Spatial–Temporal Hotspot Management of Photovoltaic Modules Based on Fiber Bragg Grating Sensor Arrays

Abstract

1. Introduction

2. Result and Discussion

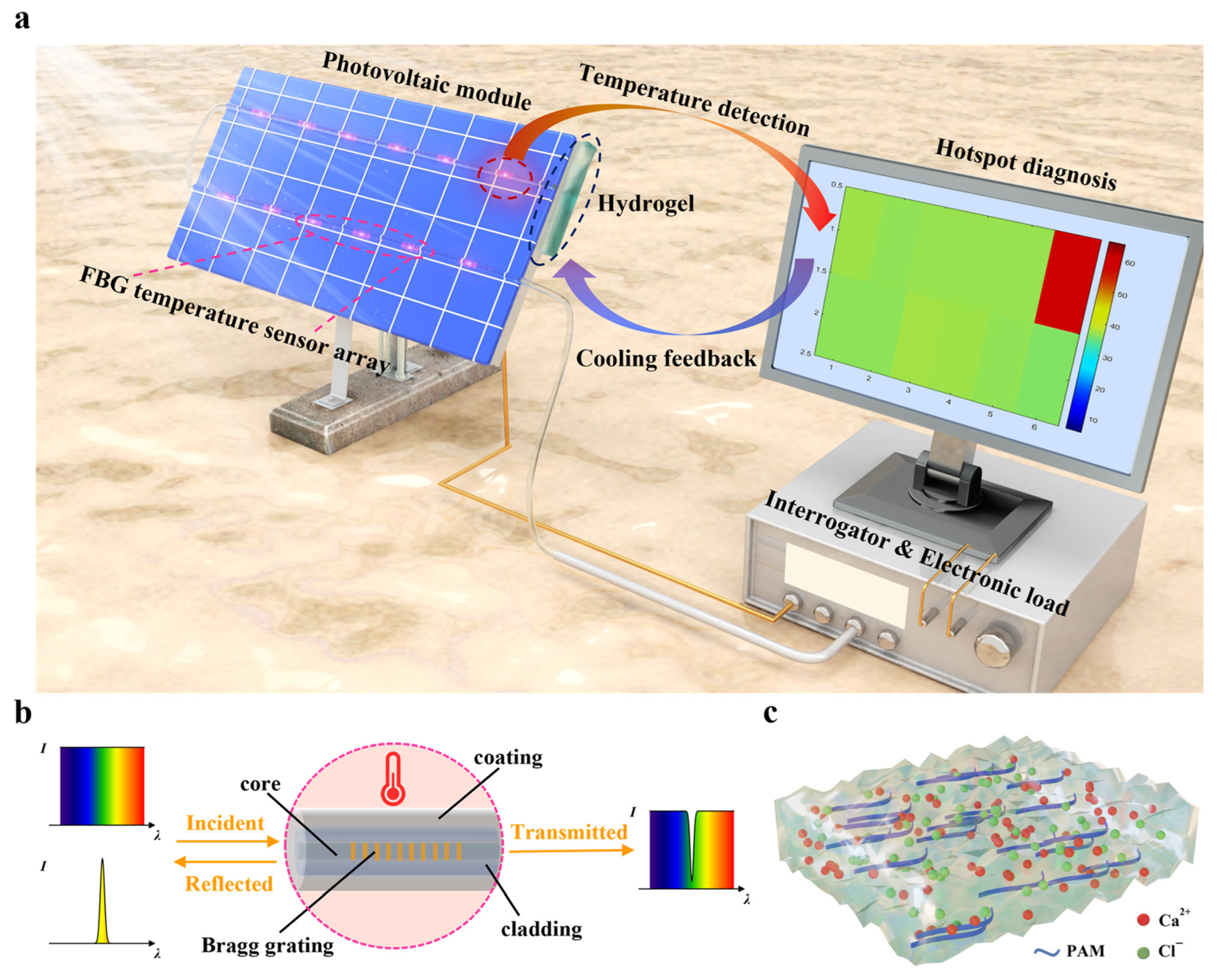

2.1. The Principle of Hotspot Management for PV Modules

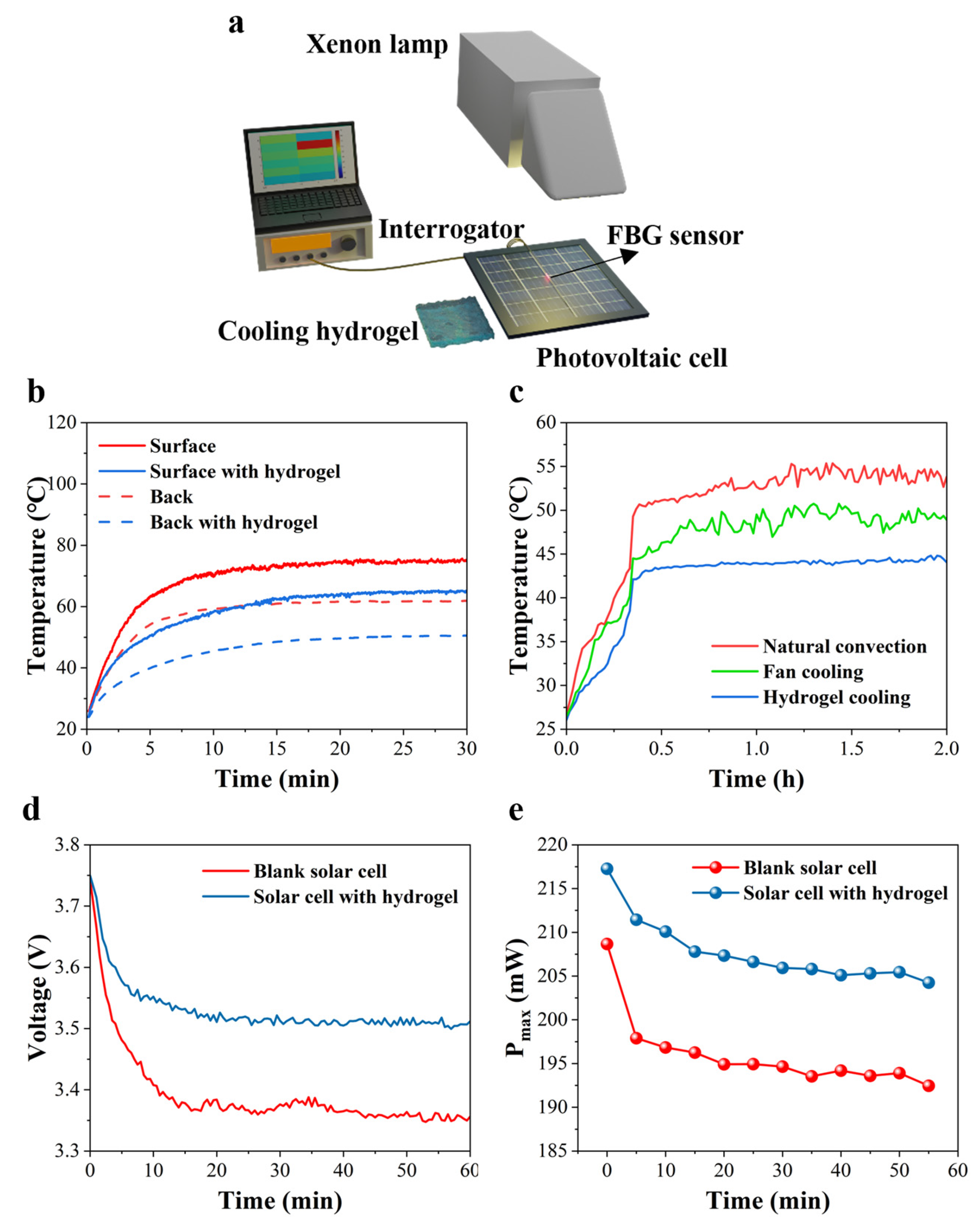

2.2. Temperature Field Analysis of a PV Cell

2.3. The Characterization of the Hotspot Management System

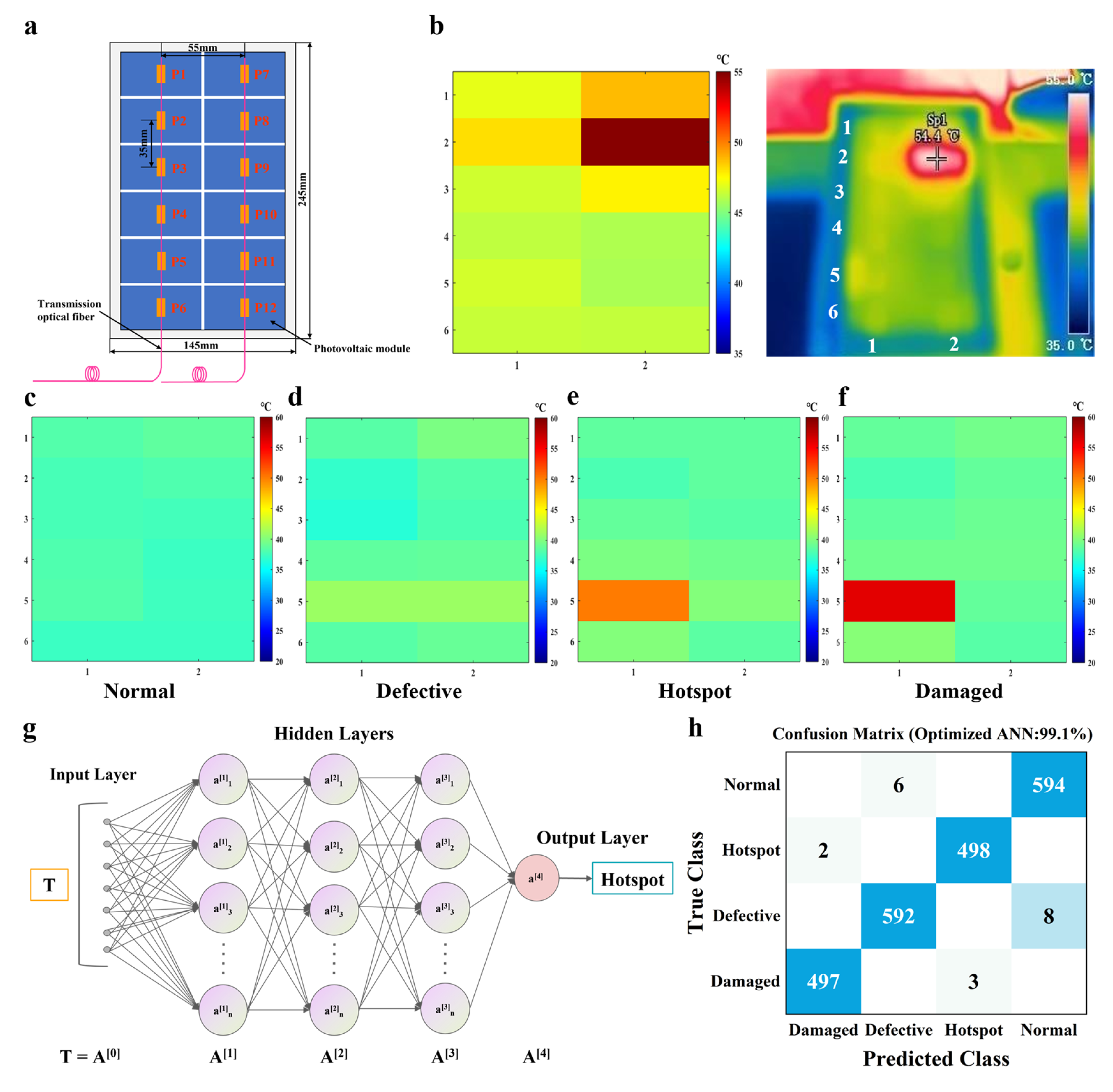

2.4. Hotspot Diagnosis for PV Panels

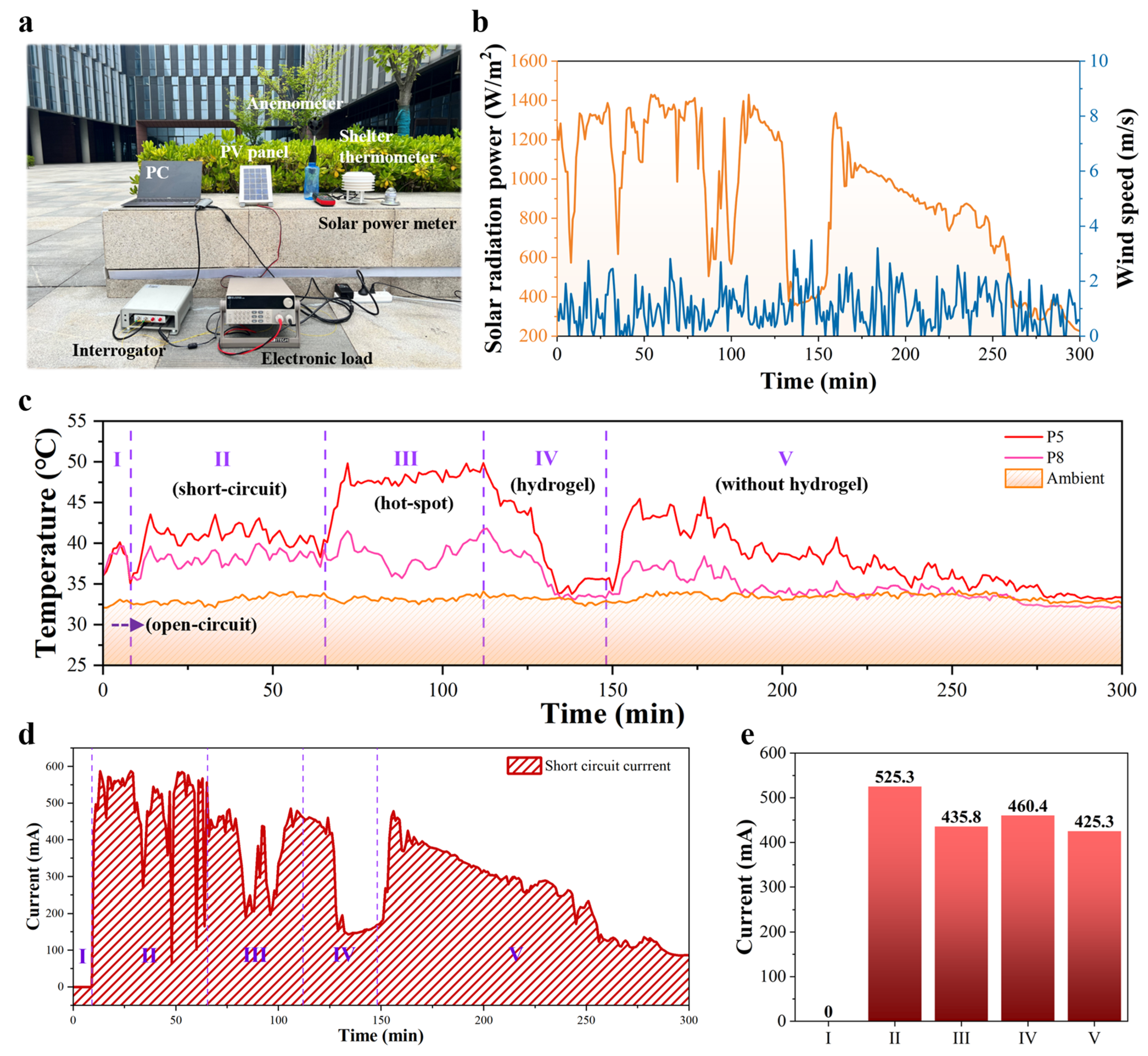

2.5. Field Tests of Cooling and Power Generation Performance

3. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Parida, B.; Iniyan, S.; Goic, R. A review of solar photovoltaic technologies. Renew. Sust. Energ. Rev. 2011, 15, 1625–1636. [Google Scholar] [CrossRef]

- Fakharuddin, A.; Jose, R.; Brown, T.M.; Fabregat-Santiago, F.; Bisquert, J. A perspective on the production of dye-sensitized solar modules. Energy Environ. Sci. 2014, 7, 3952–3981. [Google Scholar] [CrossRef]

- Yoshikawa, K.; Kawasaki, H.; Yoshida, W.; Irie, T.; Konishi, K.; Nakano, K.; Uto, T.; Adachi, D.; Kanematsu, M.; Uzu, H.; et al. Silicon heterojunction solar cell with interdigitated back contacts for a photoconversion efficiency over 26%. Nat. Energy 2017, 2, 17032. [Google Scholar] [CrossRef]

- Peters, I.M.; Karthik, S.; Liu, H.; Buonassisi, T.; Nobre, A. Urban haze and photovoltaics. Energy Environ. Sci. 2018, 11, 3043–3054. [Google Scholar] [CrossRef]

- Geisemeyer, I.; Fertig, F.; Warta, W.; Rein, S.; Schubert, M.C. Prediction of silicon PV module temperature for hot spots and worst case partial shading situations using spatially resolved lock-in thermography. Sol. Energy Mater. Sol. Cells 2014, 120, 259–269. [Google Scholar] [CrossRef]

- Tress, W.; Domanski, K.; Carlsen, B.; Agarwalla, A.; Alharbi, E.A.; Graetzel, M.; Hagfeldt, A. Performance of perovskite solar cells under simulated temperature-illumination real-world operating conditions. Nat. Energy 2019, 4, 568–574. [Google Scholar] [CrossRef]

- Satpathy, P.R.; Sharma, R. Parametric indicators for partial shading and fault prediction in photovoltaic arrays with various interconnection topologies. Energy Conv. Manag. 2020, 219, 113018. [Google Scholar] [CrossRef]

- Kumar, M.; Kumar, A. Performance assessment and degradation analysis of solar photovoltaic technologies: A review. Renew. Sustain. Energ. Rev. 2017, 78, 554–587. [Google Scholar] [CrossRef]

- Dolara, A.; Lazaroiu, G.C.; Leva, S.; Manzolini, G.; Votta, L. Snail Trails and Cell Microcrack Impact on PV Module Maximum Power and Energy Production. IEEE J. Photovolt. 2016, 6, 1269–1277. [Google Scholar] [CrossRef]

- Wang, A.; Xuan, Y. Multiscale prediction of localized hot-spot phenomena in solar cells. Renew. Energy 2020, 146, 1292–1300. [Google Scholar] [CrossRef]

- Dhimish, M.; Badran, G. Current limiter circuit to avoid photovoltaic mismatch conditions including hot-spots and shading. Renew. Energy 2020, 145, 2201–2216. [Google Scholar] [CrossRef]

- Jordan, D.C.; Kurtz, S.R. Photovoltaic Degradation Rates-an Analytical Review. Prog. Photovolt. 2013, 21, 12–29. [Google Scholar] [CrossRef]

- Wang, A.; Xuan, Y. A detailed study on loss processes in solar cells. Energy 2018, 144, 490–500. [Google Scholar] [CrossRef]

- Ma, M.; Liu, H.; Zhang, Z.; Yun, P.; Liu, F. Rapid diagnosis of hot spot failure of crystalline silicon PV module based on I-V curve. Microelectron. Reliab. 2019, 100–101, 113402. [Google Scholar] [CrossRef]

- Kim, K.A.; Seo, G.S.; Cho, B.H.; Krein, P.T. Photovoltaic Hot-Spot Detection for Solar Panel Substrings Using AC Parameter Characterization. IEEE Trans. Power Electron. 2016, 31, 1121–1130. [Google Scholar] [CrossRef]

- Bohórquez, M.A.M.; Enrique Gómez, J.M.; Andújar Márquez, J.M. A new and inexpensive temperature-measuring system: Application to photovoltaic solar facilities. Sol. Energy 2009, 83, 883–890. [Google Scholar] [CrossRef]

- Madurai Elavarasan, R.; Mudgal, V.; Selvamanohar, L.; Wang, K.; Huang, G.; Shafiullah, G.M.; Markides, C.N.; Reddy, K.S.; Nadarajah, M. Pathways toward high-efficiency solar photovoltaic thermal management for electrical, thermal and combined generation applications: A critical review. Energy Conv. Manag. 2022, 255, 115278. [Google Scholar] [CrossRef]

- Berardone, I.; Lopez Garcia, J.; Paggi, M. Analysis of electroluminescence and infrared thermal images of monocrystalline silicon photovoltaic modules after 20 years of outdoor use in a solar vehicle. Sol. Energy 2018, 173, 478–486. [Google Scholar] [CrossRef]

- Buerhop, C.; Schlegel, D.; Niess, M.; Vodermayer, C.; Weißmann, R.; Brabec, C.J. Reliability of IR-imaging of PV-plants under operating conditions. Sol. Energy Mater. Sol. Cells 2012, 107, 154–164. [Google Scholar] [CrossRef]

- Kim, K.A.; Krein, P.T. Reexamination of Photovoltaic Hot Spotting to Show Inadequacy of the Bypass Diode. IEEE J. Photovolt. 2015, 5, 1435–1441. [Google Scholar] [CrossRef]

- Nižetić, S.; Čoko, D.; Yadav, A.; Grubišić-Čabo, F. Water spray cooling technique applied on a photovoltaic panel: The performance response. Energy Conv. Manag. 2016, 108, 287–296. [Google Scholar] [CrossRef]

- Teo, H.G.; Lee, P.S.; Hawlader, M.N.A. An active cooling system for photovoltaic modules. Appl. Energy 2012, 90, 309–315. [Google Scholar] [CrossRef]

- Bahaidarah, H.; Subhan, A.; Gandhidasan, P.; Rehman, S. Performance evaluation of a PV (photovoltaic) module by back surface water cooling for hot climatic conditions. Energy 2013, 59, 445–453. [Google Scholar] [CrossRef]

- Firoozzadeh, M.; Shiravi, A.; Shafiee, M. An Experimental Study on Cooling the Photovoltaic Modules by Fins to Improve Power Generation: Economic Assessment. Iran. J. Energy Environ. 2019, 10, 80–84. [Google Scholar] [CrossRef]

- Siecker, J.; Kusakana, K.; Numbi, B.P. A review of solar photovoltaic systems cooling technologies. Renew. Sustain. Energy Rev. 2017, 79, 192–203. [Google Scholar] [CrossRef]

- Alizadeh, H.; Ghasempour, R.; Shafii, M.B.; Ahmadi, M.H.; Yan, W.-M.; Nazari, M.A. Numerical simulation of PV cooling by using single turn pulsating heat pipe. Int. J. Heat Mass Transf. 2018, 127, 203–208. [Google Scholar] [CrossRef]

- Tang, H.; Guo, C.; Fan, F.; Pan, H.; Xu, Q.; Zhao, D. Both sub-ambient and above-ambient conditions: A comprehensive approach for the efficient use of radiative cooling. Energy Environ. Sci. 2024, 17, 4498–4507. [Google Scholar] [CrossRef]

- Li, J.; Jiang, Y.; Liu, J.; Wu, L.; Xu, N.; Zhang, Z.; Zhao, D.; Li, G.; Wang, P.; Li, W.; et al. A photosynthetically active radiative cooling film. Nat. Sustain. 2024, 7, 786–795. [Google Scholar] [CrossRef]

- Raman, A.P.; Anoma, M.A.; Zhu, L.; Rephaeli, E.; Fan, S. Passive radiative cooling below ambient air temperature under direct sunlight. Nature 2014, 515, 540–544. [Google Scholar] [CrossRef]

- Nižetić, S.; Giama, E.; Papadopoulos, A.M. Comprehensive analysis and general economic-environmental evaluation of cooling techniques for photovoltaic panels, Part II: Active cooling techniques. Energy Conv. Manag. 2018, 155, 301–323. [Google Scholar] [CrossRef]

- Luo, J.; Liu, H.; Xing, H.; Zhu, R.; Chen, Z.; Xu, F. Large Curvature Bending Measurable Fiber-Optic Neurons for Multi-Joint Bending Perception. J. Light. Technol. 2023, 41, 5780–5787. [Google Scholar] [CrossRef]

- Luo, J.; Liu, S.; Chen, P.; Lu, S.; Zhang, Q.; Chen, Y.; Du, B.; Tang, J.; He, J.; Liao, C.; et al. Fiber optic hydrogen sensor based on a Fabry–Perot interferometer with a fiber Bragg grating and a nanofilm. Lab Chip 2021, 21, 1752–1758. [Google Scholar] [CrossRef] [PubMed]

- Gervillié-Mouravieff, C.; Boussard-Plédel, C.; Huang, J.; Leau, C.; Blanquer, L.A.; Yahia, M.B.; Doublet, M.L.; Boles, S.T.; Zhang, X.H.; Adam, J.L.; et al. Unlocking cell chemistry evolution with operando fibre optic infrared spectroscopy in commercial Na(Li)-ion batteries. Nat. Energy 2022, 7, 1157–1169. [Google Scholar] [CrossRef]

- Li, G.; Wang, F.; Feng, F.; Wei, B. Hot Spot Detection of Photovoltaic Module Based on Distributed Fiber Bragg Grating Sensor. Sensors 2022, 22, 4951. [Google Scholar] [CrossRef]

- Li, G.; Feng, F.; Wang, F.; Wei, B. Temperature Field Measurement of Photovoltaic Module Based on Fiber Bragg Grating Sensor Array. Materials 2022, 15, 5324. [Google Scholar] [CrossRef]

- Kim, H.; Rao, S.R.; Kapustin, E.A.; Zhao, L.; Yang, S.; Yaghi, O.M.; Wang, E.N. Adsorption-based atmospheric water harvesting device for arid climates. Nat. Commun. 2018, 9, 1191. [Google Scholar] [CrossRef] [PubMed]

- Pu, S.; Liao, Y.; Chen, K.; Fu, J.; Zhang, S.; Ge, L.; Conta, G.; Bouzarif, S.; Cheng, T.; Hu, X.; et al. Thermogalvanic Hydrogel for Synchronous Evaporative Cooling and Low-Grade Heat Energy Harvesting. Nano Lett. 2020, 20, 3791–3797. [Google Scholar] [CrossRef] [PubMed]

- Galib, R.H.; Tian, Y.; Lei, Y.; Dang, S.; Li, X.; Yudhanto, A.; Lubineau, G.; Gan, Q. Atmospheric-moisture-induced polyacrylate hydrogels for hybrid passive cooling. Nat. Commun. 2023, 14, 6707. [Google Scholar] [CrossRef]

- Wang, A.; Xuan, Y. Close examination of localized hot spots within photovoltaic modules. Energy Conv. Manag. 2021, 234, 113959. [Google Scholar] [CrossRef]

- Huang, J.; Albero Blanquer, L.; Bonefacino, J.; Logan, E.R.; Alves Dalla Corte, D.; Delacourt, C.; Gallant, B.M.; Boles, S.T.; Dahn, J.R.; Tam, H.-Y.; et al. Operando decoding of chemical and thermal events in commercial Na(Li)-ion cells via optical sensors. Nat. Energy 2020, 5, 674–683. [Google Scholar] [CrossRef]

- Mathew, J.; Schneller, O.; Polyzos, D.; Havermann, D.; Carter, R.M.; MacPherson, W.N.; Hand, D.P.; Maier, R.R.J. In-Fiber Fabry-Perot Cavity Sensor for High-Temperature Applications. J. Light. Technol. 2015, 33, 2419–2425. [Google Scholar] [CrossRef]

- Tian, T.; Li, M.; Ma, Y.; Geng, T.; Yuan, L. Point-coated long-period fiber grating for temperature measurement. Opt. Lett. 2023, 48, 2785–2788. [Google Scholar] [CrossRef]

- Huang, L.; Fan, X.; He, H.; Yan, L.; He, Z. Single-end hybrid Rayleigh Brillouin and Raman distributed fibre-optic sensing system. Light-Adv. Manu. 2023, 4, 16. [Google Scholar] [CrossRef]

- Mei, W.; Liu, Z.; Wang, C.; Wu, C.; Liu, Y.; Liu, P.; Xia, X.; Xue, X.; Han, X.; Sun, J.; et al. Operando monitoring of thermal runaway in commercial lithium-ion cells via advanced lab-on-fiber technologies. Nat. Commun. 2023, 14, 5251. [Google Scholar] [CrossRef]

- Miao, Z.; Li, Y.; Xiao, X.; Sun, Q.; He, B.; Chen, X.; Liao, Y.; Zhang, Y.; Yuan, L.; Yan, Z.; et al. Direct optical fiber monitor on stress evolution of the sulfur-based cathodes for lithium–sulfur batteries. Energy Environ. Sci. 2022, 15, 2029–2038. [Google Scholar] [CrossRef]

- Zou, W.; Ji, M.; Han, C.; Tian, E.; Mo, J. Enhancing the internal thermal conductivity of hydrogel for efficient passive heat dissipation: Experimental study of a surface simulating a cooled photovoltaic panel. Energy Conv. Manag. 2024, 306, 118328. [Google Scholar] [CrossRef]

- Li, R.; Shi, Y.; Wu, M.; Hong, S.; Wang, P. Photovoltaic panel cooling by atmospheric water sorption–evaporation cycle. Nat. Sustain. 2020, 3, 636–643. [Google Scholar] [CrossRef]

- Li, Z.P.; Ma, T.; Ji, F.; Shan, H.; Dai, Y.J.; Wang, R.Z. A Hygroscopic Composite Backplate Enabling Passive Cooling of Photovoltaic Panels. ACS Energy Lett. 2023, 8, 1921–1928. [Google Scholar] [CrossRef]

- Kim, H.; Yang, S.; Rao, S.R.; Narayanan, S.; Kapustin, E.A.; Furukawa, H.; Umans, A.S.; Yaghi, O.M.; Wang, E.N. Water harvesting from air with metal-organic frameworks powered by natural sunlight. Science 2017, 356, 430–434. [Google Scholar] [CrossRef]

- Graeber, G.; Díaz-Marín, C.D.; Gaugler, L.C.; Zhong, Y.; El Fil, B.; Liu, X.; Wang, E.N. Extreme Water Uptake of Hygroscopic Hydrogels through Maximized Swelling-Induced Salt Loading. Adv. Mater. 2024, 36, 2211783. [Google Scholar] [CrossRef]

- Debije, M.G.; Evans, R.C.; Griffini, G. Laboratory protocols for measuring and reporting the performance of luminescent solar concentrators. Energy Environ. Sci. 2021, 14, 293–301. [Google Scholar] [CrossRef]

- Xia, B.; Jin, J.; Wang, N.; Tai, Q. Degradation Evolution of Perovskite Solar Cells via In Situ Real-Time Optical Observation. Adv. Funct. Mater. 2024, 34, 2308581. [Google Scholar] [CrossRef]

- Xu, L.; Liu, W.; Liu, H.; Ke, C.; Wang, M.; Zhang, C.; Aydin, E.; Al-Aswad, M.; Kotsovos, K.; Gereige, I.; et al. Heat generation and mitigation in silicon solar cells and modules. Joule 2021, 5, 631–645. [Google Scholar] [CrossRef]

- Muzathik, A. Photovoltaic Modules Operating Temperature Estimation Using a Simple Correlation. Int. J. Energy Eng. 2014, 4, 151–158. [Google Scholar]

- Skoplaki, E.; Boudouvis, A.G.; Palyvos, J.A. A simple correlation for the operating temperature of photovoltaic modules of arbitrary mounting. Sol. Energy Mater. Sol. Cells 2008, 92, 1393–1402. [Google Scholar] [CrossRef]

- Nascimento, M.; Novais, S.; Ding, M.S.; Ferreira, M.S.; Koch, S.; Passerini, S.; Pinto, J.L. Internal strain and temperature discrimination with optical fiber hybrid sensors in Li-ion batteries. J. Power Sources 2019, 410–411, 1–9. [Google Scholar] [CrossRef]

- Kandilli, C.; Ulgen, K. Solar Illumination and Estimating Daylight Availability of Global Solar Irradiance. Energy Sources A 2008, 30, 1127–1140. [Google Scholar] [CrossRef]

- Pang, W.; Cui, Y.; Zhang, Q.; Wilson, G.J.; Yan, H. A comparative analysis on performances of flat plate photovoltaic/thermal collectors in view of operating media, structural designs, and climate conditions. Renew. Sustain. Energy Rev. 2020, 119, 109599. [Google Scholar] [CrossRef]

- Niazi, K.A.K.; Akhtar, W.; Khan, H.A.; Yang, Y.; Athar, S. Hotspot diagnosis for solar photovoltaic modules using a Naive Bayes classifier. Sol. Energy 2019, 190, 34–43. [Google Scholar] [CrossRef]

- Cardinale-Villalobos, L.; Jimenez-Delgado, E.; García-Ramírez, Y.; Araya-Solano, L.; Solís-García, L.A.; Méndez-Porras, A.; Alfaro-Velasco, J. IoT System Based on Artificial Intelligence for Hot Spot Detection in Photovoltaic Modules for a Wide Range of Irradiances. Sensors 2023, 23, 6749. [Google Scholar] [CrossRef]

- Dunderdale, C.; Brettenny, W.; Clohessy, C.; van Dyk, E.E. Photovoltaic defect classification through thermal infrared imaging using a machine learning approach. Prog. Photovolt. Res. Appl. 2020, 28, 177–188. [Google Scholar] [CrossRef]

- Ali, M.U.; Khan, H.F.; Masud, M.; Kallu, K.D.; Zafar, A. A machine learning framework to identify the hotspot in photovoltaic module using infrared thermography. Sol. Energy 2020, 208, 643–651. [Google Scholar] [CrossRef]

- Entezari, A.; Aslani, A.; Zahedi, R.; Noorollahi, Y. Artificial intelligence and machine learning in energy systems: A bibliographic perspective. Energy Strateg. Rev. 2023, 45, 101017. [Google Scholar] [CrossRef]

| Detection/Cooling Methods | Classification Accuracy | Temperature Reduction | Improved Efficiency |

|---|---|---|---|

| Infrared images with a Naive Bayes classifier [59] | 94.1% | / | / |

| Infrared images with a support vector machine classifier [62] | 92% | / | / |

| Air cooling with aluminum fins [24] | / | 7.4 °C | 2.72% |

| Liquid cooling with pulsating heat pipes [26] | / | 16.1 °C | 18% |

| This study | 99.1% | 7.7 °C | 5.6% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, H.; Guo, R.; Xing, H.; Chen, Y.; He, J.; Luo, J.; Chen, M.; Chen, Y.; Tang, S.; Xu, F. Spatial–Temporal Hotspot Management of Photovoltaic Modules Based on Fiber Bragg Grating Sensor Arrays. Sensors 2025, 25, 4879. https://doi.org/10.3390/s25154879

Ding H, Guo R, Xing H, Chen Y, He J, Luo J, Chen M, Chen Y, Tang S, Xu F. Spatial–Temporal Hotspot Management of Photovoltaic Modules Based on Fiber Bragg Grating Sensor Arrays. Sensors. 2025; 25(15):4879. https://doi.org/10.3390/s25154879

Chicago/Turabian StyleDing, Haotian, Rui Guo, Huan Xing, Yu Chen, Jiajun He, Junxian Luo, Maojie Chen, Ye Chen, Shaochun Tang, and Fei Xu. 2025. "Spatial–Temporal Hotspot Management of Photovoltaic Modules Based on Fiber Bragg Grating Sensor Arrays" Sensors 25, no. 15: 4879. https://doi.org/10.3390/s25154879

APA StyleDing, H., Guo, R., Xing, H., Chen, Y., He, J., Luo, J., Chen, M., Chen, Y., Tang, S., & Xu, F. (2025). Spatial–Temporal Hotspot Management of Photovoltaic Modules Based on Fiber Bragg Grating Sensor Arrays. Sensors, 25(15), 4879. https://doi.org/10.3390/s25154879