1. Introduction

Rotating machinery constitutes essential components within mechanical systems. Failure events in such equipment may induce substantial economic losses [

1]. These failures pose a risk of causing casualties to personnel. As a result, it is of critical importance to achieve real-time condition monitoring for rotating machinery. At the same time, it is vital to implement accurate fault identification. These capabilities can directly ensure the operational reliability of the equipment [

2,

3,

4].

Fault diagnosis has an extremely important function in ensuring the safety and the reliability of rotating machinery. For this reason, it is of great significance for rotating machinery to have accurate and effective fault diagnosis [

5,

6,

7]. Vibration signals contain a large amount of information. This information can reveal the safety status of the monitored system. Because of this, methods based on vibration signals are among the most commonly used tools in the reliability monitoring of rotating machinery. Nevertheless, the first two categories depend too much on the prior knowledge of experts. They also extract features in a manual way. This makes it hard to process large-scale data and learn advanced features. At the same time, when facing industrial data that is complex and changeable, it is difficult for ordinary shallow machine learning models to achieve ideal results.

In recent years, deep learning has developed rapidly. Deep learning algorithms are represented by various neural networks. These algorithms have strong feature extraction capabilities. They can conduct automatic representation learning from multiple types of data. Also, they have strong adaptability. There are some deep learning models. For example, there are stacked auto-encoders (SAEs) [

8], deep belief networks (DBNs) [

9], convolutional neural networks (CNNs) [

10], and recurrent neural networks (RNNs) [

11]. These models are widely applied in the fault diagnosis of rotating machinery. Praveenkumar et al. [

12] took steps to improve classification accuracy. They did this by optimizing unsupervised algorithms. These algorithms include auto-encoders and stacked auto-encoders. They made use of the unique characteristics of acoustic emission signals and overcame the gradient disappearance problem. Zhao et al. [

13] proposed a new method for fault diagnosis of rolling bearing, which uses wavelet packet decomposition (WPD) for feature extraction and chaotic sparrow search optimization algorithm (CSSOAs) to optimize the parameters of the deep belief network (DBN). This method shows the stronger feature extraction ability and excellent fault diagnosis ability of rolling bearing.

Furthermore, fault diagnosis under small-sample conditions has emerged as a significant research priority. This development reflects evolving demands in industrial applications. Chai et al. [

14] proposed a Multi-scale Residual Parametric Convolutional Capsule Network (MRCCCN) that addressed small-sample feature extraction limitations through multi-segment residual convolution and dynamic routing-enhanced capsule structures. Ding et al. [

15] developed Channel Attention Siamese Networks (CASNs) that resolved data scarcity limitations in critical machinery diagnostics through contrastive metric learning. Their framework enabled accurate fault identification under extreme small-sample conditions by mapping feature disparities between sample pairs and predicting unlabeled faults via distance-based classification. Gao et al. [

16] introduced a Multiscale Physics-Informed Network (MPINet) that mitigated data scarcity constraints in bearing diagnostics through domain-specific physical constraints. Their framework enhanced small-sample diagnostic efficacy by encoding failure-mode-specific physical knowledge into independently trained blocks and integrating multiscale features via adaptive classification. Wen et al. [

17] devised a Siamese Neural Network framework with multi-stage training that addressed data scarcity and training stagnation in motor bearing diagnostics. Zhou et al. [

18] proposed a novel semi-supervised DCGAN framework that significantly enhances gear fault diagnosis with scarce labeled data by architecturally optimizing discriminator–generator balance to improve feature extraction from limited labeled samples. Liu et al. [

19] proposed ICoT-GAN, a novel data augmentation framework integrating convolutional local feature extraction and transformer-based global interaction modeling, to address the challenge of global–local feature coupling under limited data. Li et al. [

20] develop a label-guided contrastive learning framework with weighted pseudo-labeling (LgCL-WPL) that jointly optimized hybrid contrastive losses and classification objectives during pre-training, while enabling simultaneous utilization of labeled/unlabeled data in fine-tuning through noise-robust pseudo-labeling. Han et al. [

21] introduced a pairwise sample alignment framework that enabled effective cross-domain fault diagnosis under extreme target data scarcity (1–5 samples), resolving the dual challenges of distributional discrepancy and label space mismatching through individualized domain adaptation. Their approach enhanced feature discriminability under small-sample conditions through multi-source sensor fusion, GAN, transfer learning, and other semi-supervised learning methods, validating diagnostic efficacy on industrial bearing datasets.

These studies addressed small-sample limitations through feature space refinement via domain knowledge integration, or learning strategy innovation using transfer optimization, or information utilization optimization through sensor fusion. For vibration signals, insignificant features may contain rich information, but these insignificant features are easily lost in fault diagnosis. Compared with CNN, transformers can solve this problem.

The transformer constitutes a novel neural architecture. It employs the self-attention mechanism. This mechanism was introduced by Google researchers in 2017 [

22]. Self-attention operates within cost-sensitive learning frameworks. These frameworks estimate fused features through adaptive weight assignment. In order to pursue more accurate and stable diagnosis performance, some studies have preliminarily explored and applied the method of combining the attention mechanism in transformers with CNNs. Wang et al. [

23] proposed a lightweight CNN–transformer named SEFormer for rotating machinery fault diagnosis. This study provides a feasible strategy for developing a lightweight rotating machinery fault diagnosis framework aimed at economical deployment. Xu et al. [

24] developed a new channel attention mechanism based on squeeze and excitation modules to focus on key features while reducing the computational complexity of the network. Wang et al. [

25] put forward an ECA-CNN framework with multi-sensor fusion that addressed inadequate feature representation in rotating machinery diagnostics. Their approach enhanced channel-wise feature discriminability through adaptive attention weighting and multi-source data integration, achieving efficient fault identification under noisy conditions. However, these methods do not capture and assign higher weights to important long-term dependent information, nor do they have the capability to deeply mine models.

To address these issues, this paper maps the time-domain information of vibration signals onto two-dimensional images, ensuring the generalization ability and anti-interference capability of the diagnosis model, while eliminating the influence of experts’ prior knowledge on the images. LSTM is used to model the dynamic evolution of time series signals and capture long-distance causal dependence. Additionally, label smoothing regularization (LSR) is introduced to balance the distributional differences between label samples. The method is tested on a CWRU dataset and safe injection pump fault dataset. Experimental results show that the method can accurately identify two types of faults. In particular, when the safe injection pump fault dataset has few data samples, the model shows outstanding performance. The main contributions of this paper are as follows:

A convolutional neural network model based on an attentional mechanism and deep residual is proposed. The effects of optimizers are discussed. The method has high test accuracy. A large number of safe injection pump fault simulation experiments are carried out. The effectiveness of the method is verified by the fault data collected from safe injection pumps.

The sensitivities of the attention mechanism and LSTM to the ratio of training samples are discussed, where the attention mechanism can capture channel and spatial information of the vibration signal. Then, LSTM can extract the temporal features of vibration signals. In addition, visualization techniques are also used to understand blocks in AR-CLSTM.

Two case studies were performed to validate the proposed diagnostic framework. Experimental outcomes demonstrated that AR-CLSTM exceeded six benchmark methods. This performance advantage was particularly notable with small samples.

The remaining structure of this work is organized as follows.

Section 2 presents fundamental theoretical models for fault diagnosis.

Section 3 details the AR-CLSTM framework. This section also introduces advanced regularization training strategies.

Section 4 validates the applicability of AR-CLSTM through two case studies.

Section 5 provides concluding remarks and future research directions.

2. Theoretical Background

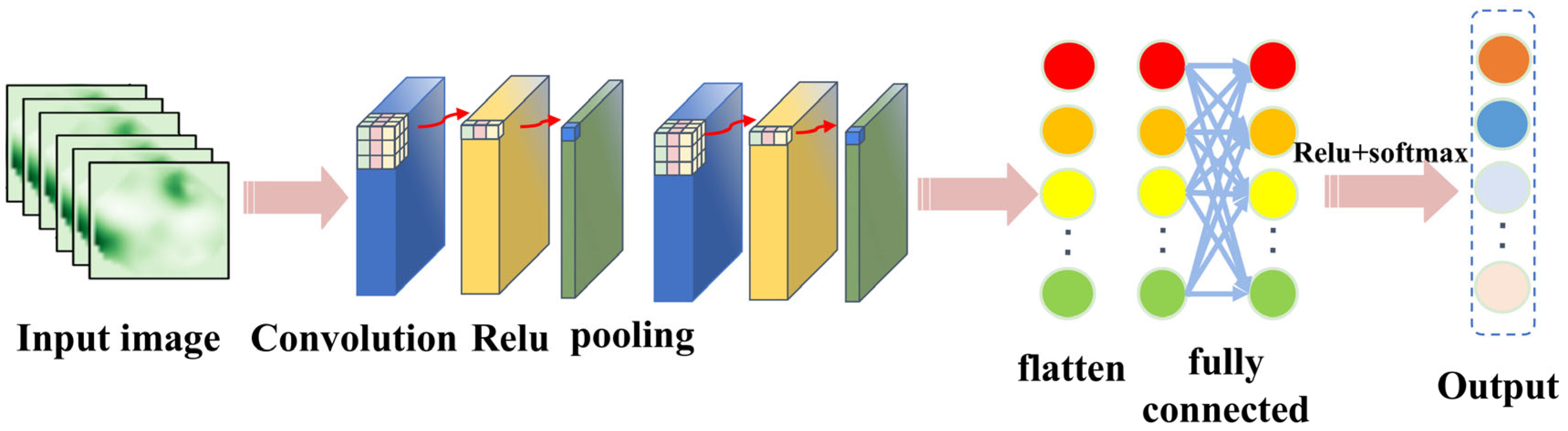

2.1. Convolutional Neural Networks

CNN is a multi-stage neural network consisting of several filtering stages and a classification stage. It is inspired by the structure of the vision system, developed by LeCun and collaborators in 1990 for image processing [

26], and is still widely used in computer vision application. A general CNN architecture is shown in

Figure 1, which mainly consists of an input layer, convolutional layer, pooling layer (downsampling), fully connected layer, and output layer.

The convolutional layer serves as the core component within convolutional neural networks (CNNs) for performing feature extraction. This layer comprises multiple learnable convolution kernels. Each element constituting a kernel corresponds to a distinct weight coefficient; additionally, each kernel is associated with a bias term. The extracted features are subsequently propagated to the next layer of the network for processing. The size of the localized input region involved in each convolution operation is determined solely by the dimensions of the convolution kernel itself. The mathematical expression for the convolution operation is as follows:

where

represents the

ith feature input of the

Ith layer,

represents the

jth weight coefficient of the

Ith layer,

represents the

jth bias of the

Ith layer, and

represents the

jth output feature of the

Ith layer.

The convolutional layer is typically succeeded by a pooling layer. This layer executes feature selection and information filtering on its input features. It reduces the number of feature parameters. This reduction eliminates redundant information. Commonly employed pooling methods include maximum pooling and average pooling. Maximum pooling sees particularly widespread application. The computational procedure for the maximum pooling layer is

where

is the output of the

mth area of the

Ith layer;

is the

mth area of the pooled

Ith layer.

In order to reduce the offset of interval covariance, a batch normalization layer is introduced by reducing the calculation load to improve the learning speed. It is usually added after the convolution layer or before the activation layer. Normalized transformations can be described as

Among them, is the output of a neuron response, , is a small constant added to the numerical stability, and and are the scale and displacement parameters that need to be learned, respectively.

Generally, the activation function is used to process the features extracted by the convolutional layer to enhance the feature expression ability of CNN. The activation function improves the nonlinear mapping capability of the model by mapping originally linearly inseparable multidimensional features to another space. Commonly used activation functions include Sigmoid, Tanh, ReLU, etc.

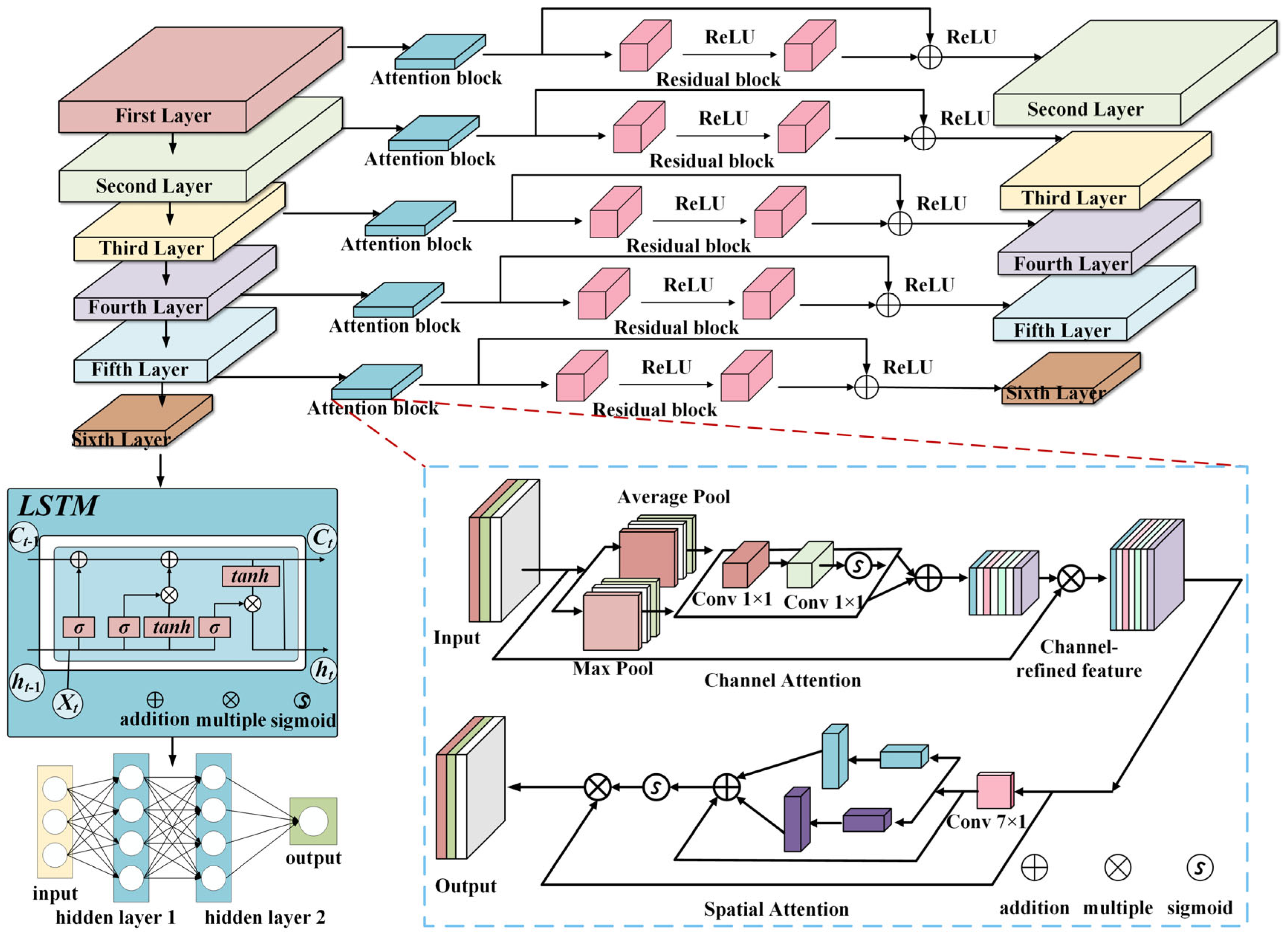

2.2. Long Short-Term Memory (LSTM)

Recurrent neural networks (RNNs) are widely used in sequence learning, but the problem of vanishing gradients in training backpropagation steps hinders their performance. To avoid this obstacle and capture the long-term dependence of data characteristics, Hochreiter et al. [

27] have improved RNN into a new architecture called long short-term memory (LSTM). It shows more efficient classification and regression performance than RNN on sound and natural language processing datasets. The structure of LSTM is shown in

Figure 2.

The LSTM network consists of one or more LSTM units used to capture long-term dependencies in time series data.

In these formulas, , , and are the activation values of the input gate, forgetting gate, and output gate at time step t; , , and are the cell state at the previous t − 1, the cell state at current t, and the hidden state at current t, respectively; is the activation function; , , , and are the weight matrices of the input gate, forgetting gate, output gate, and cell states, respectively; connects the hidden state of the previous moment and the input of the current moment into a vector; , , , and represent biased vectors of the input gate, forgetting gate, output gate, and cell states, respectively; tanh is a hyperbolic tangential activation function; and applies a hyperbolic tangent activation function to the current cell state.

2.3. Residual Neural Network

Theoretical analysis shows that making networks deeper usually improves their ability to represent features. However, experimental results demonstrate a degradation effect. When network depth passes certain critical points, generalization performance declines. This decline occurs even though architectural complexity increases. To solve this key optimization challenge, He et al. [

28] proposed the residual learning concept. They developed the important ResNet architecture using this concept.

This framework uses residual blocks as basic building units. Every block contains several operations in sequence. These typically include convolutional layers, batch normalization, and rectified linear unit activation functions. Crucially, identity skip connections integrate with these operations.

For a given input

, the output of the

lth residual block can be expressed as

where

is the shortcut connection; function

is the residual block mapping, which represents the learned residual;

is the network parameter; and

is the ReLU activation function. In this paper, the designed residual neural network includes one residual block, and the structure of the network is shown in

Figure 3.

4. Results and Discussion

The proportion of each training sample (α%) was used as the evaluation criteria. We believe that if α < 0.5, it can be considered a small sample [

30,

31]. α

0.3 is used to simulate the scenario of extreme data scarcity (e.g., safety injection pump failure), and α

0.3 is used to verify the generalization ability of the model from scarce to sufficient data. First, the advantages of the new regularization training method are verified. Then, when α = 0.1~0.5, the small-sample learning ability of different models is verified and performance evaluation is performed under different working conditions. Finally, parameter sharing for small-sample transfer learning applied to the new dataset will be discussed, and visual interpretation of AR-CLSTM will also be discussed. All experiments were performed under the same random conditions, and the experimental settings were shown in

Table 1. All datasets underwent stratified partitioning: 70% for training and 30% for testing. Final evaluation used a completely independent test set processed with non-augmenting transformations.

The experiment is implemented in PyTorch 2.1.0, Python 3.8.7, running on AMD Ryzen 7 7840H CPU @ 3.8 GHz (16G RAM). The mini-batch size is set to eight in this study. In addition, the label-smoothing training strategy is utilized to supervise the training of the AR-CLSTM model. The structure and main hyperparameters of the AR-CLSTM model are as shown in

Table 2.

4.1. Methods of Model Evaluation and Metrics

The AR–CLSTM framework, which is introduced in detail in

Section 3, is now validated through two industrial case studies. For the Case Western Reserve University (CWRU) bearing dataset, the channel attention mechanism prioritizes the fault-related frequency bands in the vibration spectrum, while the spatial attention mechanism locates the transient impulses in the two-dimension time–frequency representation. The residual block alleviates gradient dissipation during the deep feature extraction process, and LSTM captures the temporal dependencies in the motor speed variations. For the safety injection pump (Case 2), label smoothing regularization explicitly addresses the data scarcity problem by reallocating label confidences among similar fault categories. Diagnostic performance can be represented by a confusion matrix, where it has two valuable metrics. In the case of multiple classes, this is the average of the F1 scores for each class, weighted depending on the average parameters, where sensitivity (recall) and precision are key performance indicators, defined as follows, which can be obtained directly from the confusion matrix, as shown in

Table 3.

Among them, standard metrics derived from the confusion matrix include precision (TP/(TP + FP)), recall (TP/(TP + FN)), and F1 score.

To better visually present the correct and incorrect prediction results, we used a normalized confusion matrix to evaluate the performance of the model. The elements in each cell are defined as shown in

Table 4.

4.2. CWRU Database

4.2.1. Description and Distinction of Data

The public dataset from CWRU is the bearing timing signal data collected by its experimental equipment, as shown in

Figure 7. Due to human limitations, the motor shaft supported by the bearing does not rotate at a single approximate speed, and its speed changes with the change in loads; see

Table 5 for details.

This paper selects 12 kHz for experiments, as shown in

Table 6. For the drive end bearing of the SKF6205-type model (Case Western Reserve University, Cleveland, OH, USA), it is manually implanted into a single point of failure by electrical discharge machining. There are three types of fault locations: in-vehicle fault (IRF), rolling element fault (BF), and out-vehicle fault at 6 o’clock (ORF). Each fault location contains four fault dimensions: 0.007 inches, 0.014 inches, 0.021 inches, and 0.028 inches. Some data are not available, so for the sake of experiment integrity, we do not take all data with a fault size of 0.028. Therefore, in the experimental data, the bearing states under a certain load can be divided into nine fault states and one normal state, corresponding to ten domain vibration signals. Since the original data are long time series signals collected continuously, in order not to miss the fault information, we use the sliding window segmentation method to divide the entire signal into several short samples. Each fault operating condition contains 212 samples, and each sample consists of 512 non-overlapping data points. The normal state operating condition contains 840 normal samples. The entire dataset contains a total of 212 × 9 + 840 = 2748 samples.

4.2.2. Discussion of Batch_Sizes

A larger batch number can shorten the training time for each iteration, but it may also reduce the generalization ability, so a balance should be achieved between the two. Therefore, under the fault dataset A when the dataset is CWRU, the batch_size is selected as 64, α = 0.4, and only the batch_size has changed. The results are shown in

Table 7.

The training difficulties of different batches are not consistent, resulting in different training times. Obviously, it can achieve similar performance (99.93%, 100%) using a batch_size of 16 or 64, but the latter takes less time (130.76886 s), so the batch_size is set to 64.

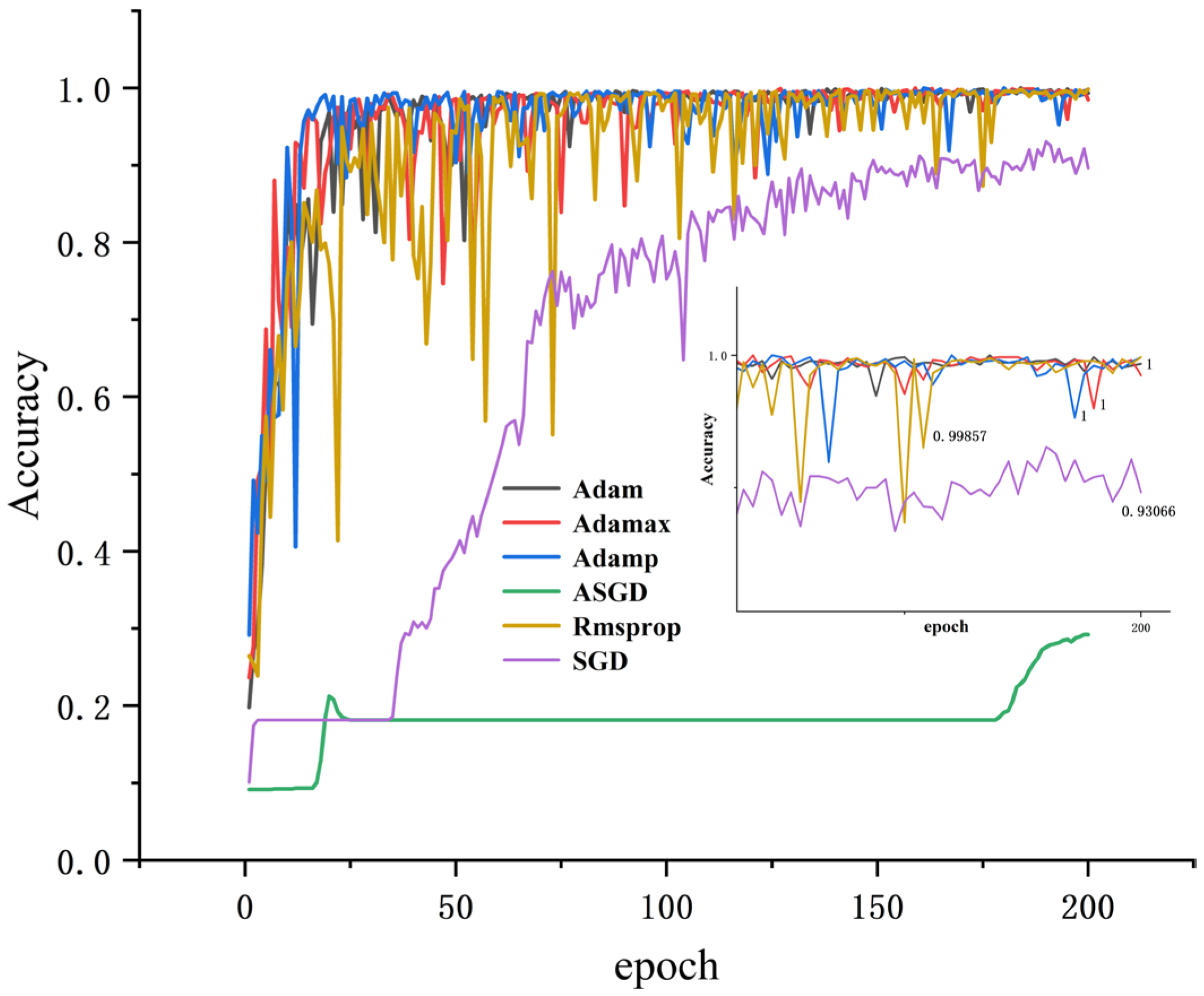

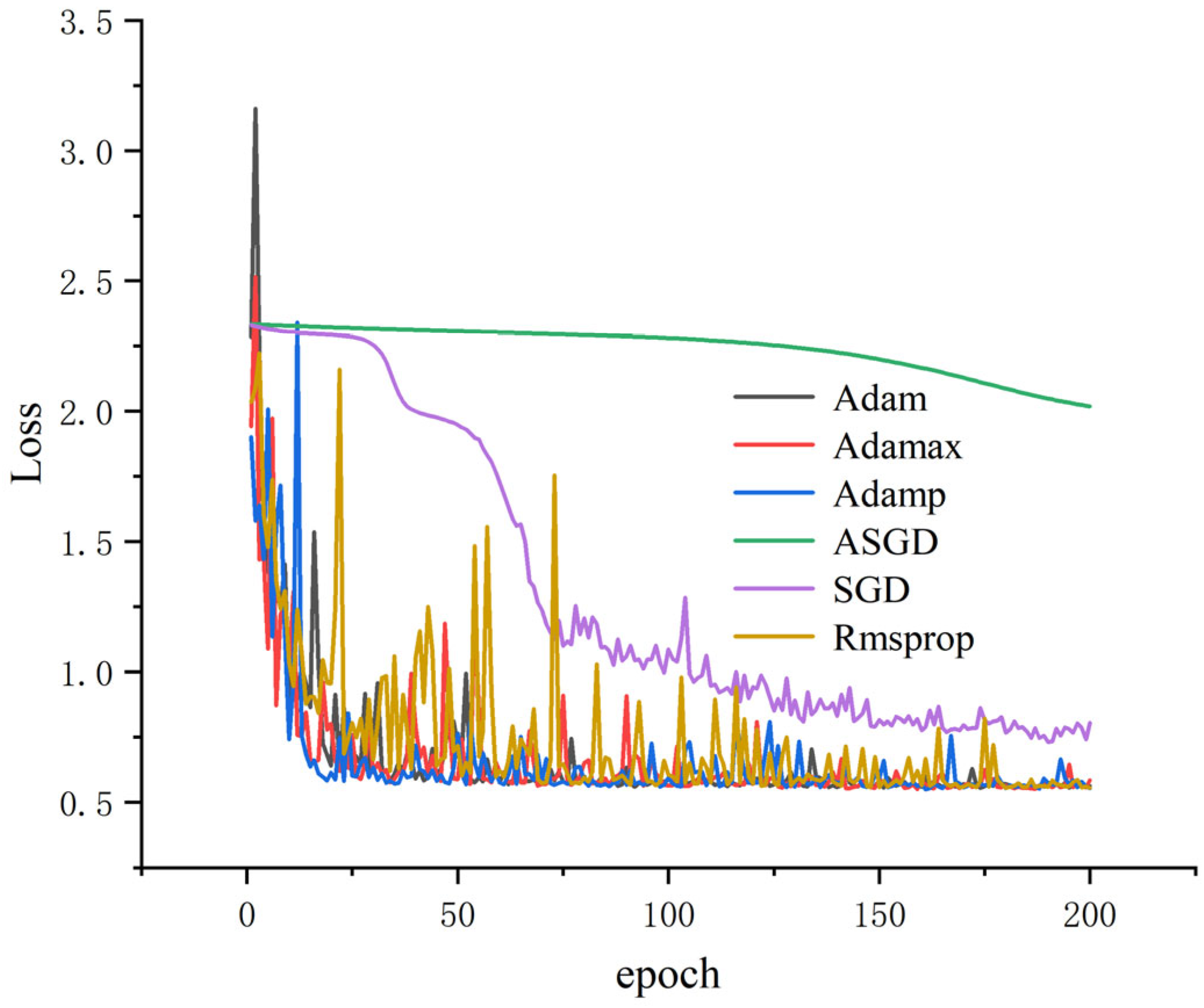

4.2.3. Discussion of Optimizers

Different optimizers will affect the accuracy and training time of each iteration. For a certain neural network, they are used to optimize the objective function, and the parameters are constantly updated until the optimal solution is achieved. The closer the solution is to global optimality, the better the neural network is generalized. In this paper, when the batch_size is 64, α = 0.4, and the number of iterations is 200, the results are shown in

Table 8. Except for ASGD, the accuracy of the other test sets is high, while the test set accuracy of Adam, Adamp, and Adamax optimizers all reach 100%, but the Adam time is the shortest (130.7688 s).

All results were obtained using dataset A, with α = 0.4, and the training loss and accuracy were obtained. As shown in

Figure 8 and

Figure 9, it can be seen that the accuracy of several optimization algorithms except SGD and ASGD has reached more than 99%. Rmsprop has the largest oscillation amplitude; Adamp and Adamax also have a larger amplitude, while the accuracy and loss rates of Adam tend to stabilize under shorter iterations. It can be seen that Adam performs well, so Adam is selected as the optimizer of this model.

4.2.4. Comparison of Ablation Experiments

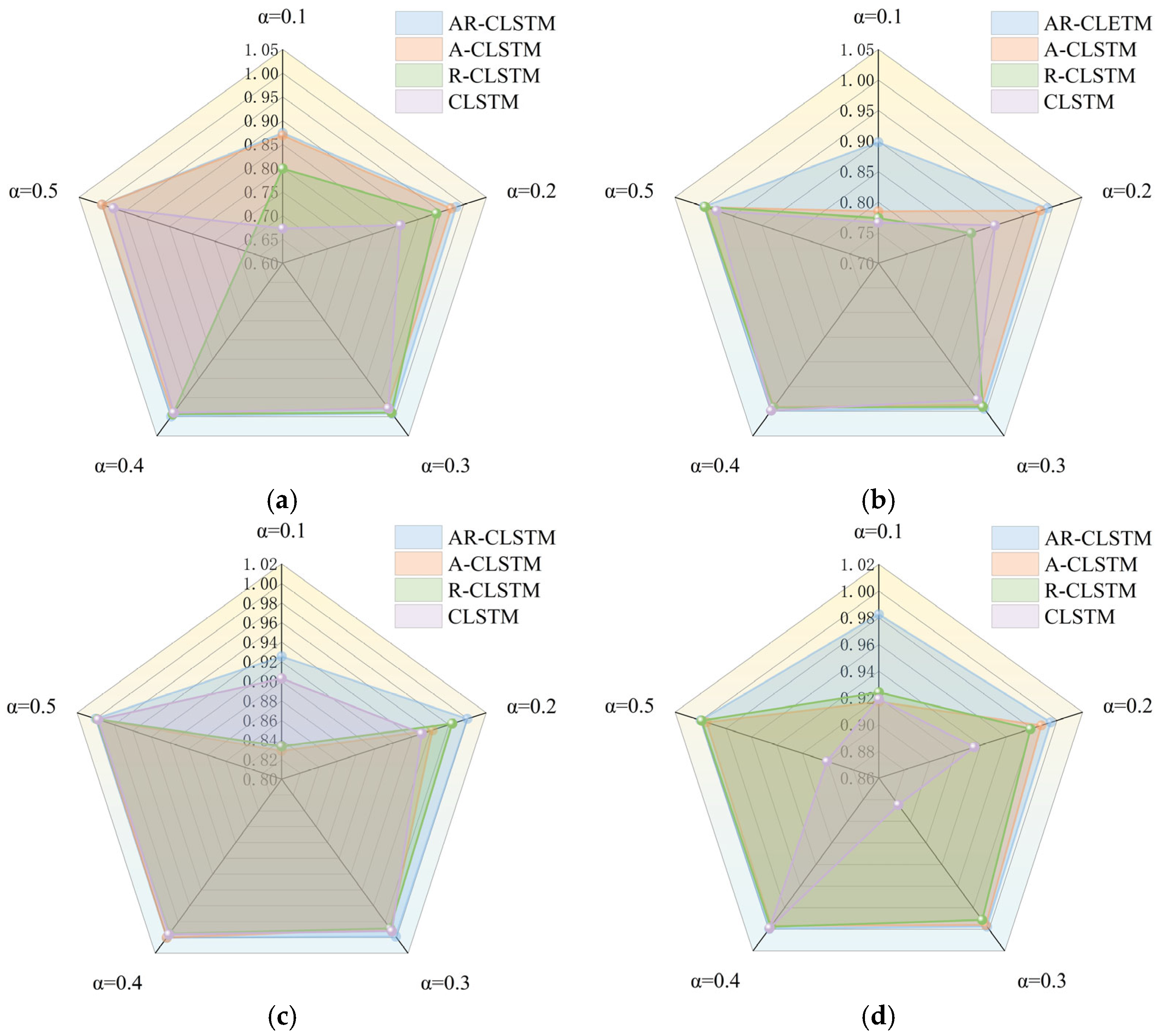

The ablation experiment of AR-CLSTM (M4) was carried out on four datasets: A, B, C, and D. The comparison models were R-CLSTM (without attention mechanism M1), A-CLSTM (without RESNET, M2), and CLSTM (without attention and RESNET, M3) with F1 scores as the indicator. A→A represents the transition from the training set to test set. The X-axis represents the ratio of training (α). At the same time, the running time of different loads under different models and different α is recorded as shown in

Table 9.

As can be seen from

Figure 10 and

Table 9, as the model increases, the F1 scores also increase. Meanwhile, as the complexity of the model increases, the computational cost of the model also grows, and the time spent on training becomes longer. In addition, as the complexity of the model increases, the computational cost of the model also grows, and the time spent on training becomes longer. The residual module solves the degradation problem of deep networks. Under dataset A, when α = 0.1, M1 = 0.7992 and M3 = 0.6729. The F1 score of M1 is 12.63% higher than that of M3. Meanwhile, under different working conditions, the performance of M1 in the case of small samples is generally better than that of M3. From M2 and M3 in

Figure 10b, when α = 0.2, M3 = 0.9006 and M2 = 0.9784; this shows that the attention mechanism has a good generalization of small samples because it can reduce the computational burden of processing high-dimensional input data, reduce the data dimension, and find significant useful information related to the current output in the input data. Combining the two, M5 = 0.9911. In general, both are beneficial to the performance of the model for small-sample cases. Furthermore, there is a trend of running time increasing with the increase in α, where the advanced model requires more time. Overall, AR-CLSTM has the highest diagnostic efficiency.

4.3. Fault Diagnosis of Safe Injection Pump Dataset

4.3.1. Database Introduction

In this case study, the proposed method is used to diagnose faults in safe injection pumps. The safe injection pump model is CDWL25-0.4 (Chongqing Pump Industry Co., Ltd., Chongqing, China), with a rated power of 30 kW, and the rated speed of the drive motor is 1460 r/min. The INV3065N2 multi-function dynamic signal testing system and piezoelectric accelerometer INV982X were used for vibration signal acquisition, and the sampling frequency was 10 kHz in the experiment. Signal collection was completed at Chongqing Water Pump Factory [

32].

As shown in

Figure 11, the diagnostic object is a vertical safe injection pump, whose drive mechanism makes a reciprocating motion in the vertical direction. Six vibration sensors are arranged vertically on the pump head and the foot of the safe injection pump, and the vibration signal data collected by the sensor are used to evaluate the effectiveness and feasibility of this method in cross-sensor domain migration.

Table 10 shows the letters for each measurement point.

The faults used in the experiment are faults that occur naturally during their operation, rather than those that are artificially caused. The failed parts of the failed safe injection pump were used in the experiment and the corresponding data were collected. As shown in

Table 10, there are seven types of faults: worm gear poorly engaged, bearing poor lubrication (0 MPa, 17.2 MPa), valve seat compression injury, valve seat erosion, valve seat depression, and gearbox pitting. The operating conditions are the vibration data measured at the measurement point. In the original signal, samples are taken at length 576. To facilitate experimentation, all signals in a certain state are integrated into a column; the label values for each state are from 0 to 7, as shown in

Table 11.

4.3.2. Discussion of Batch_Size

A larger batch_size can shorten the training time of each iteration, but it may also reduce the generalization ability, so there should be a balance between the two. Therefore, under the fault dataset with the pump, only the batch_size changes. The results are shown in

Table 12.

The training difficulty is not consistent across batches, resulting in different training times. Obviously, it can achieve similar performance (100%, 99.93%) with batch_sizes = 32 or 64, but the latter takes less time, so the batch_size = 64.

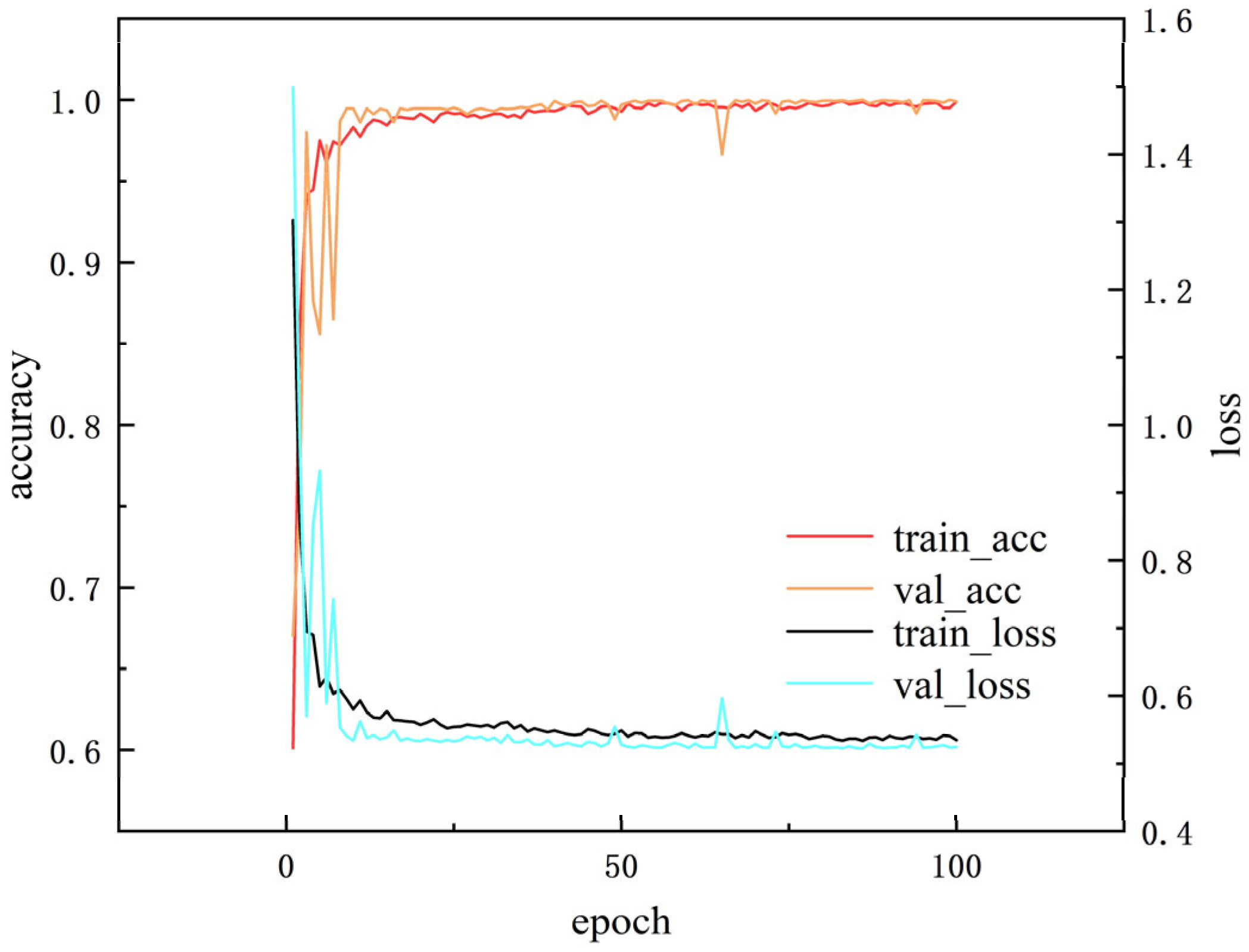

4.3.3. Evaluation with Small Samples

Figure 12 reflects the variation curves of accuracy and loss of the training set and validation set when α = 0.4, iteration number =100, and batch_size =64, indicating that AR-CLSTM has good convergence performance. When the iteration number =100, its accuracy can reach 100%.

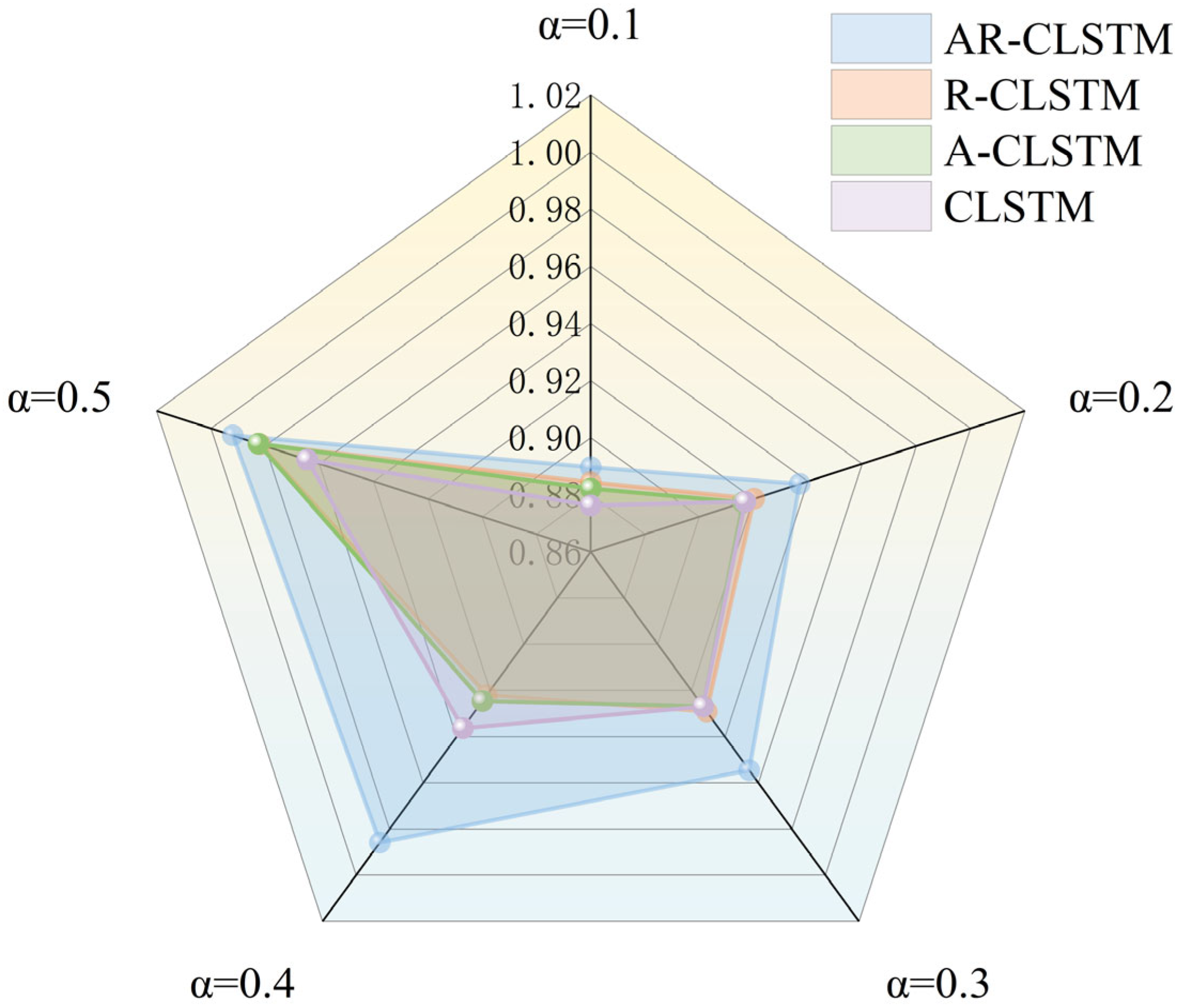

Figure 13 and

Figure 14 show the performance and training time of each model as α increases. It can be seen that the F1 scores of the test set increase as α increases. When α = 0.1, AR-CLSTM has the highest performance, with an F1 score = 0.8897 and CLSTM of 0.8763. At α = 0.5, the performance of all three models except CLSTM is almost 100%. When α < 0.3, CLSTM < A-CLSTM < RCLSTM < CLSTM, and the combination of the attention mechanism and residual block enables the model to achieve optimal performance. However, the cost of this high performance is more training time, so it is required to load the pre-training model to reduce training time.

4.3.4. Visual Analysis

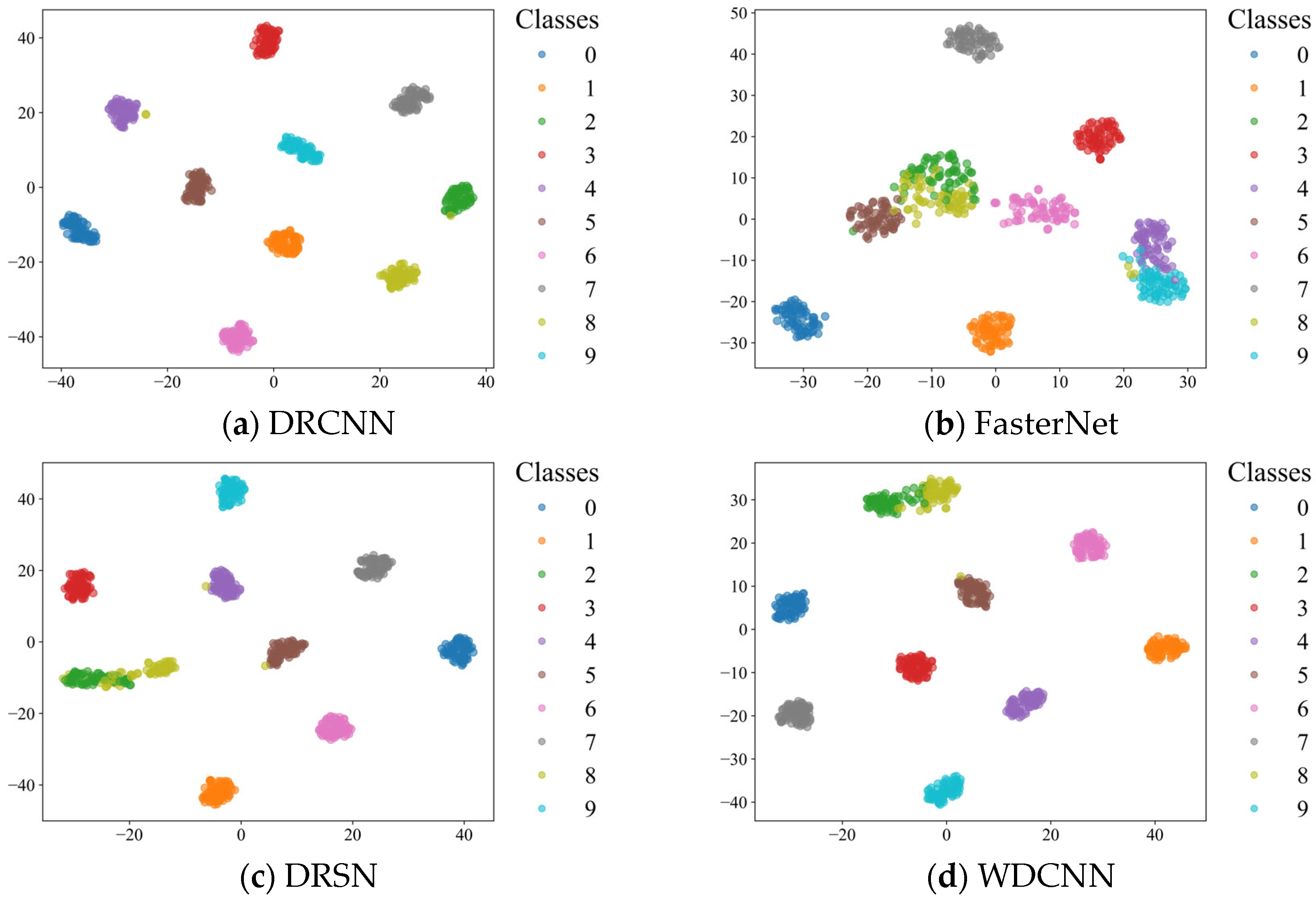

To further reveal the feature representation, we apply the T-SNE technique to feature visualization, where different colors describe different states. By comparing

Figure 15a,b, we can find that CNN initially extracts features which are further separated by the attention mechanism of each state.

Figure 15b,c show that the attention mechanism and residual block of each state classify the samples by extracting hidden features at different positions. At the same time, it can be found that the classification of small-sample data is more accurate after the model passes through the attention mechanism and residual block. Finally, the information of the whole time series is extracted by LSTM. By comparing LSTM and the attention mechanism, it can be seen that LSTM focuses on the output of neurons in all hidden layers of the model, making the fault state separation more obvious and reducing the training pressure of the diagnostic layer. Meanwhile, from the visualization of each module in

Figure 15, it can be seen that AR–CLSTM still has strong robustness in dealing with imbalanced data in the actual industrial environment. The attention mechanism suppresses irrelevant sensor noise and amplifies discriminative features in limited samples. Residual connections enable stable training in shallow layers (one residual block) and avoid overfitting on small datasets. LSR calibrates gearbox pitting (label 7) and bearing lubrication faults (labels 2–3), making it possible to identify the faults. At the same time, from the t–SNE visualization of faults 2, 3, and 7, it can be seen that the proposed model can still accurately identify fault types under conditions with small samples. In summary, AR-CLSTM can better separate different states and has amazing universality.

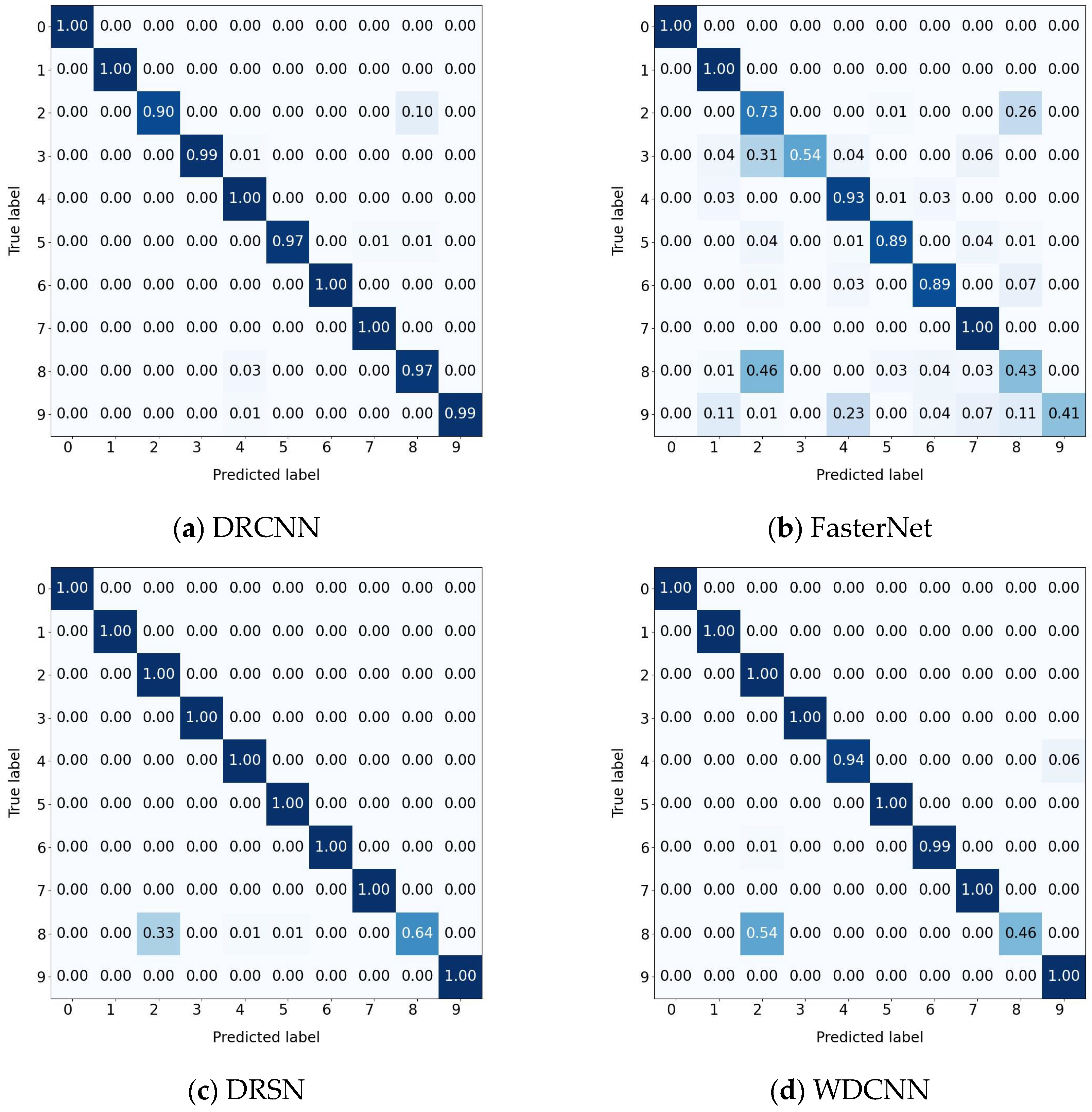

4.4. Comparison of Different Diagnostic Models

Finally, the use of rolling bearing data from CWRU is very popular in mechanical fault diagnosis studies. Compared with some methods listed in

Table 13, the optimizers and α values of all algorithms remain consistent, and AR-CLSTM still reached 100% diagnostic performance in the case with no human intervention. Specifically, compared with DRCNN, FasterNet, DRSN, WDCNN, VACNN and RNN-WDCNN, AR-CLSTM is able to achieve an average accuracy gain of 1.86%, 21.86%, 3.57%, 6.14%, 10.71%, and 4%, respectively. Meanwhile, due to the complexity of the model, the computation time exceeds that of the other six algorithms.

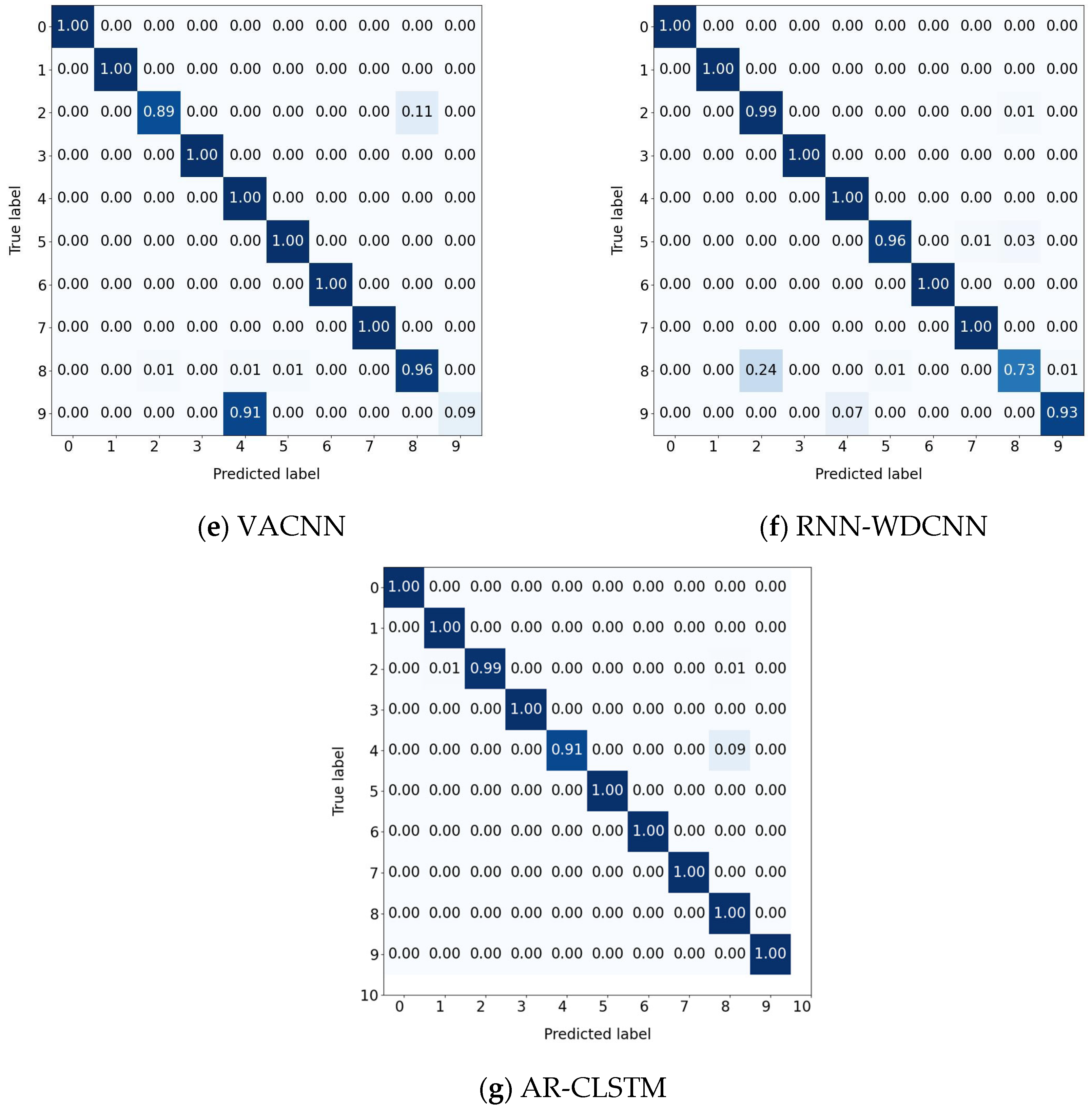

The confusion matrix results are depicted in

Figure 16. According to the result analysis, other methods clearly tend to misjudge the fault types of labels 2 and 8. This phenomenon may stem from the lack of clear distinguishable features in the original signals of these two states. In contrast, the proposed method effectively enhances the model’s ability to extract discriminative features, thereby improving the overall diagnostic performance.

To give a more intuitive result, the t-distributed stochastic neighbor embedding (t-SNE) algorithm [

39] is introduced to visualize the distributions of the results of the eight methods. As is displayed in

Figure 17, each color denotes a health state of the motor. It can be easily found that AR-CLSTM achieves a more discriminative feature distribution map than the other six methods, which further demonstrates the superiority of the proposed method.

5. Conclusions

A residual convolutional neural network based on the attention mechanism is put forward for the fault diagnosis of rotating machinery with small samples. The developed attention-reinforced CLSTM architecture demonstrates strong diagnostic capabilities for rotating machinery operating with limited training data. Experimental validation shows this method consistently achieves over 99% accuracy on both CWRU bearing and safety injection pump datasets. This performance advantage comes from combining channel attention mechanisms and spatial attention modules. The channel attention dynamically adjusts frequency-sensitive features, proving particularly effective at identifying subtle fault patterns in pump vibration spectra. Meanwhile, the spatial attention aggregates contextual information across different receptive fields. Together, these components enable reliable feature extraction from small training sets. Our ablation studies confirm that neither attention component alone delivers comparable results. This validates the architectural innovation of integrating both mechanisms. We also examined how the attention mechanism and LSTM layers respond to different training set sizes. To address distribution differences among labeled samples, we implemented label smoothing regularization. Various visualization techniques including t-SNE plots and confusion matrices further demonstrate how AR-CLSTM organizes fault representations hierarchically. Early network layers capture spectral signatures while deeper layers integrate temporal dependencies. Finally, when tested on the CWRU dataset, AR-CLSTM outperformed six other advanced algorithms, showing excellent performance and robustness.

In the upcoming work, we will focus on four key issues: (1) In some industrial scenarios, mechanical signals are often submerged by noise, which makes it difficult to fully utilize the data. We will explore the feasibility of enhancing the diagnostic ability in high-noise scenarios (SNR < 0 dB) by introducing methods such as physical information constraints. (2) Moreover, it is extremely difficult for traditional CNN models to conduct fault diagnosis under the condition of data imbalance. In the future, we will attempt to perform fault diagnosis on mechanical equipment under the imbalanced condition. Due to the advantage of generative adversarial networks (GANs) in generating a small number of samples, we will integrate GANs to synthesize minority-class fault samples to explore the feasibility of fault diagnosis under small-sample conditions after generating minority-class fault samples. (3) Our current architecture optimizes feature extraction within specific spectral regimes but lacks explicit mechanisms for cross-mechanical domain adaptation. To address this, we are developing physics-informed transfer learning modules that decouple machinery agnostic fault patterns from device-specific resonance characteristics. We will include these enhancements in future work to strengthen cross-domain robustness. (4) This study specifically examined model performance under consistent operational conditions using the CWRU dataset as a case study. Our analysis focused on scenarios where training and testing occurred within identical operational environments, represented as A→A and B→B configurations. However, we did not investigate the model’s behavior during cross-operational condition transfer learning. Specifically, performance under scenarios like A→B remains unexplored. To address this limitation in future research, we will implement a domain adaptation module utilizing transformer architecture. (5) We will integrate k-fold cross-validation in subsequent studies, leveraging cloud computing resources. Additionally, we plan to address data imbalance using synthetic minority oversampling or diffusion models.