Decomposing and Modeling Acoustic Signals to Identify Machinery Defects in Industrial Soundscapes

Abstract

1. Introduction

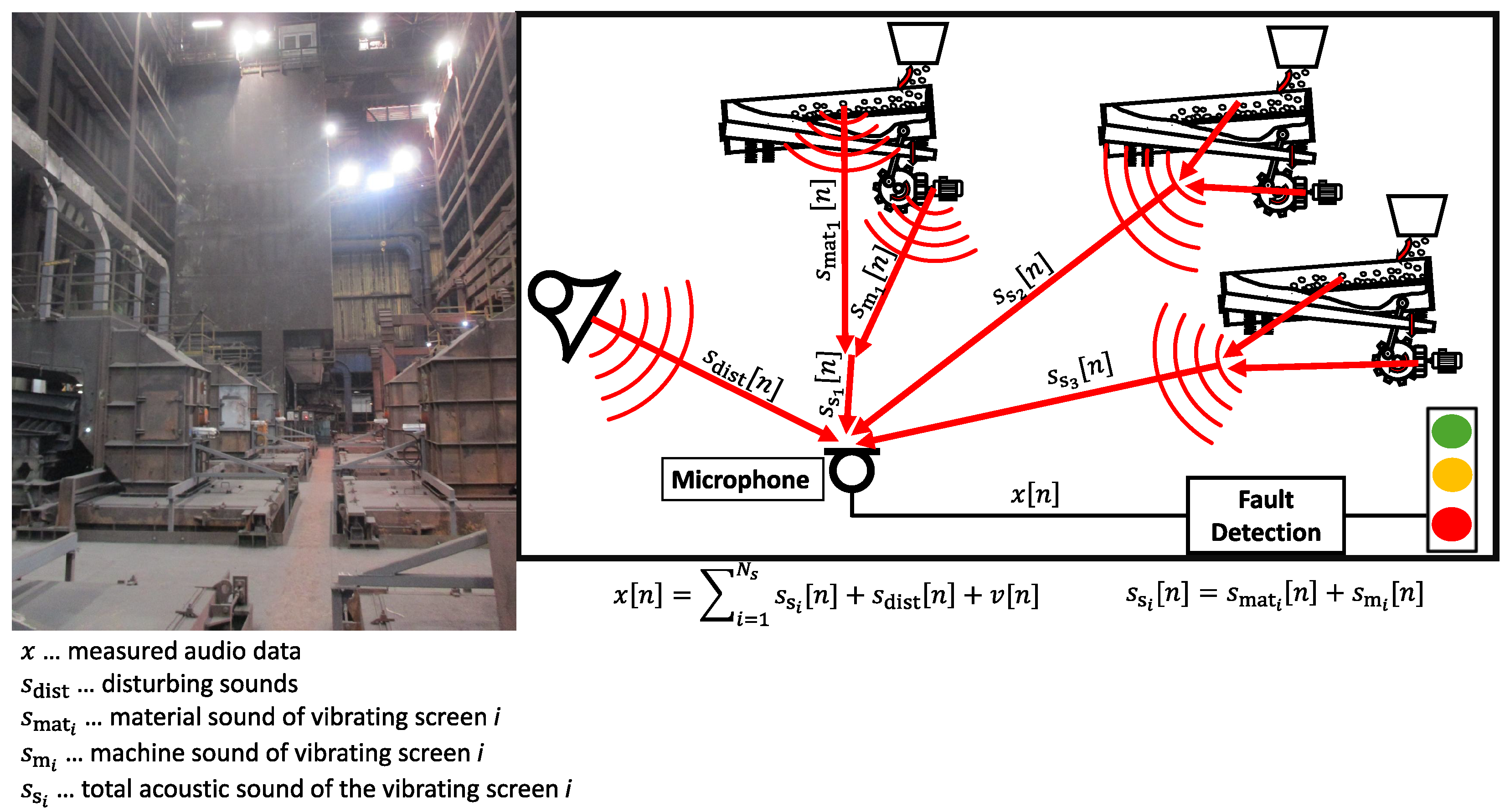

2. Measurement Set-Up and Characteristics of Signals from an Industrial Facility

2.1. Measurement Set-Up

2.2. Audio Measurements

2.3. Recreation of Fault Case

3. Signal Modeling

3.1. Disturbing Sound

3.2. Machine Signal

3.3. Material Sound

4. Fault Sound

4.1. Signal Model Proposal

4.2. Signal Model Verification

- The signal can be modeled with the convolution of a pulse train and a knocking sound (Equation (8)): .

- The interval of the pulse train corresponds to the vibration period of the screen .

- The knocking sound can be modeled as a sum of exponential decaying oscillations:.

- The amplitudes, frequencies and phases differ from knocking event to knocking event.

- The exponential decay behaves inversely proportional to the frequency.

5. Fault State Detection

5.1. Audio Feature-Based Fault Detection

5.1.1. Artificial Generated Data

5.1.2. Real Data

5.2. Signal Model-Based Fault Detection

- :

- :

5.2.1. Artificial Generated Data

5.2.2. Real Data

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hashemian, H.M.; Bean, W.C. State-of-the-Art Predictive Maintenance Techniques. IEEE Trans. Instrum. Meas. 2011, 60, 3480–3492. [Google Scholar] [CrossRef]

- Laval, X.; Mailhes, C.; Martin, N.; Bellemain, P.; Pachaud, C. Amplitude and phase interaction in Hilbert demodulation of vibration signals: Natural gear wear modeling and time tracking for condition monitoring. Mech. Syst. Signal Process. 2021, 150, 107321. [Google Scholar] [CrossRef]

- Schmidt, S.; Heyns, P.S.; De Villiers, J.P. A novelty detection diagnostic methodology for gearboxes operating under fluctuating operating conditions using probabilistic techniques. Mech. Syst. Signal Process. 2018, 100, 152–166. [Google Scholar] [CrossRef]

- Camerini, V.; Coppotelli, G.; Bendisch, S.; Kiehn, D. Impact of pulse time uncertainty on synchronous average: Statistical analysis and relevance to rotating machinery diagnosis. Mech. Syst. Signal Process. 2019, 129, 308–336. [Google Scholar] [CrossRef]

- Chen, Z.; Gryllias, K.; Li, W. Mechanical fault diagnosis using convolutional neural networks and extreme learning machine. Mech. Syst. Signal Process. 2019, 133, 106272. [Google Scholar] [CrossRef]

- Randall, R.B.; Antoni, J. Rolling element bearing diagnostics—A tutorial. Mech. Syst. Signal Process. 2011, 25, 485–520. [Google Scholar] [CrossRef]

- Nikolaou, N.; Antoniadis, I. Rolling element bearing fault diagnosis using wavelet packets. Ndt&E Int. 2002, 35, 197–205. [Google Scholar]

- Torabi, A.J.; Er, M.J.; Li, X.; Lim, B.S.; Peen, G.O. Application of clustering methods for online tool condition monitoring and fault diagnosis in high-speed milling processes. IEEE Syst. J. 2015, 10, 721–732. [Google Scholar] [CrossRef]

- Yenus, J.; Brooks, G.; Dunn, M.; Kadam, R. Application of vibration and sound signals in monitoring iron and steelmaking processes. Ironmak. Steelmak. 2020, 47, 178–187. [Google Scholar] [CrossRef]

- Bagheri, B.; Ahmadi, H.; Labbafi, R. Implementing discrete wavelet transform and artificial neural networks for acoustic condition monitoring of gearbox. Elixir Mech. Engg. 2011, 35, 2909–2911. [Google Scholar]

- Gong, C.S.; Lee, H.C.; Chuang, Y.C.; Li, T.H.; Su, C.H.; Huang, L.H.; Hsu, C.W.; Hwang, Y.S.; Lee, J.D.; Chang, C.H. Design and Implementation of Acoustic Sensing System for Online Early Fault Detection in Industrial Fans. J. Sens. 2018, 2018, 4105208. [Google Scholar] [CrossRef]

- Liu, M.K.; Tseng, Y.H.; Tran, M.Q. Tool wear monitoring and prediction based on sound signal. Int. J. Adv. Manuf. Technol. 2019, 103, 3361–3373. [Google Scholar] [CrossRef]

- Cooper, C.; Wang, P.; Zhang, J.; Gao, R.X.; Roney, T.; Ragai, I.; Shaffer, D. Convolutional neural network-based tool condition monitoring in vertical milling operations using acoustic signals. Procedia Manuf. 2020, 49, 105–111. [Google Scholar] [CrossRef]

- Rajapaksha, N.; Jayasinghe, S.; Enshaei, H.; Jayarathne, N. Acoustic Analysis Based Condition Monitoring of Induction Motors: A Review. In Proceedings of the IEEE Southern Power Electronics Conference (SPEC), Kigali, Rwanda, 6–9 December 2021; pp. 1–10. [Google Scholar]

- Entezami, M.; Stewart, E.; Tutcher, J.; Driscoll, W.; Ellis, R.; Yeo, G.; Zhang, Z.; Roberts, C.; Kono, T.; Bayram, S. Acoustic analysis techniques for condition monitoring of roller bearings. In Proceedings of the 6th IET Conference on Railway Condition Monitoring (RCM 2014), Birmingham, UK, 17–18 September 2014. [Google Scholar]

- Saufi, S.R.; Ahmad, Z.A.B.; Leong, M.S.; Lim, M.H. Challenges and opportunities of deep learning models for machinery fault detection and diagnosis: A review. IEEE Access 2019, 7, 122644–122662. [Google Scholar] [CrossRef]

- Wu, J.; Yang, F.; Hu, W. Unsupervised anomalous sound detection for industrial monitoring based on ArcFace classifier and gaussian mixture model. Appl. Acoust. 2023, 203, 109188. [Google Scholar] [CrossRef]

- Di Fiore, E.; Ferraro, A.; Galli, A.; Moscato, V.; Sperlì, G. An anomalous sound detection methodology for predictive maintenance. Expert Syst. Appl. 2022, 209, 118324. [Google Scholar] [CrossRef]

- Suefusa, K.; Nishida, T.; Purohit, H.; Tanabe, R.; Endo, T.; Kawaguchi, Y. Anomalous sound detection based on interpolation deep neural network. In Proceedings of the IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP), Barcelona, Spain, 4–8 May 2020; pp. 271–275. [Google Scholar]

- Pichler, C.; Neumayer, M.; Schweighofer, B.; Feilmayr, C.; Schuster, S.; Wegleiter, H. Acoustic-Based Detection Technique for Identifying Worn-Out Components in Large-Scale Industrial Machinery. IEEE Sens. Lett. 2023, 7, 1–4. [Google Scholar] [CrossRef]

- Jombo, G.; Zhang, Y. Acoustic-Based Machine Condition Monitoring—Methods and Challenges. Eng 2023, 4, 47–79. [Google Scholar] [CrossRef]

- Kay, S.M. Fundamentals of Statistical Signal Processing, Volume II: Detection Theory, 1st ed.; Prentice Hall: Upper Saddle River, NJ, USA, 1998. [Google Scholar]

- Pichler, C.; Neumayer, M.; Schweighofer, B.; Feilmayr, C.; Schuster, S.; Puttinger, S.; Wegleiter, H. Acoustic Condition Monitoring: Signal Analysis for Large Machinery Halls. In Proceedings of the IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Ottawa, ON, Canada, 16–19 May 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Li, F.F.; Cox, T.J. Digital Signal Processing in Audio and Acoustical Engineering; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Dohi, K.; Imoto, K.; Harada, N.; Niizumi, D.; Koizumi, Y.; Nishida, T.; Purohit, H.; Endo, T.; Yamamoto, M.; Kawaguchi, Y. Description and Discussion on DCASE 2022 Challenge Task 2: Unsupervised Anomalous Sound Detection for Machine Condition Monitoring Applying Domain Generalization Techniques. arXiv 2022, arXiv:2206.05876. [Google Scholar]

- Hosmer, D.W., Jr.; Lemeshow, S.; Sturdivant, R.X. Applied Logistic Regression; John Wiley & Sons: Hoboken, NJ, USA, 2013; Volume 398. [Google Scholar]

- Zhou, H.; Lei, Z.; Zio, E.; Wen, G.; Liu, Z.; Su, Y.; Chen, X. Conditional feature disentanglement learning for anomaly detection in machines operating under time-varying conditions. Mech. Syst. Signal Process. 2023, 191, 110139. [Google Scholar] [CrossRef]

- Rabiner, L.; Schafer, R.W.; Rader, C. The chirp Z-transform algorithm. IEEE Trans. Audio Electroacoust. 1969, 17, 86–92. [Google Scholar] [CrossRef]

| Dataset | Artificially Generated Data | Real Data | ||

|---|---|---|---|---|

| Type | normal data | fault data | normal data | fault data |

| Amount | 1200 | 1200 per SNR value | 1200 | 160 |

| SNR | - | −15 to −1 | - | ≈−7 |

| Disturbing Sounds | not included | not included | included | included |

| Name | Acronym | Domain |

|---|---|---|

| Zero Crossing Rate | ZCR | Time-Domain |

| Short Time Energy | STE | Time-Domain |

| Crest Factor | CF | Time-Domain |

| Spectral Roll-Off Frequency | SRO | Frequency-Domain |

| Spectral Centroid | SC | Frequency-Domain |

| Audio Spectral Centroid | ASC | Frequency-Domain |

| Mel-Frequency Function Coefficients | MFCC | Frequency-Domain |

| AUC | ||||

| Generated Data (−7 dB) | Real Data | |||

| Features | No bp-Filtering | bp-Filtering | No bp-Filtering | bp-Filtering |

| ZCR | 0.63 | 0.72 | 0.63 | 0.59 |

| STE | 0.73 | 0.88 | 0.75 | 0.87 |

| SRO | 0.89 | 0.51 | 0.74 | 0.73 |

| MFCC # 1 | 0.97 | 0.98 | 0.77 | 0.85 |

| MFCC # 2 | 0.61 | 0.72 | 0.78 | 0.69 |

| MFCC # 3 | 0.87 | 0.61 | 0.87 | 0.76 |

| MFCC # 4 | 0.73 | 0.53 | 0.61 | 0.71 |

| pAUC | ||||

| Generated Data (−7 dB) | Real Data | |||

| Features | No bp-Filtering | bp-Filtering | No bp-Filtering | bp-Filtering |

| ZCR | 0.11 | 0.21 | 0.02 | 0.14 |

| STE | 0.17 | 0.45 | 0.14 | 0.42 |

| SRO | 0.47 | 0.06 | 0.40 | 0.22 |

| MFCC # 1 | 0.84 | 0.88 | 0.21 | 0.39 |

| MFCC # 2 | 0.13 | 0.12 | 0.12 | 0.10 |

| MFCC # 3 | 0.34 | 0.18 | 0.55 | 0.23 |

| MFCC # 4 | 0.34 | 0.02 | 0.06 | 0.12 |

| Generated Data (−7dB) | Real Data | ||||

|---|---|---|---|---|---|

| Features | AUC | pAUC | Features | AUC | pAUC |

| no bp-filtering STE | 0.73 | 0.17 | no bp-filtering STE | 0.75 | 0.14 |

| bp-filtering STE | 0.88 | 0.45 | bp-filtering STE | 0.87 | 0.42 |

| no bp-filtering MFCC # 1 | 0.97 | 0.84 | no bp-filtering MFCC # 1 | 0.77 | 0.21 |

| bp-filtering MFCC # 1 | 0.98 | 0.88 | bp-filtering MFCC # 1 | 0.85 | 0.39 |

| GLRT | 1.00 | 0.98 | GLRT | 0.98 | 0.87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pichler, C.; Neumayer, M.; Schweighofer, B.; Feilmayr, C.; Schuster, S.; Wegleiter, H. Decomposing and Modeling Acoustic Signals to Identify Machinery Defects in Industrial Soundscapes. Sensors 2025, 25, 4923. https://doi.org/10.3390/s25164923

Pichler C, Neumayer M, Schweighofer B, Feilmayr C, Schuster S, Wegleiter H. Decomposing and Modeling Acoustic Signals to Identify Machinery Defects in Industrial Soundscapes. Sensors. 2025; 25(16):4923. https://doi.org/10.3390/s25164923

Chicago/Turabian StylePichler, Christof, Markus Neumayer, Bernhard Schweighofer, Christoph Feilmayr, Stefan Schuster, and Hannes Wegleiter. 2025. "Decomposing and Modeling Acoustic Signals to Identify Machinery Defects in Industrial Soundscapes" Sensors 25, no. 16: 4923. https://doi.org/10.3390/s25164923

APA StylePichler, C., Neumayer, M., Schweighofer, B., Feilmayr, C., Schuster, S., & Wegleiter, H. (2025). Decomposing and Modeling Acoustic Signals to Identify Machinery Defects in Industrial Soundscapes. Sensors, 25(16), 4923. https://doi.org/10.3390/s25164923