The Integrated Disturbance Estimation and Non-Singular Terminal Sliding Mode Longitudinal Motion Controller for Low-Speed Autonomous Electric Vehicles

Abstract

1. Introduction

2. Longitudinal Vehicle Dynamics Model and Experimental Validation

2.1. Longitudinal Vehicle Dynamics Modelling

2.2. Model Parameter Calibration

3. Sliding Mode Controller Design

3.1. PI Controller Design

| Algorithm 1 The switch algorithm for traction and brake PI controller |

| is smaller than the threshold value) (Calculate the positive PI control values) (Calculate the desired longitudinal speed) (Calculate the acceleration pedal position through lookup table) Else ( is larger than the threshold value) (calculate the negative PI control values) (Calculate the brake pedal position through lookup table) where is the constant value which determines the dead-zone range to disable the brake control when the error is not too big. and are PID control gains. Throttle pedal position is the function of , and this function is determined by the lookup table (Table 2). , is the maximum throttle and brake pedal position. The brake pedal position is the function of and a lookup table can describe this relationship (Table 3). |

3.2. N-S TSMC Design

3.3. N-S TSMC Design with Uncertain Parameter and Disturbance Estimator

4. Experimental and Simulation Results

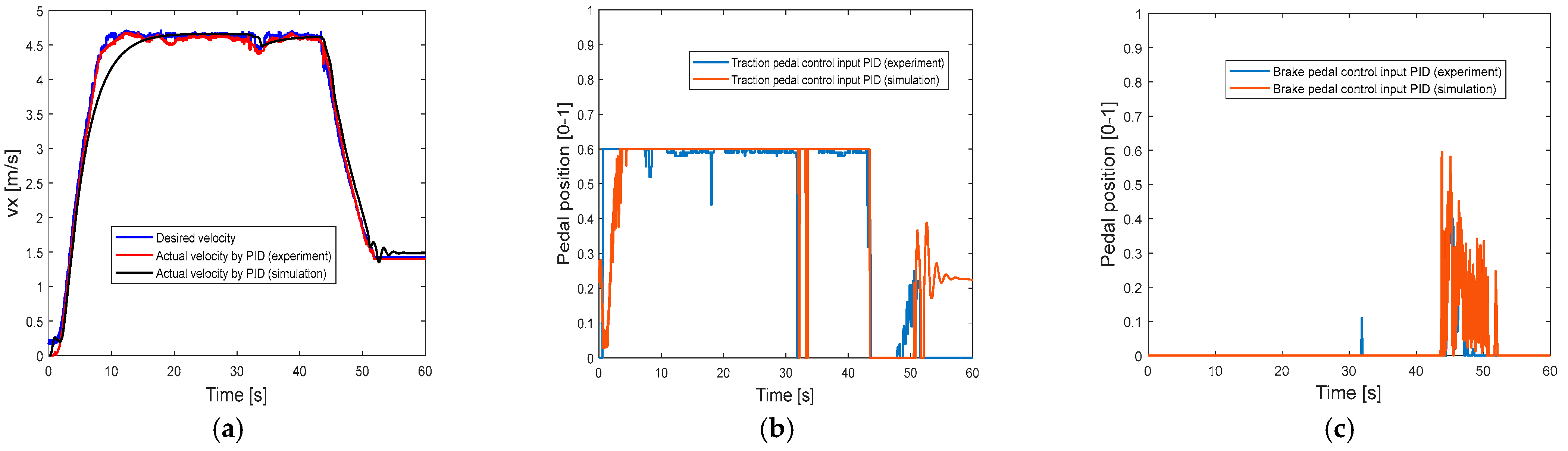

4.1. Experimental Results

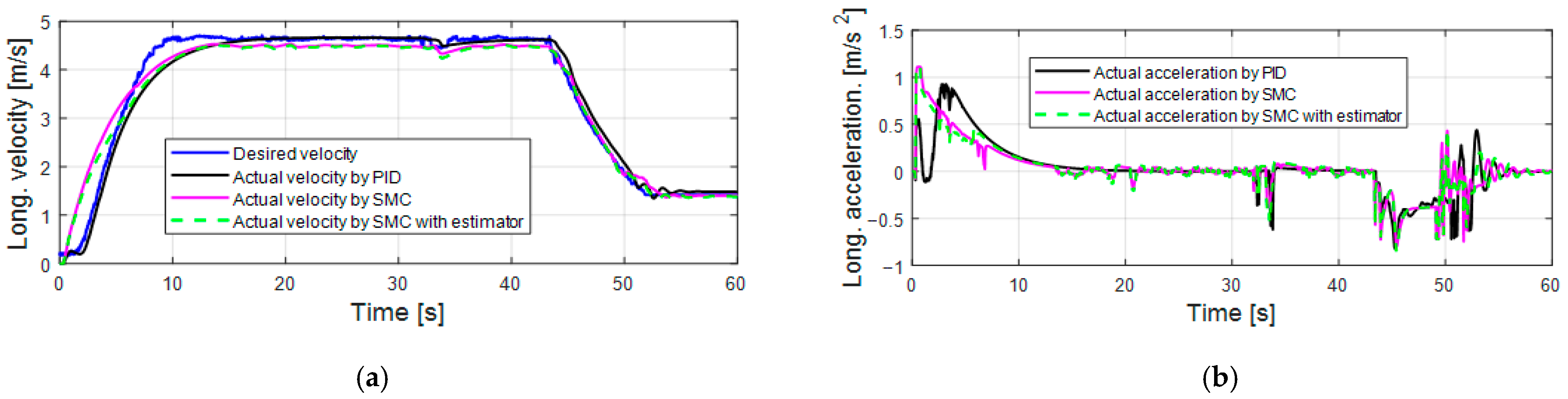

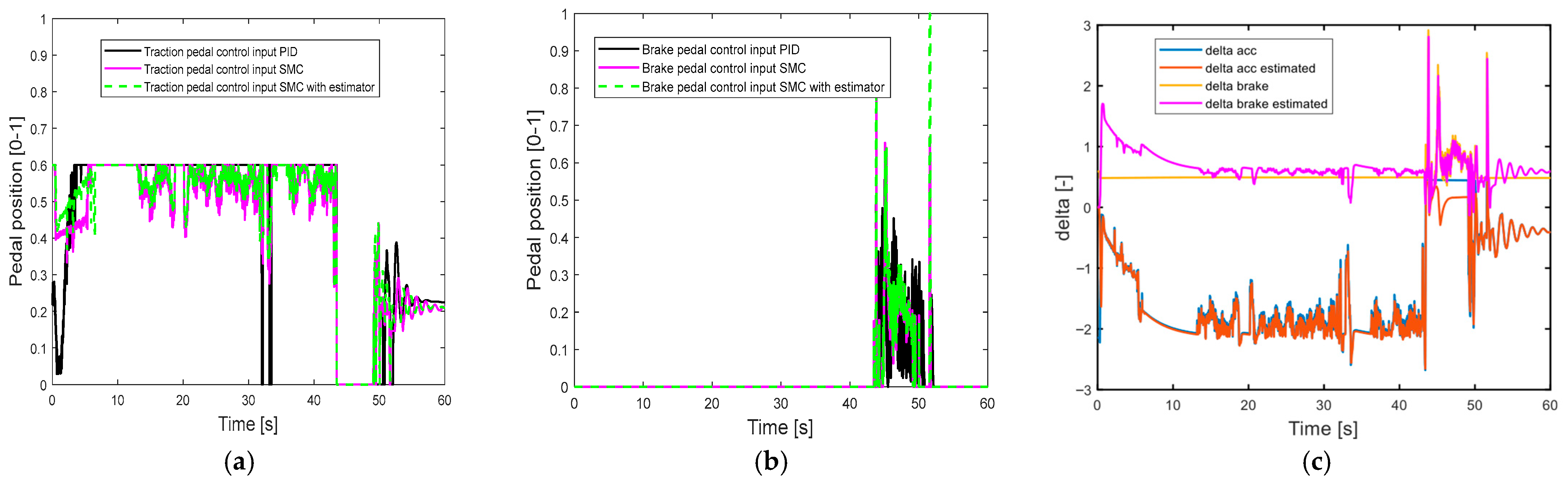

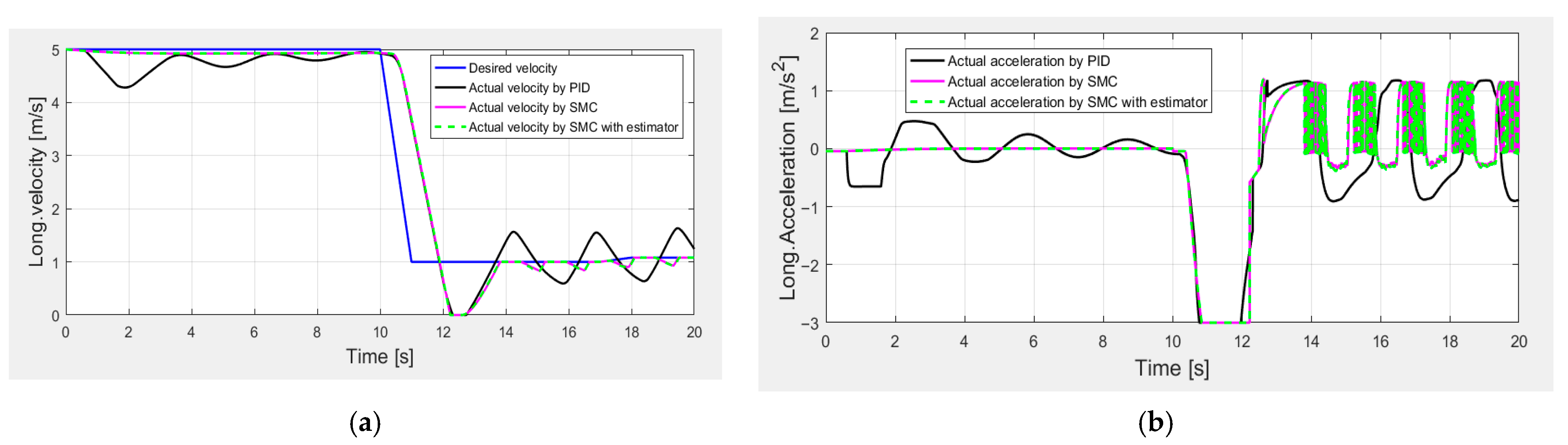

4.2. Simulation Results of Proposed N-S TSMC

5. Conclusions

- (1)

- The actual experiment was carried out to validate the proposed longitudinal vehicle dynamics model and the proposed PID controller, and the PID control can be used as the benchmark method for comparison with the control performance of the SMC.

- (2)

- When the PID control is well tuned in the first set of simulations, the PID control shows similar or even better longitudinal velocity tracking performance compared with the SMC.

- (3)

- When the simulation scenario changes, the longitudinal motion SMC is more robust with regard to parameter uncertainty and disturbances compared to the PID control and can achieve a better performance in terms of speed tracking, longitudinal acceleration, and smooth pedal control inputs.

- (4)

- For the proposed integrated disturbance estimator and the N-S TSMC approach, the disturbance estimator can successfully estimate the uncertainty parameters and disturbances, and the control effort can be reduced while maintaining good control performance.

- (5)

- In the emergency braking and icy road scenarios, the proposed SMC has better control performance in terms of longitudinal velocity tracking and acceleration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Paden, B.; Čáp, M.; Yong, S.Z.; Yershov, D.; Frazzoli, E. A survey of motion planning and control techniques for selfdriving urban vehicles. IEEE Trans. Int. Veh. 2016, 1, 33–55. [Google Scholar]

- Guanetti, J.; Kim, Y.; Borrelli, F. Control of connected and automated vehicles: State of the art and future challenges. Annu. Rev. Control 2018, 45, 18–40. [Google Scholar] [CrossRef]

- Rupp, A.; Stolz, M. Survey on control schemes for automated driving on highways. In Automated Driving; Springer: Berlin/Heidelberg, Germany, 2016; pp. 43–69. [Google Scholar]

- Gong, X.; Ge, W.; Yan, J.; Zhang, Y.; Gongye, X. Review on the development, control method and application prospect of brake-by-wire actuator. Actuators 2020, 9, 15. [Google Scholar] [CrossRef]

- Wang, J.; Longoria, R.G. Coordinated and Reconfigurable Vehicle Dynamics Control. IEEE Trans. Control Syst. Technol. 2009, 17, 723–732. [Google Scholar] [CrossRef]

- Ma, Z.; Sun, D. Energy recovery strategy based on ideal braking force distribution for regenerative braking system of a four-wheel drive electric vehicle. IEEE Access 2020, 8, 136234–136242. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Y.; Zhu, R.; Geng, R.; Zhang, J.; Fan, D.; Wang, H. Study on the control strategy of regenerative braking for the hybrid electric vehicle under typical braking condition. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 452, p. 032092. [Google Scholar]

- Dong, H.; Xi, J. Model predictive longitudinal motion control for the unmanned ground vehicle with a trajectory tracking model. IEEE Trans. Veh. Technol. 2021, 71, 1397–1410. [Google Scholar] [CrossRef]

- Papaioannou, G.; Maroof, V.; Jerrelind, J.; Drugge, L. Optimal control of a long haul automated articulated vehicle for tyre wear minimization. In Proceedings of the 2022 IEEE Vehicle Power and Propulsion Conference (VPPC), Merced, CA, USA, 1–4 November 2022; pp. 1–7. [Google Scholar]

- Htike, Z.; Papaioannou, G.; Siampis, E.; Velenis, E.; Longo, S. Fundamentals of motion planning for mitigating motion sickness in automated vehicles. IEEE Trans. Veh. Technol. 2021, 71, 2375–2384. [Google Scholar] [CrossRef]

- Fang, Z.; Duan, J.; Zheng, B. Longitudinal motion control of intelligent vehicle based on two hierarchies optimal method. In Proceedings of the 2015 Chinese Automation Congress (CAC), Wuhan, China, 27–29 November 2015; pp. 1092–1097. [Google Scholar]

- Gao, X.; Li, J.; Liu, R.; Zhang, S.; Ma, P. Research on Vehicle Longitudinal Control Method Based on Model Predictive Control. Front. Comput. Intell. Syst. 2022, 1, 42–47. [Google Scholar] [CrossRef]

- Marcano, M.; Matute, J.A.; Lattarulo, R.; Martí, E.; Pérez, J. Low speed longitudinal control algorithms for automated vehicles in simulation and real platforms. Complexity 2018, 2018, 7615123. [Google Scholar] [CrossRef]

- Walz, F.; Hohmann, S. Model predictive longitudinal motion control for low velocities on known road profiles. Veh. Syst. Dyn. 2020, 58, 1310–1328. [Google Scholar] [CrossRef]

- Yong, J.; Gao, F.; Ding, N.; He, Y. Design and validation of an electro-hydraulic brake system using hardware-in-the-loop real-time simulation. Int. J. Automot. Technol. 2017, 18, 603–612. [Google Scholar] [CrossRef]

- Dardanelli, A.; Alli, G.; Savaresi, S.M. Modeling and control of an electro-mechanical brake-by-wire actuator for a sport motorbike. IFAC Proc. Vol. 2010, 43, 524–531. [Google Scholar] [CrossRef]

- Ko, S.; Song, C.; Kim, H. Cooperative control of the motor and the electric booster brake to improve the stability of an in-wheel electric vehicle. Int. J. Automot. Technol. 2016, 17, 447–456. [Google Scholar] [CrossRef]

- Li, W.; Du, H.; Li, W. Four-wheel electric braking system configuration with new braking torque distribution strategy for improving energy recovery efficiency. IEEE Trans. Intell. Transp. Syst. 2019, 21, 87–103. [Google Scholar] [CrossRef]

- Li, W. Investigation of Advanced Brake-by-Wire Systems for Electric Vehicles. Ph.D. Thesis, University of Wollongong, Wollongong, Australia, 2019. [Google Scholar]

- Chandak, G.A.; Bhole, A.A. A review on regenerative braking in electric vehicle. In Proceedings of the 2017 Innovations in Power and Advanced Computing Technologies (i-PACT), Vellore, India, 21–22 April 2017; pp. 1–5. [Google Scholar]

- Sathishkumar, A.; Soundararajan, R.; Muthu Vel, T.J.; Arjith, M.B.S.; Sakthivel, G. Review on regenerative braking system. In E-Mobility: A New Era in Automotive Technology; Springer: Berlin/Heidelberg, Germany, 2022; pp. 149–163. [Google Scholar]

- Ray, L.R. Nonlinear state and tire force estimation for advanced vehicle control. IEEE Trans. Control Syst. Technol. 1995, 3, 117–124. [Google Scholar] [CrossRef]

- Wei, Z.; Xu, J.; Halim, D. Braking force control strategy for electric vehicles with load variation and wheel slip considerations. IET Electr. Syst. Transp. 2017, 7, 41–47. [Google Scholar] [CrossRef]

- Li, W.; Li, H.; Huang, C.; Xu, K.; Sun, T.; Du, H. Observer-based coordinated control for blended braking system with actuator delay. Actuators 2021, 10, 193. [Google Scholar] [CrossRef]

- Xu, B.; Zhang, L.; Ji, W. Improved Non-Singular Fast Terminal Sliding Mode Control with Disturbance Observer for PMSM Drives. IEEE Trans. Transp. Electrif. 2021, 7, 2753–2762. [Google Scholar] [CrossRef]

- Li, W.; Li, H.; Huang, Z.; Liu, J.; Dang, S.; Du, H. A new braking torque distribution strategy based on braking actuator characteristics and a command signal for a blended braking system. IET Intell. Transp. Syst. 2022, 16, 825–841. [Google Scholar] [CrossRef]

- Wang, C. Research on the Control Strategy of EHB-Motor Compound Braking System for the Electric Vehicle. Ph.D. Thesis, Jilin University, Changchun, China, 2017. [Google Scholar]

- Yang, Z.; Shang, F.; Brown, I.P.; Krishnamurthy, M. Comparative Study of Interior Permanent Magnet, Induction, and Switched Reluctance Motor Drives for EV and HEV Applications. IEEE Trans. Transp. Electrif. 2015, 1, 245–254. [Google Scholar] [CrossRef]

- Yang, Y.; He, Y.; Yang, Z.; Fu, C.; Cong, Z. Torque coordination control of an electro-hydraulic composite brake system during mode switching based on braking intention. Energies 2020, 13, 2031. [Google Scholar] [CrossRef]

| Symbol | Meaning | Values | Unit |

|---|---|---|---|

| Vehicle total mass | 1490 (180 kg for 3 passengers) | kg | |

| Tyre radius | 0.165 | m | |

| Tyre-road friction coefficient | 1 | N/A | |

| Coefficient of wheel rolling resistance | 0.011 | N/A | |

| Coefficient of wheel rolling resistance | N/A | ||

| Air density | 1.225 | kg/m3 | |

| A | Air drag, front area | 2.5 | m2 |

| Air drag coefficient | 0.24 | N/A | |

| Friction coefficient of braking disc | 1 | N/A | |

| Effective radius of friction brake | 0.15 | m | |

| Maximum stroke of the master cylinder | 25 | mm | |

| Cross area of the master cylinder | m2 | ||

| Bulk modulus of the brake fluid | N/A | ||

| Cross area of the wheel cylinder | m2 | ||

| Pad stiffness of the wheel cylinder | N/m | ||

| Brake fluid viscosity | 0.0025 | m2/s | |

| Fluid density | 1000 | kg/m3 | |

| Length of the pipeline | 1 | m | |

| Diameter of the pipeline | 0.008 | m | |

| Delay of the traction motor | 0.025 | s | |

| Pure delay caused by the space between braking rod and braking disc | 0.05 | s |

| Acceleration Pedal Position (%) | Desired Velocity (m/s) |

|---|---|

| 0 | 0 |

| 10 | 0.6 |

| 15 | 1.2 |

| 20 | 1.7 |

| 25 | 2.2 |

| 30 | 2.6 |

| 35 | 3.1 |

| 40 | 3.6 |

| 45 | 4 |

| 50 | 4.3 |

| 55 | 4.4 |

| 60 | 4.6 |

| Brake Pedal Position (%) | Desired Acceleration (m/s2) | Desired Stroke Displacement of Master Cylinder (mm) |

|---|---|---|

| 0 | 0 | 0 |

| −10 | −0.416 | 1.200 |

| −0.418 | 1.232 | |

| −0.420 | 1.248 | |

| −0.432 | 1.264 | |

| −30 | −0.473 | 1.280 |

| −35 | −0.573 | 1.760 |

| −40 | −0.742 | 2.320 |

| −45 | −1.169 | 3.680 |

| −50 | −1.575 | 4.800 |

| −55 | −2.158 | 6.400 |

| −75 | −4.230 | 12.800 |

| −100 | −5.000 | 16.000 |

| Symbol | Meaning | Values | Unit |

|---|---|---|---|

| Pure delay caused by the signal transmission lag | 0.3 | s | |

| First-order delay of the hydraulic brake system | 0.4 | s | |

| P control gain of PI controller of traction motor | 70 | N/A | |

| I control gain of PI controller of traction motor | 2 | N/A | |

| P control gain for PID vehicle velocity controller | 10 | N/A | |

| I control gain for PID vehicle velocity controller | 0.5 | N/A | |

| SMC gain of vehicle velocity controller in acceleration mode | 15 (with estimator) 25 (without estimator) | N/A | |

| SMC gain of vehicle velocity controller in brake mode | 30 | N/A |

| Simulation Test | PID Controller (m/s) | VeloSMC (m/s) | SMC with Estimator (m/s) |

|---|---|---|---|

| 1 | 0.1690 | 0.2406 | 0.2284 |

| 2 | 0.5538 | 0.3786 | 0.4112 |

| 0.1038 | 0.3572 | 0.3092 | |

| 0.5997 | 0.5470 | 0.5466 | |

| 0.6287 | 0.5790 | 0.5788 |

| Simulation Test | PID Controller | SMC | SMC with Estimator |

|---|---|---|---|

| 1 | 0.45 | 0.43 | 0.42 |

| 2 | 0.47 | 0.41 | 0.40 |

| 0.42 | 0.37 | 0.36 | |

| 4 | 0.75 | 0.73 | 0.72 |

| 5 | 0.75 | 0.73 | 0.72 |

| Simulation Test | PID Controller | SMC | SMC with Estimator |

|---|---|---|---|

| 1 | 0.07 | 0.07 | 0.07 |

| 2 | 0.07 | 0.07 | 0.07 |

| 0.20 | 0.11 | 0.11 | |

| 4 | 0.40 | 0.39 | 0.38 |

| 5 | 0.42 | 0.40 | 0.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Li, W.; Hua, W.; Guo, L.; Xing, H.; Tang, H.; Huang, C. The Integrated Disturbance Estimation and Non-Singular Terminal Sliding Mode Longitudinal Motion Controller for Low-Speed Autonomous Electric Vehicles. Sensors 2025, 25, 5799. https://doi.org/10.3390/s25185799

Li B, Li W, Hua W, Guo L, Xing H, Tang H, Huang C. The Integrated Disturbance Estimation and Non-Singular Terminal Sliding Mode Longitudinal Motion Controller for Low-Speed Autonomous Electric Vehicles. Sensors. 2025; 25(18):5799. https://doi.org/10.3390/s25185799

Chicago/Turabian StyleLi, Boyuan, Wenfei Li, Wei Hua, Lei Guo, Haitao Xing, Hangbin Tang, and Chao Huang. 2025. "The Integrated Disturbance Estimation and Non-Singular Terminal Sliding Mode Longitudinal Motion Controller for Low-Speed Autonomous Electric Vehicles" Sensors 25, no. 18: 5799. https://doi.org/10.3390/s25185799

APA StyleLi, B., Li, W., Hua, W., Guo, L., Xing, H., Tang, H., & Huang, C. (2025). The Integrated Disturbance Estimation and Non-Singular Terminal Sliding Mode Longitudinal Motion Controller for Low-Speed Autonomous Electric Vehicles. Sensors, 25(18), 5799. https://doi.org/10.3390/s25185799