Truncated Transfer Matrix-Based Regularization for Impact Force Localization and Reconstruction

Abstract

1. Introduction

2. Theory

2.1. The Dynamics of a Simply Supported Beam Under Impact Forces

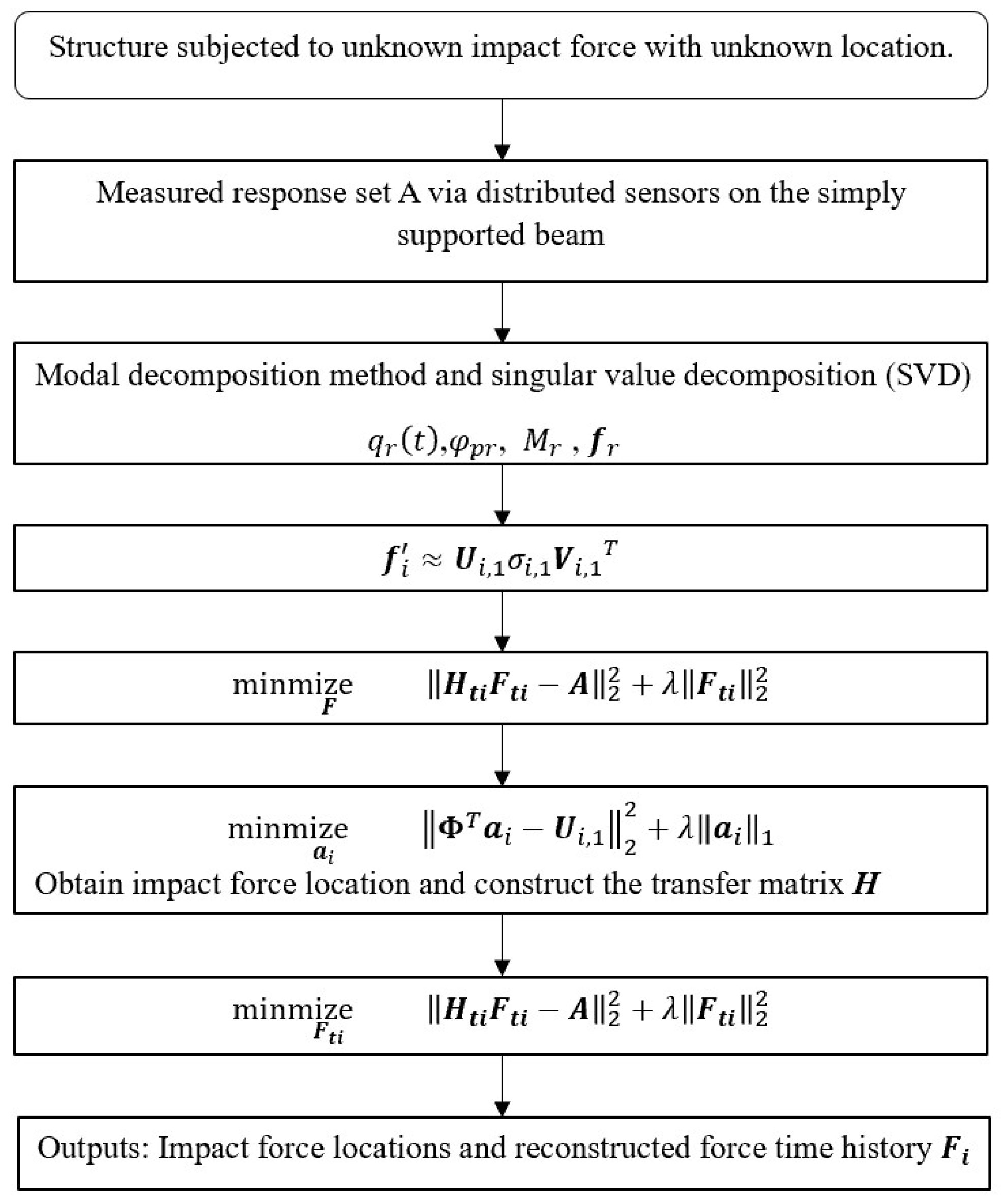

2.2. Force Localization

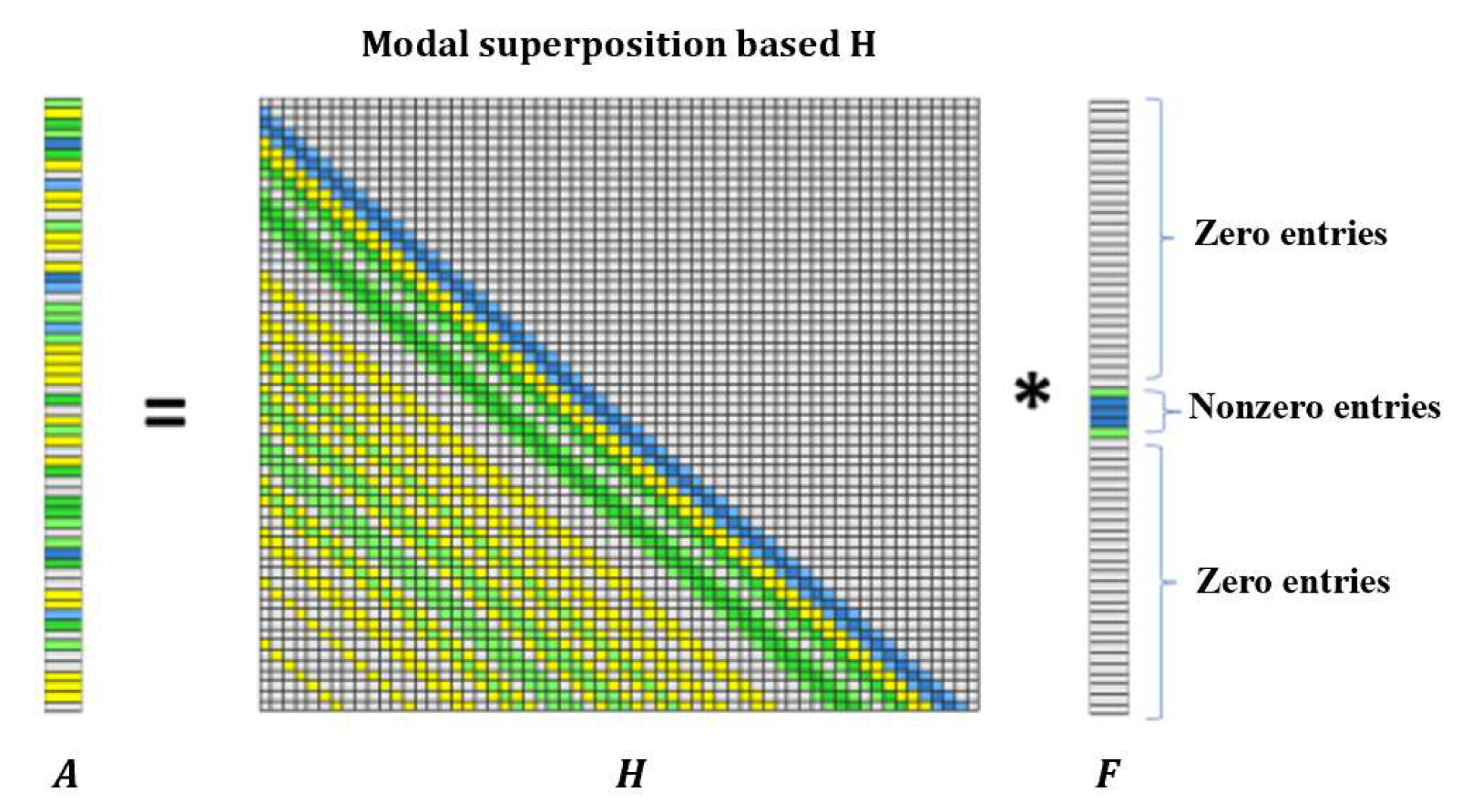

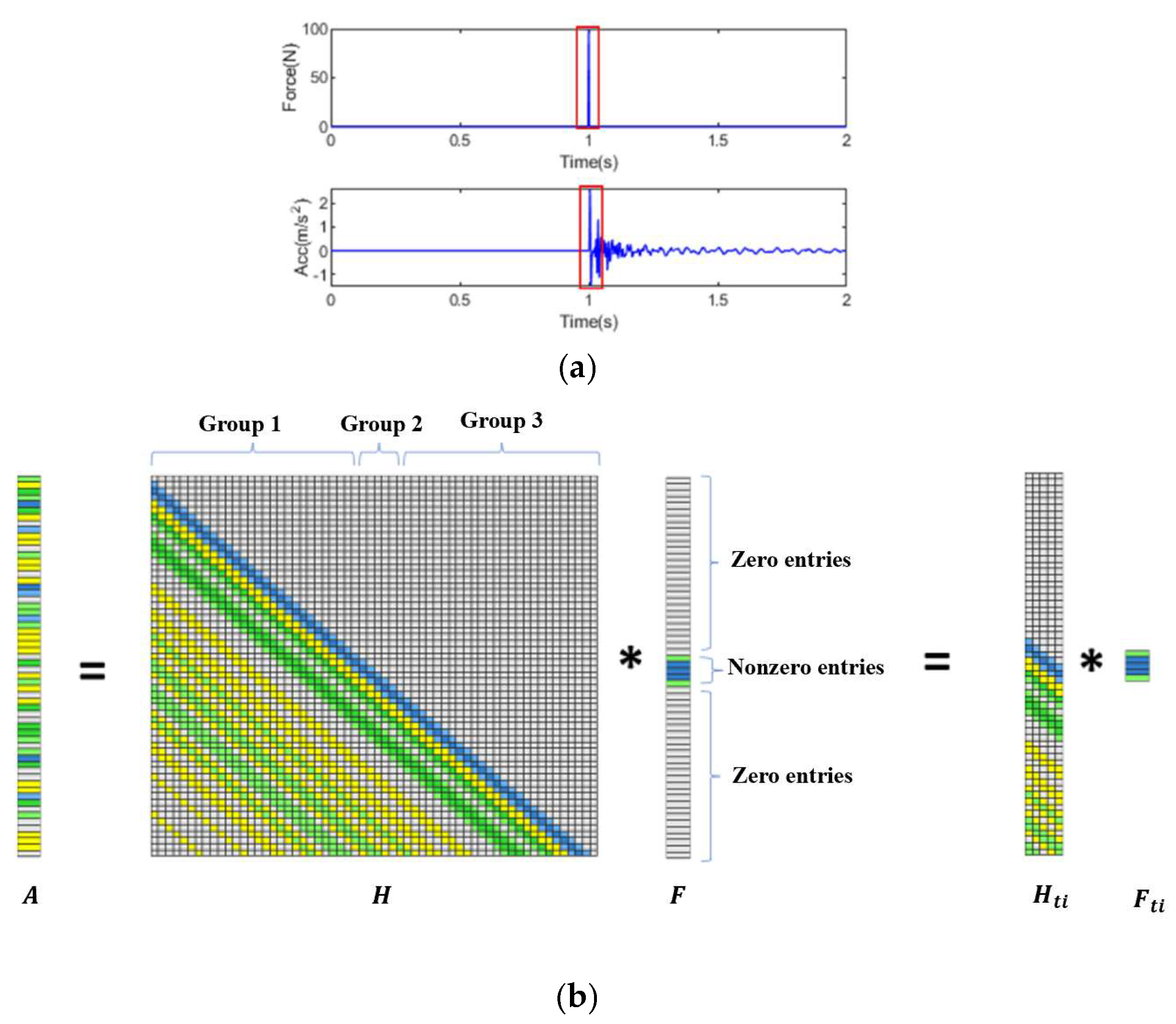

2.3. Truncated Transfer Matrix-Based Regularization Method for Impact Force Identification

2.3.1. Tikhonov Regularization Method

2.3.2. l1-Norm Regularization Method for Impact Force Identification

2.3.3. Truncated Transfer Matrix-Based Regularization Method

2.3.4. Summary

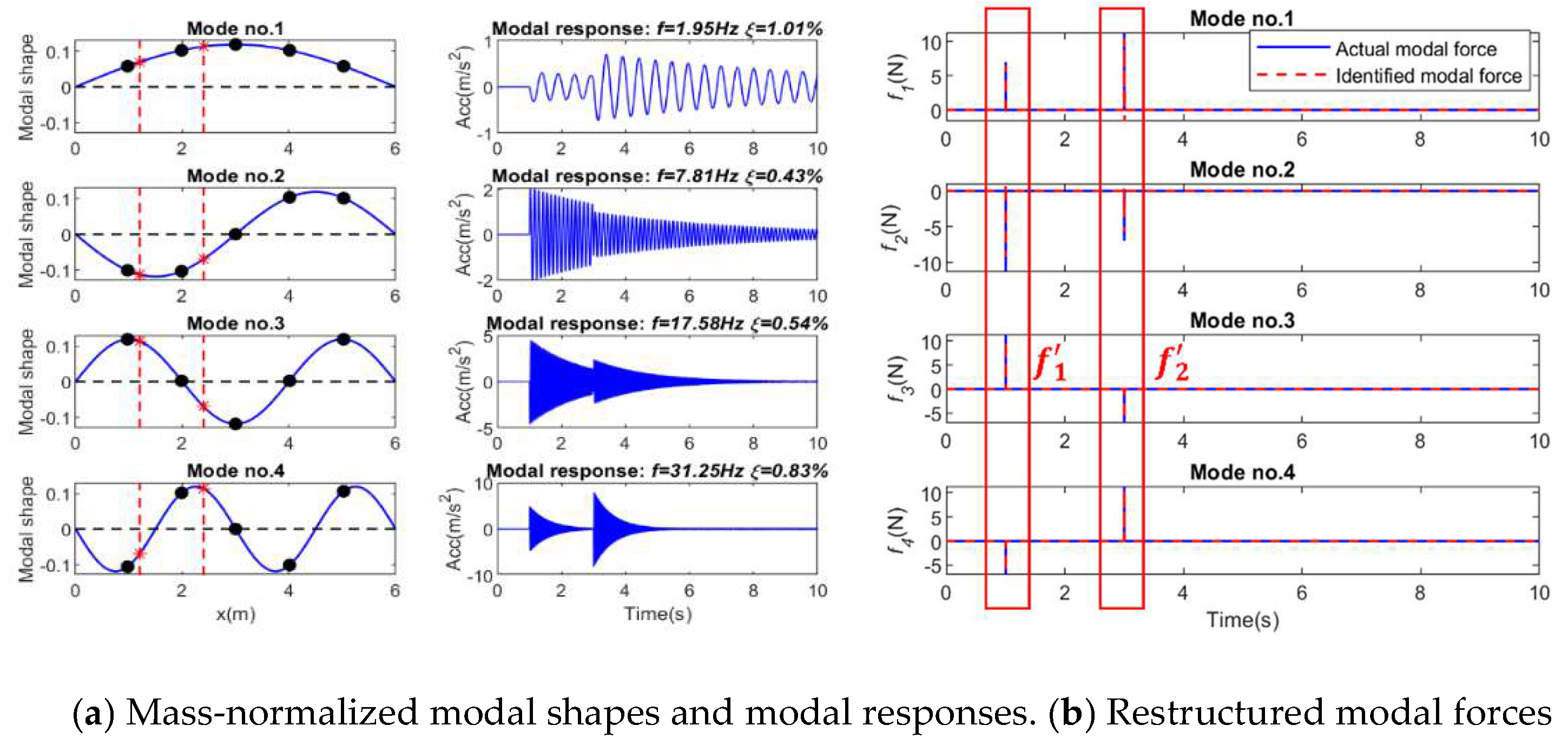

3. Numerical Study

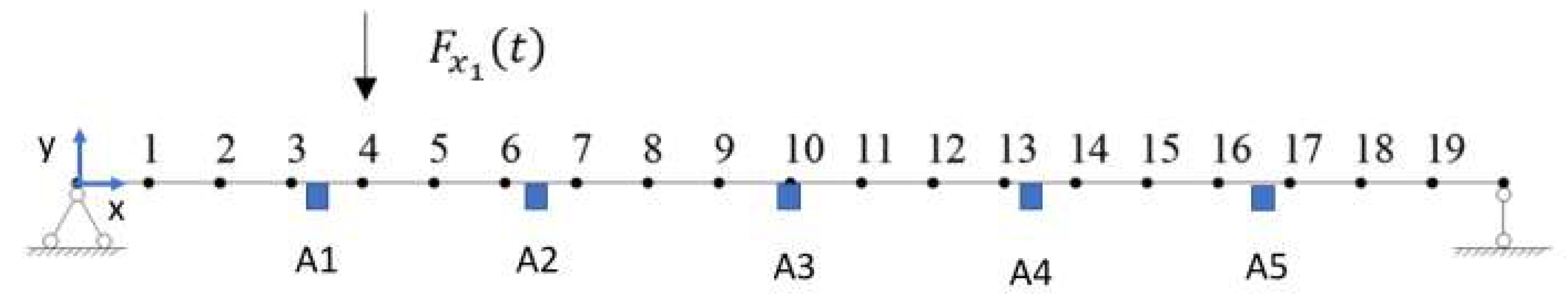

3.1. Numerical Modelling

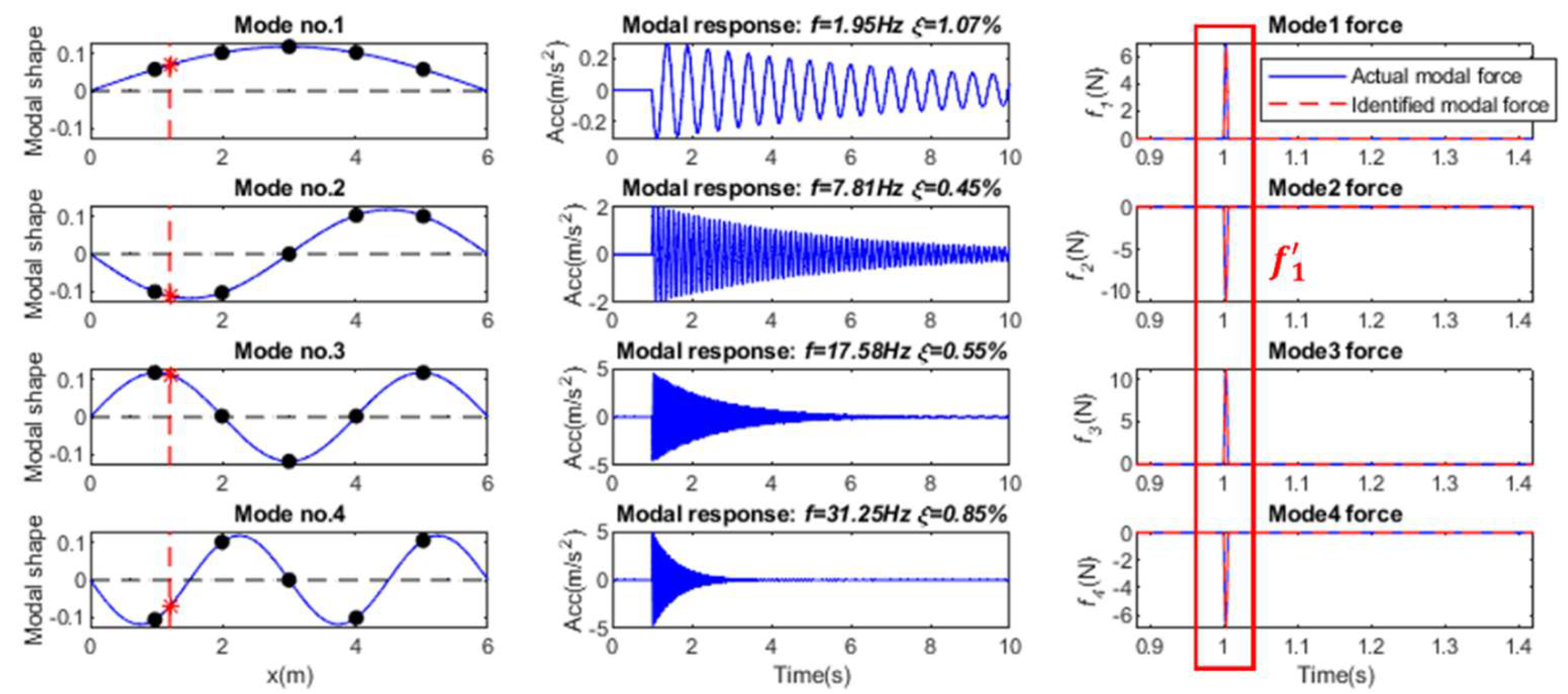

3.2. Single Impact Force Identification

3.2.1. Comparison of Different Regularization Methods

3.2.2. Effect of Measurement Noise

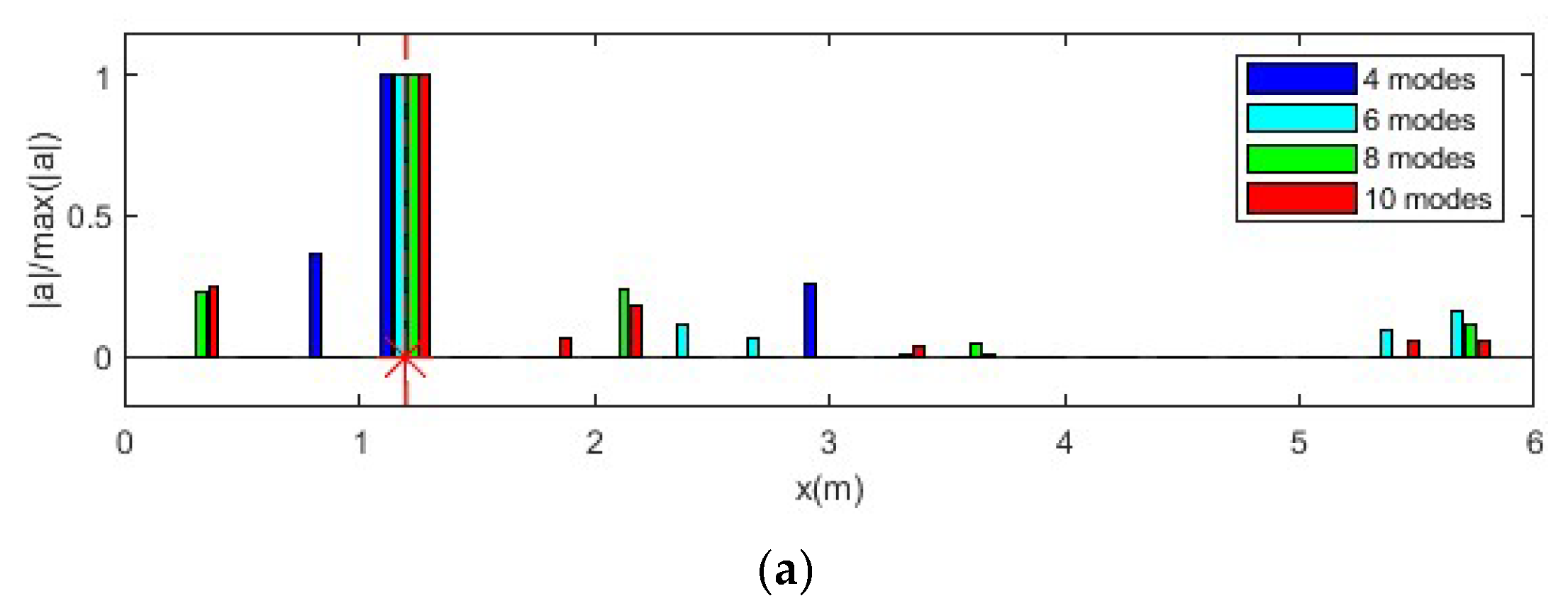

3.2.3. Effect of Number of Modes

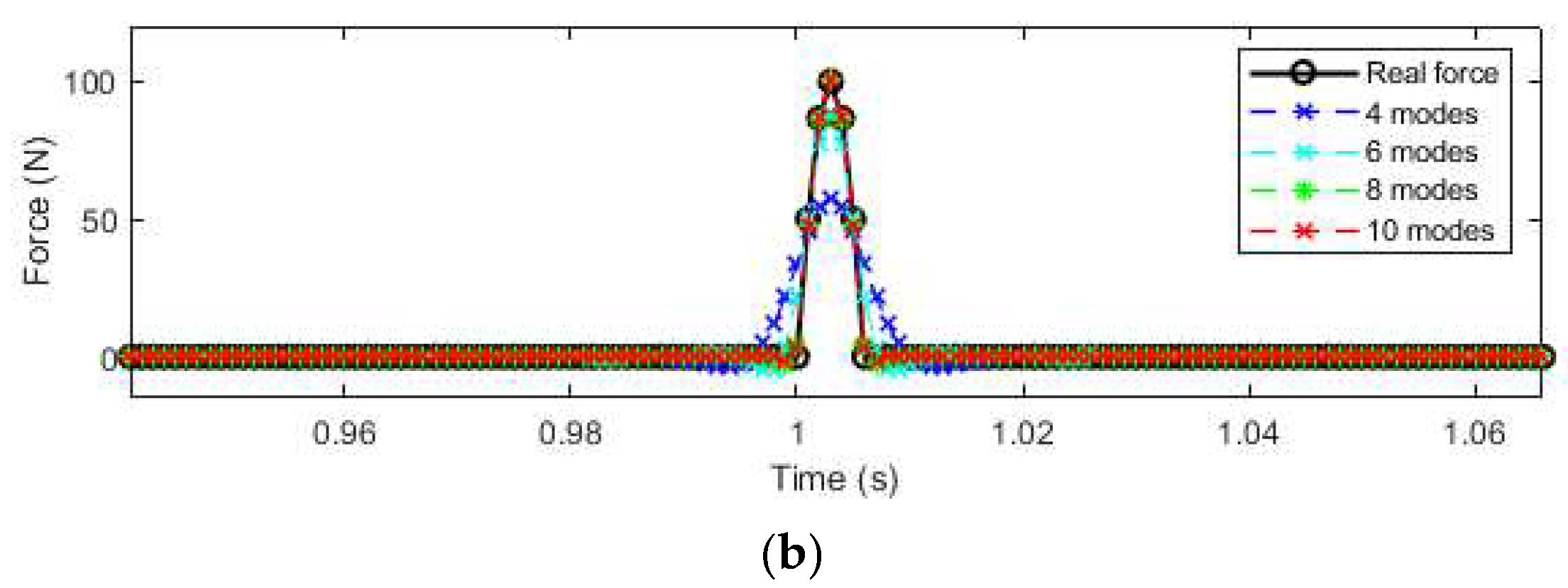

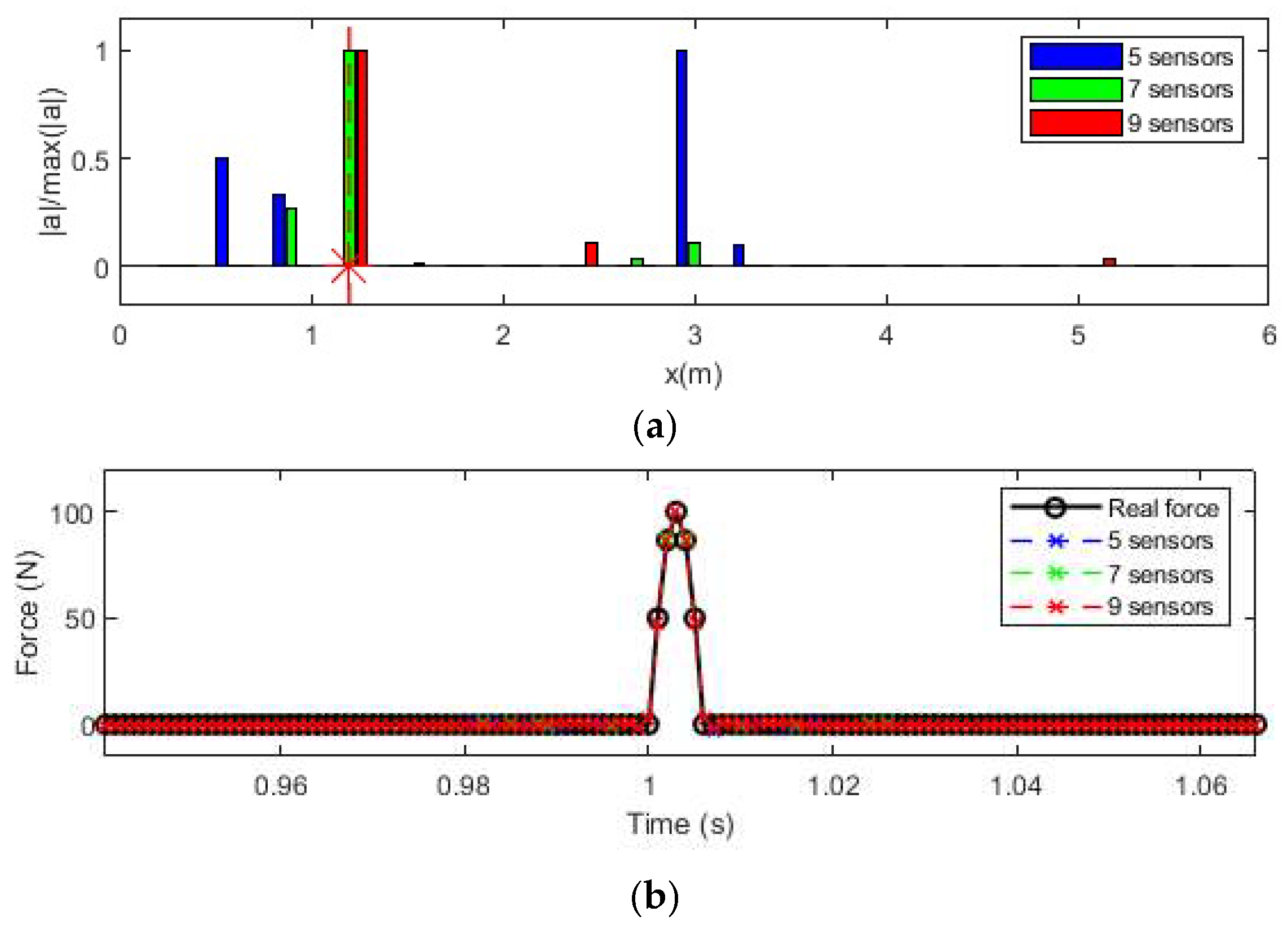

3.2.4. Effect of Number of Sensors

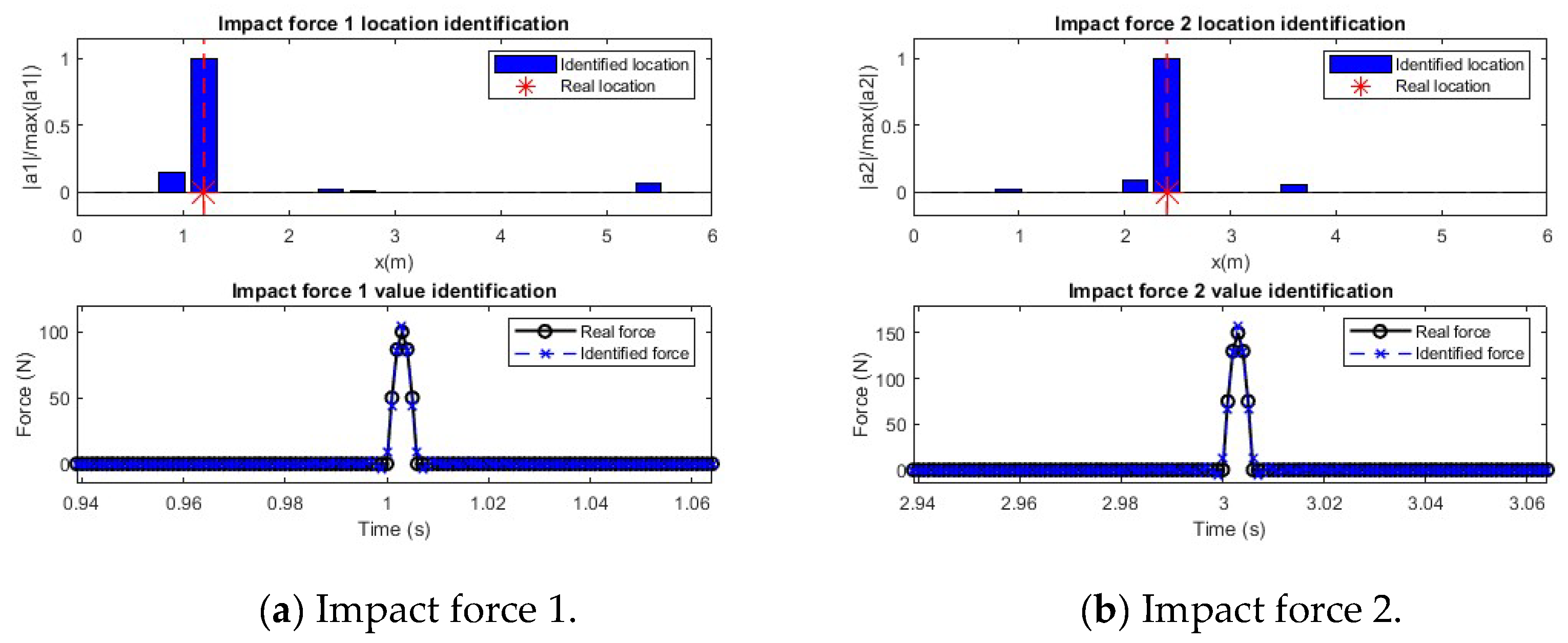

3.3. Multiple Impact Force Identification

4. Experimental Validation

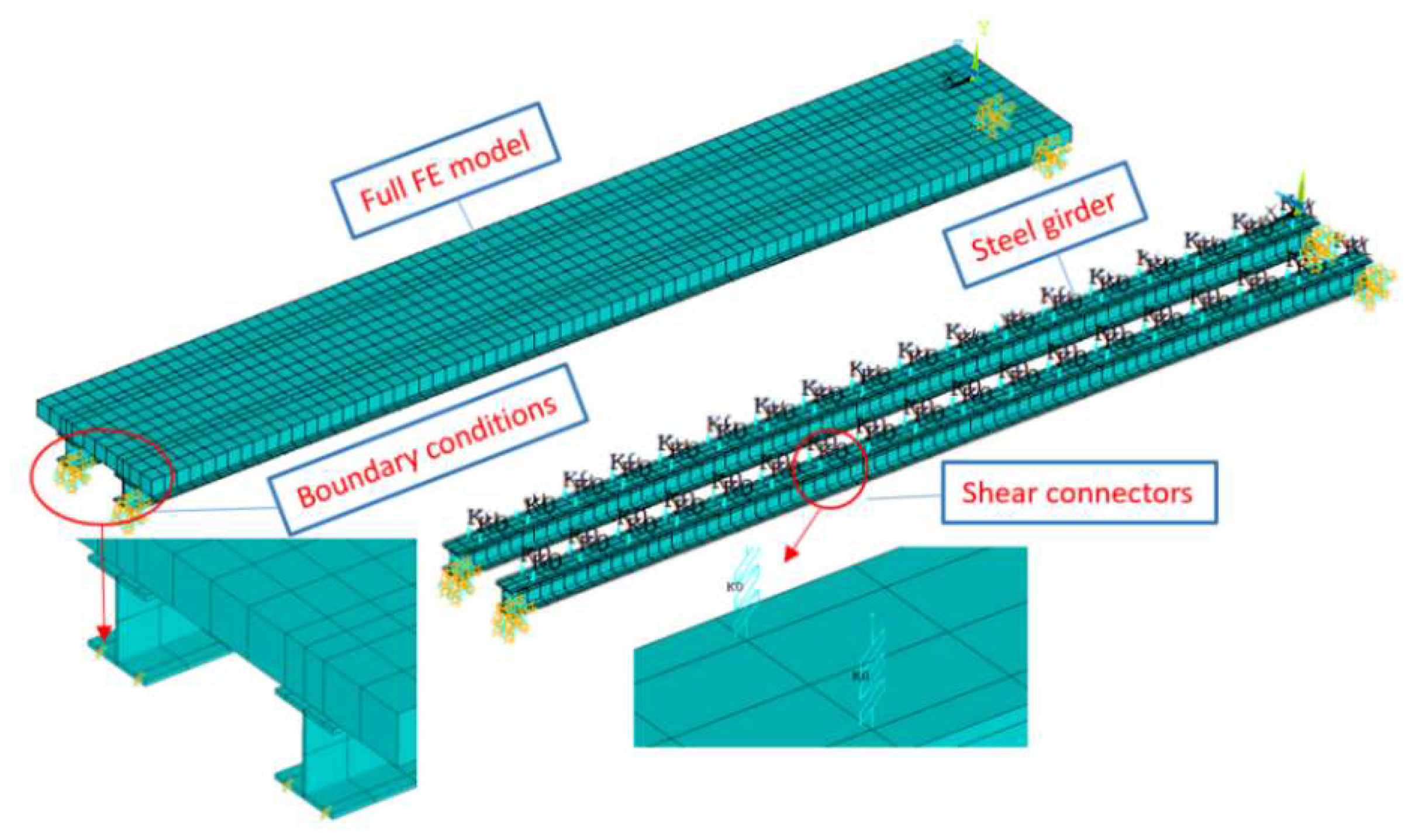

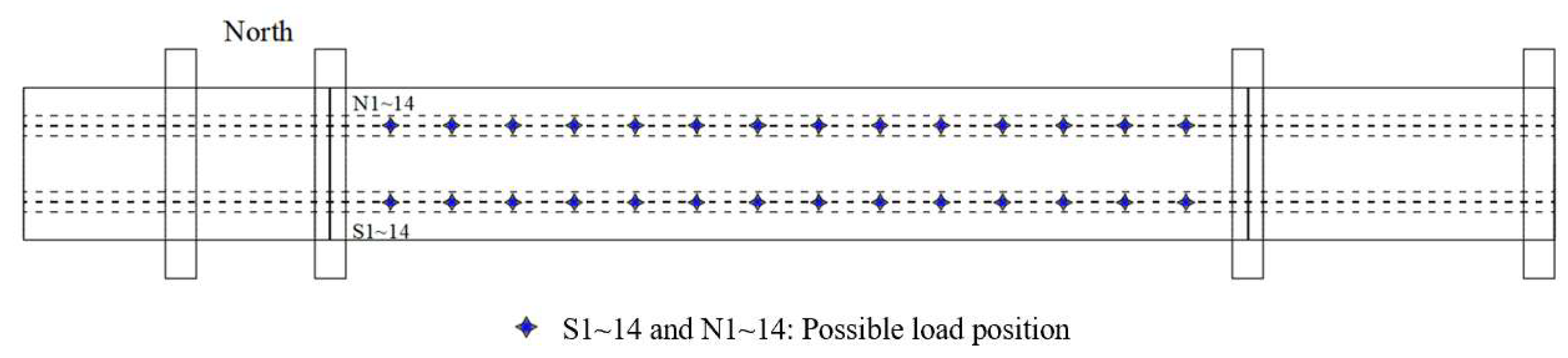

4.1. Experimental Setup

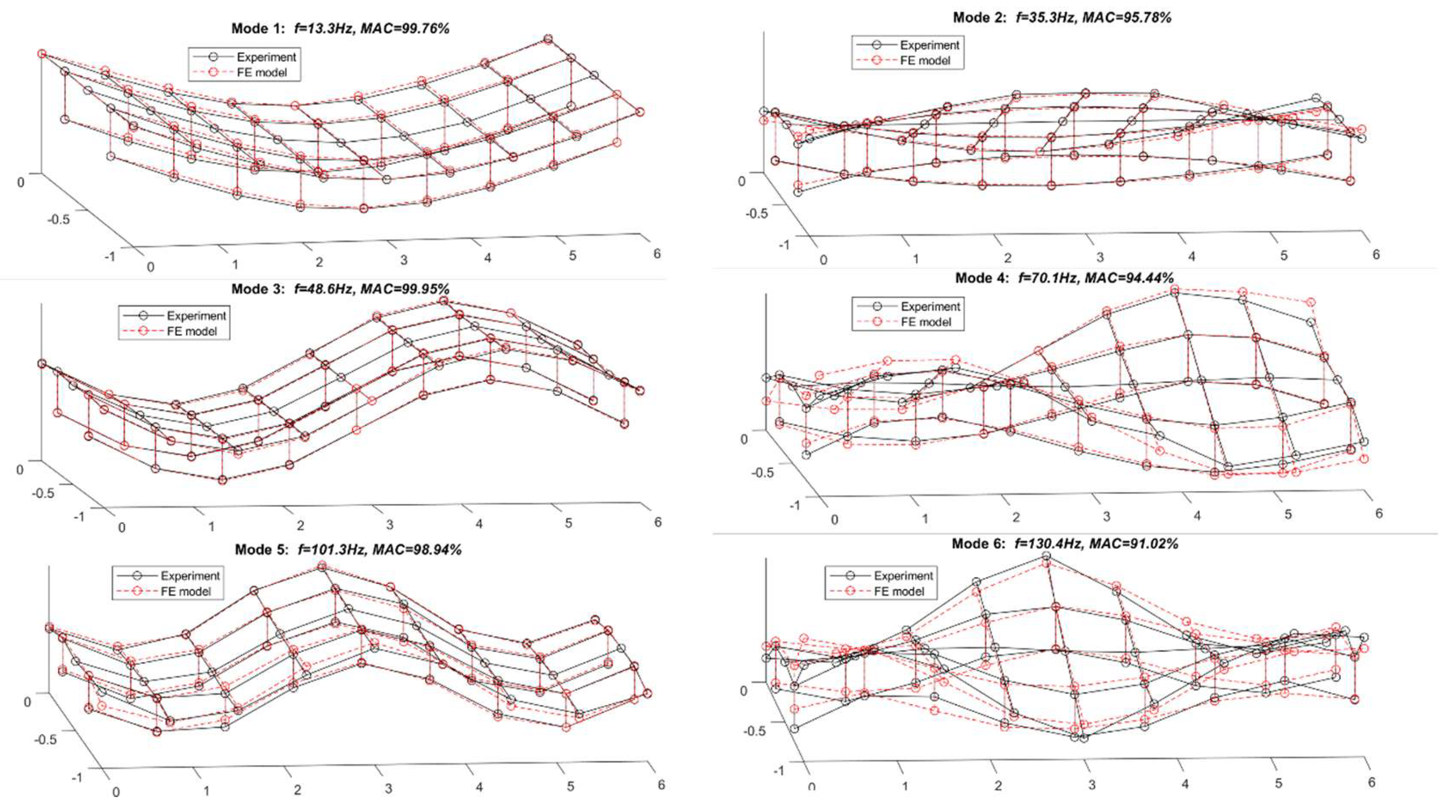

4.2. Finite Element Model Validation

4.3. Impact Force Identification

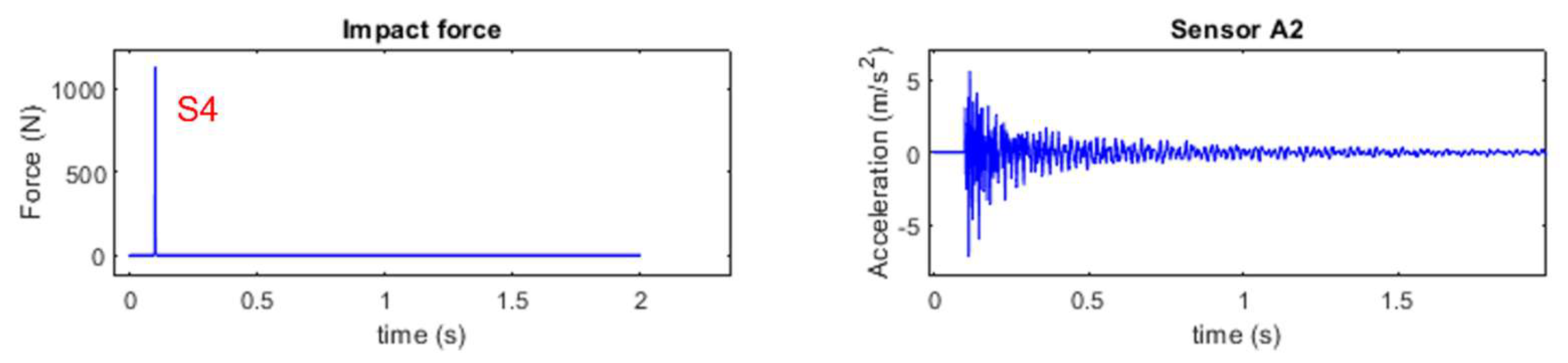

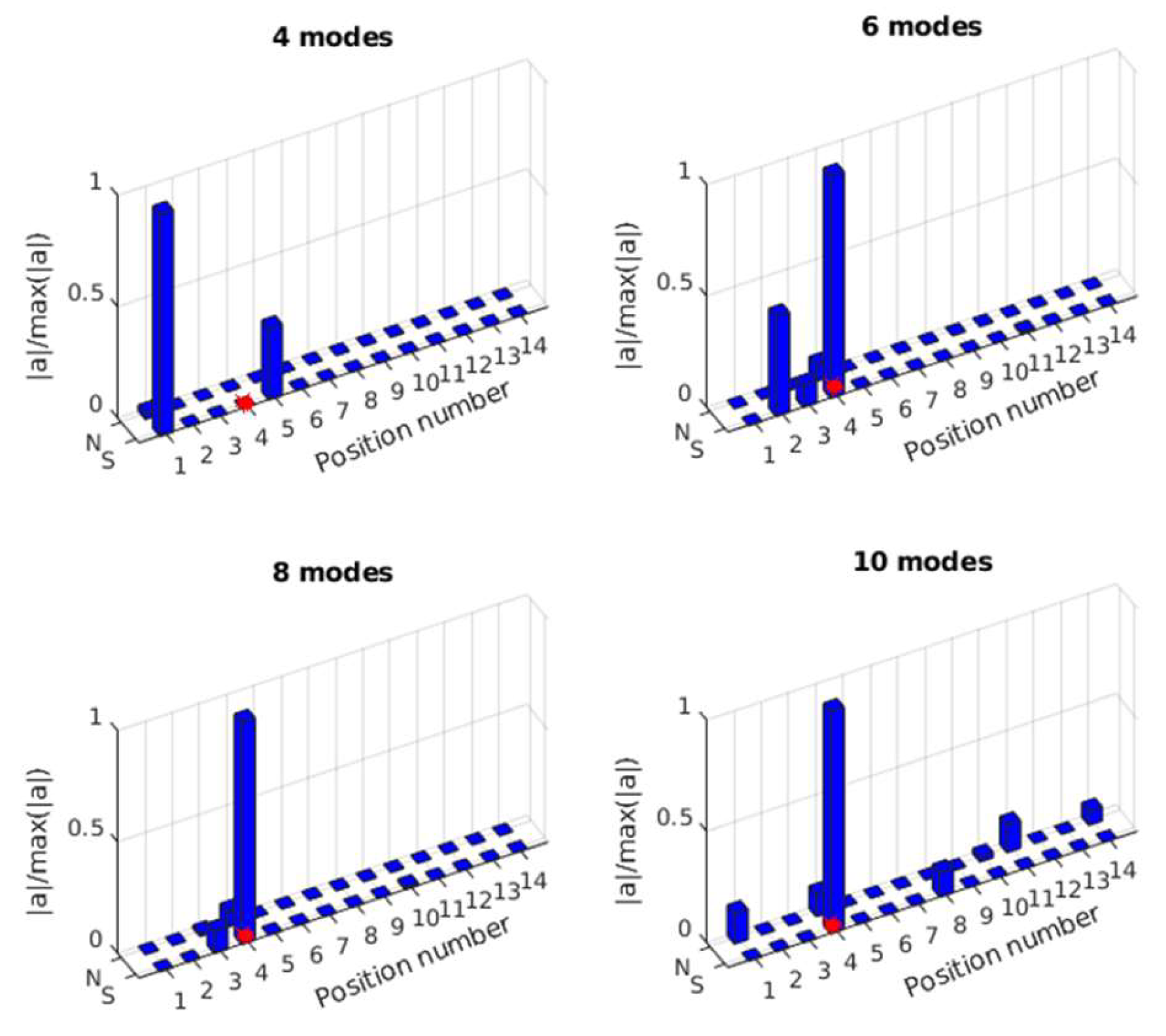

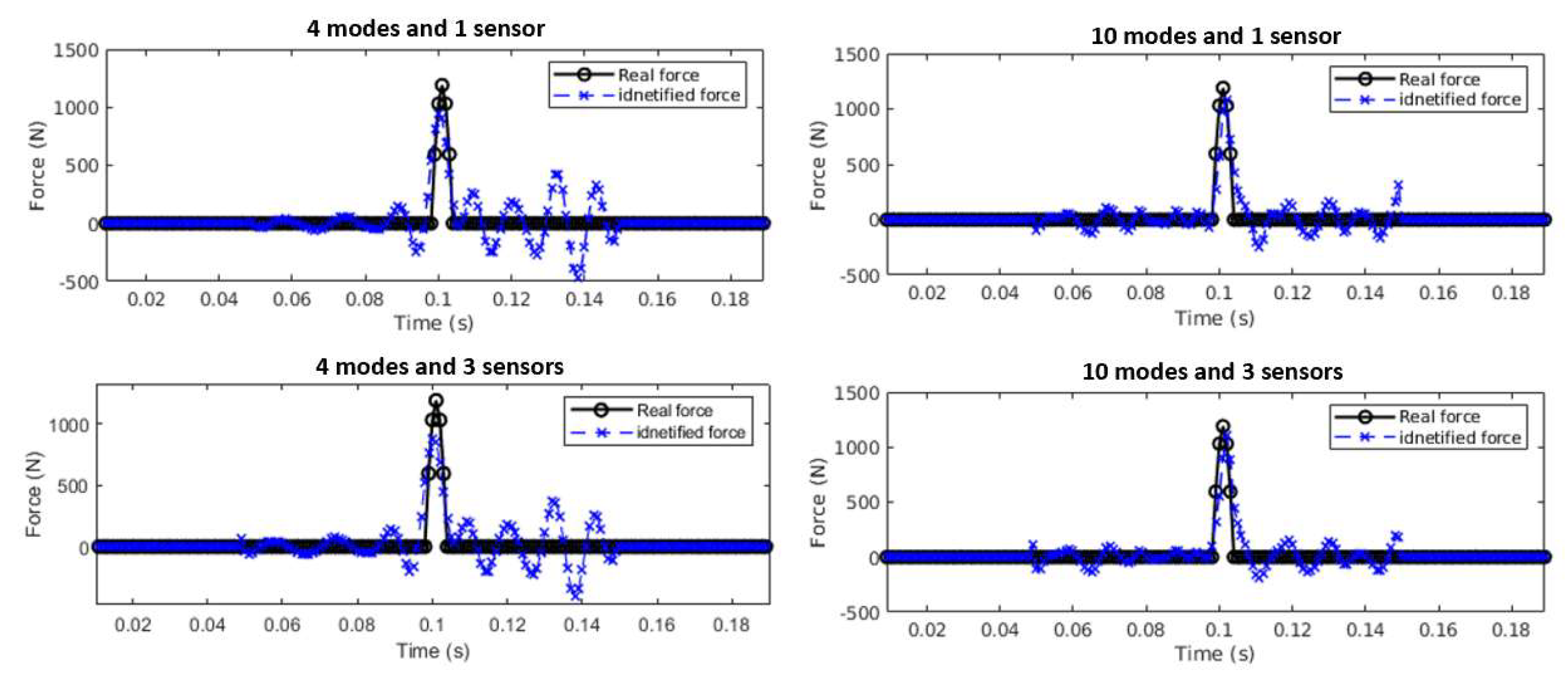

4.3.1. Single Force Identification

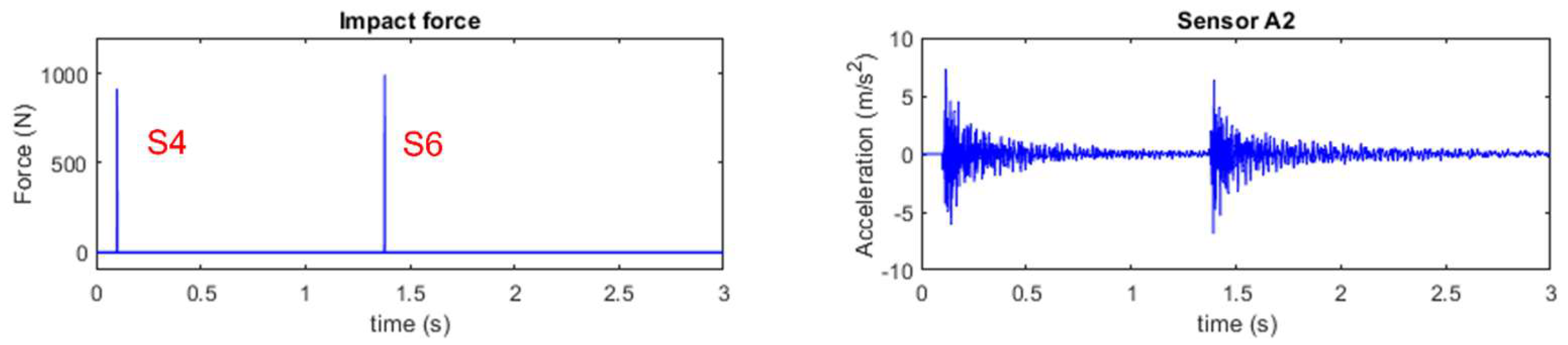

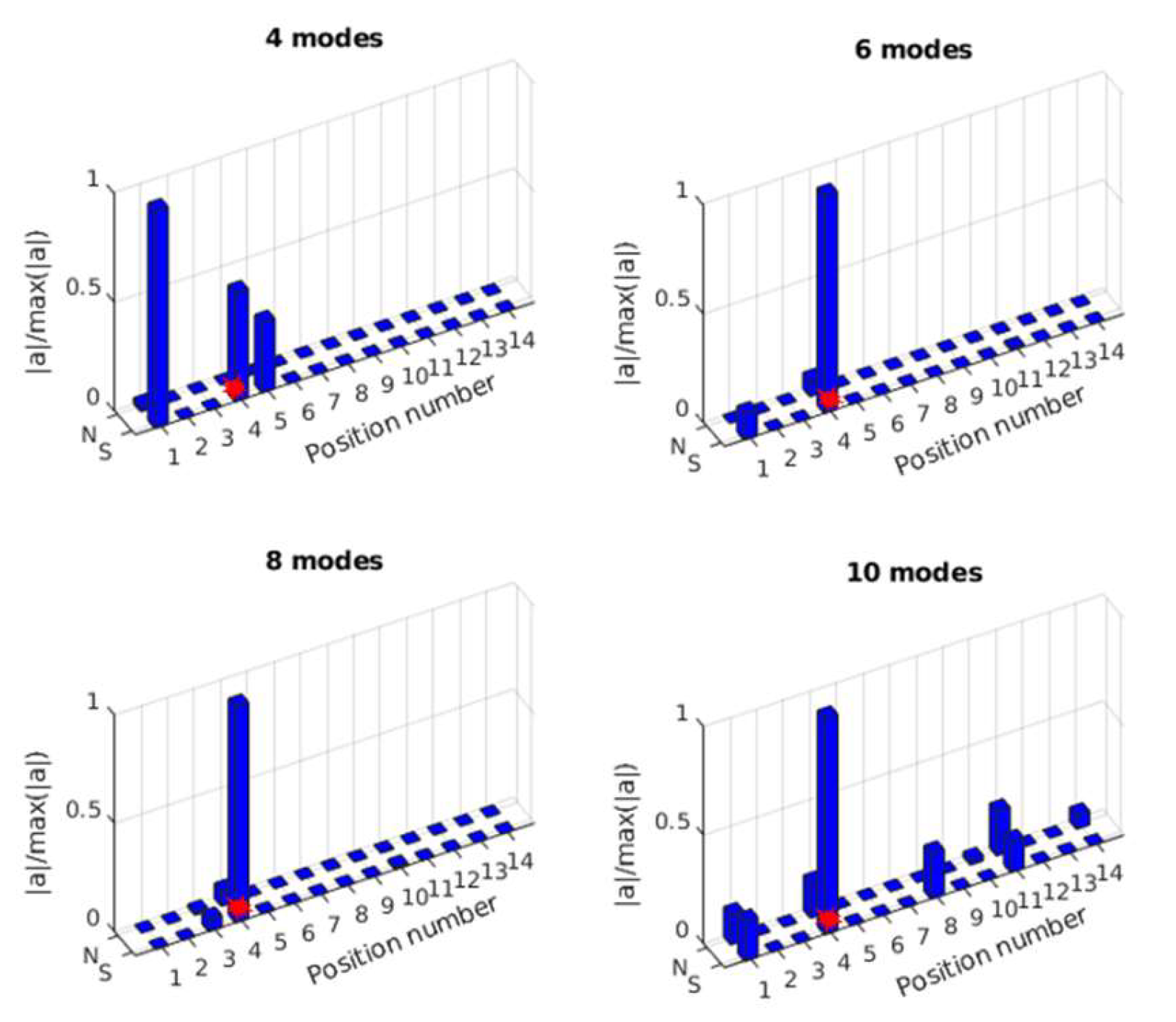

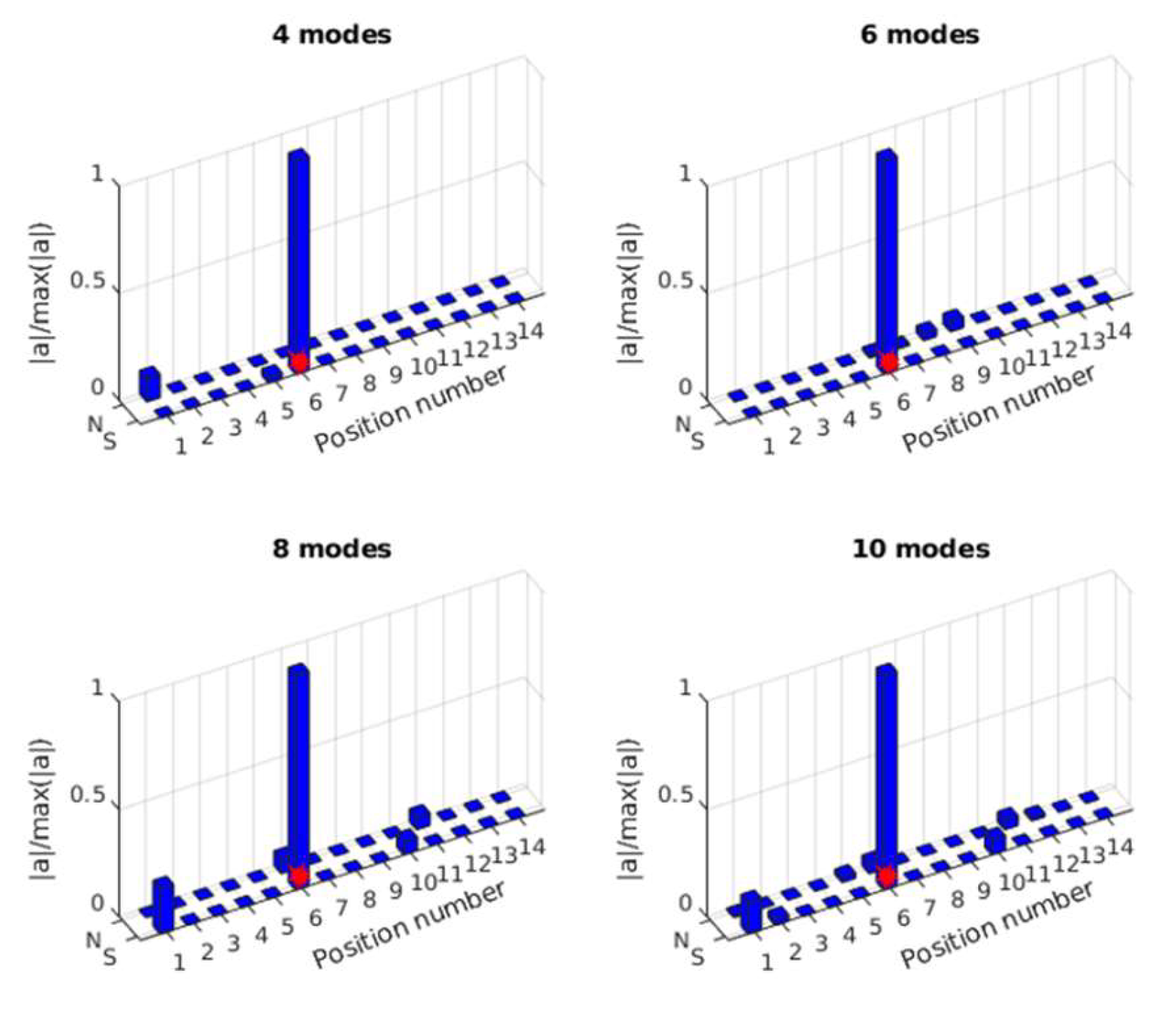

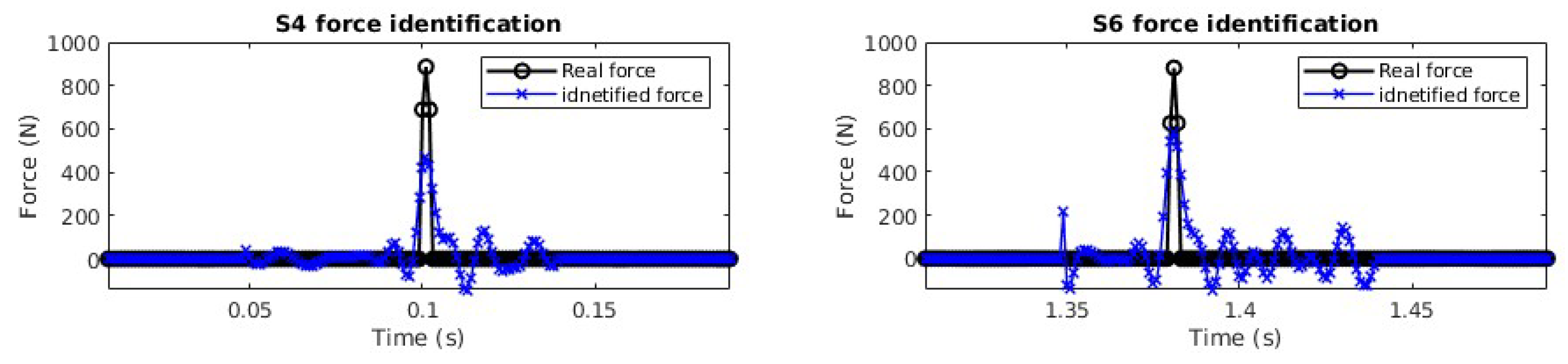

4.3.2. Multiple Force Identification

4.4. Discussion

- (1)

- The numerical results show that the proposed method could accurately localize single and multiple impacts and reconstruct their time history with low computational cost. Increasing the number of modes improves localization accuracy, while the number of sensors primarily influences the reconstructed force amplitude. The proposed method is also very robust to measurement noise.

- (2)

- The numerical and experimental results indicate that using the truncated transfer matrix with an impact time window could dramatically reduce column correlation and noise amplification. Sparse localization in modal coordinates provides reliable indicators of the true impact positions even when only a limited number of modes or sensors are available.

- (3)

- A detailed comparison with existing regularization techniques is shown in Table 4. From this table, it is shown that the existing Tikhonov and sparse regularization methods need the pre-known impact excitation location and use the full transfer matrix. The Tikhonov regularization method provides stable solutions but tends to oversmooth sharp pulses, and it is sensitive to column correlation. Standard sparse l1-norm regularization could improve sparsity but still requires the force location a priori and underestimates peak amplitudes. Group sparse methods incorporate prior knowledge of the force group structure and have been shown to reduce relative errors, but they remain computationally expensive when considering many candidate locations.

- (4)

- The proposed two-step method determines the location from the response data and applies a truncated transfer matrix for reconstruction, achieving high accuracy and efficiency. It could be extended to identity impact forces for large-scale practical structures.

| Methods | Assumptions | Advantages | Limitations |

|---|---|---|---|

| Tikhonov (l2) | Pre-known force location and full transfer matrix | Stable solutions, simple implementation | Oversmooth pulses; sensitive to noise and column correlation |

| Standard sparse (l1) | Pre-known force location and full transfer matrix | Sparse forces; reduces noise amplification | Underestimates peak amplitudes; requires location a priori |

| Proposed two-step method | Unknown location and truncated transfer matrix | Simultaneously localizes and reconstructs; high accuracy and computational efficiency; robust to noise | Requires modal parameters; two-stage implementation |

5. Conclusions

- (1)

- The numerical results show that compared with the classical Tikhonov (l2-norm) and sparse (l1-norm) regularization methods, the proposed method demonstrates superior accuracy and time efficiency in impact force value identification. For single force identification with 5% measurement noise, the relative errors of the identified entire impact force and the identified amplitude based on the proposed method are 6.41% and 1.86%, respectively.

- (2)

- The numerical and experimental results show that the proposed method is very robustness to measurement noise. Its localization accuracy increases with the number of modes, and there is no obvious effect of the number of sensors. The accuracy of the identified impact forces slightly increases with the number of sensors.

- (3)

- Numerical simulations and laboratory experimental studies demonstrated the performance of the proposed method. Further study is needed to extend the proposed method to the impact force identification of practical complex structures. The adaptive parameter selection of the impact time window for the truncated transfer matrix also needs further study. In addition, integrating machine learning techniques with the proposed method will enhance the online identification of impact forces for practical complex civil infrastructures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qiu, Y.Q.; Ji, H.L.; Tao, C.C.; Qiu, J.H. Research on the influence of impact damage on force identification for composite material. Compos. Struct. 2025, 351, 118595. [Google Scholar] [CrossRef]

- Cao, R.; Agrawal, A.K.; El-Tawil, S.; Wong, W. Data filtering in vehicle-bridge impact simulations: Evaluation of different force filtering methods and recommendations. J. Bridg. Eng. ASCE 2021, 26, 04021094. [Google Scholar] [CrossRef]

- Chen, Z.Q.; Guo, Y.; Zhang, T.S.; Li, Y.S.; Li, Z.R.; Zhou, Z.Y.; Huang, X.M.; Jia, Y.S.; Wang, S.Q. Study on vehicle impact force on bridge piers: Impact force simplification and distribution characteristics analysis. Structures 2025, 76, 108933. [Google Scholar] [CrossRef]

- Guo, J.; Liang, Z.J.; Ma, K.J.; Wu, J.Y. Multirate UKF damage identification based on computer vision monitoring of ship-bridge collisions. J. Bridg. Eng. ASCE 2024, 29, 6880. [Google Scholar] [CrossRef]

- Xu, G.J.; Wu, Q.H.; Xue, S.H.; Wang, J.S.; Tang, M.L. Experimental and numerical investigation of fairing countermeasure for tsunami forces on three different types of bridge superstructure. Ocean Eng. 2024, 305, 117888. [Google Scholar] [CrossRef]

- Wang, H.R.; Lu, W.G.; Zhan, W.Q. Dynamic response and damage mechanism of reinforced concrete beam bridges under rockfall impacts. Sci. Rep. 2025, 15, 5090. [Google Scholar] [CrossRef] [PubMed]

- Khanam, S.; Dutt, J.K.; Tandon, N. Impact Force Based Model for Bearing Local Fault Identification. J. Vib. Acoust. ASME 2015, 137, 051002. [Google Scholar] [CrossRef]

- Zhang, S.F.; Ni, P.H.; Wen, J.N.; Han, Q.; Du, X.L.; Xu, K. Non-contact impact load identification based on intelligent visual sensing technology. Struct. Heal. Monit. 2024, 23, 3525–3544. [Google Scholar] [CrossRef]

- Li, Y.X.; Luo, L.X.; Wang, X.Y.; Zhou, X.Q.; Sun, L.M.; Xia, Y. State-of-art review on load identification and response reconstruction to realize digital twin of infrastructure. Adv. Struct. Eng. 2025, 28, 1731–1765. [Google Scholar] [CrossRef]

- Jia, Y.; Yang, Z.; Song, Q. Experimental study of random dynamic loads identification based on weighted regularization method. J. Sound Vib. 2015, 342, 113–123. [Google Scholar] [CrossRef]

- LeClerc, J.R.; Worden, K.; Staszewski, W.J.; Haywood, J. Impact detection in an aircraft composite panel—A neural-network approach. J. Sound Vib. 2007, 299, 672–682. [Google Scholar] [CrossRef]

- Park, J.; Ha, S.; Chang, F.-K. Monitoring Impact Events Using a System-Identification Method. AIAA J. 2009, 47, 2011–2021. [Google Scholar] [CrossRef]

- Rashidi, M.; Tashakori, S.; Kalhori, H.; Bahmanpour, M.; Li, B. Iterative-Based Impact Force Identification on a Bridge Concrete Deck. Sensors 2023, 23, 9257. [Google Scholar] [CrossRef]

- Kalhori, H.; Tashakori, S.; Halkon, B.; Alamdari, M.M.; Li, B.; Saberi, M. Advances in impact force identification: A comprehensive review techniques and mathematical innovations. Results Eng. 2025, 26, 105568. [Google Scholar] [CrossRef]

- Zhu, X.; Law, S. Moving loads identification through regularization. J. Eng. Mech. ASCE 2002, 128, 989–1000. [Google Scholar] [CrossRef]

- Jacquelin, E.; Bennani, A.; Hamelin, P. Force reconstruction: Analysis and regularization of a deconvolution problem. J. Sound Vib. 2003, 265, 81–107. [Google Scholar] [CrossRef]

- Kalhori, H.; Alamdari, M.M.; Ye, L. Automated algorithm for impact force identification using cosine similarity searching. Measurement 2018, 122, 648–657. [Google Scholar] [CrossRef]

- Thite, A.N.; Thompson, D.J. The quantification of structure-borne transmission paths by inverse methods. Part 2: Use of regularization techniques. J. Sound Vib. 2003, 264, 433–451. [Google Scholar]

- Jayalakshmi, V.; Lakshmi, K.; Rao, A.R.M. Dynamic force reconstruction techniques from incomplete measurements. J. Vib. Control. 2018, 24, 5321–5344. [Google Scholar] [CrossRef]

- Pourzeynall, S.; Zhu, X.Q.; Zadeh, A.G.; Rashidi, M.; Samali, B. Comprehensive study of moving load identification on bridge structures using the explicit form of Newmark-β method: Numerical and experimental studies. Remote Sens. 2021, 13, 2291. [Google Scholar] [CrossRef]

- Qiao, B.; Zhang, X.; Gao, J.; Chen, X. Impact-force sparse reconstruction from highly incomplete and inaccurate measurements. J. Sound Vib. 2016, 376, 72–94. [Google Scholar] [CrossRef]

- Liu, J.; Qiao, B.; Wang, Y.; He, W.; Chen, X. Identification of Time-Varying External Force Using Group Sparse Regularization and Redundant Dictionary. Sensors 2023, 23, 151. [Google Scholar] [CrossRef]

- Huang, W.; Tao, C.; Ji, H.; Qiu, J. Enhancement of Wave Energy Dissipation in Two-Dimensional Acoustic Black Hole by Simultaneous Optimization of Profile and Damping Layer. J. Sound Vib. 2021, 491, 115764. [Google Scholar] [CrossRef]

- Samagassi, S.; Khamlichi, A.; Driouach, A.; Jacquelin, E. Reconstruction of multiple impact forces by wavelet relevance vector machine approach. J. Sound Vib. 2015, 359, 56–67. [Google Scholar] [CrossRef]

- Qiao, B.; Liu, J.; Liu, J.; Yang, Z.; Chen, X. An enhanced sparse regularization method for impact force identification. Mech. Syst. Signal Process. 2019, 126, 341–367. [Google Scholar] [CrossRef]

- Qiao, B.; Mao, Z.; Liu, J.; Zhao, Z.; Chen, X. Group sparse regularization for impact force identification in time domain. J. Sound Vib. 2019, 445, 44–63. [Google Scholar] [CrossRef]

- Liu, J.; Qiao, B.; He, W.; Yang, Z.; Chen, X. Impact force identification via sparse regularization with generalized minimax-concave penalty. J. Sound Vib. 2020, 484, 115530. [Google Scholar] [CrossRef]

- Zhong, J.; Liu, H.; Yu, L. Sparse regularization for traffic load monitoring using bridge response measurements. Measurement 2019, 131, 173–182. [Google Scholar] [CrossRef]

- Pan, C.D.; Yu, L.; Liu, H.-L.; Chen, Z.-P.; Luo, W.-F. Moving force identification based on redundant concatenated dictionary and weighted l 1 -norm regularization. Mech. Syst. Signal Process. 2018, 98, 32–49. [Google Scholar] [CrossRef]

- Qiao, B.; Ao, C.; Mao, Z.; Chen, X. Non-convex sparse regularization for impact force identification. J. Sound Vib. 2020, 477, 115311. [Google Scholar] [CrossRef]

- Liu, J.; Qiao, B.; Chen, Y.; Zhu, Y.; He, W.; Chen, X. Impact force reconstruction and localization using nonconvex overlapping group sparsity. Mech. Syst. Signal Process. 2022, 162, 107983. [Google Scholar] [CrossRef]

- Wang, B.T.; Chiu, C.-H. Determination of Unknown Impact Force Acting on a Simply Supported Beam. Mech. Syst. Signal Process. 2003, 17, 683–704. [Google Scholar] [CrossRef]

- Li, Q.; Lu, Q. Impact localization and identification under a constrained optimization scheme. J. Sound Vib. 2016, 366, 133–148. [Google Scholar] [CrossRef]

- Wambacq, J.; Maes, K.; Rezayat, A.; Guillaume, P.; Lombaert, G. Localization of dynamic forces on structures with an interior point method using group sparsity. Mech. Syst. Signal Process. 2019, 115, 593–606. [Google Scholar] [CrossRef]

- Feng, W.; Li, Q.; Lu, Q.; Li, C.; Wang, B. Group Relevance Vector Machine for sparse force localization and reconstruction. Mech. Syst. Signal Process. 2021, 161, 107900. [Google Scholar] [CrossRef]

- Yu, Z.X.; Xu, C.; Sun, J.Y.; Du, F. Impact localization and force reconstruction for composite plates based on virtual time reversal processing with time-domain spectral finite element method. Struct. Health Monit. 2023, 22, 4149–4170. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, M.Y.; Hong, L.; Wang, Z.C.; Zhou, Z.D.; Liao, W.L. An efficient impact force identification methodology via a single sensor utilizing the concept of generalized transmissibility. Mech. Syst. Signal Process. 2024, 211, 111222. [Google Scholar] [CrossRef]

- Xiao, D.; Sharif-Khodaei, Z.; Aliabadi, M.H. Impact force identification for composite structures using adaptive wavelet-regularised deconvolution. Mech. Syst. Signal Process. 2024, 220, 111608. [Google Scholar] [CrossRef]

- Li, Y.F.; Meng, J.L.; Xie, H.Y.; Su, Y.B.; Liu, S.M.; Pan, W.H.; Xie, S.L.; Luo, Y.J.; Zhang, Y.H. A fast impact force identification method via constructing a dynamic reduced dictionary. Mech. Syst. Signal Process. 2025, 224, 111995. [Google Scholar] [CrossRef]

| l2-Norm | l1-Norm | TML2 | ||||||

|---|---|---|---|---|---|---|---|---|

| RE (%) | PRE (%) | Time (s) | RE (%) | PRE (%) | Time (s) | RE (%) | PRE (%) | Time (s) |

| 30.45 | 12.39 | 24.73 | 142.54 | 258.77 | 335.51 | 6.41 | 1.86 | 1.04 |

| Noise Level | Number of Modes | Number of Sensors | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1% | 5% | 10% | 4 | 6 | 8 | 10 | 5 | 7 | 9 | |

| RE (%) | 1.02 | 1.19 | 1.82 | 136.79 | 20.45 | 6.88 | 1.19 | 1.25 | 1.22 | 1.19 |

| PRE (%) | 1.02 | 1.19 | 1.82 | 39.98 | 12.86 | 2.34 | 1.18 | 1.18 | 1.17 | 1.17 |

| Mode No. | Description | Modal Frequency (Hz) | Error | MAC | |

|---|---|---|---|---|---|

| Experiment | FE Model | ||||

| 1 | 1st bending | 13.3 | 13.44 | 1.05% | 0.9976 |

| 2 | 1st torsion | 35.3 | 34.92 | −1.08% | 0.9578 |

| 3 | 2nd bending | 48.6 | 48.37 | −0.47% | 0.9995 |

| 4 | 2nd torsion | 82.7 | 80.72 | −2.39% | 0.9444 |

| 5 | 3rd bending | 101.3 | 99.63 | −1.65% | 0.9894 |

| 6 | 3rd torsion | 130.4 | 127.11 | −2.52% | 0.9102 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Zhu, X.; Li, J. Truncated Transfer Matrix-Based Regularization for Impact Force Localization and Reconstruction. Sensors 2025, 25, 5712. https://doi.org/10.3390/s25185712

Zhang B, Zhu X, Li J. Truncated Transfer Matrix-Based Regularization for Impact Force Localization and Reconstruction. Sensors. 2025; 25(18):5712. https://doi.org/10.3390/s25185712

Chicago/Turabian StyleZhang, Bing, Xinqun Zhu, and Jianchun Li. 2025. "Truncated Transfer Matrix-Based Regularization for Impact Force Localization and Reconstruction" Sensors 25, no. 18: 5712. https://doi.org/10.3390/s25185712

APA StyleZhang, B., Zhu, X., & Li, J. (2025). Truncated Transfer Matrix-Based Regularization for Impact Force Localization and Reconstruction. Sensors, 25(18), 5712. https://doi.org/10.3390/s25185712