Sensor-Based Monitoring of Bolted Joint Reliability in Agricultural Machinery: Performance and Environmental Challenges

Abstract

1. Introduction

2. Current Status of Reliability Issues in Agricultural Machinery Bolted Connections

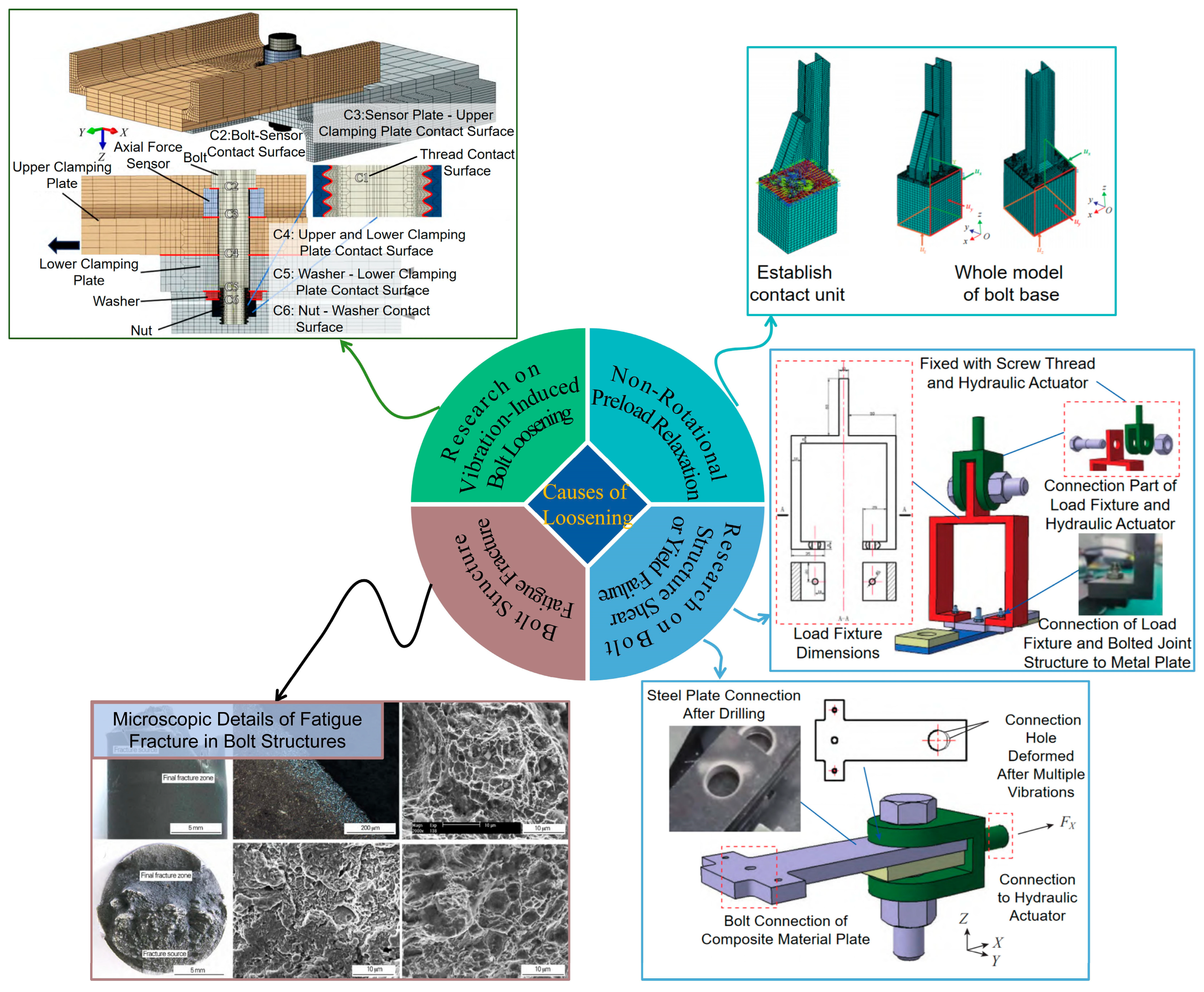

2.1. Typical Bolt Loosening Failure Modes During Agricultural Machinery Operation

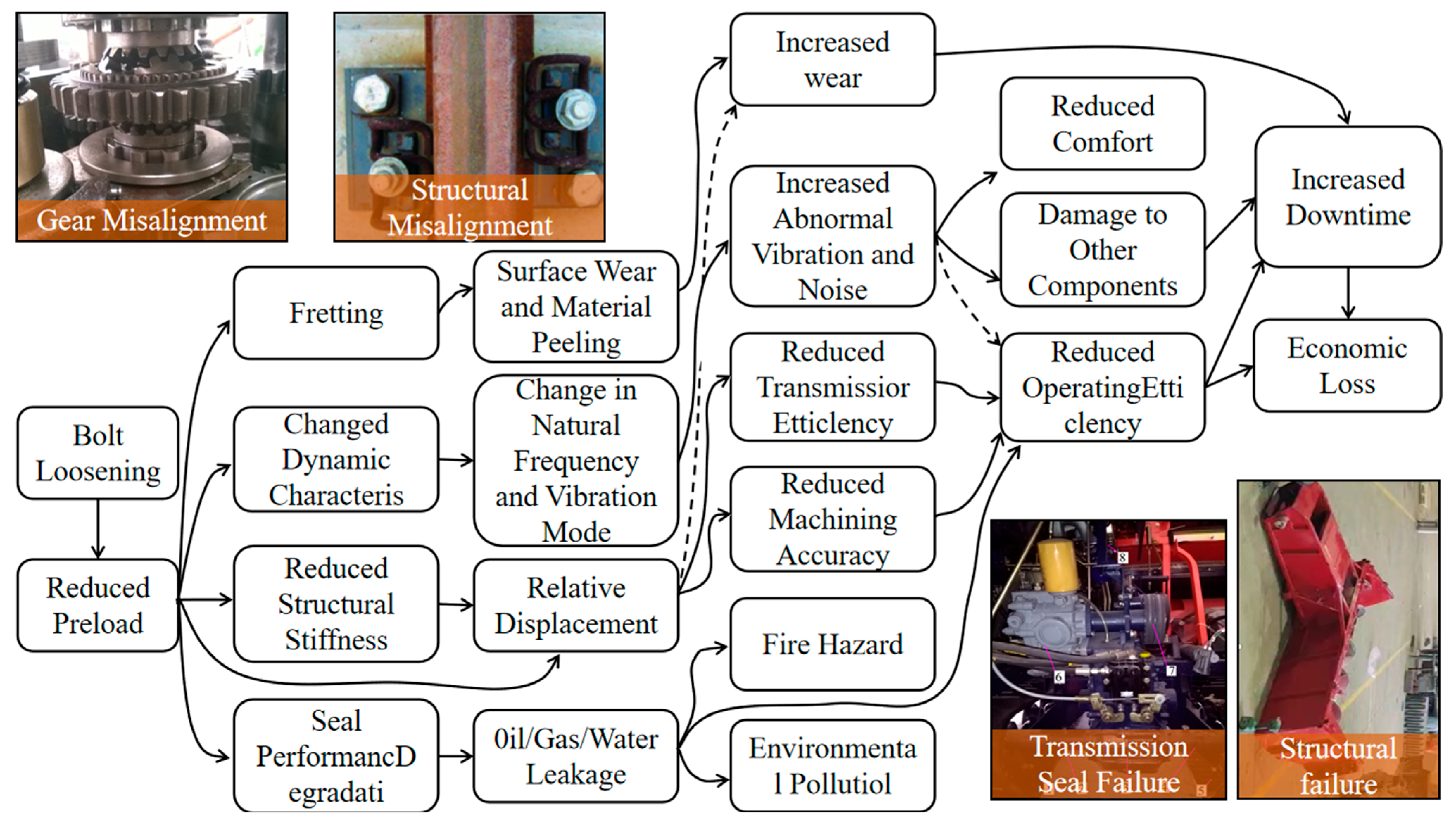

2.2. Impacts of Bolt Loosening on Agricultural Machinery Performance and Operational Efficiency

2.3. Deficiencies in Bolted Connection Management Under Existing Maintenance Paradigms

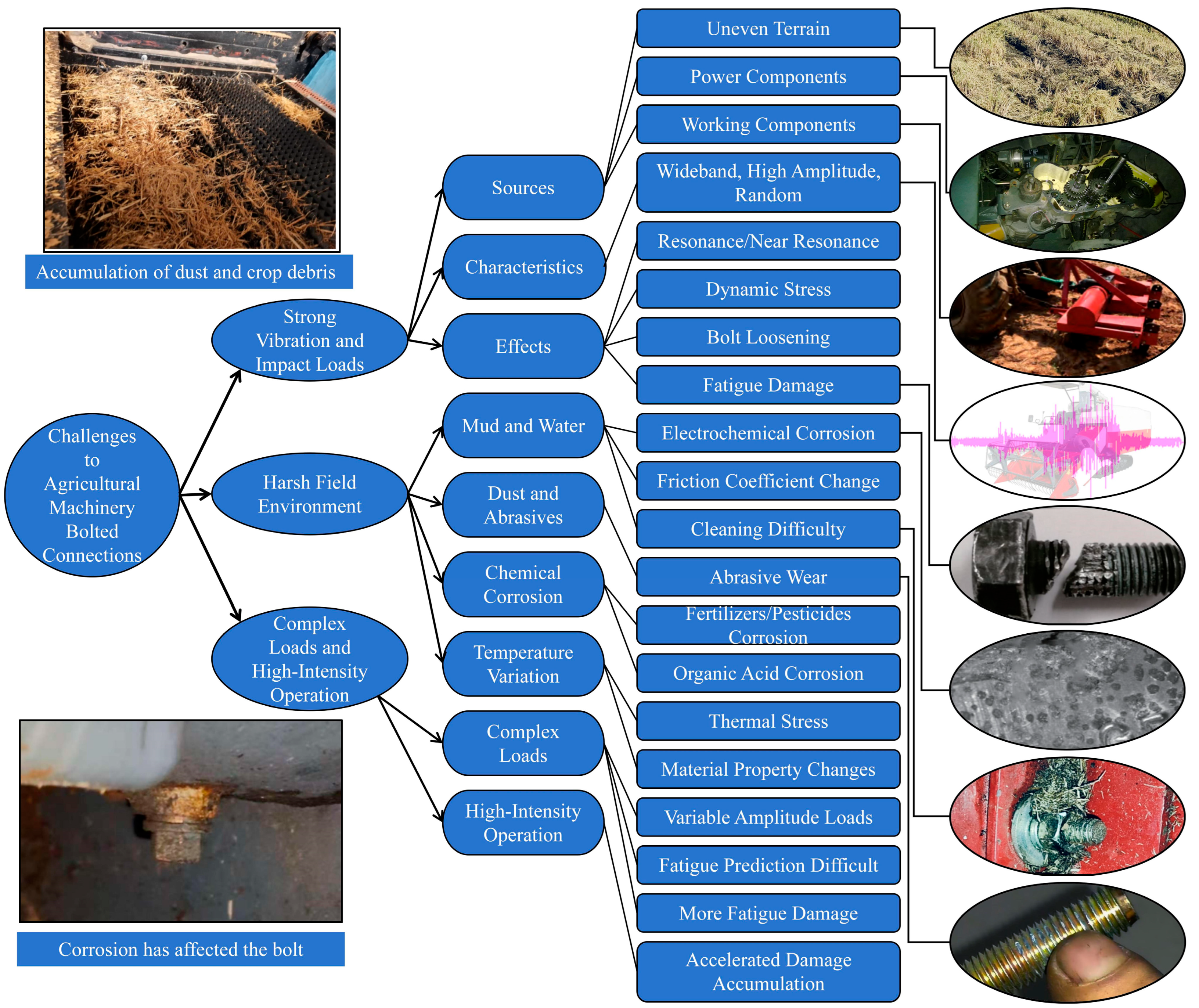

3. Impacts of Specialized Agricultural Machinery Operating Conditions and Environments on Bolted Connection Reliability

3.1. Severe Challenge Posed by Intense Vibration and Impact Loads

3.2. Accelerated Degradation Due to Harsh Field Environments

- (1)

- Mud, Water, and Humidity: Field operations frequently involve exposure to mud splashes and high humidity [86]. The presence of moisture directly accelerates electrochemical corrosion of bolts and clamped components [87,88], leading to surface rusting, reduced material strength, and impaired thread engagement. Furthermore, moisture infiltration into thread gaps can alter friction coefficients, impacting the accurate application and retention of preload, while adhered mud complicates cleaning and inspection procedures [89,90].

- (2)

- Dust and Abrasive Particles: Significant quantities of dust and fine soil particles are generated during field activities, particularly tillage and harvesting [91]. These hard particles can infiltrate contact interfaces (e.g., thread pairs, under-head bearing surfaces), acting as abrasive media. During relative micro-motion between components, this leads to severe abrasive wear, causing surface damage, diminished connection precision, and potentially inducing stress concentration [92,93,94].

- (3)

- Chemical Corrosion: Agrochemicals widely used in production (fertilizers, pesticides, herbicides) [95], along with organic acids from decomposing crop residues, possess corrosive properties [96]. When these substances adhere to surfaces or dissolve in ambient moisture, they initiate chemical reactions with bolt materials, accelerating corrosive processes [97]. This effect is particularly pronounced under conditions of high temperature and humidity [98], ultimately weakening bolt strength and impairing preload retention capability.

- (4)

- Temperature Variations: Agricultural operating zones often experience substantial diurnal and seasonal temperature fluctuations [99]. Differential thermal expansion coefficients between connected materials can induce thermal stresses within the joint, affecting preload levels [100]. Additionally, exposure to extreme temperatures (both high and low) can alter the mechanical properties of materials, thereby influencing connection reliability [101].

3.3. Cumulative Damage Under Complex Loading and High-Intensity Operation

3.4. Environmental Adaptability Requirements for Monitoring Technologies

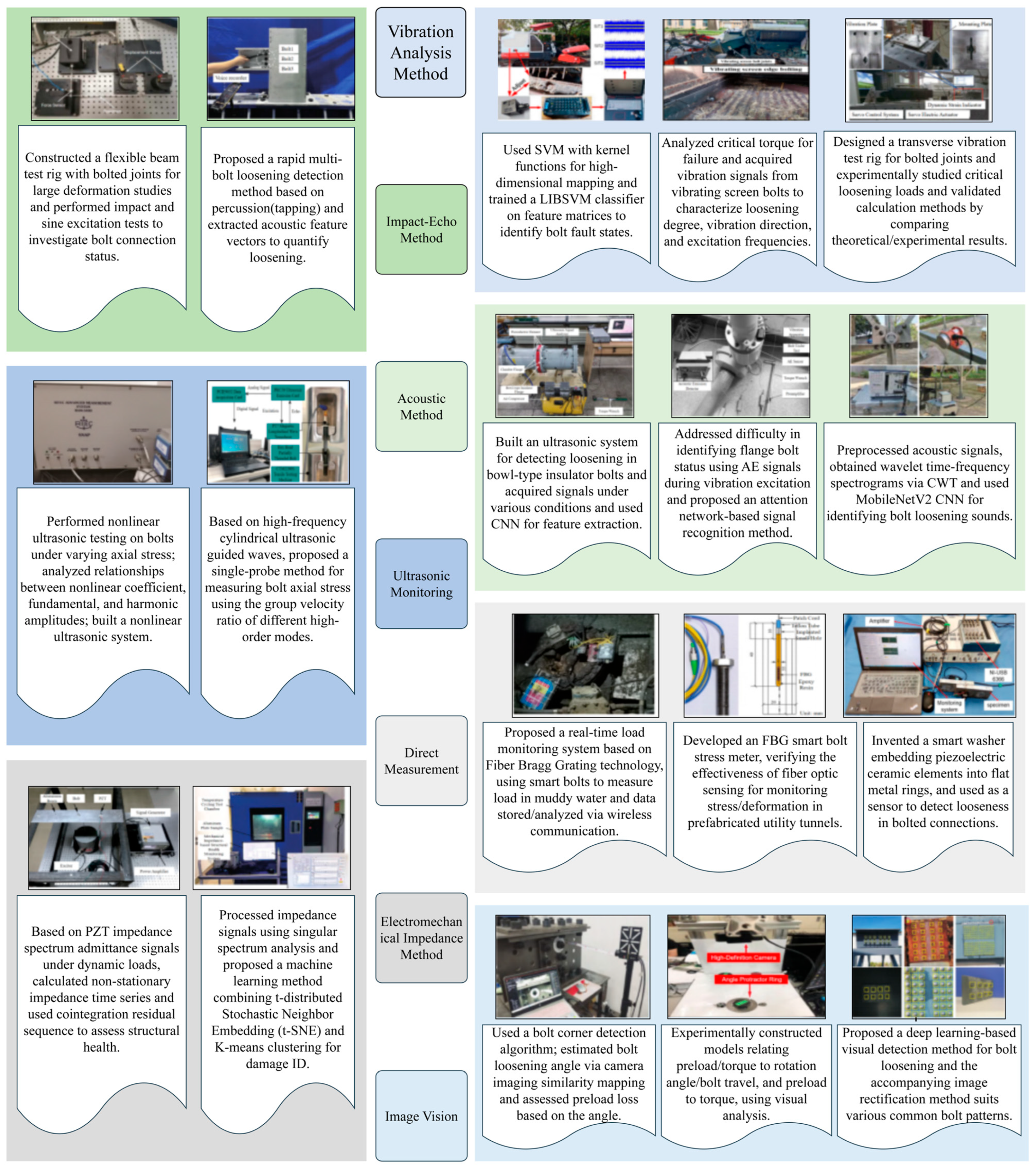

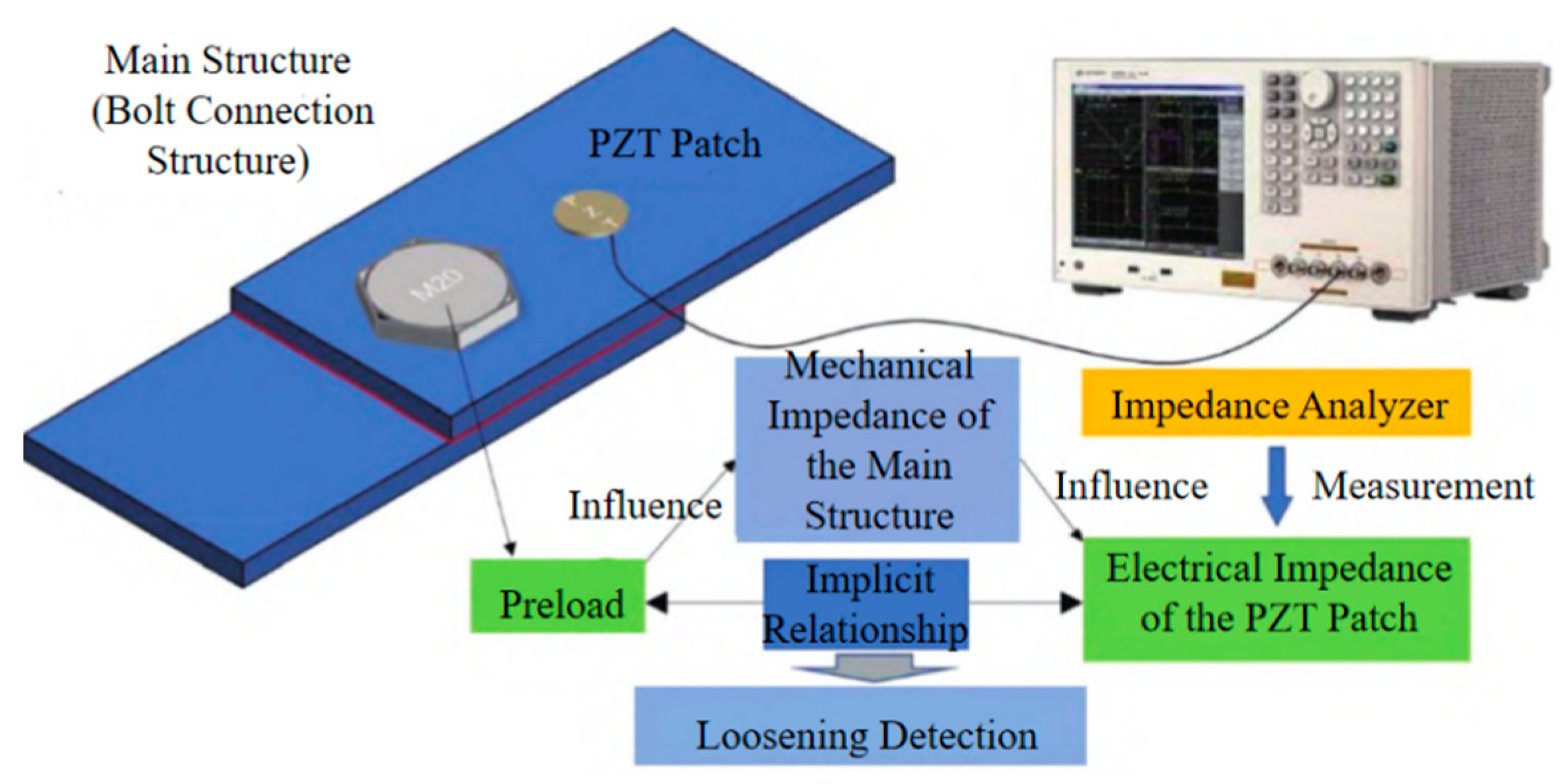

4. Principles and Classification of Bolt Loosening Detection Technologies

4.1. Principles and Characteristics of Traditional Detection Methods

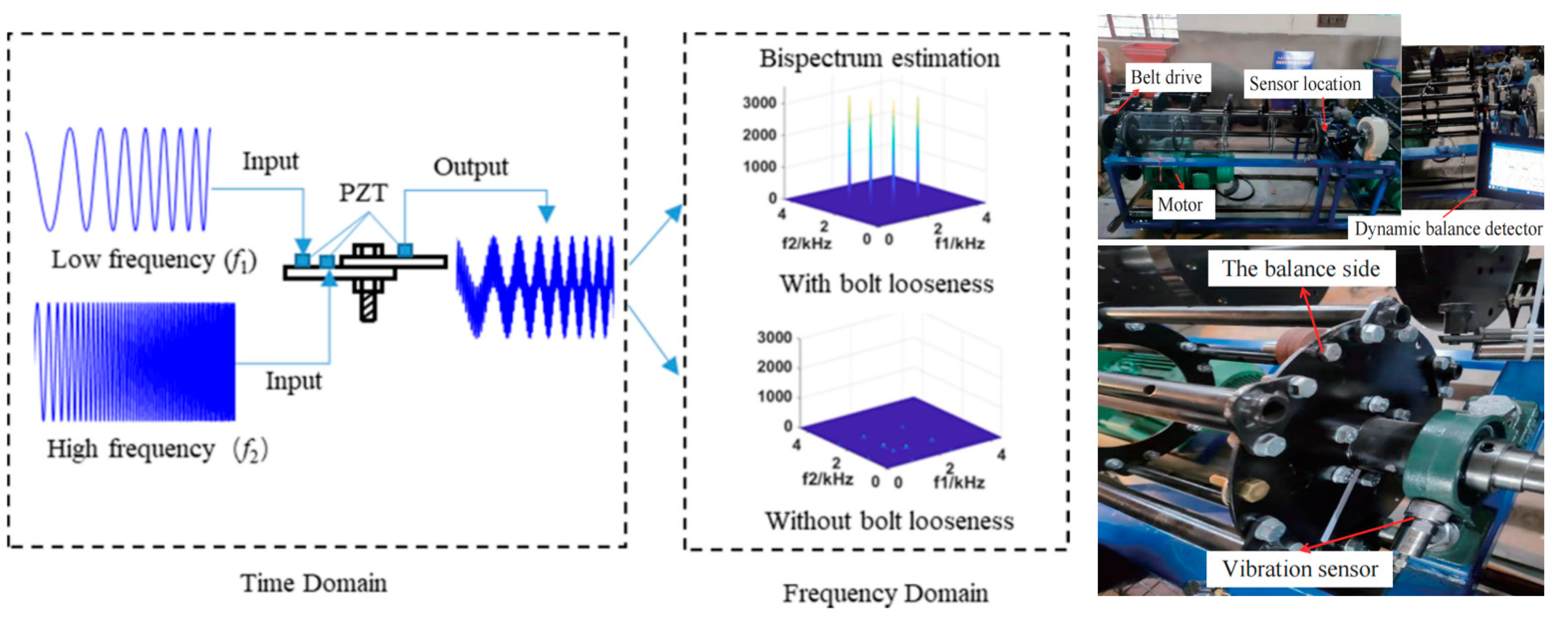

4.2. Principles of Vibration Signal-Based Detection Technologies

4.3. The Principles of Acoustic Signal-Based (AE/Ultrasonic) Detection Technologies

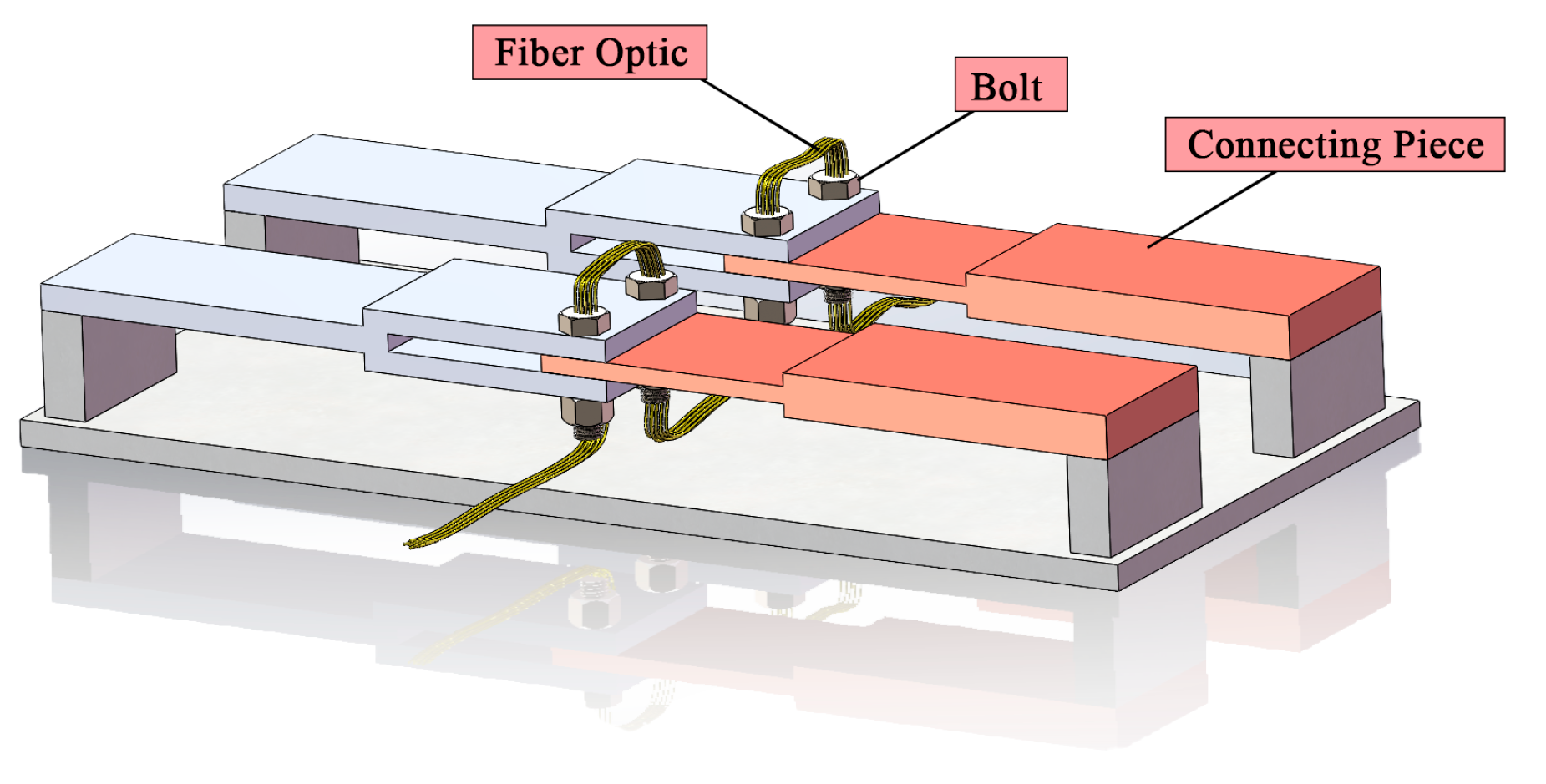

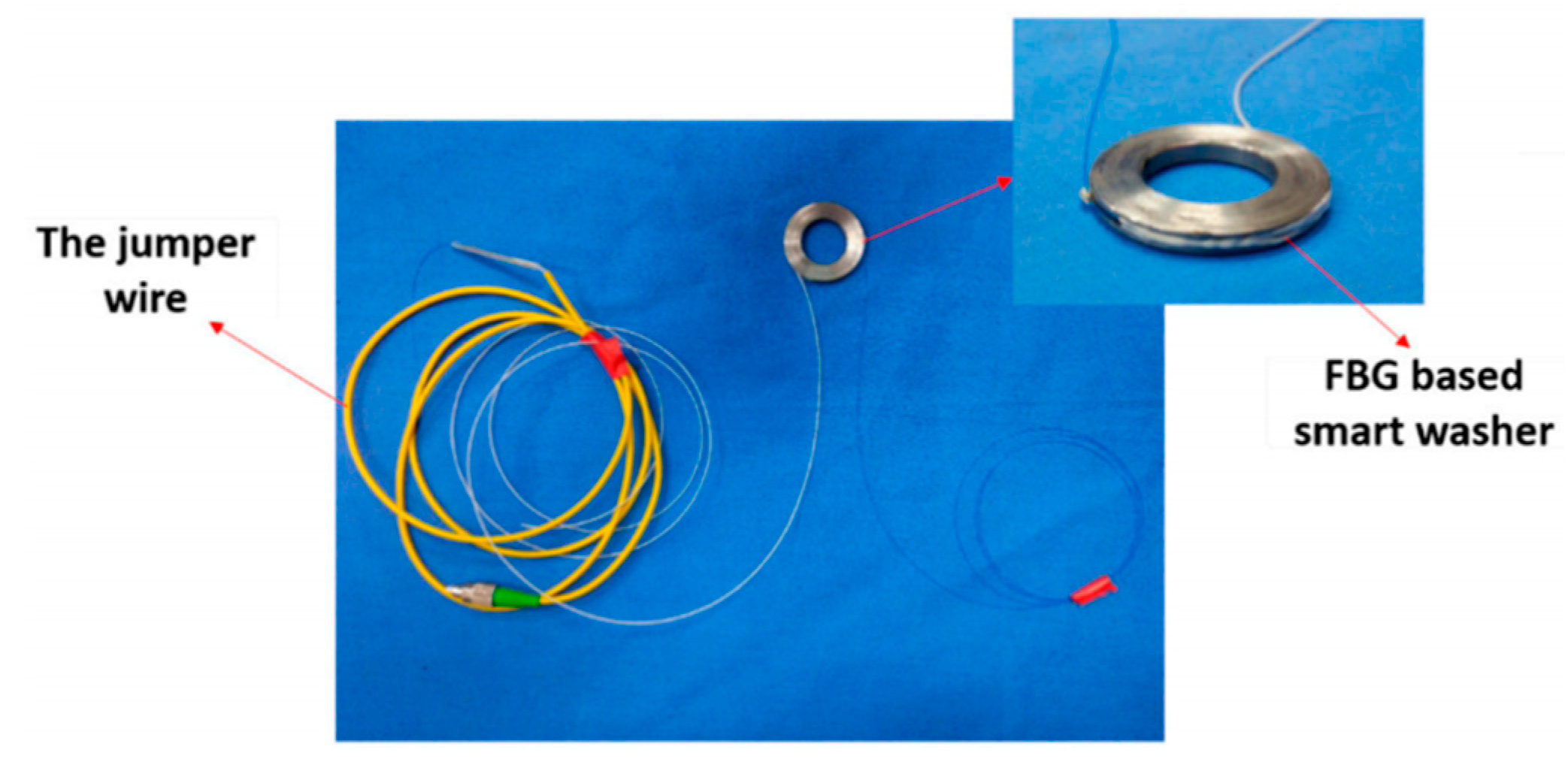

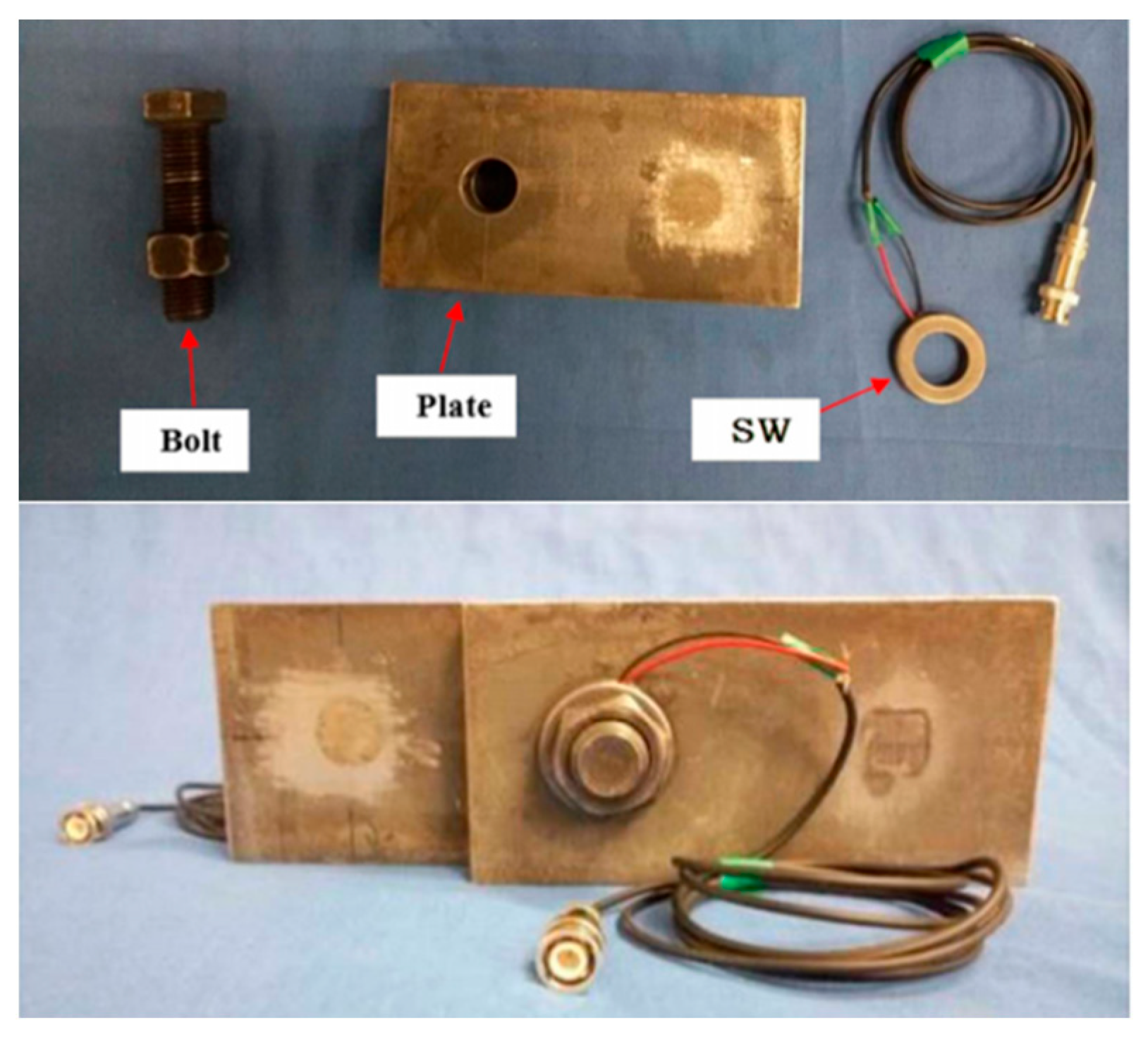

4.4. Principles of Technologies Based on Direct Measurement

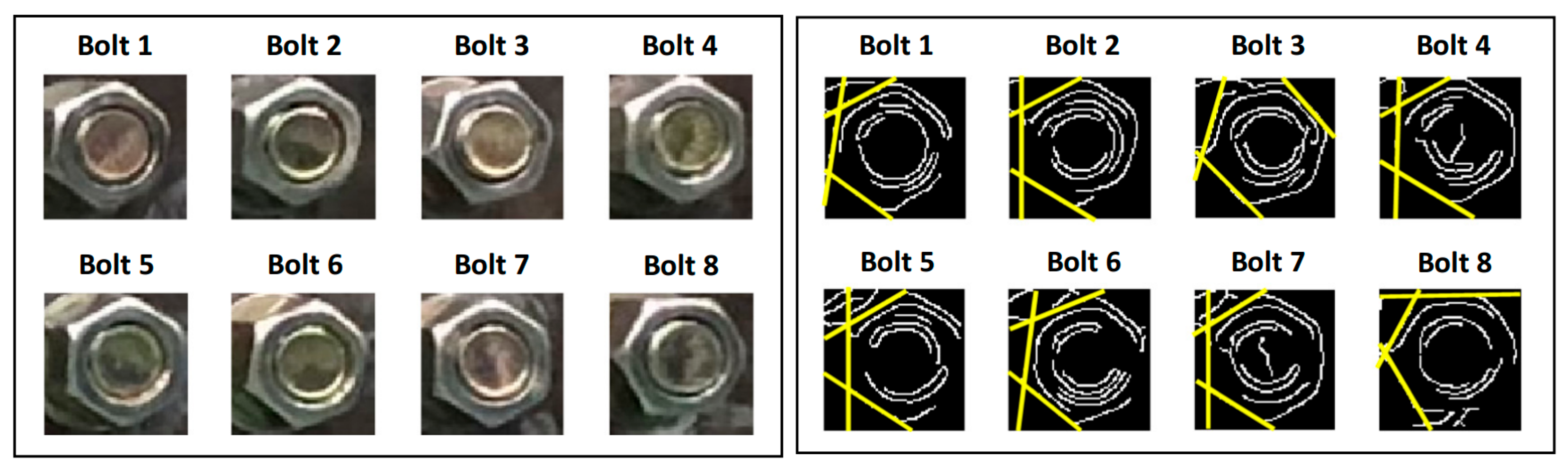

4.5. Principles of Vision/Image-Based Detection Technologies

5. Application and Limitation Analysis of Detection Technologies in Agricultural Machinery

6. Conclusion and Prospects

6.1. Summary of Main Conclusions

6.2. Technological Trends and Future Prospects

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, J.; Xie, W.; Sheng, Y.; Wang, X.; Wang, J.; Liu, C.; Hou, L. Trends of Global Agriculture and Prospects of China’s Agriculture Toward 2050. Strateg. Study CAE 2022, 24, 29–37. [Google Scholar] [CrossRef]

- Ma, N.; Cao, S.; Bai, T.; Kong, F.; Sun, W. Research Progress and Prospect of Multi-robot Collaborative SLAM in Complex Agricultural Scenarios. Smart Agric. 2024, 6, 23–43. [Google Scholar]

- Lin, H.; Li, Y.; Yuan, Z.; Wu, T.; Liu, C. Sliding Mode Anti-interference Path Tracking Method for Autonomous Operation of Paddy Field Plant Protection Machine. Trans. Chin. Soc. Agric. Mach. 2021, 52, 383–388. [Google Scholar]

- Niu, J.; Shen, C.; Zhang, L.; Li, Q.; Liu, S. Research on obstacle avoidance path of wheeled plant protection robot based on improved ACO-DWA algorithm. J. Electron. Meas. Instrum. 2024, 38, 188–200. [Google Scholar]

- Zhou, F.; Li, L.; Gao, Z. Development and test of vertical spiral subsoiling machine. J. For. Eng. 2022, 7, 148–154. [Google Scholar]

- Zhang, X.; Zhang, R.; Ru, S.; Zhang, X.; Li, Y.; Liang, D. Design and experiment of pre-soil-breaking chisel-type subsoilers for banana field in hot areas of Hainan Province, China. Trans. Chin. Soc. Agric. Eng. 2020, 36, 49–55. [Google Scholar]

- Zhang, S.; Wei, X.; Deng, Y.; Zang, C.; Ji, X.; Wang, A. Design and experiments of the whole field path tracking algorithm for a track-based harvester. Trans. Chin. Soc. Agric. Eng. 2023, 39, 36–45. [Google Scholar]

- Zeng, S.; Huang, D.; Yang, W.; Liu, W.; Wen, Z.; Zeng, L. Design and test of the chassis of triangular crawler reclaiming rice harvester. J. Jilin Univ. Eng. Technol. Ed. 2022, 52, 1943–1950. [Google Scholar]

- Lai, X.; Cheng, J.; Li, S.; Wen, C.; Wei, Y.; Song, J. Design and Experiment of Chassis Levelling Mechanism and Test of Hilly Tracked Sugarcane Harvester. Trans. Chin. Soc. Agric. Mach. 2024, 55, 100–109. [Google Scholar]

- Xiao, R.; Ma, X.; Li, H.; Cao, X.; Wei, Y.; Wang, C.e.; Zhao, X. Design and experiment of agricultural machinery auxiliary navigation system based on UWB positioning. J. South China Agric. Univ. 2022, 43, 116–123. [Google Scholar]

- Miao, J.; Zhou, X.; Huang, G. Evaluation of effectiveness of agricultural production in Jiangxi province based on DEA and obstacle model. Ecol. Sci. 2022, 41, 172–177. [Google Scholar]

- Xiao, M.; Zhang, H.; Zhou, S.; Wang, K.; Ling, C. Research progress and trend of agricultural machinery fault diagnosis technology. J. Nanjing Agric. Univ. 2020, 43, 979–987. [Google Scholar]

- Wang, J.; Zhao, S.; Gao, L.; Yuan, Y.; Yang, Y. Design and Experiment of Passive Disc Cutting Blade in Corn Ridges. Trans. Chin. Soc. Agric. Mach. 2021, 52, 59–67. [Google Scholar]

- Shi, Z.; Wang, M.; Zhang, X.; Zhang, Y.; Li, M.; Lu, D. Design and Test of Folding Cotton Wide Film Spreading Precision Seeder. Trans. Chin. Soc. Agric. Mach. 2024, 55, 53–62. [Google Scholar]

- Fu, S.; Lan, T.; Du, Y.; Mao, E.; Zhu, Z.; Li, Z. Rapid Design System For Agricultural Machinery Using Knowledge-Based Engineering: Case Study Of A Wheeled Combine Chassis. Trans. ASABE 2020, 63, 955–966. [Google Scholar] [CrossRef]

- Ding, Z.X.; Tang, Z.; Zhang, B.; Ding, Z. Vibration Response of Metal Plate and Shell Structure under Multi-Source Excitation with Welding and Bolt Connection. Agriculture 2024, 14, 816. [Google Scholar] [CrossRef]

- Wang, L.; Wang, G.Q.; Zhai, X.J.; Tang, Z.; Wang, B.Z.; Li, P.C. Response Characteristics of Harvester Bolts and the Establishment of the Strongest Response Structure’s Kinetic Model. Agriculture 2024, 14, 1174. [Google Scholar] [CrossRef]

- Liu, Z.L.; Xu, Y.M. Seeds Harvester Scheme Design for Kobresia Littledalei C. B. Clarke. In Proceedings of the 3rd International Conference on Future Computer Supported Education (FCSE 2018), Hong Kong, China, 12–14 February 2018. [Google Scholar]

- Liu, D.; Pen, H.; Zhang, H.; He, A. Fatigue Life Analysis of Power Take-Off Box Bolts of Dry-Mixed Mortar Transport Truck. J. Mech. Strength 2022, 44, 245–249. [Google Scholar]

- Wang, S.; Lu, H.; Shi, Y.; Hao, P.; Ma, Y. Research on Failure of MJ Thread Bolt Made with Precipitation-hardening Stainless Steel. Struct. Environ. Eng. 2022, 49, 82–87. [Google Scholar]

- Li, X.; Gong, Y.; Jiang, L.F.; Zhao, Y.X.; Hu, N. A parametric study on the failure strength of multi-bolt composite repairs with different configurations. Theor. Appl. Fract. Mech. 2022, 121, 103459. [Google Scholar] [CrossRef]

- Zhang, S.J.; Lei, H.G.; Zhou, Z.C.; Wang, G.Q.; Qiu, B. Fatigue life analysis of high-strength bolts based on machine learning method and SHapley Additive exPlanations (SHAP) approach. Structures 2023, 51, 275–287. [Google Scholar] [CrossRef]

- Glienke, R.; Blunk, C.; Denkert, C.; Wanner, M.C. Design and execution of joints with lock-bolts for steel structures. Stahlbau 2015, 84, 980–997. [Google Scholar] [CrossRef]

- Li, Z.B.; Chen, Y.; Sun, W.C.; Jiang, P.; Pan, J.C.; Guan, Z.Q. Study on self-loosening mechanism of bolted joint under rotational vibration. Tribol. Int. 2021, 161, 107074. [Google Scholar] [CrossRef]

- Li, Y.; Xu, L.; Gao, Z.; Lu, E.; Li, Y. Effect of Vibration on Rapeseed Header Loss and Optimization of Header Frame. Trans. ASABE 2021, 64, 1247–1258. [Google Scholar] [CrossRef]

- Jiang, K.; Liu, Z.F.; Zhang, T.; Wang, F. Influence of bolt creep induced pre-tightening force relaxation on dynamic response of the bolted joint system. J. Sound Vib. 2025, 596, 118800. [Google Scholar] [CrossRef]

- Gong, C.; Xiao, J.; Lu, X.Q.; Ding, P.S.; Zheng, X.T. Stress relaxation assessment of high-temperature bolts under combined biaxial loads: Theory and simulation. Int. J. Press. Vessel. Pip. 2024, 211, 105302. [Google Scholar] [CrossRef]

- Zhao, P.H.; Liu, J.H.; Gong, H.; Xue, F.Q. Study on Tightening, Anti-Loosening, and Fatigue Resistance Performances of Bolted Joints with Different Anti-Loosening Washers and Nuts. Appl. Sci. 2023, 13, 13253. [Google Scholar] [CrossRef]

- Qing, Y.; Li, Y.; Xu, L.; Ma, Z. Screen Oilseed Rape (Brassica napus) Suitable for Low-Loss Mechanized Harvesting. Agriculture 2021, 11, 504. [Google Scholar] [CrossRef]

- Shang, Z.Q.; Qin, X.; Zhang, Z.J.; Jiang, H.T. Bolt Loosening and Preload Loss Detection Technology Based on Machine Vision. Buildings 2024, 14, 3897. [Google Scholar] [CrossRef]

- Wang, F.R.; Song, G.B. Bolt-looseness detection by a new percussion-based method using multifractal analysis and gradient boosting decision tree. Struct. Health Monit.-Int. J. 2020, 19, 2023–2032. [Google Scholar] [CrossRef]

- Kim, Y.S.; Na, W.S. Development of a portable damage detection system based on electromechanical impedance technique for monitoring of bolted joint structures. J. Intell. Mater. Syst. Struct. 2022, 33, 2507–2519. [Google Scholar] [CrossRef]

- Nie, J.; Wu, K.; Li, Y.; Li, J.B.; Hou, B.H. Advances in hyperspectral remote sensing for precision fertilization decision-making: A comprehensive overview. Turk. J. Agric. For. 2024, 48, 1084–1104. [Google Scholar] [CrossRef]

- Morchid, A.; El Alami, R.; Raezah, A.A.; Sabbar, Y. Applications of internet of things (IoT) and sensors technology to increase food security and agricultural Sustainability: Benefits and challenges. Ain Shams Eng. J. 2024, 15, 102509. [Google Scholar] [CrossRef]

- Yue, X.; Cai, Y.; Wang, L.; Liu, Y.; Wang, J.; Hong, J. Research progress of intelligent perception and analytics of agricultural information. J. South China Agric. Univ. 2020, 41, 14–28. [Google Scholar]

- Yilmaz, O.; Jiménez-Peña, C.; Debruyne, D. Fatigue response of high strength steel bolted connections under in-plane shear and out-of-plane bending loading modes. In Proceedings of the 8th International Conference on Fatigue Design (Fatigue Design), Senlis, France, 20–21 November 2019. [Google Scholar]

- Zheng, K.; Liu, G.; Xia, J.; Liu, B.; Xu, L.; Cheng, J.; Li, D. Application of Vibration Technology in Tillage, Seeding and Harvesting Machinery:A Review. Acta Agric. Univ. Jiangxiensis 2020, 42, 1067–1077. [Google Scholar]

- Romero-Gainza, E.A. Design and Implementation of Inference Services for Random Forests. Ph.D. Thesis, The Ohio State University, Columbus, OH, USA, 2023. [Google Scholar]

- Wang, J.; Wang, D.; Zhao, Z. Mechanical properties of soil-engaging components interacted with ultrasonic vibration in agricultural machinery. Trans. Chin. Soc. Agric. Eng. 2021, 37, 35–41. [Google Scholar]

- Desnica, E.; Asonja, A.; Kljajin, M.; Glavas, H.; Pastukhov, A. Analysis of Bearing Assemblies Refit in Agricultural PTO Shafts. Teh. Vjesn.-Tech. Gaz. 2023, 30, 872–881. [Google Scholar] [CrossRef]

- Wenqiang, J.; Ze, M.; Tong, W.; Qing, Z.; Lanqi, Y.; Wei, Z. Loosening process of bolted connection in transmission tower under transverse cyclic load. Structures 2025, 73, 108399. [Google Scholar] [CrossRef]

- Hong, J.; Ma, Y.B.; Feng, S.B.; Ma, Y.H. The Mechanism and Quantitative Evaluation of Slip Damage of Bolted Joint with Spigot. In Proceedings of the 67th ASME Turbomachinery Technical Conference and Exposition (Turbo Expo) on Road Mapping the Future of Propulsion and Power, Rotterdam, The Netherlands, 13–17 June 2022. [Google Scholar]

- Chen, J.; Zhang, Y.; Meng, Y.; Yan, C.; Lin, P. Failure analysis of fatigue fracture of engine cylinder head bolts. Heat Treat. Met. 2023, 48, 308–313. [Google Scholar]

- Geng, L.; Li, K.; Pang, J.; Jin, X.; Ji, J. Test and analysis of vibration characteristics of transplanting machine based on time frequency and power spectral density. Trans. Chin. Soc. Agric. Eng. 2021, 37, 23–30. [Google Scholar]

- Hou, J.; Xie, F.; Wang, X.; Liu, D.; Ji, B. Design and test of multi-crop harvester header. J. Hunan Agric. Univ. Nat. Sci. 2023, 49, 223–230. [Google Scholar]

- Lin, J.; Liao, Q.; Zhang, Q.; Kang, Y.; Zhang, J. Vibration characteristics analysis and structural improvement of the shovel type seedbed preparation machine suitable for rapeseed mechanical direct seeding. Trans. Chin. Soc. Agric. Eng. 2023, 39, 39–48. [Google Scholar]

- Zhang, S.; Dai, F.; Zhao, W.; Tian, B.; Chen, B. Design and test of matching straw baling device for highland barley combine harvester. Acta Agric. Zhejiangensis 2020, 32, 1289–1301. [Google Scholar]

- Pan, W.J.; Li, X.M.; Sun, L.L.; Song, H.X.; Wang, M.H. General prediction model of residual pretightening force of bolt group with one-step and multi-step pretightening and analysis of influencing factors from the perspective of elastic interaction. Eng. Comput. 2023, 40, 921–956. [Google Scholar] [CrossRef]

- Zuo, W.L.; Liu, Z.F.; Zhao, Y.S.; Niu, N.A.; Zheng, M.P. Research on the tightening strategy of bolted flange for contact stiffness of joint surface. Struct. Eng. Mech. 2022, 83, 341–351. [Google Scholar] [CrossRef]

- Chen, X.; Bai, J.; Wang, X.; Fang, W.; Hong, T.; Zang, N.; Fang, L.; Wang, G. Calibration and Testing of Discrete Elemental Simulation Parameters for Pod Pepper Seeds. Agriculture 2024, 14, 831. [Google Scholar] [CrossRef]

- Wei, X.; Wang, R.; Wen, Z.; Dai, L.; Hu, Z. Influence of Bolt Relaxation of High-Speed Railway Sound Barrier on Fatigue Life. J. Southwest Jiaotong Univ. 2023, 58, 373–380. [Google Scholar]

- Li, Y.; Wang, Y.Z.; Liu, Z.F.; Yang, X.D.; Zhang, C.X.; Cheng, Y.H. A combined theoretical and experimental study on contact creep-induced clamping force relaxation of bolted joints at ambient temperature. Mar. Struct. 2022, 85, 103263. [Google Scholar] [CrossRef]

- Luyt, P.C.B.; Theron, N.J.; Pietra, F. Non-linear finite element modelling and analysis of the effect of gasket creep-relaxation on circular bolted flange connections. Int. J. Press. Vessel. Pip. 2017, 150, 52–61. [Google Scholar] [CrossRef]

- Li, C.; Zhou, Y.; Sun, B.; Yang, X. Method of fatigue-reliability assessment of the bolts with the tightened torque taken into account. J. Mach. Des. 2021, 38, 22–27. [Google Scholar]

- Tian, K.; Zhang, B.; Ji, A.; Huang, J.; Liu, H.; Shen, C. Design and experiment of the bionic disc cutter for kenaf harvesters. Int. J. Agric. Biol. Eng. 2023, 16, 116–123. [Google Scholar] [CrossRef]

- Vodolazskaya, N. Process Modeling of Increasing Reliability of Assembly Responsible Connections. Adv. Eng. Lett. 2024, 3, 91–99. [Google Scholar] [CrossRef]

- Jiang, X.J.; Ba, J.J.; Chen, Z.; Pan, F.Q.; Li, Z.; Yang, G.Q. Experimental Investigation of Self-Loosening Behavior of Bolt Joints with Superelastic Shape-Memory Alloy by Macroscopic-Mechanical Response and Microscopic Evolution. J. Eng. Mech. 2020, 146, 06020004. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Ji, K.; Zhu, R. A Fault Diagnosis Method for a Differential Inverse Gearbox of a Crawler Combine Harvester Based on Order Analysis. Agriculture 2022, 12, 1300. [Google Scholar] [CrossRef]

- Wang, K.; Yan, M.; Su, D.; Wang, P.; Hui, A.; Liu, H. Looseness Behavior of Bolted Flange Connections under Cyclic Lateral Load During Rotation Loosening Period. J. Propuls. Technol. 2023, 44, 167–180. [Google Scholar]

- Miao, X.; Huang, X.; Ding, P.; Zheng, Z. Effect of Transverse Load and Preload on the Fracture Life of Bolts. J. Northeast. Univ. Nat. Sci. 2024, 45, 68–75. [Google Scholar]

- Liu, Y.; Li, Y.; Chen, L.; Zhang, T.; Liang, Z.; Huang, M.; Su, Z. Study on Performance of Concentric Threshing Device with Multi-Threshing Gaps for Rice Combines. Agriculture 2021, 11, 1000. [Google Scholar] [CrossRef]

- Song, G.B.; Li, W.J.; Wang, B.; Ho, S.C.M. A Review of Rock Bolt Monitoring Using Smart Sensors. Sensors 2017, 17, 776. [Google Scholar] [CrossRef]

- Cui, C.; Luo, C.; Qiu, S.; Zhang, Q. An Intelligent Bolt Shedding Detection Method for Steel Bridges Based on Depth Data Enhancement. Bridge Constr. 2024, 54, 39–47. [Google Scholar]

- Wu, X.; Shao, Q.; Han, W.; Li, Y. Experimental research and feasibility analysis of high strength bolt connection of glass structure. J. Lanzhou Univ. Nat. Sci. 2020, 56, 279–284. [Google Scholar]

- Li, J.; Wang, C.; Jiang, Z.; Lin, Z. Research progress and development trend of sensor functional bolts. Mod. Manuf. Eng. 2022, 10, 148–157. [Google Scholar]

- Zhao, G.; Qi, H.; Li, S.; Liu, Y.; Yang, X.; Shi, D.; Sun, Y. Low-temperature hot corrosion fatigue damage mechanism, life model, and corrosion resistance design method of hot section components. Adv. Mech. 2022, 52, 809–851. [Google Scholar]

- Wei, Z.; Cao, G. Does urbanization promote development of agricultural mechanization?:An empirical study based on county level panel data of China. Acta Agric. Zhejiangensis 2022, 34, 2778–2788. [Google Scholar]

- Asonja, A.; Adamovic, Z.; Jevtic, N. Analysis of Reliability of Cardan Shafts Based on Condition Diagnostics of Bearing Assembly in Cardan Joints. Metal. Int. 2013, 18, 216–221. [Google Scholar]

- Chen, H.; Dai, S.; Ou, M.; Li, S.; Wang, C.; Li, Z.; Wang, G.; Chen, Y.; Jia, W. Multibody Dynamics Simulation and Vibration Test for High Clearance Orchard Sprayer. Appl. Sci. 2022, 12, 8058. [Google Scholar] [CrossRef]

- Ali Chandio, F.; Li, Y.; Xu, L.; Ma, Z.; Ahmad, F.; Minh Cuong, D.; Ali Lakhiar, I. Predicting 3D forces of disc tool and soil disturbance area using fuzzy logic model under sensor based soil-bin. Int. J. Agric. Biol. Eng. 2020, 13, 77–84. [Google Scholar] [CrossRef]

- Qian, P.; Gu, J.; Tang, Z.; Lao, L.; Lu, T.; Gu, T.; Chen, S. Development and validation of the damped pendulum model for cantilever conveyor trough using Lagrangian method. Trans. Chin. Soc. Agric. Eng. 2023, 39, 44–52. [Google Scholar]

- Liang, Z.; Liu, J.; Yang, D.; Ouyang, K. Modeling and Simulation of Reel Motion in a Foxtail Millet Combine Harvester. Agriculture 2024, 15, 19. [Google Scholar] [CrossRef]

- Lian, Y.; Wang, B.; Sun, M.; Que, K.; Xu, S.; Tang, Z.; Huang, Z. Design of a Conveyer Trough Bolt Signal Acquisition System and Bayesian Ensemble Identification Method for Working State. Agriculture 2025, 15, 970. [Google Scholar] [CrossRef]

- Hu, J.; Xu, L.; Yu, Y.; Lu, J.; Han, D.; Chai, X.; Wu, Q.; Zhu, L. Design and Experiment of Bionic Straw-Cutting Blades Based on Locusta Migratoria Manilensis. Agriculture 2023, 13, 2231. [Google Scholar] [CrossRef]

- Jing, J.; Sun, H.; Liang, R.; Chen, S.; Tang, Z.; He, X.; Chen, Y. Noise Testing of the Conveyor Trough Sprocket and Surface Noise Reduction Performance Evaluation of the Cavity Structure in a Combine Harvester. Agriculture 2025, 15, 1299. [Google Scholar] [CrossRef]

- Dai, D.; Chen, D.; Wang, S.; Li, S.; Mao, X.; Zhang, B.; Wang, Z.; Ma, Z. Compilation and Extrapolation of Load Spectrum of Tractor Ground Vibration Load Based on CEEMDAN-POT Model. Agriculture 2023, 13, 125. [Google Scholar] [CrossRef]

- Li, S.; Li, Y.; Zhang, L.; Shi, Z.; Sun, Y.; Xie, S.; Yang, M.; Gao, M. Characteristics and experimental verification of the pendulum-flywheel energy harvester for agricultural machinery. Trans. Chin. Soc. Agric. Eng. 2022, 38, 45–54. [Google Scholar]

- Qian, Z.; Jin, C.; Yuan, W.; Ni, Y.; Zhang, G. Frictional impact dynamics model of threshing process between flexible teeth and grains. J. Jilin University. Eng. Technol. Ed. 2021, 51, 1121–1130. [Google Scholar]

- Yu, Z.; Li, Y.; Xu, L.; Du, X.; Ji, K. Unbalanced variation after assembly and double-speed influence coefficient method in the threshing drum. Int. J. Agric. Biol. Eng. 2023, 16, 1–10. [Google Scholar] [CrossRef]

- Faheem, M.; Liu, J.; Chang, G.; Ahmad, I.; Peng, Y. Hanging force analysis for realizing low vibration of grape clusters during speedy robotic post-harvest handling. Int. J. Agric. Biol. Eng. 2021, 14, 62–71. [Google Scholar] [CrossRef]

- Faheem, M.; Liu, J.; Chang, G.; Abbas, I.; Xie, B.; Shan, Z.; Yang, K. Experimental Research on Grape Cluster Vibration Signals during Transportation and Placing for Harvest and Post-Harvest Handling. Agriculture 2021, 11, 902. [Google Scholar] [CrossRef]

- Xu, L.; Lu, J.; Zhang, T. Lightweight treatment of large vibrating screen using equivalent static loads. Trans. Chin. Soc. Agric. Eng. 2022, 38, 24–33. [Google Scholar]

- Chang, Y.; Wu, R.; Li, L.; Wang, M.; Guo, X.; Zhang, T. Research on Vibration Fatigue Life Analysis Method of An Airborne Explosive Bolt. Initiat. Pyrotech. 2021, 5, 14–18. [Google Scholar]

- Wei, J.; Zou, L.; Yang, H.; Ben, Q.; Yuan, D. Experiment Research of Preload Loss in Composite Bolted Joint Under Complex Loads. Aeronaut. Manuf. Technol. 2024, 67, 98–105. [Google Scholar]

- Lan, Y.; Yan, Y.; Wang, B.; Song, C.; Wang, G. Current status and future development of the key technologies for intelligent pesticide spraying robots. Trans. Chin. Soc. Agric. Eng. 2022, 38, 30–40. [Google Scholar]

- Zhang, T.; Li, Y.; Xu, L.; Liu, Y.; Ji, K.; Jiang, S. Experimental Study on Fluidization Behaviors of Wet Rice Threshed Materials with Hot Airflow. Agriculture 2022, 12, 601. [Google Scholar] [CrossRef]

- Wang, X.; Zhu, J.; Ruan, H.; Cheng, W.; Li, J. Time-dependent Characteristics of Corrosion Damage of Prestressed Rock Bolts in Oxygen-ventilated Environment. J. Yangtze River Sci. Res. Inst. 2022, 39, 86–91. [Google Scholar]

- Zhu, Q.; Zhang, H.; Zhu, Z.; Gao, Y.; Chen, L. Structural Design and Simulation of Pneumatic Conveying Line for a Paddy Side-Deep Fertilisation System. Agriculture 2022, 12, 867. [Google Scholar] [CrossRef]

- Yang, Q.; Shi, L.; Shi, A.; He, M.; Zhao, X.; Zhang, L.; Addy, M. Determination of key soil characteristic parameters using angle of repose and direct shear stress test. Int. J. Agric. Biol. Eng. 2023, 16, 143–150. [Google Scholar] [CrossRef]

- Zeng, S.; Zhai, Y.; Peng, H.; Wei, Z.; Zhang, Y.; Hu, X. Construction and Viscosity Desorption Research of Biomimetic Non-Smooth MAO-HDTM Film of Aluminum Alloy. J. Southwest Univ. Nat. Sci. Ed. 2023, 45, 142–152. [Google Scholar]

- Yuan, H.; Liang, S.; Wang, J.; Lu, Y. Numerical Simulation and Analysis of Vibrating Rice Filling Based on EDEM Software. Agriculture 2022, 12, 2013. [Google Scholar] [CrossRef]

- Guo, X.; Wang, S.; Chen, S.; Li, B.; Tang, Z.; Hu, Y. Impact of Structural Parameters on the Collision Characteristics and Coefficient of Restitution of Soybean Particles on Harvester’s Cleaning Screens. Agriculture 2024, 14, 1201. [Google Scholar] [CrossRef]

- Li, Y.H.; Li, L.T.; Tang, Y.H.; Zhang, J.J.; Xiao, H.F. Fretting wear modeling of bolted joint interface with microscopic roughness using the 1D microslip friction model and equivalent thin layer. Mech. Based Des. Struct. Mach. 2025, 53, 4786–4811. [Google Scholar] [CrossRef]

- Yang, J.; Hao, K.; Zhong, W.; Wang, W.; Miao, G.; Zhang, Q. The Loosening Behavior of Bolted Connection and Riveted Connection Under Cyclic Shear Load. Prog. Steel Build. Struct. 2024, 26, 52–61. [Google Scholar]

- Quintarelli, V.; Ben Hassine, M.; Radicetti, E.; Stazi, S.R.; Bratti, A.; Allevato, E.; Mancinelli, R.; Jamal, A.; Ahsan, M.; Mirzaei, M.; et al. Advances in Nanotechnology for Sustainable Agriculture: A Review of Climate Change Mitigation. Sustainability 2024, 16, 9280. [Google Scholar] [CrossRef]

- Zhang, T.; Li, Y.; You, G. Experimental Study on the Cleaning Performance of Hot Air Flow Cleaning Device. Agriculture 2023, 13, 1828. [Google Scholar] [CrossRef]

- Peng, L.; Li, Z.; Liu, M.; Cui, C. Wheat straw anticorrosion analysis based on pore area ratio and the effect of straw on the shear strength of silty soil. Hydrogeol. Eng. Geol. 2021, 48, 171–180. [Google Scholar]

- Chen, D.; Zhang, T.; Huang, S.; Gao, D.; Li, J.; Liu, X.; Niu, W.; Liu, Y.; Wang, Z.; Kang, Y. Effects of hydrochloric acid washing and torrefaction pretreatment on the components of bio-oil from sweet sorghum straw pyrolysis. Trans. Chin. Soc. Agric. Eng. 2021, 37, 222–229. [Google Scholar]

- Ma, Z.; Zhu, Y.; Chen, S.; Traore, S.N.; Li, Y.; Xu, L.; Shi, M.; Zhang, Q. Field Investigation of the Static Friction Characteristics of High-Yielding Rice during Harvest. Agriculture 2022, 12, 327. [Google Scholar] [CrossRef]

- Lu, X.; Wang, X.; Luo, M. Analysis of Thermal-mechanical Coupling Behavior of Brake Disc of High Speed Trains Considering Thermal Contact Resistance. J. Mech. Eng. 2021, 57, 296–304. [Google Scholar]

- Lu, J.; Yang, Q.; Zhang, Q.; Hu, J.; Xu, X. Cause analysis of cracks in bolt holes of cast steel wheel-mounted brake disc. Heat Treat. Met. 2021, 46, 238–242. [Google Scholar]

- Zhang, D.; Li, F.; Hua, Y.; Fan, J.; Zhang, T.; Liu, J.; Zhu, M. Loosening Behavior of Bolted Structures under Coupled Thermo-mechanical Loading. Lubr. Eng. 2023, 48, 38–52. [Google Scholar]

- Wang, Y.; Wang, L.; Zong, J.; Lyu, D.; Wang, S. Design and Experiment of Dynamic Loading Bench for Tractor. J. Agric. Sci. Technol. 2022, 24, 91–97. [Google Scholar]

- Huang, J.; Tan, L.; Tian, K.; Zhang, B.; Ji, A.; Liu, H.; Shen, C. Formation mechanism for the laying angle of hemp harvester based on ANSYS-ADAMS. Int. J. Agric. Biol. Eng. 2023, 16, 109–115. [Google Scholar] [CrossRef]

- Chen, X.; He, X.; Wang, W.; Qu, Z.; Liu, Y. Study on the Technologies of Loss Reduction in Wheat Mechanization Harvesting: A Review. Agriculture 2022, 12, 1935. [Google Scholar] [CrossRef]

- Ren, L.; Wang, L.; Lin, L.; Zhang, B. The Progress and Prospect of Soil Compaction by Agricultural Machinery in Arable Land: A Review. Acta Pedol. Sin. 2023, 60, 610–626. [Google Scholar]

- Wang, Q.; Xu, Q.; Lu, C.; Li, H.; He, J.; Wang, Q. Research status and development of key technologies for no-tillage seeding intellectualization. J. South China Agric. Univ. 2021, 42, 27–35. [Google Scholar]

- Zhang, J.; Li, J.; Chen, W.; Li, D.; Zhang, Y.; Li, Z.; Yang, X.; Dai, B. Research Progress on Bionic Drag Reduction and Wear Resistance Characteristics of Agricultural Soil Touching Machinery Structures. Surf. Technol. 2024, 53. [Google Scholar]

- Zhang, K.; Zhang, Y.; Feng, Z.; Huang, X.; Chen, G. An Experimental Study on Nonlinear Vibration Characteristics of Large Deformed Bolted Beams. J. Southwest Pet. Univ. Sci. Technol. Ed. 2021, 43, 126–133. [Google Scholar]

- Wang, S.; Kong, Q.; Zhou, Y. Percussion-based bolt loosening detection method in a single-row multi-bolted steel beam-column joint. J. Earthq. Eng. Eng. Vib. 2024, 44, 95–103. [Google Scholar]

- Wang, B.; Tang, Z.; Wang, K.; Li, P. Failure Feature Identification of Vibrating Screen Bolts under Multiple Feature Fusion and Optimization Method. Agriculture 2024, 14, 1433. [Google Scholar] [CrossRef]

- Xu, J.; Jing, T.; Fang, M.; Li, P.; Tang, Z. Failure State Identification and Fault Diagnosis Method of Vibrating Screen Bolt Under Multiple Excitation of Combine Harvester. Agriculture 2025, 15, 455. [Google Scholar] [CrossRef]

- Wengang, Y.; Zhangqi, W.; Liqiang, A.N.; Ze, M.O.; Wenqiang, J. Computing Method of Bolted Joint Critical Loosening Load with Flexible Thread. J. Mech. Eng. 2020, 56, 238–248. [Google Scholar] [CrossRef]

- Liang, J.; Ge, J.; Song, J.; Xu, Y.; Liu, H.; Zhong, L.; Liu, Q. Looseness detection method of gas insulated switchgear basin insulator bolts based on convolutional neural network. J. Appl. Acoust. 2023, 42, 566–576. [Google Scholar]

- Zhang, H.; Liu, B.; Li, Y. Flange bolted connection state recognition based on time series two dimensionalization and attention mechanism. J. Vib. Shock 2022, 41, 181–188. [Google Scholar]

- Zhuo, D.; Cao, H. Damage Identification of Bolt Connections Based on Wavelet Time-Frequency Diagrams and Lightweight Convolutional Neural Networks. Eng. Mech. 2021, 38, 228–238. [Google Scholar]

- Pan, Q.; Chang, M.; Pan, R.; Xu, X.; Li, S.; Zhang, Y. Research on Nonlinear Ultrasonic Testing Technology of Bolt Axial Stress. J. Mech. Eng. 2021, 57, 88–95. [Google Scholar]

- He, X.; Chen, P. Bolt axial stress measurement based on high-frequency cylindrical ultrasonic guided wave. Chin. J. Sci. Instrum. 2021, 42, 179–186. [Google Scholar]

- Wang, C.; Wang, G.a.; Wang, K. Design and Application of Real-time Monitoring System for Load of Cutter Replacement Device under Atmospheric Pressure of Extra-Large Diameter Slurry Shield. Tunn. Constr. 2021, 41, 1404–1411. [Google Scholar]

- Wei, C.; Zhu, H.; Wang, J.; Cheng, G.; Wu, H.; Wang, J. Prototype Test Study on Loading Condition of Fiber-optic Smart Bolts of an Assembled Utility Tunnel. J. Disaster Prev. Mitig. Eng. 2022, 42, 1085–1096. [Google Scholar]

- Huo, L.; Chen, D.; Kong, Q.; Li, H.; Song, G. Smart washer-a piezoceramic-based transducer to monitor looseness of bolted connection. Smart Mater. Struct. 2017, 26, 025033. [Google Scholar] [CrossRef]

- Jie, X.; Xiao, L.; Qu, W. Structural Damage Identification Under Load Based on Electromechanical Impedance Co-integration. J. Vib. Meas. Diagn. 2020, 40, 526–534. [Google Scholar]

- Chen, W.; Xiao, L.; Qu, W. Electromechanical Impedance Damage Identification Method Using Singular Spectrum Analysis Under Changing Temperature Conditions. J. Vib. Meas. Diagn. 2024, 44, 113–120. [Google Scholar]

- Guo, Z.; Zhao, W.; Chen, H.; Lyu, S. Research on a Detection Method for Loosening of High-Strength Bolts Based on Image Recognition Techniques. Ind. Constr. 2022, 52, 175. [Google Scholar]

- Wang, Q.; Wang, R.; Li, H.; Cao, H.; Liu, C. Visual detection method of rail vehicle bolt looseness and pre-tightening force. J. Railw. Sci. Eng. 2023, 20, 3511–3524. [Google Scholar]

- Yao, Z.; Chen, Z.; Liu, H.; Lu, J. Visual Detection Method of Small Loosening of High-strength Bolts in Steel Structure Engineering. China J. Highw. Transp. 2024, 37, 125–141. [Google Scholar]

- Fukuoka, T.; Minami, T.; Fujiu, M. Confirmation of Final Bolt Tightening via Deep Learning-Based Image Processing. Applied Sciences 2023, 13, 7573. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, Z.; Zhang, Z.; Song, Z.; Liu, Y.; Li, Y.; Xu, L. Durable Testing and Analysis of a Cleaning Sieve Based on Vibration and Strain Signals. Agriculture 2023, 13, 2232. [Google Scholar] [CrossRef]

- Lian, Y.; Chen, J.; Guan, Z.; Song, J. Development of a monitoring system for grain loss of paddy rice based on a decision tree algorithm. Int. J. Agric. Biol. Eng. 2021, 14, 224–229. [Google Scholar] [CrossRef]

- Liang, Z.; Li, J.; Liang, J.; Shao, Y.; Zhou, T.; Si, Z.; Li, Y. Investigation into Experimental and DEM Simulation of Guide Blade Optimum Arrangement in Multi-Rotor Combine Harvesters. Agriculture 2022, 12, 435. [Google Scholar] [CrossRef]

- Zhuang, X.; Li, Y. Segmentation and Angle Calculation of Rice Lodging during Harvesting by a Combine Harvester. Agriculture 2023, 13, 1425. [Google Scholar] [CrossRef]

- Ji, K.; Li, Y.; Liang, Z.; Liu, Y.; Cheng, J.; Wang, H.; Zheng, G. Device and Method Suitable for Matching and Adjusting Reel Speed and Forward Speed of Multi-Crop Harvesting. Agriculture 2022, 12, 213. [Google Scholar] [CrossRef]

- Zhao, Y.S.; Wu, H.C.; Yang, C.B.; Liu, Z.F.; Cheng, Q. Tangential Damping Model of Bolted Joint with the Physics-Based Friction Coefficient. Int. J. Precis. Eng. Manuf. 2021, 22, 865–875. [Google Scholar] [CrossRef]

- Wang, W.; Zhou, Y.X.; Wang, H.; Li, C.Y.; Zhang, Y.M. Vibration analysis of a coupled feed system with nonlinear kinematic joints. Mech. Mach. Theory 2019, 134, 562–581. [Google Scholar] [CrossRef]

- Li, Z.Y.; Zhang, Y.M.; Li, C.Y.; Xu, M.T.; Dai, W.B.; Liu, Z.D. Modeling and nonlinear dynamic analysis of bolt joints considering fractal surfaces. Nonlinear Dyn. 2022, 108, 1071–1099. [Google Scholar] [CrossRef]

- Hu, J.; Pan, J.; Dai, B.; Chai, X.; Sun, Y.; Xu, L. Development of an Attitude Adjustment Crawler Chassis for Combine Harvester and Experiment of Adaptive Leveling System. Agronomy 2022, 12, 717. [Google Scholar] [CrossRef]

- Liang, Z.; Qin, Y.; Su, Z. Establishment of a Feeding Rate Prediction Model for Combine Harvesters. Agriculture 2024, 14, 589. [Google Scholar] [CrossRef]

- Wang, F.; Liu, Y.; Li, Y.; Ji, K. Research and Experiment on Variable-Diameter Threshing Drum with Movable Radial Plates for Combine Harvester. Agriculture 2023, 13, 1487. [Google Scholar] [CrossRef]

- Chen, D.D.; Li, W.; Dong, Z.Q.; Fu, R.L.; Yu, Q. Multi-bolt looseness monitoring using guided waves: A cross-correlation approach of the wavelet energy envelope. Smart Mater. Struct. 2024, 33, 125019. [Google Scholar] [CrossRef]

- Song, Y.S.; Wan, C.F.; Wang, S.; Li, J.W.; Meng, J.P. Development of a Vibration-Based Pre-Alarming Method for Bolt Looseness of Seismic Sway Braces. Buildings 2024, 14, 2711. [Google Scholar] [CrossRef]

- Eraliev, O.; Lee, K.H.; Lee, C.H. Vibration-Based Loosening Detection of a Multi-Bolt Structure Using Machine Learning Algorithms. Sensors 2022, 22, 1210. [Google Scholar] [CrossRef]

- Li, Y.; Xu, L.; Lv, L.; Shi, Y.; Yu, X. Study on Modeling Method of a Multi-Parameter Control System for Threshing and Cleaning Devices in the Grain Combine Harvester. Agriculture 2022, 12, 1483. [Google Scholar] [CrossRef]

- Zhao, N.; Linsheng, H.; Song, G. Vibration acoustic modulation for bolt looseness monitoring based on frequency-swept excitation and bispectrum. Smart Mater. Struct. 2023, 32, 034004. [Google Scholar] [CrossRef]

- Sun, J.Y.; Li, D.W.; Yang, H.Y.; Xu, C. Quantitative Relationship Between Sliding-Generated Acoustic Emission and Friction Conditions at Bolted Joint Interfaces. Tribol. Lett. 2024, 72, 65. [Google Scholar] [CrossRef]

- Sun, J.Y.; Yang, H.Y.; Li, D.W.; Xu, C. Experimental investigation on acoustic emission in fretting friction and wear of bolted joints. J. Sound Vib. 2023, 558, 117773. [Google Scholar] [CrossRef]

- Fu, W.; Zhou, R.H.; Guo, Z.Y. Automatic bolt tightness detection using acoustic emission and deep learning. Structures 2023, 55, 1774–1782. [Google Scholar] [CrossRef]

- Li, S.L.; Kang, Z.Z.; Wu, G.M.; Guo, P.; Gu, S. Acoustic emission-based transition monitoring of mechanical mechanism for bolted shear connection in GFRP-UHPC hybrid beams. Measurement 2022, 198, 111358. [Google Scholar] [CrossRef]

- Tan, J.; Wang, B.; Feng, T.; Ning, Y.; Liu, B.; Zhao, F. Acoustic emission characteristics of anchored sandstone under uniaxial compression and its correlation with rockburst. J. Cent. South Univ. Sci. Technol. 2021, 52, 2828–2838. [Google Scholar]

- Qian, P.; Lu, T.; Shen, C.; Chen, S. Influence of vibration on the grain flow sensor during the harvest and the difference elimination method. Int. J. Agric. Biol. Eng. 2021, 14, 149–162. [Google Scholar] [CrossRef]

- Cai, B.Y.; Qin, Q.H.; Wang, X.; Lin, J. Passive detection of bolt joint looseness using flow-induced ambient noise. Mech. Syst. Signal Process. 2025, 224, 112110. [Google Scholar] [CrossRef]

- Yan, Y.; Liu, C. Experimental study on ultrasonic monitoring of blade root bolt load in static test of wind turbine blade. Renesable Energy Resour. 2021, 39, 1063–1068. [Google Scholar]

- Zhao, Y.S.; Liu, P.; Niu, N.N. Finite Element Numerical Analysis on Ultrasonic Testing of Bolt Stress. In Proceedings of the International Conference on Mechanical Design and Simulation (MDS), Wuhan, China, 18–20 March 2022. [Google Scholar]

- Niwinski, T.J.; Kraemer, F.; Klein, M.; Oechsner, M.; Herter, S.; Becker, M.M. Ultraschallbasierte in situ Vorspannkr aftermittlung an Schrauben ohne Referenzmessung im nicht verspannten Zustand durch Kombination von Longitudinal- und TransversalwellenUltrasonic in situ evaluation of the bolt preload without referencing an unloaded state using a combination of longitudinal and transverse waves. Mater. Und Werkst. 2023, 54, 945–956. [Google Scholar] [CrossRef]

- Su, J.; Ding, X. Bolt axial stress detection of electromagnetic ultrasonic signal based on Gabor time-frequency filtering. J. Appl. Acoust. 2024, 43, 584–590. [Google Scholar]

- Li, Z.X.; Zhao, Z.; Zhang, J.Y.; Liu, C.S. A novel experimental method for bolt stress distribution during the assembly process. Structures 2024, 69, 107413. [Google Scholar] [CrossRef]

- Jerome, T.W. Determining Contact Stiffness, Contact Pressure, and Modal Frequencies of Fastened Metallic Joints. Ph.D. Thesis, The Pennsylvania State University, University Park, PA, USA, 2020. [Google Scholar]

- Fu, R.L.; Mao, R.W.; Yuan, B.; Chen, D.D.; Huo, L.S. Multi-resolution bolt preload monitoring based on the acoustoelastic effect of ultrasonic guided waves. Smart Struct. Syst. 2022, 30, 513–520. [Google Scholar] [CrossRef]

- Ding, J.; Wang, H.; Yuan, B.; Sun, W.; Sun, Q.; Ma, Q. Ultrasonic guided wave bolt preload identification based on the fusion of energy entropy and support vector machine. Comput. Integr. Manuf. Syst. 2022, 28, 1001–1010. [Google Scholar]

- Shah, J.K.; Majhi, S.; Mukherjee, A.; Wang, H. Investigating corrosion-induced deterioration in bolted steel plate joints using guided wave ultrasonic inspection. J. Civ. Struct. Health Monit. 2025, 15, 745–758. [Google Scholar] [CrossRef]

- Li, Z.; Yu, J.G.; Zhang, X.M.; Elmaimouni, L. Study on propagation characteristics of ultrasonic guided wave and detection of the defect in resin bolts. Appl. Acoust. 2022, 195, 108843. [Google Scholar] [CrossRef]

- Huang, M.; Jiang, X.; He, L.; Choi, D.; Pecchia, J.; Li, Y. Development of a Robotic Harvesting Mechanism for Button Mushrooms. Trans. ASABE 2021, 64, 565–575. [Google Scholar] [CrossRef]

- Han, D.; Zhang, H.; Li, G.; Wang, G.; Wang, X.; Chen, Y.; Chen, X.; Wen, X.; Yang, Q.; Zhao, R. Development of a Bionic Picking Device for High Harvest and Low Loss Rate Pod Pepper Harvesting and Related Working Parameter Optimization Details. Agriculture 2024, 14, 859. [Google Scholar] [CrossRef]

- Ji, W.; He, G.; Xu, B.; Zhang, H.; Yu, X. A New Picking Pattern of a Flexible Three-Fingered End-Effector for Apple Harvesting Robot. Agriculture 2024, 14, 102. [Google Scholar] [CrossRef]

- Sun, X.Y.; Shao, J.G.; Zhou, Y.; Yuan, C.; Li, Y.; Li, D.L. The method of bolt axial force looseness monitoring and control by piezoelectric ceramics in bolted joint structures. Proc. Inst. Mech. Eng. Part C-J. Mech. Eng. Sci. 2022, 236, 3277–3292. [Google Scholar] [CrossRef]

- Xue, S.T.; Wang, H.L.; Xie, L.Y.; Li, X.Z.; Zheng, Z.Q.; Wan, G.C. Bolt loosening detection method based on double-layer slotted circular patch antenna. Struct. Health Monit.-Int. J. 2024, 23, 3371–3386. [Google Scholar] [CrossRef]

- Chen, D.D.; Huo, L.S.; Li, H.N.; Song, G.B. A Fiber Bragg Grating (FBG)-Enabled Smart Washer for Bolt Pre-Load Measurement: Design, Analysis, Calibration, and Experimental Validation. Sensors 2018, 18, 2586. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Cui, X.M.; Xu, Y.P. A Novel RFID-Based Sensing Method for Low-Cost Bolt Loosening Monitoring. Sensors 2016, 16, 168. [Google Scholar] [CrossRef]

- Zhao, Z.; Ma, D.; Ding, J.; Zhai, Y.; Zhao, W.; Zhang, K. Weak supervision detection method for pin-missing bolts of transmission lines based on SAW-PCL. J. Beijing Univ. Aeronaut. Astronaut. 2024, 50, 3319–3326. [Google Scholar]

- Iwasaki, T.; Tokumasu, O.; Mitsugi, J. Wireless Loose Bolt Detection with Multiple Battery-free Backscatter Sensors. In Proceedings of the IEEE Sensors Conference, Dallas, TX, USA, 30 October–2 November 2022; IEEE: Piscataway, NJ, USA, 2022. [Google Scholar]

- Wang, T.; Wang, H.; Yang, D.; Tan, B.H.; Deng, S.H.; Lu, G.T. Early bolt looseness monitoring using the leading waves energy in piezoelectric active sensing. Smart Mater. Struct. 2024, 33, 035033. [Google Scholar] [CrossRef]

- Tian, X.Q.; Liu, Y.X.; Chen, W.S.; Deng, J.; Liu, J.K. Development and experiment evaluation of an H-shape linear piezoelectric actuator operated in stepping mode. Ceram. Int. 2018, 44, S246–S249. [Google Scholar] [CrossRef]

- Dreisbach, A.L.; Fritzen, C.P. A Novel Approach for Preload Monitoring in Bolted Connections Using Electro-Mechanical Impedance Spectra. In Proceedings of the 10th European Workshop on Structural Health Monitoring (EWSHM), Palermo, Italy, 4–7 July 2022. [Google Scholar]

- Maurya, K.K.; Rawat, A.; Jha, G. Smart materials and electro-mechanical impedance technique: A review. In Proceedings of the 2nd International Conference on Processing and Characterization of Materials (ICPCM), Rourkela, India, 12–14 December 2019. [Google Scholar]

- Huang, H.; He, Q.B. Bolt looseness localization with connection-stiffness-varying flange. Smart Mater. Struct. 2024, 33, 095005. [Google Scholar] [CrossRef]

- Huang, X.; Qu, W.Z.; Xiao, L. Temperature compensation method for impedance signals of bolt loosening under temperature varying conditions using TransUnet. Smart Mater. Struct. 2024, 33, 105035. [Google Scholar] [CrossRef]

- Dong, H.; Yao, J.; He, C.; Li, J. Visual detection algorithm of loose fasteners under the subway. J. Railw. Sci. Eng. 2024, 21, 3775–3786. [Google Scholar]

- Wang, Q.; Qin, W.; Liu, M.; Zhao, J.; Zhu, Q.; Yin, Y. Semantic Segmentation Model-Based Boundary Line Recognition Method for Wheat Harvesting. Agriculture 2024, 14, 1846. [Google Scholar] [CrossRef]

- Chen, J.; Song, J.; Guan, Z.; Lian, Y. Measurement of the distance from grain divider to harvesting boundary based on dynamic regions of interest. Int. J. Agric. Biol. Eng. 2021, 14, 226–232. [Google Scholar] [CrossRef]

- Wang, S.; Li, B.; Chen, S.; Tang, Z.; Zhou, W.; Guo, X. Design and Performance Test of Soybean Profiling Header Suitable for Harvesting Bottom Pods on Film. Agriculture 2024, 14, 1058. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, S.; Wang, H. Machine Vision-based Bulk Angle Identification of Loose Steel Structure Bolt Groups. Mach. Des. Res. 2024, 40, 214–219. [Google Scholar]

- Qi, Y.; Geng, S.; Zhao, Z.; Lyu, X.; Sun, M. A method for super resolution processing of bolt image based on feature transfer. CAAI Trans. Intell. Syst. 2023, 18, 858–866. [Google Scholar]

- Huynh, T.C.; Park, J.H.; Jung, H.J.; Kim, J.T. Quasi-autonomous bolt-loosening detection method using vision-based deep learning and image processing. Autom. Constr. 2019, 105, 102844. [Google Scholar] [CrossRef]

- Zhang, T.; Yan, Z.; Qiao, T.; Ding, X. Bolt Looseness Detection Method Based on Visual Vibration Measurement and Convolution Neural Network. Struct. Environ. Eng. 2022, 49, 48–56. [Google Scholar]

- Lu, E.; Xu, L.; Li, Y.; Tang, Z.; Ma, Z. Modeling of working environment and coverage path planning method of combine harvesters. Int. J. Agric. Biol. Eng. 2020, 13, 132–137. [Google Scholar] [CrossRef]

- Chen, J.; Lian, Y.; Zou, R.; Zhang, S.; Ning, X.; Han, M. Real-time grain breakage sensing for rice combine harvesters using machine vision technology. Int. J. Agric. Biol. Eng. 2020, 13, 194–199. [Google Scholar] [CrossRef]

- Yuan, C.; Wang, S.Y.; Qi, Y.Z.; Kong, Q.Z. Automated structural bolt looseness detection using deep learning-based prediction model. Struct. Control. Health Monit. 2022, 29, e2899. [Google Scholar] [CrossRef]

- Gao, X.; Wang, W. Bolt load looseness measurement for slip-critical blind bolt by ultrasonic technique: A feasibility study with calibration and experimental verification. Struct. Health Monit.-Int. J. 2024, 23, 527–538. [Google Scholar] [CrossRef]

- Guo, H.Y.; Zhong, J.F.; Feng, B.; Chen, Y.L.; Zhong, S.C. Detection Method for Bolt Loosening Based on Summation Coefficient of Absolute Spectrum Ratio. Sensors 2025, 25, 246. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Zhang, W.Y.; Luo, X.W.; Zhang, Z.G.; Lu, Y.T.; Wang, B. Developing an IoT-Enabled Cloud Management Platform for Agricultural Machinery Equipped with Automatic Navigation Systems. Agriculture 2022, 12, 310. [Google Scholar] [CrossRef]

- Luo, X.; Liao, J.; Hu, L.; Zhou, Z.; Zhang, Z.; Zang, Y.; Wang, P.; He, J. Research progress of intelligent agricultural machinery and practice of unmanned farm in China. J. South China Agric. Univ. 2021, 42, 8–17. [Google Scholar]

- Zhang, Y.; Zhao, Z.; Li, X.; Xue, Z.; Jin, M.; Deng, B. Near-Infrared-Based Measurement Method of Mass Flow Rate in Grain Vibration Feeding System. Agriculture 2024, 14, 1476. [Google Scholar] [CrossRef]

- Li, W.J.; Dong, W.; Zhang, X.; Zhang, J.Z. A New Remote Sensing Service Mode for Agricultural Production and Management Based on Satellite-Air-Ground Spatiotemporal Monitoring. Agriculture 2023, 13, 2063. [Google Scholar] [CrossRef]

- Wang, X.; Hong, T.; Fang, W.; Chen, X. Optimized Design for Vibration Reduction in a Residual Film Recovery Machine Frame Based on Modal Analysis. Agriculture 2024, 14, 543. [Google Scholar] [CrossRef]

- Gu, X.F.; He, L.P.; Yu, G.; Liu, L.; Zhou, J.W.; Cheng, G.M. Research and analysis of an energy harvester of piezoelectric cantilever beam based on nonlinear magnetic action. Rev. Sci. Instrum. 2022, 93, 4659. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Chai, X.; Huang, J.; Hu, J.; Cui, Z. Efficient and Low-Loss Cleaning Method for Non-Uniform Distribution of Threshed Materials Based on Multi-Wing Curved Combination Air Screen in Computational Fluid Dynamics/Discrete Element Method Simulations. Agriculture 2024, 14, 895. [Google Scholar] [CrossRef]

- Chai, X.; Hu, J.; Ma, T.; Liu, P.; Shi, M.; Zhu, L.; Zhang, M.; Xu, L. Construction and Characteristic Analysis of Dynamic Stress Coupling Simulation Models for the Attitude-Adjustable Chassis of a Combine Harvester. Agronomy 2024, 14, 1874. [Google Scholar] [CrossRef]

- Liu, W.; Chen, X.; Zeng, S. Design and Parameter Optimization of a Rigid–Flexible Coupled Rod Tooth Threshing Device for Ratoon Rice Based on MBD-DEM. Agriculture 2024, 14, 2083. [Google Scholar] [CrossRef]

- Ding, B.; Liang, Z.; Qi, Y.; Ye, Z.; Zhou, J. Improving Cleaning Performance of Rice Combine Harvesters by DEM–CFD Coupling Technology. Agriculture 2022, 12, 1457. [Google Scholar] [CrossRef]

- An, Y.; Wang, Y.; Diao, F.; Liu, T.; Zhang, X.; Li, J.; Yang, B.; Deng, J.; Xu, Z.; Lan, Z. Preparation Parameters of ZnO Piezoelectric Coatings Prepared by Arc Ion Plating. Chin. J. Rare Met. 2024, 48, 60–67. [Google Scholar]

- Park, Y.J.; Ahn, D.V.; Kim, H.S.; Kim, S.C.; Yu, J.H.; Cho, S.J.; Kim, J.G. Bolt Strength Evaluation of Tractor Rear Axle Based on Simulation Model. Int. J. Precis. Eng. Manuf. 2022, 23, 1049–1063. [Google Scholar] [CrossRef]

- Liu, Y.; Shao, L.; Wang, W.Z.; Chen, J.F.; Zhang, H.; Yang, Y.; Hu, B.C. Study on Fugitive Dust Control Technologies of Agricultural Harvesting Machinery. Agriculture 2022, 12, 1038. [Google Scholar] [CrossRef]

- Bechar, A.; Vigneault, C. Agricultural robots for field operations: Concepts and components. Biosyst. Eng. 2016, 149, 94–111. [Google Scholar] [CrossRef]

- Narváez, F.Y.; Gregorio, E.; Escolà, A.; Rosell-Polo, J.R.; Torres-Torriti, M.; Cheein, F.A. Terrain classification using ToF sensors for the enhancement of agricultural machinery traversability. J. Terramechanics 2018, 76, 1–13. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, E.; Mao, H.; Zuo, Z.; Peng, H.; Zhao, M.; Yu, Y.; Li, Z. Design and Testing of an Electric Side-Mounted Cabbage Harvester. Agriculture 2024, 14, 1741. [Google Scholar] [CrossRef]

- Golinelli, N.; Spaggiari, A.; Castagnetti, D.; Fornari, L.; Dragoni, E.; Gualdi, G.; Brunazzi, A. Development of a driveshaft torque transducer for low-cost structural health monitoring of off-highway vehicles. Proc. Inst. Mech. Eng. Part L-J. Mater.-Des. Appl. 2019, 233, 714–720. [Google Scholar] [CrossRef]

- Chen, X.S.; Dang, P.A.; Zhang, E.Z.; Chen, Y.X.; Tang, C.Y.; Qi, L. Accurate recognition of rice plants based on visual and tactile sensing. J. Sci. Food Agric. 2024, 104, 4268–4277. [Google Scholar] [CrossRef]

- Wei, J.; Zhang, M.F.; Wu, C.C.; Ma, Q.; Wang, W.T.; Wan, C.F. Accurate crop row recognition of maize at the seedling stage using lightweight network. Int. J. Agric. Biol. Eng. 2024, 17, 189–198. [Google Scholar] [CrossRef]

- Jin, Y.; Liu, J.; Xu, Z.; Yuan, S.; Li, P.; Wang, J. Development status and trend of agricultural robot technology. Int. J. Agric. Biol. Eng. 2021, 14, 1–19. [Google Scholar] [CrossRef]

- Cong, C.; Guangqiao, C.; Jinlong, Z.; Jianping, H. Dynamic Monitoring of Harvester Working Progress Based on Traveling Trajectory and Header Status. Eng. Agrícola 2023, 43, e20220196. [Google Scholar] [CrossRef]

- Chen, S.; Qi, J.; Gao, J.; Chen, W.; Fei, J.; Meng, H.; Ma, Z. Research on the Control System for the Conveying and Separation Experimental Platform of Tiger Nut Harvester Based on Sensing Technology and Control Algorithms. Agriculture 2025, 15, 115. [Google Scholar] [CrossRef]

- Zhong, L.Q.; Fan, S.S.; Li, R.Y.; Yang, D. The Study of Control Strategy for Bolt Tightening Robot on Power Transmission Lines. In Proceedings of the International Conference on Electronic Industry and Automation (EIA), Suzhou, China, 23–25 June 2017. [Google Scholar]

- Zhang, M.; Ji, Y.; Li, S.; Cao, R.; Xu, H.; Zhang, Z. Research Progress of Agricultural Machinery Navigation Technology. Trans. Chin. Soc. Agric. Mach. 2020, 51, 1–18. [Google Scholar]

- El-Mesery, H.S.; Qenawy, M.; Ali, M.; Hu, Z.; Adelusi, O.A.; Njobeh, P.B. Artificial intelligence as a tool for predicting the quality attributes of garlic (Allium sativum L.) slices during continuous infrared-assisted hot air drying. J. Food Sci. 2024, 89, 7693–7712. [Google Scholar] [CrossRef]

- Chen, R.; Tian, W.; Bao, H.; Li, D.; Xie, X.; Zheng, Y.; Tan, Y. Three-Dimensional Environment Perception Technology for Agricultural Wheeled Robots:A Review. Smart Agric. 2023, 5, 16–32. [Google Scholar]

- Luo, Y.; Wei, L.; Xu, L.; Zhang, Q.; Liu, J.; Cai, Q.; Zhang, W. Stereo-vision-based multi-crop harvesting edge detection for precise automatic steering of combine harvester. Biosyst. Eng. 2022, 215, 115–128. [Google Scholar] [CrossRef]

- Wan, H.; Ou, Y.; Guan, X.; Jiang, R.; Zhou, Z.; Luo, X. Review of the perception technologies for unmanned agricultural machinery operating environment. Trans. Chin. Soc. Agric. Eng. 2024, 40, 1–18. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, X.; Wang, B.; Tang, Z.; Wang, H. Sensor-Based Monitoring of Bolted Joint Reliability in Agricultural Machinery: Performance and Environmental Challenges. Sensors 2025, 25, 5098. https://doi.org/10.3390/s25165098

Gu X, Wang B, Tang Z, Wang H. Sensor-Based Monitoring of Bolted Joint Reliability in Agricultural Machinery: Performance and Environmental Challenges. Sensors. 2025; 25(16):5098. https://doi.org/10.3390/s25165098

Chicago/Turabian StyleGu, Xinyang, Bangzhui Wang, Zhong Tang, and Haiyang Wang. 2025. "Sensor-Based Monitoring of Bolted Joint Reliability in Agricultural Machinery: Performance and Environmental Challenges" Sensors 25, no. 16: 5098. https://doi.org/10.3390/s25165098

APA StyleGu, X., Wang, B., Tang, Z., & Wang, H. (2025). Sensor-Based Monitoring of Bolted Joint Reliability in Agricultural Machinery: Performance and Environmental Challenges. Sensors, 25(16), 5098. https://doi.org/10.3390/s25165098