Temperature Field and Temperature Effects for Concrete Box Girder Bridges Based on Monitoring Data and Numerical Simulation

Abstract

1. Introduction

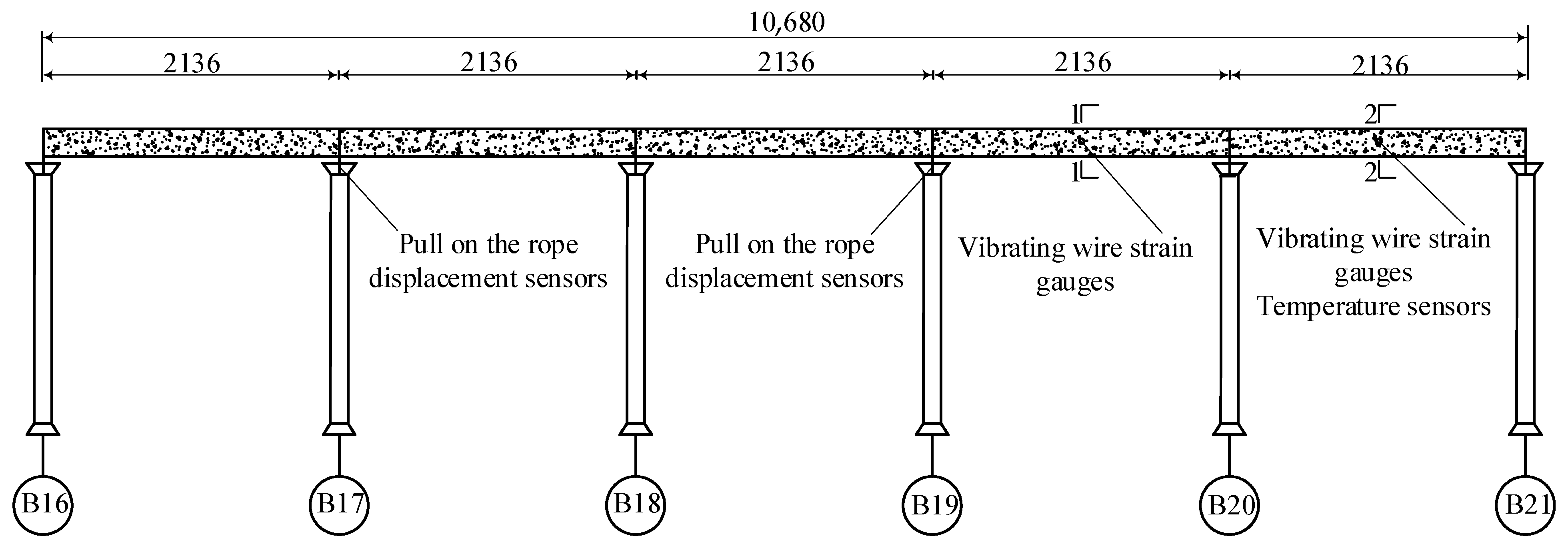

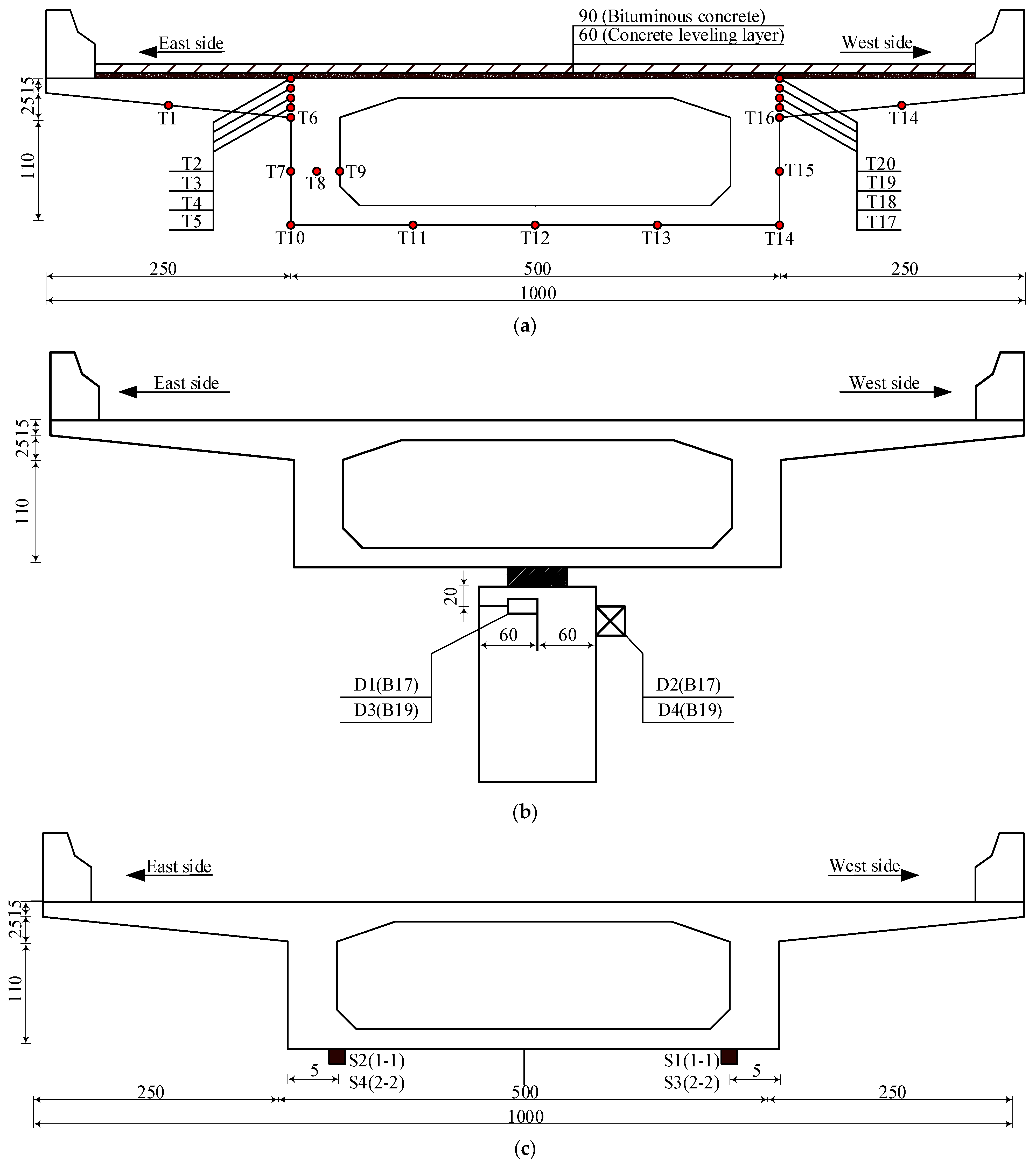

2. Measurement Point Layout and Monitoring Data Analysis

2.1. Measurement Point Layout

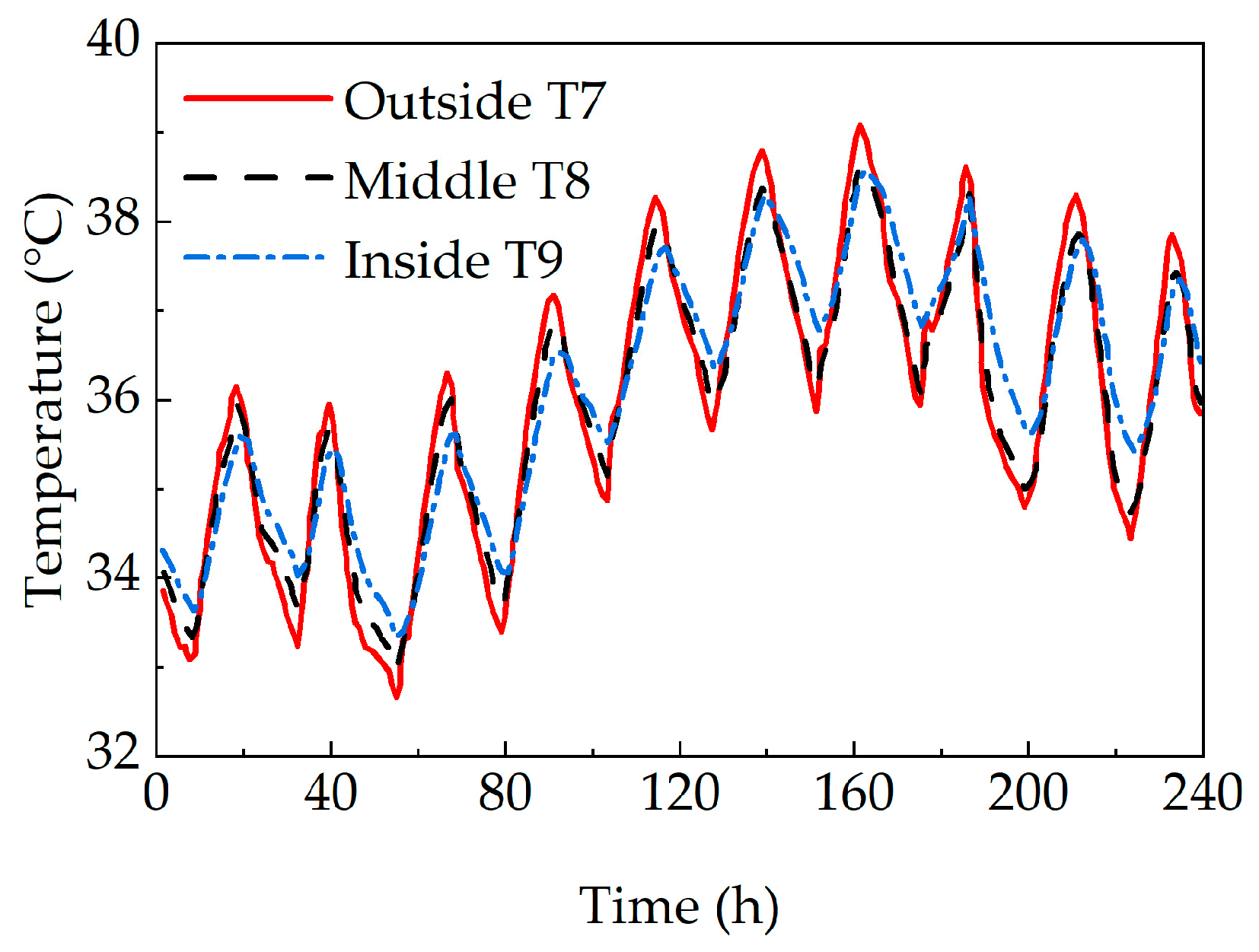

2.2. Analysis of Temperature Field Monitoring Data

3. Temperature Field of Concrete Box Girder Bridge

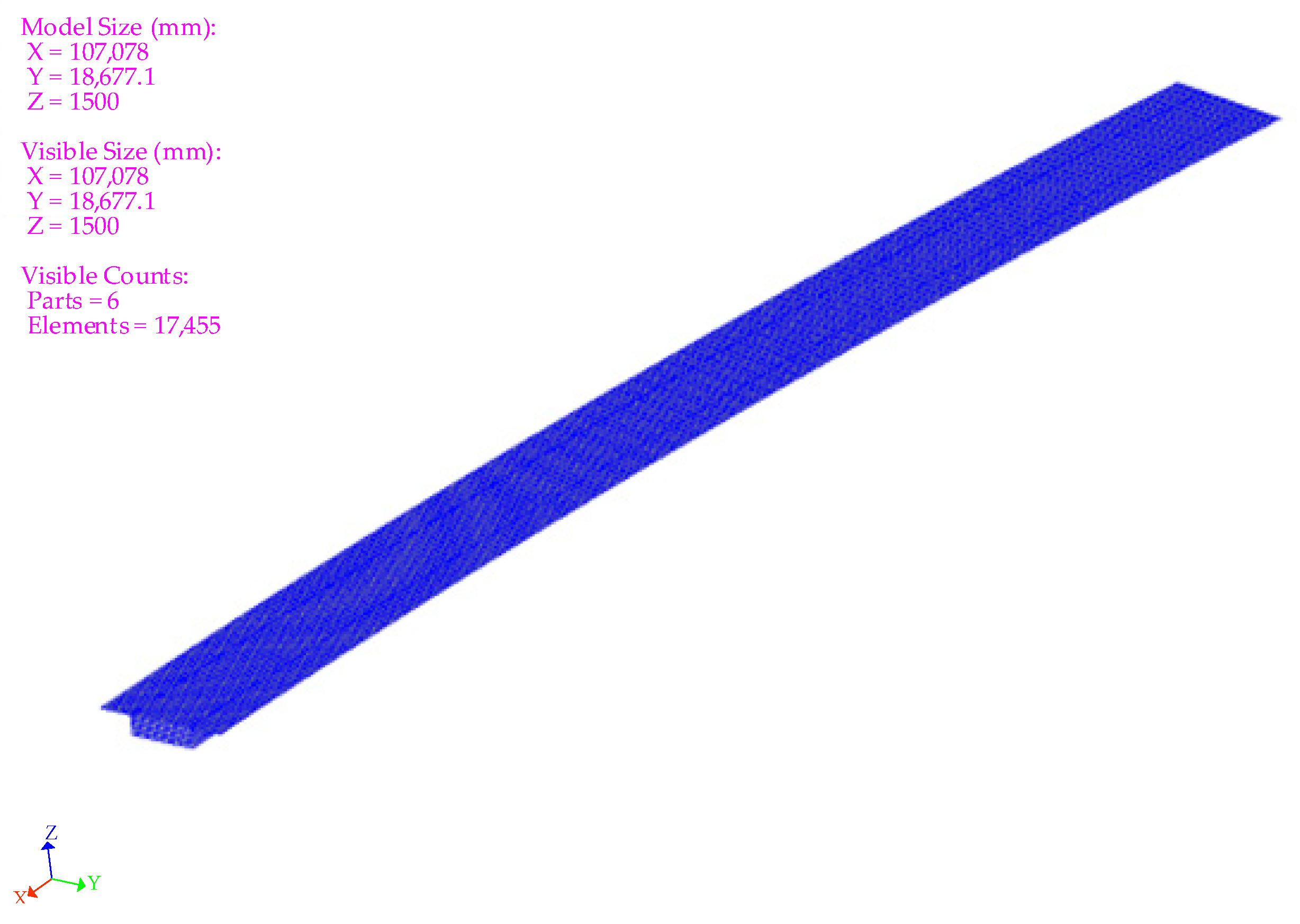

3.1. Temperature Field Model of Concrete Box Girder Bridge

3.1.1. Establishment of Temperature Field Model

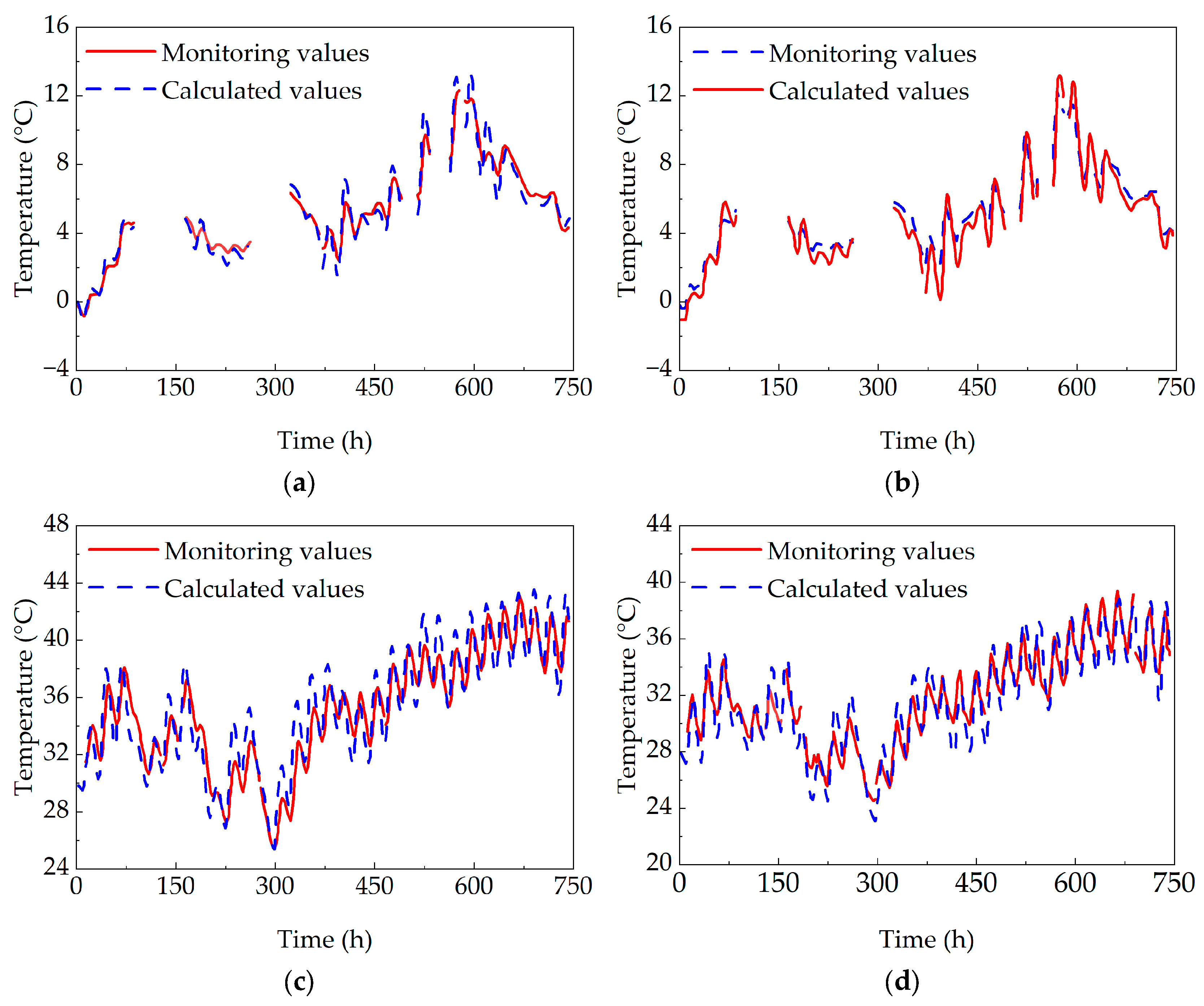

3.1.2. Verification of Temperature Field Model

3.2. Temperature Gradient Patterns of Box Girder Under Extreme Weather Conditions

3.2.1. Determining Extreme Weather Conditions

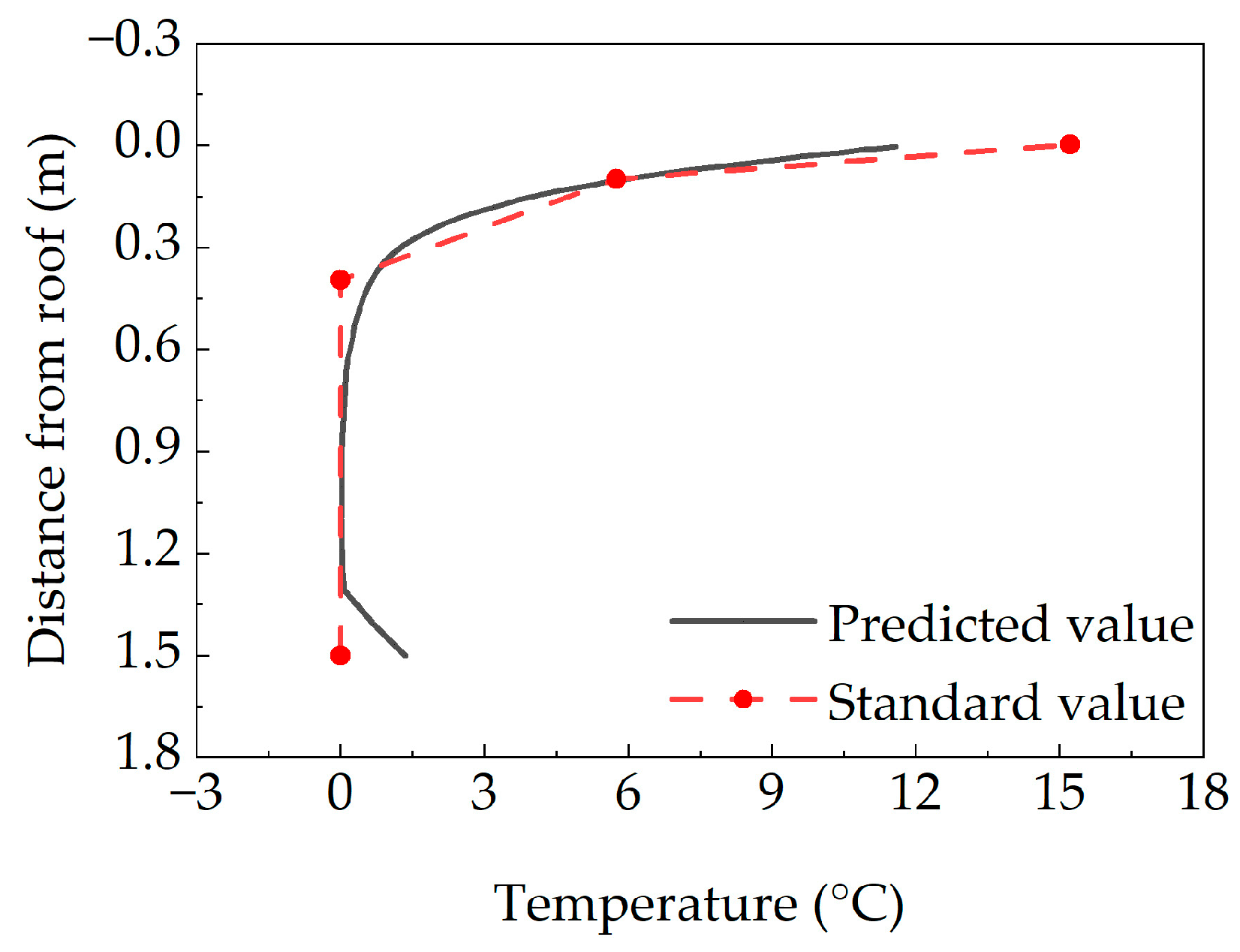

3.2.2. Prediction of Vertical Temperature Gradient

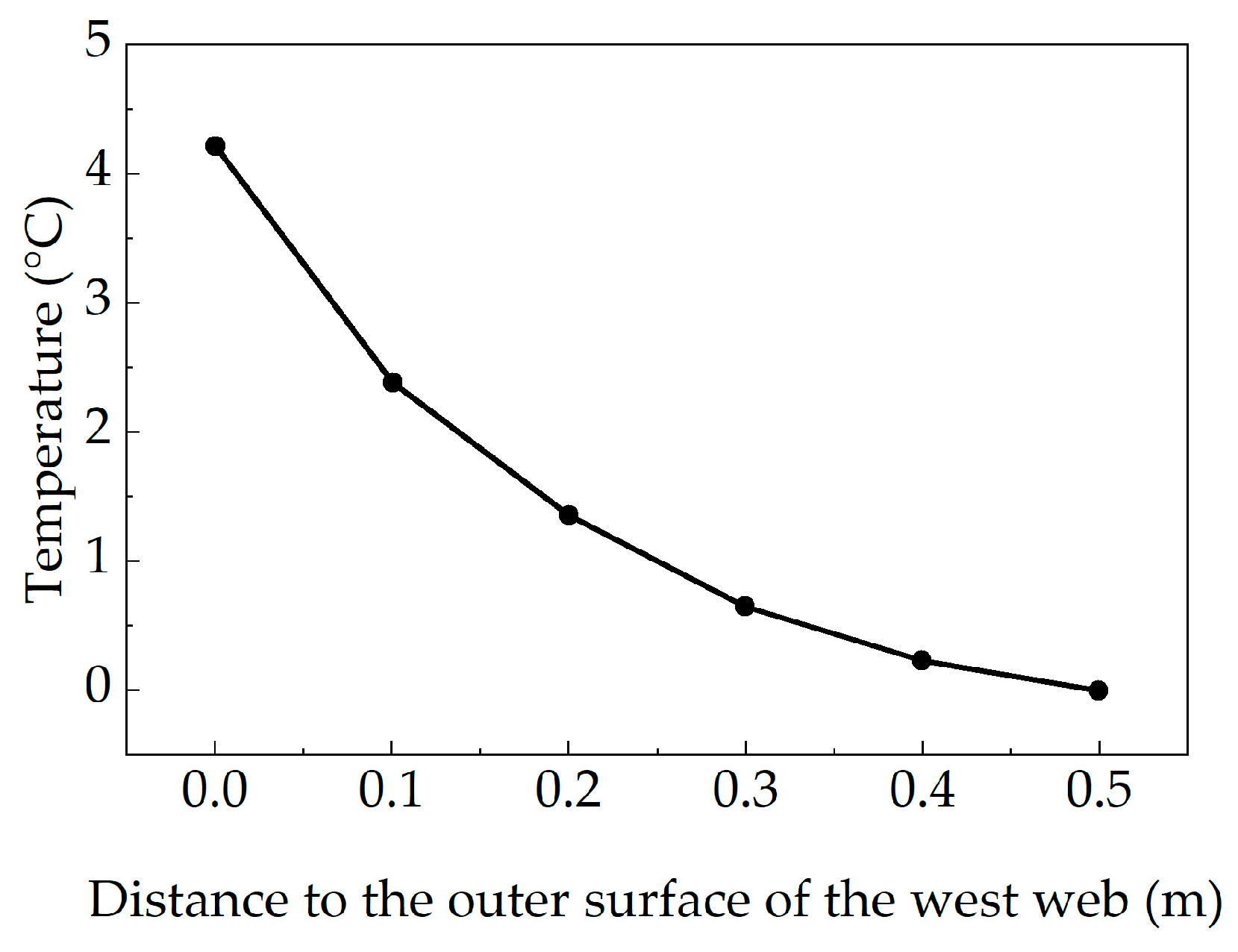

3.2.3. Prediction of Lateral Temperature Gradient

4. Analysis of Temperature Effect of Concrete Box Girder Bridge

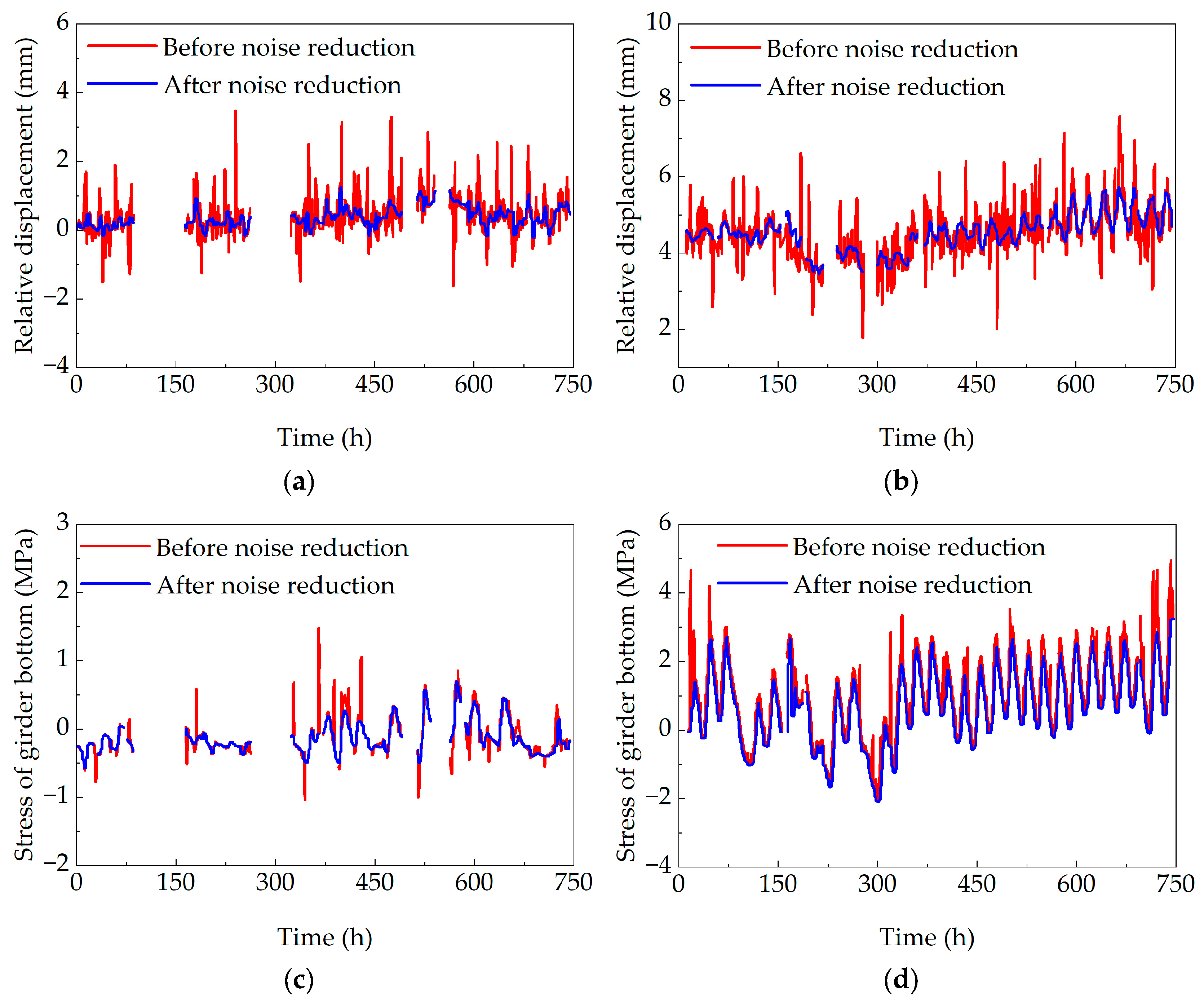

4.1. Processing of Temperature Effect Monitoring Data

4.2. Relationship Between Temperature Effects and Temperature

5. Conclusions

- Based on temperature monitoring data of the concrete box girder bridge, the distribution characteristics of the bridge temperature field were investigated. Annually, the top slab experiences the largest temperature variation, followed by the web, with the bottom slab exhibiting the smallest variation. Significant vertical temperature differences were identified within the same cross-section, along with certain lateral temperature gradients.

- The simulated temperature field showed good agreement with the monitoring data, validating the accuracy of the established model. This demonstrates that the combined finite element simulation approach can reliably capture the thermal behavior of concrete box girder bridges, can be extended to similar structural analyses.

- Extreme weather conditions in Wuhan with a 100-year return period were constructed and used in conjunction with the temperature field model to predict the most unfavorable lateral and vertical temperature gradient distributions. The maximum vertical temperature difference is 11.73 °C, and the maximum lateral temperature difference is 4.21 °C. Comparisons with current highway bridge design specifications revealed that the specified values for the top slab are reasonable. However, unregulated yet significant temperature gradients were found in the upper web and bottom slab, indicating the need for potential specification refinement.

- Wavelet analysis was employed to denoise the original monitoring data of pier girder relative displacement and bottom slab stress for the concrete box girder bridge, effectively reducing interference. The processed data demonstrated that the temporal variations in displacement and stress closely followed those of girder temperature, exhibiting strong correlations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Engelfriet, L.; Koomen, E. The impact of urban form on commuting in large Chinese cities. Transportation 2018, 45, 1269–1295. [Google Scholar] [CrossRef]

- Zhao, L.; Jia, Y. Interactive correlation between economy and integrated transportation development of metropolitan areas in China: Quantitative study. J. Urban. Plan. Dev. 2021, 147, 05021041. [Google Scholar] [CrossRef]

- Ma, C.; Wang, J.; Wang, S.; Lu, X.; Guo, B. Research on a collaborative control strategy of an urban expressway merging bottleneck area. Appl. Sci. 2022, 12, 11397. [Google Scholar] [CrossRef]

- Shi, J.; Xiao, H.; Zheng, K.; Shen, J.; Zhou, G. Essential stressing state features of a large-curvature continuous steel box-girder bridge model revealed by modeling experimental data. Thin-Walled Struct. 2019, 143, 106247. [Google Scholar] [CrossRef]

- Glisic, B. Concise Historic Overview of Strain Sensors Used in the Monitoring of Civil Structures: The First One Hundred Years. Sensors 2022, 22, 2397. [Google Scholar] [CrossRef]

- Crespi, P.; Zucca, M.; Longarini, N.; Giordano, N. Seismic Assessment of Six Typologies of Existing RC Bridges. Infrastructures 2020, 5, 52. [Google Scholar] [CrossRef]

- Ojha, S.; Pal, P.K.; Mehta, P.K. Computational Analysis of Curved Prestressed Concrete Box-Girder Bridges Using Finite Element Method. Sci. Rep. 2025, 15, 7050. [Google Scholar] [CrossRef]

- Jiang, L.; Yang, H.; Liu, W.; Ye, Z.; Pei, J.; Liu, Z.; Fan, J. Early Warning for Continuous Rigid Frame Bridges Based on Nonlinear Modeling for Temperature-Induced Deflection. Sensors 2024, 24, 3587. [Google Scholar] [CrossRef]

- Yang, H.; Wu, N.; Cao, H.; Zhang, W. Two-stage stochastic model updating approach based on Bayesian framework and hybrid multi-population migrant genetic-metropolis-hastings algorithm for heavy-haul railway bridges. Eng. Optim. 2025, 57, 1343–1366. [Google Scholar] [CrossRef]

- Wu, N.; Yang, H.; Afsar, H.; Wang, B.; Fan, J. Analysis of Train–Track–Bridge Coupling Vibration Characteristics for Heavy-Haul Railway Based on Virtual Work Principle. Sensors 2023, 23, 8550. [Google Scholar] [CrossRef]

- Pawlus, D. Stability of three-layered annular plate in stationary temperature field. Thin-Walled Struct. 2019, 144, 106280. [Google Scholar] [CrossRef]

- Xu, H.; Yan, X. Numerical Analysis of Temperature Influence on Transverse Cracks in Concrete Box-Girder Bridges. Math. Probl. Eng. 2020, 2020, 3295037. [Google Scholar] [CrossRef]

- Yang, H.; Jiang, L.; Xu, F.; Gu, J.; Ye, Z.; Peng, Y.; Liu, Z.; Cheng, R. Safety Evaluation for Fabricated Small Box Girder Bridges Based on Fuzzy Analytic Hierarchy Process and Monitoring Data. Sensors 2024, 24, 4592. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Cai, J.; Feng, Q.; Jia, W.; He, Y. Experimental Study and Numerical Analysis of Hydration Heat Effect on Precast Prestressed Concrete Box Girder. Buildings 2025, 15, 859. [Google Scholar] [CrossRef]

- K Li, H.; Ba, Y.-K.; Zhang, N.; Liu, Y.-J.; Shi, W. Temperature Distribution Characteristics and Action Pattern of Concrete Box Girder under Low-Temperature and Cold Wave Conditions. Appl. Sci. 2024, 14, 3102. [Google Scholar] [CrossRef]

- Yang, K.; Ding, Y.; Jiang, H.; Sheng, W.; Zhao, H. Time-Lag Effect of Temperature-Induced Strain for Concrete Box Girder Bridges: Field Monitoring and FEM Study. J. Civ. Struct. Health Monit. 2024, 14, 303–320. [Google Scholar] [CrossRef]

- Hossain, T.; Segura, S.; Okeil, A.M. Structural effects of temperature gradient on a continuous prestressed concrete girder bridge: Analysis and field measurements. Struct. Infrastruct. Eng. 2020, 16, 1539–1550. [Google Scholar] [CrossRef]

- Nassar, M.; Amleh, L. Transient Thermal Analysis of Concrete Box Girders: Assessing Temperature Variations in Canadian Climate Zones. Sensors 2023, 23, 8206. [Google Scholar] [CrossRef]

- Yang, H.; Wu, N.; Zhang, W.; Liu, Z.; Fan, J.; Wang, C. Dynamic response of spatial train-track-bridge interaction system due to unsupported track using virtual work principle. Appl. Sci. 2022, 12, 6156. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Y.; Deng, Y. Temperature gradient modeling of a steel box-girder suspension bridge using Copulas probabilistic method and field monitoring. Adv. Struct. Eng. 2020, 24, 947–961. [Google Scholar] [CrossRef]

- Zhou, L.; Xia, Y.; Brownjohn, J.M.W.; Koo, K.Y. Temperature analysis of a long-span suspension bridge based on field monitoring and numerical simulation. J. Bridge Eng. 2016, 21, 04015027. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, H.; Cao, H.; Zhang, X.; Zhang, A.; Wu, N.; Liu, Z. Separation of Temperature-Induced Response for Bridge Long-Term Monitoring Data Using Local Outlier Correction and Savitzky–Golay Convolution Smoothing. Sensors 2023, 23, 2632. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Sun, L. Insights into temperature effects on structural deformation of a cable-stayed bridge based on structural health monitoring. Struct. Health Monit. 2018, 18, 778–791. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, X. Temporal change of climate zones in China in the context of climate warming. Theor. Appl. Climatol. 2014, 115, 167–175. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, X.; Chen, Z. Geographic distribution of global climate zones under future scenarios. Int. J. Climatol. 2017, 37, 4327–4334. [Google Scholar] [CrossRef]

- He, W.; Zhao, S.; Wu, Q.; Jiang, Y.; Wan, S. Simulating evaluation and projection of the climate zones over China by CMIP5 models. Clim. Dyn. 2019, 52, 2597–2612. [Google Scholar] [CrossRef]

- Fan, J.; Liu, Y.; Liu, C. Experiment study and refined modeling of temperature field of steel-concrete composite beam bridges. Eng. Struct. 2021, 240, 112350. [Google Scholar] [CrossRef]

- Tan, H.; Qian, D.; Xu, Y.; Yuan, M.; Zhao, H. Analysis of vertical temperature gradients and their effects on hybrid girder cable-stayed bridges. Sustainability 2023, 15, 1053. [Google Scholar] [CrossRef]

- Roberis-Wollman, C.L.; Breen, J.E.; Cawrse, J. Measurement of thermal gradients and their effects on segmental concrete bridge. J. Bridge Eng. 2002, 7, 166–174. [Google Scholar] [CrossRef]

- Li, D.; Maes, M.A.; Dilger, W.H. Evaluation of temperature data of Confederation Bridge: Thermal loading and movement at expansion joint. In Proceedings of the 2008 Structures Congress, Vancouver, BC, Canada, 24–26 April 2008. [Google Scholar] [CrossRef]

- Lee, J.H.; Kalkan, I. Analysis of thermal environmental effects on precast, prestressed concrete bridge girders: Temperature differentials and thermal deformations. Adv. Struct. Eng. 2012, 15, 447–459. [Google Scholar] [CrossRef]

- Taysi, N.; Abid, S. Temperature distributions and variations in concrete box-girder bridges: Experimental and finite element parametric studies. Adv. Struct. Eng. 2015, 18, 469–486. [Google Scholar] [CrossRef]

- Moravcik, M.; Krkoska, L. Thermal effects on box girder concrete bridges. Key Eng. Mater. 2017, 738, 273–283. [Google Scholar] [CrossRef]

- Mathew, C.S.; Ingle, R.K. Temperature analysis of segmental box girder bridges. Int. J. Struct. Eng. 2018, 9, 289–301. [Google Scholar] [CrossRef]

- JTG D60-2015; General Specifications for Design of Highway Bridges and Culverts. Ministry of Transport of the People’s Republic of China: Beijing, China, 2015.

- GB 50019-2015; Design Code for Heating Ventilation and Air Conditioning of Industrial Buildings. Ministry of Housing and Urban-Rural Development of the People′s Republic of China and General Administration of Quality Supervision Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2017.

- Yang, B.-C.; Xu, F.-Z.; Zhao, Y.; Yao, T.-Y.; Hu, H.-Y.; Jia, M.-Y.; Zhou, Y.-J.; Li, M.-Z. Complete Ensemble Empirical Mode Decomposition and Wavelet Algorithm Denoising Method for Bridge Monitoring Signals. Buildings 2024, 14, 2056. [Google Scholar] [CrossRef]

| Material | Density (kg·m−3) | Thermal Conductivity (W·m−1·°C−1) | Heat Capacity (J·kg−1·°C −1) | Absorbency | Reflectivity |

|---|---|---|---|---|---|

| Concrete | 2500 | 1.74 | 970 | 0.65 | 0.85 |

| Asphalt | 2300 | 0.7 | 860 | 0.88 | 0.93 |

| Year | Maximum Temperature (°C) | Year | Maximum Temperature (°C) |

|---|---|---|---|

| 2010 | 39.6 | 2015 | 36.4 |

| 2011 | 37.3 | 2016 | 38.4 |

| 2012 | 37.5 | 2017 | 39.7 |

| 2013 | 39.5 | 2018 | 38.6 |

| 2014 | 37.1 | 2019 | 38.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, M.; Yang, H.; Li, B.; Hao, J.; Zhou, W.; Cao, H.; Liu, Z. Temperature Field and Temperature Effects for Concrete Box Girder Bridges Based on Monitoring Data and Numerical Simulation. Sensors 2025, 25, 5036. https://doi.org/10.3390/s25165036

Zhai M, Yang H, Li B, Hao J, Zhou W, Cao H, Liu Z. Temperature Field and Temperature Effects for Concrete Box Girder Bridges Based on Monitoring Data and Numerical Simulation. Sensors. 2025; 25(16):5036. https://doi.org/10.3390/s25165036

Chicago/Turabian StyleZhai, Mengxiang, Hongyin Yang, Bin Li, Jing Hao, Weihua Zhou, Hongyou Cao, and Zhangjun Liu. 2025. "Temperature Field and Temperature Effects for Concrete Box Girder Bridges Based on Monitoring Data and Numerical Simulation" Sensors 25, no. 16: 5036. https://doi.org/10.3390/s25165036

APA StyleZhai, M., Yang, H., Li, B., Hao, J., Zhou, W., Cao, H., & Liu, Z. (2025). Temperature Field and Temperature Effects for Concrete Box Girder Bridges Based on Monitoring Data and Numerical Simulation. Sensors, 25(16), 5036. https://doi.org/10.3390/s25165036