Authentication of Counterfeit Electronics Using Rapid THz Time-of-Flight Imaging

Abstract

1. Introduction

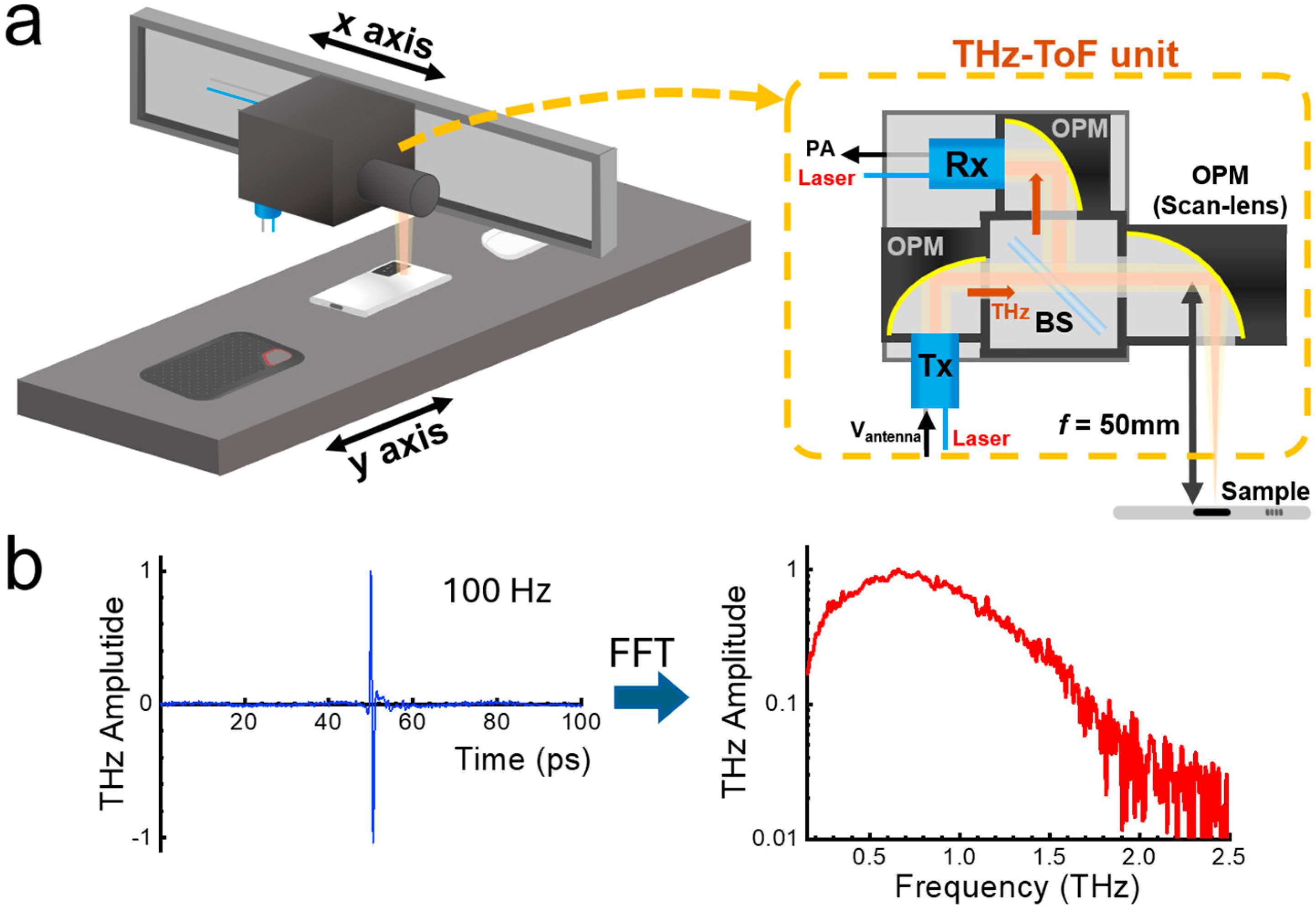

2. Experimental Setup

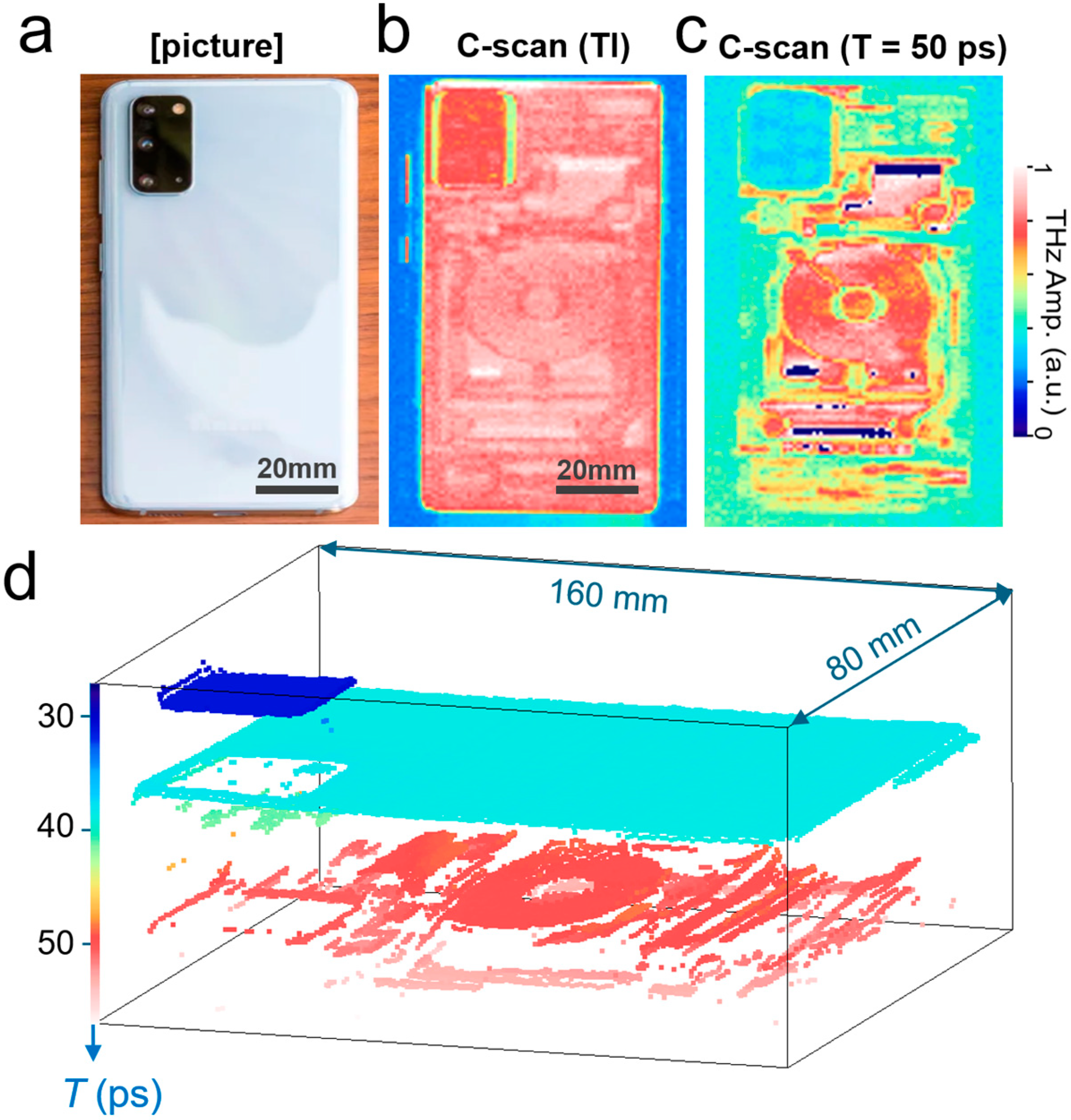

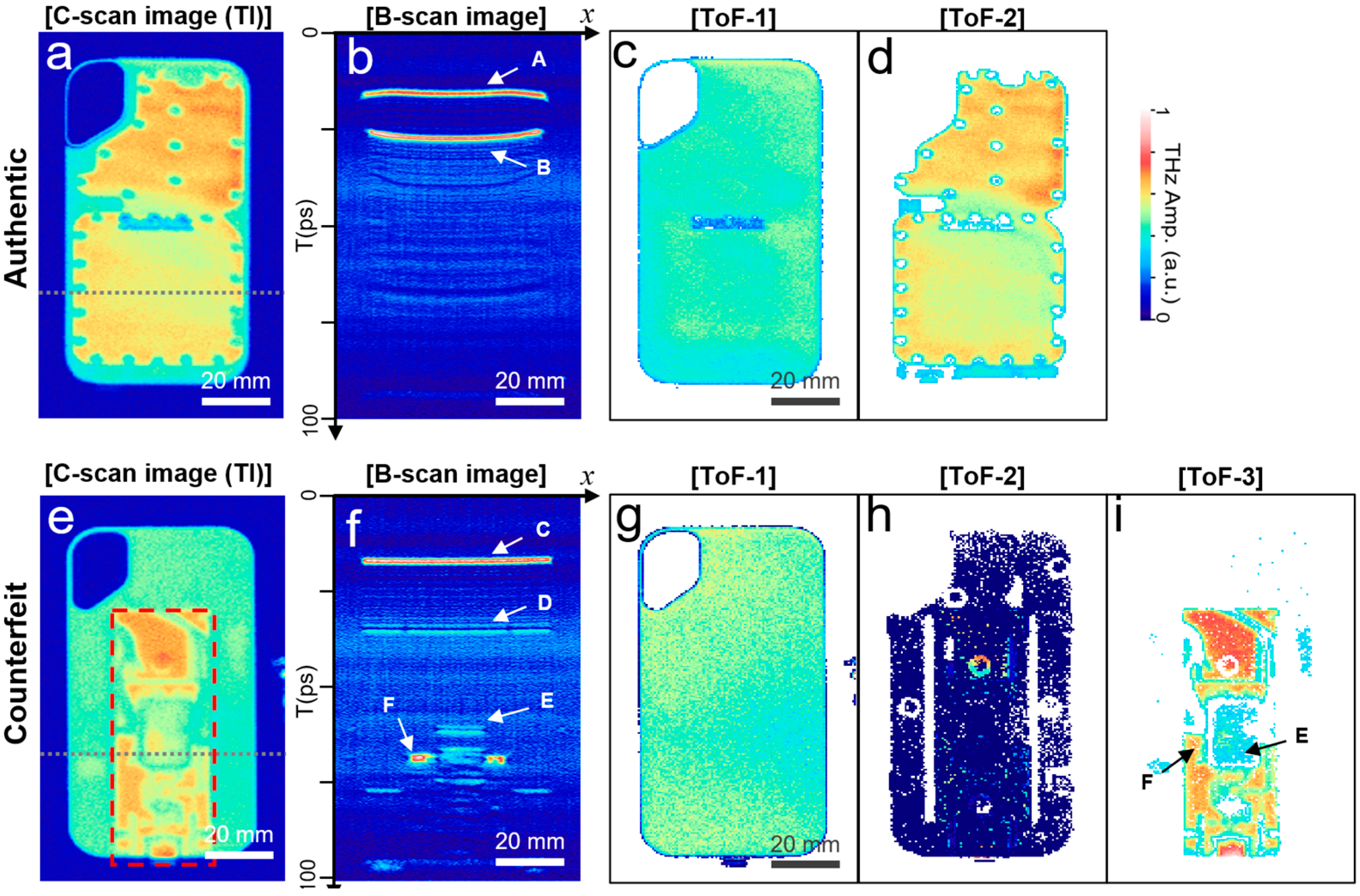

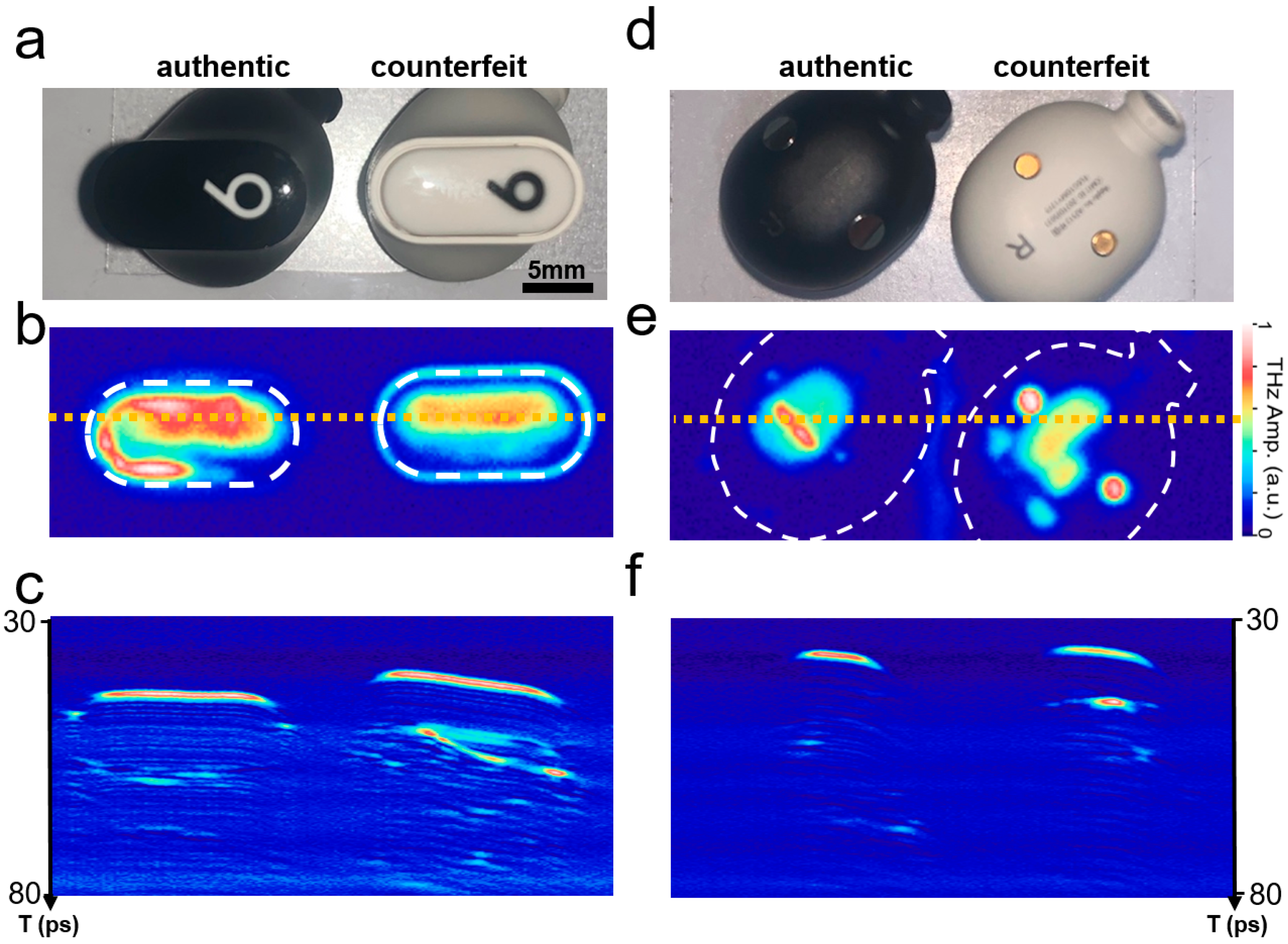

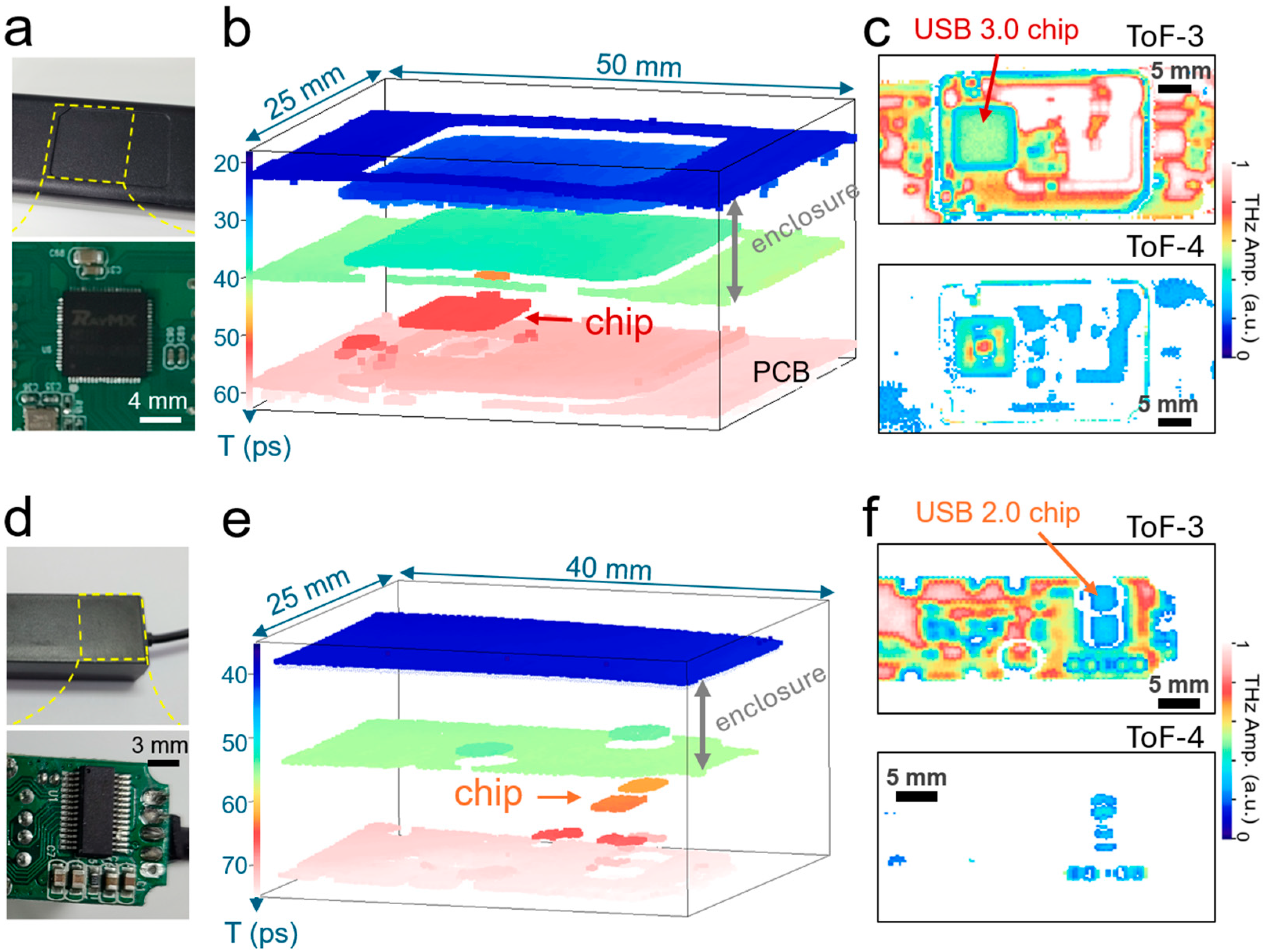

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bian, X.; Moutinho, L. The role of brand image, product involvement, and knowledge in explaining consumer purchase behaviour of counterfeits: Direct and indirect effects. Eur. J. Mark. 2011, 45, 191–216. [Google Scholar] [CrossRef]

- Pecht, M.; Tiku, S. Bogus: Electronic manufacturing and consumers confront a rising tide of counterfeit electronics. IEEE Spectr. 2006, 43, 37–46. [Google Scholar] [CrossRef]

- Hieke, S. Effects of counterfeits on the image of luxury brands: An empirical study from the customer perspective. J. Brand Manag. 2010, 18, 159–173. [Google Scholar] [CrossRef]

- Nath, B.; Reynolds, F.; Want, R. Rfid technology and applications. IEEE Pervasive Comput. 2006, 5, 22–24. [Google Scholar] [CrossRef]

- Xiao, Q.; Gibbons, T.; Lebrun, H. Rfid technology, security vulnerabilities, and countermeasures. In Supply Chain the Way to Flat Organisation; Publisher-Intech: London, UK, 2009; pp. 357–382. [Google Scholar]

- Hanke, R.; Fuchs, T.; Uhlmann, N. X-ray based methods for non-destructive testing and material characterization. Nucl. Instrum. Methods Phys. Res. A 2008, 591, 14–18. [Google Scholar] [CrossRef]

- Wall, B.; Kendall, G.; Edwards, A.; Bouffler, S.; Muirhead, C.; Meara, J. What are the risks from medical x-rays and other low dose radiation? Br. J. Radiol. 2006, 79, 285–294. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; Molleda, J.; Bulnes, F.G. Infrared thermography for temperature measurement and non-destructive testing. Sensors 2014, 14, 12305–12348. [Google Scholar] [CrossRef]

- Yilmaz, B.; Asokkumar, A.; Jasiūnienė, E.; Kažys, R.J. Air-coupled, contact, and immersion ultrasonic non-destructive testing: Comparison for bonding quality evaluation. Appl. Sci. 2020, 10, 6757. [Google Scholar] [CrossRef]

- Fercher, A.F.; Drexler, W.; Hitzenberger, C.K.; Lasser, T. Optical coherence tomography-principles and applications. Rep. Prog. Phys. 2003, 66, 239. [Google Scholar] [CrossRef]

- Fu, M.-Y.; Yin, Z.-H.; Yao, X.-Y.; Xu, J.; Liu, Y.; Dong, Y.; Shen, Y.-C. The progress of optical coherence tomography in industry applications. Adv. Devices Instrum. 2024, 5, 0053. [Google Scholar] [CrossRef]

- Fan, S.; He, Y.; Ung, B.S.; Pickwell-MacPherson, E. The growth of biomedical terahertz research. J. Phys. D Appl. Phys. 2014, 47, 374009. [Google Scholar] [CrossRef]

- Tao, Y.H.; Fitzgerald, A.J.; Wallace, V.P. Non-contact, non-destructive testing in various industrial sectors with terahertz technology. Sensors 2020, 20, 712. [Google Scholar] [CrossRef]

- Naftaly, M.; Vieweg, N.; Deninger, A. Industrial applications of terahertz sensing: State of play. Sensors 2019, 19, 4203. [Google Scholar] [CrossRef]

- Smolyanskaya, O.; Chernomyrdin, N.; Konovko, A.; Zaytsev, K.; Ozheredov, I.; Cherkasova, O.; Nazarov, M.; Guillet, J.-P.; Kozlov, S.; Kistenev, Y.V. Terahertz biophotonics as a tool for studies of dielectric and spectral properties of biological tissues and liquids. Prog. Quantum Electron. 2018, 62, 1–77. [Google Scholar] [CrossRef]

- Ogawa, Y.; Hayashi, S.i.; Oikawa, M.; Otani, C.; Kawase, K. Interference terahertz label-free imaging for protein detection on a membrane. Opt. Express 2008, 16, 22083–22089. [Google Scholar] [CrossRef]

- Peng, Y.; Shi, C.; Zhu, Y.; Gu, M.; Zhuang, S. Terahertz spectroscopy in biomedical field: A review on signal-to-noise ratio improvement. PhotoniX 2020, 1, 12. [Google Scholar] [CrossRef]

- Jeong, T.H.; Jun, S.W.; Ahn, Y.H. Metamaterial sensing of cyanobacteria using thz thermal curve analysis. Biosensors 2024, 14, 519. [Google Scholar] [CrossRef]

- Nsengiyumva, W.; Zhong, S.; Zheng, L.; Liang, W.; Wang, B.; Huang, Y.; Chen, X.; Shen, Y. Sensing and nondestructive testing applications of terahertz spectroscopy and imaging systems: State-of-the-art and state-of-the-practice. IEEE Trans. Instrum. Meas. 2023, 72, 1–83. [Google Scholar] [CrossRef]

- Zhong, S. Progress in terahertz nondestructive testing: A review. Front. Mech. Eng. 2019, 14, 273–281. [Google Scholar] [CrossRef]

- Federici, J.F.; Schulkin, B.; Huang, F.; Gary, D.; Barat, R.; Oliveira, F.; Zimdars, D. Thz imaging and sensing for security applications—Explosives, weapons and drugs. Semicond. Sci. Technol. 2005, 20, S266. [Google Scholar] [CrossRef]

- Park, S.; Hong, J.; Choi, S.; Kim, H.; Park, W.; Han, S.; Park, J.; Lee, S.; Kim, D.; Ahn, Y. Detection of microorganisms using terahertz metamaterials. Sci. Rep. 2014, 4, 4988. [Google Scholar] [CrossRef]

- Zhang, J.-Y.; Ren, J.-J.; Li, L.-J.; Gu, J.; Zhang, D.-D. Thz imaging technique for nondestructive analysis of debonding defects in ceramic matrix composites based on multiple echoes and feature fusion. Opt. Express 2020, 28, 19901–19915. [Google Scholar] [CrossRef]

- Fan, S.; Li, T.; Zhou, J.; Liu, X.; Liu, X.; Qi, H.; Mu, Z. Terahertz non-destructive imaging of cracks and cracking in structures of cement-based materials. AIP Adv. 2017, 7, 115202. [Google Scholar] [CrossRef]

- Nguyen, K.L.; Johns, M.L.; Gladden, L.F.; Worrall, C.H.; Alexander, P.; Beere, H.E.; Pepper, M.; Ritchie, D.A.; Alton, J.; Barbieri, S. Three-dimensional imaging with a terahertz quantum cascade laser. Opt. Express 2006, 14, 2123–2129. [Google Scholar] [CrossRef]

- Lee, A.W.; Hu, Q. Real-time, continuous-wave terahertz imaging by use of a microbolometer focal-plane array. Opt. Lett. 2005, 30, 2563–2565. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, C.; Huai, B.; Wang, S.; Zhang, Y.; Wang, D.; Rong, L.; Zheng, Y. Continuous-wave thz imaging for biomedical samples. Appl. Sci. 2020, 11, 71. [Google Scholar] [CrossRef]

- Damyanov, D.; Batra, A.; Friederich, B.; Kaiser, T.; Schultze, T.; Balzer, J.C. High-resolution long-range thz imaging for tunable continuous-wave systems. IEEE Access 2020, 8, 151997–152007. [Google Scholar] [CrossRef]

- Friederich, F.; Von Spiegel, W.; Bauer, M.; Meng, F.; Thomson, M.D.; Boppel, S.; Lisauskas, A.; Hils, B.; Krozer, V.; Keil, A. Thz active imaging systems with real-time capabilities. IEEE Trans. Terahertz Sci. Technol. 2011, 1, 183–200. [Google Scholar] [CrossRef]

- Kim, J.-Y.; Song, H.-J.; Yaita, M.; Hirata, A.; Ajito, K. Cw-thz vector spectroscopy and imaging system based on 1.55-µm fiber-optics. Opt. Express 2014, 22, 1735–1741. [Google Scholar] [CrossRef] [PubMed]

- Lee, I.-S.; Lee, J.W. Nondestructive internal defect detection using a cw–thz imaging system in xlpe for power cable insulation. Appl. Sci. 2020, 10, 2055. [Google Scholar] [CrossRef]

- Mathanker, S.K.; Weckler, P.R.; Wang, N. Terahertz (thz) applications in food and agriculture: A review. Trans. ASABE 2013, 56, 1213–1226. [Google Scholar] [CrossRef]

- Afsah-Hejri, L.; Hajeb, P.; Ara, P.; Ehsani, R.J. A comprehensive review on food applications of terahertz spectroscopy and imaging. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1563–1621. [Google Scholar] [CrossRef]

- Guerboukha, H.; Nallappan, K.; Skorobogatiy, M. Toward real-time terahertz imaging. Adv. Opt. Photon. 2018, 10, 843–938. [Google Scholar] [CrossRef]

- Schirmer, M.; Fujio, M.; Minami, M.; Miura, J.; Araki, T.; Yasui, T. Biomedical applications of a real-time terahertz color scanner. Biomed. Opt. Express 2010, 1, 354–366. [Google Scholar] [CrossRef] [PubMed]

- Kawase, K.; Ogawa, Y.; Watanabe, Y.; Inoue, H. Non-destructive terahertz imaging of illicit drugs using spectral fingerprints. Opt. Express 2003, 11, 2549–2554. [Google Scholar] [CrossRef] [PubMed]

- Hu, B.B.; Nuss, M.C. Imaging with terahertz waves. Opt. Lett. 1995, 20, 1716–1718. [Google Scholar] [CrossRef]

- Mittleman, D.M.; Hunsche, S.; Boivin, L.; Nuss, M.C. T-ray tomography. Opt. Lett. 1997, 22, 904–906. [Google Scholar] [CrossRef]

- Zhong, S.; Shen, Y.-C.; Ho, L.; May, R.K.; Zeitler, J.A.; Evans, M.; Taday, P.F.; Pepper, M.; Rades, T.; Gordon, K.C. Non-destructive quantification of pharmaceutical tablet coatings using terahertz pulsed imaging and optical coherence tomography. Opt. Lasers Eng. 2011, 49, 361–365. [Google Scholar] [CrossRef]

- Park, S.-H.; Jang, J.-W.; Kim, H.-S. Non-destructive evaluation of the hidden voids in integrated circuit packages using terahertz time-domain spectroscopy. J. Micromech. Microeng. 2015, 25, 095007. [Google Scholar] [CrossRef]

- Tomaino, J.; Jameson, A.; Paul, M.; Kevek, J.; Van Der Zande, A.; Barton, R.; Choi, H.; McEuen, P.; Minot, E.; Lee, Y.-S. High-contrast imaging of graphene via time-domain terahertz spectroscopy. J. Infrared Millim. Terahertz Waves 2012, 33, 839–845. [Google Scholar] [CrossRef]

- Burford, N.M.; El-Shenawee, M.O.; O’neal, C.B.; Olejniczak, K.J. Terahertz imaging for nondestructive evaluation of packaged power electronic devices. Int. J. Emerg. Technol. Adv. Eng. 2014, 4, 395–401. [Google Scholar]

- Cha, S.H.; Park, S.J.; Ahn, Y.H. Investigation of sensitivity distribution in thz metamaterials using surface functionalization. Curr. Opt. Photon. 2019, 3, 566–570. [Google Scholar]

- Kim, Y.C.; Yim, J.H.; Khan, A.A.; Kim, J.; Ahn, Y.H. Rapid thz time-of-flight imaging on single layer graphene for conductivity assessment. Infrared Phys. Technol. 2024, 137, 105201. [Google Scholar] [CrossRef]

- Ahi, K.; Shahbazmohamadi, S.; Asadizanjani, N. Quality control and authentication of packaged integrated circuits using enhanced-spatial-resolution terahertz time-domain spectroscopy and imaging. Opt. Lasers Eng. 2018, 104, 274–284. [Google Scholar] [CrossRef]

- Ibrahim, M.; Headland, D.; Withayachumnankul, W.; Wang, C. Nondestructive testing of defects in polymer–matrix composite materials for marine applications using terahertz waves. J. Nondestruct. Eval. 2021, 40, 37. [Google Scholar] [CrossRef]

- Zhong, H.; Xu, J.; Xie, X.; Yuan, T.; Reightler, R.; Madaras, E.; Zhang, X.-C. Nondestructive defect identification with terahertz time-of-flight tomography. IEEE Sens. J. 2005, 5, 203–208. [Google Scholar] [CrossRef]

- Jun, S.; Ahn, Y. Terahertz thermal curve analysis for label-free identification of pathogens. Nat. Commun. 2022, 13, 3470. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.S.; Ha, N.Y.; Park, J.-Y.; Lee, S.; Kim, D.-S.; Ahn, Y.H. Phonon-polaritons in lead halide perovskite film hybridized with thz metamaterials. Nano Lett. 2020, 20, 6690–6696. [Google Scholar] [CrossRef] [PubMed]

- Yoo, H.; Kim, J.; Ahn, Y.H. High-speed thz time-of-flight imaging with reflective optics. Sensors 2023, 23, 873. [Google Scholar] [CrossRef]

- Yu, L.; Hao, L.; Meiqiong, T.; Jiaoqi, H.; Wei, L.; Jinying, D.; Xueping, C.; Weiling, F.; Yang, Z. The medical application of terahertz technology in non-invasive detection of cells and tissues: Opportunities and challenges. RSC Adv. 2019, 9, 9354–9363. [Google Scholar] [CrossRef]

- Zanotto, L.; Piccoli, R.; Dong, J.; Caraffini, D.; Morandotti, R.; Razzari, L. Time-domain terahertz compressive imaging. Opt. Express 2020, 28, 3795–3802. [Google Scholar] [CrossRef]

- Hu, Q.; Wei, X.; Pang, Y.; Lang, L. Advances on terahertz single-pixel imaging. Front. Phys. 2022, 10, 982640. [Google Scholar] [CrossRef]

- Dutta, B.; Root, K.; Ullmann, I.; Wagner, F.; Mayr, M.; Seuret, M.; Thies, M.; Stromer, D.; Christlein, V.; Schür, J. Deep learning for terahertz image denoising in nondestructive historical document analysis. Sci. Rep. 2022, 12, 22554. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Li, G.; Ge, H.; Wang, F.; Li, L.; Chen, X.; Lu, M.; Zhang, Y. Machine learning and application in terahertz technology: A review on achievements and future challenges. IEEE Access 2022, 10, 53761–53776. [Google Scholar] [CrossRef]

- Yim, J.H.; Kim, S.-y.; Kim, Y.; Cho, S.; Kim, J.; Ahn, Y.H. Rapid 3d-imaging of semiconductor chips using thz time-of-flight technique. Appl. Sci. 2021, 11, 4770. [Google Scholar] [CrossRef]

- Kim, H.S.; Baik, S.Y.; Lee, J.W.; Kim, J.; Ahn, Y.H. Nondestructive tomographic imaging of rust with rapid thz time-domain spectroscopy. Appl. Sci. 2021, 11, 10594. [Google Scholar] [CrossRef]

- Hochrein, T.; Wilk, R.; Mei, M.; Holzwarth, R.; Krumbholz, N.; Koch, M. Optical sampling by laser cavity tuning. Opt. Express 2010, 18, 1613–1617. [Google Scholar] [CrossRef] [PubMed]

- Jin, K.H.; Kim, Y.-G.; Cho, S.H.; Ye, J.C.; Yee, D.-S. High-speed terahertz reflection three-dimensional imaging for nondestructive evaluation. Opt. Express 2012, 20, 25432–25440. [Google Scholar] [CrossRef]

- Kim, H.S.; Kim, J.; Ahn, Y.H. Terahertz nondestructive time-of-flight imaging with a large depth range. Curr. Opt. Photon. 2022, 6, 619–626. [Google Scholar]

- Bartels, A.; Thoma, A.; Janke, C.; Dekorsy, T.; Dreyhaupt, A.; Winnerl, S.; Helm, M. High-resolution thz spectrometer with khz scan rates. Opt. Express 2006, 14, 430–437. [Google Scholar] [CrossRef]

- Chen, C.; Song, W.; Chen, J.-W.; Wang, J.-H.; Chen, Y.H.; Xu, B.; Chen, M.-K.; Li, H.; Fang, B.; Chen, J. Spectral tomographic imaging with aplanatic metalens. Light Sci. Appl. 2019, 8, 99. [Google Scholar] [CrossRef] [PubMed]

- Poon, T.-C. Digital Holography and Three-Dimensional Display: Principles and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Lowne, A. Detecting Counterfeit ICs. Electronic Design, 22 December 2021. Available online: https://www.electronicdesign.com/technologies/test-measurement/article/21185936/saelig-detecting-counterfeit-ics (accessed on 30 December 2024).

- Yuan, Z.; Ding, D.; Zhang, W. Effect of thermal via design on heat dissipation of high-lead qfn packages mounted on pcb. Appl. Sci. 2023, 13, 12653. [Google Scholar] [CrossRef]

- Ghaffarian, R. Quad flat no-lead (qfn) evaluation testing. In NASA Electronic Parts and Packaging (NEPP) Program Office of Safety and Mission Success; Jet Propulsion Laboratory California Institute of Technology: Pasadena, CA, USA, 2017. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ryu, H.; Son, B.H.; Kim, J.; Kim, J.; Ahn, Y.H. Authentication of Counterfeit Electronics Using Rapid THz Time-of-Flight Imaging. Sensors 2025, 25, 5160. https://doi.org/10.3390/s25165160

Ryu H, Son BH, Kim J, Kim J, Ahn YH. Authentication of Counterfeit Electronics Using Rapid THz Time-of-Flight Imaging. Sensors. 2025; 25(16):5160. https://doi.org/10.3390/s25165160

Chicago/Turabian StyleRyu, Hyeonseung, Byung Hee Son, Jihwan Kim, Jangsun Kim, and Yeong Hwan Ahn. 2025. "Authentication of Counterfeit Electronics Using Rapid THz Time-of-Flight Imaging" Sensors 25, no. 16: 5160. https://doi.org/10.3390/s25165160

APA StyleRyu, H., Son, B. H., Kim, J., Kim, J., & Ahn, Y. H. (2025). Authentication of Counterfeit Electronics Using Rapid THz Time-of-Flight Imaging. Sensors, 25(16), 5160. https://doi.org/10.3390/s25165160