [PubMed]

- Broth, Z.E.; Hoult, N.A. Field Monitoring of Reinforced Concrete Structures under Dynamic Loading Using Distributed Fiber-Optic Sensors. J. Perform. Constr. Facil. 2020, 34, 04020070. [Google Scholar] [CrossRef]

- Bao, X.; Wang, Y. Recent Advancements in Rayleigh Scattering-Based Distributed Fiber Sensors. Adv. Devices Instrum. 2021, 2021, 8696571. [Google Scholar] [CrossRef]

- Moser, D.; Martin-Candilejo, A.; Cueto-Felgueroso, L.; Santillán, D. Use of Fiber-Optic Sensors to Monitor Concrete Dams: Recent Breakthroughs and New Opportunities. Structures 2024, 67, 106968. [Google Scholar] [CrossRef]

- Xiao, Z.; Di Murro, V.; Osborne, J.A.; Zhu, H.; Li, Z. Distributed Fibre Optic Sensing and Novel Data Processing Method for Tunnel Circumferential Deformation—A Case Study of an Ageing Tunnel at CERN. Tunn. Undergr. Space Technol. 2024, 153, 106014. [Google Scholar] [CrossRef]

- Kishida, K.; Aung, T.L.; Lin, R. Monitoring a Railway Bridge with Distributed Fiber Optic Sensing Using Specially Installed Fibers. Sensors 2025, 25, 98. [Google Scholar] [CrossRef] [PubMed]

- Wheeler, L.N.; Pannese, E.; Hoult, N.A.; Take, W.A.; Le, H. Measurement of Distributed Dynamic Rail Strains Using a Rayleigh Backscatter-Based Fiber Optic Sensor: Lab and Field Evaluation. Transp. Geotech. 2018, 14, 70–80. [Google Scholar] [CrossRef]

- Wong, L.; Chiu, W.K.; Kodikara, J. Using Distributed Optical Fibre Sensor to Enhance Structural Health Monitoring of a Pipeline Subjected to Hydraulic Transient Excitation. Struct. Health Monit. 2018, 17, 298–312. [Google Scholar] [CrossRef]

- Barrias, A.; Casas, J.R.; Villalba, S. Fatigue Performance of Distributed Optical Fiber Sensors in Reinforced Concrete Elements. Constr. Build. Mater. 2019, 218, 214–223. [Google Scholar] [CrossRef]

- Brault, A.; Hoult, N.; Greenough, T.; Trudeau, I. Monitoring of Beams in an RC Building during a Load Test Using Distributed Sensors. J. Perform. Constr. Facil. 2019, 33, 04018096. [Google Scholar] [CrossRef]

- Brault, A.; Hoult, N.A. Monitoring Reinforced Concrete Serviceability Performance Using Fiber-Optic Sensors. ACI Struct. J. 2019, 116, 57–70. [Google Scholar] [CrossRef]

- Schiff, A.J. (Ed.) The Loma Prieta, California, Earthquake of October 17, 1989—Lifelines. In U.S. Geological Survey Professional Paper 1552-A; U.S. Government Printing Office: Washington, DC, USA, 1998. [Google Scholar]

- Mylonakis, G.; Syngros, C. The Collapse of Fukae (Hanshin Expressway) Bridge, Kobe, 1995: The Role of Soil and Soil-Structure Interaction. In Proceedings of the Fifth International Conference on Case Histories in Geotechnical Engineering, New York, NY, USA, 13–17 April 2004; pp. 1–12. [Google Scholar]

- Canterbury Earthquakes Royal Commission. Final Report—Volume 6: Canterbury Television Building (CTV); Department of Internal Affairs: Wellington, New Zealand, 2012; ISBN 978-0-478-39573-0.

- Mayoral, J.M.; Hutchinson, T.C.; Franke, K.W. (Eds.) Geotechnical Engineering Reconnaissance of the 19 September 2017 Mw 7.1 Puebla–Mexico City Earthquake. In GEER Report No. GEER-055A; Geotechnical Extreme Events Reconnaissance Association: Atlanta, Georgia, 2017. [Google Scholar]

- Massenzio, M.; Jacquelin, E.; Ovigne, P.A. Natural frequency evaluation of a cracked RC beam with or without composite strengthening for a damage assessment. Mater. Struct. 2005, 38, 865–873. [Google Scholar]

- Kashani, M.M.; Ge, X.; Dietz, M.S.; Crewe, A.J.; Alexander, N.A. Significance of Non-Stationary Characteristics of Ground-Motion on Structural Damage: Shaking Table Study. Bull. Earthq. Eng. 2019, 17, 4885–4907. [Google Scholar]

- Ge, X.; Dietz, M.S.; Alexander, N.A.; Kashani, M.M. Nonlinear Dynamic Behaviour of Severely Corroded Reinforced Concrete Columns: Shaking Table Study. Bull. Earthq. Eng. 2020, 18, 1417–1443. [Google Scholar] [CrossRef]

- Zhang, Z.; Cao, F.; Yang, J.; He, Z. Experiment on Natural Frequency Change of Reinforced Concrete Members under Low Cycle Loading. Shock. Vib. 2018, 2018, 6504519. [Google Scholar] [CrossRef]

| Attribute | Strain Gauge (Electrical) | FBG Array (Point-Multiplexed Optics) | D-OFDR (This Work) |

|---|---|---|---|

| Spatial sampling | Point only; gaps between points | Discrete points (cm–m spacing) | Continuous along fiber; ~mm over tens of m |

| Real-time dynamics (seismic band) | Very high at instrumented points | High-rate per channel (demodulator-dependent) | ~100 Hz distributed; <1 s end-to-end |

| EMI/noise | EMI/corrosion/wiring sensitive | EMI-immune | EMI-immune; high dynamic SNR |

| Install & maintenance | Many wires; shielding; periodic replacement | Good bonding/anchoring and surface prep; fewer cables via multiplexing; connector hygiene; temperature compensation | Good bonding/bend-radius control; low-loss routing; baseline/latency management |

| RC-specific diagnostics | Curvature/drift only where paired gauges exist; no continuous zone length | Curvature/drift possible at grating pairs; may miss between points | Opposite-face curvature/drift from continuous profiles; inelastic-zone length; staged Δf/f0 for global softening |

| Best use-cases | Calibration/validation; control points; local high-rate events | Multi-point with moderate granularity | In-shake localization; post-event screening; component-level triage |

| Key limitations | Un-instrumented spans; wiring complexity; durability | Still discrete; may miss between gratings; per-point cost | Shorter range than low-rate DFOS; sensitive to adhesive/micro-bending; careful installation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Jung, H.; Kim, M.J.; Kim, Y.H. Real-Time Structural Health Monitoring of Reinforced Concrete Under Seismic Loading Using Dynamic OFDR. Sensors 2025, 25, 5818. https://doi.org/10.3390/s25185818

Lee J, Jung H, Kim MJ, Kim YH. Real-Time Structural Health Monitoring of Reinforced Concrete Under Seismic Loading Using Dynamic OFDR. Sensors. 2025; 25(18):5818. https://doi.org/10.3390/s25185818

Chicago/Turabian StyleLee, Jooyoung, Hyoyoung Jung, Myoung Jin Kim, and Young Ho Kim. 2025. "Real-Time Structural Health Monitoring of Reinforced Concrete Under Seismic Loading Using Dynamic OFDR" Sensors 25, no. 18: 5818. https://doi.org/10.3390/s25185818

APA StyleLee, J., Jung, H., Kim, M. J., & Kim, Y. H. (2025). Real-Time Structural Health Monitoring of Reinforced Concrete Under Seismic Loading Using Dynamic OFDR. Sensors, 25(18), 5818. https://doi.org/10.3390/s25185818