Principles, Applications, and Future Evolution of Agricultural Nondestructive Testing Based on Microwaves

Abstract

1. Introduction

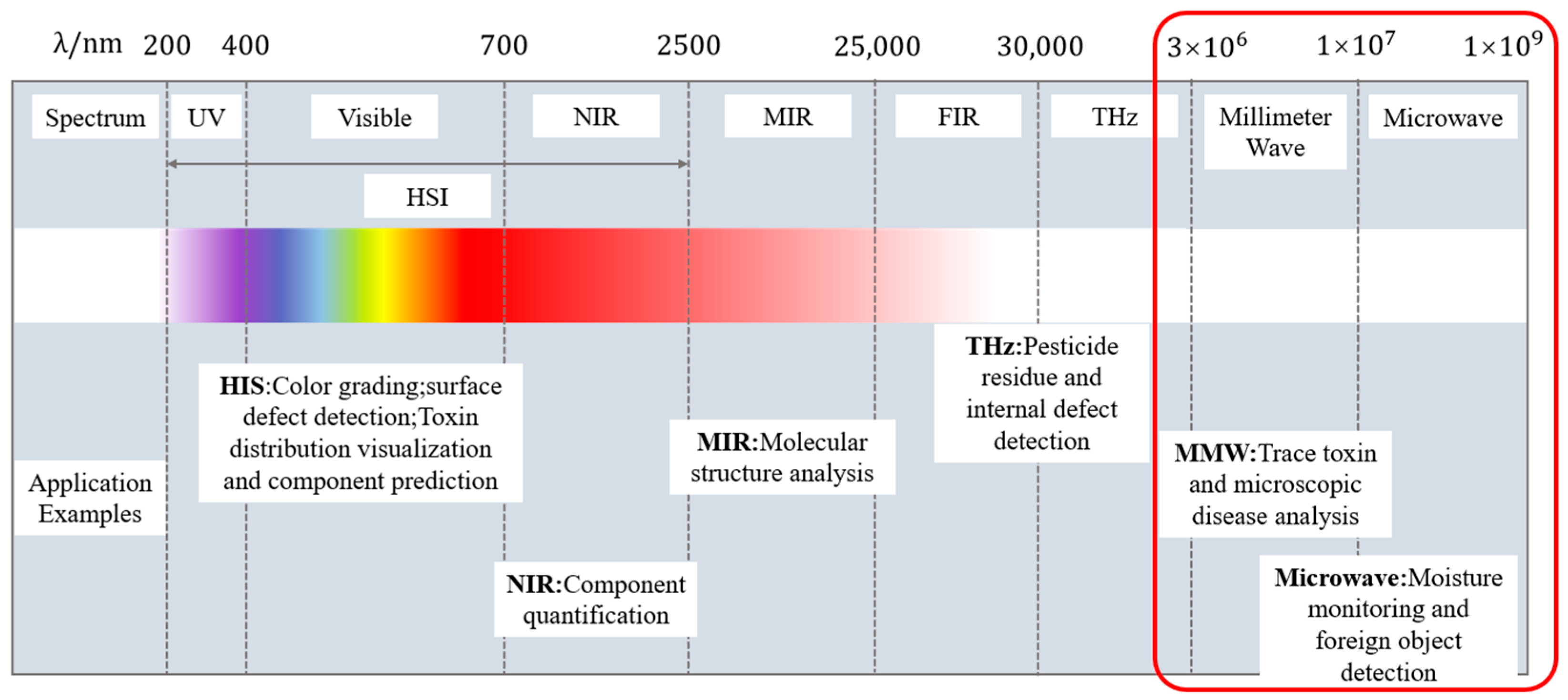

1.1. Comparison of Microwave Technology with Traditional Technology and New Needs for Agricultural Testing

1.2. Objectives of the Review

2. Core Mechanisms and Agricultural Adaptability of Microwave Technology

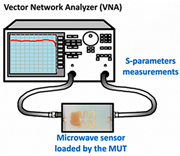

2.1. The Physical Basis of Microwave Detection

2.2. Band Selection and Agricultural Scenario Adaptation

2.3. Advantages and Limitations

3. Extended Application Scenarios of Microwave Technology

3.1. Typical Application Scenarios: Moisture Content Detection

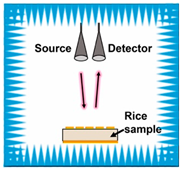

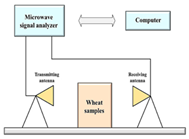

3.1.1. Cereal Crop Moisture Testing

3.1.2. Oil-Bearing Crop

3.1.3. Other Materials

3.2. Emerging Application Directions

3.2.1. Agricultural Storage and Processing Monitoring

3.2.2. Mycotoxin Detection

3.2.3. Food Adulteration Identification

| Applications | System Schematic | Measurement Technique | Frequency | Signal Processing Methods | Ref. |

|---|---|---|---|---|---|

| Milk biofilm detection |  | Reflection coefficient (S11) and resonance frequency shift analysis | 1.52 GHz | Frequency offsets and amplitude changes | [142] |

| Storage grain identification |  | Reflection spectrum measurement (free-space method) | 7.11–7.52 GHz | Full-wave simulation and measurement results analysis; multi-reflection interference theory | [144] |

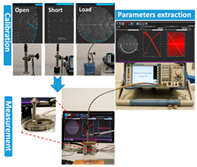

| Wheat aflatoxin B1 (AFB1) quantification |  | Dual-heterodyne mixing technology, broadband free-space transmission | 2.5–11.5 GHz | Least squares filtering preprocessing, bootstrap soft shrinkage (BOSS) algorithm for feature optimization, and Support Vector Machine (SVM) ion (R2) = 0.97 | [98] |

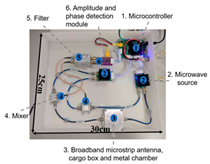

| AFB1 and mold co-detection |  | A miniaturized microwave detection device with a double heterodyne mixing structure | 4.5–11.5 GHz | A multi-task CNN model for feature self-learning and model calibration | [123] |

| Phytopathogenic fungi differentiation |  | Open-ended coaxial probe technique | 200 MHz–13.6 GHz | The DAK 3.5 software extracts the dielectric parameters of the material by measuring the complex reflection coefficient at the probe end | [146] |

| Lead (Pb) residue in edible oil | Employing the penetrating, absorbing, and reflecting properties of microwaves to detect and analyze sample properties | 300 MHz–300 GHz | Convolutional neural networks (CNNs), residual neural networks, and attention mechanisms | [147] | |

| Talc adulteration in wheat flour |  | Amplitude attenuation and phase changes | 2.5–11.5 GHz | Feature selection strategies (such as BOSS, CARS, and MEF-LASSO) are employed to reduce data dimensions and extract key features | [148] |

| Animal-derived biological tissues (beef, pork, chicken, liver, and skin) |  | Improved ring resonator (CPW-fed, meander-miniaturized), ex vivo biological tissue capacitive perturbation measurement | 0.5–5 GHz | Measure resonance shift and Q-factor change; fit S-parameters via EM simulation to extract complex permittivity | [150] |

3.2.4. Biometric Identification

3.3. The Forward-Looking Potential of Millimeter Wave Technology

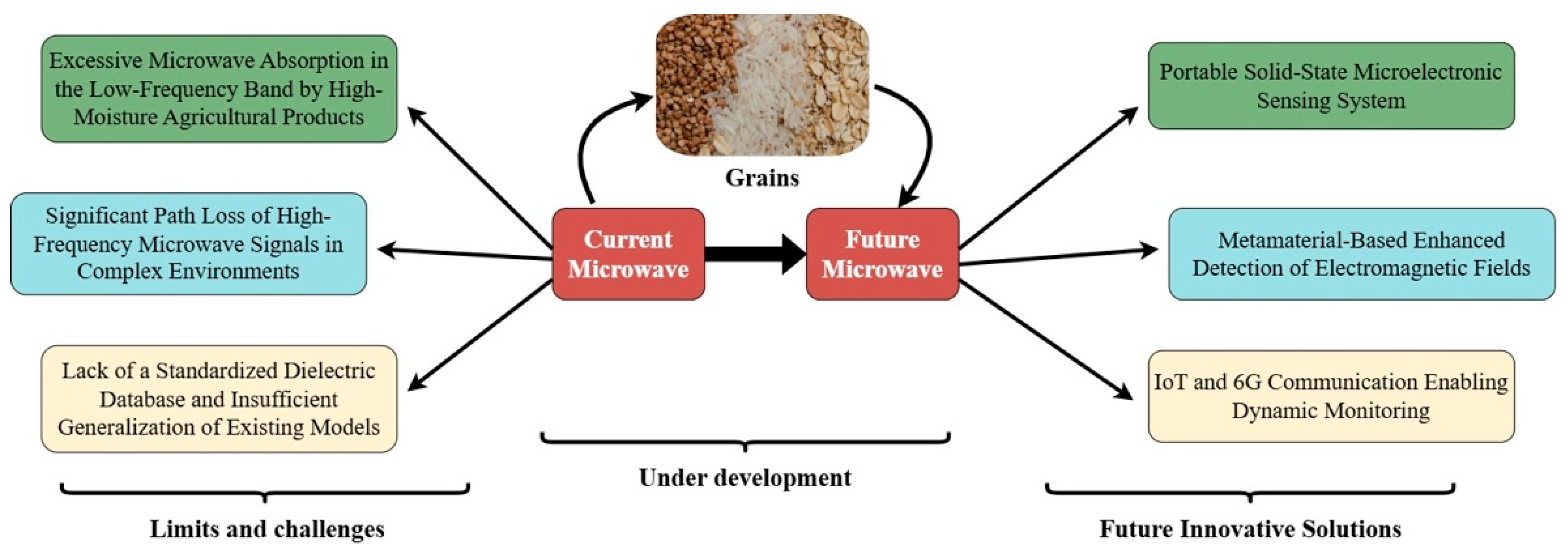

4. Challenges and Future Perspectives

4.1. Current Technology: Three Technical Bottlenecks

4.2. Innovative Solutions: Future Evolution Paths

4.2.1. Portable Sensing System Based on Solid-State Microelectronics

4.2.2. Metamaterial-Based Electromagnetic Field Enhancement Detection

4.2.3. IoT and 6G Communications-Enabled Dynamic Monitoring

4.3. Discussion on Limitations and Future Perspectives

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, L.; Sun, D.-W.; Pu, H.; Cheng, J.-H. Quality Analysis, Classification, and Authentication of Liquid Foods by near-Infrared Spectroscopy: A Review of Recent Research Developments. Crit. Rev. Food Sci. Nutr. 2017, 57, 1524–1538. [Google Scholar] [CrossRef]

- Ferreira, D.S.; Galão, O.F.; Pallone, J.A.L.; Poppi, R.J. Comparison and Application of Near-Infrared (NIR) and Mid-Infrared (MIR) Spectroscopy for Determination of Quality Parameters in Soybean Samples. Food Control 2014, 35, 227–232. [Google Scholar] [CrossRef]

- He, H.-J.; Sun, D.-W. Hyperspectral Imaging Technology for Rapid Detection of Various Microbial Contaminants in Agricultural and Food Products. Trends Food Sci. Technol. 2015, 46, 99–109. [Google Scholar] [CrossRef]

- Hussain, N.; Sun, D.-W.; Pu, H. Classical and Emerging Non-Destructive Technologies for Safety and Quality Evaluation of Cereals: A Review of Recent Applications. Trends Food Sci. Technol. 2019, 91, 598–608. [Google Scholar] [CrossRef]

- Qi, H.; Luo, J.; Wu, X.; Zhang, C. Application of Nondestructive Techniques for Peach (Prunus persica) Quality Inspection: A Review. J. Food Sci. 2024, 89, 6863–6887. [Google Scholar] [CrossRef]

- Lapchareonsuk, R.; Sirisomboon, P. Sensory Quality Evaluation of Rice Using Visible and Shortwave Near-Infrared Spectroscopy. Int. J. Food Prop. 2015, 18, 1128–1138. [Google Scholar] [CrossRef]

- Manley, M. Near-Infrared Spectroscopy and Hyperspectral Imaging: Non-Destructive Analysis of Biological Materials. Chem. Soc. Rev. 2014, 43, 8200–8214. [Google Scholar] [CrossRef]

- Jo, K.; Lee, S.; Jeong, S.-K.-C.; Lee, D.-H.; Jeon, H.; Jung, S. Hyperspectral Imaging–Based Assessment of Fresh Meat Quality: Progress and Applications. Microchem. J. 2024, 197, 109785. [Google Scholar] [CrossRef]

- Cheng, J.-H.; Nicolai, B.; Sun, D.-W. Hyperspectral Imaging with Multivariate Analysis for Technological Parameters Prediction and Classification of Muscle Foods: A Review. Meat Sci. 2017, 123, 182–191. [Google Scholar] [CrossRef]

- Whitfield, M.B.; Chinn, M.S. Near Infrared Spectroscopic Data Handling and Chemometric Analysis with the R Statistical Programming Language: A Practical Tutorial. J. Near Infrared Spectrosc. 2017, 25, 363–380. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, T.; Wu, B.; Zhou, H. Identification of Lambda-Cyhalothrin Residues on Chinese Cabbage Using Fuzzy Uncorrelated Discriminant Vector Analysis and MIR Spectroscopy. Int. J. Agric. Biol. Eng. 2022, 15, 217–224. [Google Scholar] [CrossRef]

- Wang, K.; Sun, D.-W.; Pu, H.; Wei, Q. Principles and Applications of Spectroscopic Techniques for Evaluating Food Protein Conformational Changes: A Review. Trends Food Sci. Technol. 2017, 67, 207–219. [Google Scholar] [CrossRef]

- Xu, M.; Sun, J.; Yao, K.; Wu, X.; Shen, J.; Cao, Y.; Zhou, X. Nondestructive Detection of Total Soluble Solids in Grapes Using VMD-RC and Hyperspectral Imaging. J. Food Sci. 2022, 87, 326–338. [Google Scholar] [CrossRef]

- Orina, I.; Manley, M.; Williams, P.J. Non-Destructive Techniques for the Detection of Fungal Infection in Cereal Grains. Food Res. Int. 2017, 100, 74–86. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Zhou, H.; Wu, B.; Fu, H. Determination of Apple Varieties by near Infrared Reflectance Spectroscopy Coupled with Improved Possibilistic Gath–Geva Clustering Algorithm. J. Food Process. Preserv. 2020, 44, e14561. [Google Scholar] [CrossRef]

- He, F.; Wu, X.; Wu, B.; Zeng, S.; Zhu, X. Green Tea Grades Identification via Fourier Transform Near-infrared Spectroscopy and Weighted Global Fuzzy Uncorrelated Discriminant Transform. J. Food Process Eng. 2022, 45, e14109. [Google Scholar] [CrossRef]

- Ding, Y.; Yan, Y.; Li, J.; Chen, X.; Jiang, H. Classification of Tea Quality Levels Using Near-Infrared Spectroscopy Based on CLPSO-SVM. Foods 2022, 11, 1658. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, X.; He, C.; Wu, B.; Zhang, S.; Sun, J. Near-Infrared Spectroscopy Combined with Fuzzy Improved Direct Linear Discriminant Analysis for Nondestructive Discrimination of Chrysanthemum Tea Varieties. Foods 2024, 13, 1439. [Google Scholar] [CrossRef]

- Wu, X.; He, F.; Wu, B.; Zeng, S.; He, C. Accurate Classification of Chunmee Tea Grade Using NIR Spectroscopy and Fuzzy Maximum Uncertainty Linear Discriminant Analysis. Foods 2023, 12, 541. [Google Scholar] [CrossRef]

- Deng, J.; Chen, Z.; Jiang, H.; Chen, Q. High-Precision Detection of Dibutyl Hydroxytoluene in Edible Oil via Convolutional Autoencoder Compressed Fourier-Transform near-Infrared Spectroscopy. Food Control 2025, 167, 110808. [Google Scholar] [CrossRef]

- Rodriguez-Saona, L.E.; Allendorf, M.E. Use of FTIR for Rapid Authentication and Detection of Adulteration of Food. Annu. Rev. Food Sci. Technol. 2011, 2, 467–483. [Google Scholar] [CrossRef] [PubMed]

- Amir, R.M.; Anjum, F.M.; Khan, M.I.; Khan, M.R.; Pasha, I.; Nadeem, M. Application of Fourier Transform Infrared (FTIR) Spectroscopy for the Identification of Wheat Varieties. J. Food Sci. Technol. 2013, 50, 1018–1023. [Google Scholar] [CrossRef] [PubMed]

- Deng, J.; Jiang, H.; Chen, Q. Characteristic Wavelengths Optimization Improved the Predictive Performance of Near-Infrared Spectroscopy Models for Determination of Aflatoxin B1 in Maize. J. Cereal Sci. 2022, 105, 103474. [Google Scholar] [CrossRef]

- Wang, B.; Deng, J.; Jiang, H. Markov Transition Field Combined with Convolutional Neural Network Improved the Predictive Performance of Near-Infrared Spectroscopy Models for Determination of Aflatoxin B1 in Maize. Foods 2022, 11, 2210. [Google Scholar] [CrossRef]

- Liu, T.; He, J.; Yao, W.; Jiang, H.; Chen, Q. Determination of Aflatoxin B1 Value in Corn Based on Fourier Transform Near-Infrared Spectroscopy: Comparison of Optimization Effect of Characteristic Wavelengths. LWT 2022, 164, 113657. [Google Scholar] [CrossRef]

- Shahin, M.A.; Symons, S.J.; Hatcher, D.W. Quantification of Mildew Damage in Soft Red Winter Wheat Based on Spectral Characteristics of Bulk Samples: A Comparison of Visible-Near-Infrared Imaging and Near-Infrared Spectroscopy. Food Bioprocess Technol. 2014, 7, 224–234. [Google Scholar] [CrossRef]

- Luo, W.; Deng, J.; Li, C.; Jiang, H. Quantitative Analysis of Peanut Skin Adulterants by Fourier Transform Near-Infrared Spectroscopy Combined with Chemometrics. Foods 2025, 14, 466. [Google Scholar] [CrossRef]

- Zhou, H.; Fu, H.; Wu, X.; Wu, B.; Dai, C. Discrimination of Tea Varieties Based on FTIR Spectroscopy and an Adaptive Improved Possibilistic C-means Clustering. J. Food Process. Preserv. 2020, 44, e14795. [Google Scholar] [CrossRef]

- Wu, X.; Wang, Y.; Wu, B.; Sun, J. Classification of Fritillaria Using a Portable Near-Infrared Spectrometer and Fuzzy Generalized Singular Value Decomposition. Ind. Crops Prod. 2024, 218, 119032. [Google Scholar] [CrossRef]

- Malavi, D.; Nikkhah, A.; Alighaleh, P.; Einafshar, S.; Raes, K.; Van Haute, S. Detection of Saffron Adulteration with Crocus Sativus Style Using NIR-Hyperspectral Imaging and Chemometrics. Food Control 2024, 157, 110189. [Google Scholar] [CrossRef]

- Zhao, M.; Peng, Y.; Li, L. A Robot System for the Autodetection and Classification of Apple Internal Quality Attributes. Postharvest Biol. Technol. 2021, 180, 111615. [Google Scholar] [CrossRef]

- Wu, X.; Wang, Y.; He, C.; Wu, B.; Zhang, T.; Sun, J. Several Feature Extraction Methods Combined with Near-Infrared Spectroscopy for Identifying the Geographical Origins of Milk. Foods 2024, 13, 1783. [Google Scholar] [CrossRef]

- Ieong, H.F.; Yuan, Z. Abnormal Resting-State Functional Connectivity in the Orbitofrontal Cortex of Heroin Users and Its Relationship with Anxiety: A Pilot fNIRS Study. Sci. Rep. 2017, 7, 4652. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Cheng, J.; Xu, M.; Yao, K. A Method for Freshness Detection of Pork Using Two-Dimensional Correlation Spectroscopy Images Combined with Dual-Branch Deep Learning. J. Food Compos. Anal. 2024, 129, 106144. [Google Scholar] [CrossRef]

- Yasmin, J.; Ahmed, M.R.; Wakholi, C.; Lohumi, S.; Mukasa, P.; Kim, G.; Kim, J.; Lee, H.; Cho, B.-K. Near-Infrared Hyperspectral Imaging for Online Measurement of the Viability Detection of Naturally Aged Watermelon Seeds. Front. Plant Sci. 2022, 13, 98675. [Google Scholar] [CrossRef]

- Xin, P.; Liu, Y.; Yang, L.; Yan, H.; Feng, S.; Zheng, D. Nutritional Quality Analysis and Classification Detection of Buckwheat in Different Harvest Periods. Foods 2024, 13, 2576. [Google Scholar] [CrossRef]

- Wu, D.; Sun, D.-W. Advanced Applications of Hyperspectral Imaging Technology for Food Quality and Safety Analysis and Assessment: A Review—Part II: Applications. Innov. Food Sci. Emerg. Technol. 2013, 19, 15–28. [Google Scholar] [CrossRef]

- Feng, Y.-Z.; Sun, D.-W. Determination of Total Viable Count (TVC) in Chicken Breast Fillets by near-Infrared Hyperspectral Imaging and Spectroscopic Transforms. Talanta 2013, 105, 244–249. [Google Scholar] [CrossRef]

- Kamruzzaman, M.; Makino, Y.; Oshita, S. Non-Invasive Analytical Technology for the Detection of Contamination, Adulteration, and Authenticity of Meat, Poultry, and Fish: A Review. Anal. Chim. Acta 2015, 853, 19–29. [Google Scholar] [CrossRef]

- Jin, S.; Liu, X.; Wang, J.; Pan, L.; Zhang, Y.; Zhou, G.; Tang, C. Hyperspectral Imaging Combined with Fluorescence for the Prediction of Microbial Growth in Chicken Breasts under Different Packaging Conditions. LWT 2023, 181, 114727. [Google Scholar] [CrossRef]

- Mishra, G.; Panda, B.K.; Ramirez, W.A.; Jung, H.; Singh, C.B.; Lee, S.; Lee, I. Research Advancements in Optical Imaging and Spectroscopic Techniques for Nondestructive Detection of Mold Infection and Mycotoxins in Cereal Grains and Nuts. Comp. Rev. Food Sci. Food Safe 2021, 20, 4612–4651. [Google Scholar] [CrossRef]

- Dai, C.; Sun, J.; Huang, X.; Zhang, X.; Tian, X.; Wang, W.; Sun, J.; Luan, Y. Application of Hyperspectral Imaging as a Nondestructive Technology for Identifying Tomato Maturity and Quantitatively Predicting Lycopene Content. Foods 2023, 12, 2957. [Google Scholar] [CrossRef]

- Cao, Y.; Li, H.; Sun, J.; Zhou, X.; Yao, K.; Nirere, A. Nondestructive Determination of the Total Mold Colony Count in Green Tea by Hyperspectral Imaging Technology. J. Food Process Eng. 2020, 43, e13570. [Google Scholar] [CrossRef]

- Lu, B.; Jun, S.; Ning, Y.; Xiaohong, W.; Xin, Z. Identification of Tea White Star Disease and Anthrax Based on Hyperspectral Image Information. J. Food Process Eng. 2021, 44, e13584. [Google Scholar] [CrossRef]

- Ningqiu, T.; Jun, S.; Min, X.; Kunshan, Y.; Yan, C.; Dengjie, L. Identification of Fumigated and Dyed Lycium Barbarum by Hyperspectral Imaging Technology. J. Food Process Eng. 2022, 45, e13950. [Google Scholar] [CrossRef]

- Xu, M.; Sun, J.; Cheng, J.; Yao, K.; Wu, X.; Zhou, X. Non-destructive Prediction of Total Soluble Solids and Titratable Acidity in Kyoho Grape Using Hyperspectral Imaging and Deep Learning Algorithm. Int. J. Food Sci. Technol. 2023, 58, 9–21. [Google Scholar] [CrossRef]

- Zhou, X.; Sun, J.; Zhang, Y.; Tian, Y.; Yao, K.; Xu, M. Visualization of Heavy Metal Cadmium in Lettuce Leaves Based on Wavelet Support Vector Machine Regression Model and Visible-near Infrared Hyperspectral Imaging. J. Food Process Eng. 2021, 44, e13897. [Google Scholar] [CrossRef]

- Cheng, J.; Sun, J.; Yao, K.; Dai, C. Generalized and Hetero Two-Dimensional Correlation Analysis of Hyperspectral Imaging Combined with Three-Dimensional Convolutional Neural Network for Evaluating Lipid Oxidation in Pork. Food Control 2023, 153, 10994. [Google Scholar] [CrossRef]

- Tian, Y.; Sun, J.; Zhou, X.; Yao, K.; Tang, N. Detection of Soluble Solid Content in Apples Based on Hyperspectral Technology Combined with Deep Learning Algorithm. Food Process. Preserv. 2022, 46, e16414. [Google Scholar] [CrossRef]

- Shi, L.; Sun, J.; Zhang, B.; Wu, Z.; Jia, Y.; Yao, K.; Zhou, X. Simultaneous Detection for Storage Condition and Storage Time of Yellow Peach under Different Storage Conditions Using Hyperspectral Imaging with Multi-Target Characteristic Selection and Multi-Task Model. J. Food Compos. Anal. 2024, 135, 106647. [Google Scholar] [CrossRef]

- Tian, Y.; Sun, J.; Zhou, X.; Wu, X.; Lu, B.; Dai, C. Research on Apple Origin Classification Based on Variable Iterative Space Shrinkage Approach with Stepwise Regression—Support Vector Machine Algorithm and Visible-near Infrared Hyperspectral Imaging. J. Food Process Eng. 2020, 43, e13432. [Google Scholar] [CrossRef]

- Sun, J.; Nirere, A.; Dusabe, K.D.; Yuhao, Z.; Adrien, G. Rapid and Nondestructive Watermelon (Citrullus lanatus) Seed Viability Detection Based on Visible Near-infrared Hyperspectral Imaging Technology and Machine Learning Algorithms. J. Food Sci. 2024, 89, 4403–4441. [Google Scholar] [CrossRef]

- Cheng, J.; Sun, J.; Xu, M.; Zhou, X. Nondestructive Detection of Lipid Oxidation in Frozen Pork Using Hyperspectral Imaging Technology. J. Food Compos. Anal. 2023, 123, 105497. [Google Scholar] [CrossRef]

- Cheng, J.; Sun, J.; Yao, K.; Xu, M.; Dai, C. Multi-Task Convolutional Neural Network for Simultaneous Monitoring of Lipid and Protein Oxidative Damage in Frozen-Thawed Pork Using Hyperspectral Imaging. Meat Sci. 2023, 201, 109196. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Yang, F.; Cheng, J.; Wang, S.; Fu, L. Nondestructive Identification of Soybean Protein in Minced Chicken Meat Based on Hyperspectral Imaging and VGG16-SVM. J. Food Compos. Anal. 2024, 125, 10571. [Google Scholar] [CrossRef]

- Ahmad, H.; Sun, J.; Nirere, A.; Shaheen, N.; Zhou, X.; Yao, K. Classification of Tea Varieties Based on Fluorescence Hyperspectral Image Technology and ABC-SVM Algorithm. J. Food Process. Preserv. 2021, 45, e15241. [Google Scholar] [CrossRef]

- Yao, K.; Sun, J.; Zhou, X.; Nirere, A.; Tian, Y.; Wu, X. Nondestructive Detection for Egg Freshness Grade Based on Hyperspectral Imaging Technology. J. Food Process Eng. 2020, 43, e13422. [Google Scholar] [CrossRef]

- Kim, M.-J.; Yu, W.-H.; Song, D.-J.; Chun, S.-W.; Kim, M.S.; Lee, A.; Kim, G.; Shin, B.-S.; Mo, C. Prediction of Soluble-Solid Content in Citrus Fruit Using Visible–Near-Infrared Hyperspectral Imaging Based on Effective-Wavelength Selection Algorithm. Sensors 2024, 24, 1512. [Google Scholar] [CrossRef]

- Zhou, X.; Sun, J.; Tian, Y.; Lu, B.; Hang, Y.; Chen, Q. Hyperspectral Technique Combined with Deep Learning Algorithm for Detection of Compound Heavy Metals in Lettuce. Food Chem. 2020, 321, 126503. [Google Scholar] [CrossRef]

- Wang, S.; Sun, J.; Fu, L.; Xu, M.; Tang, N.; Cao, Y.; Yao, K.; Jing, J. Identification of Red Jujube Varieties Based on Hyperspectral Imaging Technology Combined with CARS-IRIV and SSA-SVM. J. Food Process Eng. 2022, 45, e14137. [Google Scholar] [CrossRef]

- Afsah-Hejri, L.; Akbari, E.; Toudeshki, A.; Homayouni, T.; Alizadeh, A.; Ehsani, R. Terahertz Spectroscopy and Imaging: A Review on Agricultural Applications. Comput. Electron. Agric. 2020, 177, 105628. [Google Scholar] [CrossRef]

- Ma, S.; Li, Y.; Peng, Y. Spectroscopy and Computer Vision Techniques for Noninvasive Analysis of Legumes: A Review. Comput. Electron. Agric. 2023, 206, 10769. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Wang, Y.; Hu, L.; Wang, P. Detection of Tomato Water Stress Based on Terahertz Spectroscopy. Front. Plant Sci. 2023, 14, 109543. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Wang, X.; Chen, K.; Han, C.; Guan, H.; Wang, Y.; Zhao, Y. Feasibility and Potential of Terahertz Spectral and Imaging Technology for Apple Valsa Canker Detection: A Preliminary Investigation. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2025, 327, 12530. [Google Scholar] [CrossRef]

- Wang, C.; Zhou, R.; Huang, Y.; Xie, L.; Ying, Y. Terahertz Spectroscopic Imaging with Discriminant Analysis for Detecting Foreign Materials among Sausages. Food Control 2019, 97, 100–104. [Google Scholar] [CrossRef]

- Nie, P.; Qu, F.; Lin, L.; He, Y.; Feng, X.; Yang, L.; Gao, H.; Zhao, L.; Huang, L. Trace Identification and Visualization of Multiple Benzimidazole Pesticide Residues on Toona Sinensis Leaves Using Terahertz Imaging Combined with Deep Learning. Int. J. Mol. Sci. 2021, 22, 3425. [Google Scholar] [CrossRef]

- Kou, T.; Ye, J.; Wang, J.; Peng, Y.; Wang, Z.; Shi, C.; Wu, X.; Hu, X.; Chen, H.; Zhang, L.; et al. Terahertz Spectroscopy for Accurate Identification of Panax Quinquefolium Basing on Nonconjugated 24(R)-Pseudoginsenoside F11. Plant Phenomics 2021, 2021, 6793457. [Google Scholar] [CrossRef]

- Wei, X.; Li, S.; Zhu, S.; Zheng, W.; Zhou, S.; Wu, W.; Xie, Z. Quantitative Analysis of Soybean Protein Content by Terahertz Spectroscopy and Chemometrics. Chemom. Intell. Lab. Syst. 2021, 208, 104199. [Google Scholar] [CrossRef]

- Shen, Y.; Yin, Y.; Li, B.; Zhao, C.; Li, G. Detection of Impurities in Wheat Using Terahertz Spectral Imaging and Convolutional Neural Networks. Comput. Electron. Agric. 2021, 181, 105931. [Google Scholar] [CrossRef]

- Jay, S.; Baret, F.; Thomas, S.; Weiss, M. Registration of Close-Range, Multi-Lens Multispectral Imagery by Retrieving the Scene 3D Structure. ISPRS J. Photogramm. Remote Sens. 2025, 227, 125–144. [Google Scholar] [CrossRef]

- Trabelsi, S.; Nelson, S.O. Free-Space Measurement of Dielectric Properties of Cereal Grain and Oilseed at Microwave Frequencies. Meas. Sci. Technol. 2003, 14, 589–600. [Google Scholar]

- Zhang, J.; Bao, Y.; Du, D.; Wang, J.; Wei, Z. OM2S2: On-Line Moisture-Sensing System Using Multifrequency Microwave Signals Optimized by a Two-Stage Frequency Selection Framework. IEEE Trans. Ind. Electron. 2021, 68, 11501–11510. [Google Scholar] [CrossRef]

- Li, C.; Zhao, C.; Ren, Y.; He, X.; Yu, X.; Song, Q. Microwave Traveling-Standing Wave Method for Density-Independent Detection of Grain Moisture Content. Measurement 2022, 198, 111373. [Google Scholar] [CrossRef]

- Hu, J.; Zhan, C.; Wang, Q.; Shi, H.; He, Y.; Ouyang, A. Research on Highly Sensitive Quantitative Detection of Aflatoxin B2 Solution Based on THz Metamaterial Enhancement. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2023, 300, 122809. [Google Scholar] [CrossRef]

- Abdolrazzaghi, M.; Daneshmand, M.; Iyer, A.K. Strongly Enhanced Sensitivity in Planar Microwave Sensors Based on Metamaterial Coupling. IEEE Trans. Microw. Theory Tech. 2018, 66, 1843–1855. [Google Scholar] [CrossRef]

- Abdolrazzaghi, M.; Nayyeri, V.; Martin, F. Techniques to Improve the Performance of Planar Microwave Sensors: A Review and Recent Developments. Sensors 2022, 22, 6946. [Google Scholar] [CrossRef]

- Guzik, P.; Kulawik, P.; Zając, M.; Migdał, W. Microwave Applications in the Food Industry: An Overview of Recent Developments. Crit. Rev. Food Sci. Nutr. 2022, 62, 7989–8008. [Google Scholar] [CrossRef]

- Xu, L.; Chen, Z.; Bai, X.; Deng, J.; Zhao, X.; Jiang, H. Determination of Aflatoxin B1 in Peanuts Based on Millimetre Wave. Food Chem. 2025, 464, 141867. [Google Scholar] [CrossRef]

- Xu, J.; Riccioli, C.; Sun, D. An Overview on Nondestructive Spectroscopic Techniques for Lipid and Lipid Oxidation Analysis in Fish and Fish Products. Comp. Rev. Food Sci. Food Safe 2015, 14, 466–477. [Google Scholar] [CrossRef]

- Richert, R. On Revealing Structural Relaxation of Ionic Liquids by High-Field Dielectric Techniques. J. Non-Cryst. Solids 2023, 616, 122483. [Google Scholar] [CrossRef]

- Kraszewski, W.; Nelson, S.O. Microwave resonator for sensing moisture. Can. Agric. Eng. 1994, 36, 231–238. [Google Scholar]

- Nelson, S.O.; Kraszewski, A.W.; Trabelsi, S.; Lawrence, K.C. Using Cereal Grain Permittivity for Sensing Moisture Content. IEEE Trans. Instrum. Meas. 2000, 49, 470–475. [Google Scholar] [CrossRef]

- Zhong, R.; Xiang, T.; Zheng, Q.; Xu, B. Measurement and Analysis of Dielectric Properties of Agricultural By-Product Powders in Microwave Frequency Range. E3S Web Conf. 2019, 78, 02012. [Google Scholar] [CrossRef]

- El-Mesery, H.S.; Mao, H.; Abomohra, A.E.-F. Applications of Non-Destructive Technologies for Agricultural and Food Products Quality Inspection. Sensors 2019, 19, 846. [Google Scholar] [CrossRef] [PubMed]

- Nitika; Kaur, J.; Khanna, R. Exploration of Adulteration in Common Raw Spices Using Antenna-Based Sensor. Int. J. Microw. Wirel. Technol. 2023, 15, 1117–1129. [Google Scholar] [CrossRef]

- Abduljabar, A.A.; Porch, A.; Barrow, D.A. Real-Time Measurements of Size, Speed, and Dielectric Property of Liquid Segments Using a Microwave Microfluidic Sensor. In Proceedings of the 2014 IEEE MTT-S International Microwave Symposium (IMS2014), Tampa, FL, USA, 1–6 June 2014; pp. 1–4. [Google Scholar]

- Wang, J.; Wang, H.; Cheng, L.; Fang, W.; Zhang, X.; Tao, B.; Liao, R. Terahertz Relaxation Polarization Modeling of Micro-Water inside Nano-Modified Dielectrics and Imaging Distribution of Free/Bound Water. Polym. Test. 2023, 122, 108031. [Google Scholar] [CrossRef]

- Chen, Y.; Fanourakis, D.; Tsaniklidis, G.; Aliniaeifard, S.; Yang, Q.; Li, T. Low UVA Intensity during Cultivation Improves the Lettuce Shelf-Life, an Effect That Is Not Sustained at Higher Intensity. Postharvest Biol. Technol. 2021, 172, 111376. [Google Scholar] [CrossRef]

- Jiao, X.; Yang, H.; Li, X.; Cao, H.; Zhang, N.; Yan, B.; Hu, B.; Huang, J.; Zhao, J.; Zhang, H.; et al. Green and Sustainable Microwave Processing of Surimi Seafood: A Review of Protein Component Interactions, Mechanisms, and Industrial Applications. Trends Food Sci. Technol. 2024, 143, 104266. [Google Scholar] [CrossRef]

- Chen, Y.-F.; Zheng, Y.-T.; Zhang, F.-Y.; Liu, Z.-G.; Zhang, L.-Y.; Yang, L.; Sun, X.-D.; Deng, Y.; Wang, Y. High-Temperature Polymer-Based Nanocomposites for High Energy Storage Performance with Robust Cycling Stability. Rare Met. 2023, 42, 3682–3691. [Google Scholar] [CrossRef]

- Zhong, R.; Zheng, Q.; Yao, B.; Xiang, T. A Modified Formula for Calculating Dielectric Properties of Granular Agricultural Products in the Microwave Band. E3S Web Conf. 2021, 245, 01002. [Google Scholar] [CrossRef]

- Trabelsi, S.; Paz, A.M.; Nelson, S.O. Microwave Dielectric Method for the Rapid, Non-Destructive Determination of Bulk Density and Moisture Content of Peanut Hull Pellets. Biosyst. Eng. 2013, 115, 332–338. [Google Scholar] [CrossRef]

- Yoshikawa, N.; Kawahira, K.; Saito, Y.; Todoroki, H.; Taniguchi, S. Estimation of Microwave Penetration Distance and Complex Permittivity of Graphite by Measurement of Permittivity and Direct Current Conductivity of Graphite Powder Mixtures. J. Appl. Phys. 2015, 117, 084105. [Google Scholar] [CrossRef]

- Tang, S.-Y.; Xia, Z.-N.; Fu, Y.-J.; Gou, Q. Advances and Applications of Microwave Spectroscopy. Chin. J. Anal. Chem. 2008, 36, 1145–1151. [Google Scholar] [CrossRef]

- Jang, J.; Park, J.; Shin, H.J. Terahertz Spectral Analysis: An in-Depth Exploration of Spectroscopy Approaches for Ultrafast Dynamics. Curr. Appl Phys. 2024, 59, 197–207. [Google Scholar] [CrossRef]

- Zeng, S.; Zhang, H.; Wang, B.; Zhang, Q.; Lv, H.; Yang, L.; Zhao, D.; Lv, W.; Xiao, H. Advancements in Green and Innovative Low Frequency Microwaves for Agricultural Product Processing: A Comprehensive Review. Food Rev. Int. 2025, 1–21. [Google Scholar] [CrossRef]

- Krupka, J.; Derzakowski, K.; Hartnett, J.G. Measurements of the Complex Permittivity and the Complex Permeability of Low and Medium Loss Isotropic and Uniaxially Anisotropic Metamaterials at Microwave Frequencies. Meas. Sci. Technol. 2009, 20, 10570. [Google Scholar] [CrossRef]

- Xu, L.; Ni, L.; Deng, J.; Bai, X.; Jiang, H. Feasibility Study on Rapid Determination of Aflatoxin B1 in Wheat by Self-Made Microwave Detection Device. Microchem. J. 2022, 182, 107869. [Google Scholar] [CrossRef]

- Gao, Z.; Nanayakkara, O. Application Research of Microwave Non-Destructive Testing Technology in Detecting Reinforcement Corrosion in Concrete. MATEC Web Conf. 2025, 409, 03004. [Google Scholar] [CrossRef]

- Menzel, M.I.; Tittmann, S.; Bühler, J.; Preis, S.; Wolters, N.; Jahnke, S.; Walter, A.; Chlubek, A.; Leon, A.; Hermes, N.; et al. Non-invasive Determination of Plant Biomass with Microwave Resonators. Plant Cell Environ. 2009, 32, 368–379. [Google Scholar] [CrossRef]

- Zhu, Z.; Guo, W. Frequency, Moisture Content, and Temperature Dependent Dielectric Properties of Potato Starch Related to Drying with Radio-Frequency/Microwave Energy. Sci. Rep. 2017, 7, 9311. [Google Scholar] [CrossRef]

- Matsuo, M.; Osada, A.; Kon, S. Non-destructive Prediction of Forage Crop Moisture Contents Using Microwave Transmitted Signals with a Microstrip Transmission Line Sensor. Grassl. Sci. 2020, 66, 225–230. [Google Scholar] [CrossRef]

- Li, Z.; Meng, Z.; Soutis, C.; Wang, P.; Gibson, A. Detection and Analysis of Metallic Contaminants in Dry Foods Using a Microwave Resonator Sensor. Food Control 2022, 133, 108634. [Google Scholar] [CrossRef]

- Reimer, A.; Wiebe, K.; Rao, J.; Yao, B.; Gui, Y.; Jian, F.; Fields, P.; Jayas, D.S.; Hu, C.-M. A Compact Microwave Device for Monitoring Insect Activity in Grain Samples. Biosyst. Eng. 2018, 175, 27–35. [Google Scholar] [CrossRef]

- Xie, J.; Chen, J.; Li, Z.; Yuan, W. Flexible Microwave Sensor Films Based on Nested-Complementary Split Ring Resonator for Liquid Dielectric Constant Detection. Sens. Actuators A 2023, 359, 114461. [Google Scholar] [CrossRef]

- Kuang, X.; Zhu, Z.; Guo, J.; Xiang, S. Non-Destructive Detection of Wheat Moisture Content with Frequency Modulated Continuous Wave System under L and S Bands. Comput. Electron. Agric. 2024, 227, 109644. [Google Scholar] [CrossRef]

- Yadav, D.N.; Anand, T.; Sharma, M.; Gupta, R.K. Microwave Technology for Disinfestation of Cereals and Pulses: An Overview. J. Food Sci. Technol. 2014, 51, 3568–3576. [Google Scholar] [CrossRef] [PubMed]

- Varzakas, T. Quality and Safety Aspects of Cereals (Wheat) and Their Products. Crit. Rev. Food Sci. Nutr. 2016, 56, 2495–2510. [Google Scholar] [CrossRef] [PubMed]

- LeBlanc, A.P.; Trabelsi, S.; Rasheed, K.; Miller, J.A. Machine Learning Algorithms for Nondestructive Sensing of Moisture Content in Grain and Seed. IEEE Open J. Instrum. Meas. 2025, 4, 2500214. [Google Scholar] [CrossRef]

- Slima, M.B.; Morawski, R.Z.; Kraszewski, A.W.; Barwicz, A.; Nelson, S.O. Calibration of a Microwave System for Measuring Grain Moisture Content. IEEE Trans. Instrum. Meas. 1999, 48, 778–783. [Google Scholar] [CrossRef]

- Koyama, C.N.; Liu, H.; Takahashi, K.; Shimada, M.; Watanabe, M.; Khuut, T.; Sato, M. In-Situ Measurement of Soil Permittivity at Various Depths for the Calibration and Validation of Low-Frequency SAR Soil Moisture Models by Using GPR. Remote Sens. 2017, 9, 580. [Google Scholar] [CrossRef]

- Muzalevskiy, K.; Fomin, S.; Karavayskiy, A. Optimum Frequency Range for Remote Sensing of Soil Moisture with Various Texture, Density and Organic Matter Content. In Proceedings of the 2022 IEEE International Multi-Conference on Engineering, Computer and Information Sciences (SIBIRCON), Yekaterinburg, Russia, 11 November 2022; pp. 1130–1133. [Google Scholar]

- Trabelsi, S.; Nelson, S.O. Microwave Sensing of Quality Attributes of Agricultural and Food Products. IEEE Instrum. Meas. Mag. 2016, 19, 37–41. [Google Scholar] [CrossRef]

- Xie, C.; Yang, L.; Zhang, D.; Cui, T.; Zhang, K.; He, X.; Du, Z. Design of Smart Seed Sensor Based on Microwave Detection Method and Signal Calculation Model. Comput. Electron. Agric. 2022, 199, 107178. [Google Scholar] [CrossRef]

- Zainal Abidin, Z.; Omar, F.N.; Biak, D.R.A.; Man, Y.C. Alternative for Rapid Detection and Screening of Pork, Chicken, and Beef Using Dielectric Properties in the Frequency of 0.5 to 50 GHz. Int. J. Food Prop. 2016, 19, 1127–1138. [Google Scholar] [CrossRef]

- Lei, D.; Xie, Y.; Jia, Z.; Sun, W.; Peng, Z.; Liu, Y. Dielectric Properties of In-Shell Peanuts with Radio Frequency and Microwave Heating Treatment and RF Heating Performance. Postharvest Biol. Technol. 2024, 211, 112800. [Google Scholar] [CrossRef]

- Li, M.; Hou, T.; Cai, C.; Lv, Z.; Wu, Y.; Qin, Y. Nondestructive Wheat Moisture Detection System with Metasurface Plane Wave Antenna and De-Embedding Algorithm. IEEE Trans. Instrum. Meas. 2023, 72, 1–9. [Google Scholar] [CrossRef]

- Kumar, S.V.; Peters-Lidard, C.D.; Arsenault, K.R.; Getirana, A.; Mocko, D.; Liu, Y. Quantifying the Added Value of Snow Cover Area Observations in Passive Microwave Snow Depth Data Assimilation. J. Hydrometeorol. 2015, 16, 1736–1741. [Google Scholar] [CrossRef]

- Jawad, H.; Lanteri, J.; Migliaccio, C.; Pichot, C.; Platt, I.G.; Tan, A.E.-C.; Eccleston, K.W.; Woodhead, I.M. Microwave Modeling and Experiments for Non Destructive Control Improved Quality of Fruit. In Proceedings of the 2017 IEEE Conference on Antenna Measurements & Applications (CAMA), Tsukuba, Japan, 4–6 December 2017; pp. 124–127. [Google Scholar]

- Wahab, A.; Aziz, M.M.A.; Sam, A.R.M.; You, K.Y.; Bhatti, A.Q.; Kassim, K.A. Review on Microwave Nondestructive Testing Techniques and Its Applications in Concrete Technology. Constr. Build. Mater. 2019, 209, 135–146. [Google Scholar] [CrossRef]

- Nelson, S.O.; Trabelsi, S. Principles for Microwave Moisture and Density Measurement in Grain and Seed. J. Microw. Power Electromagn. Energy 2004, 39, 107–117. [Google Scholar] [CrossRef]

- Ramli, N.A.M.; Rahiman, M.H.F.; Kamarudin, L.M.; Zakaria, A.; Mohamed, L. A Review on Frequency Selection in Grain Moisture Content Detection. IOP Conf. Ser. Mater. Sci. Eng. 2019, 705, 012002. [Google Scholar] [CrossRef]

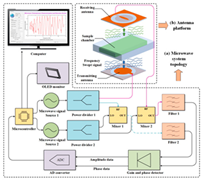

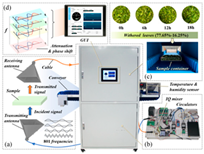

- Deng, J.; Ni, L.; Bai, X.; Jiang, H.; Xu, L. Simultaneous Analysis of Mildew Degree and Aflatoxin B1 of Wheat by a Multi-Task Deep Learning Strategy Based on Microwave Detection Technology. LWT 2023, 184, 115047. [Google Scholar] [CrossRef]

- Liu, J.; Qiu, S.; Wei, Z. Real-Time Measurement of Moisture Content of Paddy Rice Based on Microstrip Microwave Sensor Assisted by Machine Learning Strategies. Chemosensors 2022, 10, 37. [Google Scholar] [CrossRef]

- Tlili, M.; Deshours, F.; Alquié, G.; Kokabi, H.; Hardinata, S.; Koskas, F. Microwave Resonant Sensor for Non-Invasive Characterization of Biological Tissues. IRBM 2018, 39, 445–450. [Google Scholar] [CrossRef]

- Zhang, J.; Li, M.; Cheng, J.; Wang, J.; Ding, Z.; Yuan, X.; Zhou, S.; Liu, X. Effects of Moisture, Temperature, and Salt Content on the Dielectric Properties of Pecan Kernels during Microwave and Radio Frequency Drying Processes. Foods 2019, 8, 385. [Google Scholar] [CrossRef]

- Jones, S.B.; Sheng, W.; Or, D. Dielectric Measurement of Agricultural Grain Moisture—Theory and Applications. Sensors 2022, 22, 2083. [Google Scholar] [CrossRef] [PubMed]

- Tripathi, M.; Sahu, J.N.; Ganesan, P.; Monash, P.; Dey, T.K. Effect of Microwave Frequency on Dielectric Properties of Oil Palm Shell (OPS) and OPS Char Synthesized by Microwave Pyrolysis of OPS. J. Anal. Appl. Pyrolysis 2015, 112, 306–312. [Google Scholar] [CrossRef]

- Bai, X.; Ni, L.; Deng, J.; Zhao, X.; Xu, L.; Jiang, H. Quantitative Determination of Wheat Moisture Content Based on Microwave Detection Technique Combined with Multivariate Data Analysis. J. Stored Prod. Res. 2024, 105, 102237. [Google Scholar] [CrossRef]

- Dong, J.; Shen, F.; Dong, Y.; Wang, Y.; Fu, W.; Li, H.; Ye, D.; Zhang, B.; Huangfu, J.; Qiao, S.; et al. Noncontact Measurement of Complex Permittivity of Electrically Small Samples at Microwave Frequencies. IEEE Trans. Microw. Theory Techn. 2016, 64, 2883–2893. [Google Scholar] [CrossRef]

- Gilmore, C.; Zakaria, A.; Mojabi, P.; Ostadrahimi, M.; Pistorius, S.; Vetri, J.L. The University of Manitoba microwave imaging repository: A two-dimensional microwave scattering database for testing inversion and calibration algorithms [measurements corner]. IEEE Antennas Propag. Mag. 2011, 535, 126–133. [Google Scholar] [CrossRef]

- Li, M.; Ma, Y.; Pan, Q.; Qin, Y.; Yuan, M.; Wu, Y.; Cai, C. Density-Independent Wheat Moisture Content Detection Based on DMLA. J. Food Eng. 2025, 388, 112390. [Google Scholar] [CrossRef]

- McKeown, M.S.; Trabelsi, S.; Nelson, S.O.; Tollner, E.W. Microwave Sensing of Moisture in Flowing Biomass Pellets. Biosyst. Eng. 2017, 155, 152–160. [Google Scholar] [CrossRef]

- Li, C.; Yu, X.; Chen, Z.; Song, Q.; Xu, Y. Free Space Traveling–Standing Wave Attenuation Method for Microwave Sensing of Grain Moisture Content. Meas. Control. 2021, 54, 336–345. [Google Scholar] [CrossRef]

- Trabelsi, S.; Nelson, S.O. Microwave Sensing Technique for Nondestructive Determination of Bulk Density and Moisture Content in Unshelled and Shelled Peanuts. Trans. ASABE 2006, 49, 1563–1568. [Google Scholar] [CrossRef]

- Ma, F.; Wang, D.; Yin, Y.; Yin, H.; Song, C.; Xu, X.; Sun, Y.; Xue, Y.; Zhao, L. Determining Peanut Moisture Content by Scattering Coefficient. J. Food Eng. 2023, 344, 111398. [Google Scholar] [CrossRef]

- Julrat, S.; Trabelsi, S. Influence of Peanut Orientation on Microwave Sensing of Moisture Content in Cleaned Unshelled Peanuts. IEEE Sensors J. 2022, 22, 10515–10523. [Google Scholar] [CrossRef]

- Zhou, B.; Yuan, Y.; Wei, Z.; Li, S. A Non-Destructive Moisture Detection System for Unshelled Green Tea Seed Kernels Based on Microwave Technology with Multi-Frequency Scanning Signals. Sensors 2025, 25, 1324. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.; Qian, J.; Zhang, J.; Wang, J.; Li, B.; Wei, Z. Moisture Measurement of Tea Leaves during Withering Using Multifrequency Microwave Signals Optimized by Ant Colony Optimization. J. Food Eng. 2022, 335, 111174. [Google Scholar] [CrossRef]

- Yan, Y.; Lin, X.; Chen, Z.; Cai, Y.; Chen, Z. A Microwave Sensor for Leaf Moisture Detection Based on Split-Ring Resonator. In Proceedings of the 2020 IEEE Asia-Pacific Microwave Conference (APMC), Hong Kong, China, 8 December 2020; pp. 427–429. [Google Scholar]

- Dadshani, S.; Kurakin, A.; Amanov, S.; Hein, B.; Rongen, H.; Cranstone, S.; Blievernicht, U.; Menzel, E.; Léon, J.; Klein, N.; et al. Non-Invasive Assessment of Leaf Water Status Using a Dual-Mode Microwave Resonator. Plant Methods 2015, 11, 8. [Google Scholar] [CrossRef]

- Bhattacharya, R.; Cornell, K.; Browning, J. Simulation of a Radio-Frequency Wave Based Bacterial Biofilm Detection Method in Dairy Processing Facilities. Appl. Sci. 2024, 14, 4342. [Google Scholar] [CrossRef]

- Lewis, M.A.; Trabelsi, S.; Bennett, R.S.; Chamberlin, K.D. Utilization of a Resonant Cavity for Characterization of Single In-Shell Peanuts. Food Anal. Methods 2024, 17, 855–866. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, J.; Cao, J.; Mao, B. Microwave Metamaterial Absorber for Non-Destructive Sensing Applications of Grain. Sensors 2018, 18, 1912. [Google Scholar] [CrossRef]

- Dyroff, C.; Weibring, P.; Fried, A.; Richter, D.; Walega, J.G.; Zahn, A.; Freude, W.; Werle, P. Stark-Enhanced Diode-Laser Spectroscopy of Formaldehyde Using a Modified Herriott-Type Multipass Cell. Appl. Phys. B Lasers Opt. 2007, 88, 117–123. [Google Scholar] [CrossRef]

- Feng, L.; Zhang, M.; Dong, Z.; Guo, J.; Zhang, H.; Liu, Z. Electrical Impedance Spectroscopy: Potential Non-Destructive Method for Aflatoxin B1 in Peanut. J. Food Meas. Charact. 2024, 18, 9353–9363. [Google Scholar] [CrossRef]

- Soulier, M.; Maho, T.; Lo, J.; Guillot, P.; Muja, C. Bread Wheat (Triticum aestivum L.) Fungal and Mycotoxin Contamination Control Enhanced by a Dual-Frequency Cold Plasma. Food Control 2024, 163, 110477. [Google Scholar] [CrossRef]

- Hussein, M.I.; Jithin, D.; Rajmohan, I.J.; Sham, A.; Saeed, E.E.M.A.; AbuQamar, S.F. Microwave Characterization of Hydrophilic and Hydrophobic Plant Pathogenic Fungi Using Open-Ended Coaxial Probe. IEEE Access 2019, 7, 45841–45849. [Google Scholar] [CrossRef]

- Deng, J.; Zhao, X.; Luo, W.; Bai, X.; Xu, L.; Jiang, H. Microwave Detection Technique Combined with Deep Learning Algorithm Facilitates Quantitative Analysis of Heavy Metal Pb Residues in Edible Oils. J. Food Sci. 2024, 89, 6005–6015. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Chen, Z.; Deng, J.; Bai, X.; Gao, Y.; Jiang, H. Rapid Quantitative and Qualitative Analysis of Talcum Powder in Wheat Flour by Microwave Detection Combined with Multivariate Analysis. Microchem. J. 2024, 204, 111125. [Google Scholar] [CrossRef]

- Anjaneyulu, B.; Reddy, N.S.S. Design of Low Power High-Speed Full, Swing 11T CNTFET Adder. e-Prime Adv. Electr. Eng. Electron. Energy 2024, 8, 100516. [Google Scholar] [CrossRef]

- Voinigescu, S.P.; Dickson, T.O.; Beerkens, R.; Khalid, I.; Westgaard, P. A Comparison of Si CMOS, SiGe BiCMOS, and InP HBT Technologies for High-Speed and Millimeter-Wave ICs. In Proceedings of the Digest of Papers. 2004 Topical Meeting on Silicon Monolithic Integrated Circuits in RF Systems, Atlanta, GA, USA, 8–10 September 2004; pp. 111–114. [Google Scholar]

- Wan, J.; Fei, Z.; Liu, Z.; Qi, Q.; Han, F.; Li, X.; Chen, Z. A 20.65-to-40.55 GHz Dual-Core Quad-Mode VCO with Mode-Independent Transformer-Switching Technique in 65-Nm CMOS. IEEE Trans. Circuits Syst. II 2023, 70, 4073–4077. [Google Scholar] [CrossRef]

- Liu, X.; Chao, Y.; Luong, H.C. A 59-to-276-GHz CMOS Signal Generator Using Varactor-Less VCO and Dual-Mode ILFD. IEEE J. Solid-State Circuits 2021, 56, 2324–2334. [Google Scholar] [CrossRef]

- Fan, L.-F.; Chai, Z.-Q.; Zhao, P.-F.; Tian, Z.-F.; Wen, S.-Q.; Li, S.-M.; Wang, Z.-Y.; Huang, L. Nondestructive Measurement of Husk-Covered Corn Kernel Layer Dynamic Moisture Content in the Field. Comput. Electron. Agric. 2021, 182, 106034. [Google Scholar] [CrossRef]

- Min, H.; Cho, B.-K. Spectroscopic Techniques for Nondestructive Detection of Fungi and Mycotoxins in Agricultural Materials: A Review. J. Biosyst. Eng. 2015, 40, 67–77. [Google Scholar] [CrossRef]

- Vuran, M.C.; Lunar, M.M.; Nie, S.; Ge, Y.; Pitla, S.; Bai, G.; Koksal, C.E. Millimeter-Wave Agricultural Channel Measurements in Corn and Soybean Fields at Different Growth Stages. In Proceedings of the 2022 IEEE International Symposium on Antennas and Propagation and USNC-URSI Radio Science Meeting (AP-S/URSI), Denver, CO, USA, 10 July 2022; pp. 1686–1687. [Google Scholar]

- Cui, F.; Dong, G.; Chen, B.; Yong, P.; Peng, S. Application of Ground Penetrating Radar Technology in Moisture Content Detection of Stored Grain. J. Agric. Eng. 2023, 54, 1472. [Google Scholar]

- Pattanayak, S.S.; Laskar, S.H.; Sahoo, S. Progress on Agricultural Residue-Based Microwave Absorber: A Review and Prospects. J. Mater. Sci. 2021, 56, 4097–4119. [Google Scholar] [CrossRef]

- Geisslitz, S.; Longin, C.F.H.; Scherf, K.A.; Koehler, P. Comparative Study on Gluten Protein Composition of Ancient (Einkorn, Emmer and Spelt) and Modern Wheat Species (Durum and Common Wheat). Foods 2019, 8, 409. [Google Scholar] [CrossRef] [PubMed]

- Wu, K.; Lambot, S. Effect of Radar Incident Angle on Full-Wave Inversion for the Retrieval of Medium Surface Permittivity for Drone-Borne Applications. IEEE Trans. Geosci. Remote Sens. 2022, 60, 1–10. [Google Scholar] [CrossRef]

- Xu, Z.; Li, H.; Jin, X.; Su, F.; Xu, G.; Lambot, S. A Synergistic GPR Approach of Back Projection Algorithm and Full-Wave Inversion for Reconstruction in Unknown Multilayered Environments. IEEE Trans. Geosci. Remote Sens. 2024, 62, 1–18. [Google Scholar] [CrossRef]

- El-Aassar, O.; Rebeiz, G.M. Octave-Tuning Dual-Core Folded VCO Leveraging a Triple-Mode Switch-Less Tertiary Magnetic Loop. IEEE J. Solid-State Circuits 2021, 56, 1475–1486. [Google Scholar] [CrossRef]

- Liao, Y.; Wang, K.; Zhu, H.; Ji, X. Crosstalk in CMOS Terahertz Detector Array with On-Chip SPR Antenna. IEEE Photonics J. 2022, 14, 1–6. [Google Scholar] [CrossRef]

- Zhong, S.; Su, L.; Xu, M.; Loke, D.; Yu, B.; Zhang, Y.; Zhao, R. Recent Advances in Artificial Sensory Neurons: Biological Fundamentals, Devices, Applications, and Challenges. Nano Micro Lett. 2024, 17, 61. [Google Scholar] [CrossRef]

- Rogdakis, K.; Psaltakis, G.; Fagas, G.; Quinn, A.; Martins, R.; Kymakis, E. Hybrid Chips to Enable a Sustainable Internet of Things Technology: Opportunities and Challenges. Discov. Mater. 2024, 4, 4. [Google Scholar] [CrossRef]

- Hasler, J.; Hao, C. Programmable Analog System Benchmarks Leading to Efficient Analog Computation Synthesis. ACM Trans. Reconfig. Technol. Syst. 2024, 17, 1–25. [Google Scholar] [CrossRef]

- Fujishima, M. Key Technologies for THz Wireless Link by Silicon CMOS Integrated Circuits. Photonics 2018, 5, 50. [Google Scholar] [CrossRef]

- Joseph, A.; Dahlstrom, M.; Liu, Q.; Orner, B.; Liu, X.; Sheridan, D.; Rassel, R.; Dunn, J.; Ahlgren, D. SiGe HBT BiCMOS Technology for Millimeter-wave Applications. Phys. Status Solidi C 2006, 3, 448–451. [Google Scholar] [CrossRef]

- Racanelli, M.; Kempf, P. SiGe BiCMOS Technology for RF Circuit Applications. IEEE Trans. Electron Devices 2005, 52, 1259–1270. [Google Scholar] [CrossRef]

- Soyuer, M.; Ainspan, H.A.; Meghelli, M.; Plouchart, J.-O. Low-Power Multi-GHz and Multi-Gb/s SiGe BiCMOS Circuits. Proc. IEEE 2000, 88, 1572–1582. [Google Scholar] [CrossRef]

- Preisler, E. A Commercial Foundry Perspective of SiGe BiCMOS Process Technologies. In Proceedings of the 2020 IEEE BiCMOS and Compound Semiconductor Integrated Circuits and Technology Symposium (BCICTS), Monterey, CA, USA, 16 November 2020; pp. 1–5. [Google Scholar]

- Ghosh, S.; Sarkar, M.; Frentrup, M.; Kappers, M.J.; Oliver, R.A. Microstructure and Reflectance of Porous GaN Distributed Bragg Reflectors on Silicon Substrates. J. Appl. Phys. 2024, 136, 043105. [Google Scholar] [CrossRef]

- Kazior, T.E.; LaRoche, J.R.; Hoke, W.E. More Than Moore: GaN HEMTs and Si CMOS Get It Together. In Proceedings of the 2013 IEEE Compound Semiconductor Integrated Circuit Symposium (CSICS), Monterey, CA, USA, 13–16 October 2013; pp. 1–4. [Google Scholar]

- Yang, X.; Zhao, Z.; Wang, C.; Xu, J.; Liu, K.; Qiu, J. Analysis and Parameter Design of SiC-Based Current Source Inverter (CSI). World Electr. Veh. J. 2022, 13, 187. [Google Scholar] [CrossRef]

- Hamouche, H.; Shabat, M.M.; Zoppi, G. Field Enhancement in Hydrogen Storage by Periodic Layered Structures. Surf. Interfaces 2022, 32, 102085. [Google Scholar] [CrossRef]

- Singh, H.; Sharma, A.; Gupta, A.; Singhal, A. A Polarization-insensitive Metamaterial Absorber for Moisture-sensing Applications of Agriculture Products. Microw. Opt. Technol. Lett. 2023, 66, e33907. [Google Scholar] [CrossRef]

- Tian, S.; Yang, X.; Peng, H.; Zhang, T.; Gao, F.; Wu, J. Frequency Domain Time Reversal Adaptive Focusing on Nondestructive Testing Imaging Method for Composite Materials. J. Nondestruct. Eval. 2025, 44, 82. [Google Scholar] [CrossRef]

- Musa, A.; Hakim, M.L.; Alam, T.; Islam, M.T.; Alamri, S.; Alshammari, A.S.; Soliman, M.S. Permeability Negative Split Square Resonator for Solid Materials Dielectric Constant and Aqueous Solution pH Sensing Applications. Sens. Actuators A 2024, 369, 115107. [Google Scholar] [CrossRef]

- Kazemi, N.; Abdolrazzaghi, M.; Musilek, P.; Baladi, E. A Planar Compact Absorber for Microwave Sensing Based on Transmission-Line Metamaterials. IEEE Sens. J. 2024, 24, 41864–41874. [Google Scholar] [CrossRef]

- Chen, L.; Yu, X.; Gao, M.; Xu, C.; Zhang, J.; Zhang, X.; Zhu, M.; Cheng, Y. Renewable Biomass-Based Aerogels: From Structural Design to Functional Regulation. Chem. Soc. Rev. 2024, 53, 7489–7530. [Google Scholar] [CrossRef]

- Chen, T.; Li, S.; Sun, H. Metamaterials Application in Sensing. Sensors 2012, 12, 2742–2765. [Google Scholar] [CrossRef]

- Prasath, B.; Akila, M. AETC: An Automated Pest Detection and Classification Model Using Optimal Integration of Yolo + SSD and Adaptive Ensemble Transfer CNN with IoT-Assisted Pest Images. Knowl. Inf. Syst. 2024, 66, 7077–7108. [Google Scholar] [CrossRef]

- Song, Q.; Zhou, Y.; Jia, E.; Wang, J.; Zhang, M.; Zhang, B. Large Area Crystalline Weyl Semimetal with Nano Au Film Based Micro-Fold Line Array for THz Detector. Sci. China Technol. Sci. 2023, 66, 3267–3275. [Google Scholar] [CrossRef]

- Sitharthan, R.; Rajesh, M.; Vimal, S.; Saravana Kumar, E.; Yuvaraj, S.; Jacob Raglend, I.; Vengatesan, K. A Novel Autonomous Irrigation System for Smart Agriculture Using AI and 6G Enabled IoT Network. Microprocess. Microsyst. 2023, 101, 104905. [Google Scholar]

- Adamou Ismael, H.; Laguidi, A.; Mejdoub, Y. A Comparative Study on LPWAN Standards: Nb-IoT and LTE-M. ITM Web Conf. 2023, 52, 01007. [Google Scholar] [CrossRef]

- Palta, P.; Kaur, P.; Mann, K.S. Dielectric Behavior of Soil as a Function of Frequency, Temperature, Moisture Content and Soil Texture: A Deep Neural Networks Based Regression Model. J. Microw. Power Electromagn. Energy 2022, 56, 145–167. [Google Scholar] [CrossRef]

- Zhang, H.; He, L.; Gioia, F.D.; Choi, D.; Elia, A.; Heinemann, P. LoRaWAN Based Internet of Things (IoT) System for Precision Irrigation in Plasticulture Fresh-Market Tomato. Smart Agric. Technol. 2022, 2, 100053. [Google Scholar] [CrossRef]

- Marini, R.; Mikhaylov, K.; Pasolini, G.; Buratti, C. Low-Power Wide-Area Networks: Comparison of LoRaWAN and NB-IoT Performance. IEEE Internet Things J. 2022, 9, 21051–21063. [Google Scholar] [CrossRef]

- Xiong, R.; Liang, C.; Zhang, H.; Xu, X.; Luo, J. FlyingLoRa: Towards Energy Efficient Data Collection in UAV-Assisted LoRa Networks. Comput. Netw. 2023, 220, 109511. [Google Scholar] [CrossRef]

- Dangana, M.; Ansari, S.; Abbasi, Q.H.; Hussain, S.; Imran, M.A. Suitability of NB-IoT for Indoor Industrial Environment: A Survey and Insights. Sensors 2021, 21, 5284. [Google Scholar] [CrossRef] [PubMed]

- Nauman, A.; Jamshed, M.A.; Ahmad, Y.; Saad, M.; Bilal, M.; Shanmuganathan, V.; Kim, S.W. Injecting Cognitive Intelligence into Beyond-5G Networks: A MAC Layer Perspective. Comput. Electr. Eng. 2023, 108, 108717. [Google Scholar] [CrossRef]

- Sneha; Malik, P.; Sharma, R.; Ghosh, U.; Alnumay, W.S. Internet of Things and Long-Range Antenna’s; Challenges, Solutions and Comparison in next Generation Systems. Microprocess. Microsyst. 2023, 103, 104934. [Google Scholar] [CrossRef]

- Liu, X.; An, P.; Chen, Y.; Huang, X. An Improved Lossless Image Compression Algorithm Based on Huffman Coding. Multimed. Tools Appl. 2021, 81, 4781–4795. [Google Scholar] [CrossRef]

- Jang, Y.S.; Usman, M.R.; Usman, M.A.; Shin, S.Y. Swapped Huffman Tree Coding Application for Low-Power Wide-Area Network (LPWAN). In Proceedings of the 2016 International Conference on Smart Green Technology in Electrical and Information Systems (ICSGTEIS), Denpasar, Indonesia, 6–8 October 2016; pp. 53–58. [Google Scholar]

- Shahra, E.Q.; Wu, W.; Basurra, S.; Aneiba, A. Intelligent Edge-Cloud Framework for Water Quality Monitoring in Water Distribution System. Water 2024, 16, 196. [Google Scholar] [CrossRef]

- Pu, H.; Yu, J.; Sun, D.-W.; Wei, Q.; Wang, Z. Feature Construction Methods for Processing and Analysing Spectral Images and Their Applications in Food Quality Inspection. Trends Food Sci. Technol. 2023, 138, 726–737. [Google Scholar] [CrossRef]

- Srivastava, S.; Sadistap, S. Non-Destructive Sensing Methods for Quality Assessment of on-Tree Fruits: A Review. J. Food Meas. Charact. 2017, 12, 497–526. [Google Scholar] [CrossRef]

| Technical Dimension | NIR and FTIR | HIS | THz-TDS | Microwave | Millimeter Wave |

|---|---|---|---|---|---|

| Frequency range [3] | 700–2500 nm | 400–2500 nm | 0.1–10 THz | 300 MHz–3000 GHz | 30–300 GHz |

| 2.5–25 μm | |||||

| Major applications [66] | Surface composition analysis | Visualization of toxin distribution | Pesticide residue detection | Moisture detection | Trace toxin detection |

| Detecting sensitivity [66] | Tolerance ± 0.3–2.1 μg/kg | Tolerance 6.65 mg/k | Sensitivity 94.51–100% | Tolerance < 0.5% | Limit of detection 0.1 μg/kg |

| Scope of application [23] | Laboratory precision composition analysis | Imaging of toxin distribution in surface homogeneous samples | High-precision molecular fingerprinting in the laboratory | Real-time field testing | High value-added scenarios |

| Equipment cost [7,63] | Medium (tungsten halogen lamp + silicon-based detector) | High (high-precision spectrometer + imaging system) | Very high (cryogenic detector + precision optics) | Low (portable antenna + CMOS chip) | Medium (CMOS integrated design) |

| Field suitability [3] | Requires shading and is susceptible to dust disturbance | Dependent on a stable light source, with weak outdoor adaptability | Requires a dry nitrogen environment, complicated pre-treatment | Strong adaptability (stable operation in rain and fog) | Highly resistant to interference (supports real-time detection of dynamic environments) |

| Penetration [78] | Low (surface micron level) | Low (surface detection) | Medium (millimeters, suppressed by moisture) | High (centimeters, penetrating non-metallic materials) | High (millimeters to support package integrity testing) |

| Data dimensions and processing efficiency [49] | One-dimensional spectra with simple processing | Three-dimensional data cube, requiring dimensionality reduction | Time domain spectroscopy + imaging with terabytes of data | 1D/2D imaging with real-time processing | Multi-dimensional signal fusion with support for edge computing |

| Material | System | Detection Principle | Key Metrics | Ref. |

|---|---|---|---|---|

| Wheat |  | Combining Competitive Adaptive Re-weighted Sampling (CARS), Genetic Algorithm (GA), and Support Vector Regression (SVR) feature selection and modeling. | R2 = 0.976 | [129] |

| Wheat |  | Multi-band (L/S) dielectric response; Partial Least Squares (PLS)/SVR/Extreme Learning Machine (ELM) modeling | R2 = 0.984 | [104] |

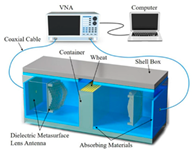

| Wheat |  | Dielectric Hypersurface Lens Antenna; density-independent calibration | RMSE = 0.178% | [132] |

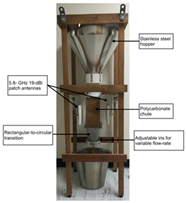

| Peanut-hull pellets and pine-sawdust pellets |  | Single-frequency (5.8 GHz) density-independent calibration via permittivity function | Moisture Root mean square deviation (RMSD) < 0.5% (flowing vs. static) at 0.2–3.2 kg/s flow rates | [133] |

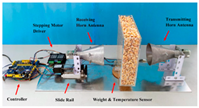

| Rice and maize |  | Traveling–standing wave attenuation | Rice: R2 = 0.988, SEP = 0.59% Maize: R2 = 0.991, SEP = 0.34% | [133] |

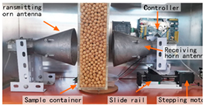

| Wheat and soybean |  | Traveling–standing wave nodes; density-independent calibration | Soybean: R2 = 0.995, SEP = 0.56% Wheat: R2 = 0.975, SEP = 0.98% | [73] |

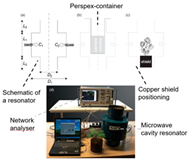

| Single in-shell peanuts |  | Resonant cavity perturbation at 3.7–4.1 GHz (measuring Δf, Q factor, S21); dielectric property calculation | AI classification accuracy: 86.3% (89.5% training) Intact/Empty ID accuracy: 91%/100% | [143] |

| Peanut (shelled) |  | Scattering parameters (S-parameters); Fully Connected Deep Neural Network (FC-DNN) modeling | SEP = 0.56% | [136] |

| Peanut |  | Dielectric method (pellets) | R2 = 1.000, RMSE = 0.159% | [92] |

| Unshelled tea seeds |  | Multi-frequency (2–10 GHz) microwave scanning (attenuation and phase shift spectra) with ANN modeling and moisture calibration function | ANN R2 = 0.988–0.996 for seed MC; calibrated kernel MC R2 = 0.989; and MC range: 6.94–26.88% wet basis | [138] |

| Tea leaves |  | Multi-frequency optimization (Ant Colony Optimization), stacked ensemble modeling | R2 = 0.994 | [139] |

| Oil–water mixtures |  | Nested-Complementary Split Ring Resonator (NCSRR); resonance frequency shift | An increase in the dielectric constant of the liquid to be measured leads to a linear decrease in the resonant frequency of the sensor | [105] |

| Tomato and tobacco |  | Microwave resonator; dielectric shift vs. fresh weight | Tomato: R2 = 0.93 Tobacco: R2 = 0.81 | [100] |

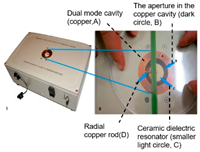

| Plant leaves |  | Dual-frequency resonator (2.4 GHz/150 MHz); water content and ionic conductivity | Correlation (p < 0.05) | [141] |

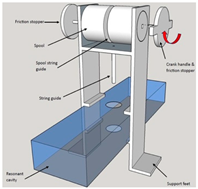

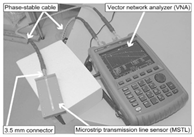

| Silage |  | Microstrip transmission line; phase-amplitude ratio (Δφ/ΔA) | Barley: R2 = 0.962 Maize: R2 = 0.808 | [142] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, R.; Xu, L.; Bai, X.; Chen, J. Principles, Applications, and Future Evolution of Agricultural Nondestructive Testing Based on Microwaves. Sensors 2025, 25, 4783. https://doi.org/10.3390/s25154783

Tao R, Xu L, Bai X, Chen J. Principles, Applications, and Future Evolution of Agricultural Nondestructive Testing Based on Microwaves. Sensors. 2025; 25(15):4783. https://doi.org/10.3390/s25154783

Chicago/Turabian StyleTao, Ran, Leijun Xu, Xue Bai, and Jianfeng Chen. 2025. "Principles, Applications, and Future Evolution of Agricultural Nondestructive Testing Based on Microwaves" Sensors 25, no. 15: 4783. https://doi.org/10.3390/s25154783

APA StyleTao, R., Xu, L., Bai, X., & Chen, J. (2025). Principles, Applications, and Future Evolution of Agricultural Nondestructive Testing Based on Microwaves. Sensors, 25(15), 4783. https://doi.org/10.3390/s25154783