Novel Physics-Informed Indicators for Leak Detection in Water Supply Pipelines

Abstract

Highlights

- A robust physics-informed indicator for leak detection in water supply pipelines is proposed, grounded in the physical mechanism of leakage noise sources.

- The proposed physics-informed indicator consistently ranks first in feature importance in both experiment and field testing, showing a clear advantage over conventional statistical features.

- Both the SVM and XGBoost models achieve high recognition accuracy in the experiment and field testing, demonstrating the robustness and generalization capability of the recognition models built on the proposed indicator.

- A robust physics-informed indicator for leak detection in water supply pipelines is proposed, grounded in the physical mechanism of leakage noise sources.

- The proposed physics-informed indicator provides a reliable and interpretable feature for leak detection, with high robustness and strong sensitivity to leakage events.

- The proposed method provides a practical and effective physical feature indicator for complex operating conditions in in-service pipeline networks, demonstrating strong potential for engineering applications.

Abstract

1. Introduction

2. Physical Indicator Derived from the Leakage Noise Source Mechanism

2.1. Leakage Noise Power Spectral Density

2.2. Physical Indicator

3. Methodology

3.1. Signal Processing

3.2. Feature Extraction and Feature Selection Criteria

3.3. Leak Identification

4. Experiment Verification and Results

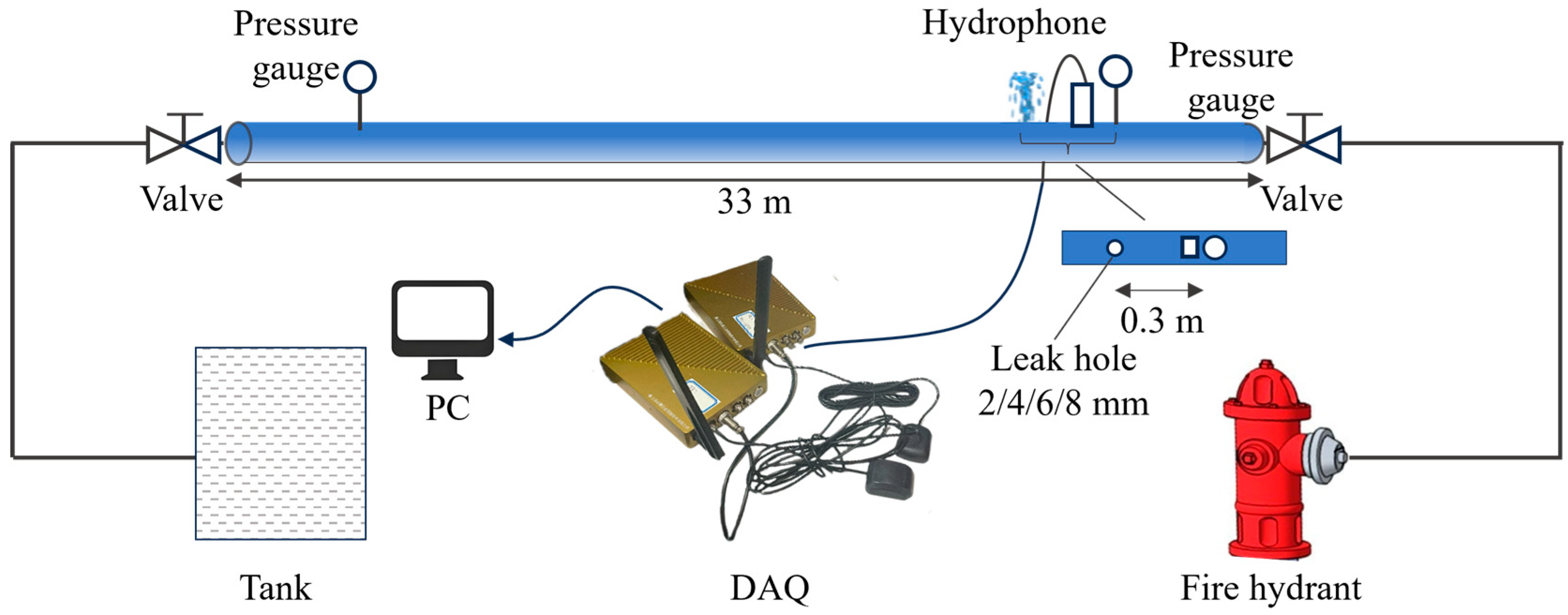

4.1. Experimental Setup

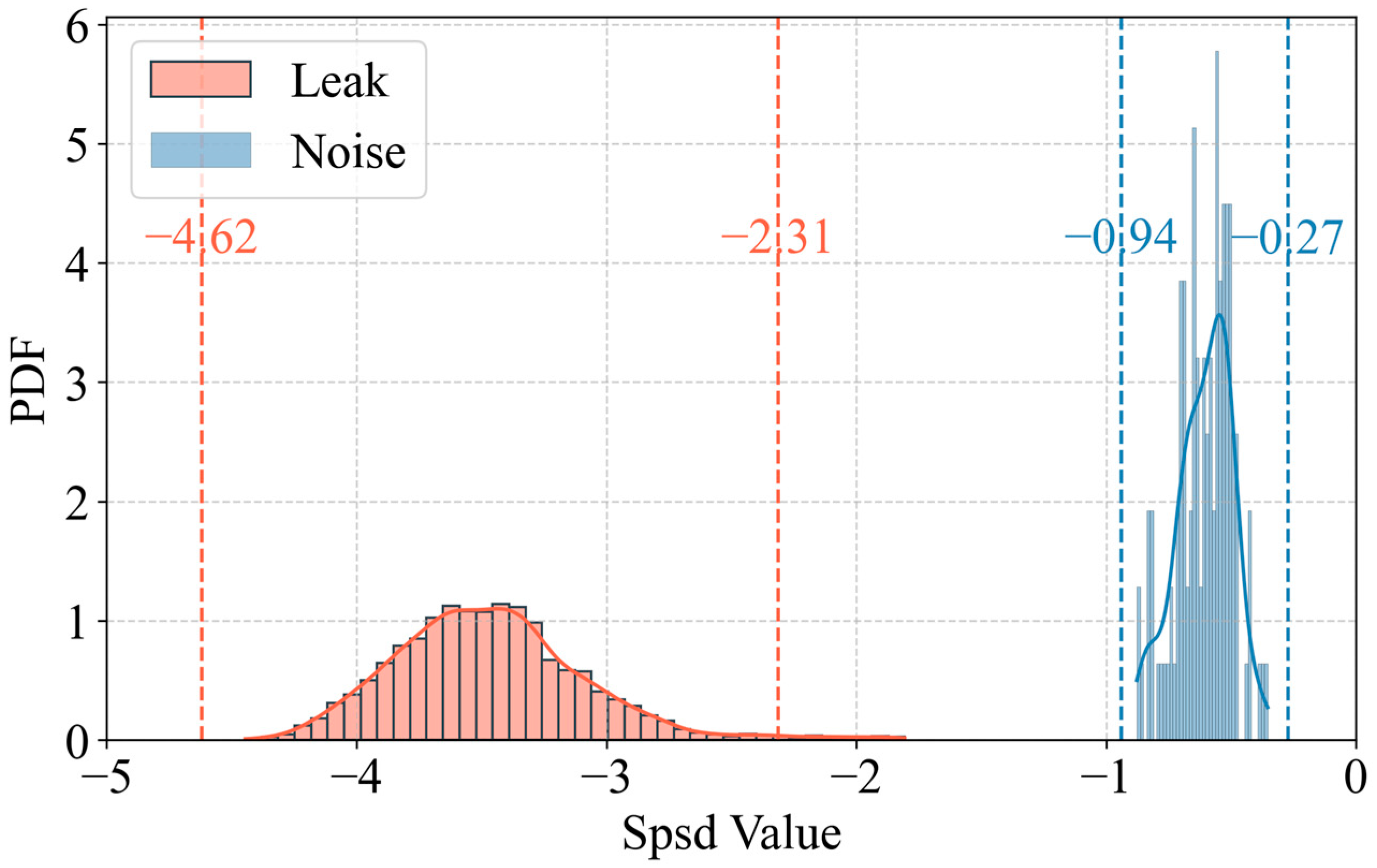

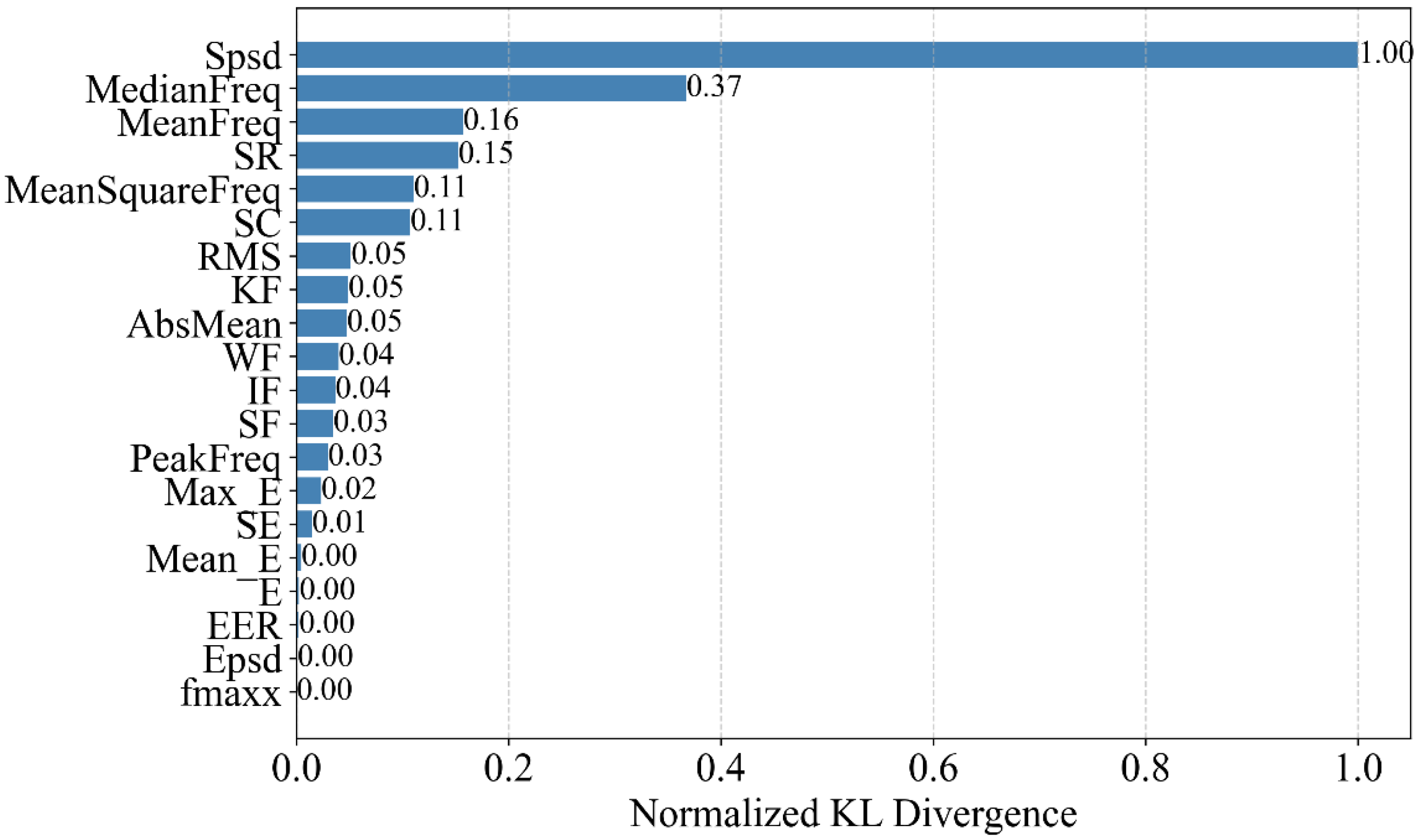

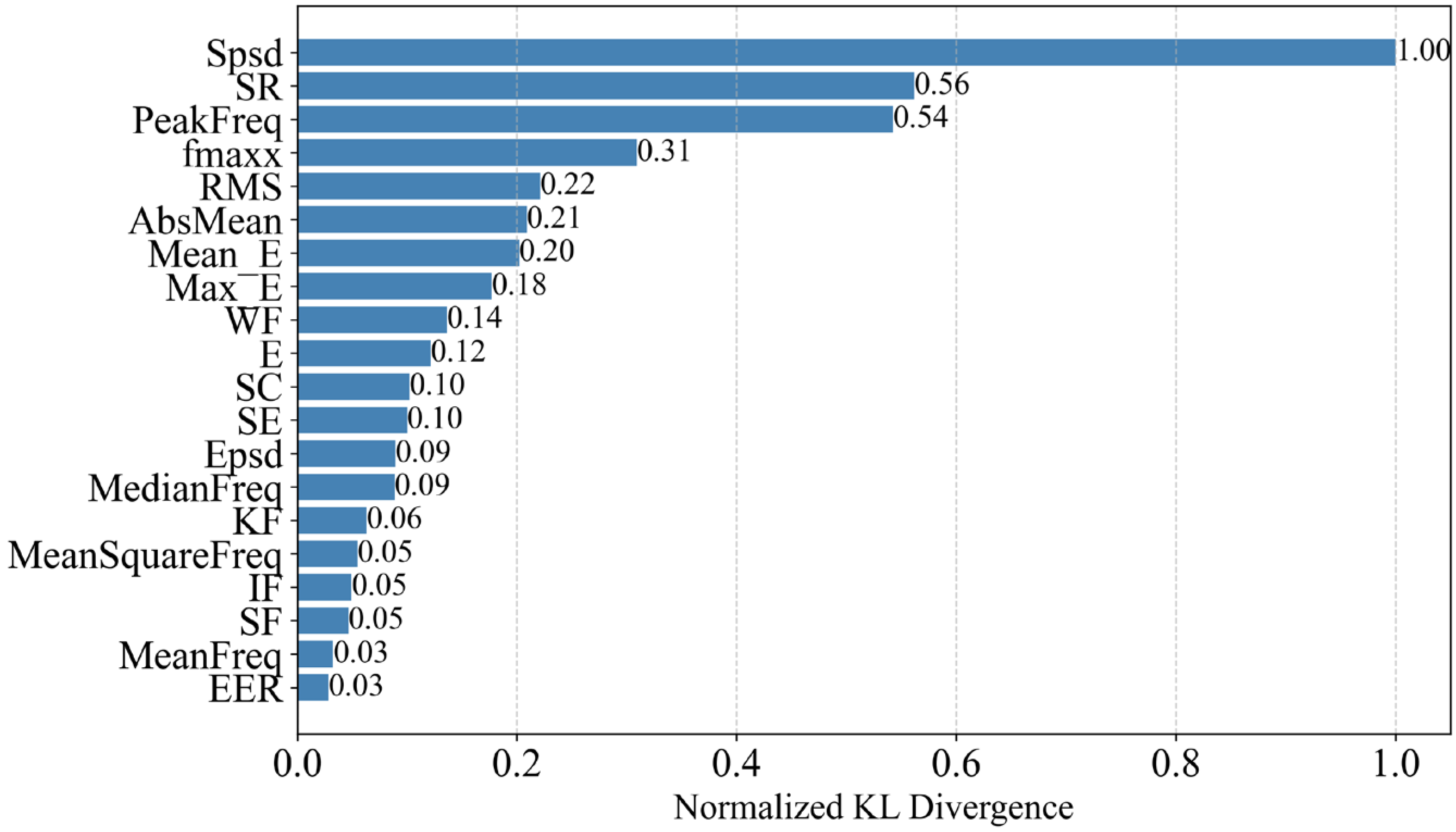

4.2. Feature Selection in the Experiment

4.3. Results of Leak Detection Models in the Experiment

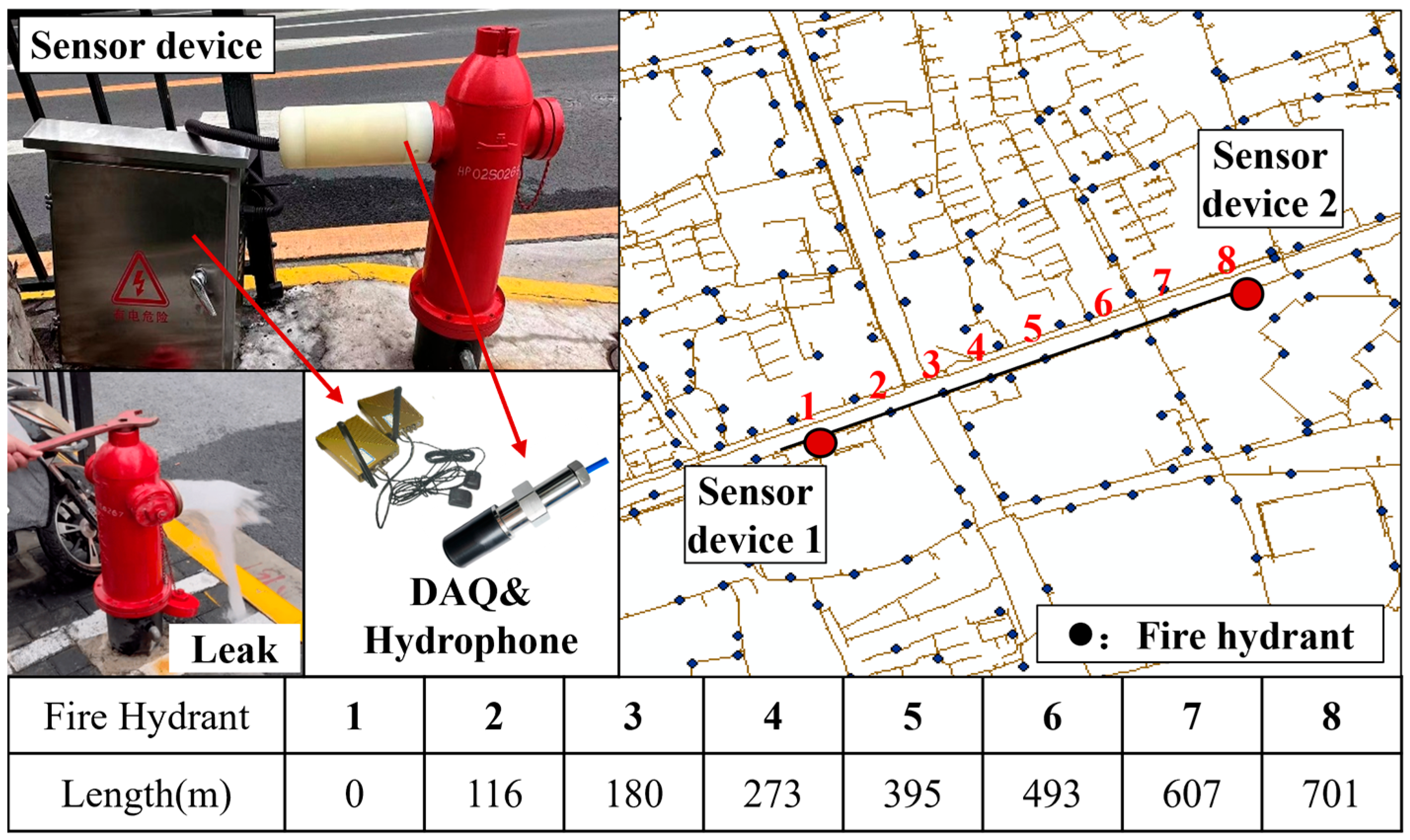

5. Field Testing

5.1. Overview

5.2. Feature Selection in Field Testing

5.3. Results of Leak Detection Models in Field Testing

6. Conclusions

- (1)

- The turbulence at the leakage hole is considered the primary sound source for leakage noise, and an integral form of the source power spectral density is established. Through analysis, it is concluded that the power spectral density follows an exponential relationship with frequency.

- (2)

- The leakage noise power spectral density will asymptotically follow a function relationship with frequency in the slightly higher frequency range. In the log–log scale, the power spectral density of leakage noise exhibits a linear relationship with frequency. The characteristic exponent within the frequency range of 101 Hz to 103 Hz, where the main frequency of the water pipeline leakage sound signal is concentrated, is extracted as the physical characteristic for pipeline leakage detection.

- (3)

- The indicator is derived under the assumption of an ideal, infinitely long, rigid pipeline. Therefore, this leakage indicator is applicable only to leakage detection in rigid pipes. Notably, the indicator is minimally affected by parameters such as pipe diameter and leak orifice size, demonstrating strong robustness. The distributions of for leakage/non-leakage and feature ranking results conditions indicate that this indicator can effectively identify leakage events and exhibits good robustness.

- (4)

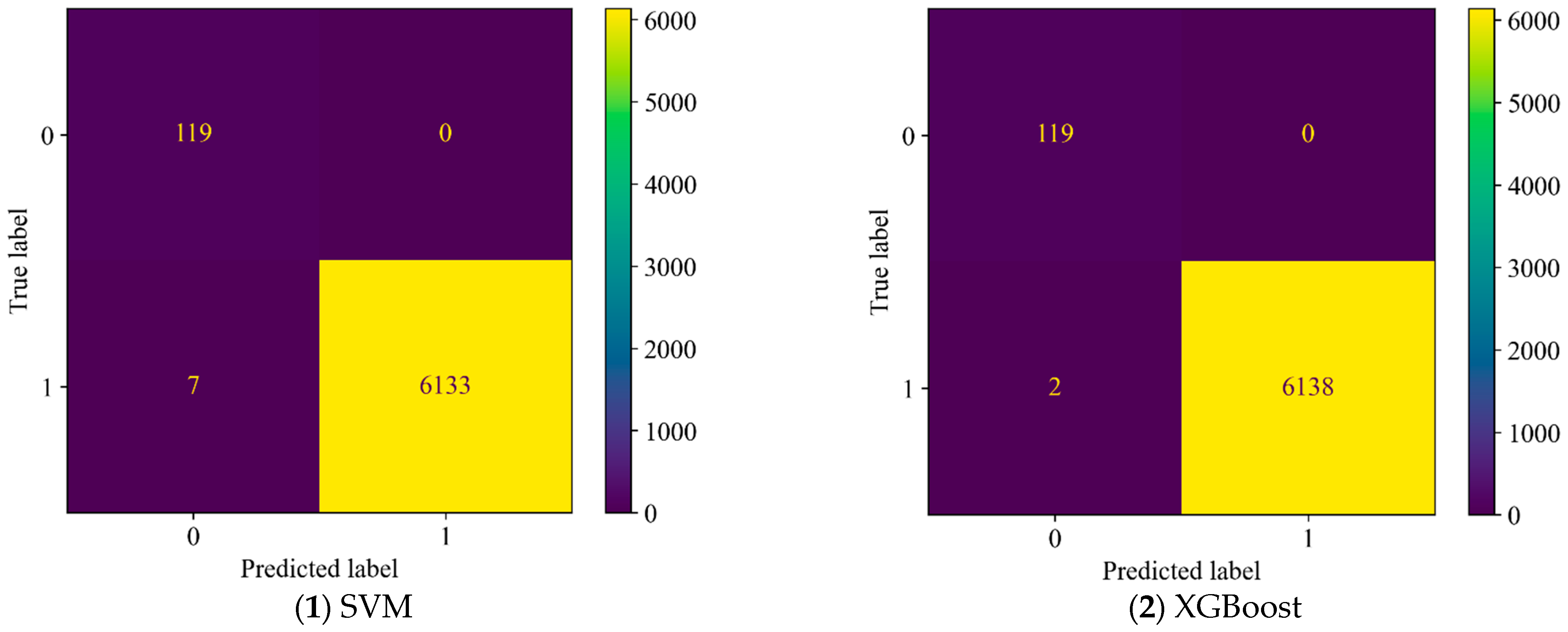

- Both SVM and XGBoost can be effectively used to establish leakage detection models. In the experiments, the SVM model achieved an accuracy of 99.89%, while XGBoost achieved 99.97%, with XGBoost demonstrating a slight advantage across various metrics. These results indicate that the laboratory experiments strongly validate the physical correctness of the proposed feature as well as its effectiveness in leakage detection.

- (5)

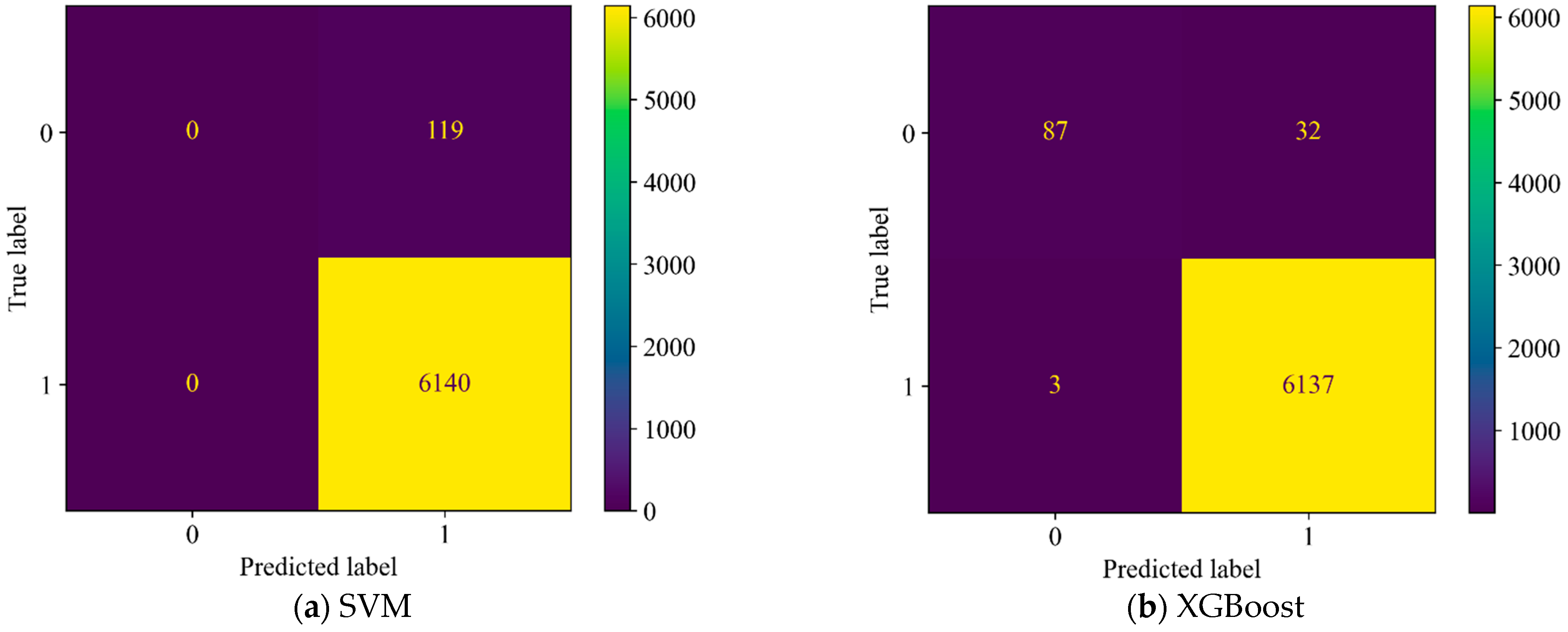

- In the field test, the physical feature is still ranked first in the feature ranking with a substantial lead, demonstrating strong leakage indication capability and good robustness. The prediction accuracies of the SVM and XGBoost models were 97.92% and 99.31%, respectively, slightly lower than those in the platform experiments. However, due to the interference of complex internal flow conditions and strong ambient noise, both the false acceptance rate (FAR) and false rejection rate (FRR) increased, with FAR showing a more pronounced rise. Overall, the leakage detection models based on the physical feature exhibited strong potential for practical engineering applications.

- (6)

- The theoretical and experimental investigation of the physical indicator for leakage requires further refinement. Future research will focus on developing a more detailed physical model of the leakage acoustic source and performing both theoretical and experimental studies on influencing parameters such as leakage orifice geometry, pipeline attachments (e.g., branch pipes, tees, etc.), and more complex pipeline network configurations. These advancements are expected to improve the applicability and robustness of the proposed method in complex and variable real-world engineering environments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- 2024 National Underground Pipeline Accident Statistics and Analysis Report. Available online: https://mp.weixin.qq.com/s/nNxwNhBLVdkVWYQH1JWIKw (accessed on 10 August 2025).

- Quy, T.B.; Kim, J.M. Leak localization in industrial-fluid pipelines based on acoustic emission burst monitoring. Measurement 2020, 151, 107150. [Google Scholar] [CrossRef]

- Wang, J.; Ren, L.; Jia, Z.; Jiang, T.; Wang, G.-X. A novel pipeline leak detection and localization method based on the FBG pipe-fixture sensor array and compressed sensing theory. Mech. Syst. Signal Process. 2022, 169, 108669. [Google Scholar] [CrossRef]

- Li, J.; Zheng, Q.; Qian, Z.; Yang, X. A novel location algorithm for pipeline leakage based on the attenuation of negative pressure wave. Process Saf. Environ. Prot. 2019, 123, 309–316. [Google Scholar] [CrossRef]

- Liu, C.W.; Li, Y.X.; Fu, J.T.; Liu, G.X. Experimental study on acoustic propagation-characteristics-based leak location method for natural gas pipelines. Process Saf. Environ. Prot. 2015, 96, 43–60. [Google Scholar]

- Huang, Y.; Liu, Z.; Li, S. Leak detection and localization of fluid-filled pipeline using accelerometer pairs and mode separation method. Measurement 2025, 239, 115491. [Google Scholar] [CrossRef]

- Fan, H.; Tariq, S.; Zayed, T. Acoustic leak detection approaches for water pipelines. Autom. Constr. 2022, 138, 104226. [Google Scholar] [CrossRef]

- Almeida, F.; Brennan, M.; Joseph, P.; Whitfield, S.; Dray, S.; Paschoalini, A. On the acoustic filtering of the pipe and sensor in a buried plastic water pipe and its effect on leak detection: An experimental investigation. Sensors 2014, 14, 5595–5610. [Google Scholar] [CrossRef]

- Khulief, Y.A.; Khalifa, A.; Mansour, R.B.; Habib, M.A. Acoustic Detection of Leaks in Water Pipelines Using Measurements inside Pipe. J. Pipeline Syst. Eng. 2012, 3, 47–54. [Google Scholar] [CrossRef]

- Rayleigh, L. On waves propagated along the plane surface of an elastic solid. Proc. Lond. Math. Soc. 1885, 1, 4–11. [Google Scholar] [CrossRef]

- Bakhtawar, B.; Zayed, T. Review of water leak detection and localization methods through hydrophone technology. J. Pipeline Syst. Eng. Pract. 2021, 12, 03121002. [Google Scholar] [CrossRef]

- Meng, L.; Yuxing, L.; Wuchang, W.; Juntao, F. Experimental Study on Leak Detection and Location for Gas Pipeline Based on Acoustic Method. J. Loss Prev. Process Ind. 2012, 25, 90–102. [Google Scholar] [CrossRef]

- Wang, F.; Lin, W.; Liu, Z.; Wu, S.; Qiu, X. Pipeline Leak Detection by Using Time-Domain Statistical Features. IEEE Sens. J. 2017, 17, 6431–6442. [Google Scholar] [CrossRef]

- Fabbiano, L.; Vacca, G.; Dinardo, G. Smart Water Grid: A Smart Methodology to Detect Leaks in Water Distribution Networks. Measurement 2020, 151, 107260. [Google Scholar] [CrossRef]

- Sitaropoulos, K.; Salamone, S.; Sela, L. Frequency-based leak signature investigation using acoustic sensors in urban water distribution networks. Adv. Eng. Inform. 2023, 55, 101905. [Google Scholar] [CrossRef]

- Yazdekhasti, S.; Piratla, K.R.; Atamturktur, S.; Khan, A.A. Novel Vibration-Based Technique for Detecting Water Pipeline Leakage. Struct. Infrastruct. Eng. 2017, 13, 731–742. [Google Scholar] [CrossRef]

- Quy, T.B.; Kim, J.M. Leak detection in a gas pipeline using spectral portrait of acoustic emission signals. Meas. J. Int. Meas. Confed. 2020, 152, 107403. [Google Scholar]

- El-Zahab, S.; Abdelkader, E.M.; Zayed, T. An accelerometer-based leak detection system. Mech. Syst. Signal Process. 2018, 108, 276–291. [Google Scholar] [CrossRef]

- Shukla, H.; Piratla, K. Leakage Detection in Water Pipelines Using Supervised Classification of Acceleration Signals. Autom. Constr. 2020, 117, 103256. [Google Scholar] [CrossRef]

- Kolmogorov, A. The local structure of turbulence in incompressible viscous fluid for very large Reynold’s numbers. Proc. R. Soc. A 1941, 30, 301–305. [Google Scholar]

- Lighthill, M.J. On Sound Generated Aerodynamically II. Turbulence as a Source of Sound. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1954, 222, 1–32. [Google Scholar]

- Blake, W.K. Dipole sound from cylinders. In Mechanics of Flow-Induced Sound and Vibration; Elsevier: Amsterdam, The Netherlands, 2017; pp. 251–322. [Google Scholar] [CrossRef]

- De Karman, T.; Howarth, L. On the statistical theory of isotropic turbulence. Proceedings of the Royal Society of London. Ser. A—Math. Phys. Sci. 1938, 164, 192–215. [Google Scholar]

- Xu, T.; Zeng, Z.; Huang, X.; Li, J.; Feng, H. Pipeline Leak Detection Based on Variational Mode Decomposition and Support Vector Machine Using an Interior Spherical Detector. Process Saf. Environ. Prot. 2021, 153, 167–177. [Google Scholar] [CrossRef]

- Li, J.; Chen, Y.; Qian, Z.; Lu, C. Research on VMD based adaptive denoising method applied to water supply pipeline leakage location. Measurement 2020, 151, 107153. [Google Scholar] [CrossRef]

- Khorshidi, M.S.; Nikoo, M.R.; Taravatrooy, N.; Sadegh, M.; Al-Wardy, M.; Al-Rawas, G.A. Pressure sensor placement in water distribution networks for leak detection using a hybrid information-entropy approach. Inf. Sci. 2020, 516, 56–71. [Google Scholar] [CrossRef]

- Tu, L.T.N.; Kim, J. Discriminative feature analysis based on the crossing level for leakage classification in water pipelines. J. Acoust. Soc. Am. 2019, 145, EL611–EL617. [Google Scholar] [CrossRef] [PubMed]

- Cortes, C.; Vapnik, V. Support-vector networks. Mach. Learn. 1995, 20, 273–297. [Google Scholar] [CrossRef]

- Chen, T.; Guestrin, C. Xgboost: A scalable tree boosting system. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; pp. 785–794. [Google Scholar]

| Time Domain Feature | Expression | Frequency Domain Feature | Expression | Frequency Domain Feature | Expression |

|---|---|---|---|---|---|

| Absolute Mean (‘AbsMean’) | Mean Frequency (‘MeanFreq’) | Waveform Factor (‘WF’) | |||

| RMS (‘RMS’) | Mean Square Frequency (‘MeanSquareFreq’) | Spectral Centroid (‘SC’) | |||

| Energy (‘E’) | Peak Frequency (‘PeakFreq’) | Spectral Roll-off Frequency (‘SR’) | |||

| Mean Energy (‘Mean_E’) | Median Frequency (‘MedianFreq’) | Spectral Entropy) (‘SE’) | |||

| Maximum Instantaneous Energy (‘Max_E’) | Peak PSD Frequency (‘fmaxx’) | Energy-to-Entropy Ratio (‘EER’) | |||

| Kurtosis Factor (‘KF’) | Energy (‘Epsd’) | ||||

| Skewness Factor (‘SF’) | Impulse Factor (‘IF’) |

| Hydrophone | Parameter | Sensitivity @1 kHz | Frequency Range | Preamplifier Gain |

| Value | −156 dB V/μPa | 1 Hz–2 KHz | 40 dB | |

| High- Frequency Pressure Sensor | Parameter | Measurement Range | Frequency Range | Accuracy |

| Value | 0–3 MPa | 0–2 KHz | ±0.2% FS |

| Variable | Value |

|---|---|

| Leak position (Distance from the hydrophone) | 0.3 m, 9.3 m, 24.3 m |

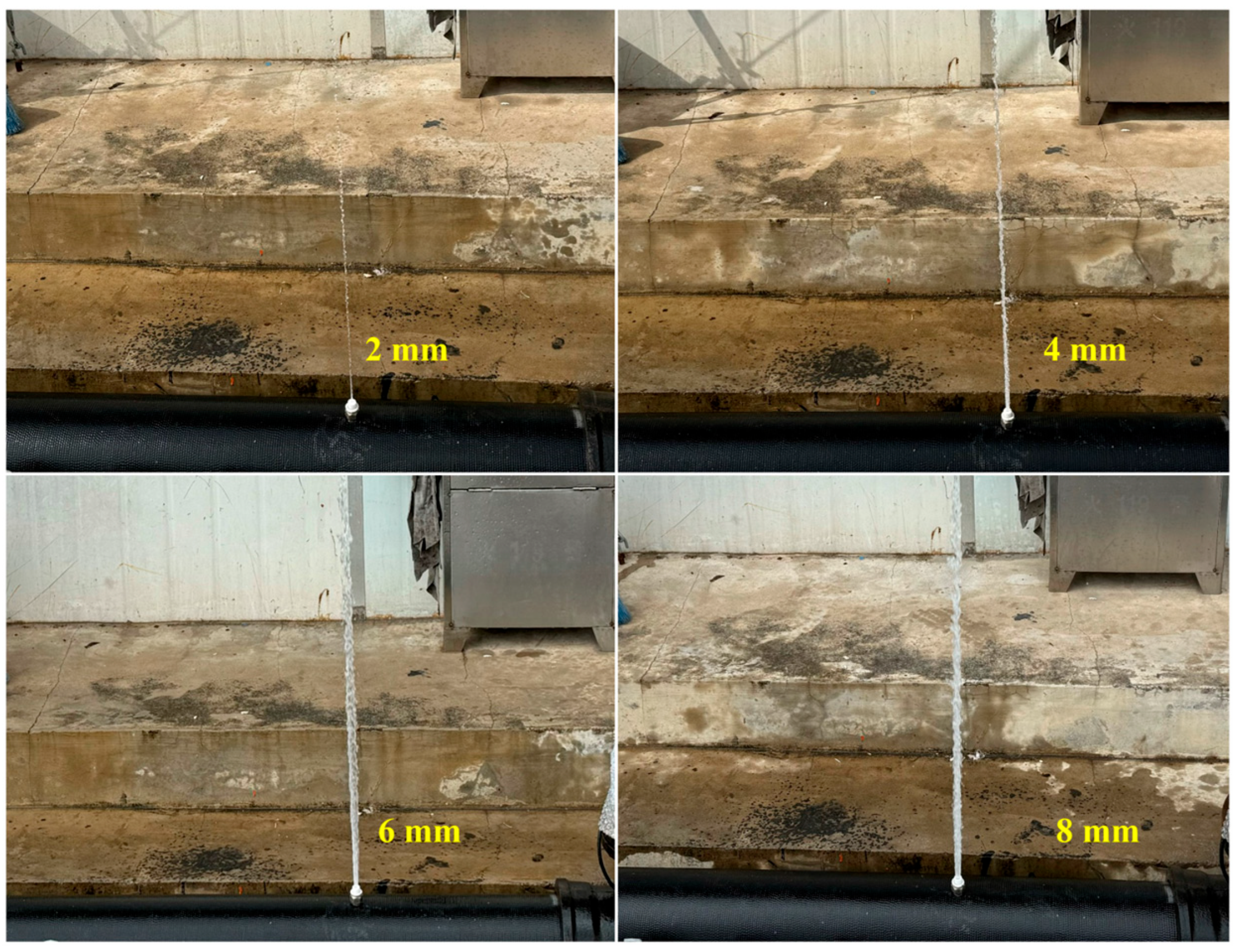

| leakage diameters 2a | 2 mm, 4 mm, 6 mm, 8 mm |

| Model | Accuracy | FAR | FRR |

|---|---|---|---|

| SVM | 99.89% | 0% | 0.11% |

| XGBoost | 99.97% | 0% | 0.03% |

| Model | Accuracy | FAR | FRR |

|---|---|---|---|

| SVM | 98.10% | 100% | 0% |

| XGBoost | 99.44% | 26.89% | 0.05% |

| Model | Accuracy | FAR | FRR |

|---|---|---|---|

| SVM | 97.92% | 3.24% | 1.12% |

| XGBoost | 99.31% | 1.17% | 0.30% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Li, S. Novel Physics-Informed Indicators for Leak Detection in Water Supply Pipelines. Sensors 2025, 25, 5069. https://doi.org/10.3390/s25165069

Zhang Y, Li S. Novel Physics-Informed Indicators for Leak Detection in Water Supply Pipelines. Sensors. 2025; 25(16):5069. https://doi.org/10.3390/s25165069

Chicago/Turabian StyleZhang, Yi, and Suzhen Li. 2025. "Novel Physics-Informed Indicators for Leak Detection in Water Supply Pipelines" Sensors 25, no. 16: 5069. https://doi.org/10.3390/s25165069

APA StyleZhang, Y., & Li, S. (2025). Novel Physics-Informed Indicators for Leak Detection in Water Supply Pipelines. Sensors, 25(16), 5069. https://doi.org/10.3390/s25165069