Equivalent Self-Noise Suppression of Distributed Hydroacoustic Sensing System Using SDM Signals Based on Multi-Core Fiber

Abstract

Highlights

- The distributed acoustic sensing system based on multi-core optical fiber is applied in the field of hydroacoustic detection.

- The self-noise level of the system is suppressed by the space division multiplexing of dual-core signals.

- The system’s detection capability of weak hydroacoustic signals can be enhanced.

- The sensing unit meets the requirement of small size in this method.

Abstract

1. Introduction

2. Materials and Methods

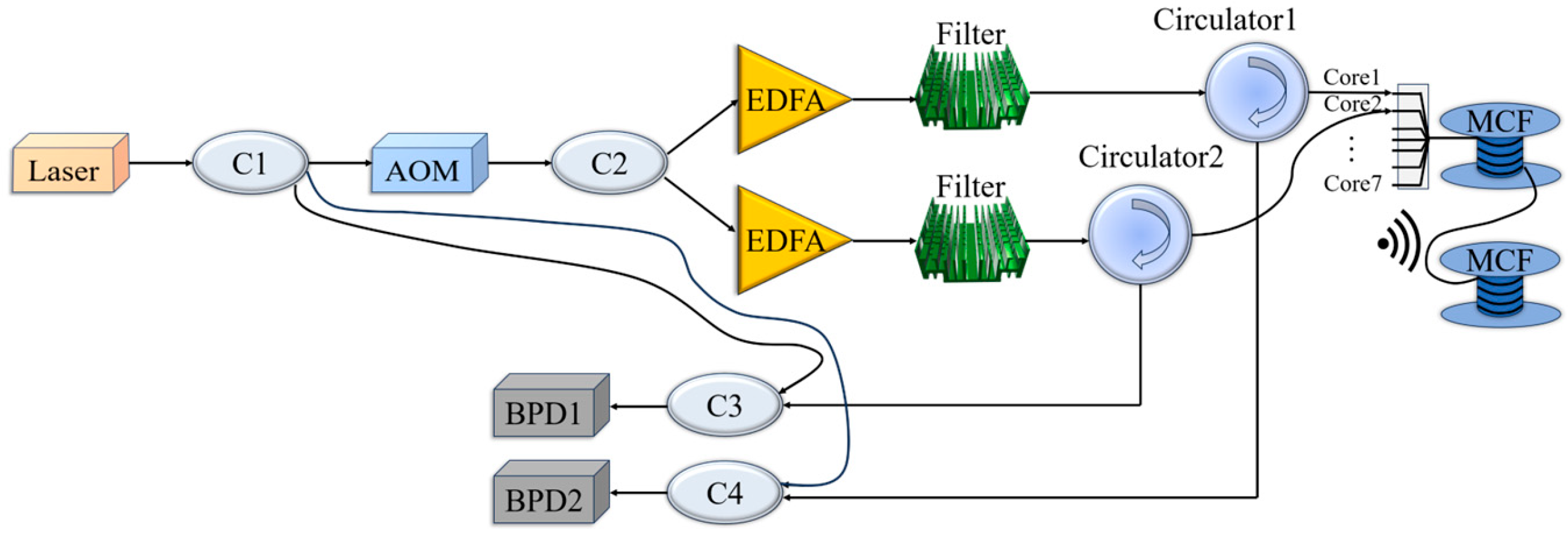

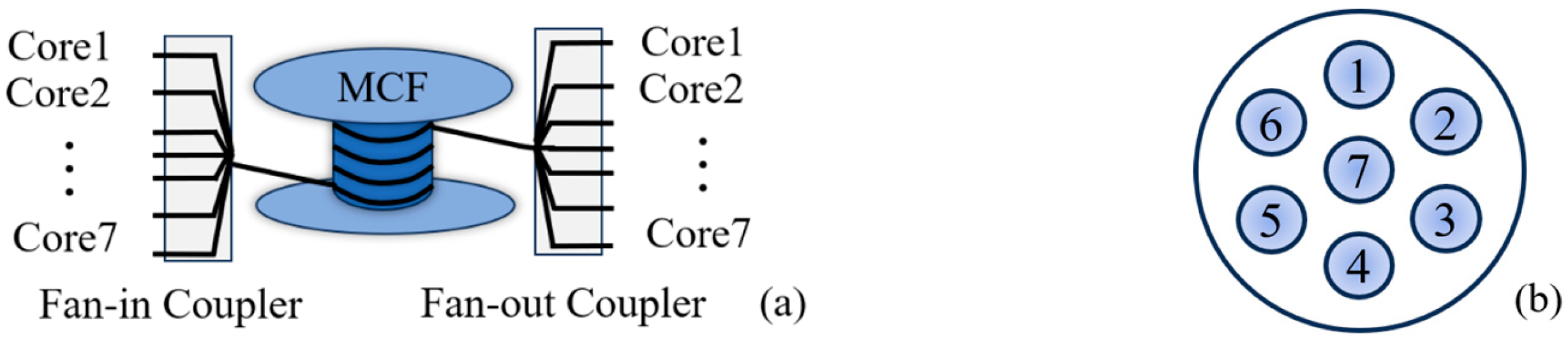

2.1. Dual-Channel DAS System Based on Φ-OTDR

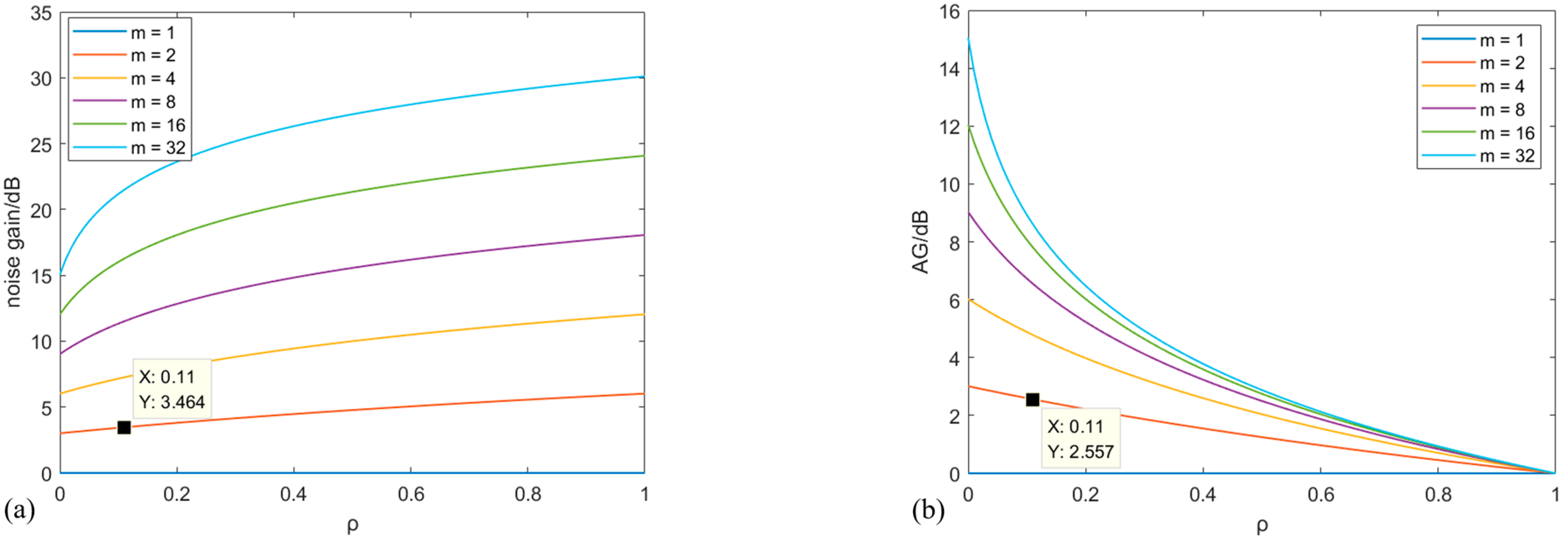

2.2. Array Gain Accumulation Principle

3. Results

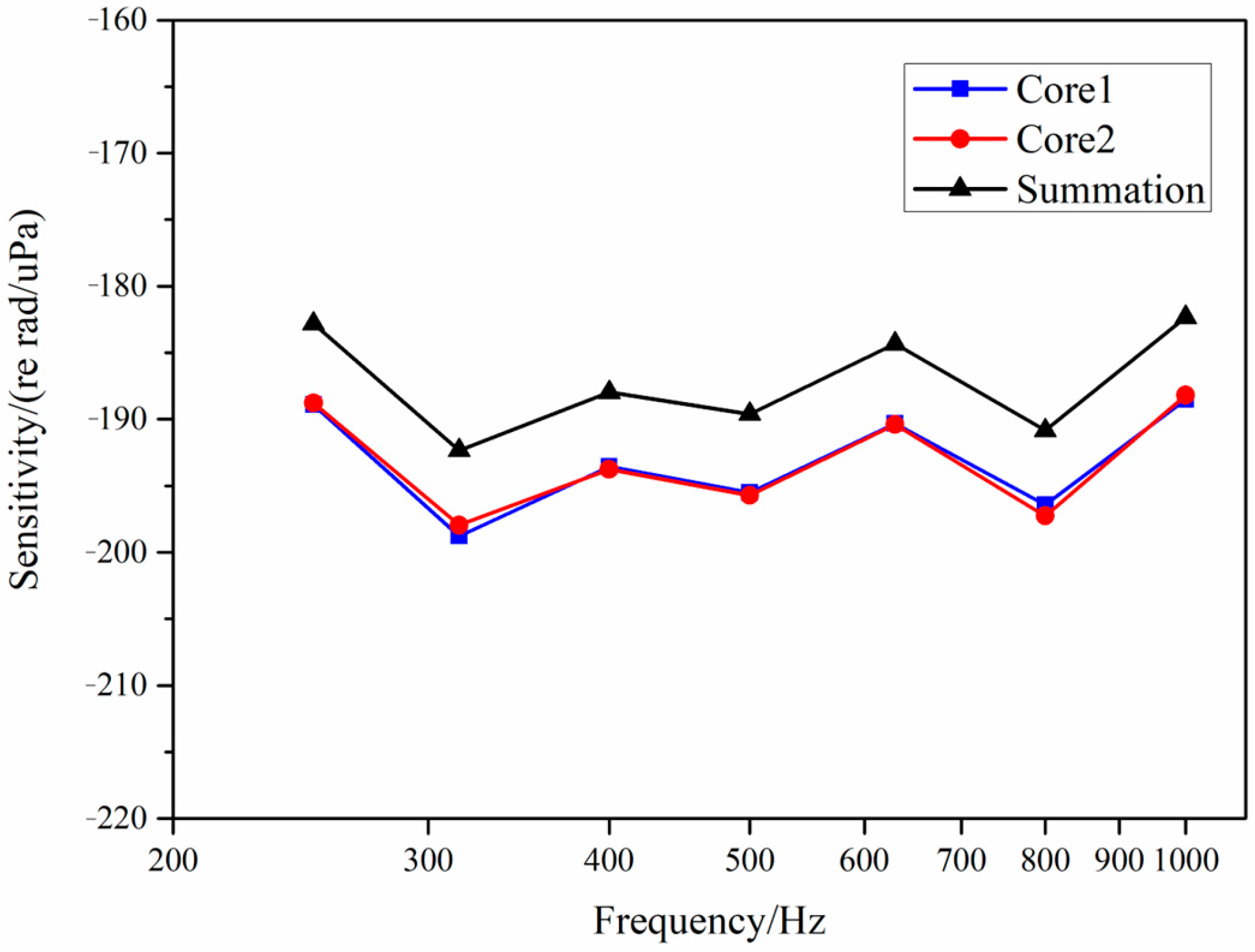

3.1. Sensitivity Analysis

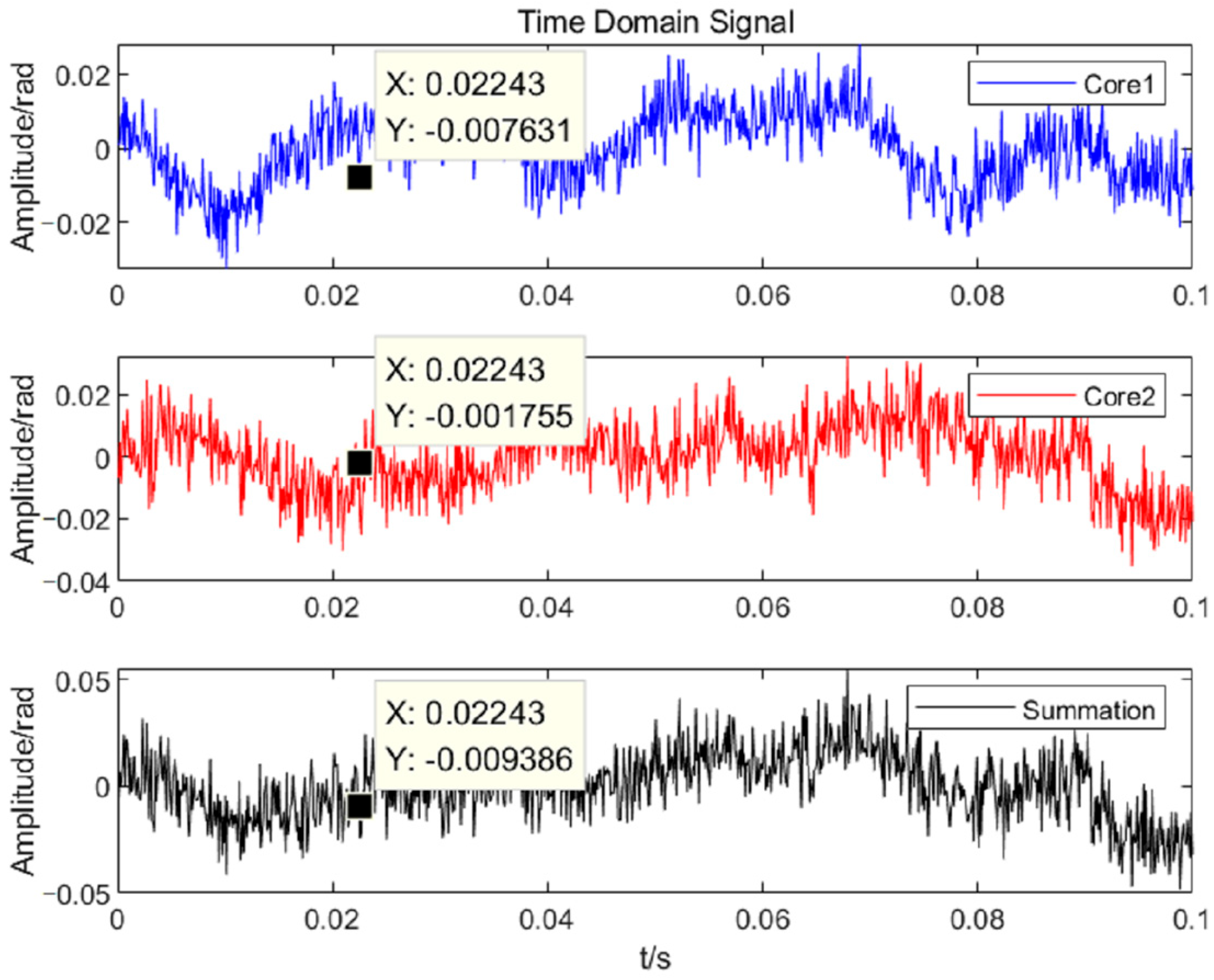

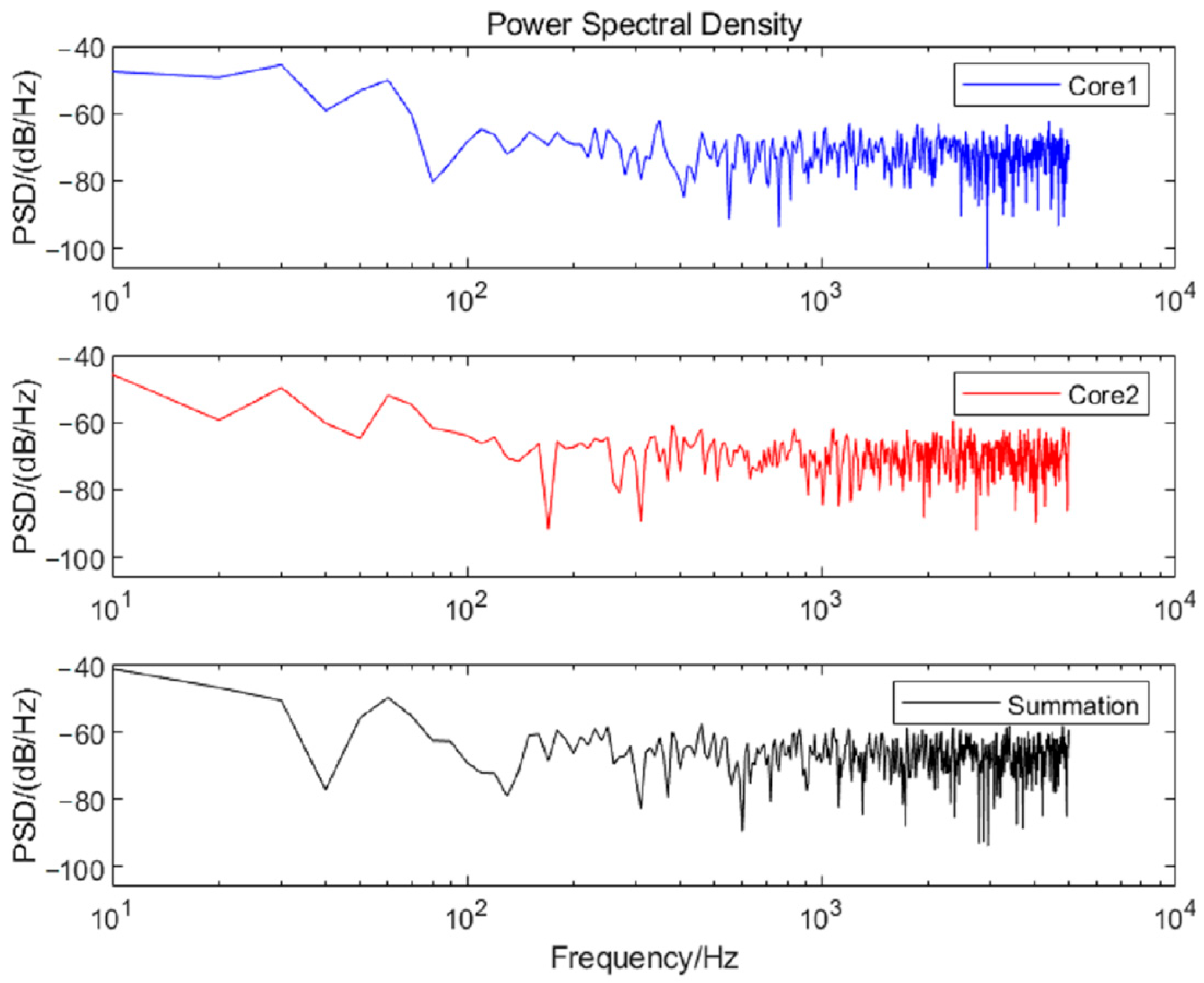

3.2. Analysis of Noise Performance

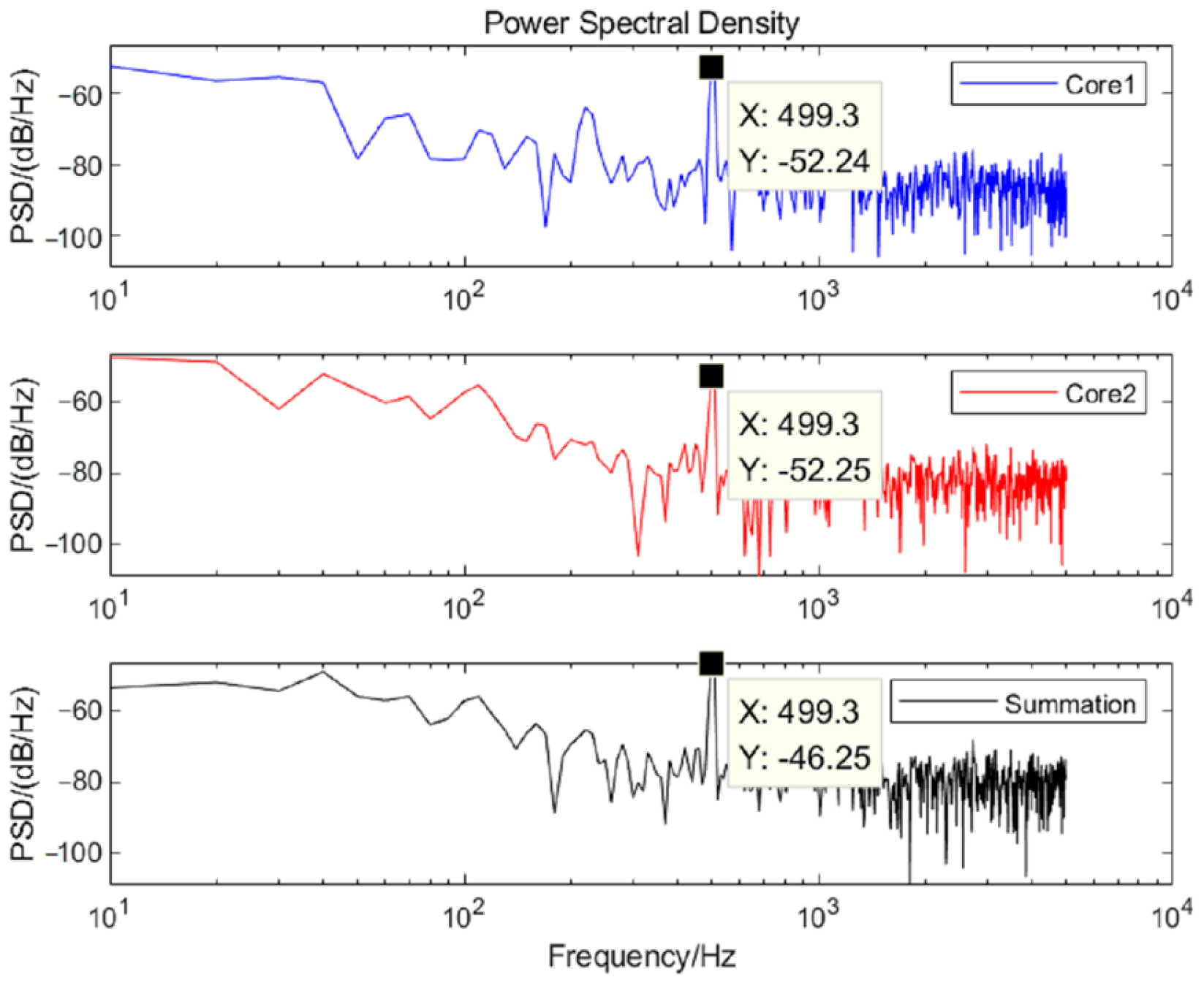

3.3. Analysis of Equivalent Self-Noise Pressure Suppression Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cao, W.H.; Cheng, G.L.; Xing, G.X.; Liu, B. Near-field target localisation based on the distributed acoustic sensing optical fiber in shallow water. Opt. Fiber Technol. 2023, 75, 103198. [Google Scholar] [CrossRef]

- Sun, M.Y.; Yu, M.; Wang, H.R.; Song, K.; Guo, X.; Xue, S.; Zhang, H.; Shao, Y.; Cui, H.; Chang, T. Intelligent water perimeter security event recognition based on NAM-MAE and distributed optic fiber acoustic sensing system. Opt. Express 2023, 31, 37058–37073. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Liu, Q.; He, Z. Phase-detection distributed fiber-optic vibration sensor without fading-noise based on time-gated digital OFDR. Opt. Express 2017, 25, 8315. [Google Scholar] [CrossRef]

- Si, Z.P.; Bu, Z.H.; Mao, B.N.; Zhao, C.L.; Xu, B.; Kang, J.; Li, Y.; Jin, S.Z. Review of research on phase sensitive optical time-domain reflectometer based on phase demodulation. Laser Optoelectron. Prog. 2022, 59, 1100007. [Google Scholar]

- Gabai, H.; Eyal, A. On the sensitivity of distributed acoustic sensing. Opt. Lett. 2016, 41, 5648–5651. [Google Scholar] [CrossRef]

- Westbrook, P.S.; Feder, K.S.; Ortiz, R.M.; Kremp, T.; Monberg, E.M.; Wu, H.; Simoff, D.A.; Shenk, S. Kilometer length low loss enhanced back scattering fiber for distributed sensing. In Proceedings of the 2017 25th Optical Fiber Sensors Conference (OFS), Jeju, Republic of Korea, 24–28 April 2017; IEEE: New York, NY, USA, 2017; pp. 1–5. [Google Scholar]

- Jason, J.; Popov, S.M.; Butov, O.V.; Chamorovskiy, Y.K.; Golant, K.M.; Fotiadi, A.A.; Wuilpart, M. Sensitivity of high Rayleigh scattering fiber in acoustic/vibration sensing using phase-OTDR. In Proceedings of the Optical Sensing and Detection V, San Francisco, CA, USA, 27 July 2018; Volume 10680. [Google Scholar]

- Westbrook, P.S.; Kremp, T.; Feder, K.S.; Ko, W.; Monberg, E.M.; Wu, H.; Simoff, D.A.; Ortiz, R.M. Improving Distributed Sensing with Continuous Gratings in Single and Multi-core Fibers. In Proceedings of the Optical Fiber Communication Conference, San Francisco, CA, USA, 11–15 March 2018; Optical Society of America: Washington, DC, USA, 2018; p. WIK. 1. [Google Scholar]

- Handerek, V.A.; Karimi, M.; Nkansah, A.; Yau, A.; Westbrook, P.S.; Feder, K.S.; Ortiz, R.M.; Kremp, T.; Monberg, E.M.; Wu, H.; et al. Improved Optical Power Budget in Distributed Acoustic Sensing Using Enhanced Scattering Optical Fiber. In Proceedings of the Optical Fiber Sensors. Lausanne Switzerland, 24–28 September 2018; Optical Society of America: Washington, DC, USA, 2018; p. TuC5. [Google Scholar]

- Feng, S.W.; Xu, T.W.; Huang, J.F.; Yang, Y.; Li, F.; Zhou, J.M.; Yu, H. Enhanced SNR phase-sensitive OTDR system with active fiber. In Proceedings of the Fiber Optic Sensing and Optical Communication, Bellingham, WA, USA, 12 December 2018; International Society for Optics and Photonics: Bellingham, WA, USA, 2018; Volume 10849. [Google Scholar]

- Zhu, F.; Zhang, Y.X.; Xia, L.; Wu, X.L.; Zhang, X.P. Improved Φ-OTDR sensing system for high-precision dynamic strain measurement based on ultra-weak fiber Bragg grating array. J. Light. Technol. 2015, 33, 4775–4780. [Google Scholar]

- Wang, C.; Shang, Y.; Liu, X.H.; Wang, C.; Yu, H.-H.; Jiang, D.-S.; Peng, G.-D. Distributed OTDR interferometric sensing network with identical ultra-weak fiber Bragg gratings. Opt. Express 2015, 23, 29038–29046. [Google Scholar] [CrossRef]

- Sun, F.A.Q.Z.; Zhang, W.; Liu, T.; Yan, Z.J.; Liu, D.M. Wideband fully-distributed vibration sensing by using UWFBG based coherent OTDR. In Proceedings of the Optical Fiber Communication Conference, Los Angeles, CA, USA, 19 March 2017; p. W2A.19. [Google Scholar]

- Nadav, A.; Moshe, T.; Avishay, E. Fiber-Optic Sensor Array for Distributed Underwater Ultrasound Sensing. J. Light. Technol. 2024, 42, 945–954. [Google Scholar]

- Guan, H.; Han, B.; Han, Z.W.; Wang, W.; Ran, Z.; Yan, G.; Gong, Y.; Rao, Y.-J. High performance DAS-based optical fiber hydrophone. In Proceedings of the Asia Communications and Photonics Conference, Beijing, China, 24–27 October 2020. [Google Scholar]

- Shang, Y.; Wang, C.; Ni, J.S.; Zhao, W.-A.; Li, C.; Cao, B.; Huang, S.; Wang, C.; Peng, G.-D. Discussion on the sensitivity of optical cables based on distributed acoustic sensing. Opt. Rev. 2019, 26, 659–663. [Google Scholar] [CrossRef]

- Yan, G.F.; Wang, D.L.; Long, J.Q.; Jiang, L.; Gong, Y.; Ran, Z.; Rao, Y. High-performance towing cable hydrophone array with an improved ultra-sensitive fiber-optic distributed acoustic sensing system. Opt. Express 2023, 31, 25545–25556. [Google Scholar] [CrossRef]

- He, X.G.; Wen, P.F.; Yang, H.; Gu, L.J.; Lu, H.L.; Zhang, M. Marine towing cable seismic acquisition with small trace interval based on distributed optical fiber sensing. Geophys. Prospect. Pet. 2022, 61, 70–77. [Google Scholar]

- Yan, G.F.; Long, J.Q.; Jiang, L.; Zhang, M.; Wang, D.; Rao, Y. High performance marine towing cable system based on ultra-sensitive fiber-optic distributed acoustic sensing. In Proceedings of the 2022 Asia Communications and Photonics Conference (ACP), Shenzhen, China, 5–8 November 2022; pp. 174–177. [Google Scholar]

- Liu, X.; Wang, C.; Shang, Y.; Wang, C.; Zhao, W.A.; Peng, G.D.; Wang, H.Z. Distributed acoustic sensing with Michelson interferometer demodulation. Photonic Sens. 2017, 7, 193–198. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, T.; Feng, S.; Huang, J.; Fang, L. Optical fiber hydrophone based on distributed acoustic sensing. Fiber Opt. Sens. Opt. Commun. 2018, 10849, 59–63. [Google Scholar]

- Yan, B.Q.; Zhang, K.Q.; Li, H.; Xiao, X.P.; Chen, J.F.; Fan, C.Z.; Yan, Z.J.; Sun, Q.Z. Acoustic Field Imaging of Pipeline Turbulence for Noninvasive and Distributed Gas Flow Measurement. IEEE Sens. J. 2023, 23, 12868–12875. [Google Scholar] [CrossRef]

- Lavrov, V.S.; Plotnikov, M.Y.; Aksarin, S.M.; Efimov, M.E.; Shulepov, V.A.; Kulikov, A.V.; Kireenkov, A.U. Experimental investigation of the thin fiber-optic hydrophone array based on fiber Bragg gratings. Opt. Fiber Technol. 2017, 34, 47–51. [Google Scholar] [CrossRef]

- Li, Z.Y.; Wang, C.J.; Gui, X.; Fu, X.L.; Wang, Y.M.; Wang, Z.; Wang, Y.B. A high-performance fiber-optic hydrophone for large scale arrays. J. Light. Technol. 2023, 41, 4201–4210. [Google Scholar] [CrossRef]

- Pang, Y.D. Research on Key Technology of Ultra-Fine Line Fiber Optic Hydrophone Based on Grating Array of Wire Drawing Tower. Ph.D. Thesis, Wuhan University of Technology, Wuhan, China, 2020. [Google Scholar]

- Ding, P.; Huang, J.B.; Yao, G.F.; Gu, H.C.; Liu, W.; Tang, J.S. Weak reflection fiber Bragg grating hydrophone with secondary coating sensitization. Chin. Lasers 2021, 48, 0906003. [Google Scholar]

- Ding, P.; Huang, J.B.; Pang, Y.D.; Zhou, C.M.; Gu, H.C.; Tang, J.S. A towed line array with weak fiber Bragg grating hydrophones. Acta Photonica Sin. 2021, 50, 0706004. [Google Scholar]

- Wu, S.; Huang, J.B.; Pang, Y.D.; Wang, J.B.; Gu, H.C. Direction-Finding Study of a 1.7 mm Diameter Towed Hydrophone Array Based on UWFBG. Sensors 2024, 24, 4300. [Google Scholar] [CrossRef]

- Gu, H.C.; Wang, J.B.; Wang, P.; Zhu, M.; Yao, G.F.; Lv, J.Q. Directivity Analysis and Test of a Distributed Weak Reflection Fiber Bragg Grating Linear Hydrophone Array. Acta Armamentar 2025. [Google Scholar] [CrossRef]

- Chen, J.F.; Li, H.; Liu, T.; Fan, C.Z.; Yan, Z.J.; Sun, Q.Z. Fully distributed hydroacoustic sensing based on lightweight optical cable assisted with scattering enhanced fiber. In Proceedings of the 2021 Optical Fiber Communications Conference and Exhibition (OFC), San Francisco, CA, USA, 6–10 June 2021; IEEE Press: New York, NY, USA, 2021. [Google Scholar]

- Chen, J.F.; Li, H.; Xiao, X.P.; Fan, C.Z.; Wen, P.F.; Yan, Z.J.; Sun, Q.Z. Fully continuous fiber-optic hydrophone streamer with small channel spacing for marine seismic acquisition. In Proceedings of the 27th International Conference on Optical Fiber Sensors, Alexandria, VA, USA, 29 August–2 September 2022; Optica Publishing Group: Washington, DC, USA, 2022; p. W4.45. [Google Scholar]

- Lv, Y.J.; Xiao, X.P.; Yang, Z.Y.; Li, H.; Yan, Z.J.; Sun, Q.Z. High spatial resolution and large measurement range strain sensor based on special fiber OFDR system. In Proceedings of the 2023 Conference on Lasers and Electro-Optics, Munich, Germany, 26–30 June 2023; IEEE: New York, NY, USA, 2023. [Google Scholar]

- Xiao, X.P.; Song, Q.G.; Zhao, W.L.; Li, H.; Sun, Q.Z.; Yan, Z.J. Hybrid coding ultra-weak fiber Bragg grating (UWFBG) array for high spatial resolution temperature sensing. In Proceedings of the 2023 Optical Fiber Communications Conference and Exhibition, San Diego, CA, USA, 5–9 March 2023; IEEE: New York, NY, USA, 2023. [Google Scholar]

- Fan, C.Z.; Xiao, X.P.; Li, H.; Zhao, W.L.; Yan, Z.J.; Sun, Q.Z. Full link SNR equalization DAS system over 80 km based on gradient discrete scattering enhanced fiber. In Proceedings of the 2023 Optical Fiber Communication Conference, San Diego, CA, USA, 5–9 March 2023; IEEE: New York, NY, USA, 2023. [Google Scholar]

- Liu, D.M.; He, T.; Xu, Z.J.; Sun, Q.Z. New type of microstructure fiber distributed acoustic sensing technology and its applications. J. Appl. Sci. 2020, 38, 296–309. [Google Scholar]

- Fang, J.; Li, Y.W.; Ji, P.N.; Wang, T. Drone detection and localization using enhanced fiber-optic acoustic sensor and distributed acoustic sensing technology. J. Light. Technol. 2023, 41, 822–831. [Google Scholar] [CrossRef]

- Chen, J.F.; Li, H.; Xiao, X.P.; Fan, C.Z.; Yan, B.Q.; Zhang, S.X.; Liu, H.G.; Ai, K.; Yan, Z.J.; Sun, Q.Z. Fully distributed hydroacoustic sensing based on ultra-highly sensitive and lightweight fiber-optic hydrophone cable. Opt. Lasers Eng. 2023, 169, 107734. [Google Scholar] [CrossRef]

- Lu, B.; Wu, B.Y.; Gu, J.F.; Yang, J.Q.; Gao, K.; Wang, Z.Y.; Ye, L.; Ye, Q.; Qu, R.G.; Chen, X.B.; et al. Distributed optical fiber hydrophone based on Φ-OTDR and its field test. Opt. Express 2021, 29, 3147–3162. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhao, Y.; Song, C.; Wang, J.; Xu, W.; Li, Z. GA-BP-Based Low-Noise FBG Hydroacoustic Monitoring System with Reference Sensor. Sensors 2024, 24, 5733. [Google Scholar] [CrossRef]

- Feng, C.; Niu, H.; Wang, H.; Wang, D.H.; Wei, L.X.; Ju, T.; Yuan, L.B. Probe-Type Multi-Core Fiber Optic Sensor for Simultaneous Measurement of Seawater Salinity, Pressure, and Temperature. Sensors 2024, 24, 1766. [Google Scholar] [CrossRef]

- Gu, J.F.; Lu, B.; Yang, J.Q.; Wang, Z.Y.; Ye, L.; Ye, Q.; Qu, R.H.; Cai, H.W. Distributed acoustic sensing based on multi-core fiber. Acta Opt. Sin. 2021, 41, 0706003. [Google Scholar] [CrossRef]

- Xiao, Y.H.; Liu, H.H.; Li, J.L.; Shen, X.L.; Zhao, Z.Y.; Dang, H.; Zou, D.F.; Zhang, A.Y.; Wang, P.H.; Zhao, Z.Y.; et al. Fading suppression and noise reduction of a DAS system integrated with multi-core fiber. Opt. Express 2024, 32, 26793–26807. [Google Scholar] [CrossRef]

- Liu, X.; Wang, R.H.; Chen, F.Y.; Qiao, X.G. Sensitivity enhancement of interferometric fiber-optic accelerometers using multi-core fiber. Opt. Laser Technol. 2023, 167, 109818. [Google Scholar] [CrossRef]

- Turov, A.T.; Barkov, F.L.; Konstantinov, Y.A.; Korobko, D.A.; Lopez Mercado, C.A.; Fotiadi, A.A. Activation Function Dynamic Averaging as a Technique for Nonlinear 2D Data Denoising in Distributed Acoustic Sensors. Algorithms 2023, 16, 440. [Google Scholar] [CrossRef]

- Yu, Z.; Lu, Y.; Hu, X.; Zhou, M. Polarization dependence of the noise of phase measurement based on phase-sensitive OTDR. J. Opt. 2017, 19, 125602. [Google Scholar] [CrossRef]

- Zabihi, M.; Chen, Y.S.; Zhou, T.; Liu, J.X.; Shan, Y.Y.; Meng, Z.; Wang, F.; Zhang, Y.X.; Zhang, X.P.; Chen, M.M. Continuous Fading Suppression Method for Φ-OTDR Systems Using Optimum Tracking over Multiple Probe Frequencies. J. Light. Technol. 2019, 37, 3602–3610. [Google Scholar] [CrossRef]

- Qin, Z.G.; Chen, H.; Chang, J. Signal-to-noise ratio enhancement based on empirical mode decomposition in phase-sensitive optical time domain reflectometry systems. Sensors 2017, 17, 1870. [Google Scholar] [CrossRef]

- Peng, H.T.; Wang, M.Q.; He, W.B.; Lv, X.M.; Li, X. Φ-OTDR denoising Algorithm Based on Empirical Mode Decomposition and Butterworth Filtering. Adv. Lasers Optoelectron. 2024, 61, 222–227. [Google Scholar]

- Mao, B.; Bu, Z.; Xu, B.; Gong, H.P.; Li, Y.; Wang, H.L.; Kang, J.; Jin, S.Z.; Zhao, C.L. Denoising method based on VMD-PCC in cp-OTDR system. Opt. Fiber Technol. 2022, 74, 103081. [Google Scholar] [CrossRef]

- He, H.J.; Shao, L.Y.; Li, H.C.; Pan, W.; Luo, B.; Zou, X.H.; Yan, L.S. SNR Enhancement in Phase-Sensitive OTDR with Adaptive 2-D Bilateral Filtering Algorithm. IEEE Photonics J. 2017, 9, 6802610. [Google Scholar] [CrossRef]

- Li, S.C.; Liu, K.; Jiang, J.F.; Xu, T.H.; Ding, Z.Y.; Sun, Z.S.; Huang, Y.L.; Xue, K.; Jin, X.; Liu, T.G. An Ameliorated Denoising Scheme Based on Deep Learning for Φ-OTDR System with 41-km Detection Range. IEEE Sens. J. 2022, 22, 19666–19674. [Google Scholar] [CrossRef]

- Fang, G.S.; Xu, T.W.; Feng, S.W.; Li, F. Phase-sensitive optical time domain reflectometer based on phase-generated carrier algorithm. J. Light. Technol. 2015, 33, 2811–2816. [Google Scholar] [CrossRef]

- Urick, R.J. Principle of Underwater Sound; Company of McGraw Hill Books: New York, NY, USA, 1990. [Google Scholar]

| Frequency /Hz | Core1 | Core2 | Average Value | Summation | Actual Gain | Actual Average Gain |

|---|---|---|---|---|---|---|

| 250 | −188.90 | −188.78 | −188.84 | −182.82 | 6.02 | 5.97 |

| 315 | −198.78 | −197.96 | −198.37 | −192.34 | 6.03 | |

| 400 | −193.57 | −193.76 | −193.67 | −187.98 | 5.69 | |

| 500 | −195.52 | −195.73 | −195.63 | −189.61 | 6.02 | |

| 630 | −190.31 | −190.39 | −190.35 | −184.33 | 6.02 | |

| 800 | −196.42 | −197.26 | −196.84 | −190.84 | 6.00 | |

| 1000 | −188.51 | −188.19 | −188.35 | −182.34 | 6.01 |

| Serial Number | Core1 | Core2 | Summation Theoretical Value | Summation Actual Value | Actual Gain | Actual Average Gain |

|---|---|---|---|---|---|---|

| 1 | −66.81 | −66.56 | −63.68 | −63.26 | 3.42 | 3.46 |

| 2 | −66.41 | −66.73 | −63.57 | −63.01 | 3.55 | |

| 3 | −66.79 | −66.52 | −63.64 | −63.18 | 3.46 | |

| 4 | −66.47 | −66.76 | −63.61 | −63.10 | 3.51 | |

| 5 | −66.84 | −66.61 | −63.72 | −63.33 | 3.39 |

| Frequency /Hz | Core1 | Core2 | Average Value | Summation | Actual Gain | Actual Average Gain |

|---|---|---|---|---|---|---|

| 500 | −52.24 | −52.25 | −52.25 | −46.25 | 6.00 | 5.99 |

| 630 | −48.03 | −47.77 | −47.90 | −41.89 | 6.01 | |

| 800 | −56.82 | −57.15 | −56.99 | −51.04 | 5.95 | |

| 1000 | −38.73 | −38.31 | −38.52 | −32.51 | 6.01 |

| Frequency /Hz | Core1 | Core2 | Average Value | Summation | Actual Gain | Actual Average Gain |

|---|---|---|---|---|---|---|

| 500 | 23.36 | 23.16 | 23.26 | 25.94 | 2.68 | 2.54 |

| 630 | 23.72 | 24.20 | 23.96 | 26.58 | 2.62 | |

| 800 | 25.49 | 26.20 | 25.85 | 28.24 | 2.39 | |

| 1000 | 25.03 | 25.10 | 25.07 | 27.52 | 2.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Gu, H.; Wang, P.; Yao, G.; Huang, J.; Liu, W.; Xu, D.; Wu, S. Equivalent Self-Noise Suppression of Distributed Hydroacoustic Sensing System Using SDM Signals Based on Multi-Core Fiber. Sensors 2025, 25, 4877. https://doi.org/10.3390/s25154877

Wang J, Gu H, Wang P, Yao G, Huang J, Liu W, Xu D, Wu S. Equivalent Self-Noise Suppression of Distributed Hydroacoustic Sensing System Using SDM Signals Based on Multi-Core Fiber. Sensors. 2025; 25(15):4877. https://doi.org/10.3390/s25154877

Chicago/Turabian StyleWang, Jiabei, Hongcan Gu, Peng Wang, Gaofei Yao, Junbin Huang, Wen Liu, Dan Xu, and Su Wu. 2025. "Equivalent Self-Noise Suppression of Distributed Hydroacoustic Sensing System Using SDM Signals Based on Multi-Core Fiber" Sensors 25, no. 15: 4877. https://doi.org/10.3390/s25154877

APA StyleWang, J., Gu, H., Wang, P., Yao, G., Huang, J., Liu, W., Xu, D., & Wu, S. (2025). Equivalent Self-Noise Suppression of Distributed Hydroacoustic Sensing System Using SDM Signals Based on Multi-Core Fiber. Sensors, 25(15), 4877. https://doi.org/10.3390/s25154877