Development and Validation of a Low-Cost Arduino-Based Lee Disc System for Thermal Conductivity Analysis of Sustainable Roofing Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

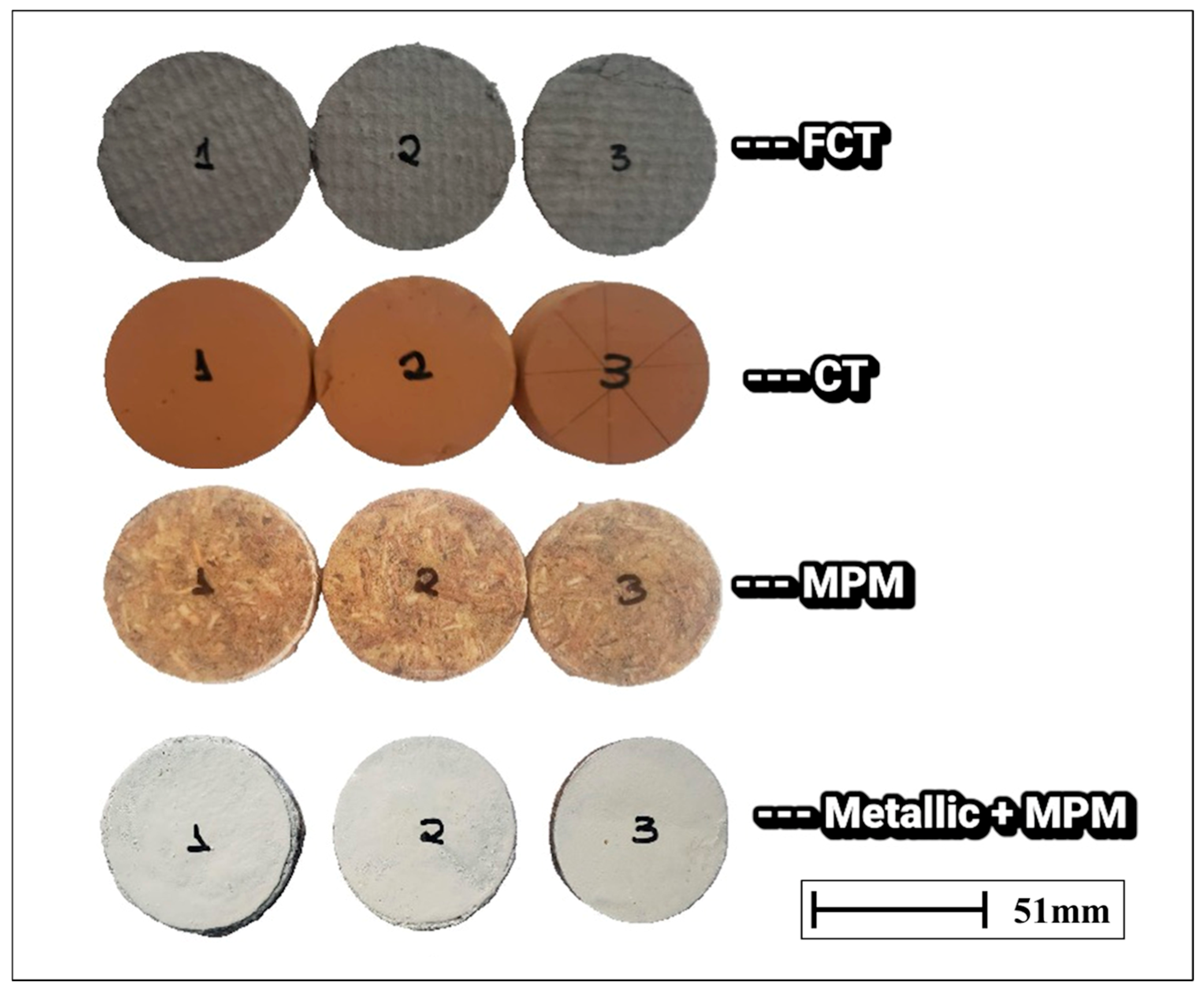

- Fiber Cement Tile (FCT): Samples purchased from the manufacturer Eternit S.A., standard corrugated model “Eternit Bigfort 6 mm”, in accordance with ABNT NBR 15575 [29]. The measured dimensions were 2.20 m long, 1.20 m wide, and 5 mm thick. The average density was approximately 1800 kg·m−3, and the nominal thermal conductivity provided by the manufacturer is 0.80 W·m−1·K−1.

- Ceramic Tile (CT): Commercial colonial-type samples provided by Cerâmica Ananindeua Ltd.a., identified as model “Colonial 40 × 23 cm”, also in accordance with ABNT NBR 15575 [29]. The measured dimensions were 0.401 m × 0.233 m × 0.010 m (length × width × thickness). The average density was 1500 kg·m−3, and the thermal conductivity was estimated between 0.70 and 1.05 W·m−1·K−1, according to the literature and manufacturer’s specifications.

- Galvanized Metal Tile (TG): Trapezoidal sheets of the TP-25 profile, supplied by Brasilit S.A., with dimensions of 1.80 m × 1.00 m and a thickness of 0.84 mm, confirmed with a digital caliper (accuracy 0.01 mm). Due to the high thermal conductivity of galvanized steel (≈52 W·m−1·K−1), this type of tile is usually used in conjunction with insulating materials, which was considered in subsequent analyses.

- Polyurethane/Miriti Fiber (MPM): A bi-component castor oil-based polyurethane system (IMPERVEG® AGT 1315) reinforced with miriti palm fibers (Mauritia flexuosa), applied in the form of an insulating blanket. A fiber mass fraction of 10% was adopted, based on recent studies [33,35]. This sample was tested independently, in order to evaluate the intrinsic thermal behavior of the composite material.

- Metallic + MPM: Galvanized metal roofing sheets (TP-25 profile, supplied by Brasilit S.A.) coated on the inner surface with the polyurethane/miriti fiber composite described above. This hybrid condition was created to reduce the high thermal conductivity of bare metallic tiles (≈52 W·m−1·K−1) and represents a practical configuration for real roofing applications.

2.1.1. Insulation and Composite Materials

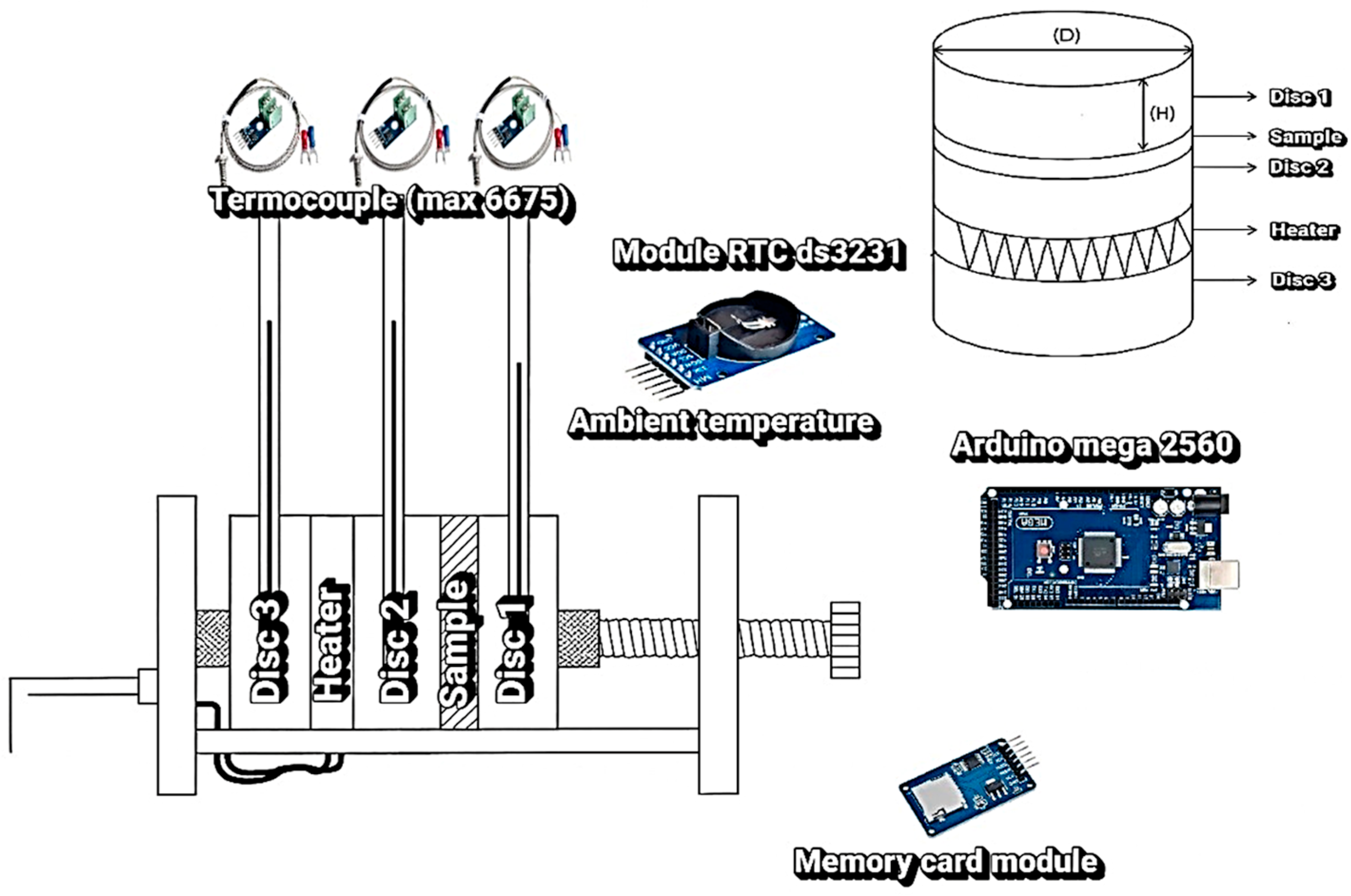

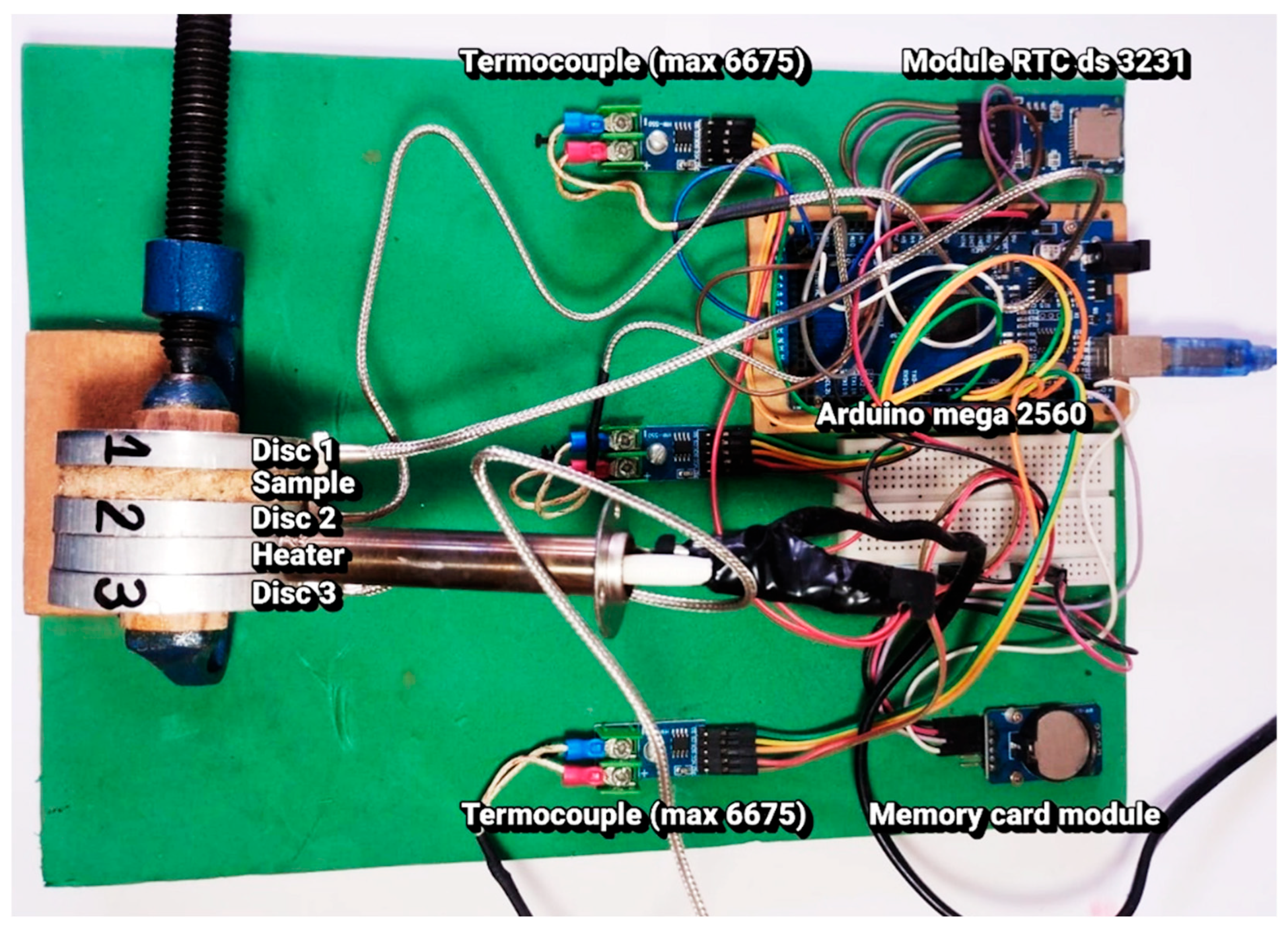

2.1.2. Lee Prototype Components

- Metal discs: Four aluminum discs were employed, each with a diameter of 10 cm and thickness of 1 cm. The discs were machined to a surface roughness below 0.8 µm to ensure optimal thermal contact with the samples. The mass of each disc was measured using a high-precision analytical balance (Shimadzu) with a resolution of 0.1 mg, ensuring accuracy in the thermal capacity calculations.

- Circular roofing samples: The samples were extracted using a diamond-tipped hole saw, maintaining a standardized diameter of 10 cm. The thickness corresponded to the original typology of each roofing material, and the edges were sanded carefully to correct surface imperfections and ensure adequate flatness, thereby minimizing thermal contact resistance between the layers.

2.1.3. Instrumentation and Sensors

2.1.4. Sealing and Thermal Insulation Materials

2.2. Methods

2.2.1. Experimental Prototype Development

2.2.2. Sample Preparation

2.2.3. Experimental Procedure

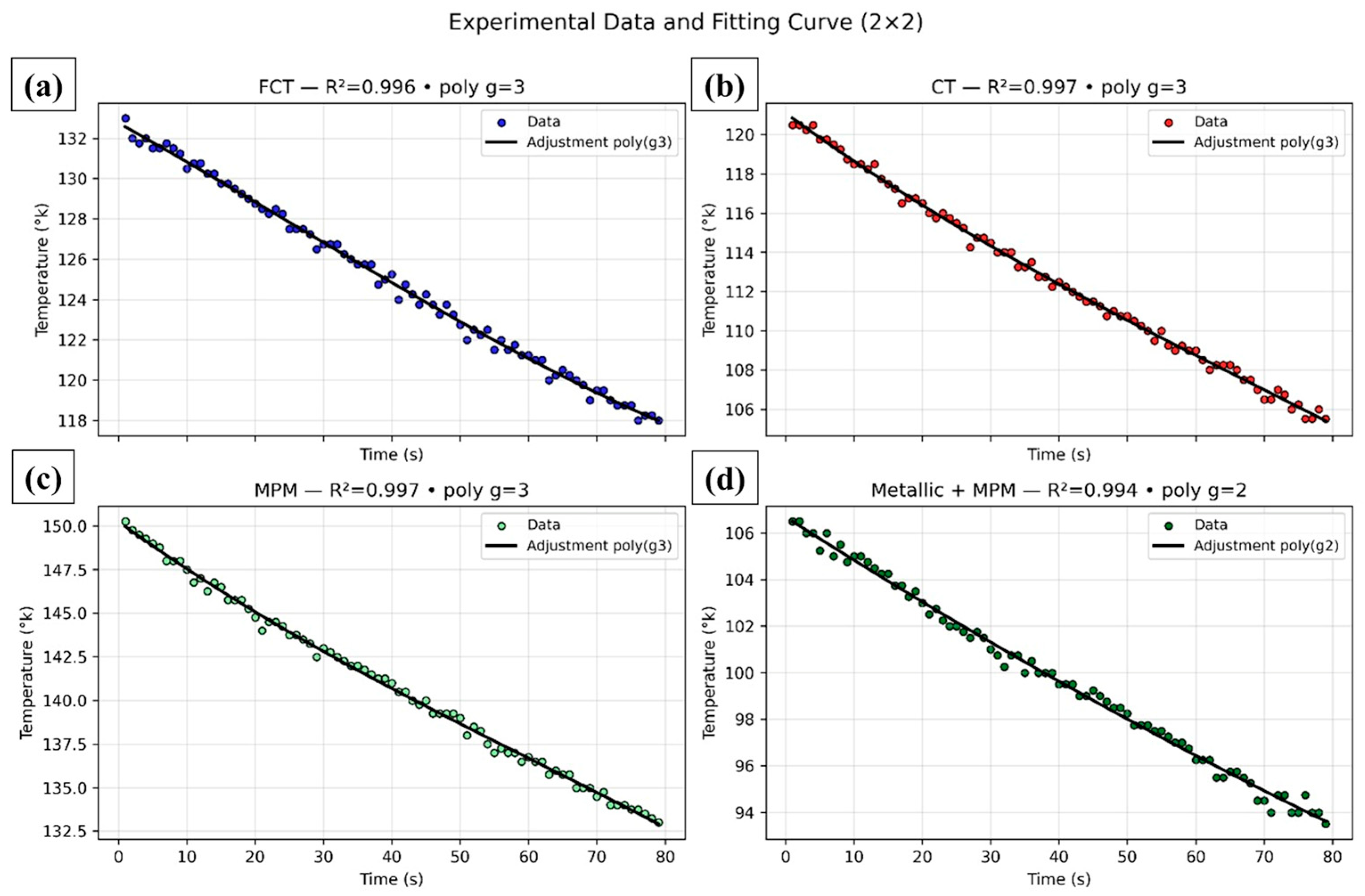

2.2.4. Data Analysis

2.2.5. Uncertainty Analysis

- Temperature measurement: The K-type thermocouples coupled with MAX6675 converters presented a combined uncertainty of ±0.1 °C after calibration with a reference thermometer. For the observed gradients (30–70 K), this corresponds to a relative uncertainty below 0.3%.

- Sample thickness: Measured at three points with a digital micrometer (resolution 0.01 mm). For samples 5–12 mm thick, the relative uncertainty was estimated at ±0.2%.

- Disc mass and heat capacity: The aluminum discs were measured with ±0.1 mg precision, yielding negligible error (<0.1%). The adopted specific heat capacity (c = 9 × 102 J·kg−1·K−1) may vary by ±2% depending on purity and processing, which was considered as a systematic contribution.

- Cooling rate determination: The slope of the initial cooling curve was obtained by linear regression of the first 60 s after heater switch-off. The standard deviation of the fit was typically below 2%.

3. Results and Discussions

3.1. Prototype Validation and Experimental Performance

3.2. Measuring the Thermal Conductivity of Roof Tiles

3.3. Critical Analysis and Comparison with Literature

3.4. Limitations and Experimental Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, L.; Zhang, N.; Yuan, Y.; Haghighat, F.; Dardir, M.; Panchabikesan, K.; Sun, Q. A double-glazed solar air-phase change material collector for nocturnal heating: Model development and sensitivity analysis. Energy Build. 2023, 289, 113070. [Google Scholar] [CrossRef]

- Liu, B.; Wang, H.; Lin, H.; Su, Y.; Wei, G.; Xu, Z. Effect of phase change cooling vest on related thermal regulation factors in moderately hot environments. Build. Environ. 2023, 242, 110566. [Google Scholar] [CrossRef]

- Yang, R.; Li, D.; Arıcı, M.; López Salazar, S.; Wu, Y.; Liu, C.; Yıldız, Ç. Spectrally selective nanoparticle-enhanced phase change materials: A study on data-driven optical/thermal properties and application of energy-saving glazing under different climatic conditions. Renew. Sustain. Energy Rev. 2023, 186, 113646. [Google Scholar] [CrossRef]

- Wang, G.; Fang, J.; Yan, C.; Huang, D.; Hu, K.; Zhou, K. Advancements in Smart Building Envelopes: A Comprehensive Review. Energy Build. 2024, 312, 114190. [Google Scholar] [CrossRef]

- Li, Z.; Che, S.; Zhao, H.; Zhang, L.; Wang, P.; Du, S.; Zhang, H.; Feng, Y.; Sun, H. Loss analysis of high-speed permanent magnet motor based on energy saving and emission reduction. Energy Rep. 2023, 9, 2379–2394. [Google Scholar] [CrossRef]

- Fan, L.F.; Ding, H.; Zhong, W.L.; Xu, C.B. A rapid approach for determining the mechanical properties of geopolymer concrete based on image processing technology (IPT). Constr. Build. Mater. 2023, 378, 131165. [Google Scholar] [CrossRef]

- Choonya, G.; Larsson, U.; Moshfegh, B. Experimental investigations of flow and thermal behavior of wall confluent jets as a heating device for large-space enclosures. Build. Environ. 2023, 236, 110282. [Google Scholar] [CrossRef]

- Nicolini, A.; Rodrigues, A.V.; Bragança, S.R.; Jacobi, M.M. Evaluation of latex polymeric mortar properties for laying bricks in non-structural masonry. J. Build. Eng. 2022, 59, 105080. [Google Scholar] [CrossRef]

- Skovajsa, J.; Drabek, P.; Sehnalek, S.; Zalesak, M. Design and experimental evaluation of phase change material based cooling ceiling system. Appl. Therm. Eng. 2022, 205, 118011. [Google Scholar] [CrossRef]

- Yen, W.-T.; Wang, K.-K.; Wu, H.-J. Hybridization of n-type Bi2Te3 crystals with liquid-like copper chalcogenide elicits record-high thermoelectric performance. Mater. Today Phys. 2023, 34, 101065. [Google Scholar] [CrossRef]

- Foroushani, S.; Bernhardt, R.; Bernhardt, M. On the use of the reference building approach in modern building energy codes. Energy Build. 2022, 256, 111726. [Google Scholar] [CrossRef]

- Alfi, A.A.; Alamrani, N.A.; Azher, O.A.; Snari, R.M.; Abumelha, H.M.; Al-Ahmed, Z.A.; El-Metwaly, N.M. Development of carbon dots sensor dipstick from sugarcane bagasse agricultural waste toward all-cellulose-derived tetracycline sensor. J. Mater. Res. Technol. 2022, 19, 4697–4707. [Google Scholar] [CrossRef]

- Xue, Y.; Lofland, S.; Hu, X. Thermal Conductivity of Protein-Based Materials: A Review. Polymers 2019, 11, 456. [Google Scholar] [CrossRef]

- Lapka, P.; Dietrich, F.; Furmański, P.; Sinka, M.; Sahmenko, G.; Bajare, D. Experimental and Numerical Estimation of Thermal Conductivity of Bio-Based Building Composite Materials with an Enhanced Thermal Capacity. J. Energy Storage 2024, 97, 112943. [Google Scholar] [CrossRef]

- Apaza Apaza, F.R.; Vázquez, V.F.; Paje, S.E.; Saiz, L.; Gulisano, F.; Gallego, J. The potential effect of crumb rubber on the maximum sound absorption performance of asphalt mixtures. Constr. Build. Mater. 2023, 389, 131789. [Google Scholar] [CrossRef]

- Santos, W.N.d. Advances on the Hot Wire Technique. J. Eur. Ceram. Soc. 2008, 28, 15–20. [Google Scholar] [CrossRef]

- Mao, Y.; Li, J.; Liu, Z.; Fan, W.; Zhang, X. Design of cylindrical saddle-shaped transverse gradient coils with small aspect ratios and high linearity for micro comagnetometers. Sens. Actuators A Phys. 2023, 361, 114561. [Google Scholar] [CrossRef]

- Salustro, S.; Lavagna, L.; Fernicola, V.; Smorgon, D.; Mondello, A.; Chiavazzo, E.; Pavese, M. Thermal Characterization and Cost Analysis of Cement-Based Composite Materials for Thermochemical Energy Storage. J. Energy Storage 2024, 93, 112308. [Google Scholar] [CrossRef]

- Wang, Z.; Li, P.; Zhang, H.; Zhang, Q.; Ye, C.; Han, W.; Tian, W. A binocular vision method for precise hole recognition in satellite assembly systems. Measurement 2023, 221, 113455. [Google Scholar] [CrossRef]

- Swacha, J. Topic Evolution in the Research on Educational Gamification. Educ. Sci. 2022, 12, 640. [Google Scholar] [CrossRef]

- Deschamps, J.; Kieser, C.; Hoess, P.; Deguchi, T.; Ries, J. MicroFPGA: An affordable FPGA platform for microscope control. HardwareX 2023, 13, e00407. [Google Scholar] [CrossRef]

- Rosti, B.; Jankovic, A.; Goia, F.; Mathisen, H.M.; Cao, G. Design and Performance Analysis of a Low-Cost Monitoring System for Advanced Building Envelopes. Build. Environ. 2025, 269, 112344. [Google Scholar] [CrossRef]

- Wang, J.; Chen, L.; Li, C.; Xu, C.; Feng, J. A Novel and Simple Method for Determinations of Phonon and Photon Thermal Conductivities of Oxides: PrTaO4 as a Study Case. Ceram. Int. 2025; in press. [Google Scholar] [CrossRef]

- Damaira, Y.A.; Muninggar, J.; Setiawan, A. Thermal Conductivity Measurement Experiment of Metal Using Heat Sensor and Arduino. J. Phys. Conf. Ser. 2024, 2684, 012006. [Google Scholar] [CrossRef]

- Lees, C.H. On the Determination of Thermal Conductivity an Other Properties of Poor Conductors. Philos. Mag. 1898, 45, 1–19. [Google Scholar]

- Veliu, C.; Petzold, V.; Reichelt, D.; Stange, M.; Ihlenfeldt, S. A Case Study on the Use of Open Source Hardware in Mechanical Engineering. Procedia CIRP 2024, 128, 680–685. [Google Scholar] [CrossRef]

- Marín-Marín, J.-A.; García-Tudela, P.A.; Duo-Terrón, P. Computational Thinking and Programming with Arduino in Education: A Systematic Review for Secondary Education. Heliyon 2024, 10, e29177. [Google Scholar] [CrossRef] [PubMed]

- Visco, G.; Dell’Aglio, E.; Tomassetti, M.; Fontanella, L.U.; Sammartino, M.P. An Open-Source, Low-Cost Apparatus for Conductivity Measurements Based on Arduino and Coupled to a Handmade Cell. Analytica 2023, 4, 217–230. [Google Scholar] [CrossRef]

- Associação Brasileira de Normas Técnicas (ABNT). Residential Buildings—Performance—Part 5: Requirements for Roofing Systems (NBR 15575-5); ABNT: Rio de Janeiro, Brazil, 2013. [Google Scholar]

- Dong, C.; Zhu, Z.; Li, Z.; Shi, X.; Cheng, S.; Fan, P. Design of fishtail structure based on oscillating mechanisms using PVC gel actuators. Sens. Actuators A Phys. 2022, 341, 113588. [Google Scholar] [CrossRef]

- Wang, X.; Banthia, N.; Yoo, D.-Y. Reinforcement bond performance in 3D concrete printing: Explainable ensemble learning augmented by deep generative adversarial networks. Autom. Constr. 2024, 158, 105164. [Google Scholar] [CrossRef]

- Barragán, V.M.; Maroto, J.C.; Pastuschuk, E.; Muñoz, S. Testing a simple Lee’s disc method for estimating through-plane thermal conductivity of polymeric ion-exchange membranes. Int. J. Heat Mass Transf. 2022, 184, 122295. [Google Scholar] [CrossRef]

- Alam, M.; Rahman, S.; Halder, P.K.; Raquib, A.; Hasan, M. Lee’s and Charlton’s Method for Investigation of Thermal Conductivity of Insulating Materials. IOSR J. Mech. Civ. Eng. 2012, 3, 53–60. [Google Scholar] [CrossRef]

- Silva, R.; Martins, F.; Cravino, J.; Martins, P.; Costa, C.; Lopes, J.B. Using Educational Robotics in Pre-Service Teacher Training: Orchestration between an Exploration Guide and Teacher Role. Educ. Sci. 2023, 13, 210. [Google Scholar] [CrossRef]

- Negreiros, W.J.A.G.; Rodrigues, J.d.S.; Ribeiro, M.M.; Silva, D.S.; Junio, R.F.P.; Monteiro, S.N.; Corrêa, A.d.C. Potential Use of Castor Oil-Based Polyurethane Matrix Composite with Miriti Fiber Filling as Thermal Insulation Applied to Metal Tiles. Polymers 2025, 17, 892. [Google Scholar] [CrossRef] [PubMed]

- Alazzawi, S.; Mahmood, W.A.; Shihab, S.K. Comparative Study of Natural Fiber-Reinforced Composites for Sustainable Thermal Insulation in Construction. Int. J. Thermofluids 2024, 24, 100839. [Google Scholar] [CrossRef]

- Ba, L.; Trabelsi, A.; Ngo, T.T.; Pliya, P.; El Abbassi, I.; Kane, C.S.E. Thermal Performance of Bio-Based Materials for Sustainable Building Insulation: A Numerical Study. Fibers 2025, 13, 52. [Google Scholar] [CrossRef]

- Qpedia. Decreasing Thermal Contact Resistance by Using Thermal Interface Materials (TIMs). Qpedia Thermal Management Library, Vol. 1. Available online: https://www.qats.com/qpedia-thermal-eMagazine (accessed on 8 August 2025).

- Franco, A. An Apparatus for the Routine Measurement of Thermal Conductivity of Materials for Building Application Based on a Transient Hot-Wire Method. Appl. Therm. Eng. 2007, 27, 2495–2504. [Google Scholar] [CrossRef]

- Urbano, O.; Perles, A.; Pedraza, C.; Rubio-Arraez, S.; Castelló, M.L.; Ortola, M.D.; Mercado, R. Cost-Effective Implementation of a Temperature Traceability System Based on Smart RFID Tags and IoT Services. Sensors 2020, 20, 1163. [Google Scholar] [CrossRef]

- Pearce, J.M. Building Research Equipment with Free, Open-Source Hardware. Science 2012, 337, 1303–1304. [Google Scholar] [CrossRef]

- Carslaw, H.S.; Jaeger, J.C. Conduction of Heat in Solids, 2nd ed.; Oxford University Press: Oxford, UK, 1959. [Google Scholar]

- ASTM C177-19; Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded-Hot-Plate Apparatus. ASTM International: West Conshohocken, PA, USA, 2019.

- Nasr, Y.; El Zakhem, H.; Hamami, A.E.A.; El Bachawati, M.; Belarbi, R. Comprehensive Review of Innovative Materials for Sustainable Buildings’ Energy Performance. Energies 2023, 16, 7440. [Google Scholar] [CrossRef]

- Nguyen, N.-H.; Abellán-García, J.; Lee, S.; Nguyen, T.-K.; Vo, T.P. Simultaneous prediction the strain and energy absorption capacity of ultra-high performance fiber reinforced concretes by using multi-output regression model. Constr. Build. Mater. 2023, 384, 131418. [Google Scholar] [CrossRef]

- Kraemer, D. A Simple Differential Steady-State Method to Measure Thermal Conductivity; Technical Report; U.S. Department of Energy: Washington, DC, USA, 2014. [Google Scholar]

- Khomenko, O.; Sribniak, N.; Ivchenko, V.; Ujma, A.; Pomada, M. Thermal Conductivity Study of Different Engobed Ceramic Brick. Cerâmica 2024, 70, eZAOY1947. [Google Scholar] [CrossRef]

- Integrated Environmental Solutions Limited. Asbestos Cement Decking, in Table of Thermal Conductivity, Specific Heat Capacity and Density. 2011–2021. Available online: https://help.iesve.com/ve2021/table_6_thermal_conductivity__specific_heat_capacity_and_density.htm# (accessed on 8 August 2025).

- Zu, Y.; Zhang, T.; Jing, L.; Gao, H.; Wang, W.; Yang, K.; Zeng, B.; Gan, R.; Gong, D.; Liu, P.; et al. Bifunctional ligand passivation enables robust-stability perovskite nanocrystals for backlit display. Dyes Pigment. 2025, 242, 112983. [Google Scholar] [CrossRef]

- Gu, W.; Luo, Z.; Wang, J.; Tan, X.; Tao, Z.; Zhou, P.; Zhang, H.; Lan, D.; Xia, A. Multifunctional lightweight rGO/polyimide hybrid aerogels for highly efficient infrared-radar-acoustic compatibility via heterogeneous interface engineering strategies. J. Mater. Sci. Technol. 2026, 243, 102–114. [Google Scholar] [CrossRef]

- Li, Y.; Han, Y.; Lan, D.; Zhang, S.; Gao, Z.; Wu, G.; Jia, Z. Photoacoustic synchronization system based on anisotropic nanofibers. Nano Res. 2025, 18, 94907470. [Google Scholar] [CrossRef]

| Parameters | FCT | CT | MPM | Metallic + MPM |

|---|---|---|---|---|

| Thickness (mm) | 4.8 | 11.6 | 7.2 | 6.4 |

| Cooling rate (K·s−1) | 0.1908 | 0.1899 | 0.1476 | 0.2072 |

| Stationary temperature difference (T2-T1) (K) | 31.25 | 54.25 | 59.50 | 70 |

| Parameter | Value |

|---|---|

| Mass (kg) | 0.0393 |

| Height (mm) | 7.2 |

| Heat capacity of aluminum (J·kg−1·K−1) | 9 × 102 |

| Radius (mm) | 25.5 |

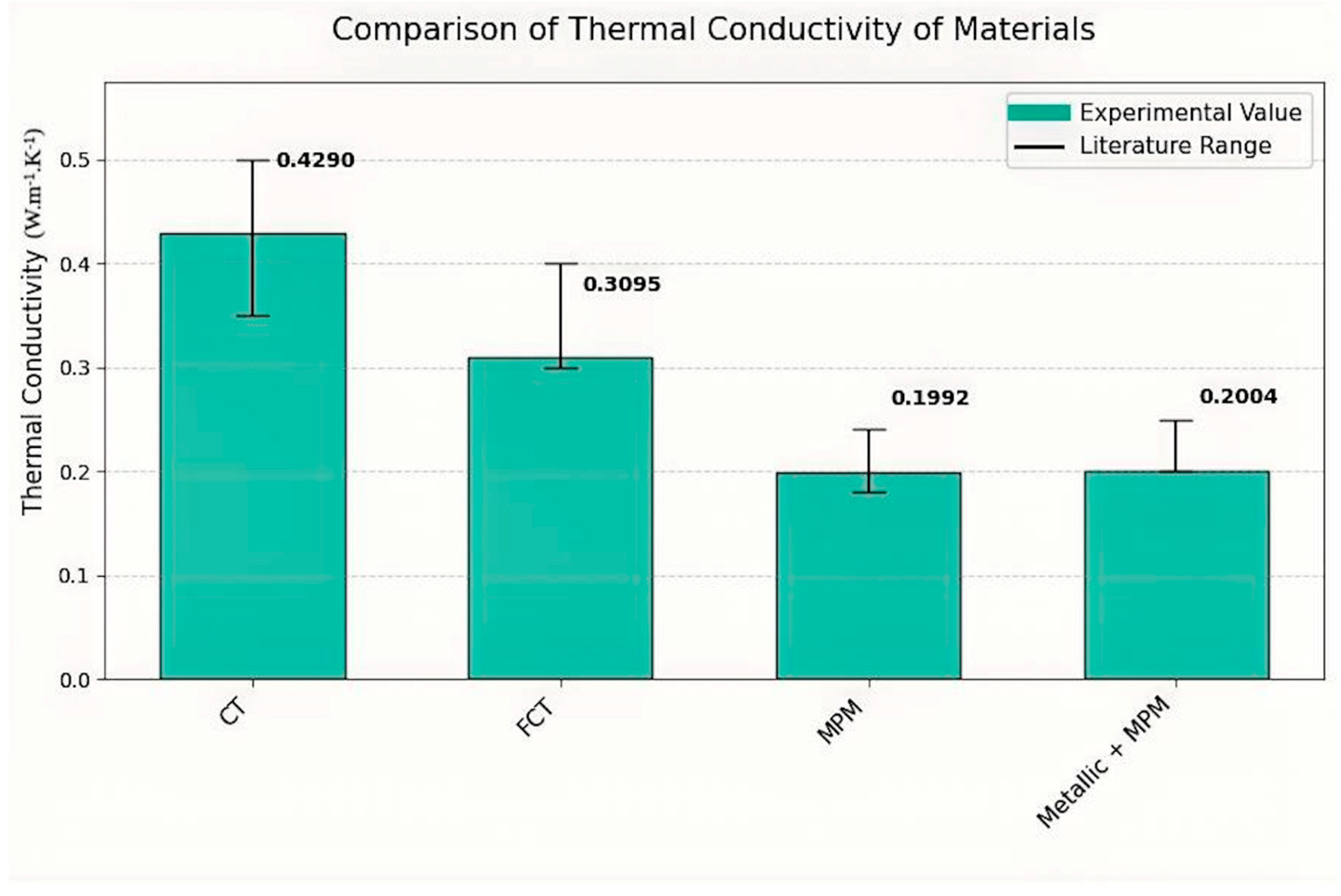

| Sample | k [W·m−1·K−1] | Standard Deviation |

|---|---|---|

| CT | 0.429 | 0.012 |

| FCT | 0.309 | 0.009 |

| MPM | 0.180 | 0.008 |

| Metallic + MPM | 0.200 | 0.007 |

| Material | Experimental Value (W·m−1·K−1) | Literature Range (W·m−1·K−1) | References |

|---|---|---|---|

| CT | 0.429 | 0.35–0.50 | [47] |

| FCT | 0.3095 | 0.30–0.40 | [48] |

| MPM | 0.1992 | 0.18–0.24 | [35] |

| Metallic + MPM | 0.2004 | 0.20–0.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Negreiros, W.J.A.G.; Rodrigues, J.d.S.; Ribeiro, M.M.; Silva, D.S.; Junio, R.F.P.; Seruffo, M.C.d.R.; Monteiro, S.N.; Corrêa, A.d.C. Development and Validation of a Low-Cost Arduino-Based Lee Disc System for Thermal Conductivity Analysis of Sustainable Roofing Materials. Sensors 2025, 25, 5447. https://doi.org/10.3390/s25175447

Negreiros WJAG, Rodrigues JdS, Ribeiro MM, Silva DS, Junio RFP, Seruffo MCdR, Monteiro SN, Corrêa AdC. Development and Validation of a Low-Cost Arduino-Based Lee Disc System for Thermal Conductivity Analysis of Sustainable Roofing Materials. Sensors. 2025; 25(17):5447. https://doi.org/10.3390/s25175447

Chicago/Turabian StyleNegreiros, Waldemiro José Assis Gomes, Jean da Silva Rodrigues, Maurício Maia Ribeiro, Douglas Santos Silva, Raí Felipe Pereira Junio, Marcos Cesar da Rocha Seruffo, Sergio Neves Monteiro, and Alessandro de Castro Corrêa. 2025. "Development and Validation of a Low-Cost Arduino-Based Lee Disc System for Thermal Conductivity Analysis of Sustainable Roofing Materials" Sensors 25, no. 17: 5447. https://doi.org/10.3390/s25175447

APA StyleNegreiros, W. J. A. G., Rodrigues, J. d. S., Ribeiro, M. M., Silva, D. S., Junio, R. F. P., Seruffo, M. C. d. R., Monteiro, S. N., & Corrêa, A. d. C. (2025). Development and Validation of a Low-Cost Arduino-Based Lee Disc System for Thermal Conductivity Analysis of Sustainable Roofing Materials. Sensors, 25(17), 5447. https://doi.org/10.3390/s25175447