Predictive Maintenance System to RUL Prediction of Li-Ion Batteries and Identify the Fault Type of Brushless DC Electric Motor from UAVs

Abstract

1. Introduction

1.1. State of Art

1.2. Structure of the Work

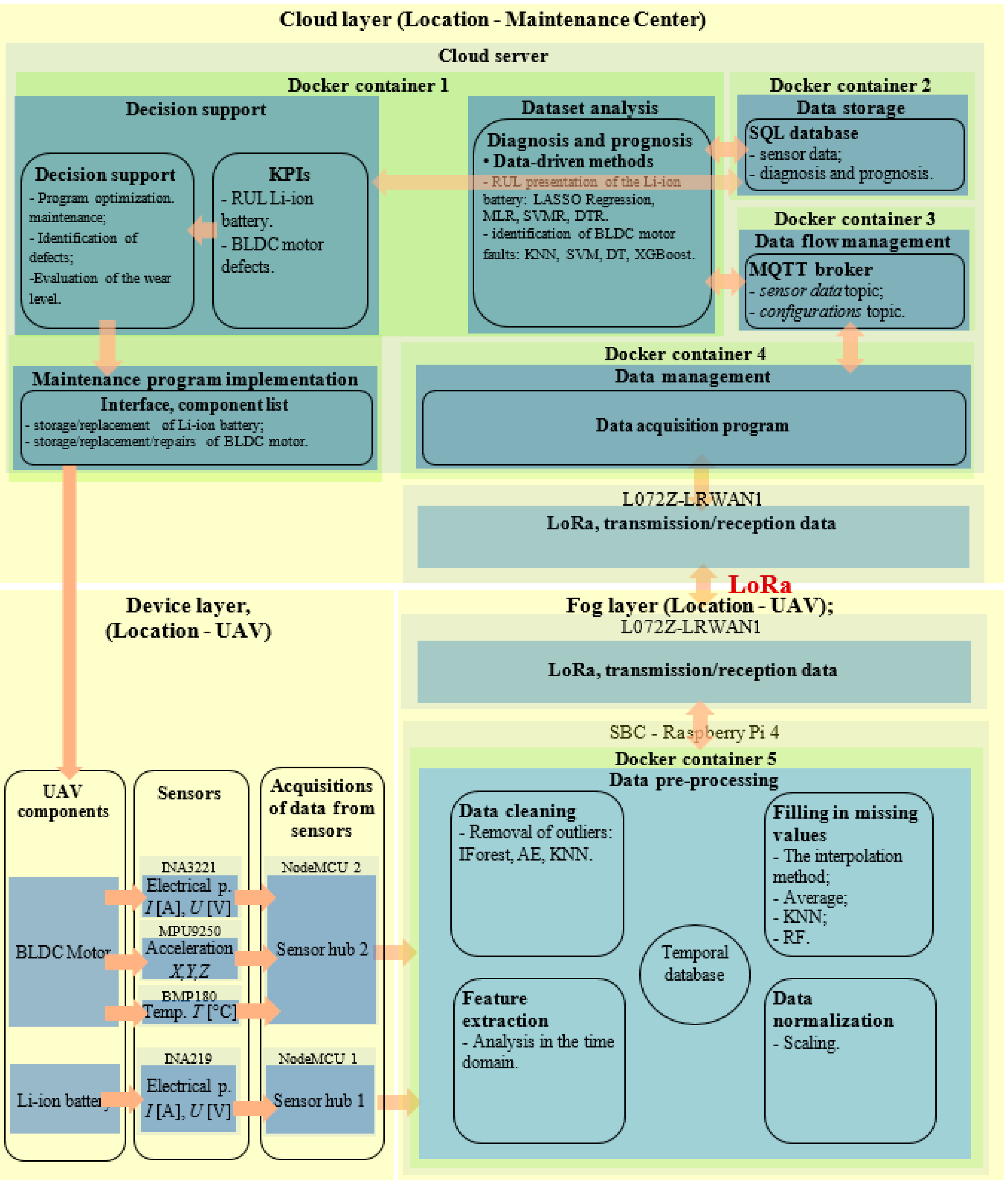

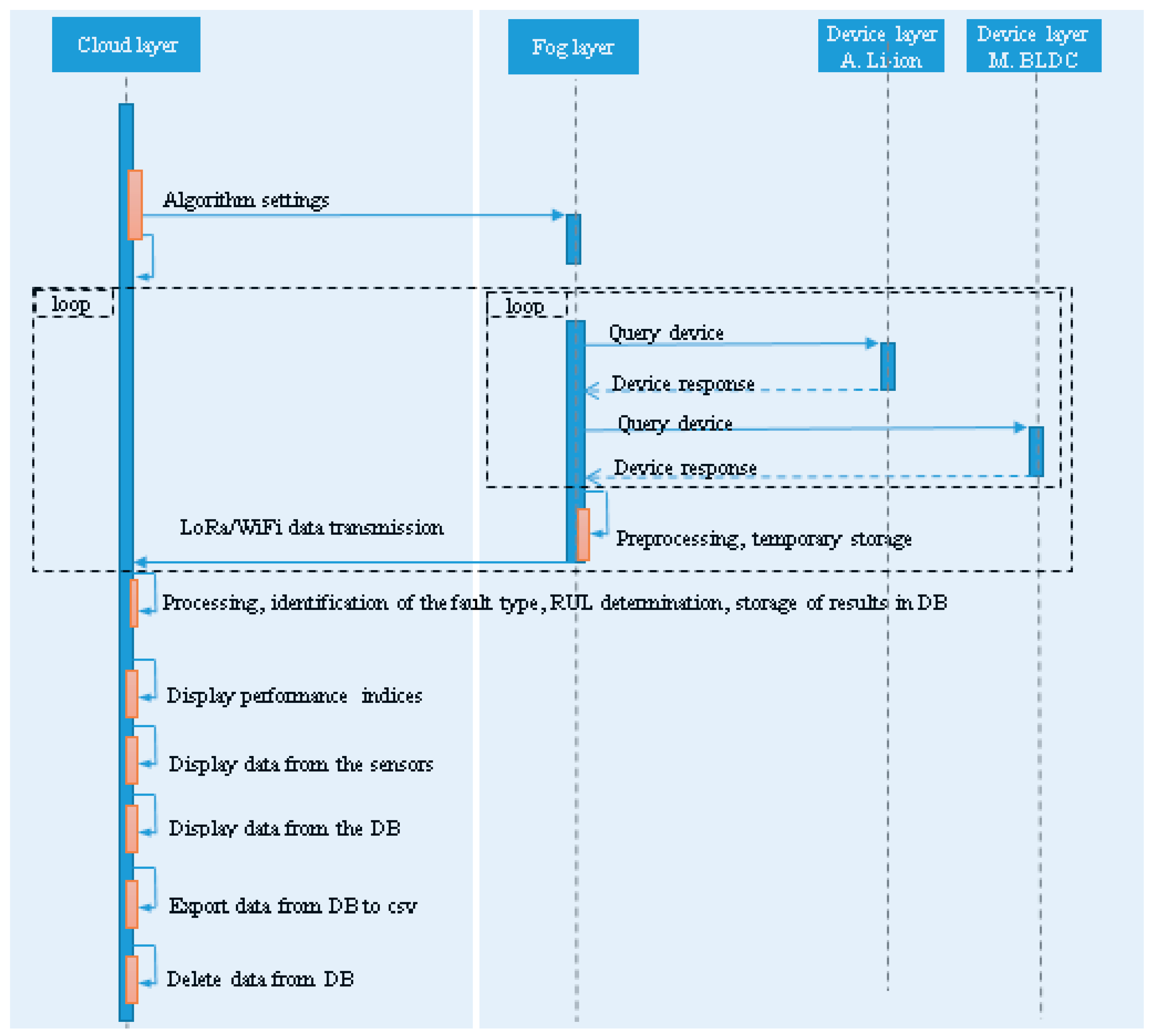

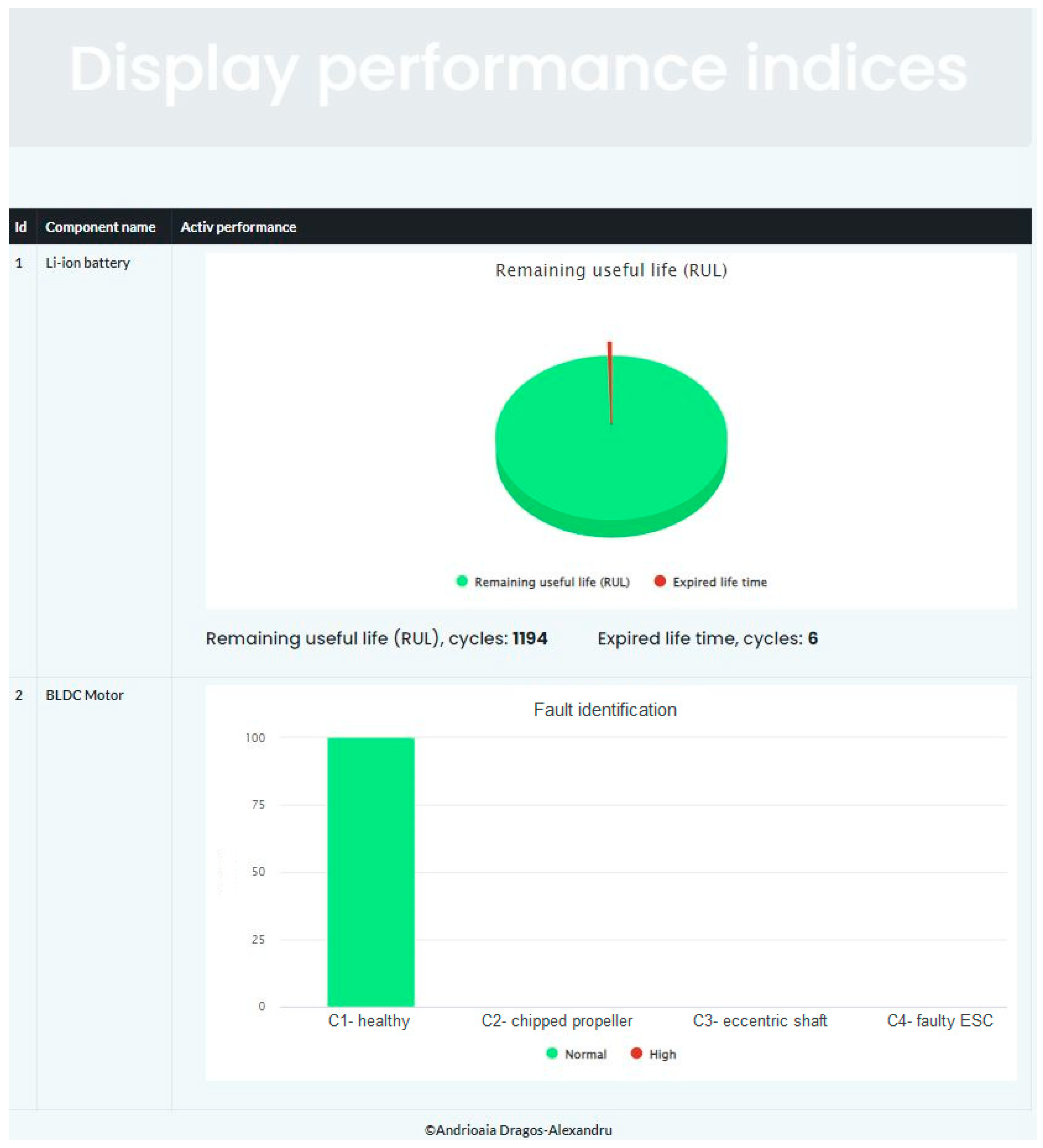

2. Architecture of the Proposed PdM System

2.1. The Devices Layer

2.2. The Fog Layer

2.3. The Cloud Layer

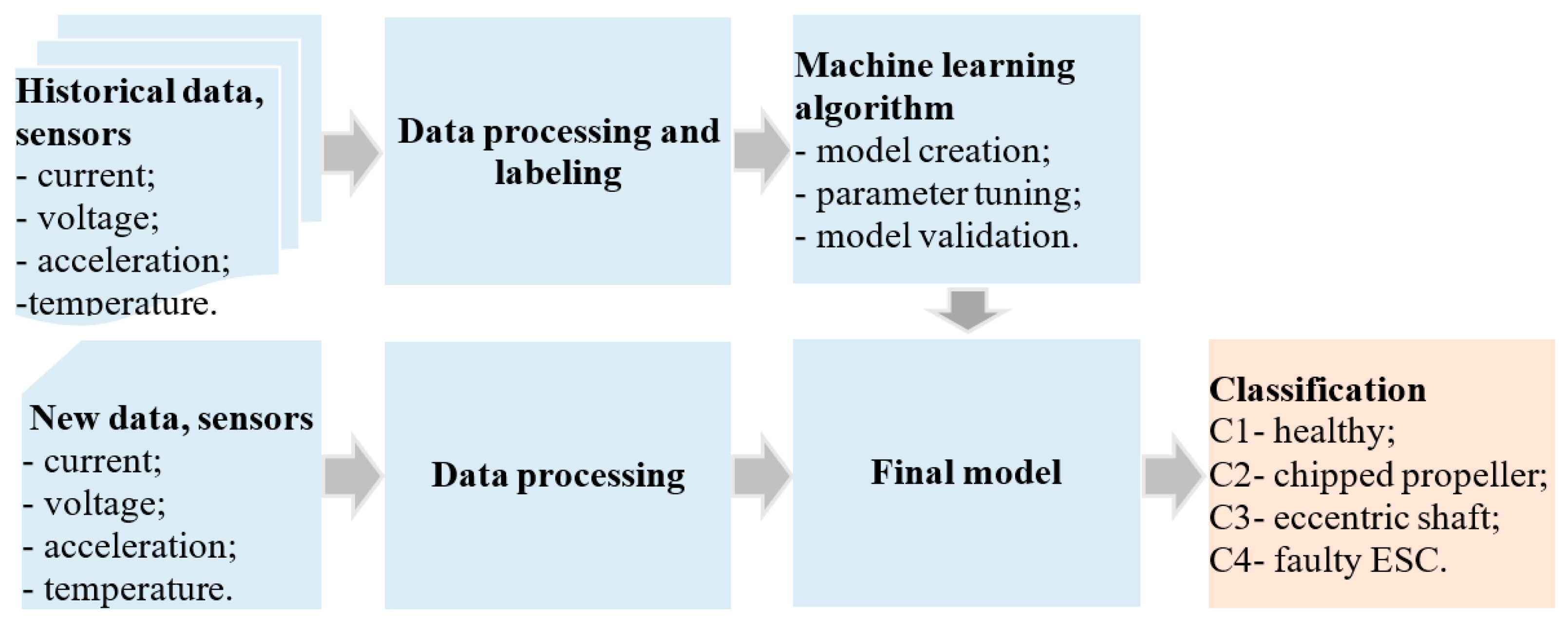

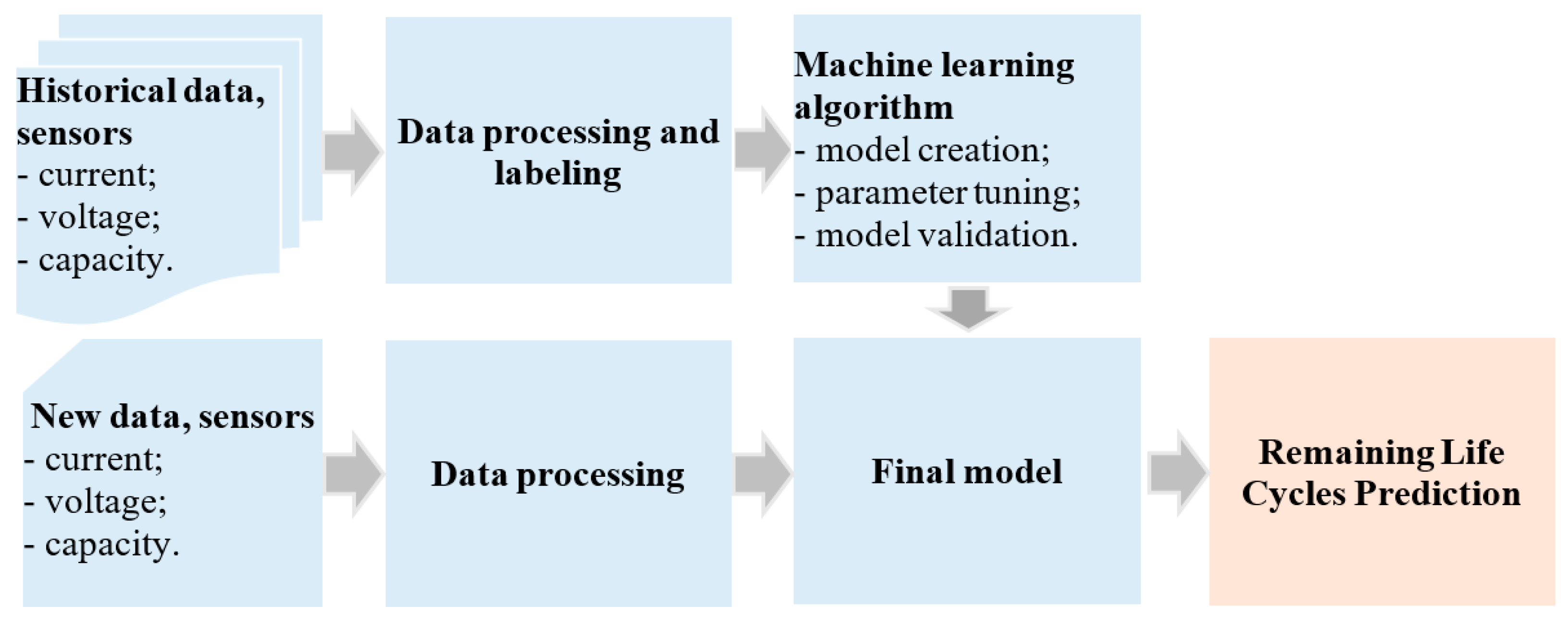

3. Creating ML Models That Allow Prediction of the RUL of Li-Ion Batteries and Identification of the Fault Type of BLDC Motors in the PdM Component of UAVs

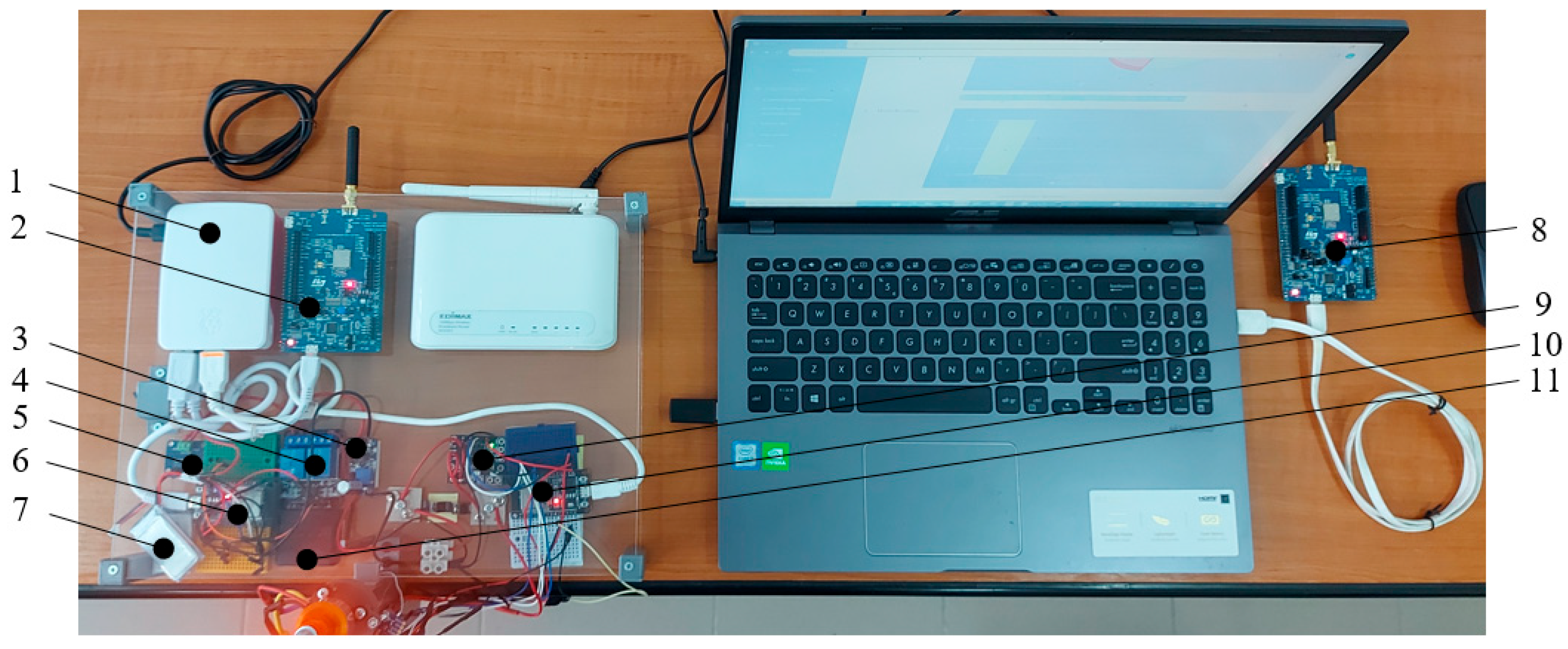

4. The Experimental Stand

5. Results and Discussions

6. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| BLDC | Brushless DC |

| CC | Cloud Computing |

| CPS | Cyber-Physical Systems |

| DL | Deep Learning |

| DM | Data Mining |

| DT | Decision Trees |

| DTR | Decision Tree Regression |

| FC | Fog Computing |

| HVAC | Heating, Ventilation, and Air-Conditioning |

| IoS | Internet of Services |

| IoT | Internet of Things |

| K-NN | K-Nearest Neighbor |

| LASSO | Least Absolute Shrinkage and Selection Operator |

| LSTM | Long Short-Term Memory |

| LSTM-AE | Long Short-Term Memory Autoencoder |

| ML | Machine Learning |

| MLR | Multiple Linear Regression |

| PdM | Predictive Maintenance |

| PV | Photovoltaic |

| PvM | Preventive Maintenance |

| R2F | Run-to-Failure |

| RUL | Remaining Useful Life |

| SBC | Single-Board Computer |

| SVM | Support Vector Machine |

| SVMR | Support Vector Machines Regression |

| UAV | Unmanned Aerial Vehicle |

| XGBoost | eXtreme Gradient Boosting |

References

- Nangia, S.; Makkar, S.; Hassan, R. IoT based Predictive Maintenance in Manufacturing Sector. In Proceedings of the International Conference on Innovative Computing & Communications (ICICC) 2020, New Delhi, India, 21–23 February 2020; pp. 1–7. [Google Scholar] [CrossRef]

- Nagy, M.; Figura, M.; Valaskova, K.; Lăzăroiu, G. Predictive Maintenance Algorithms, Artificial Intelligence Digital Twin Technologies, and Internet of Robotic Things in Big Data-Driven Industry 4.0 Manufacturing Systems. Mathematics 2025, 13, 981. [Google Scholar] [CrossRef]

- Mallick, M.; Shim, Y.-D.; Won, H.-I.; Choi, S.-K. Ensemble-Based Model-Agnostic Meta-Learning with Operational Grouping for Intelligent Sensory Systems. Sensors 2025, 25, 1745. [Google Scholar] [CrossRef] [PubMed]

- Kalafatelis, A.S.; Nomikos, N.; Giannopoulos, A.; Alexandridis, G.; Karditsa, A.; Trakadas, P. Towards Predictive Maintenance in the Maritime Industry: A Component-Based Overview. J. Mar. Sci. Eng. 2025, 13, 425. [Google Scholar] [CrossRef]

- Jachymczyk, U.; Knap, P.; Lalik, K. Improved Intelligent Condition Monitoring with Diagnostic Indicator Selection. Sensors 2025, 25, 137. [Google Scholar] [CrossRef]

- Nayfeh, M.; Li, Y.; Shamaileh, K.A.; Devabhaktuni, V.; Kaabouch, N. Machine Learning Modeling of GPS Features with Applications to UAV Location Spoofing Detection and Classification. Comput. Secur. 2023, 126, 103085. [Google Scholar] [CrossRef]

- Muthanna, M.S.A.; Muthanna, A.; Nguyen, T.N.; Alshahrani, A.; Abd El-Latif, A.A. Towards optimal positioning and energy-efficient UAV path scheduling in IoT applications. Comput. Commun. 2022, 191, 145–160. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, Y.; Chen, H.; Hu, Y.; Wang, L. Research on precise route control of unmanned aerial vehicles based on physical simulation systems. Results Phys. 2024, 56, 107200. [Google Scholar] [CrossRef]

- Karthik, K.; Balasubramanian, C. Improved Green Anaconda Optimization Algorithm-based Coverage Path Planning Mechanism for heterogeneous unmanned aerial vehicles. Sustain. Comput. Inform. Syst. 2024, 42, 100961. [Google Scholar] [CrossRef]

- Gaigalas, J.; Perkauskas, L.; Gricius, H.; Kanapickas, T.; Kriščiūnas, A. A Framework for Autonomous UAV Navigation Based on Monocular Depth Estimation. Drones 2025, 9, 236. [Google Scholar] [CrossRef]

- Sazdic-Jotic, B.; Andric, M.; Bondzulic, B.; Simic, S.; Pokrajac, I. FLEDNet: Enhancing the Drone Classification in the Radio Frequency Domain. Drones 2025, 9, 243. [Google Scholar] [CrossRef]

- Garrido, S.; Muñoz, J.; López, B.; Quevedo, F.; Monje, C.A.; Moreno, L. Fast Marching Techniques for Teaming UAV’s Applications in Complex Terrain. Drones 2023, 7, 84. [Google Scholar] [CrossRef]

- Mu, D.; Yue, C.; Chen, A. Are we working on the safety of UAVs? An LDA-based study of UAV safety technology trends. Saf. Sci. 2022, 152, 105767. [Google Scholar] [CrossRef]

- Li, B.; Liu, H.; Ahn, C.K.; Gong, W. Optimized intelligent tracking control for a quadrotor unmanned aerial vehicle with actuator failures. Aerosp. Sci. Technol. 2024, 144, 108803. [Google Scholar] [CrossRef]

- Radi, M.A.; AlMallahi, M.N.; Al-Sumaiti, A.S.; Semeraro, C.; Abdelkareem, M.A.; Olabi, A.-G. Progress in Artificial Intelligence-Based Visual Servoing of Autonomous Unmanned Aerial Vehicles (UAVs). Int. J. Thermofluids 2024, 21, 100590. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Y.; Xiang, S.; Wei, L. KDP-Net: An Efficient Semantic Segmentation Network for Emergency Landing of Unmanned Aerial Vehicles. Drones 2024, 8, 46. [Google Scholar] [CrossRef]

- Fu, Z.; Liu, X.; Liu, J. Research on the fault diagnosis of dual-redundancy BLDC motor. Energy Rep. 2021, 7, 17–22. [Google Scholar] [CrossRef]

- Altinors, A.; Yol, F.; Yaman, O. A sound based method for fault detection with statistical feature extraction in UAV motors. Appl. Acoust. 2021, 183, 108325. [Google Scholar] [CrossRef]

- Yaman, O.; Yol, F.; Altinors, A. A Fault Detection Method Based on Embedded Feature Extraction and SVM Classification for UAV Motors. Microprocess. Microsyst. 2022, 94, 104683. [Google Scholar] [CrossRef]

- Andrioaia, D.A.; Gaitan, V.G. Finding fault types of BLDC motors within UAVs using machine learning techniques. Heliyon 2024, 10, e30251. [Google Scholar] [CrossRef]

- Andrioaia, D.A.; Gaitan, V.G.; Culea, G.; Banu, I.V. Predicting the RUL of Li-Ion Batteries in UAVs Using Machine Learning Techniques. Computers 2024, 13, 64. [Google Scholar] [CrossRef]

- Li, Z.; Wang, K.; He, Y. Industry 4.0—Potentials for Predictive Maintenance. In Proceedings of the 6th International Workshop of Advanced Manufacturing and Automation, Manchester, UK, 10–11 November 2016; pp. 42–46. [Google Scholar] [CrossRef]

- Andrioaia, D.A.; Gaitan, V.G. A Specialty Literature Review of the Predictive Maintenance Systems. J. Eng. Stud. Res. 2023, 29, 17–23. [Google Scholar] [CrossRef]

- Wang, K.; Dai, G.; Guo, L. Intelligent Predictive Maintenance (IPdM) for Elevator Service- Through CPS, IOTaS and Data Mining. In Proceedings of the International Workshop of Advanced Manufacturing and Automation (IWAMA 2016), Manchester, UK, 10–11 November 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Jimenez Cortadi, A.; Irigoien, I.; Boto, F.; Sierra, B.; Rodriguez, G. Predictive Maintenance on the Machining Process and Machine Tool. Appl. Sci. 2019, 10, 224. [Google Scholar] [CrossRef]

- Oliveira, A.; Dias, A.; Santos, T.; Rodrigues, P.; Martins, A.; Almeida, J. LiDAR-Based Unmanned Aerial Vehicle Offshore Wind Blade Inspection and Modeling. Drones 2024, 8, 617. [Google Scholar] [CrossRef]

- Cinar, E.; Kalay, S.; Saricicek, I. A Predictive Maintenance System Design and Implementation for Intelligent Manufacturing. Machines 2022, 10, 1006. [Google Scholar] [CrossRef]

- Pruteanu, E.; Puiu, P.G. Intelligent Measuring System Using Network Wireless Sensors for Structural Diagnostics. In Proceedings of the 2019 22nd International Conference on Control Systems and Computer Science (CSCS), Bucharest, Romania, 28–30 May 2019; pp. 492–495. [Google Scholar]

- Ruiz-Sarmiento, J.-R.; Monroy, J.; Moreno, F.-A.; Galindo, C.; Bonelo, J.-M.; Gonzalez-Jimenez, J. A predictive model for the maintenance of industrial machinery in the context of industry 4.0. Eng. Appl. Artif. Intell. 2020, 87, 103289. [Google Scholar] [CrossRef]

- Marti-Puig, P.; Touhami, I.A.; Perarnau, R.C.; Serra-Serra, M. Industrial AI in condition-based maintenance: A case study in wooden piece manufacturing. Comput. Ind. Eng. 2024, 188, 109907. [Google Scholar] [CrossRef]

- Arafat, M.Y.; Hossain, M.J.; Alam, M.M. Machine learning scopes on microgrid predictive maintenance: Potential frameworks, challenges, and prospects. Renew. Sustain. Energy Rev. 2024, 190, 114088. [Google Scholar] [CrossRef]

- Dogaru, L. The Main Goals of the Fourth Industrial Revolution. Renewable Energy Perspectives. Procedia Manuf. 2020, 46, 397–401. [Google Scholar] [CrossRef]

- Tsao, Y.-C.; Pantisoontorn, A.; Vu, T.-L.; Chen, T.-H. Optimal production and predictive maintenance decisions for deteriorated products under advance-cash-credit payments. Int. J. Prod. Econ. 2024, 269, 109132. [Google Scholar] [CrossRef]

- Shetty, R. Predictive Maintenance in the IoT Era. In Prognostics and Health Management of Electronics: Fundamentals, Machine Learning, and the Internet of Things; John Wiley and Sons Ltd.: Hoboken, NJ, USA, 2018; pp. 589–612. [Google Scholar]

- Pei, X.; Li, X.; Gao, L. A novel machinery RUL prediction method based on exponential model and cross-domain health indicator considering first-to-end prediction time. Mech. Syst. Signal Process. 2024, 209, 111122. [Google Scholar] [CrossRef]

- Alsuwian, T.; Ansari, S.; Ammirrul Atiqi Mohd Zainuri, M.; Ayob, A.; Hussain, A.; Hossain Lipu, M.S.; Alhawari, A.R.H.; Almawgani, A.H.M.; Almasabi, S.; Taher Hindi, A. A review of expert hybrid and co-estimation techniques for SOH and RUL estimation in battery management system with electric vehicle application. Expert Syst. Appl. 2024, 246, 123123. [Google Scholar] [CrossRef]

- Lu, W.; Wang, Y.; Zhang, M.; Gu, J. Physics guided neural network: Remaining useful life prediction of rolling bearings using long short-term memory network through dynamic weighting of degradation process. Eng. Appl. Artif. Intell. 2024, 127, 107350. [Google Scholar] [CrossRef]

- Cai, N.; Qin, Y.; Chen, X.; Wu, K. Dual time-scale state-coupled co-estimation of state of charge, state of health and remaining useful life for lithium-ion batteries via Deep Inter and Intra-Cycle Attention Network. J. Energy Storage 2024, 77, 109797. [Google Scholar] [CrossRef]

- Dalan, D. An Overview of Edge Computing. Int. J. Eng. Res. Technol. 2019, 7, 1–4. [Google Scholar]

- Francis, T. A Comparison of Cloud Execution Mechanisms Fog, Edge, and Clone Cloud Computing. Int. J. Electr. Comput. Eng. (IJECE) 2018, 8, 4646. [Google Scholar] [CrossRef][Green Version]

- Andrioaia, D.A.; Culea, G.; Puiu, P.G. Environmental Temperature and Humidity Monitoring System Using Raspberry Pi 4 and Thingspeack. J. Eng. Stud. Res. 2022, 27, 16–19. [Google Scholar] [CrossRef]

- Yu, T.; Wang, X. Real-Time Data Analytics in Internet of Things Systems. In Handbook of Real-Time Computing; Springer: Singapore, 2020; pp. 1–28. [Google Scholar]

- Ben Hassen, H.; Ayari, N.; Hamdi, B. A home hospitalization system based on the Internet of things, Fog computing and cloud computing. Inform. Med. Unlocked 2020, 20, 100368. [Google Scholar] [CrossRef]

- Qin, M.; Li, M.; Othman Yahya, R. Dynamic IoT service placement based on shared parallel architecture in fog-cloud computing. Internet Things 2023, 23, 100856. [Google Scholar] [CrossRef]

- Shinde, S.V.; Hemanth, D.J.; Elhoseny, M. Chapter 1—Introduction to different computing paradigms: Cloud computing, fog computing, and edge computing. In Intelligent Edge Computing for Cyber Physical Applications; Hemanth, D.J., Gupta, B.B., Elhoseny, M., Shinde, S.V., Eds.; Academic Press: Cambridge, MA, USA, 2023; pp. 1–16. [Google Scholar]

- Zhao, L.; Chen, B.; Hu, F. Research on Swarm Control Based on Complementary Collaboration of Unmanned Aerial Vehicle Swarms Under Complex Conditions. Drones 2025, 9, 119. [Google Scholar] [CrossRef]

- Abohamama, A.S.; El-Ghamry, A.; Hamouda, E. Real-Time Task Scheduling Algorithm for IoT-Based Applications in the Cloud–Fog Environment. J. Netw. Syst. Manag. 2022, 30, 1–35. [Google Scholar] [CrossRef]

- Zaidi, S.; Attalah, M.A.; Khamer, L.; Calafate, C.T. Task Offloading Optimization Using PSO in Fog Computing for the Internet of Drones. Drones 2025, 9, 23. [Google Scholar] [CrossRef]

- Aldossri, R.; Aljughaiman, A.; Albuali, A. Advancing Drone Operations through Lightweight Blockchain and Fog Computing Integration: A Systematic Review. Drones 2024, 8, 153. [Google Scholar] [CrossRef]

- Wang, K. Intelligent Predictive Maintenance (IPdM) System—Industry 4.0 Scenario. WIT Trans. Eng. Sci. 2016, 113, 259–268. [Google Scholar]

- Killeen, P.; Ding, B.; Kiringa, I.; Yeap, T. IoT-based predictive maintenance for fleet management. Procedia Comput. Sci. 2019, 151, 607–613. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.; Wang, K.-S. Intelligent predictive maintenance for fault diagnosis and prognosis in machine centers: Industry 4.0 scenario. Adv. Manuf. 2017, 5, 377–387. [Google Scholar] [CrossRef]

- Sezer, E.; Romero, D.; Guedea, F.; Macchi, M.; Emmanouilidis, C. An Industry 4.0-Enabled Low Cost Predictive Maintenance Approach for SMEs. In Proceedings of the 2018 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Stuttgart, Germany, 17–20 June 2018; pp. 1–8. [Google Scholar]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. Intelligent Predictive Maintenance and Remote Monitoring Framework for Industrial Equipment Based on Mixed Reality. Front. Mech. Eng. 2020, 6, 578379. [Google Scholar] [CrossRef]

- Van, T.T.; Chan, I.; Parthasarathi, S.; Lim, C.P.; Chua, Y.Q. IoT and machine learning enable predictive maintenance for manufacturing systems: A use-case of laser welding machine implementation. In Proceedings of the 12th Conference on Learning Factories (CLF 2022), Singapore, 4 April 2022; pp. 1–6. [Google Scholar]

- Niyonambaza, I.; Zennaro, M.; Uwitonze, A. Predictive Maintenance (PdM) Structure Using Internet of Things (IoT) for Mechanical Equipment Used into Hospitals in Rwanda. Future Internet 2020, 12, 224. [Google Scholar] [CrossRef]

- Hassan, M.U.; Steinnes, O.-M.H.; Gustafsson, E.G.; Løken, S.; Hameed, I.A. Predictive Maintenance of Norwegian Road Network Using Deep Learning Models. Sensors 2023, 23, 2935. [Google Scholar] [CrossRef] [PubMed]

- Tian, R.; Gomez-Rosero, S.; Capretz, M.A.M. Health Prognostics Classification with Autoencoders for Predictive Maintenance of HVAC Systems. Energies 2023, 16, 7094. [Google Scholar] [CrossRef]

- Iqbal, M.; Suhail, S.; Matulevičius, R.; Shah, F.A.; Malik, S.U.R.; McLaughlin, K. IoV-TwinChain: Predictive maintenance of vehicles in internet of vehicles through digital twin and blockchain. Internet Things 2025, 30, 101514. [Google Scholar] [CrossRef]

- Syamsuddin, A.; Adhi, A.C.; Kusumawardhani, A.; Prahasto, T.; Widodo, A. Predictive maintenance based on anomaly detection in photovoltaic system using SCADA data and machine learning. Results Eng. 2024, 24, 103589. [Google Scholar] [CrossRef]

- Andrioaia, D.A.; Gaitan, V.G. Monitoring the Discharge Voltage of Li-Ion Batteries in the UAV Component Through the Thingspeak IoT Cloud Platform Using LoRa. Int. J. Reconfigurable Embed. Syst. 2023, 11, 16–19. [Google Scholar]

- Culea, G.; Cristea, I.; Puiu, P.G. Modeling and Analysis of Processing Flow in a Flexible Manufacturing System Using Synchronized Petri Nets. Appl. Mech. Mater. 2015, 809–810, 1474–1479. [Google Scholar] [CrossRef]

- Mejia-Herrera, M.; Botero-Valencia, J.; Ortega, J.; Hernández-García, R. Development of a Solar-Powered Edge Processing Perimeter Alert System with AI and LoRa/LoRaWAN Integration for Drone Detection and Enhanced Security. Drones 2025, 9, 43. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, T.; Hu, N.; Zhang, P.; Zhang, Y. The method of Internet of Things access and network communication based on MQTT. Comput. Commun. 2020, 153, 169–176. [Google Scholar] [CrossRef]

- Schelle, A.; Völk, F.; Schwarz, R.T.; Knopp, A.; Stütz, P. Evaluation of a Multi-Mode-Transceiver for Enhanced UAV Visibility and Connectivity in Mixed ATM/UTM Contexts. Drones 2022, 6, 80. [Google Scholar] [CrossRef]

- Mileva, A.; Velinov, A.; Hartmann, L.; Wendzel, S.; Mazurczyk, W. Comprehensive analysis of MQTT 5.0 susceptibility to network covert channels. Comput. Secur. 2021, 104, 102207. [Google Scholar] [CrossRef]

- Wind, J.; Vie, P.J.S. Entropy Profiles for Li-Ion Batteries—Effects of Chemistries and Degradation. Entropy 2025, 27, 364. [Google Scholar] [CrossRef] [PubMed]

- Bruj, O.; Calborean, A. Electrochemical Impedance Spectroscopy Investigation on the Charge–Discharge Cycle Life Performance of Lithium-Ion Batteries. Energies 2025, 18, 1324. [Google Scholar] [CrossRef]

- Bruj, O.; Calborean, A. Lifecycle Evaluation of Lithium-Ion Batteries Under Fast Charging and Discharging Conditions. Batteries 2025, 11, 65. [Google Scholar] [CrossRef]

- Ahwiadi, M.; Wang, W. Battery Health Monitoring and Remaining Useful Life Prediction Techniques: A Review of Technologies. Batteries 2025, 11, 31. [Google Scholar] [CrossRef]

- Wei, J.; Chen, C. A multi-timescale framework for state monitoring and lifetime prognosis of lithium-ion batteries. Energy 2021, 229, 120684. [Google Scholar] [CrossRef]

- Fei, Z.; Yang, F.; Tsui, K.-L.; Li, L.; Zhang, Z. Early prediction of battery lifetime via a machine learning based framework. Energy 2021, 225, 120205. [Google Scholar] [CrossRef]

- Hosen, M.S.; Jaguemont, J.; Van Mierlo, J.; Berecibar, M. Battery lifetime prediction and performance assessment of different modeling approaches. iScience 2021, 24, 102060. [Google Scholar] [CrossRef] [PubMed]

- Ahwiadi, M.; Wang, W. An AI-Driven Particle Filter Technology for Battery System State Estimation and RUL Prediction. Batteries 2024, 10, 437. [Google Scholar] [CrossRef]

- Safavi, V.; Mohammadi Vaniar, A.; Bazmohammadi, N.; Vasquez, J.C.; Guerrero, J.M. Battery Remaining Useful Life Prediction Using Machine Learning Models: A Comparative Study. Information 2024, 15, 124. [Google Scholar] [CrossRef]

- Ortiz, F.M.; de Almeida, T.T.; Ferreira, A.E.; Costa, L.H.M. Experimental vs. simulation analysis of LoRa for vehicular communications. Comput. Commun. 2020, 160, 299–310. [Google Scholar] [CrossRef]

| Performance Indicator | KNN | SVM | DT | XGBoost |

|---|---|---|---|---|

| ACC | 0.932 | 0.966 | 0.979 | 0.982 |

| PRmacro avg | 0.934 | 0.968 | 0.980 | 0.982 |

| Recallmacro avg | 0.932 | 0.966 | 0.979 | 0.982 |

| F1macro avg | 0.932 | 0.966 | 0.979 | 0.982 |

| Performance Indicator | LASSO Regression | MLR | SVMR | DTR |

|---|---|---|---|---|

| MAE | 67.399 | 67.210 | 18.877 | 8.993 |

| MSE | 7615.849 | 7614.101 | 1007.653 | 154.687 |

| RMSE | 87.268 | 87.258 | 31.743 | 12.437 |

| R2 Score | 0.938 | 0.938 | 0.992 | 0.998 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andrioaia, D.A. Predictive Maintenance System to RUL Prediction of Li-Ion Batteries and Identify the Fault Type of Brushless DC Electric Motor from UAVs. Sensors 2025, 25, 4782. https://doi.org/10.3390/s25154782

Andrioaia DA. Predictive Maintenance System to RUL Prediction of Li-Ion Batteries and Identify the Fault Type of Brushless DC Electric Motor from UAVs. Sensors. 2025; 25(15):4782. https://doi.org/10.3390/s25154782

Chicago/Turabian StyleAndrioaia, Dragos Alexandru. 2025. "Predictive Maintenance System to RUL Prediction of Li-Ion Batteries and Identify the Fault Type of Brushless DC Electric Motor from UAVs" Sensors 25, no. 15: 4782. https://doi.org/10.3390/s25154782

APA StyleAndrioaia, D. A. (2025). Predictive Maintenance System to RUL Prediction of Li-Ion Batteries and Identify the Fault Type of Brushless DC Electric Motor from UAVs. Sensors, 25(15), 4782. https://doi.org/10.3390/s25154782