1. Introduction

The advantages of optical fiber sensors (OFSs) over their electronic counterparts are well known and widely recognized [

1]. Their immunity to electromagnetic interference, electrical isolation, resistance to harsh environments, flexibility, multiplexing ability, and remote operation capability make OFSs a reliable choice for a broad range of applications such as measurements of temperature [

2], PH level [

3], humidity [

4], force, and pressure [

5]. Among them, optical fiber force sensors have been applied in fields ranging from industrial to biochemical, especially in challenging environments where high-performance force monitoring is crucial [

6]. However, despite their many advantages, the high cost of equipment required to fabricate optical fiber sensors can be a drawback, limiting their practical applications.

Fabry–Pérot interferometric (FPI) optical fiber sensors are often used for force measurements due to their ultra-compact size, high sensitivity, and excellent thermal stability. More recently, cascading multiple FPIs to exploit the Vernier effect has been shown to improve the performance of FPI-based sensors [

7]. The operating principle of FPI sensors is based on the dependence of the output transmission or reflection from the cavity on its length or refractive index (RI). Depending on the sensor’s design, both parameters may vary in response to an externally applied displacement, pressure, or force. In the open cavity configuration, the Fabry–Pérot cavity is directly in contact with the external environment, allowing for parameter detection by monitoring the shift in the reflection spectrum induced by changes in the cavity length or its RI [

8].

Over the past few decades, FPI force sensors have been extensively researched. For example, in 2014, Chen et al. presented a compact, highly sensitive microfiber coupler-based reflective micro-force sensor [

9]. The device was fabricated by fusing two twisted optical fibers and then connecting two pigtails to form a Sagnac loop with a high sensitivity of 3754 nm/N. In 2017, Liu et al. [

10] proposed a strain and force sensor based on a fiber inline Fabry–Pérot (FP) microcavity, fabricated using a simple and cost-effective method that involved only fiber cleaving, tapering, and splicing, achieving a sensitivity of 841.59 nm/N. In 2018, Arnaldo et al. [

11] proposed a force sensor based on polymer optical fiber Bragg gratings inscribed in cyclic, transparent, amorphous fluoropolymers, achieving a sensitivity of 34.17 nm/N. In 2024, Fu et al. [

12] proposed a sensor based on two cascaded FP cavities that utilize the Vernier effect, achieving an ultra-high sensitivity of 1.40813 × 10

5 nm/N. However, the above sensor required a relatively high-power laser source (800 mW).

Despite these advances, many existing sensors suffer from limited sensitivity, low reliability, high complexity, or high fabrication costs, making them unsuitable for mass production. This work proposes and investigates a new force-sensing structure composed of two cascaded fiber optic FPIs to utilize the Vernier effect. This proposed sensor offers high sensitivity and potentially lower fabrication costs, using a low-power optical source to address the limitations of current optical fiber force sensors.

2. Materials and Methods

AFPI is a well-established configuration extensively applied in lasers [

13], telecommunications [

14], and optical fiber sensing [

15]. An FPI consists of two parallel reflecting surfaces separated by a certain distance, known as an etalon [

16]. The interference within an FPI occurs due to multiple superpositions of reflected and transmitted beams within the resonator cavity. Constructive interference occurs when the beams are in phase, resulting in resonant enhancement within the resonator. Conversely, only a small portion of the launched light is stored inside the resonator when the beams are out of phase. Consequently, the stored, transmitted, and reflected light is spectrally modified compared to the incident light.

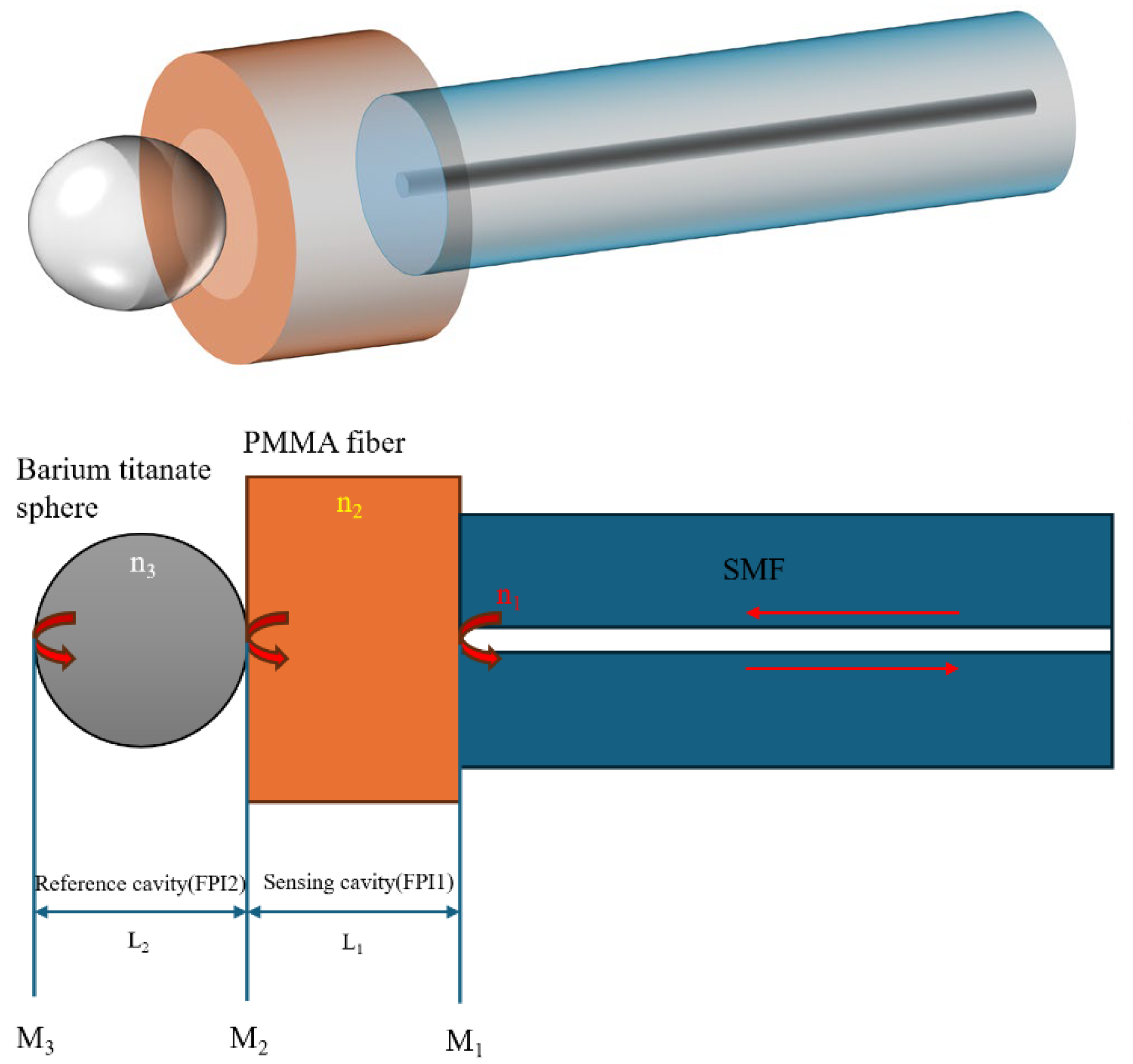

Figure 1 shows a schematic diagram of the proposed cascaded FPI sensor structure. The first interferometer is formed by a short section of a PMMA fiber, and an 80 μm diameter barium titanate microsphere forms the second cavity. Light from a broadband source launched into the SMF section experiences partial reflections at the interfaces between the two end faces of the PMMA fiber (M

1 and M

2), forming a sensing cavity.

A portion of light reflected at the interface between the PMMA fiber and the barium titanate microsphere is recoupled back into the SMF, where it interferes with the light reflected by the first PMMA interface. Meanwhile, a portion of the input light transmitted through the PMMA–microsphere interface undergoes further reflections at the opposite end of the sphere (M3), which, together with M2, forms the reference cavity.

The performance of FPI-based sensors can be characterized by several parameters. One of the critical parameters is the free spectral range (FSR) of the interference spectrum. The FSR is defined as the spectral distance between two adjacent interference wavelength peaks and is inversely proportional to the cavity length. A longer cavity results in a smaller FSR and vice versa. The expression for the FSR can be derived by first considering the interference conditions for the m-th and (m + 1)-th modes. The FSR of two cascaded interferometers (FPI1 and FPI2) can be calculated as follows [

4]:

where

λ0 is the central wavelength of the nearest transmission peak,

n is the refractive index of the cavity medium, and

L is its length. If the FSR values of the two cavities are comparable, the Vernier effect can be observed in the overall transmitted or reflected spectrum, with an FSR of [

4]

The enhancement of sensitivity can be illustrated by the magnification ratio M of the Vernier effect:

The Vernier effect has been proven to be an effective method of enhancing the sensitivity of optical fiber sensors. The principle of the Vernier effect involves combining two interferometers with a slight difference in their FSRs and generating a superimposed spectrum, which allows for an increase in sensitivity by measuring the spectral shift of the “envelope.”

As mentioned above, the key requirement for achieving a “strong” Vernier effect is to ensure that the FSRs of the two cascaded interferometers are similar but not equal [

7]. This can be achieved by adjusting the parameters of the two cascaded Fabry–Pérot cavities. In the proposed structure, light is reflected at multiple interfaces, including the end surfaces of the SMF, the PMMA fiber, and the opposite curved surfaces of the microsphere, which is placed in line with the SMF and PMMA fiber sections, leading to multimode interference. The PMMA fiber and barium titanate sphere form the cavities and mirrors. The use of PMMA ensures high force sensitivity due to its low Young’s modulus, while utilizing the barium titanate sphere enhances reflections and visibility of the interference spectrum due to its relatively high refractive index.

The reflection coefficients

R1, R2, and

R3 for each of the mirrors M

1–M

3, can be found as follows:

where

n1 and

n2 are the refractive indices of the materials on both sides of the mirror surfaces.

The reflectance spectrum for the structure consisting of a PMMA cavity (FPI1) formed by M

1 and M

2 is a typical two-beam interference spectrum. The intensity of the light incident from the SMF returning to the SMF again after passing through the two reflecting surfaces can be expressed as follows [

15]:

where

, and

k1 is the transmission loss of the resonant cavity FPI1,

ϕ1 is the phase shift due to light transmission in FPI1,

n1 is the effective refractive index of PMMA, and

λ is the wavelength of the input light in vacuum. Resonant troughs are found in the interference spectrum under the condition that the phase shift

1 satisfies an even multiple of

π. Due to the change in the interferometer cavity length, the phase shift changes with the applied force, which causes the wavelength at the center of the resonant trough in the interferometer spectrum to drift.

In the same way, the intensity of the interference spectrum of the incident light after passing through the entire cascaded structure (three reflectors) to form FPI2 can be expressed by

where

,

k2 is the transmission loss of the resonant cavity FPI2,

ϕ2 is the phase shift due to light reflections in FPI2, and

n2 is the effective refractive index of the barium titanate sphere.

The effect of a force applied to the structure in the axial direction can be analyzed by considering the contraction of the PMMA fiber as follows.

The force at the contact between the barium titanate microsphere and PMMA section can be calculated using explicit solutions for axially symmetric profiles following Johnson–Kendall–Roberts (JKR) theory [

17]:

where

R1 is the radius of the sphere,

d1 is the combined decrease in the axial length of the sphere and PMMA fiber due to compression, and

E1* is the effective Young’s modulus defined as follows:

where

E1 and

E2 are the Young’s moduli, and

υ1 and

υ2 are the Poisson’s ratios associated with the barium titanate sphere and PMMA fiber. The Young’s modulus of PMMA is 3000 MPa [

18], while the Young’s modulus of barium titanate is 150,000 MPa [

19].

The force at the boundary between the PMMA fiber and SMF can be calculated as follows [

17]:

where

R2 is the radius of the SMF,

d2 is the combined decrease in the axial length of the SMF and PMMA due to compression, and the

E2* of the SMF and PMMA fiber can be calculated using Equation (9).

Due to the balance of forces, the axial forces on the sensor are equal:

Since the Young’s moduli of barium titanate (microsphere) and silica (SMF) are much higher than the Young’s modulus of the PMMA, the compressed length of the sphere and SMF is much smaller than that of the PMMA fiber and can thus be neglected. Therefore,

d1 and

d2 can be seen as the compressed length of the PMMA at the sphere and the SMF sides, respectively. Assuming that the contractions in the axial lengths of both the barium titanate sphere and the SMF are small, the total decrease in the PMMA length is

Therefore, the relationship between the force on the sensor and the decrease in the PMMA’s length

(d) can be expressed as the following nonlinear function:

The relationship between the compressed length of the PMMA fiber and the applied axial force, as illustrated in Equation (13), is nonlinear. This suggests that the spectral shift resulting from compression exhibits a nonlinear correlation with the force. However, by restricting the force to a narrow range, the results can be regarded as approximately linear.

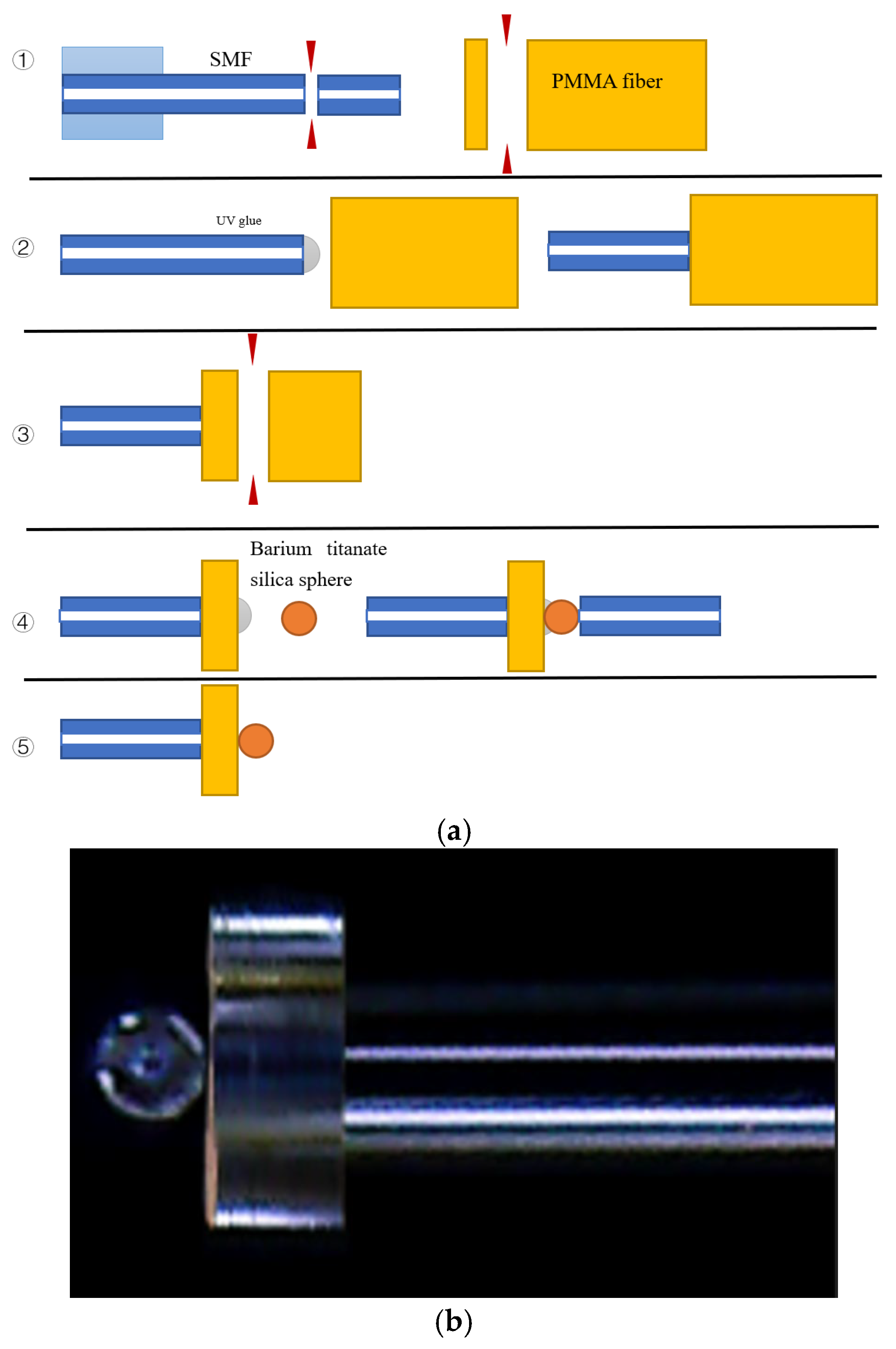

To analyze the influence of the applied force on the reflection spectrum of the proposed structure in more detail, we conducted simulations using the RSoft software package (BeamPROP mode, Rsoft 2018). The optical path model diagram is shown in

Figure 2a. In the simulation, the compressed length

d of the PMMA fiber varied from 0 to 0.2 μm in 0.05 μm increments. The results of the simulations are presented in

Figure 2b,d. We considered two interferometric cavities cascaded, as illustrated in

Figure 1. The PMMA fiber and barium titanate cavities’ lengths were assumed to be 100 μm and 80 μm, and the corresponding refractive indices were set as 1.5 and 2.22. The surrounding refractive index was set to 1. X and Z coordinates in

Figure 2a show the dimensions of the simulation area. The light source launch panel (SMF fiber mode, free space source wavelength of 1.5 μm) and the monitor panel are indicated in

Figure 2a by arrows. The pathway monitor panel was set at the border between the PMMA fiber and the SMF with major backward mode and launch power type. The length of the SMF connecting the sensor to the light source was set to 1000 μm, and the SMF had core and cladding diameters of 8.3 μm and 125 μm, respectively. All materials’ properties were chosen from the RSoft database. The spectra in

Figure 2b were simulated from 1.4 to 1.6 μm with 500 steps using the Beam PROP simulation tool.

The FSRs for the PMMA cavity, cascaded PMMA fiber–microsphere interferometers, and the Vernier envelope are estimated as 6.43 nm, 3.66 nm, and 27.6 nm, respectively. The simulated spectra of the Vernier envelope of the cascaded structure at different applied forces, ranging from 0 to 2.55 mN, are plotted in

Figure 2c. The resulting sensitivity of the structure is estimated to be 10,466.28 nm/N from

Figure 2d, which illustrates the spectral shift of the envelope as a function of the applied force. It should be noted that in

Figure 2b,c, all spectra are separated along the vertical axis for better visibility, and arbitrary vertical offsets are introduced for the transmission values to illustrate more clearly how the spectrum shifts under the influence of the applied force, which shows a blue shift with an increase in force.

In this research, a PMMA-based UV glue was used to fix the sphere, PMMA fiber, and SMF with the layers’ thickness less than 2 μm. The simulation results related to the effect of the glue layers on the spectra of the proposed structure and the corresponding simulation model are illustrated in

Figure 2e. The thicknesses of the glue layers were set to 0, 1, 2, 3, 4, and 5 μm. As one can see from the graphs, increasing the thickness of the glue layers leads to increased spectral shifts (up to 15 nm), changes in FSR (27 ± 2.8 nm), and power losses. However, for layers thinner than 2 μm, such effects are small and can be neglected. It should be noted that the variability in the UV glue layer thickness is likely to pose reproducibility issues. Thus, during fabrication, it is necessary to utilize automated dispensing and curing techniques to control the glue thickness within acceptable tolerances.

4. Experimental Results and Discussion

The schematic diagram of the experimental setup is shown in

Figure 4. In this experiment, we utilized a broadband superluminescent light diode (SLED, 1550 nm, Thorlabs, Ely, UK) with a maximum power in the wavelength range of 1520–1580 nm. Light from the SLED was launched into the FPI through an optical circulator, and the reflected output spectrum was observed using a optical spectrum analyzer (OSA) with a 3 pm wavelength resolution. The structure of the proposed sensor has been described in

Section 2.

The sensor was fixed on a two-dimensional translation stage using a fiber holder. The force was applied to the sensor by pushing it against the surface of a commercial electronic weight scale (Mettle Toledo, PL83-S, Greifense, Switzerland) vertically using the translation stage with a resolution of 0.5 µm. The weight scale had a resolution of 0.001 gf (gram-force), and its readings were sent to a PC through a 51MCU development board (STC89C52RC) and converted into Newtons (1 gf = 0.00980665 N). The first step was to move the sensor into physical contact with the scale, at which position the scale displayed 0.189 g (1.85 mN). Each subsequent step involved moving the sensor towards the scale by one micrometer, resulting in the corresponding readings of the scale: 0.314 g (3.08 mN), 0.477 g (4.68 mN), and 0.675 g (6.62 mN). All experiments followed the same steps to ensure a consistent test range. It should be noted that the SMF is essentially a connecting fiber, and its length has a negligible effect on the overall spectrum. Thus, the entire structure can be viewed as two cascaded FPIs.

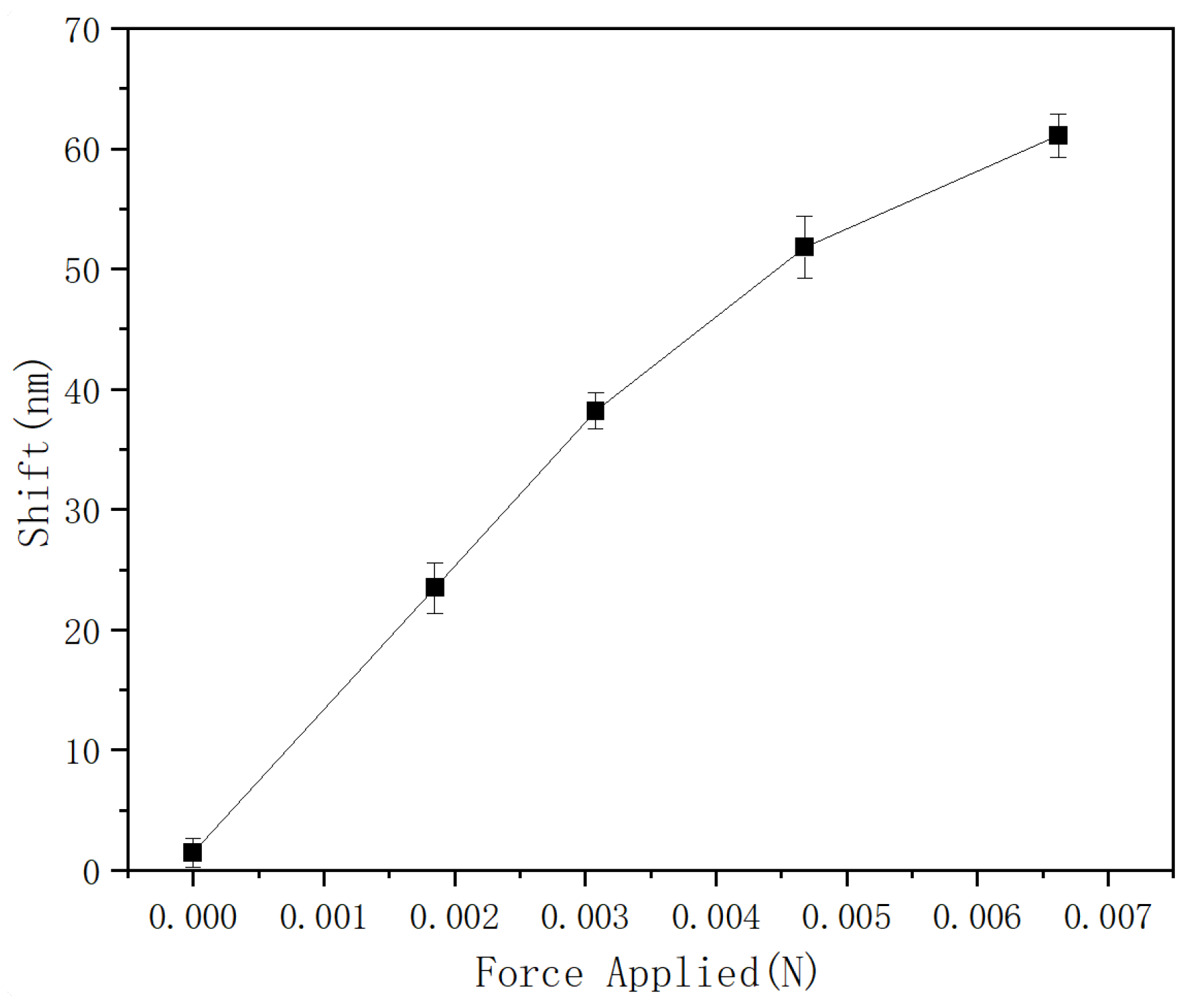

The experimental results are illustrated in

Figure 5.

When the structure is compressed, the length of the PMMA cavity decreases, resulting in a blue spectral shift, as shown in

Figure 5b. Similar to the graphs in

Figure 2a,b, the data along the vertical axis in

Figure 5b are plotted on the same graph for easier comparison only, and the transmission values are in arbitrary units.

As shown in

Figure 5c, the sensitivity of the three samples with PMMA fiber lengths of 103, 116, and 121 μm is quite similar but shows a tendency to increase with the increase of the PMMA length, and the shift can be measured by tracking the peak shift of the envelope of each spectrum. They are calculated as 7240.55, 8188.44, and 9279.66 nm/N, corresponding to an approximate sensitivity improvement by a factor of 120 for all three samples compared to the result for the PMMA fiber without the microsphere, which is estimated at 77.25 nm/N. The experimental sensitivities agree with the simulated results, and the slight difference between the simulated and experimental results can be attributed to fabrication errors and the influence of the glue layers required to secure all parts of the sensor. The regression coefficients R

2 of the three sensors are 96.3%, 97.6%, and 93.4%; therefore, within the proposed force sensing range, the results can be considered approximately linear. The results matched the relationship between the force and shift shown in the simulations. Compared to the simulation result, the experimental results showed lower sensitivity, which could be attributed to several reasons, for example, due to the influence of the glue on the Young’s moduli, propagation losses within the structure, and possible misalignment of the various contact surfaces within the structure, leading to a reduction in the axial force.

It should be noted that while the Vernier effect has been proven to improve sensitivity, the measurement accuracy of Vernier effect sensors may decrease compared with single-FPI sensors. Due to the Vernier effect, the resulting interference pattern of the proposed sensor, known as a Vernier fringe, has much wider spacing between the resonant peaks than those for the individual interferometers. This wider spacing is more sensitive to small changes. Small shifts in wavelength or phase that may be difficult to detect in a standard interferometer cause a much more significant change in the Vernier fringe. This magnification of the shift makes it easier to detect small changes, thus improving the sensor’s sensitivity. The measurement accuracy of a Vernier effect sensor depends on several factors, including the number of envelope-fitting data points, the signal-to-noise ratio at each data point, the full width at half maximum, and the valley contrast of the interference fringe [

20]. To improve measurement accuracy in our experiments, we increased the number of measurement points to 1000 per scan and set the highest available wavelength resolution (0.03 nm) for the OSA. Furthermore, the measurement accuracy can be further increased by reducing the similarity of phase shifts between the two FPI cavities, resulting in a decrease in the FWHM of the fringes. However, this would lead to reduced sensitivity.

To mitigate this, in our future work, we aim to explore fine-tuning the difference between the FSRs of the cascaded FPIs to optimize the envelope’s full width at half maximum, thereby balancing fringe spacing and detectability. Implementing digital signal processing or machine learning-based fringe-tracking algorithms may also enhance accuracy without compromising sensitivity.

Finally, the repeatability of the proposed sensor’s performance was studied, and the corresponding results are presented in

Figure 6.

The sensor with a 121 μm PMMA fiber length was used for repeatability testing. In this experiment, measurements were repeated five times within 48 h for the same sample, and the average value and error for every force-sensing point test are shown in

Figure 6. The highest error, which occurred at a force value of 4.68 mN, is ±2.6 nm, and the smallest is ±1.2 nm. This means that, for the proposed sensor, the maximum sensing error is approximately ±0.3 mN, illustrating the sensor’s good repeatability. It is worth noting that the proposed sensor’s measurement range is relatively narrow. The FSR of the Vernier envelope primarily limits the measurement range, since an increase in the applied force beyond 3 mN would result in a spectral shift greater than the FSR of the envelope, leading to measurement ambiguity. It is possible to increase the FSR of the Vernier envelope by achieving a closer match between the FSRs of the cascaded interferometers, but this requires higher fabrication accuracy, and, on the other hand, decreases the accuracy in tracking of the envelope’s spectrum (as its spectral features become less sharp). Despite its relatively narrow range, the proposed sensor has numerous potential applications, including minimally invasive surgery, in robotics where it can be integrated into robotic grippers and hands, allowing robots to handle delicate objects without damaging them by providing feedback on the applied force, in assembly lines, where the proposed sensor can monitor the force exerted during the assembly process, and many others.

Table 1 compares the proposed structure with those previously reported in the literature.

As

Table 1 shows, the proposed sensor offers competitive sensitivity compared with previously reported Vernier effect FPI force sensors. Moreover, compared to previously reported sensors, the proposed sensor offers an ultra-compact size (200 μm), a more straightforward fabrication process, and potentially lower cost. Compared to the sensor reported in [

6], our sensor has lower sensitivity but can operate with a lower-power light source (22 mW versus 800 mW), resulting in reduced power consumption. The proposed sensor’s ultra-compact size and low power consumption make it ideal for integration into microsystem applications, such as minimally invasive biomedical instruments and confined robotic systems.