A Novel Multi-Core Parallel Current Differential Sensing Approach for Tethered UAV Power Cable Break Detection

Abstract

1. Introduction

- Multi-core Parallel Optimized Cable Architecture: By distributing current across multi-cores in parallel, the system achieves an >83% improvement in MTBF compared to traditional configurations. This design enables fault detection through real-time monitoring of current differentials (ΔI > Irate/2), eliminating the need for auxiliary energy storage;

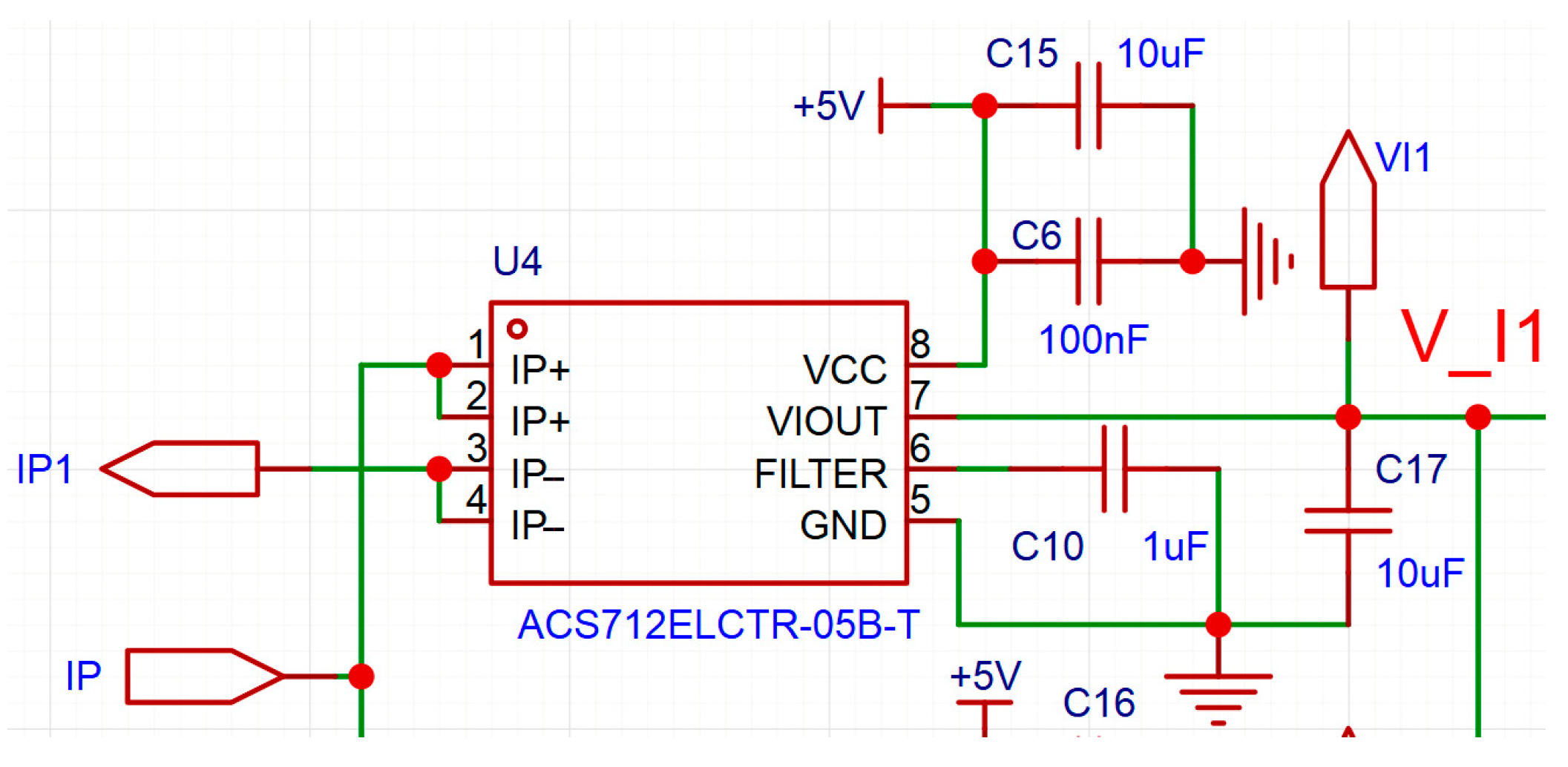

- Ultra-Low-Cost Analog Signal Processing: Leveraging off-the-shelf components—ACS712 Hall effect sensors (USD 0.63 per unit) and LMV324 operational amplifiers (USD 0.07 per unit)—the hardware solution totals just USD 3, representing a 1/3000 cost reduction compared to FBG systems [29]. The analog circuitry achieves sub-10 ms response times, 8 times faster than impedance-based methods [30];

- Lightweight Break Detection: The detection circuit with low voltage and small current is composed of ACS712 Hall sensors (Allegro MicroSystems, Worcester, MA, USA) [31] and LMV324 operational amplifiers (Texas Instruments Incorporated, Dallas, TX, USA) [32], completely eliminating the need for UAV backup power supplies, reducing the UAV load by 18%, and the detection circuit reduces power consumption by 23% compared with traditional schemes.

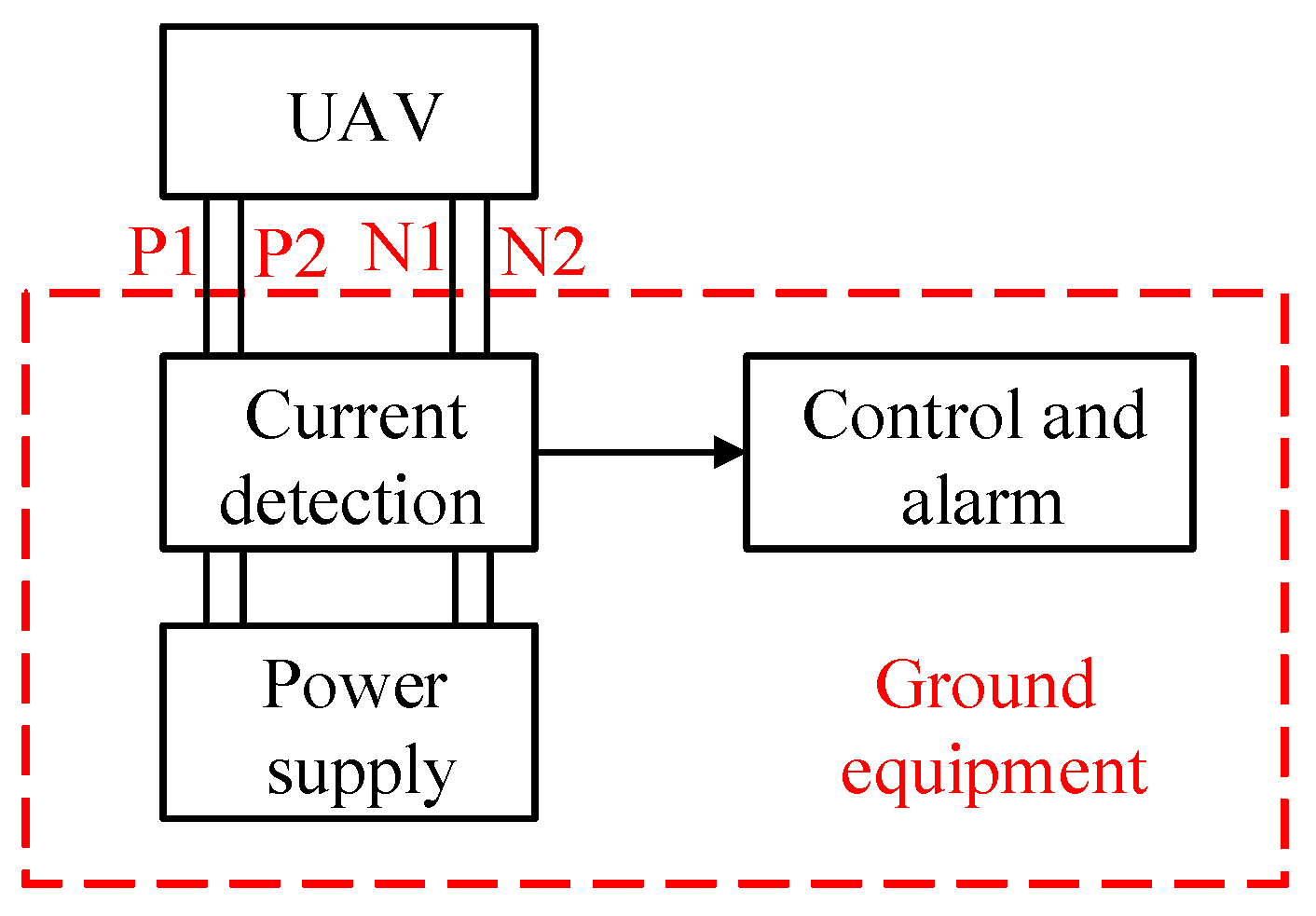

2. System Design

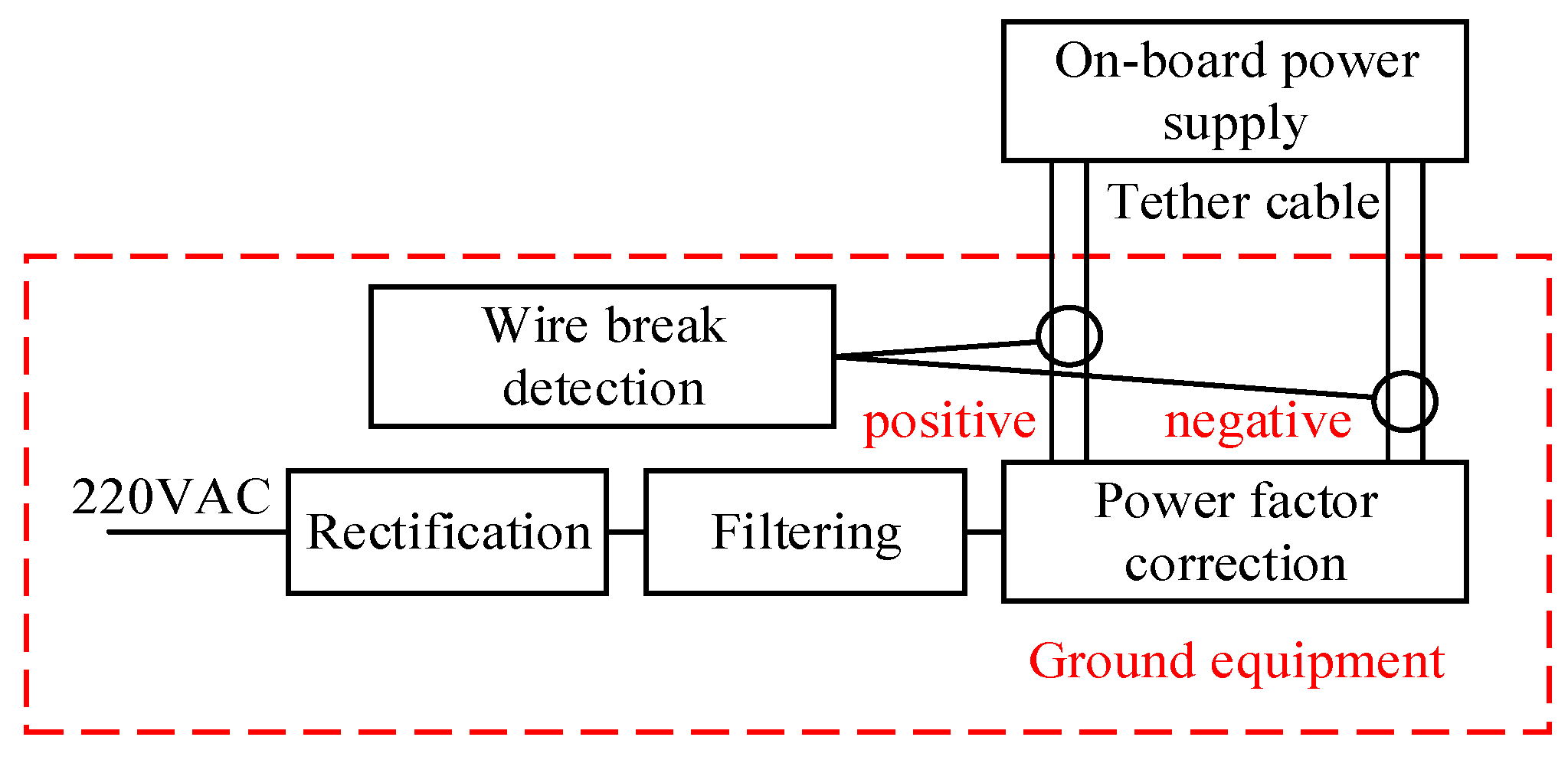

2.1. Multi-Core Parallel Power Supply Architecture

2.2. System Reliability Analysis

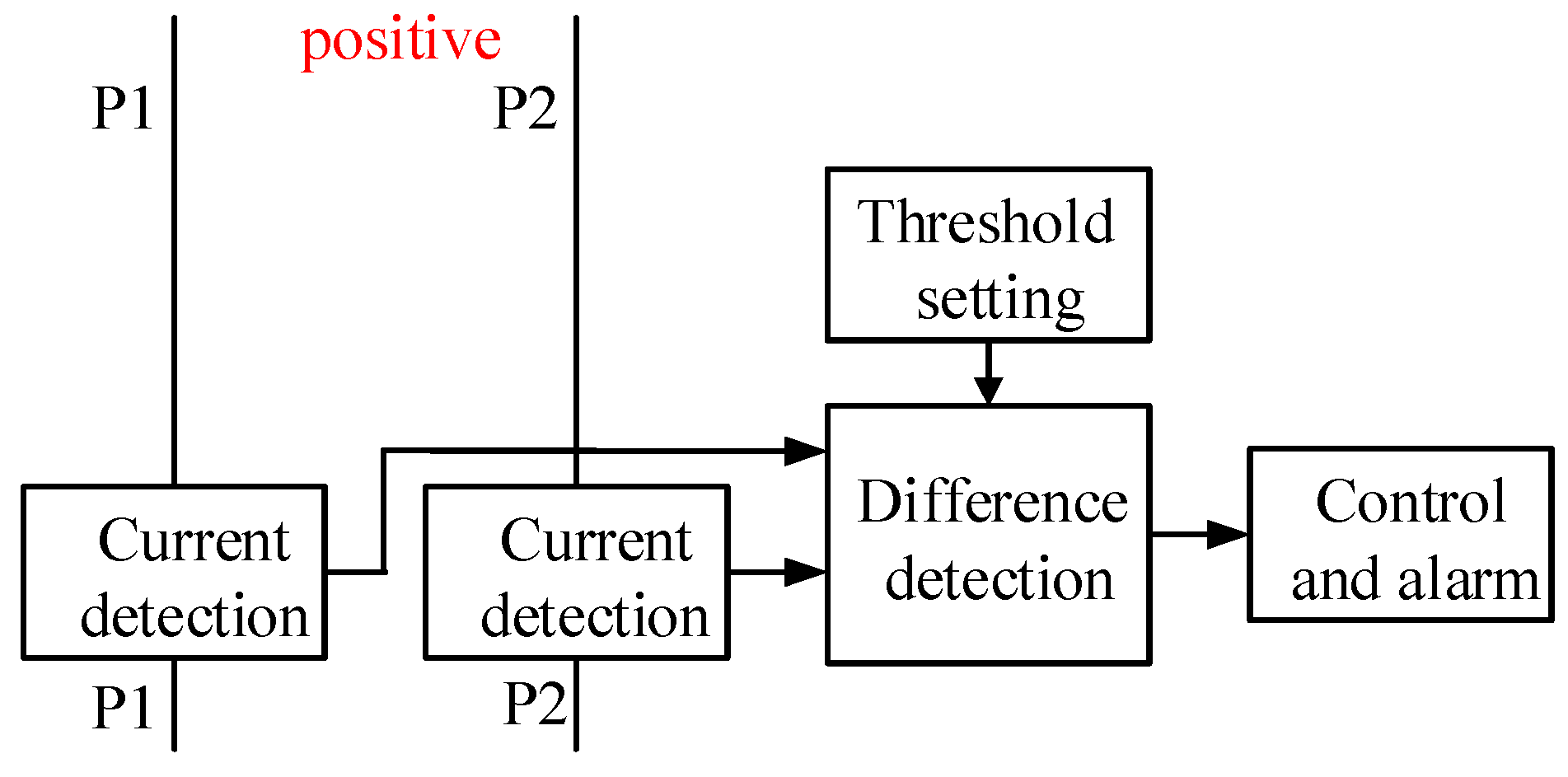

2.3. Break Detection Principle and Algorithm

3. Experiments and Results

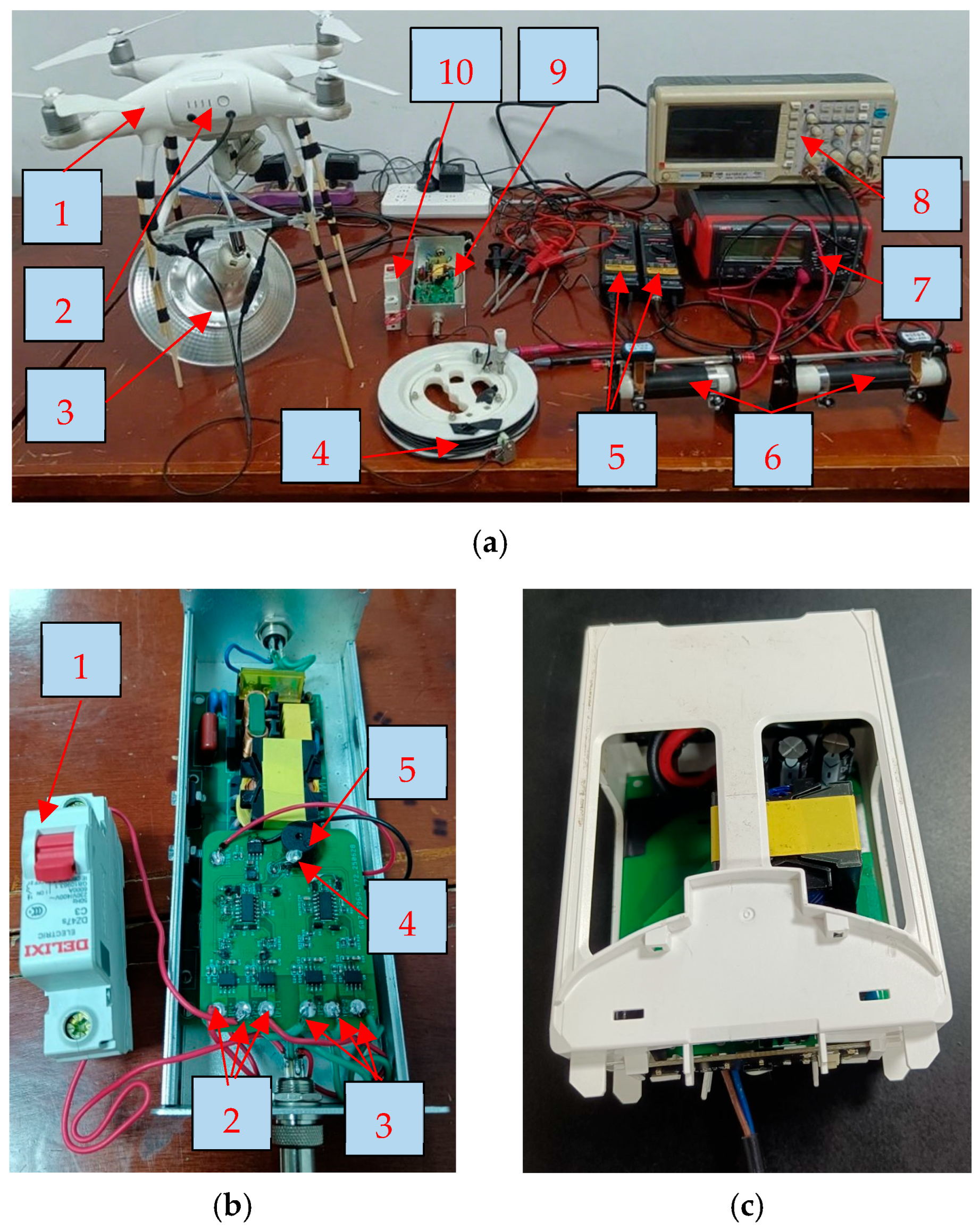

3.1. Test Platform

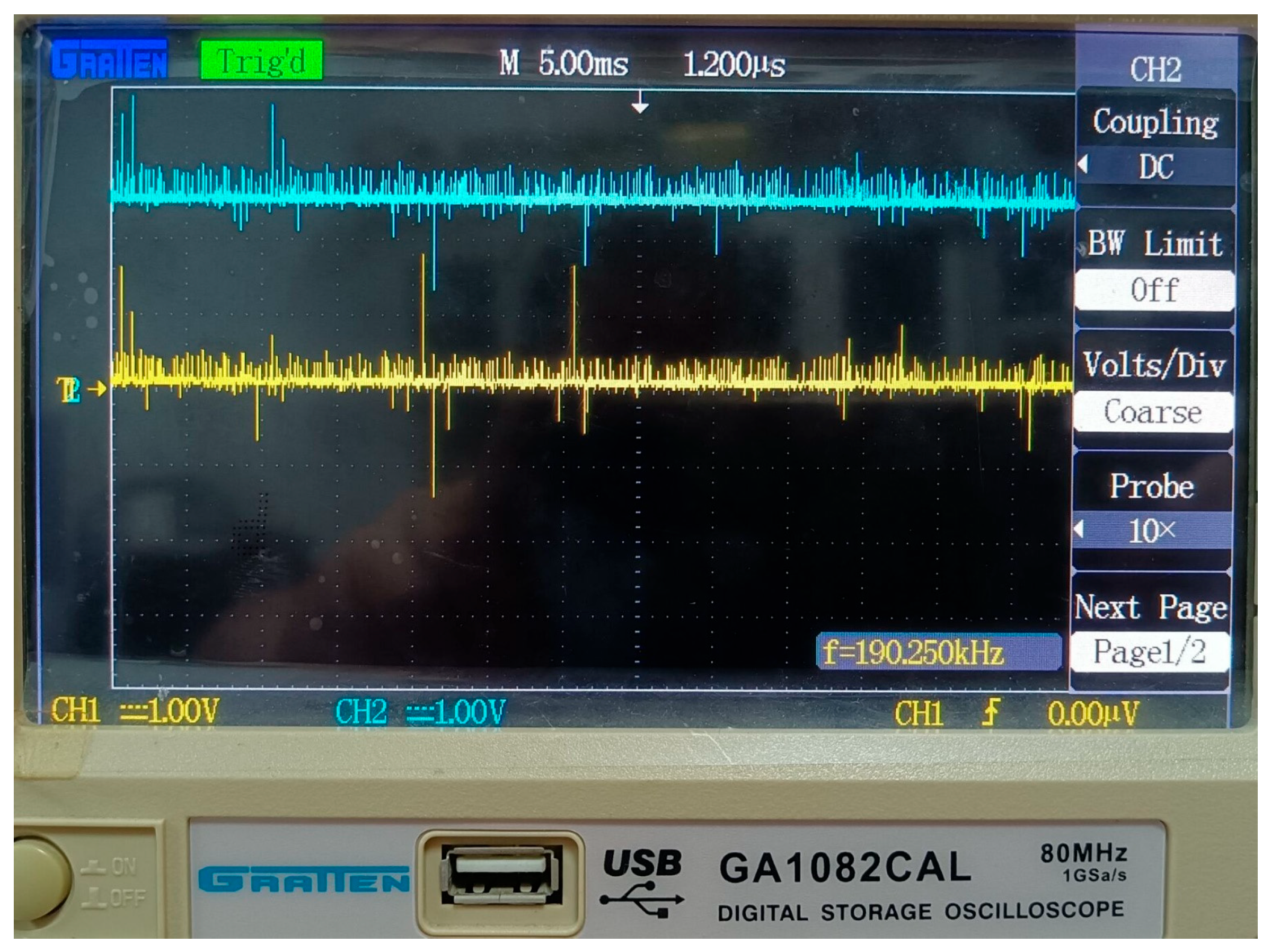

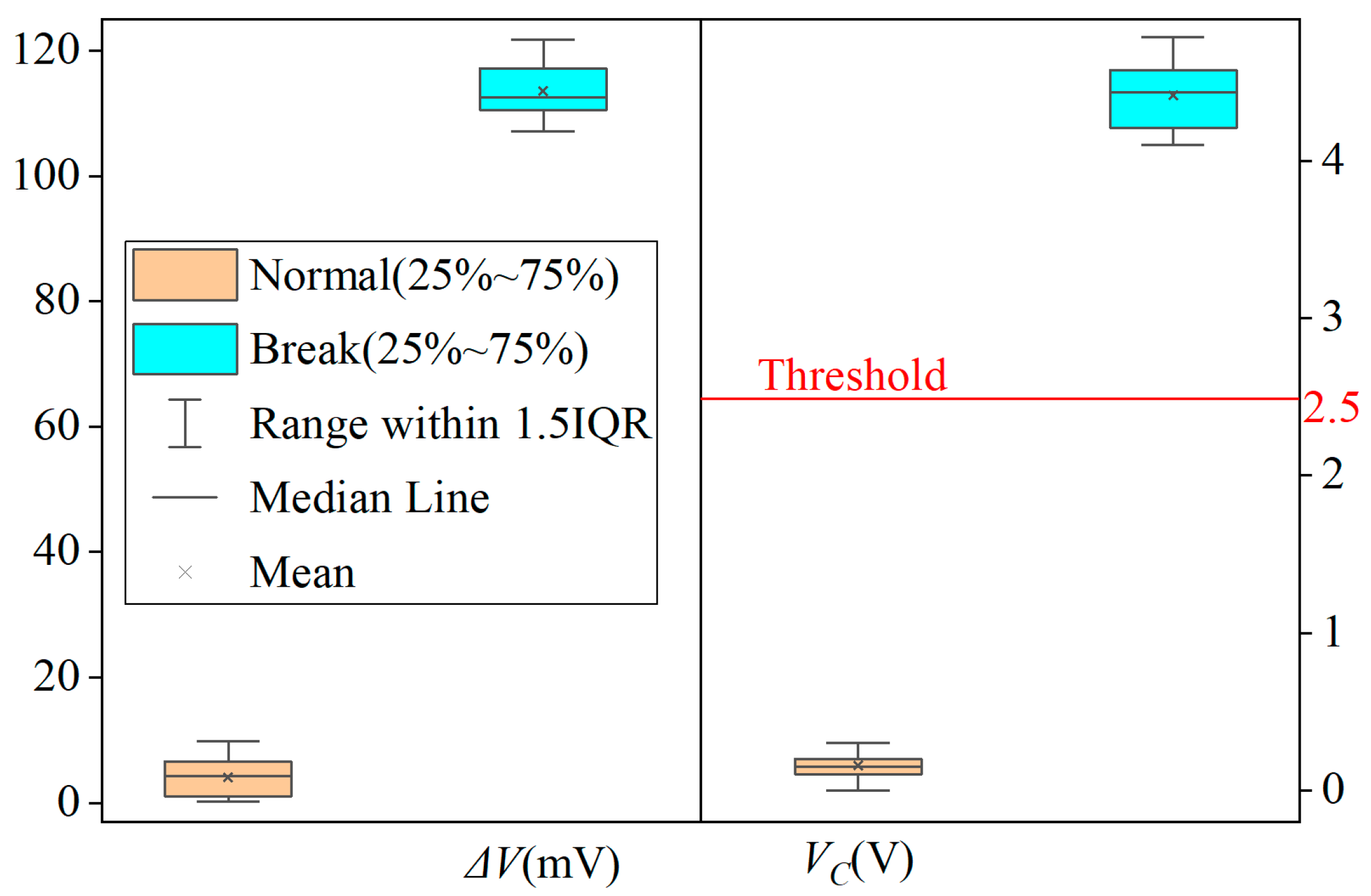

3.2. Cable Break Experimental Test

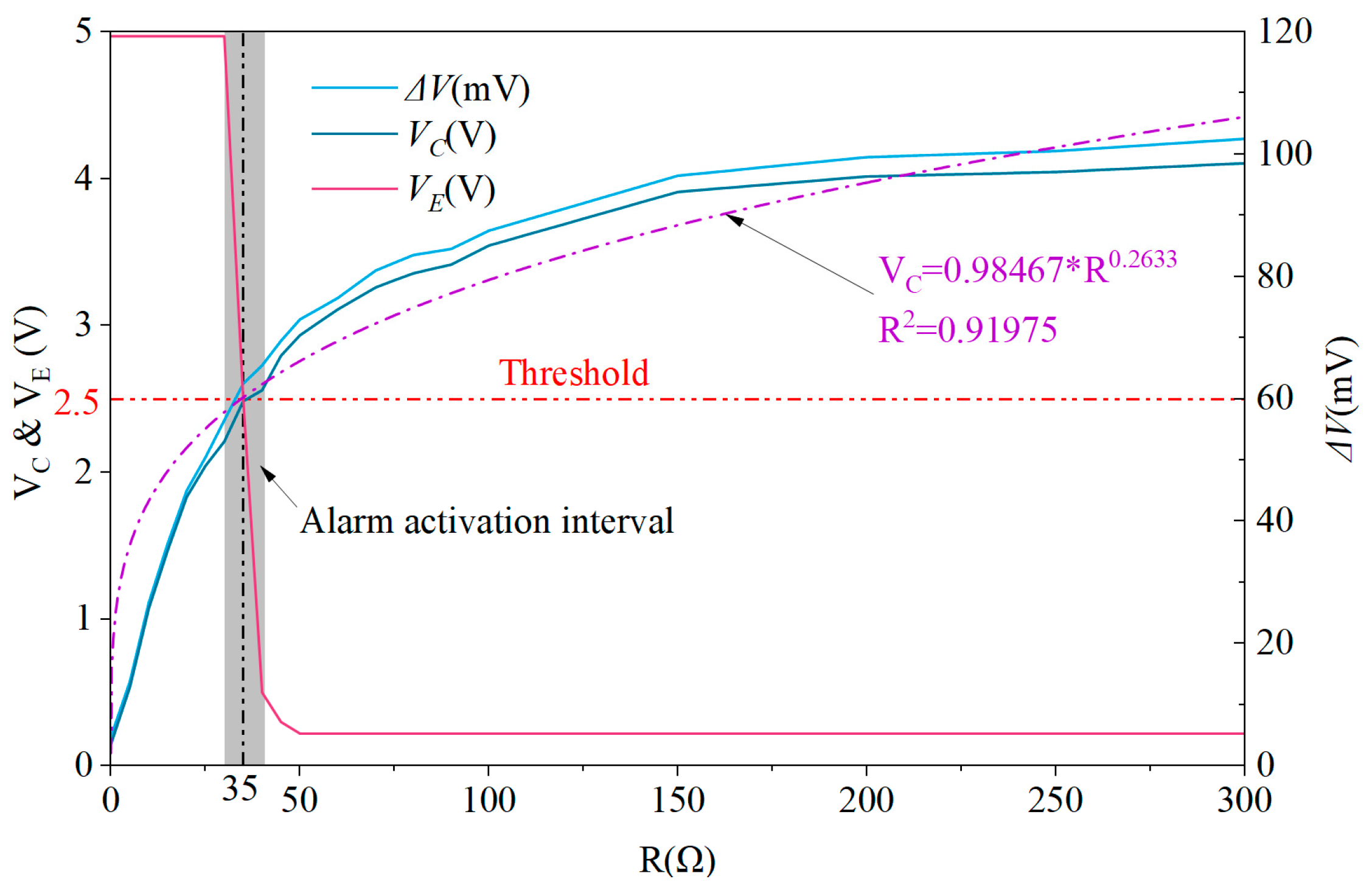

3.3. Progressive Break Simulation Experiment

- If the alarm is triggered, operators can replace the cable at 23.3% degradation, proactively reducing the risk of complete rupture;

- If the alarm remains unactivated, the UAV can continue operating. As tests in Section 3.2 demonstrated, even with 100% core break, safe flight is maintained for over 30 min—with safety margins being even greater at 23.3% degradation.

4. Discussion

4.1. Comparative Analysis with Conventional Detection Techniques

4.1.1. Fiber Bragg Grating (FBG) Sensing

- High deployment cost (more than 3000 times higher than our solution) and more than 30 min per sensor installation;

- Environmental sensitivity, as adhesive degradation under varying temperatures affects signal stability.

4.1.2. Impedance Analysis

- 35% payload increase from additional hardware, conflicting with UAV lightweight design;

- 12% false alarm rate due to capacitance variations in aged cables;

- 23% higher power consumption from continuous signal injection.

4.2. Multi-Core Architecture Trade-Offs: 2P2N vs. 3P3N

- 2P2N: ΔI threshold = Irate/2 = 0.3 A, corresponding to 110+ mV voltage deviation.

- 3P3N: ΔI threshold = Irate/3 = 0.2 A, requiring tighter manufacturing tolerance.

4.3. Limitations and Mitigation Strategies

4.3.1. Extreme Tensile Scenarios

4.3.2. Environmental Interference

- Inherent Signal Stability: The primary signals are DC currents in power supply cables, which are inherently less susceptible to external interference compared to voltage signals.

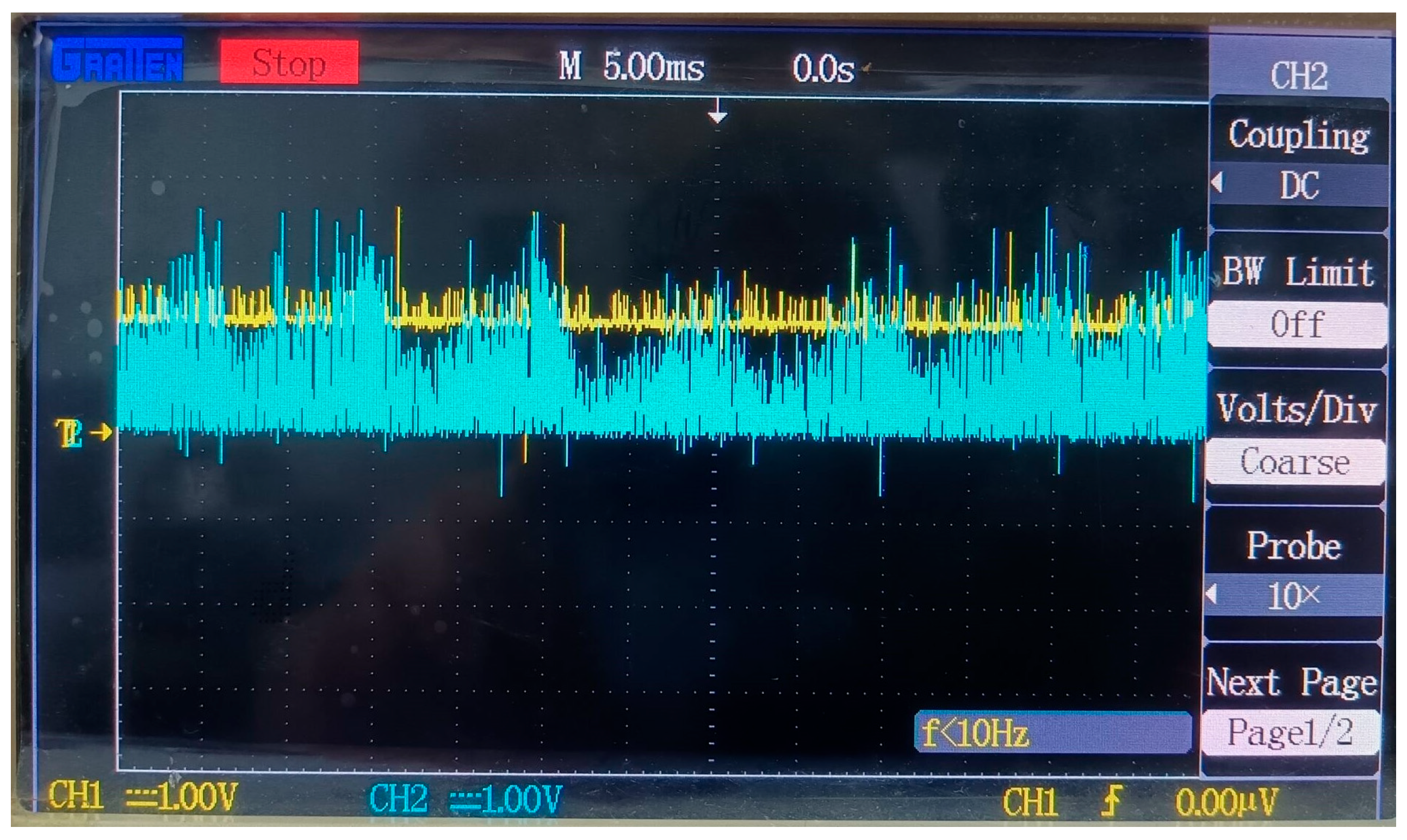

- DC Signal Processing: The detection circuitry employs DC signals, which can be effectively filtered using simple RC networks (e.g., cutoff frequency ≤ 15 Hz) to suppress ambient noise.

- Signal-to-Noise Margin: Useful signals (sub-volt level, ≥110 mV) exceed the typical noise floor (millivolt level, ≤5 mV) by two orders of magnitude, minimizing false triggers.

- System-Level Protection: When deployed in extreme environments (e.g., high humidity or EMI), the detection system benefits from the same environmental shielding as the UAV, ensuring consistent performance.

- Alert Mechanism Robustness: As detailed in Section 4.2, the visual/audio alarm triggers require sustained signal deviations (>50 ms), filtering out transient noise spikes (<10 μs) that might otherwise cause false positives.

4.3.3. Manufacturing Tolerances

4.3.4. Fault Localization

4.3.5. Underwater Applications

5. Conclusions

5.1. Innovative Technical Breakthroughs and Theoretical Innovations

5.2. Industrial Application Value

5.3. Future Directions

- Advanced 6-Core Architecture Optimization: Expanding to 3P3N configurations to achieve a 143% MTBF improvement, pushing the boundaries of high-reliability sensor design for tethered UAVs.

- Intelligent Predictive Maintenance Models: Integrating LSTM networks to enable proactive fault forecasting, targeting an 80% earlier detection window for pre-break signals compared to the current reactive alarm system.

- Hybrid Multi-Modal Sensing: Developing a fused monitoring framework that combines current differential sensing with thermal and vibration data, drawing inspiration from multi-modal fusion approaches in Refs. [8,9]. For instance, integrating YOLOv8 (Ref. [8]) for visual cable inspection and thermal imaging (Ref. [9]) will enable electrical-mechanical-thermal feature fusion, enhancing early-warning capabilities beyond single-parameter monitoring.

- Environmental Hardening and Validation: Addressing identified limitations through targeted improvements: conducting EMI susceptibility tests in anechoic chambers (per IEC 61000-4-3/4 standards [33,34]) to quantify electromagnetic resilience and developing hermetic encapsulation techniques to validate underwater adaptability—ensuring the system performs reliably across diverse operational environments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| UAV | Unmanned aerial vehicle |

| MTBF | mean time between failures |

| FBG | Fiber Bragg Grating |

| 1P1N | 1 positive core and 1 negative core |

| 2P2N | 2 positive cores and 2 negative cores |

| 3P3N | 3 positive cores and 3 negative cores |

References

- Seidaliyeva, U.; Ilipbayeva, L.; Taissariyeva, K.; Smailov, N.; Matson, E.T. Advances and Challenges in Drone Detection and Classification Techniques: A State-of-the-Art Review. Sensors 2024, 24, 125. [Google Scholar] [CrossRef] [PubMed]

- Trethowan, J.; Wang, Z.; Wong, K.C. The Viability of a Grid of Autonomous Ground-Tethered UAV Platforms in Agricultural Pest Bird Control. Machines 2023, 11, 377. [Google Scholar] [CrossRef]

- Yamamoto, S.; Nakazato, J.; Tran, G.K. Multi-IRS-Assisted MmWave UAV-BS Network for Coverage Extension. Sensors 2024, 24, 2006. [Google Scholar] [CrossRef] [PubMed]

- Hashesh, A.O.; Hashima, S.; Zaki, R.M.; Fouda, M.M.; Hatano, K.; Eldien, A.S.T. AI-Enabled UAV Communications: Challenges and Future Directions. IEEE Access 2022, 10, 92048–92066. [Google Scholar] [CrossRef]

- Kim, S. Collaborative Game-Based Task Offloading Scheme in the UAV-TB-Assisted Battlefield Network Platform. EURASIP J. Wirel. Commun. Netw. 2024, 2024, 11. [Google Scholar] [CrossRef]

- Zheng, K.; Fu, J.; Liu, X. Relay Selection and Deployment for NOMA Enabled Multi-UAV-Assisted WSN. IEEE Sens. J. 2025, 25, 16235–16249. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, Z.; Wen, X.; Wang, Z.; Lu, Z. Modeling and Performance Analysis of Mobile Tethered UAV Networks with Spatial Repulsion. IEEE Internet Things J. 2025, 12, 9465–9475. [Google Scholar] [CrossRef]

- Santos, T.; Cunha, T.; Dias, A.; Moreira, A.P.; Almeida, J. UAV Visual and Thermographic Power Line Detection Using Deep Learning. Sensors 2024, 24, 5678. [Google Scholar] [CrossRef]

- Tsellou, A.; Livanos, G.; Ramnalis, D.; Polychronos, V.; Plokamakis, G.; Zervakis, M.; Moirogiorgou, K. A UAV Intelligent System for Greek Power Lines Monitoring. Sensors 2023, 23, 8441. [Google Scholar] [CrossRef] [PubMed]

- Martinez Rocamora, B., Jr.; Lima, R.R.; Samarakoon, K.; Rathjen, J.; Gross, J.N.; Pereira, G.A.S. Oxpecker: A Tethered UAV for Inspection of Stone-Mine Pillars. Drones 2023, 7, 73. [Google Scholar] [CrossRef]

- Hormeno, A.J.; Gomez, D.M.; De La Escalera Hueso, A.; Moreno, J.M.A. A Precise Positioning Methodology for Autonomous Navigation of a Tethered UAV for Photogrammetry. In Proceedings of the 2024 11th International Workshop on Metrology for AeroSpace (MetroAeroSpace), Lublin, Poland, 3–5 June 2024; pp. 437–442. [Google Scholar] [CrossRef]

- Viegas, C.; Chehreh, B.; Andrade, J.; Lourenço, J. Tethered UAV with Combined Multi-Rotor and Water Jet Propulsion for Forest Fire Fighting. J. Intell. Robot. Syst. 2022, 104, 21. [Google Scholar] [CrossRef]

- Rong, Y.; Gutierrez, R.; Mishra, K.V.; Bliss, D.W. Noncontact Vital Sign Detection with UAV-Borne Radars: An Overview of Recent Advances. IEEE Veh. Technol. Mag. 2021, 16, 118–128. [Google Scholar] [CrossRef]

- Saif, A.; Shah, N.S.M.; Al-Moliki, Y.M.; Jiang, W.; Alsamhi, S.H. Enhancing Resilience Communication in B5G: Optimal Deployment of Tethered Networked Flying Platforms for Disaster Recovery. J. Supercomput. 2025, 81, 614. [Google Scholar] [CrossRef]

- Khan, A.; Gupta, S.; Gupta, S.K. Emerging UAV Technology for Disaster Detection, Mitigation, Response, and Preparedness. J. Field Robot. 2022, 39, 905–955. [Google Scholar] [CrossRef]

- Tang, Z.; Liu, C.; Jiang, H.; Hou, F.; Wang, S. Analyzing the Effect of Tethered Cable on the Stability of Tethered UAVs Based on Lyapunov Exponents. Appl. Sci. 2024, 14, 4253. [Google Scholar] [CrossRef]

- He, W.; Zhang, S. Vibration Response Analysis of a Tethered Unmanned Aerial Vehicle System Under Transient Wind Field. Int. J. Aerosp. Eng. 2024, 2024, 4982665. [Google Scholar] [CrossRef]

- Tao, Y.; Zhang, S. Research on the Vibration and Wave Propagation in Ship-Borne Tethered UAV Using Stress Wave Method. Drones 2022, 6, 349. [Google Scholar] [CrossRef]

- Liang, D.; Ding, L.; Lu, M.; Ma, R.; Cao, J. Quantitative Stability Analysis of an Unmanned Tethered Quadrotor. Int. J. Aeronaut. Space Sci. 2023, 24, 905–918. [Google Scholar] [CrossRef]

- Lima, R.R.; Rocamora, B.M., Jr.; Pereira, G.A.S. Continuous Vector Fields for Precise Cable-Guided Landing of Tethered UAVs. IEEE Robot. Autom. Lett. 2023, 8, 4370–4377. [Google Scholar] [CrossRef]

- Tao, Y.; Xu, X.; Dai, J. Dangerous Area of Tethered UAV Due to Impact. IEEE Access 2022, 10, 121152–121158. [Google Scholar] [CrossRef]

- Yan, C.; Yang, J.; Zhang, D.; Zhang, S.; Zhang, T. Comprehensive Design and Experimental Validation of Tethered Fixed-Wing Unmanned Aerial Vehicles. Aerospace 2025, 12, 150. [Google Scholar] [CrossRef]

- Saravanakumar, Y.N.; Sultan, M.T.H.; Shahar, F.S.; Giernacki, W.; Łukaszewicz, A.; Nowakowski, M.; Holovatyy, A.; Stępień, S. Power Sources for Unmanned Aerial Vehicles: A State-of-the-Art. Appl. Sci. 2023, 13, 11932. [Google Scholar] [CrossRef]

- Yingst, A.; Marojevic, V. Power Tether for Long Duration Multi-Copter Flight. HardwareX 2023, 15, e00466. [Google Scholar] [CrossRef] [PubMed]

- Burkin, E.Y.; Sviridov, V.V.; Bombizov, A.A. Power Supply System of a Tethered Unmanned Aerial Vehicle. Instrum. Exp. Tech. 2024, 67, 41–47. [Google Scholar] [CrossRef]

- Gonçalves, R.S.; De Oliveira, M.; Rocioli, M.; Souza, F.; Gallo, C.; Sudbrack, D.; Trautmann, P.; Clasen, B.; Homma, R. Drone–Robot to Clean Power Line Insulators. Sensors 2023, 23, 5529. [Google Scholar] [CrossRef]

- Tomaszewski, M.; Gasz, R.; Osuchowski, J. Detection of Power Line Insulators in Digital Images Based on the Transformed Colour Intensity Profiles. Sensors 2023, 23, 3343. [Google Scholar] [CrossRef]

- Zhuang, W.; Xing, F.; Lu, Y. Task Offloading Strategy for Unmanned Aerial Vehicle Power Inspection Based on Deep Reinforcement Learning. Sensors 2024, 24, 2070. [Google Scholar] [CrossRef]

- Yuan, L.; Liu, W.; Zhao, Y. Multi-Point Sensing System for Cable Fault Detection Using Fiber Bragg Grating. Opt. Fiber Technol. 2024, 87, 103942. [Google Scholar] [CrossRef]

- Li, C.; Tam, K.W.; Lin, H.; Zhang, Z.; Chio, C.-H.; Teng, C.; Dai, N.; Lao, K.-W.; Kong, N.; Zhang, G. Design of Reconfigurable Impedance Transformer and Its Application to Medium Voltage XLPE Power Cable with Joint in TV White Space. IEEE Trans. Dielectr. Electr. Insul. 2024, 31, 1281–1287. [Google Scholar] [CrossRef]

- Allegro MicroSystems. ACS712 Data Sheet. Available online: https://item.szlcsc.com/datasheet/ACS712ELCTR-05B-T/45473.html (accessed on 22 April 2025).

- Texas Instruments. LMV324 Data Sheet. Available online: https://www.ti.com/lit/ds/symlink/lmv324.pdf (accessed on 22 April 2025).

- IEC 61000-4-3:2020; Electromagnetic Compatibility (EMC)—Part 4-3: Testing and Measurement Techniques—Radiated, Radio—Frequency, Electromagnetic Field Immunity Test. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2020. Available online: https://www.iecee.org/certification/iec-standards/iec-61000-4-32020 (accessed on 14 August 2025).

- IEC 61000-4-4:2012; Electromagnetic Compatibility (EMC)—Part 4-4: Testing and Measurement Techniques—Electrical Fast Transient/Burst Immunity Test. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2012. Available online: https://www.iecee.org/certification/iec-standards/iec-61000-4-42012 (accessed on 14 August 2025).

| Architecture | MTBF (h) | Reliability Improvement |

|---|---|---|

| Traditional (1P1N) | 1/(2λ) | 0% (baseline) |

| 4-Core (2P2N) | 11/(12λ) | 83% |

| 6-Core (3P3N) | 73/(60λ) | 143% |

| Parameters | Value |

|---|---|

| Wire Diameter (AWG) | 28 |

| Resistance (Ω/km) | 227 |

| Current carrying capacity (A) | 0.5 |

| Condition | I1 (A) | I2 (A) | VA (V) | VB (V) | VC (V) | VD (V) | VE and VF (V) | LED and BUZZER |

|---|---|---|---|---|---|---|---|---|

| normal | 0.3 | 0.3 | 0 | 0 | 0 | 2.5 | 5 | Off |

| Broken P1 | 0 | 0.6 | 4.44 | 0 | 4.44 | 2.5 | 0 | On |

| Broken P2 | 0.6 | 0 | 0 | 4.44 | 4.44 | 2.5 | 0 | On |

| Experimental Condition | I1 (A) | I2 (A) | ΔV (mV) | VA (V) | VB (V) | VC (V) | VE (V) |

|---|---|---|---|---|---|---|---|

| Normal 1 | 0.32 | 0.31 | 3 | 0.1 | 0.1 | 0.1 | 4.97 |

| Broken P1 2 | 0 | 0.63 | 113 | 4.33 | 0.1 | 4.32 | 0.22 |

| Broken P2 2 | 0.63 | 0 | 112 | 0.1 | 4.31 | 4.31 | 0.22 |

| Rheostat Resistance (Ω) | ΔV (mV) | VC (V) | VE (V) |

|---|---|---|---|

| 0 | 3 ± 0.5 | 0.15 ± 0.1 | 4.97 |

| 5 | 13.8 ± 0.5 | 0.54 ± 0.1 | 4.97 |

| 10 | 26.7 ± 0.5 | 1.07 ± 0.1 | 4.97 |

| 15 | 36.4 ± 0.5 | 1.47 ± 0.1 | 4.97 |

| 20 | 45 ± 0.5 | 1.83 ± 0.1 | 4.97 |

| 25 | 50.5 ± 0.5 | 2.05 ± 0.1 | 4.97 |

| 30 | 56.5 ± 0.5 | 2.21 ± 0.1 | 4.97 |

| 35 | 62.5 ± 0.5 | 2.49 ± 0.1 | 2 ± 1 |

| 40 | 65.5 ± 0.5 | 2.56 ± 0.1 | 0.5 ± 0.1 |

| 45 | 69.5 ± 0.5 | 2.8 ± 0.1 | 0.3 |

| 50 | 73 ± 0.5 | 2.93 ± 0.1 | 0.22 |

| 60 | 76.5 ± 0.5 | 3.11 ± 0.1 | 0.22 |

| 70 | 81 ± 0.5 | 3.26 ± 0.1 | 0.22 |

| 80 | 83.5 ± 0.5 | 3.36 ± 0.1 | 0.22 |

| 90 | 84.5 ± 0.5 | 3.42 ± 0.1 | 0.22 |

| 100 | 87.5 ± 0.5 | 3.55 ± 0.1 | 0.22 |

| 150 | 96.5 ± 0.5 | 3.91 ± 0.1 | 0.22 |

| 200 | 99.5 ± 0.5 | 4.02 ± 0.1 | 0.22 |

| 250 | 100.5 ± 0.5 | 4.05 ± 0.1 | 0.22 |

| 300 | 102.5 ± 0.5 | 4.11 ± 0.1 | 0.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Luo, Z.; Wang, Z.; Huang, Z.; He, Y.; Wen, Z.; Ding, Y.; Xu, Z. A Novel Multi-Core Parallel Current Differential Sensing Approach for Tethered UAV Power Cable Break Detection. Sensors 2025, 25, 5112. https://doi.org/10.3390/s25165112

Chen Z, Luo Z, Wang Z, Huang Z, He Y, Wen Z, Ding Y, Xu Z. A Novel Multi-Core Parallel Current Differential Sensing Approach for Tethered UAV Power Cable Break Detection. Sensors. 2025; 25(16):5112. https://doi.org/10.3390/s25165112

Chicago/Turabian StyleChen, Ziqiao, Zifeng Luo, Ziyan Wang, Zhou Huang, Yongkang He, Zhiheng Wen, Yuanjun Ding, and Zhengwang Xu. 2025. "A Novel Multi-Core Parallel Current Differential Sensing Approach for Tethered UAV Power Cable Break Detection" Sensors 25, no. 16: 5112. https://doi.org/10.3390/s25165112

APA StyleChen, Z., Luo, Z., Wang, Z., Huang, Z., He, Y., Wen, Z., Ding, Y., & Xu, Z. (2025). A Novel Multi-Core Parallel Current Differential Sensing Approach for Tethered UAV Power Cable Break Detection. Sensors, 25(16), 5112. https://doi.org/10.3390/s25165112